Effects of Methanol Addition on the Combustion Process of the Methanol/Diesel Dual-Fuel Based on an Optical Engine

Abstract

:1. Introduction

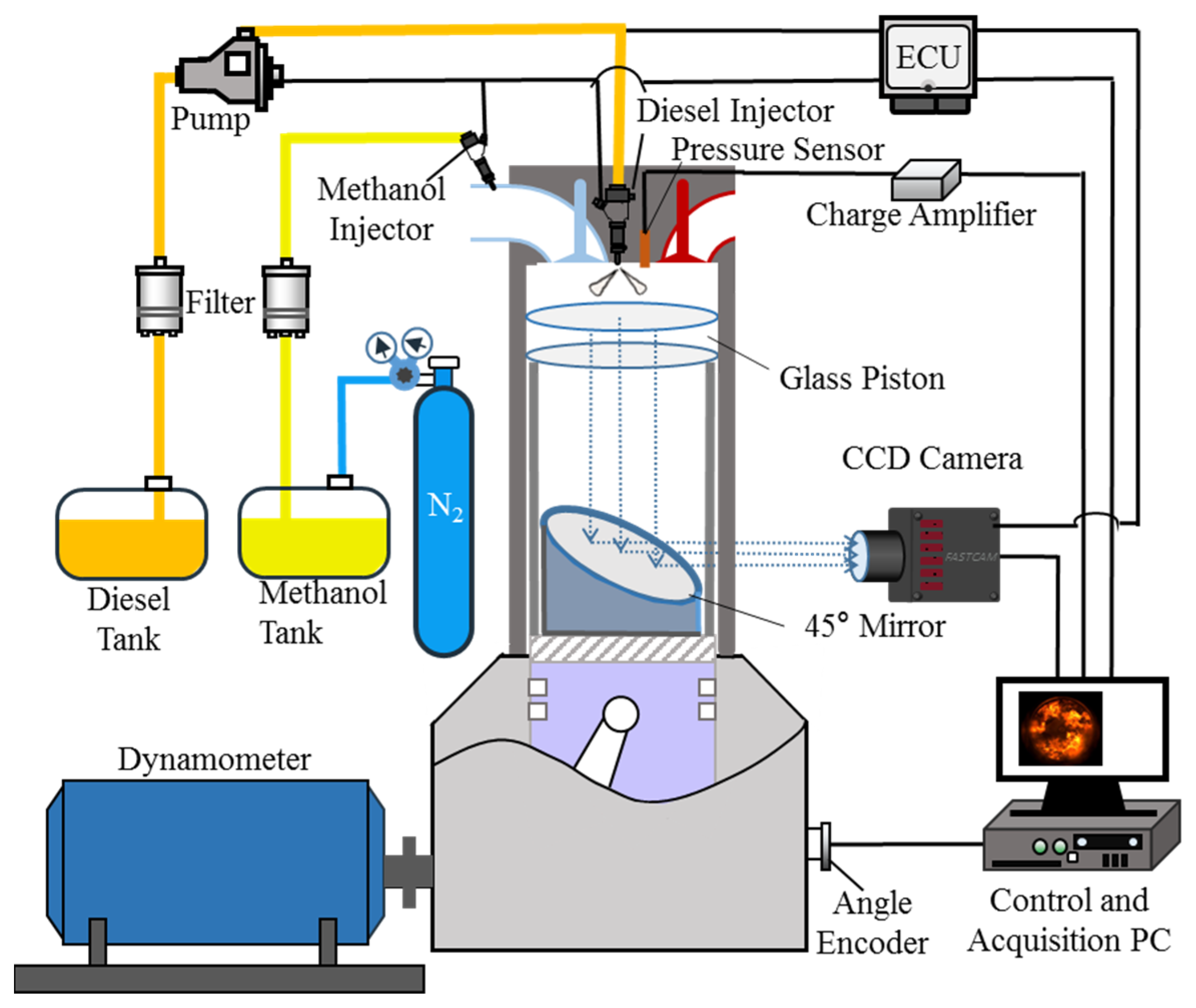

2. Experiment Setup

2.1. Engine

2.2. Fuel Properties and Hardware

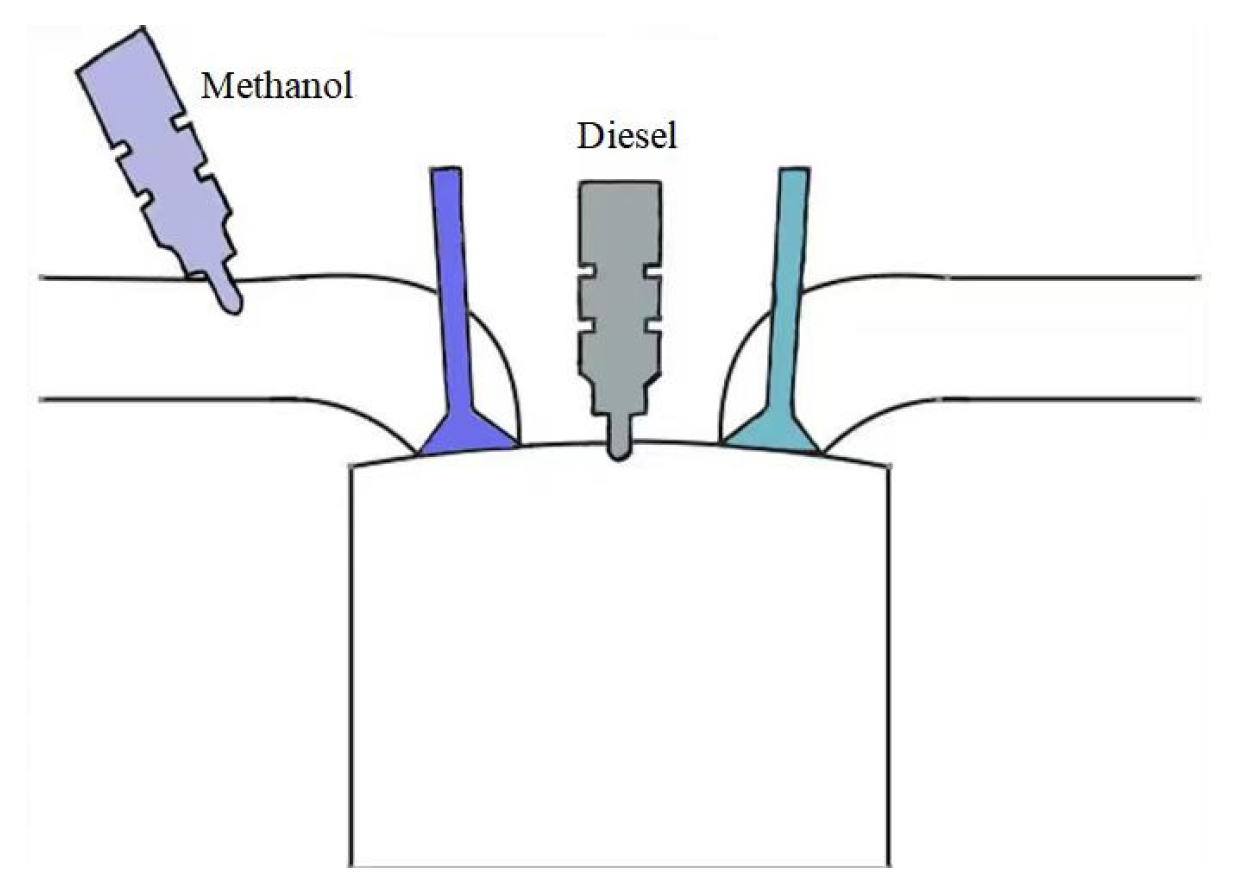

2.3. Injection Setup

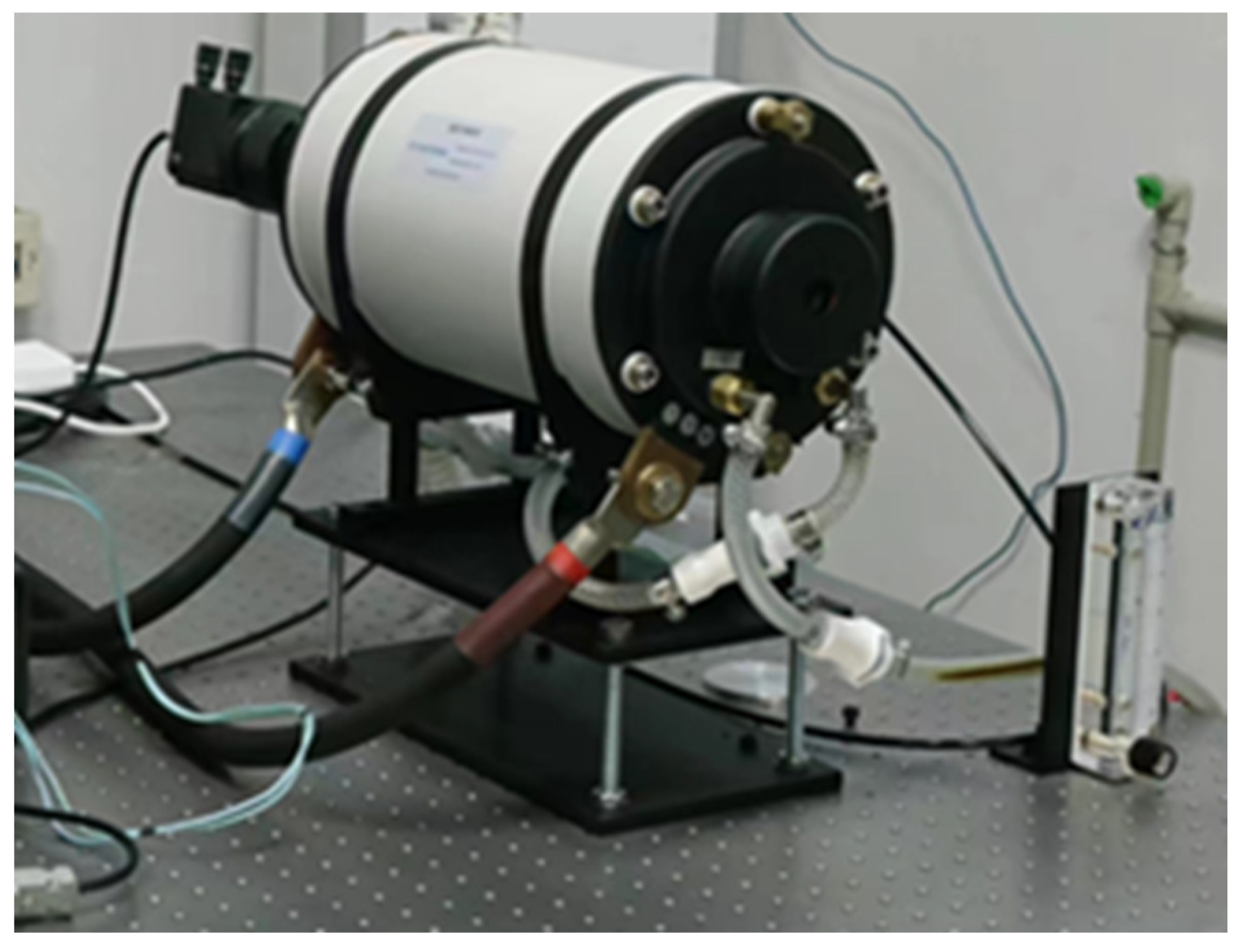

2.4. Method

3. Results and Discussions

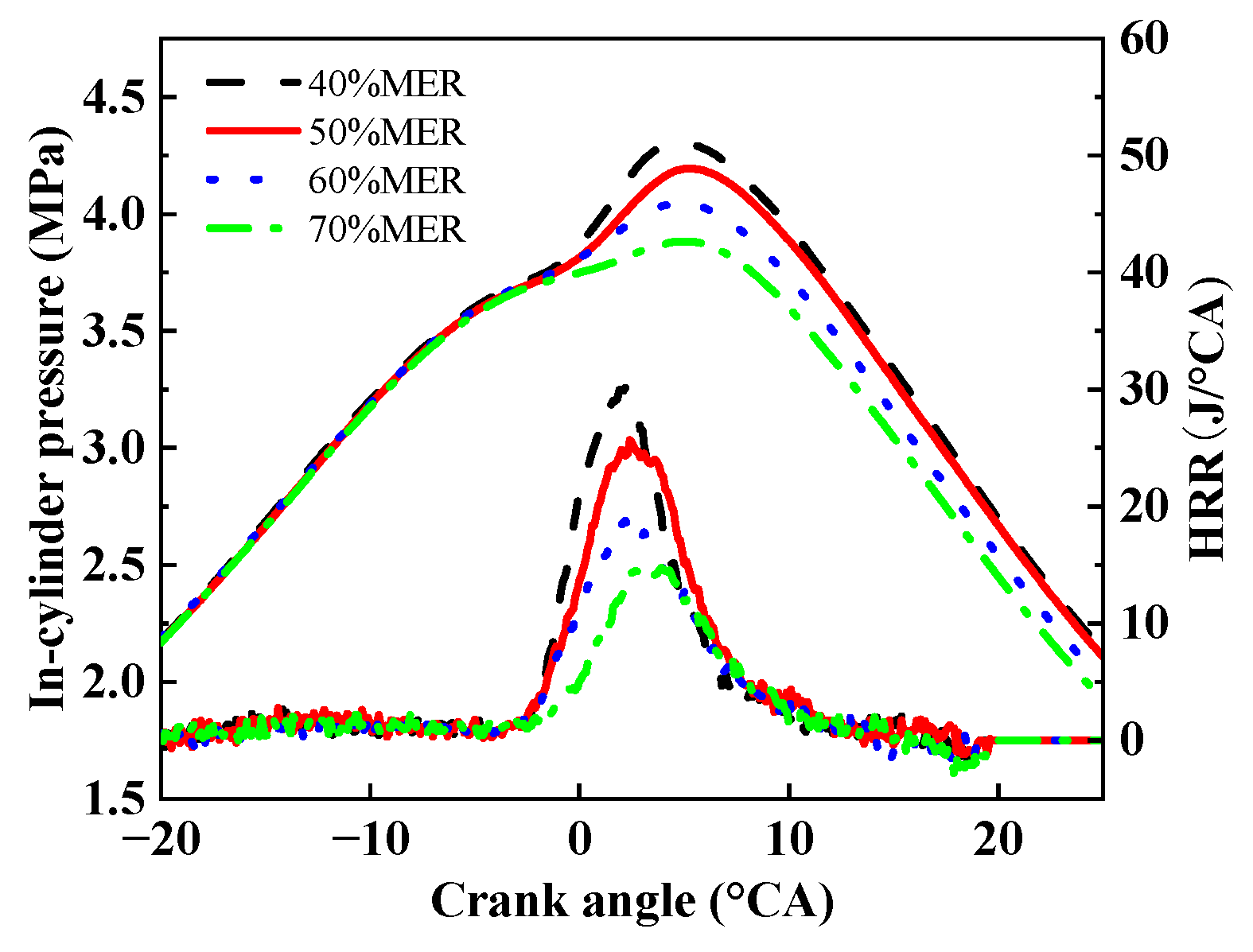

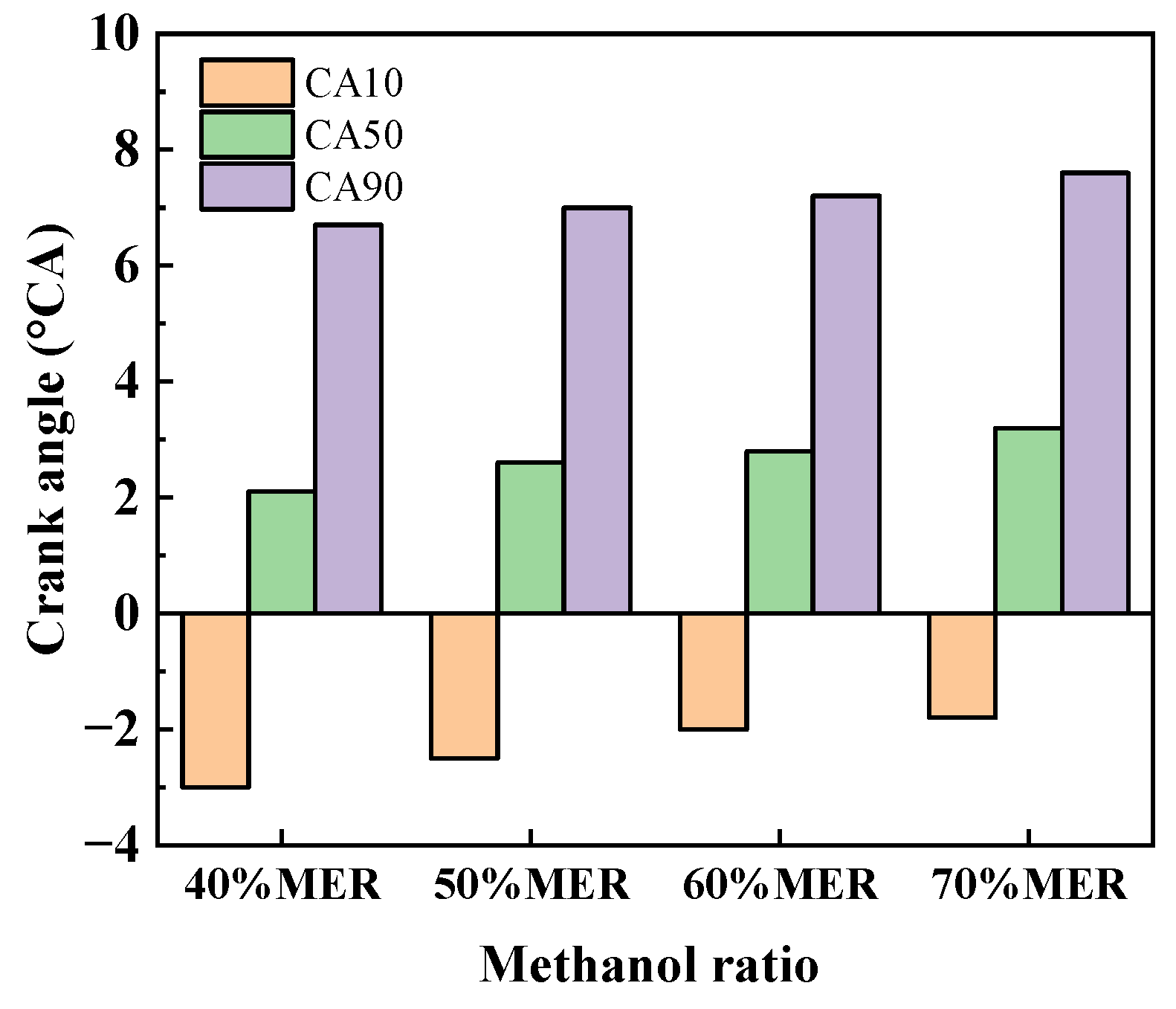

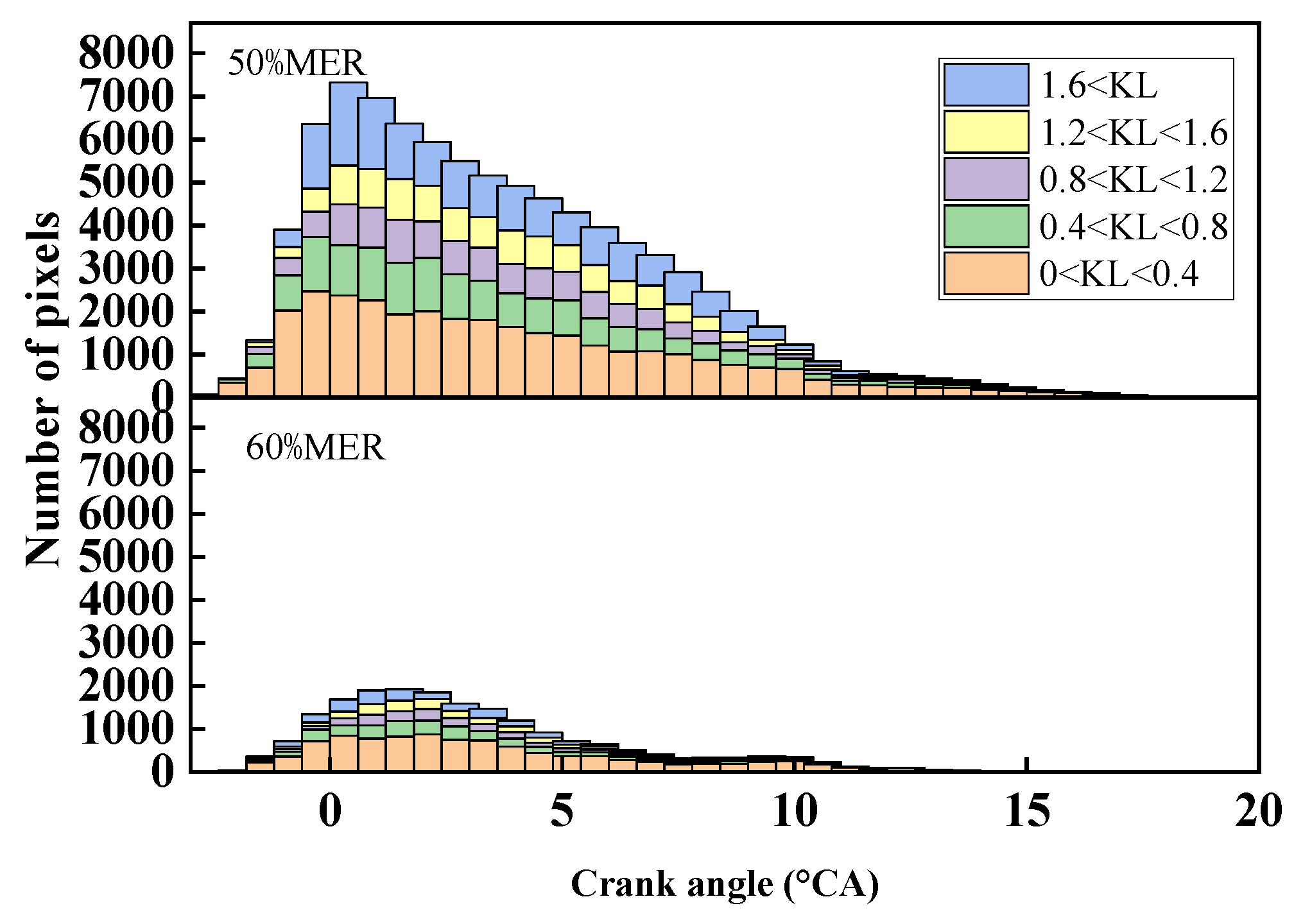

3.1. Methanol Ratio

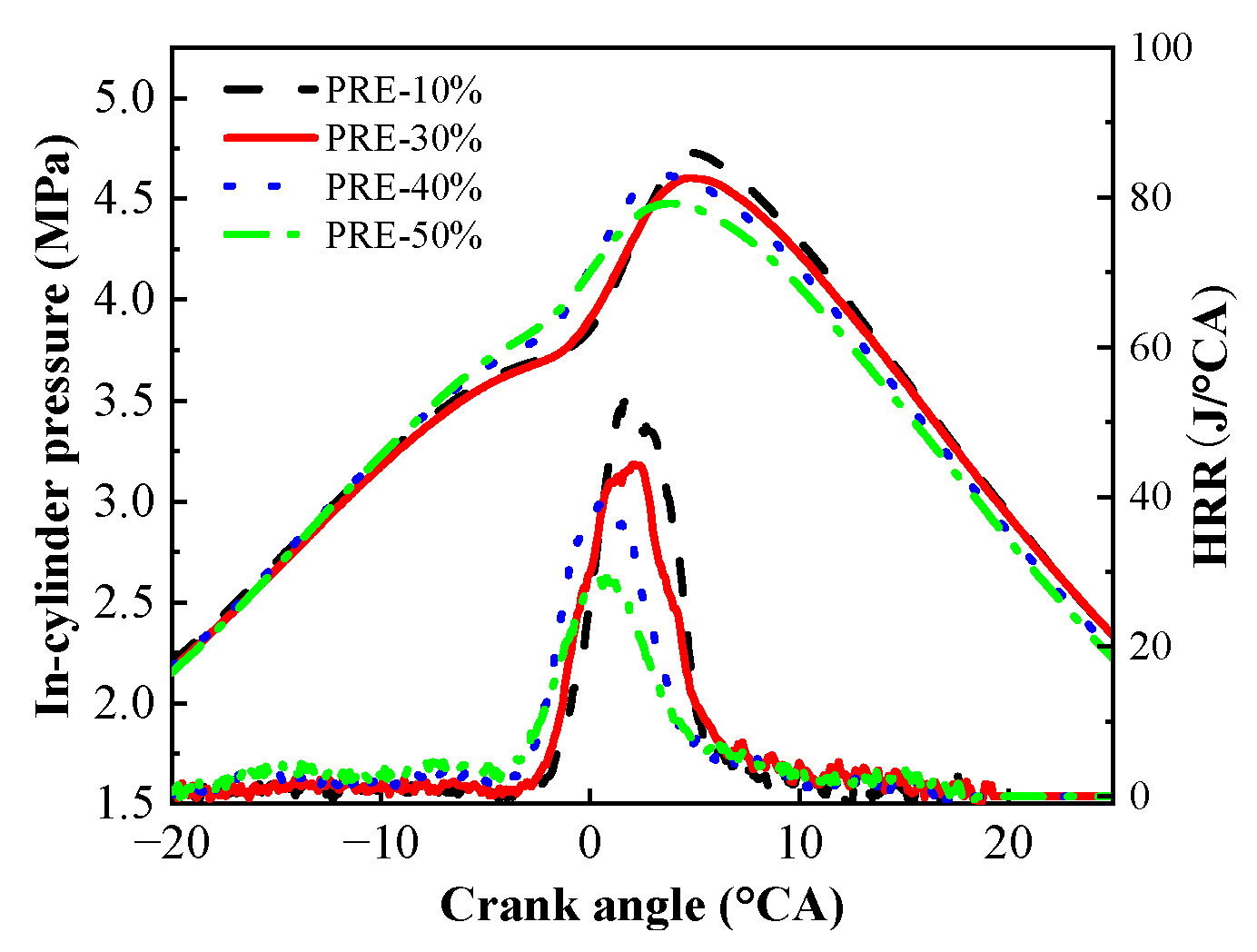

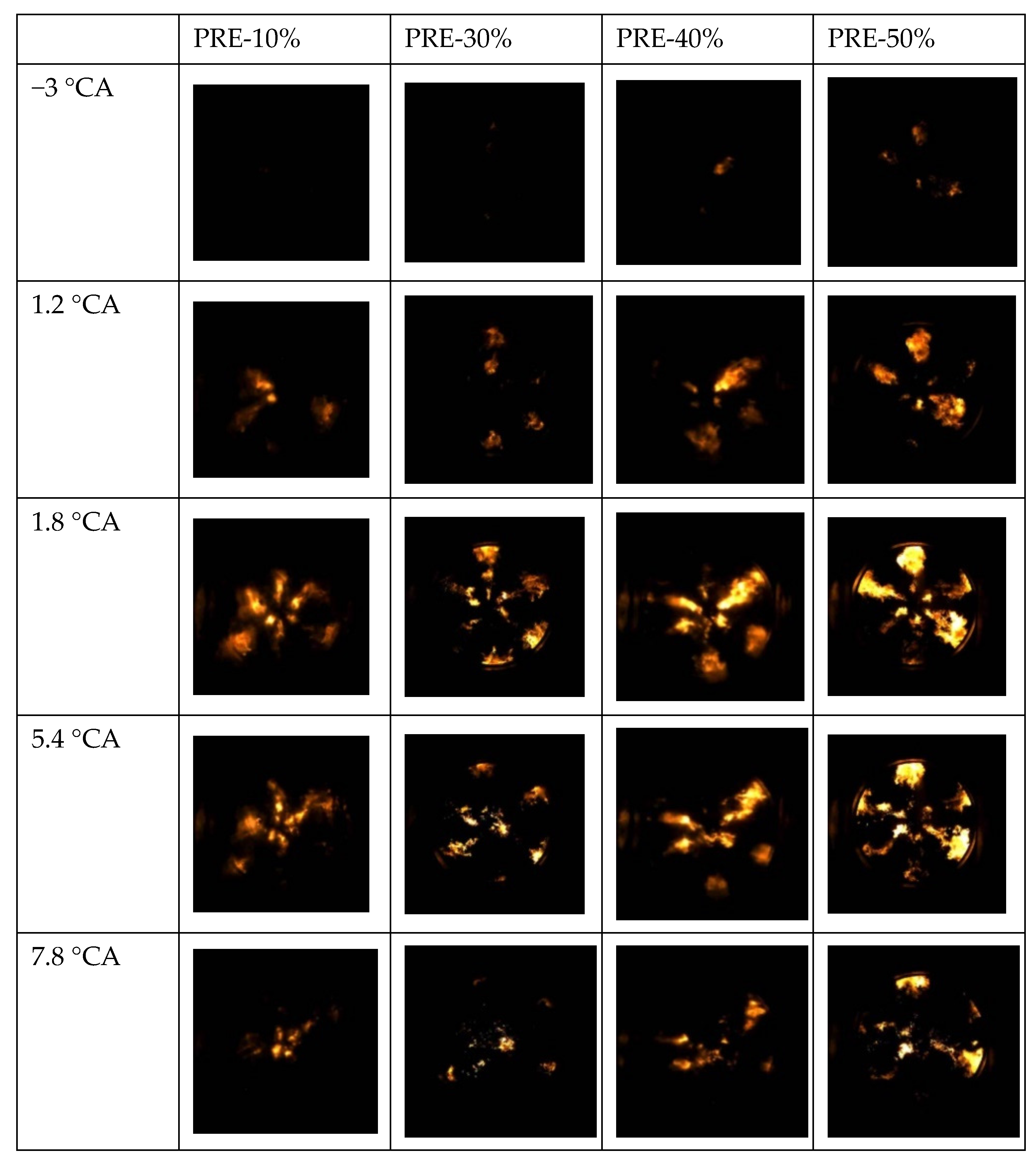

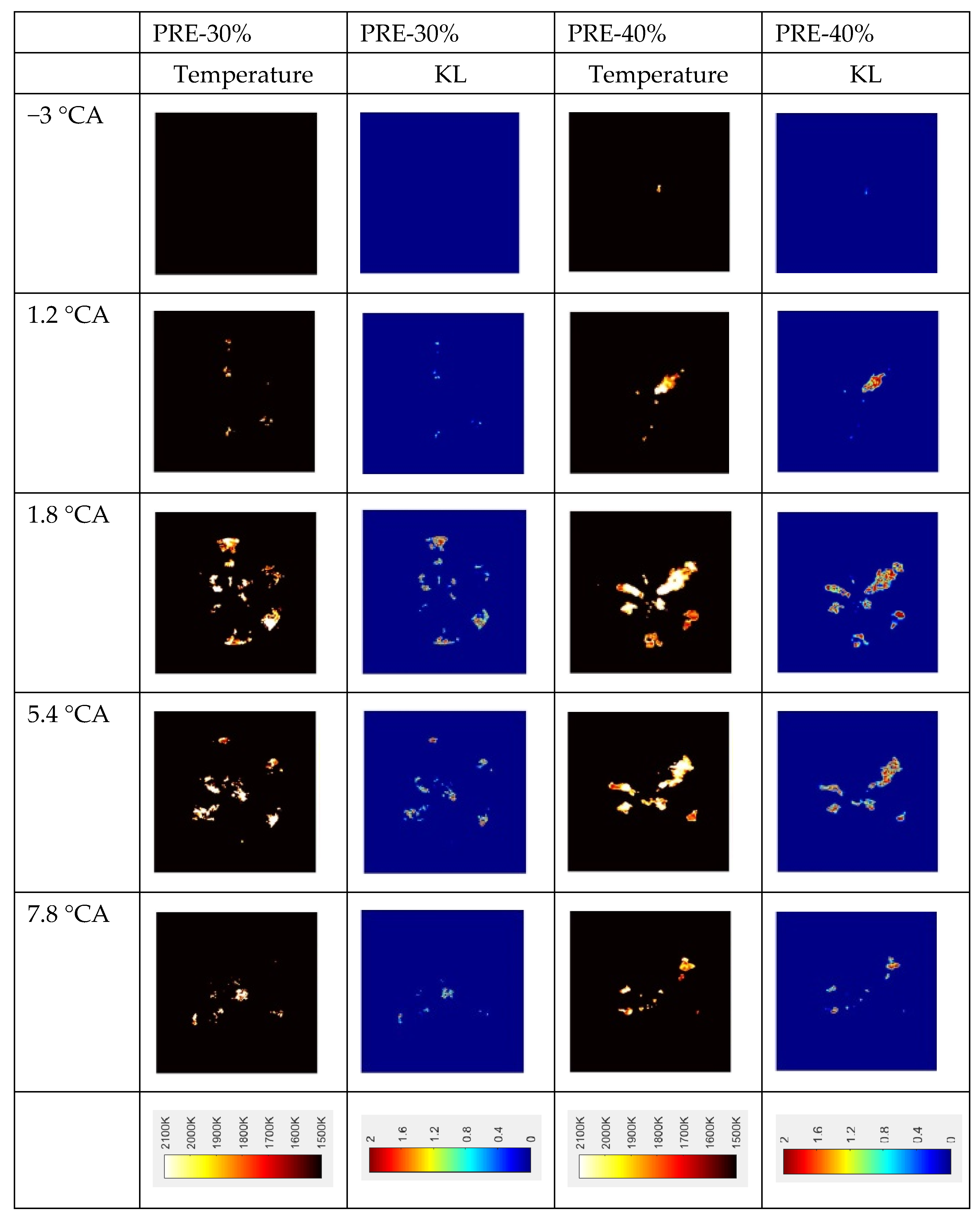

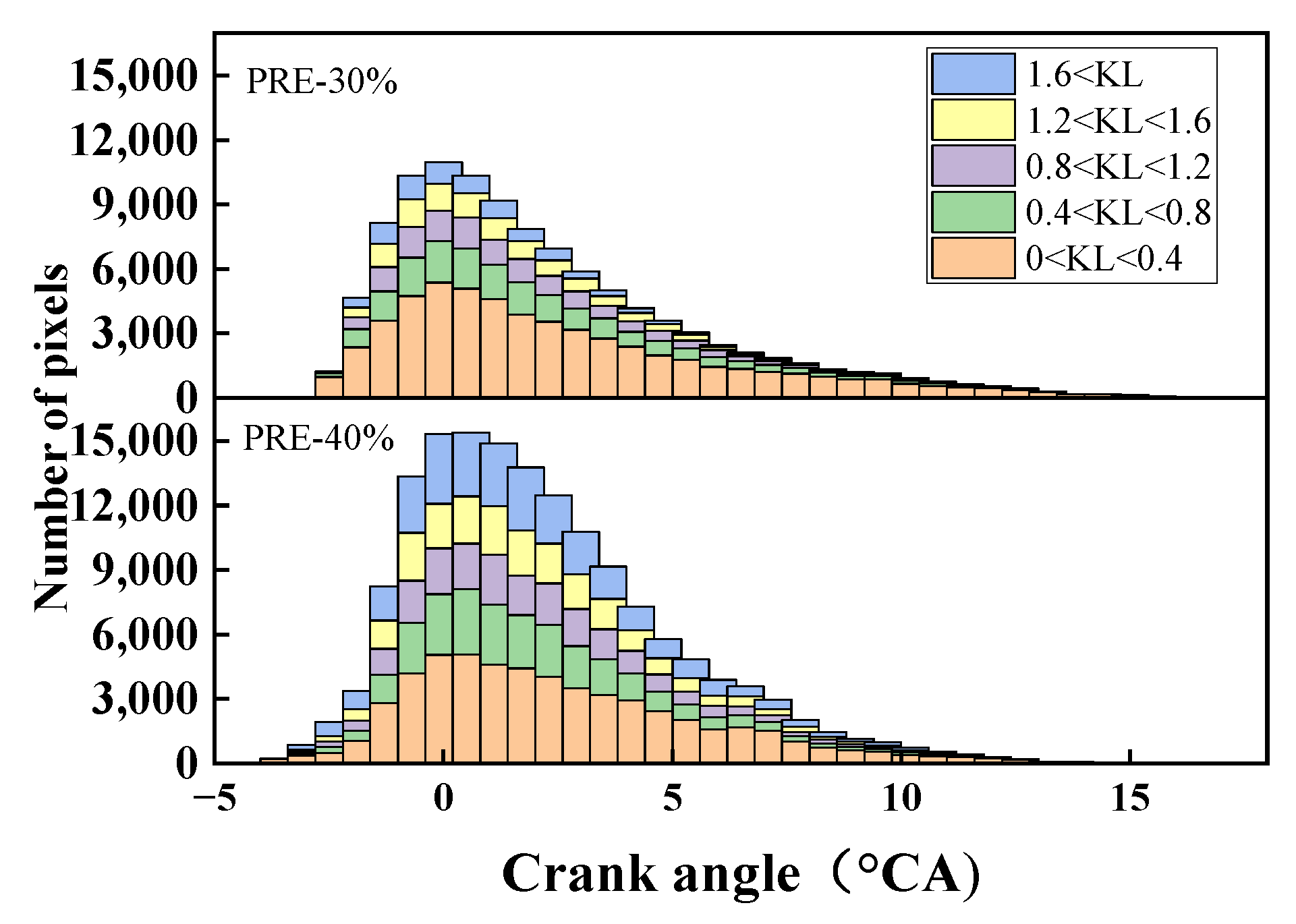

3.2. Pre-Injection Mass of Diesel

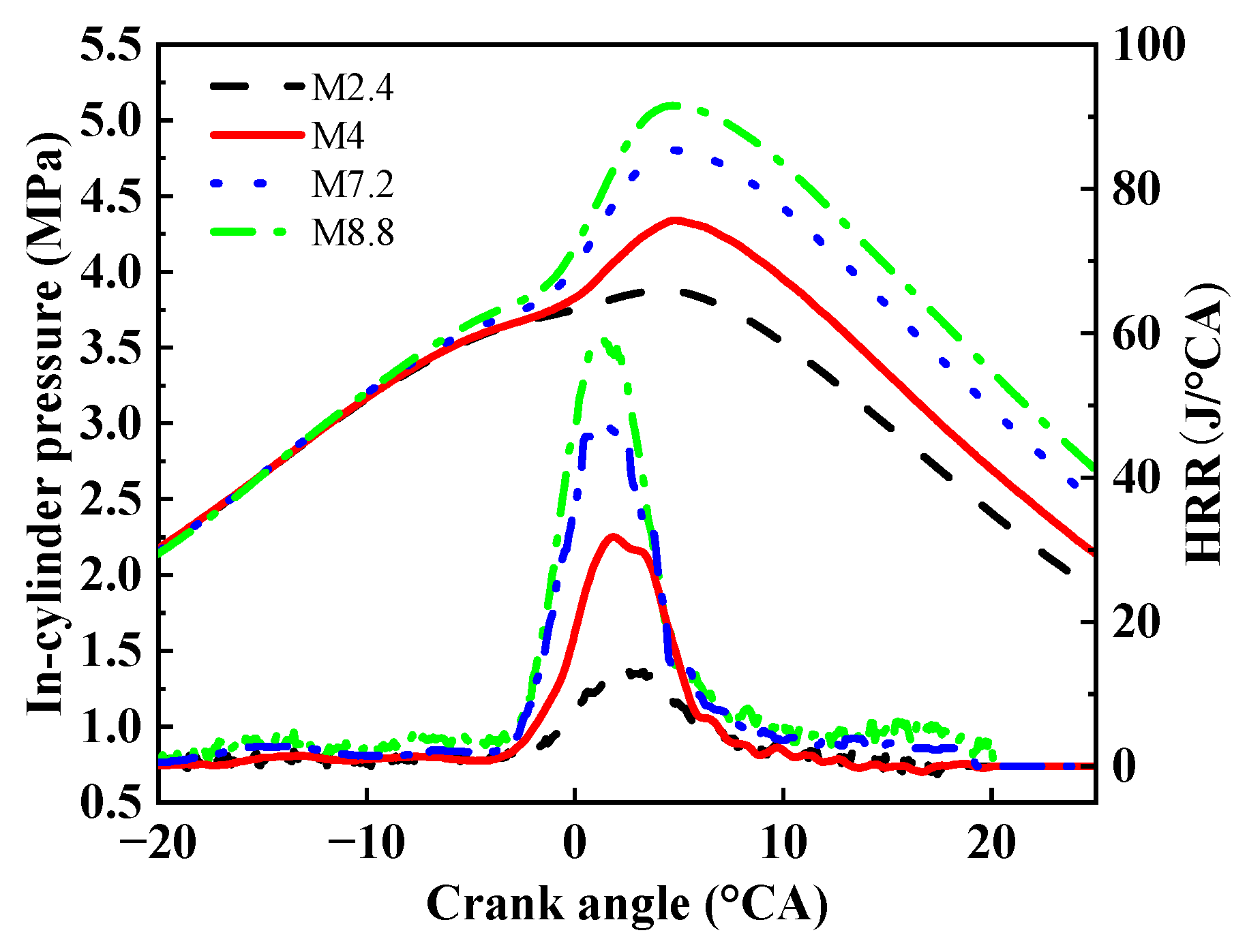

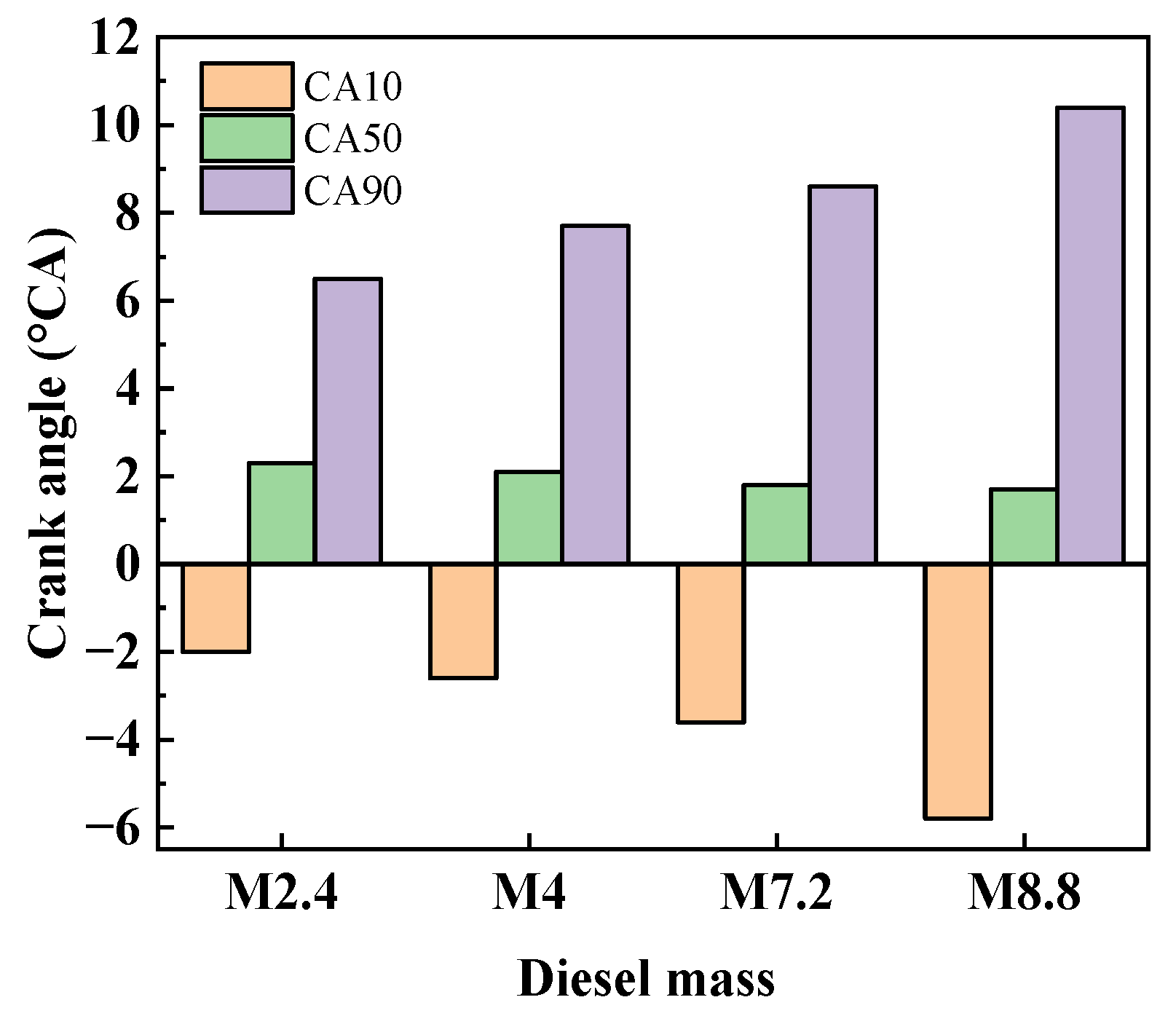

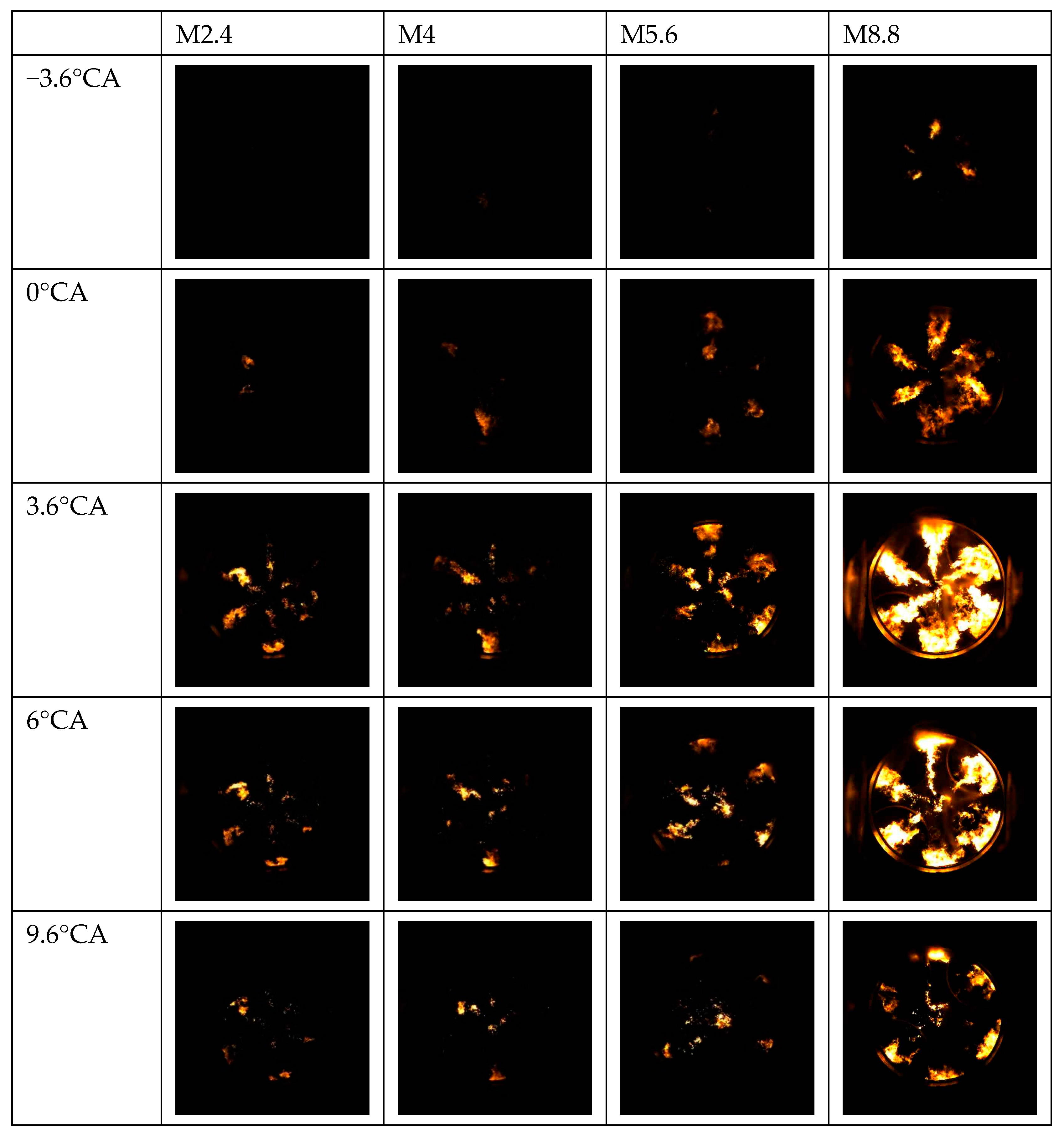

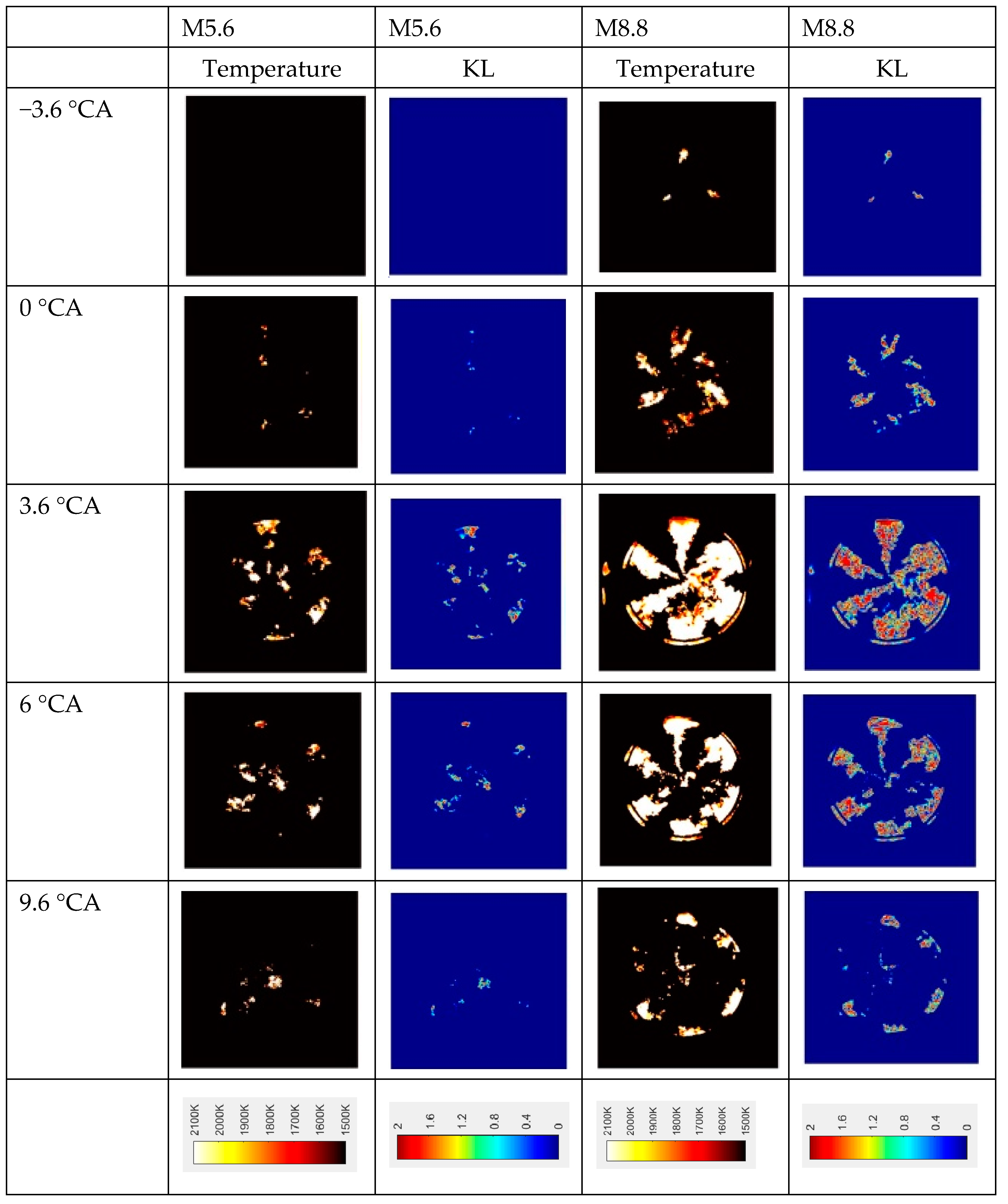

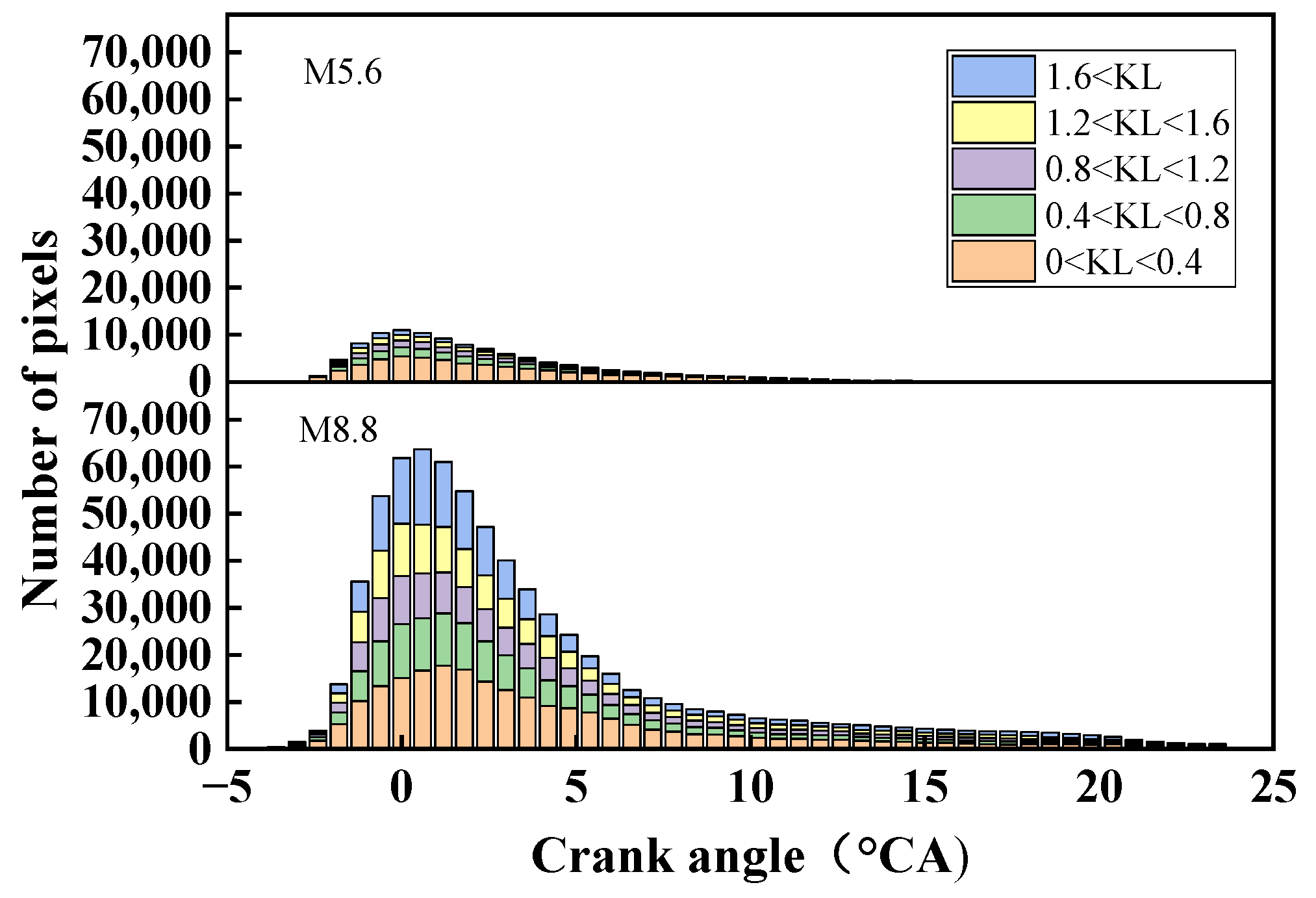

3.3. Total Mass of Diesel

4. Conclusions

- (1)

- The peak pressure and HRR decrease with the methanol ratio increase. CA10, CA50, and CA90 are correspondingly delayed as the methanol ratio increases because of the increased heat absorption by methanol vaporization. The number of pixels representing the KL factor of soot significantly decreases.

- (2)

- The diesel injected in the early stage increases, which indicates that the activity of the fuel in the early stage increases. The higher activity of the fuel has a positive effect on the main injection fuel, leading to a shortened ignition delay. The CA10 and CA50 advance, respectively. The KL increases slightly as the mass of pre-injected diesel increases.

- (3)

- The concentration of the mixture increases when the total mass of diesel increases, resulting in an increase in heat generation and an increase in cylinder pressure. CA10 and CA50 are advanced, respectively, and CA90 is postponed. The KL increases when the total mass of diesel increases.

- (4)

- The peak cylinder pressure for 50%MER, 60%MER, and 70%MER decreased by 2.53%, 6.04%, and 9.76%, respectively, compared with 40%MER. The peak cylinder pressure for PRE-30, PRE-40, and PRE-50 decreased by 2.54%, 2.37%, and 5.29%, respectively, compared with PRE-10. The peak cylinder pressure for M4.0, M7.7, and M8.8 decreased by 11.89%, 23.88%, and 31.43%, respectively, compared with M2.4.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xia, H.; Wang, Z.; Liu, S. Research on fuel spray characteristics of coal-made Fisch-Tropsch process diesel/methanol. Energy Sources Part A Recover. Util. Environ. Eff. 2022, 44, 9074–9085. [Google Scholar] [CrossRef]

- Zhen, X.; Wang, Y.; Liu, D. Bio-butanol as a new generation of clean alternative fuel for SI (spark ignition) and CI (compression ignition) engines. Renew. Energy 2019, 147, 2494–2521. [Google Scholar] [CrossRef]

- Junghwan, K.; Scott, S.C.; Robert, M.W. Combustion Studies with FACE Diesel Fuels: A Literature Review. SAE Int. J. Engines 2012, 5, 1648–1660. [Google Scholar]

- Reijnders, J.; Boot, M.; de Goey, P. Impact of aromaticity and cetane number on the soot-NOx trade-off in conventional and low temperature combustion. Fuel 2016, 186, 24–34. [Google Scholar] [CrossRef]

- Kumar, B.R.; Saravanan, S.; Rana, D.; Nagendran, A. Use of some advanced biofuels for overcoming smoke/NOx trade-off in a light-duty DI diesel engine. Renew. Energy 2016, 96, 687–699. [Google Scholar] [CrossRef]

- Atelge, M.; Arslan, E.; Kahraman, N.; Ünalan, S. Evaluation of hybrid nanoparticles to oxygenated fuel with ethanol and n- butanol on combustion behavior. Fuel 2023, 344, 128048. [Google Scholar] [CrossRef]

- Emiroğlu, A.O. Effect of fuel injection pressure on the characteristics of single cylinder diesel engine powered by butanol-diesel blend. Fuel 2019, 256, 115928. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Micó, C.; Guzmán-Mendoza, M. Parametric evaluation of neat methanol combustion in a light-duty compression ignition engine. Fuel Process. Technol. 2023, 249, 107850. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, X.; Li, Z.; Liu, B.; Chen, Z.; Liu, J. Combustion and Emission Characteristics of Diesel Engines Using Diesel, DMF/Diesel, and N-Pentanol/Diesel Fuel Blends. J. Energy Eng. 2018, 144, 04018030. [Google Scholar] [CrossRef]

- Awad, O.I.; Mamat, R.; Ali, O.M.; Sidik, N.; Yusaf, T.; Kadirgama, K.; Kettner, M. Alcohol and ether as alternative fuels in spark ignition engine: A review. Renew. Sustain. Energy Rev. 2018, 82, 2586–2605. [Google Scholar] [CrossRef]

- Tian, W.; Zhang, H.; Wang, L.; Han, Z.; Yu, W. Effect of Premixed n-Butanol Ratio on the Initial Stage of Combustion in a Light-Duty Butanol/Diesel Dual-Fuel Engine. Energies 2020, 13, 4295. [Google Scholar] [CrossRef]

- Nag, S.; Sharma, P.; Gupta, A.; Dhar, A. Combustion, vibration and noise analysis of hydrogen-diesel dual fuelled engine. Fuel 2018, 241, 488–494. [Google Scholar] [CrossRef]

- Yang, B.; Zeng, K. Effects of natural gas injection timing and split pilot fuel injection strategy on the combustion performance and emissions in a dual-fuel engine fueled with diesel and natural gas. Energy Convers. Manag. 2018, 168, 162–169. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Xie, G.; Li, J.; Xu, W.; Jiang, F.; Huang, Y.; Tan, D. Investigation on the combustion and emission characteristics of diesel engine fueled with diesel/methanol/n-butanol blends. Fuel 2022, 314, 123088. [Google Scholar] [CrossRef]

- Yao, C.; Pan, W.; Yao, A. Methanol fumigation in compression-ignition engines: A critical review of recent academic and technological developments. Fuel 2017, 209, 713–732. [Google Scholar] [CrossRef]

- AAl-Rawashdeh, H.; Hasan, A.O.; Gomaa, M.R.; Abu-jrai, A.; Shalby, M. Determination of Carbonyls Compound, Ketones and Aldehydes Emissions from CI Diesel Engines Fueled with Pure Diesel/Diesel Methanol Blends. Energies 2022, 15, 7933. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J.; Ji, Q.; Sun, P.; Li, J.; Wei, M.; Liu, S. Experimental study on the high load extension of PODE/methanol RCCI combustion mode with optimized injection strategy. Fuel 2021, 314, 122726. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, L.; Wei, H.; Li, J.; Ding, Y.; Chen, R.; Pan, J. Experimental investigation on reactivity-controlled compression ignition (RCCI) combustion characteristic of n-heptane/ammonia based on an optical engine. Int. J. Engine Res. 2022, 24, 2478–2488. [Google Scholar] [CrossRef]

- Wei, H.; Yao, C.; Dou, Z.; Wang, B.; Chen, C.; Liu, M. Comparison of the conversion efficiency of DOC and DPOC to unregulated emissions from a DMDF engine. Fuel 2017, 204, 71–84. [Google Scholar] [CrossRef]

- Wang, B.; Yao, A.; Yao, C.; Chen, C.; Lu, H.; Feng, J. Experimental investigation on methanol auto-ignition in a compression ignition engine under DMDF mode. Fuel 2018, 237, 133–141. [Google Scholar] [CrossRef]

- Kumar, D.; Sonawane, U.; Chandra, K.; Agarwal, A.K. Experimental investigations of methanol fumigation via port fuel injection in preheated intake air in a single cylinder dual-fuel diesel engine. Fuel 2022, 324, 124340. [Google Scholar] [CrossRef]

- Liu, X.; Zhong, W.; Jiang, P.; Dai, L.; He, Z.; Wang, Q. Optimizing RCCI combustion for improved engine performance under low load conditions: Impact of low-reactivity fuel and direct injection timing. Fuel 2023, 351, 128871. [Google Scholar] [CrossRef]

- Vera-Tudela, W.; Schneider, B.; Wüthrich, S.; Herrmann, K. Study on the ignitability of a high-pressure direct-injected methane jet using a scavenged pre-chamber under a wide range of conditions. Int. J. Engine Res. 2023, 24, 1603–1616. [Google Scholar] [CrossRef]

- Kim, W.; Park, C.; Bae, C. Combustion Phenomena and Emissions in a Dual-Fuel Optical Engine Fueled with Diesel and Natural Gas. SAE Int. J. Adv. Curr. Pract. Mobil. 2021, 4, 502–513. [Google Scholar] [CrossRef]

- Di Iorio, S.; Magno, A.; Mancaruso, E.; Vaglieco, B.M. Analysis of the effects of diesel/methane dual fuel combustion on nitrogen oxides and particle formation through optical investigation in a real engine. Fuel Process. Technol. 2017, 159, 200–210. [Google Scholar] [CrossRef]

- Matamis, A.; Lonn, S.; Luise, L.; Vaglieco, B.M.; Tuner, M.; Andersson, O.; Alden, M.; Richter, M. Optical characterization of methanol compression-ignition combustion in a heavy-duty engine. Proc. Combust. Inst. 2020, 38, 5509–5517. [Google Scholar] [CrossRef]

- Cheng, Q.; Ahmad, Z.; Kaario, O.; Martti, L. Cycle-to-cycle variations of dual-fuel combustion in an optically accessible engine. Appl. Energy 2019, 254, 113611. [Google Scholar] [CrossRef]

- Gao, T.; Yu, S.; Li, T.; Zheng, M. Impacts of multiple pilot diesel injections on the premixed combustion of ethanol fuel. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 232, 738–754. [Google Scholar] [CrossRef]

- Tao, W.; Sun, T.; Guo, W.; Lu, K.; Shi, L.; Lin, H. The effect of diesel pilot injection strategy on combustion and emission characteristic of diesel/methanol dual fuel engine. Fuel 2022, 324, 124653. [Google Scholar] [CrossRef]

- Zhou, A.; Jin, H.; Cao, W.; Pang, M.; Li, Y.; Zhu, C. Influence of Pilot Injection on Combustion Characteristic of Methanol–Diesel Dual-Fuel Engine. Energies 2022, 15, 3578. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Gnatowska, R.; Nowak, Ł. Comparative Analysis of the Combustion Stability of Diesel-Methanol and Diesel-Ethanol in a Dual Fuel Engine. Energies 2019, 12, 971. [Google Scholar] [CrossRef]

- Jeon, J.; Park, S. Effect of injection pressure on soot formation/oxidation characteristics using a two-color photometric method in a compression-ignition engine fueled with biodiesel blend (B20). Appl. Therm. Eng. 2018, 131, 284–294. [Google Scholar] [CrossRef]

| Items | Specifications |

|---|---|

| Engine type | 1-cylinder |

| Engine speed/rpm | 1000 |

| Bore/mm | 95 |

| Stroke/mm | 115 |

| Connecting rod length/mm | 210 |

| Compression ratio | 15 |

| Nozzle diameter/mm | 0.15 |

| Spray angle/(°) | 150 |

| Swirl rate | 1.2 |

| IVC | −133 |

| EVO | 125 |

| Intake temperature/(K) | 333 |

| Fuel injection pressure/(MPa) | 60 |

| Ambient temperature/(K) | 300 |

| Ambient pressure/(MPa) | 0.101 |

| Fuel temperature/(K) | 305 |

| Instruments | Accuracy | Uncertainty (%) |

|---|---|---|

| Engine speed | ±10 rpm | ±0.1 |

| Intake gas temperature | ±1 °C | ±0.1 |

| Pressure pick up | ±0.1 bar | ±0.05 |

| Crank angle encoder | ±10 | ±0.05 |

| Property | Diesel | Methanol |

|---|---|---|

| Molecular formula | - | CH3OH |

| Density at 20 °C (kg/m3) | 840 | 790 |

| Low heating value (MJ/kg) | 42.5 | 19.7 |

| Auto-ignition temperature (°C) | 250 | 450 |

| Content of C (%) | 86 | 38 |

| Content of H (%) | 13 | 12 |

| Content of O (%) | - | 50 |

| Cetane number | 51 | 3–5 |

| Latent heat of evaporation (kJ/kg) | 250 | 1110 |

| Parameters | Test 1 | Test 2 | Test 3 | |

|---|---|---|---|---|

| Engine speed (rpm) | 1000 | 1000 | 1000 | |

| Diesel total mass (mg) | 5.6 | 5.6 | 2.4, 4, 7.2, 8.8 | |

| MSR% | 40%, 50%, 60%, 70% | 30% | ||

| Diesel pre-injection ratio % | 30% | 10%, 30%, 40%, 50% | 30% | |

| Diesel injection time °CA | −30 | −30 | −30 | −30 |

| −6 | −6 | −6 | −6 | |

| Methanol injection time °CA | −300 | −300 | −300 | −300 |

| PI fuel | Methanol | Methanol | Methanol | Methanol |

| DI fuel | Diesel | Diesel | Diesel | Diesel |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Guo, G.; Wei, M. Effects of Methanol Addition on the Combustion Process of the Methanol/Diesel Dual-Fuel Based on an Optical Engine. Energies 2023, 16, 7946. https://doi.org/10.3390/en16247946

Liu J, Guo G, Wei M. Effects of Methanol Addition on the Combustion Process of the Methanol/Diesel Dual-Fuel Based on an Optical Engine. Energies. 2023; 16(24):7946. https://doi.org/10.3390/en16247946

Chicago/Turabian StyleLiu, Jinping, Guangzhao Guo, and Mingrui Wei. 2023. "Effects of Methanol Addition on the Combustion Process of the Methanol/Diesel Dual-Fuel Based on an Optical Engine" Energies 16, no. 24: 7946. https://doi.org/10.3390/en16247946

APA StyleLiu, J., Guo, G., & Wei, M. (2023). Effects of Methanol Addition on the Combustion Process of the Methanol/Diesel Dual-Fuel Based on an Optical Engine. Energies, 16(24), 7946. https://doi.org/10.3390/en16247946