The Waste-to-Energy (WtE) Technology to Support Alternative Fuels for Agriculture in the Context of Effective Solid Waste Management in the Jabodetabek Area, Indonesia

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Source Selection

2.2. Review Approach

2.3. WtE Technology Weighting

3. Results and Discussion

3.1. Various WtE Options

3.1.1. Thermal Processing

- Incineration

- Gasification

- Pyrolysis

3.1.2. Non-Thermal Processing

- Landfilling

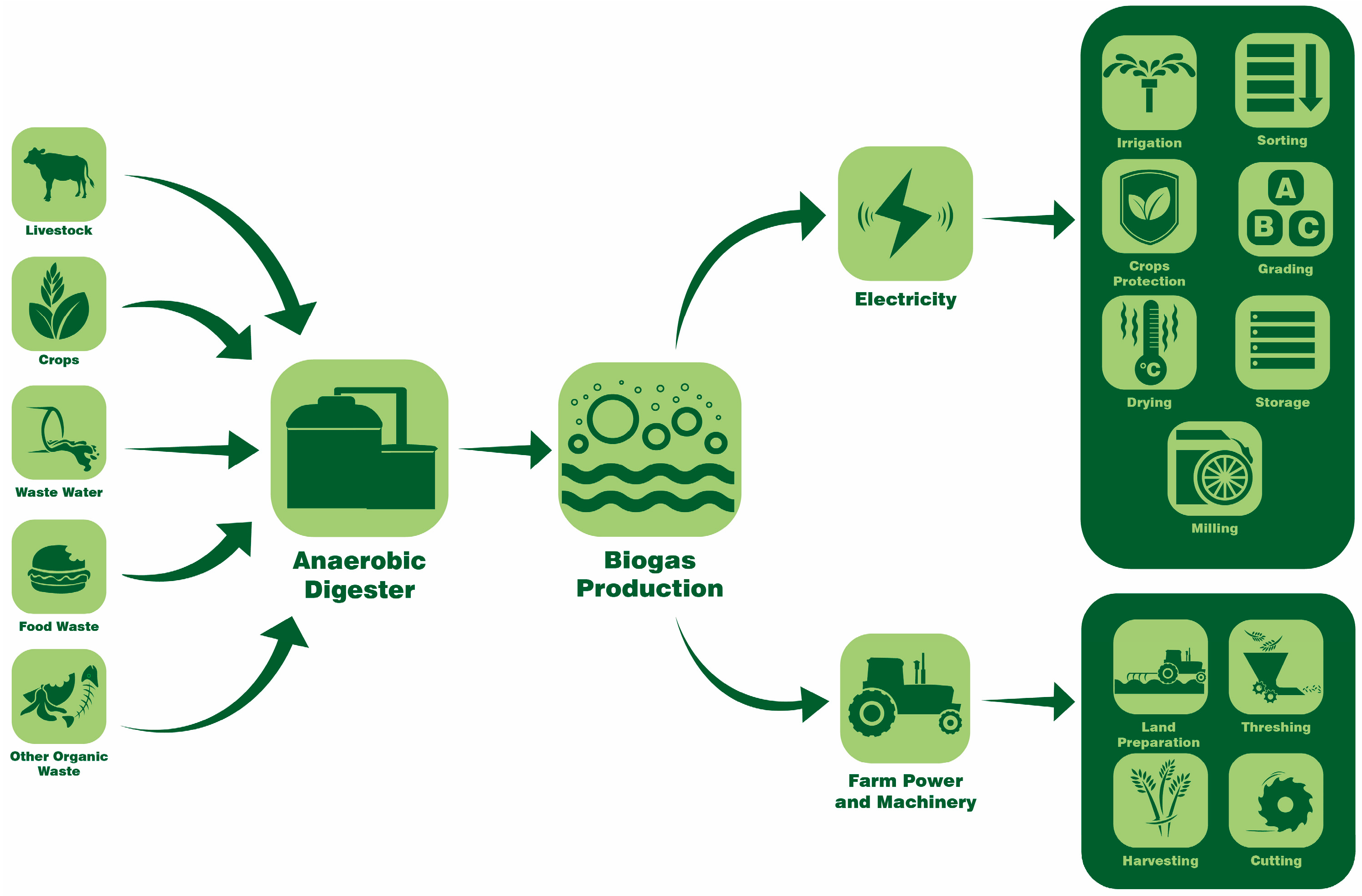

- Anaerobic digester

3.2. WtE Technology Characteristics

3.2.1. Strengths and Weaknesses

3.2.2. Technology Suitability by Waste Type

3.2.3. General Performance Indicators of WtE Technologies

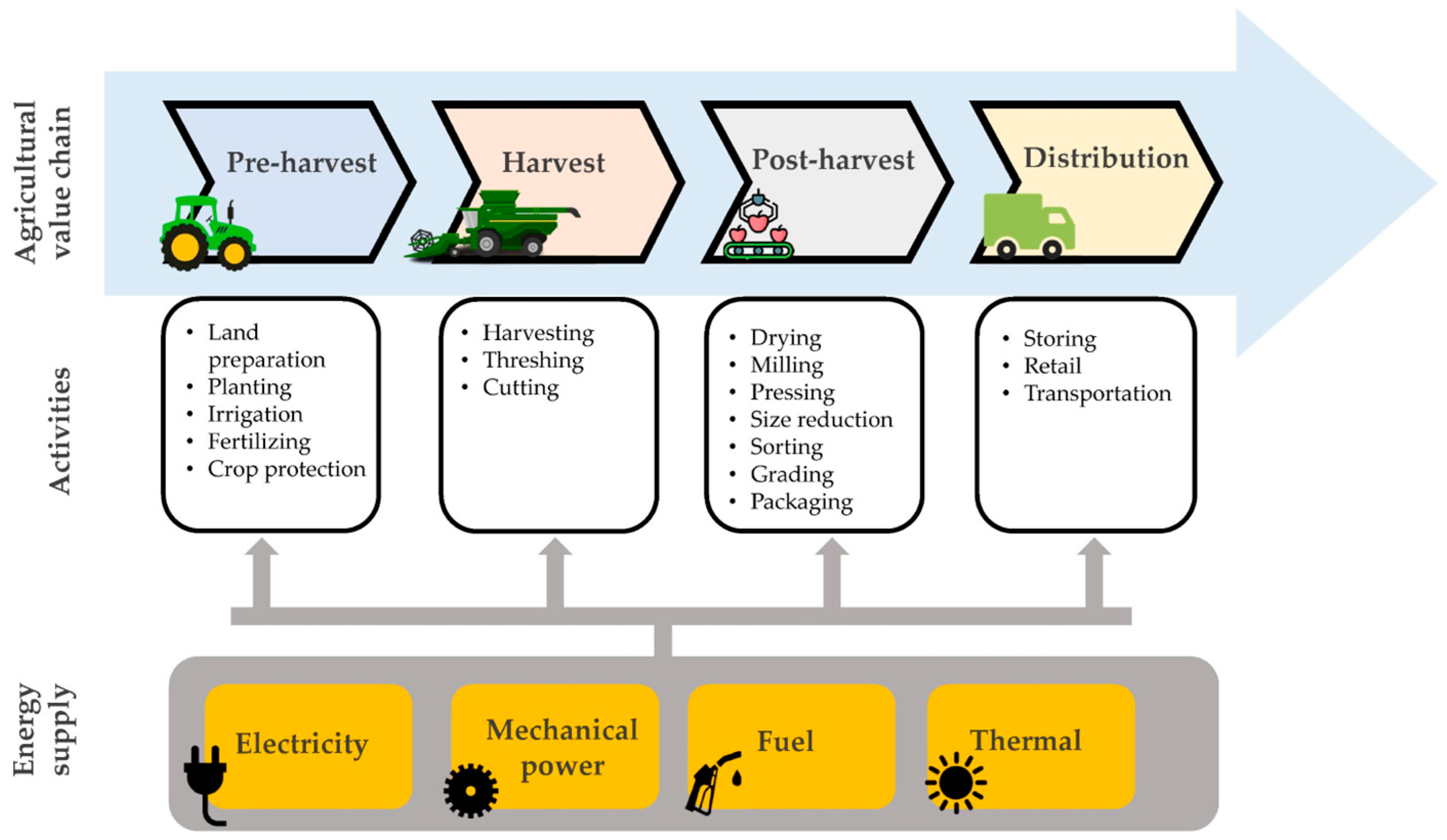

3.3. Energy Input in Agricultural Production

3.4. WtE Technology to Support Alternative Fuels for Agriculture in Jabodetabek

3.4.1. Waste Management

3.4.2. Current Status of WtE Technology

3.4.3. Potential of Suitable WtE Technology

3.4.4. Anaerobic Digester as Alternative Fuel Source

3.5. WtE Technology in Southeast Asian Countries

3.6. Critical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ismangoen, M.H.; Nanda, M.A.; Nelwan, L.O.; Budiastra, I.W.; Seminar, K.B. Estimation of energy generation from municipal solid waste in the Jabodetabek Metropolitan Area, Indonesia. Int. J. Environ. Waste Manag. 2022, 30, 453–471. [Google Scholar] [CrossRef]

- Kumar, S.; Ankaram, S. Waste-to-Energy Model/Tool Presentation. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 239–258. [Google Scholar]

- Mor, S.; Ravindra, K. Municipal solid waste landfills in lower-and middle-income countries: Environmental impacts, challenges and sustainable management practices. Process Saf. Environ. Prot. 2023, 174, 510–530. [Google Scholar] [CrossRef]

- Mukherjee, C.; Denney, J.; Mbonimpa, E.; Slagley, J.; Bhowmik, R. A review on municipal solid waste-to-energy trends in the USA. Renew. Sustain. Energy Rev. 2020, 119, 109512. [Google Scholar] [CrossRef]

- Tun, M.M.; Palacky, P.; Juchelkova, D.; Síťař, V. Renewable waste-to-energy in southeast Asia: Status, challenges, opportunities, and selection of waste-to-energy technologies. Appl. Sci. 2020, 10, 7312. [Google Scholar] [CrossRef]

- Rahman, M.M.; Khan, I.; Field, D.L.; Techato, K.; Alameh, K. Powering agriculture: Present status, future potential, and challenges of renewable energy applications. Renew. Energy 2022, 188, 731–749. [Google Scholar] [CrossRef]

- Rani, G.M.; Pathania, D.; Umapathi, R.; Rustagi, S.; Huh, Y.S.; Gupta, V.K.; Kaushik, A.; Chaudhary, V. Agro-waste to sustainable energy: A green strategy of converting agricultural waste to nano-enabled energy applications. Sci. Total Environ. 2023, 875, 162667. [Google Scholar]

- Ouda, O.K.; Raza, S.; Nizami, A.; Rehan, M.; Al-Waked, R.; Korres, N. Waste to energy potential: A case study of Saudi Arabia. Renew. Sustain. Energy Rev. 2016, 61, 328–340. [Google Scholar] [CrossRef]

- Ofori-Boateng, C.; Lee, K.T.; Mensah, M. The prospects of electricity generation from municipal solid waste (MSW) in Ghana: A better waste management option. Fuel Process. Technol. 2013, 110, 94–102. [Google Scholar] [CrossRef]

- Khan, A.H.; López-Maldonado, E.A.; Alam, S.S.; Khan, N.A.; López, J.R.L.; Herrera, P.F.M.; Abutaleb, A.; Ahmed, S.; Singh, L. Municipal solid waste generation and the current state of waste-to-energy potential: State of art review. Energy Convers. Manag. 2022, 267, 115905. [Google Scholar] [CrossRef]

- Sadiq, R.B.; Safie, N.; Abd Rahman, A.H.; Goudarzi, S. Artificial intelligence maturity model: A systematic literature review. PeerJ Comput. Sci. 2021, 7, e661. [Google Scholar] [CrossRef]

- Cocchia, A. Smart and digital city: A systematic literature review. In Smart City: How to Create Public and Economic Value with High Technology in Urban Space; Springer: Berlin/Heidelberg, Germany, 2014; pp. 13–43. [Google Scholar]

- Perrot, J.-F.; Subiantoro, A. Municipal waste management strategy review and waste-to-energy potentials in New Zealand. Sustainability 2018, 10, 3114. [Google Scholar] [CrossRef]

- Makarichi, L.; Jutidamrongphan, W.; Techato, K.-a. The evolution of waste-to-energy incineration: A review. Renew. Sustain. Energy Rev. 2018, 91, 812–821. [Google Scholar] [CrossRef]

- Consonni, S.; Viganò, F. Waste gasification vs. conventional Waste-To-Energy: A comparative evaluation of two commercial technologies. Waste Manag. 2012, 32, 653–666. [Google Scholar] [CrossRef]

- Chen, D.; Yin, L.; Wang, H.; He, P. Pyrolysis technologies for municipal solid waste: A review. Waste Manag. 2014, 34, 2466–2486. [Google Scholar] [CrossRef] [PubMed]

- Assamoi, B.; Lawryshyn, Y. The environmental comparison of landfilling vs. incineration of MSW accounting for waste diversion. Waste Manag. 2012, 32, 1019–1030. [Google Scholar] [CrossRef]

- Anyaoku, C.C.; Baroutian, S. Decentralized anaerobic digestion systems for increased utilization of biogas from municipal solid waste. Renew. Sustain. Energy Rev. 2018, 90, 982–991. [Google Scholar] [CrossRef]

- Zaman, A.U. Comparative study of municipal solid waste treatment technologies using life cycle assessment method. Int. J. Environ. Sci. Technol. 2010, 7, 225–234. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef]

- Whiting, A.; Azapagic, A. Life cycle environmental impacts of generating electricity and heat from biogas produced by anaerobic digestion. Energy 2014, 70, 181–193. [Google Scholar] [CrossRef]

- Nanda, M.A.; Wijayanto, A.K.; Imantho, H.; Nelwan, L.O.; Budiastra, I.W.; Seminar, K.B. Factors Determining Suitable Landfill Sites for Energy Generation from Municipal Solid Waste: A Case Study of Jabodetabek Area, Indonesia. Sci. World J. 2022, 2022, 9184786. [Google Scholar] [CrossRef]

- Lombardi, L.; Carnevale, E.; Corti, A. A review of technologies and performances of thermal treatment systems for energy recovery from waste. Waste Manag. 2015, 37, 26–44. [Google Scholar] [CrossRef]

- Leme, M.M.V.; Rocha, M.H.; Lora, E.E.S.; Venturini, O.J.; Lopes, B.M.; Ferreira, C.H. Techno-economic analysis and environmental impact assessment of energy recovery from Municipal Solid Waste (MSW) in Brazil. Resour. Conserv. Recycl. 2014, 87, 8–20. [Google Scholar] [CrossRef]

- Takaoka, M.; Takeda, N.; Yamagata, N.; Masuda, T. Current status of waste to power generation in Japan and resulting reduction of carbon dioxide emissions. J. Mater. Cycles Waste Manag. 2011, 13, 198–205. [Google Scholar] [CrossRef]

- Melikoglu, M. Vision 2023: Assessing the feasibility of electricity and biogas production from municipal solid waste in Turkey. Renew. Sustain. Energy Rev. 2013, 19, 52–63. [Google Scholar] [CrossRef]

- Murphy, J.D.; McKeogh, E. Technical, economic and environmental analysis of energy production from municipal solid waste. Renew. Energy 2004, 29, 1043–1057. [Google Scholar] [CrossRef]

- Baggio, P.; Baratieri, M.; Gasparella, A.; Longo, G.A. Energy and environmental analysis of an innovative system based on municipal solid waste (MSW) pyrolysis and combined cycle. Appl. Therm. Eng. 2008, 28, 136–144. [Google Scholar] [CrossRef]

- Abduli, M.; Naghib, A.; Yonesi, M.; Akbari, A. Life cycle assessment (LCA) of solid waste management strategies in Tehran: Landfill and composting plus landfill. Environ. Monit. Assess. 2011, 178, 487–498. [Google Scholar] [CrossRef]

- Iravanian, A.; Ravari, S.O. Types of contamination in landfills and effects on the environment: A review study. IOP Conf. Ser. Earth Environ. Sci. 2020, 614, 012083. [Google Scholar] [CrossRef]

- Mazzi, A.; Sciarrone, M.; Raga, R. Environmental profile of anaerobic and semi-aerobic landfills within sustainable waste management: An overview. Environ. Eng. Manag. J. 2022, 21, 1683–1698. [Google Scholar] [CrossRef]

- Bishop, C.P.; Shumway, C.R.; Wandschneider, P.R. Agent heterogeneity in adoption of anaerobic digestion technology: Integrating economic, diffusion, and behavioral innovation theories. Land Econ. 2010, 86, 585–608. [Google Scholar] [CrossRef]

- Scarlat, N.; Motola, V.; Dallemand, J.F.; Monforti-Ferrario, F.; Mofor, L. Evaluation of energy potential of municipal solid waste from African urban areas. Renew. Sustain. Energy Rev. 2015, 50, 1269–1286. [Google Scholar] [CrossRef]

- Pham, T.P.T.; Kaushik, R.; Parshetti, G.K.; Mahmood, R.; Balasubramanian, R. Food waste-to-energy conversion technologies: Current status and future directions. Waste Manag. 2015, 38, 399–408. [Google Scholar] [CrossRef]

- Arena, U. Process and technological aspects of municipal solid waste gasification. A review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef]

- Molino, A.; Larocca, V.; Chianese, S.; Musmarra, D. Biofuels production by biomass gasification: A review. Energies 2018, 11, 811. [Google Scholar] [CrossRef]

- Hlaba, A.; Rabiu, A.; Osibote, O. Thermochemical Conversion of Municipal Solid Waste—An Energy Potential and Thermal Degradation Behavior Study. Int. J. Environ. Sci. Dev. 2016, 7, 661. [Google Scholar] [CrossRef]

- Ley, E.; Macauley, M.K.; Salant, S.W. Spatially and intertemporally efficient waste management: The costs of interstate trade restrictions. J. Environ. Econ. Manag. 2002, 43, 188–218. [Google Scholar] [CrossRef][Green Version]

- Jones, P.T.; Geysen, D.; Tielemans, Y.; Van Passel, S.; Pontikes, Y.; Blanpain, B.; Quaghebeur, M.; Hoekstra, N. Enhanced Landfill Mining in view of multiple resource recovery: A critical review. J. Clean. Prod. 2013, 55, 45–55. [Google Scholar] [CrossRef]

- Krook, J.; Svensson, N.; Eklund, M. Landfill mining: A critical review of two decades of research. Waste Manag. 2012, 32, 513–520. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Lu, H.; Liu, J.; Wang, W.; Zhang, X. Hydraulic and mechanical behavior of landfill clay liner containing SSA in contact with leachate. Environ. Technol. 2018, 39, 1307–1315. [Google Scholar] [CrossRef]

- Shrestha, S.; Fonoll, X.; Khanal, S.K.; Raskin, L. Biological strategies for enhanced hydrolysis of lignocellulosic biomass during anaerobic digestion: Current status and future perspectives. Bioresour. Technol. 2017, 245, 1245–1257. [Google Scholar] [CrossRef]

- Appels, L.; Lauwers, J.; Degrève, J.; Helsen, L.; Lievens, B.; Willems, K.; Van Impe, J.; Dewil, R. Anaerobic digestion in global bio-energy production: Potential and research challenges. Renew. Sustain. Energy Rev. 2011, 15, 4295–4301. [Google Scholar] [CrossRef]

- Balasubramaniyam, U.; Zisengwe, L.S.; Meriggi, N.; Buysman, E. Biogas Production in Climates with Long Cold Winters; Wageningen University: Wageningen, The Netherlands, 2008; p. 68. [Google Scholar]

- Ram, C.; Kumar, A.; Rani, P. Municipal solid waste management: A review of waste to energy (WtE) approaches. Bioresources 2021, 16, 4275. [Google Scholar] [CrossRef]

- Annepu, R.K. Sustainable Solid Waste Management in India; Columbia University: New York, NY, USA, 2012; Volume 2. [Google Scholar]

- Fluck, R.C. Energy in Farm Production; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Mikkola, H.J.; Ahokas, J. Indirect energy input of agricultural machinery in bioenergy production. Renew. Energy 2010, 35, 23–28. [Google Scholar] [CrossRef]

- Kosemani, B.S.; Bamgboye, A.I. Energy input-output analysis of rice production in Nigeria. Energy 2020, 207, 118258. [Google Scholar] [CrossRef]

- Energypedia. Energy Inputs in Agricultural Value Chains. Available online: https://energypedia.info/wiki/file:energy_inputs_in_agricultural_value_chains_(best,_2014).jpg (accessed on 16 May 2023).

- Ozkan, B.; Akcaoz, H.; Fert, C. Energy input–output analysis in Turkish agriculture. Renew. Energy 2004, 29, 39–51. [Google Scholar] [CrossRef]

- Bojaca, C.; Schrevens, E. Energy assessment of peri-urban horticulture and its uncertainty: Case study for Bogota, Colombia. Energy 2010, 35, 2109–2118. [Google Scholar] [CrossRef]

- Mohammadi, A.; Omid, M. Economical analysis and relation between energy inputs and yield of greenhouse cucumber production in Iran. Appl. Energy 2010, 87, 191–196. [Google Scholar] [CrossRef]

- Rafiee, S.; Avval, S.H.M.; Mohammadi, A. Modeling and sensitivity analysis of energy inputs for apple production in Iran. Energy 2010, 35, 3301–3306. [Google Scholar] [CrossRef]

- Mohammadi, A.; Rafiee, S.; Mohtasebi, S.S.; Rafiee, H. Energy inputs–yield relationship and cost analysis of kiwifruit production in Iran. Renew. Energy 2010, 35, 1071–1075. [Google Scholar] [CrossRef]

- Kizilaslan, H. Input–output energy analysis of cherries production in Tokat Province of Turkey. Applied Energy 2009, 86, 1354–1358. [Google Scholar] [CrossRef]

- Pimentel, D.; Pimentel, M.H. Food, Energy, and Society; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Indonesian Central Bureau of Statistics (BPS). Statistik Indonesia 2020; Indonesian Central Bureau of Statistics: Jakarta, Indonesia, 2020.

- Rahayu, A.C.; Hidayat, K. Pemerintah Targetkan Pemanfaatan Biogas Menjadi Biometana Capai 1.230 MMBTU Per Hari. Available online: https://industri.kontan.co.id/news/pemerintah-targetkan-pemanfaatan-biogas-menjadi-biometana-capai-1230-mmbtu-per-hari (accessed on 2 August 2023).

- Sejati, L.; Arifien, Y.; Maad, F. Economic valuation of rice agricultural land in Bogor regency. J. Phys. Conf. Ser. 2020, 1517, 012024. [Google Scholar] [CrossRef]

- Seminar, K.B.; Nelwan, L.O.; Budiastra, I.W.; Sutawijaya, A.; Wijayanto, A.K.; Imantho, H.; Nanda, M.A.; Ahamed, T. Using Precision Agriculture (PA) Approach to Select Suitable Final Disposal Sites for Energy Generation. Information 2022, 14, 8. [Google Scholar] [CrossRef]

- Khuc, Q.V.; Dang, T.; Tran, M.; Nguyen, D.T.; Nguyen, T.; Pham, P.; Tran, T. Household-level strategies to tackle plastic waste pollution in a transitional country. Urban Sci. 2023, 7, 20. [Google Scholar] [CrossRef]

- Notosudjono, D.; Ramadhon, B.D.; Prasetyo, A.T.; Samaulloh, H.; Mudianto, A.; Asri, A. Characteristic evaluation of organic waste power plant in Bantargebang waste processing plant. AIP Conf. Proc. 2020, 2228, 030026. [Google Scholar]

- Adnan Sundra & Low. Waste to Energy Plants—Key Legislation in Malaysia. Available online: https://www.lexology.com/library/detail.aspx?g=36494579-a25c-4932-9fa4-34e5721dfd29#:~:text=the%20ministry%20of%20housing%20and,incentive%20to%2031%20december%202023 (accessed on 12 May 2023).

- Wongchantra, P.; Wongchantra, K.; Kaeongam, S.; Junkaew, L.; Sookngam, K.; Ongon, S.; Phansiri, C.; Oncharoen, A. The Project Feasibility Analysis of a Waste-Electric Power Plant of Kamalasai Sub-district Municipality, Kamalasai district, Kalasin province. Int. J. Agric. Technol. 2017, 13, 1773–1789. [Google Scholar]

- Bangkokpost. TPCH Sees Revenue Spike Ahead. Available online: https://www.bangkokpost.com/business/2336648/tpch-sees-revenue-spike-ahead (accessed on 11 May 2023).

- Tong, H.; Yao, Z.; Lim, J.W.; Mao, L.; Zhang, J.; Ge, T.S.; Peng, Y.H.; Wang, C.-H.; Tong, Y.W. Harvest green energy through energy recovery from waste: A technology review and an assessment of Singapore. Renew. Sustain. Energy Rev. 2018, 98, 163–178. [Google Scholar] [CrossRef]

- Chailertpong, T.; Phimolsathien, T. Antecedents to Creating Shared Value at Thai Waste-to-Energy Facilities. J. Sustain. Dev. Energy Water Environ. Syst. 2018, 6, 649–664. [Google Scholar] [CrossRef]

- Olalo, K.F.; Nakatani, J.; Fujita, T. Optimal Process network for integrated solid waste management in Davao City, Philippines. Sustainability 2022, 14, 2419. [Google Scholar] [CrossRef]

- Thestar. Brunei Plans to Build Waste-To-Electricity Incinerator Plant. Available online: https://www.thestar.com.my/aseanplus/aseanplus-news/2023/03/20/brunei-plans-to-build-waste-to-electricity-incinerator-plant (accessed on 11 May 2023).

- Quang, B. Vietnam’s Biggest Waste-to-Power Plant Enters Operation. Available online: https://theinvestor.vn/vietnams-biggest-waste-to-power-plant-enters-operation-d1226.html (accessed on 11 May 2023).

- Grafakos, S.; Kang, J.; Senshaw, D. Unlocking Potential for Large-Scale Waste Treatment Plants with a Focus on Energy Recovery and Modular Project Design; Global Green Growth Institute: Seoul, Republic of Korea, 2022. [Google Scholar]

- Pisei, H. COVID Delays WtE Power Plant. Available online: https://www.phnompenhpost.com/business/covid-delays-wte-power-plant (accessed on 11 May 2023).

- Thitsa, P. Myanmar’s First-Ever Yangon Waste to Energy Plant Generates 760 kW of Electricity Daily. Available online: https://www.mdn.gov.mm/en/myanmars-first-ever-yangon-waste-energy-plant-generates-760-kw-electricity-daily (accessed on 11 May 2023).

- Gonzaga Fraga, L.; Teixeira, C.F.J.; Ferreira, E.C.M. The potential of renewable energy in Timor-Leste: An assessment for biomass. Energies 2019, 12, 1441. [Google Scholar] [CrossRef]

- Fabry, F.; Rehmet, C.; Rohani, V.; Fulcheri, L. Waste gasification by thermal plasma: A review. Waste Biomass Valorization 2013, 4, 421–439. [Google Scholar] [CrossRef]

| Search String |

|---|

| (“Waste-to-energy (WtE) Technology”) |

| (“Strengths and Weaknesses” AND “WtE technology”) |

| (“Solid Waste Management” OR “Waste Management” AND “Jabodetabek”) |

| (“Alternative Fuels” AND “Agriculture”) |

| (“Alternative Energy Source” AND “Agriculture”) |

| Performance Indicators | Weight (%) |

|---|---|

| Waste type | 5 |

| Energy production efficiency | 5 |

| Produced energy | 10 |

| Technology readiness | 5 |

| Capacity | 5 |

| Byproducts | 15 |

| Cost | 10 |

| Air pollution | 15 |

| Water pollution | 15 |

| Soil pollution | 15 |

| Total | 100 |

| WtE Technology | Strengths | Weaknesses | Source |

|---|---|---|---|

| Incineration |

|

| [4,14,34] |

| Gasification |

|

| [15,35,36] |

| Pyrolysis |

|

| [16,37] |

| Landfilling |

|

| [17,38,39,40,41] |

| Anaerobic Digester |

|

| [18,42,43,44] |

| Waste Type | The Potential of Suitable WtE Technology to Produce Alternative Fuels for Agriculture | ||||

|---|---|---|---|---|---|

| Incineration | Gasification | Pyrolysis | Landfilling | Anaerobic Digester | |

| Mixed waste | √ | √ | √ | - | √ |

| Segregated waste | |||||

| √ | √ | √ | - | √ |

| √ | √ | √ | - | √ |

| √ | √ | √ | - | - |

| √ | √ | √ | - | - |

| √ | √ | √ | - | - |

| Indicators | Notes | WtE Technology | ||||

|---|---|---|---|---|---|---|

| Incineration | Gasification | Pyrolysis | Landfilling | Anaerobic Digester | ||

| Input waste type | Waste type | All | All | All | Specific | Specific |

| Energy production efficiency | % | 21.0 | 35.0 | 20.5 | none | 10.4 |

| Produced energy | GJ | 5,806,909 | 9,665,899 | 5,661,455 | none | 1,015,671 |

| Technology readiness | Maturity level | Very mature | Moderately mature | Less mature | Extremely mature | Mature |

| Capacity | Tons per year | 150,000 | 250,000 | 250,000 | 2,737,500 | 100,000 |

| Byproducts | Type | Residue ash | Syngas | Pyrolysis gas | Leachate | Biosludge |

| Capital cost | US$/tons | 400–700 | 250–850 | 400–700 | 10–30 | 50–350 |

| Global warming potential | kg CO2 | 424 | 412 | 412 | 746 | 222 |

| Air pollution | NOx level | Extremely high | High | Moderately high | Very high | Low |

| Water pollution | Water pollution level | Very high | High | Moderately high | Extremely high | Low |

| Soil pollution | Soil pollution level | Very high | High | Moderately high | Extremely high | Low |

| Reference | [5,13,19,20,45] | [5,13,19,20,45] | [5,13,19,20,45] | [5,13,20,21,22,45] | [5,13,19,20,45] | |

| Input | Unit | Energy Equivalent (MJ Unit−1) | References |

|---|---|---|---|

| Human labor | h | 1.96 | [52] |

| Machinery | h | 62.70 | [53] |

| Fuel | |||

| L | 41.75 | [47] |

| L | 56.31 | [47] |

| Chemical fertilizer | |||

| ha | 66.13 | [54] |

| ha | 12.44 | [54] |

| ha | 11.15 | [54] |

| ha | 1.12 | [54] |

| ha | 8.40 | [54] |

| Planting | ha | 6.64 | [49] |

| Irrigation | m3 | 1.02 | [55] |

| Electricity | kWh | 3.6 | [56] |

| Drying | kg | 0.84 | [47] |

| Transportation | kg | 1.16 | [47] |

| Performance Indicators | Raw Input Score on Various WtE Technologies | ||||

|---|---|---|---|---|---|

| Incineration | Gasification | Pyrolysis | Landfilling | Anaerobic Digester | |

| Waste type | 5 | 5 | 5 | 1 | 3 |

| Energy production efficiency | 4 | 5 | 3 | 1 | 2 |

| Produced energy | 4 | 5 | 3 | 1 | 2 |

| Technology readiness | 4 | 2 | 1 | 5 | 3 |

| Capacity | 3 | 4 | 4 | 5 | 2 |

| Byproducts | 4 | 3 | 2 | 1 | 5 |

| Cost | 2 | 3 | 2 | 5 | 4 |

| Air pollution | 1 | 3 | 4 | 2 | 5 |

| Water pollution | 2 | 3 | 4 | 1 | 5 |

| Soil pollution | 2 | 3 | 4 | 1 | 5 |

| Total | 31 | 36 | 32 | 23 | 36 |

| Performance Indicators | The Weighted Total Score on Various WtE Technologies | ||||

|---|---|---|---|---|---|

| Incineration | Gasification | Pyrolysis | Landfilling | Anaerobic Digester | |

| Waste type | 0.25 | 0.25 | 0.25 | 0.05 | 0.15 |

| Energy production efficiency | 0.20 | 0.25 | 0.15 | 0.05 | 0.10 |

| Produced energy | 0.40 | 0.50 | 0.30 | 0.10 | 0.20 |

| Technology readiness | 0.20 | 0.10 | 0.05 | 0.25 | 0.15 |

| Capacity | 0.15 | 0.20 | 0.20 | 0.25 | 0.10 |

| Byproduct | 0.60 | 0.45 | 0.30 | 0.15 | 0.75 |

| Cost | 0.20 | 0.30 | 0.20 | 0.50 | 0.40 |

| Air pollution | 0.15 | 0.45 | 0.60 | 0.30 | 0.75 |

| Water pollution | 0.30 | 0.45 | 0.60 | 0.15 | 0.75 |

| Soil pollution | 0.30 | 0.45 | 0.60 | 0.15 | 0.75 |

| Total | 2.75 | 3.40 | 3.25 | 1.95 | 4.10 |

| Country | WtE Plant Name or Installation Site | Status | WtE Technology Type | Capacity (Tons Day−1) | Generated Electricity (MW Day−1) | References |

|---|---|---|---|---|---|---|

| Indonesia | Bantargebang | ao | Gasification | 7500 | 15.6 | [22,63] |

| Malaysia | Taman Beringin | wr | Incineration | 1200 | 18.8 | [2,5,64] |

| Thailand | Nonthaburi | ao | Gasification | 1000 | 2.8 | [65,66] |

| Singapore | TuasOne | ao | Incineration | 3600 | 120 | [67,68] |

| Filipina | Davao City | sp | Incineration | 600 | 0.204 | [69] |

| Brunei | Sungai Paku | wr | Incineration | 800–1000 | nr | [70] |

| Vietnam | Hanoi | wr | Incineration | 7500 | 75 | [71] |

| Laos | Nam Son | wr | Incineration | 4000 | 75 | [72] |

| Cambodia | Phnom Penh | wr | Incineration | 3000 | 50 | [73] |

| Myanmar | Yangon | ao | Incineration | 60 | 0.76 | [74] |

| Timor-Leste | Dili | su | Biogas | 203 | 10 | [75] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nanda, M.A.; Sugandi, W.; Wijayanto, A.K.; Imantho, H.; Sutawijaya, A.; Nelwan, L.O.; Budiastra, I.W.; Seminar, K.B. The Waste-to-Energy (WtE) Technology to Support Alternative Fuels for Agriculture in the Context of Effective Solid Waste Management in the Jabodetabek Area, Indonesia. Energies 2023, 16, 7980. https://doi.org/10.3390/en16247980

Nanda MA, Sugandi W, Wijayanto AK, Imantho H, Sutawijaya A, Nelwan LO, Budiastra IW, Seminar KB. The Waste-to-Energy (WtE) Technology to Support Alternative Fuels for Agriculture in the Context of Effective Solid Waste Management in the Jabodetabek Area, Indonesia. Energies. 2023; 16(24):7980. https://doi.org/10.3390/en16247980

Chicago/Turabian StyleNanda, Muhammad Achirul, Wahyu Sugandi, Arif Kurnia Wijayanto, Harry Imantho, Arya Sutawijaya, Leopold Oscar Nelwan, I Wayan Budiastra, and Kudang Boro Seminar. 2023. "The Waste-to-Energy (WtE) Technology to Support Alternative Fuels for Agriculture in the Context of Effective Solid Waste Management in the Jabodetabek Area, Indonesia" Energies 16, no. 24: 7980. https://doi.org/10.3390/en16247980

APA StyleNanda, M. A., Sugandi, W., Wijayanto, A. K., Imantho, H., Sutawijaya, A., Nelwan, L. O., Budiastra, I. W., & Seminar, K. B. (2023). The Waste-to-Energy (WtE) Technology to Support Alternative Fuels for Agriculture in the Context of Effective Solid Waste Management in the Jabodetabek Area, Indonesia. Energies, 16(24), 7980. https://doi.org/10.3390/en16247980