An Experimental Investigation and Numerical Simulation of Photovoltaic Cells with Enhanced Surfaces Using the Simcenter STAR-CCM+ Software

Abstract

:1. Introduction

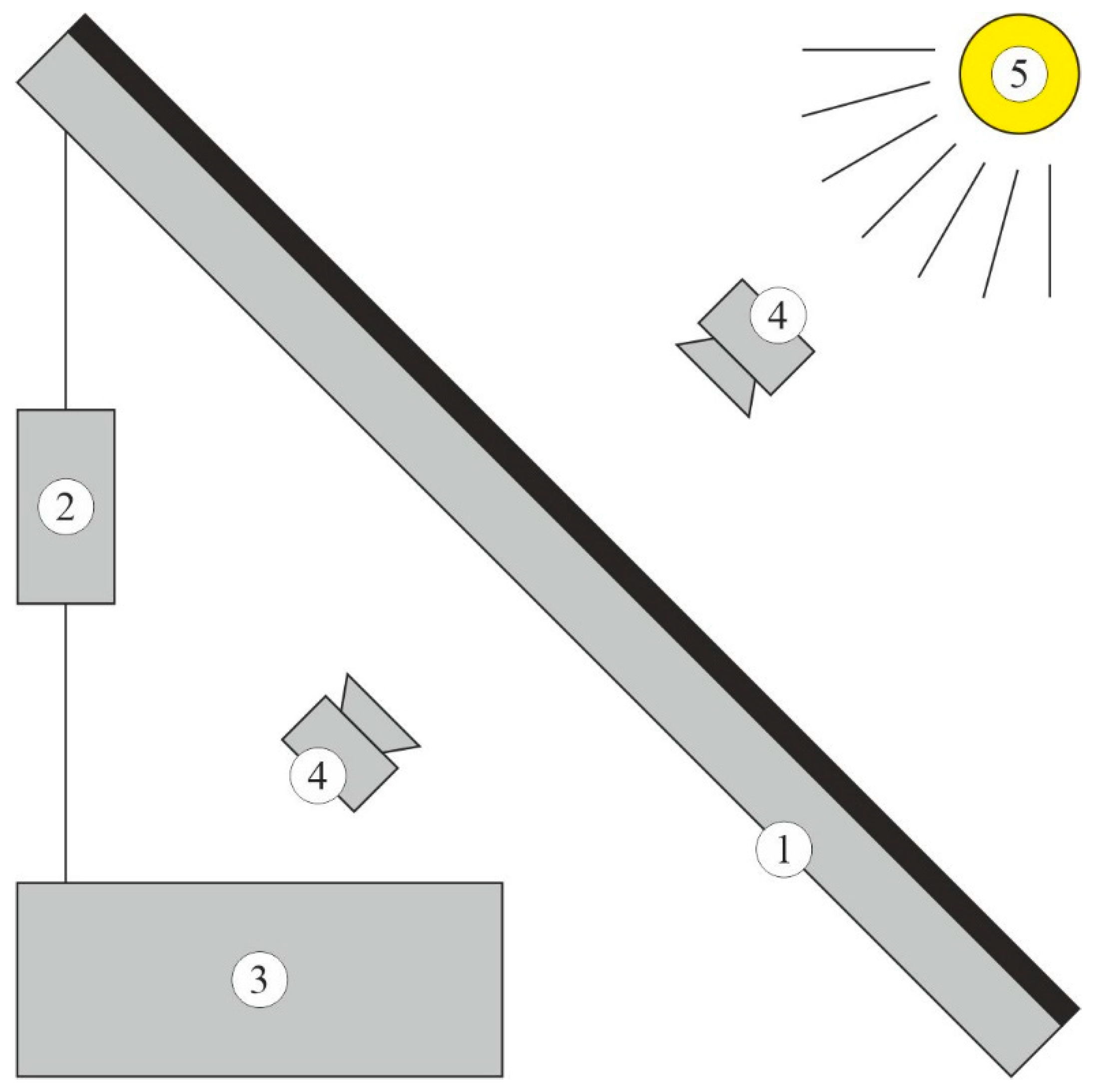

2. Experiment

2.1. Experimental Stand

2.2. Experimental Procedure

2.3. Experimental Data and Uncertainties

3. Numerical Simulation with Mesh Validation

3.1. CAD Model of the PV Panel

3.2. Characteristics of Numerical Calculations

- A steady-state condition was assumed for the experiment.

- The ambient air temperature was assumed to be similar to that measured in the experiment.

- The temperature of the panel from the sunlight side corresponded to the average temperature based on the infrared measurements on the outer PV surface according to the data collected in the experiment.

- The K-epsilon turbulence and Reynolds-averaged Navier–Stokes (RANS) computational models were adopted for the volume corresponding to the air surrounding the PV panel. The main physical parameters of the air were described using the real gas and equilibrium air modules.

- The properties of the PV panel materials were independent in terms of temperature.

3.3. Mesh Validation Analysis Based on the Grid Convergence Index (GCI)

4. Results from Numerical Simulations

- With drilled holes on the surface of the free spaces between the PV panel [6], the temperature difference was up to 19 °C (depending on the number of holes);

- Using perforations on the surface of the front panel [7] helped to reduce the temperature by 4 °C;

- The application of water to the bottom surface of the photovoltaic panel for cooling (a cold plate attached to the PV panel consisting of several channels) [8] led to a temperature reduction of up to 23.5 °C;

- Using a hybrid cooling system (thermoelectric modules and water) [9] resulted in a reduction in operating temperature by 9 °C;

- Considering the effect of composite phase-change materials (paraffin jelly–expanded perlite) [13] led to a reduction of 5.1 °C in the average temperature difference.

5. Validation of the Calculation Results with Experimental Data

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maleki, A.; Haghighi, A.; El Haj Assad, M.; Mahariq, I.; Alhuyi Nazari, M. A review on the approaches employed for cooling PV cells. Sol. Energy 2020, 209, 170–185. [Google Scholar] [CrossRef]

- Bilen, K.; Erdoğan, İ. Effects of cooling on performance of photovoltaic/thermal (PV/T) solar panels: A comprehensive review. Sol. Energy 2023, 262, 111829. [Google Scholar] [CrossRef]

- Sharaf, M.; Yousef, M.S.; Huzayyin, A.S. Review of cooling techniques used to enhance the efficiency of photovoltaic power systems. Environ. Sci. Pollut. Res. 2022, 29, 26131–26159. [Google Scholar] [CrossRef] [PubMed]

- Bošnjaković, M.; Stojkov, M.; Katinić, M.; Lacković, I. Effects of Extreme Weather Conditions on PV Systems. Sustainability 2023, 15, 16044. [Google Scholar] [CrossRef]

- Tripathi, A.K.; Murthy, C.S.N.; Aruna, M. Performance analysis of PV panel under varying surface temperature. MATEC Web Conf. 2018, 144, 04004. [Google Scholar] [CrossRef]

- Abd-Elhadya, M.S.; Seragb, Z.; Kandilc, H.A. An innovative solution to the overheating problem of PV panels. Energy Convers. Manag. 2018, 157, 452–459. [Google Scholar] [CrossRef]

- Nižetić, S.; Marinić-Kragić, I.; Grubišić-Čabol, F.; Papadopoulos, A.M.; Xie, G. Analysis of novel passive cooling strategies for free-standing silicon photovoltaic panels. J. Therm. Anal. Calorim. 2020, 141, 163–175. [Google Scholar] [CrossRef]

- Chin, C.S.; Gao, Z.; Han, M.; Zhang, C. Enhancing performance of photovoltaic panel by cold plate design with guided channels. IET Renew. Power Gener. 2020, 14, 1606–1617. [Google Scholar] [CrossRef]

- Amelia, A.R.; Jusoh, M.A.; Idris, I.S. Effect of Thermoelectric Cooling (TEC) module and the water flow heatsink on Photovoltaic (PV) panel performance. EPJ Web Conf. 2017, 162, 01077. [Google Scholar] [CrossRef]

- Jafari, R.; Erkılıç, K.T.; Ugurer, D.; Kanbur, Y.; Yıldız, M.Ö.; Ayhan, E.B. Enhanced photo-voltaic panel energy by minichannel coolerand natural geothermal system. Int. J. Energy Res. 2021, 45, 13646–13656. [Google Scholar] [CrossRef]

- Omri, M.; Selimefendigil, F.; Smaoui, H.T.; Kolsi, L. Cooling system design for photovoltaic thermal management by using multiple porous deflectors and nanofluid. Case Stud. Therm. Eng. 2022, 39, 102405. [Google Scholar] [CrossRef]

- Ocłoń, P.; Cisek, P.; Kozak-Jagieła, E.; Taler, J.; Taler, D.; Skrzyniowska, D.; Fedorczak-Cisak, M. Modeling and experimental validation and thermal performance assessment of a sun-tracked and cooled PVT system under low solar irradiation. Energy Convers. Manag. 2020, 222, 113289. [Google Scholar] [CrossRef]

- Govindasamy, D.; Kumar, A. Effect of composite phase-change materials on improving the efficiency of solar photovoltaic panels. Heat. Mass. Transf. 2023, 59, 1949–1970. [Google Scholar] [CrossRef]

- Available online: https://termopasty.pl/produkty/pasta-silikonowa-termoprzewodzaca-h/ (accessed on 2 October 2023).

- Available online: https://www.everysolarthing.com/solar/panels/plus-power-tech-co-ltd/ (accessed on 3 September 2023).

- Available online: https://www.flir.com/products/e96/ (accessed on 15 October 2023).

- Piasecka, M.; Maciejewska, B.; Piasecki, A. Heat Transfer Calculations during Flow in Mini-Channels with Estimation of Temperature Uncertainty Measurements. Energies 2023, 16, 1222. [Google Scholar] [CrossRef]

- Available online: https://www.label.pl/po/rejestrator-lb532.termometry-elektroniczne.html (accessed on 10 November 2023).

- Piasecka, M.; Piasecki, A.; Dadas, N. Experimental Study and CFD Modeling of Fluid Flow and Heat Transfer Characteristics in a Mini-channel Heat Sink Using Simcenter STAR-CCM+ Software. Energies 2022, 15, 536. [Google Scholar] [CrossRef]

- Elqady, H.I.; Ookawara, S.; El-Shazly, A.H.; Elkady, M.F. Influence of encapsulation materials on the thermal performance of concentrator photovoltaic cells. Case Stud. Therm. Eng. 2021, 26, 101135. [Google Scholar] [CrossRef]

- Celik, I.B.; Ghia, U.; Roache, P.J.; Freitas, C.J.; Coleman, H.; Raad, P.E. Procedure for estimation and reporting of uncertainty due to discretization in CFD applications. J. Fluids Eng. Trans. ASME 2008, 130, 0780011–0780014. [Google Scholar] [CrossRef]

- Sosnowski, M. Evaluation of Heat Transfer Performance of a Multi-Disc Sorption Bed Dedicated for Adsorption Cooling Technology. Energies 2019, 12, 4660. [Google Scholar] [CrossRef]

| Citation | Characteristics of Investigations with PV Panel Cooling | Main Findings |

|---|---|---|

| [6] |

|

|

| [7] |

|

|

| [8] |

|

|

| [9] |

|

|

| [10] |

|

|

| [11] |

|

|

| [12] |

|

|

| [13] |

|

|

| Parameter | Value |

|---|---|

| Average temperature on the outer surface of the PV panel from the top side, K | 325.60 |

| Temperature of the ambient air, K | 295.15 |

| Atmospheric pressure, Pa | 101,325 |

| Relative humidity, % | 41.2 |

| Parameter | Measurement Range | Measurement Uncertainty |

|---|---|---|

| Relative humidity, % | 0–100 | ±2.0 |

| Temperature, °C | 0–+40 | 0.11 |

| Pressure, hPa | 700–1100 | 1.0 |

| Designation of PV Panel: PV A-W-H | A, mm | G, mm | W, mm | P, mm | H, mm |

|---|---|---|---|---|---|

| PV bare (used in the experiment and simulation) | - | - | - | - | - |

| PV with a cooper sheet with a smooth outer surface (used in the experiment and simulation) | - | 2 | - | - | - |

| PV 1-0.5-1 | 1 | 2 | 0.5 | 1.5 | 1 |

| PV 2-0.5-1 | 2 | 2 | 0.5 | 2.5 | 1 |

| PV 2-1-1 | 2 | 2 | 1 | 3 | 1 |

| PV 2-1.5-1 | 2 | 2 | 1.5 | 3.5 | 1 |

| PV 4-1-0.5 (used in the experiment and simulation) | 4 | 2 | 1 | 5 | 0.5 |

| PV 4-1-1 | 4 | 2 | 1 | 5 | 1 |

| PV 6-1-1 | 6 | 2 | 1 | 7 | 1 |

| Models Used for the Fluid |

|---|

| K-epsilon turbulence |

| Segregated fluid temperature |

| Reynolds-averaged Navier–Stokes |

| Steady |

| Constant density |

| Segregated flow |

| Three-dimensional model |

| Material of the PV Panel Components | Density | Thermal Conductivity | Specific Heat |

|---|---|---|---|

| EVA | 960 | 0.311 | 2090 |

| Silicon | 2330 | 130 | 677 |

| Glass pane | 3000 | 2 | 500 |

| Element | Air | Copper Sheet | Glass | EVA (Top Side) | Silicon | EVA (Bottom Side) | |

|---|---|---|---|---|---|---|---|

| Fine Mesh | Cells | 637,219 | 730,292 | 769,735 | 3,260,947 | 3,927,365 | 3,260,134 |

| Faces | 4,497,251 | 3,371,534 | 4,178,783 | 14,431,146 | 17,089,479 | 14,427,322 | |

| Vertices | 3,9464,12 | 2,317,029 | 3,172,407 | 9,648,596 | 11,870,043 | 9,645,604 | |

| Medium Mesh | Cells | 629,440 | 663,401 | 604,430 | 2,365,707 | 2,502,711 | 2,377,716 |

| Faces | 4,446,619 | 2,907,102 | 2,996,423 | 10,741,002 | 11,323,517 | 10,826,120 | |

| Vertices | 3,901,707 | 1,924,429 | 2,160,637 | 7,616,690 | 8,820,739 | 7,726,620 | |

| Coarse Mesh | Cells | 512,583 | 646,805 | 574,856 | 1,684,657 | 871,050 | 1,676,866 |

| Faces | 3,601,988 | 2,811,248 | 2,794,824 | 7,616,690 | 4,397,346 | 7,544,567 | |

| Vertices | 3,166,144 | 1,849,253 | 1,991,685 | 9,643,857 | 4,351,275 | 5,344,702 |

| Mesh | (−) | (−) | (K) | (−) | (K) | (−) | (%) | (%) |

|---|---|---|---|---|---|---|---|---|

| Fine | 5.22 × 10−4 | 12,585,692 | 318.49 | 1.112 | 0.283 | 1.714 | 0.09 | 0.55 |

| Medium | 5.80 × 10−4 | 9,143,405 | 318.78 | |||||

| 1.153 | 0.928 | 0.29 | 1.32 | |||||

| Coarse | 6.69 × 10−4 | 5,966,817 | 319.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piasecka, M.; Piasecki, A.; Dadas, N. An Experimental Investigation and Numerical Simulation of Photovoltaic Cells with Enhanced Surfaces Using the Simcenter STAR-CCM+ Software. Energies 2023, 16, 8047. https://doi.org/10.3390/en16248047

Piasecka M, Piasecki A, Dadas N. An Experimental Investigation and Numerical Simulation of Photovoltaic Cells with Enhanced Surfaces Using the Simcenter STAR-CCM+ Software. Energies. 2023; 16(24):8047. https://doi.org/10.3390/en16248047

Chicago/Turabian StylePiasecka, Magdalena, Artur Piasecki, and Norbert Dadas. 2023. "An Experimental Investigation and Numerical Simulation of Photovoltaic Cells with Enhanced Surfaces Using the Simcenter STAR-CCM+ Software" Energies 16, no. 24: 8047. https://doi.org/10.3390/en16248047

APA StylePiasecka, M., Piasecki, A., & Dadas, N. (2023). An Experimental Investigation and Numerical Simulation of Photovoltaic Cells with Enhanced Surfaces Using the Simcenter STAR-CCM+ Software. Energies, 16(24), 8047. https://doi.org/10.3390/en16248047