Multi-Criteria Optimization of Energy and Water Consumption in Fruit- and Vegetable-Processing Plants in Poland

Abstract

:1. Introduction

- On the basis of empirical studies in fruit- and vegetable-processing plants, a dataset was collected on the basis of which three regression models of heat, electricity and water consumption were developed.

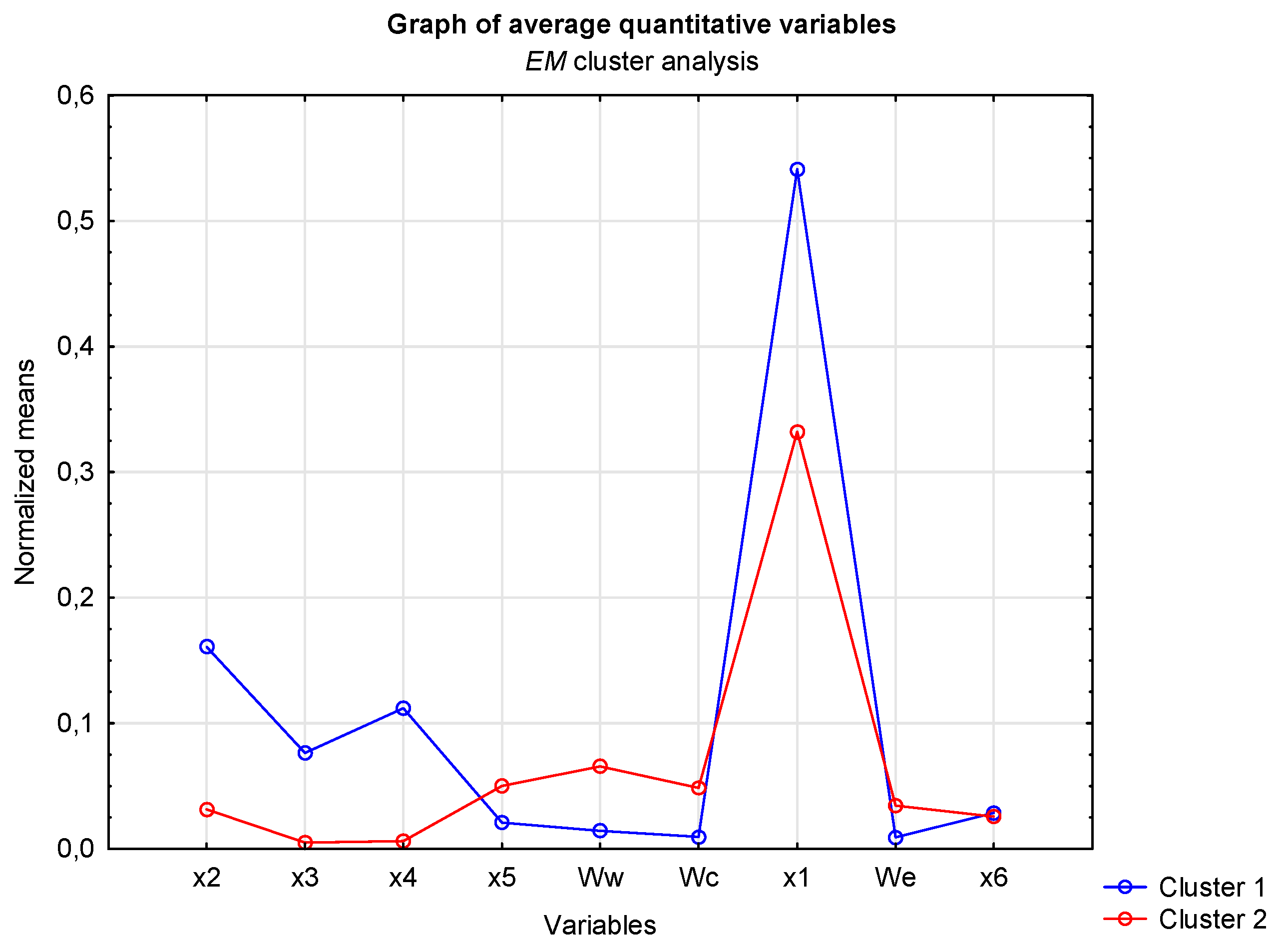

- The dataset was subjected to preliminary data analysis, excluding incomplete and outlier cases. The resulting 808 data cases were subjected to a non-hierarchical cluster analysis method, determining a set of 604 cases excluding cases with low values of independent variables (in such cases, the process is incomplete due to the limited volume of processed product and, in such a process, the use of equipment is inefficient).

- The dataset of 604 cases was subjected to an analysis of variance (ANOVA) to isolate the variables (predictors) that have the most significant impact on all three dependent variables (heat, electricity and water consumption).

- The extracted dataset and predictors were the basis for developing a neural model of the process describing heat, electricity and water consumption together.

- The neural model of heat, electricity and water consumption was the basis for formulating a multi-criteria optimization task.

- The solution of the optimization task was performed using genetic algorithms obtaining a set of optimal solutions in the Pareto sense.

2. Analysis of Fruit and Vegetable Processing

2.1. Thermal Energy Consumption

2.2. Electric Energy Usage

2.3. Water Consumption

3. Data Analysis

4. Modelling of ANN Architecture

5. Multi-Criteria Optimization of Fruit and Vegetable Processing

5.1. Pareto Solutions Using a Multi-Criteria Genetic Algorithm

5.2. The Optimization Results

6. Conclusions

- The power of the equipment installed in the plant and the production structure of selected products have the greatest impact on the consumption of energy and water in the processing of fruit and vegetables.

- The optimization results showed that with similar power of the installed devices, it is possible to use up to five times less thermal energy and several times less water consumption, but the processing structure needs to be selected appropriately.

- Sensitivity analysis of the neural model shows that the production of juices and beverages and the power of equipment installed in the plant have more than twice the impact on energy and water consumption than other independent variables.

- The results of Pareto optimization can be the basis for the use of sustainable technology in selected fruit- and vegetable-processing plants.

- Electricity consumption is inversely proportional to water and heat consumption in fruit and vegetable processing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| ANOVA for Continuous Variables, Number of Clusters: 2, Total Number of Training Cases: 808 | ||||||

|---|---|---|---|---|---|---|

| Outgroup SS | df | Intragroup SS | df | F | p-Value | |

| x2 | 1.943046 × 105 | 1 | 1.837805 × 106 | 806 | 85.2155 | 0.000000 |

| x3 | 4.484888 × 105 | 1 | 7.026927 × 106 | 806 | 51.4424 | 0.000000 |

| x4 | 1.628664 × 105 | 1 | 2.308415 × 106 | 806 | 56.8660 | 0.000000 |

| x5 | 2.088467 × 103 | 1 | 8.127049 × 104 | 806 | 20.7124 | 0.000006 |

| Ww | 6.805427 × 105 | 1 | 5.072564 × 106 | 806 | 108.1341 | 0.000000 |

| Wc | 2.218745 × 104 | 1 | 1.817085 × 105 | 806 | 98.4163 | 0.000000 |

| x1 | 1.323167 × 109 | 1 | 1.400941 × 1010 | 806 | 76.1255 | 0.000000 |

| We | 1.440855 × 108 | 1 | 1.963493 × 109 | 806 | 59.1461 | 0.000000 |

| x6 | 3.956767 × 101 | 1 | 7.864680 × 105 | 806 | 0.0406 | 0.840459 |

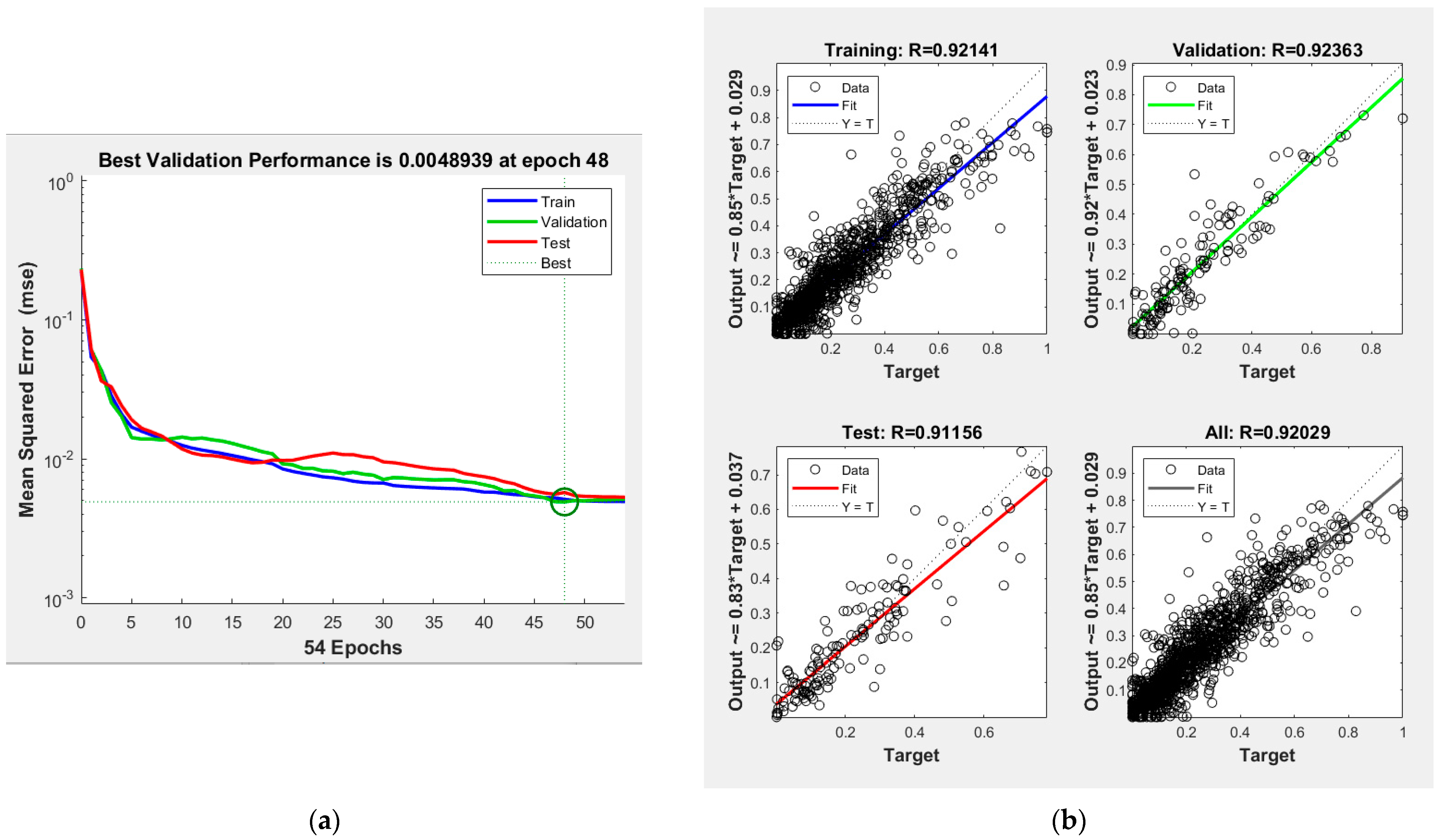

| ID | Activate Function in the Hidden Layer | Number of Neurons in the Hidden Layer | Activate Function in the Output Layer | Statistical Analysis | |

|---|---|---|---|---|---|

| MSE | R | ||||

| 1 | log-sigmoid | 4 | 0.0168040 | 0.75844 | |

| 2 | 9 | pureline | 0.0169810 | 0.70719 | |

| 3 | 14 | 0.1732000 | 0.73911 | ||

| 4 | 4 | 0.0271820 | 0.63388 | ||

| 5 | 9 | log-sigmoid | 0.0072654 | 0.88576 | |

| 6 | 14 | 0.0048939 | 0.92363 | ||

| 7 | tan-sigmoid | 4 | 0.0160180 | 0.71191 | |

| 8 | 9 | pureline | 0.0123480 | 0.74598 | |

| 9 | 14 | 0.0062469 | 0.88769 | ||

| 10 | 4 | 0.0110210 | 0.77659 | ||

| 11 | 9 | log-sigmoid | 0.0086862 | 0.81746 | |

| 12 | 14 | 0.0059845 | 0.90975 | ||

References

- Cuéllar, A.D.; Webber, M.E. Wasted food, wasted energy: The embedded energy in food waste in the United States. Environ. Sci. Technol. 2010, 44, 6464–6469. [Google Scholar] [CrossRef]

- Hitchens, D.M.; Trainor, M.; Clausen, J.; Thankappan, S.; de Marchi, B. Fruit & Vegetable Processing Industry. In Small and Medium Sized Companies in Europe; Environmental Performance, Competitiveness and Management. International EU Case Studies; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2003; pp. 117–159. [Google Scholar]

- Jongen, W. (Ed.) Fruit and Vegetable Processing: Improving Quality; Elsevier: Amsterdam, The Netherlands, 2002; ISBN 0-8493-1547-1. [Google Scholar]

- Lozano, J. Overview of the Fruit Processing Industry. In Fruit Manufacturing; Springer: Boston, MA, USA, 2006; p. 27. [Google Scholar] [CrossRef]

- Lu, J.; Vigneault, C.; Charles, M.T.; Raghavan, G.V. Heat treatment application to increase fruit and vegetable quality. Stewart Postharvest Rev. 2007, 3, 4. [Google Scholar]

- Classen, J.; Siebenmorgen, T.J.; Griffis, C.L.; Young, J.C. Processing energy requirements for several vegetables. Trans. ASEA 1992, 35, 973–974. [Google Scholar] [CrossRef]

- Grzybek, A. Impact of selected technologies on the environment and energy consumption of fruit and vegetable processing (In Polish: Wpływ wybranych technologii na środowisko i energochłonność przetwórstwa owocowo-warzywnego). Rozprawy habilitacyjne nr 12. Inżynieria Rol. 2003, 2. Available online: http://ir.ptir.org/ (accessed on 13 December 2023).

- Wojdalski, J.; Dróżdż, B.; Lubach, M. Conditions of heat management in fruit and vegetable processing plants. (In Polish: Uwarunkowania gospodarki cieplnej w zakładach przetwórstwa owocowo-warzywnego). MOTROL Motoryz. Energetyka Rol. 2006, 8A, 286–293. [Google Scholar]

- Wojdalski, J.; Drożdż, B.; Lubach, M. Factors influencing electrical energy consumption in fruit and vegetables processing plants. Pol. J. Food Nutr. Sci. 2007, 57, 195–199. [Google Scholar]

- Wojdalski, J.; Dróżdż, B.; Lubach, M. Factors influencing energy consumption in fruit and vegetable processing plants. MOTROL Motoryz. I Energetyka Rol. 2007, 7, 277–285. [Google Scholar]

- Asgharnejad, H.; Khorshidi Nazloo, E.; Madani Larijani, M.; Hajinajaf, N.; Rashidi, H. Comprehensive review of water management and wastewater treatment in food processing industries in the framework of water-food-environment nexus. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4779–4815. [Google Scholar] [CrossRef]

- Derden, A.; Vercaemst, P.; Dijkmans, R. Best available techniques (BAT) for the fruit and vegetable processing industry. Resour. Conserv. Recycl. 2002, 34, 261–271. [Google Scholar] [CrossRef]

- Hackett, B.; Chow, R. Energy efficiency opportunities in fresh fruit and vegetable processing/cold storage facilities. In Proceedings of the 2005 ACEEE Summer Study on Energy Efficiency in Industry, Washington, DC, USA, 19 July 2005; American Council for an Energy-Efficient: Washington, DC, USA, 2005. [Google Scholar]

- Masanet, E. Energy efficiency improvement and cost saving opportunities for the fruit and vegetable processing industry. In An Energy Star Guide for Energy and Plant Managers; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2008; pp. 68–70. Available online: http://escholarship.org/uc/item/8h25n5pr (accessed on 13 December 2023).

- Strzelczyk, M.; Steinhoff-Wrześniewska, A.; Rajmund, A. Indicators of water consumption and the quantity of wastewater formed in selected branches of food industry. Pol. J. Chem. Technol. 2010, 12, 6–10. [Google Scholar] [CrossRef]

- Gil, M.I.; Selma, M.V.; López-Gálvez, F.; Allende, A. Fresh-cut product sanitation and wash water disinfection: Problems and solutions. Int. J. Food Microbiol. 2009, 134, 37–45. [Google Scholar] [CrossRef]

- Wróbel-Jędrzejewska, M.; Stęplewska, U.; Kuleta, P.; Przybysz, Ł.; Polak, E. Carbon footprint of fruit paste technology. Pol. J. Environ. Stud. 2016, 25, 341–349. [Google Scholar] [CrossRef]

- Rahim, R.; Ramann, A.A.A. Cleaner production implementation in a fruit juice production plant. J. Clean. Prod. 2015, 101, 215–221. [Google Scholar] [CrossRef]

- Muhirwa, F.; Shen, L.; Elshkaki, A.; Chiaka, J.C.; Zhong, S.; Bönecke, E.; Hirwa, H.; Seka, A.M.; Habiyakare, T.; Tuyishimire, A.; et al. Alert in the dynamics of water-energy-food production in African countries from a nexus perspective. Resour. Conserv. Recycl. 2023, 194, 106990. [Google Scholar] [CrossRef]

- Trajer, J.; Winiczenko, R.; Dróżdż, B. Analysis of Water Consumption in Fruit and Vegetable Processing Plants with the Use of Artificial Intelligence. Appl. Sci. 2021, 11, 10167. [Google Scholar] [CrossRef]

- Wojdalski, J.; Dróżdż, B.; Lubach, M. Factors influencing water consumption in fruit and vegetable processing plants. (In Polish: Czynniki wpływające na zużycie wody w zakładach przetwórstwa owocowo-warzywnego). Postępy Tech. Przetwórstwa Spożywczego 2005, 15, 39–43. [Google Scholar]

- Gorbenko, E.; Cheban, A. Optimizations of Technological Process of Processing of Fruit and Vegetable Raw Material on Juice. Motrol 2008, 10b, 220–229. [Google Scholar]

- Man, Y.; Han, Y.; Liu, Y.; Lin, R.; Ren, J. Multi-criteria decision making for sustainability assessment of boxboard production: A life cycle perspective considering water consumption, energy consumption, GHG emissions, and internal costs. J. Environ. Manag. 2020, 255, 109860. [Google Scholar] [CrossRef]

- Mitroczuk, I.J. Energy Transformation: Challenges and Opportunities—The Polish Case. Environ. Prot. Nat. Res. 2022, 33, 21–34. [Google Scholar] [CrossRef]

- Lemes, D.L.; Jacques, M.M.; Sousa, N.B.; Bernardon, D.P.; Sperandio, M.; Silva, J.A.; Chiara, L.M. Estimation of Electrical Energy Consumption in Irrigated Rice Crops in Southern Brazil. Energies 2023, 16, 6742. [Google Scholar] [CrossRef]

- Singh, R.P. Energy Accounting of Food Processing Operations (in Energy in Food Processing); Elsevier: Amsterdam, The Netherlands; Oxford, UK; New York, NY, USA; Tokyo, Japan, 1986; Volume 33, p. 36. [Google Scholar]

- Gasparino, F.J.; Vitali, A.A.; Viegas, F.C.P.; Rao, M.A. Energy consumption in a concentrated orange juice plant. J. Food Process. Energy 1984, 7, 77–89. [Google Scholar] [CrossRef]

- Sogut, Z.; Ilten, N.; Oktay, Z. Energetic and exergetic performance evaluation of the quadruple-effect evaporator unit in tomato paste production. Energy 2010, 9, 3821–3826. [Google Scholar] [CrossRef]

- Alvarez, S.; Riera, F.A.; Alvarez, R.; Coca, J.; Cuperus, F.P.; Bouwer, S.T.; Panyor, L. A new integrated membrane process for producing clarified apple juice and apple juice aroma concent. J. Food Eng. 2000, 46, 109–125. [Google Scholar] [CrossRef]

- Kubicki, M. (Ed.) Environmental Protection in the Fruit and Vegetable Industry. (In Polish: Ochrona Środowiska w Przemyśle Owocowo-Warzywnym); Wyd. FAPA: Warszawa, Poland, 1998; pp. 30–36, 38–43. [Google Scholar]

- WS Atkins International. Ochrona Środowiska w Przemyśle Rolno-Spożywczym; Standardy środowiskowe; Fapa: Warszawa, Poland, 1998; pp. 66–69, 107. [Google Scholar]

- Grzybek, A.; Rogulska, M. Material and Energy Inputs and Cumulative Energy Consumption in the Production of Fruit and Vegetable Preserves (In Polish: Nakłady Materiałowo-Energetyczne i Energochłonność Skumulowana Produkcji Przetworów Owocowo-Warzywnych); Zeszyt IBMER: Warszawa, Poland, 1992. [Google Scholar]

- McDonald, K.; Sun, D.W. Vacuum cooling technology for the food processing industry: A review. J. Food Eng. 2000, 45, 55–65. [Google Scholar] [CrossRef]

- Morris, C.; Brody, A.L.; Wicker, L. Non-thermal food processing/preservation technologies: A review with packaging implications. Packag. Technol. Sci. 2007, 20, 275–286. [Google Scholar] [CrossRef]

- Rico, D.; Martin-Diana, A.B.; Barat, J.M.; Barry-Ryan, C. Extending and measuring the quality of fresh-cut fruit and vegetables: A review. Trends Food Sci. Technol. 2007, 18, 373–386. [Google Scholar] [CrossRef]

- Szymańska, E.J.; Mroczek, R. Energy Intensity of Food Industry Production in Poland in the Process of Energy Transformation. Energies 2023, 16, 1843. [Google Scholar] [CrossRef]

- Witten, I.H.; Frank, E. Data Mining: Practical Machine Learning Tools and Techniques; Morgan Kaufmann: Burlington, NY, USA, 2000. [Google Scholar]

- MATLAB 7.6 R2008a. Documentation R.; MathWorks Inc.: Natick, MA, USA, 2008.

- Deb, K. Optimization for Engineering Design: Algorithms and Examples; Prentice-Hall: New Delhi, India, 1996. [Google Scholar]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization and Machine Learning; Addison-Wesley: Boston, MA, USA, 1989. [Google Scholar]

- Sahu, M.; Bhattacharjee, B.; Kaushik, S.C. Thermal design of air conditioned building for tropical climate using admittance method and genetic algorithm. Energy Build 2012, 5, 1–6. [Google Scholar] [CrossRef]

- Dyer, J.D.; Hartfield, R.J.; Dozier, G.V.; Burkhalter, J.E. Aerospace design optimization using a steady state real-coded genetic algorithm. Appl. Math Comput. 2012, 218, 4710–4730. [Google Scholar] [CrossRef]

- Winiczenko, R.; Górnicki, K.; Kaleta, A.; Martynenko, A.; Janaszek-Mańkowska, M.; Trajer, J. Multi-Objective Optimization of Convective Drying of Apple Cubes. Comput. Electron. Agric. 2018, 145, 341–348. [Google Scholar] [CrossRef]

| Group of Independent Variables | Regression Equations | R2 | SE | Independent Variables | |

|---|---|---|---|---|---|

| Designation, Dimension | Numerical Range | ||||

| II | Ac = −260.8 + 0.74⋅P2 + 25.15⋅ | 0.618 | 269.0 | P1 [kW] P2 [kW] | 41–1715 25–932 |

| III | Ac = 200.5 + 3.6Z3 + 211.9⋅logZ1 + 443.0⋅logZ2 | 0.596 | 276.7 | Z1 [kg] Z2 [kg] Z3 [kg] | (0.585–772.980) × 103 (2.920–8.640) × 103 (0.765–191.094) × 103 |

| IV | Wc = −0.39 + 0.0014K2 | 0.845 | 8.9 | K2 [m3/kg] | (307–307.692) × 10−3 |

| Group of Independent Variables | Regression Equations | R2 | SE | Independent Variables | |

|---|---|---|---|---|---|

| Designation, Dimension | Numerical Range | ||||

| I | Ae = 6806.04 + 0.0006⋅P2 | 0.635 | 23,360 | P [kW] | 413–14,237 |

| II | Ae = −45,896.0 + 0.0013⋅ + 29,020.5⋅log P4 | 0.708 | 20,920 | P1 [kW] P2 [kW] | 81–6566 35–3588 |

| III | Ae = 8356.4 + 736.6⋅Z5 + 3468.1⋅ 13,703.4⋅logZ1 + 1.35⋅ | 0.630 | 23,560 | Z1 [kg] Z4 [kg] Z5 [kg] Z6 [kg] | (0.6–773.0) × 103 (0.1–282.0) × 103 (0.7–155.6) × 103 (0.5–312.3) × 103 |

| IV | We = 46.7 + 4.12 Km | 0.942 | 420 | Km [kW/kg] | (9–7929) × 10−3 |

| Group of Independent Variables | Regression Equations | R2 | SE | Independent Variables | |

|---|---|---|---|---|---|

| Designation, Dimension | Numerical Range | ||||

| II | Aw = 408.4 + 2.30⋅P1 | 0.543 | 1029 | P1 [kW] | 41–1715 |

| III | Aw = 2180.0 + 66.6⋅logZ1 + 140.50⋅ − 1420.0/Z5 | 0.476 | 1003 | Z1 [kg] Z3 [kg] Z5 [kg] | (64.0–773) × 103 (11.1–191.1) × 103 (3.8–105.0) × 103 |

| IV | Ww = 1.4 + 0.005K2 | 0.843 | 133.7 | K2 [m3/kg] | (563–307,692) × 10−3 |

| Inputs | Outputs | |||||||

|---|---|---|---|---|---|---|---|---|

| ID | x1 [kW] | x2 × 103 [kg/Day] | x3 × 103 [kg/Day] | x4 × 103 [kg/Day] | x5 × 103 [kg/Day] | We × 10−3 [kWh/kg] | Ww × 10−3 [m3/kg] | Wc × 10−3 [GJ/kg] |

| 1 | 3470 | 192 | 204 | 282 | 28 | 3.693 | 0.567 | 0.002 |

| 2 | 4422 | 160 | 231 | 180 | 20 | 2.405 | 0.777 | 0.005 |

| 3 | 4750 | 165 | 191 | 193 | 24 | 2.992 | 0.688 | 0.005 |

| 4 | 3928 | 162 | 211 | 182 | 21 | 2.045 | 1.120 | 0.008 |

| 5 | 3541 | 163 | 219 | 192 | 22 | 1.894 | 1.224 | 0.009 |

| 6 | 4334 | 155 | 216 | 177 | 23 | 1.732 | 1.355 | 0.013 |

| 7 | 3786 | 155 | 217 | 186 | 24 | 1.621 | 1.510 | 0.015 |

| 8 | 3627 | 159 | 214 | 196 | 25 | 1.588 | 1.610 | 0.017 |

| 9 | 3859 | 153 | 216 | 177 | 25 | 1.477 | 1.752 | 0.020 |

| 10 | 4113 | 152 | 210 | 180 | 26 | 1.433 | 1.873 | 0.024 |

| 11 | 3600 | 163 | 216 | 177 | 27 | 1.400 | 1.981 | 0.025 |

| 12 | 3742 | 154 | 202 | 179 | 26 | 1.356 | 2.151 | 0.028 |

| 13 | 3433 | 156 | 208 | 186 | 28 | 1.324 | 2.230 | 0.029 |

| 14 | 3650 | 151 | 203 | 175 | 27 | 1.288 | 2.392 | 0.033 |

| 15 | 3510 | 153 | 201 | 177 | 28 | 1.283 | 2.456 | 0.034 |

| 16 | 3514 | 151 | 199 | 173 | 28 | 1.274 | 2.579 | 0.036 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trajer, J.; Winiczenko, R.; Dróżdż, B.; Wojdalski, J.; Sałat, R. Multi-Criteria Optimization of Energy and Water Consumption in Fruit- and Vegetable-Processing Plants in Poland. Energies 2023, 16, 8118. https://doi.org/10.3390/en16248118

Trajer J, Winiczenko R, Dróżdż B, Wojdalski J, Sałat R. Multi-Criteria Optimization of Energy and Water Consumption in Fruit- and Vegetable-Processing Plants in Poland. Energies. 2023; 16(24):8118. https://doi.org/10.3390/en16248118

Chicago/Turabian StyleTrajer, Jędrzej, Radosław Winiczenko, Bogdan Dróżdż, Janusz Wojdalski, and Robert Sałat. 2023. "Multi-Criteria Optimization of Energy and Water Consumption in Fruit- and Vegetable-Processing Plants in Poland" Energies 16, no. 24: 8118. https://doi.org/10.3390/en16248118

APA StyleTrajer, J., Winiczenko, R., Dróżdż, B., Wojdalski, J., & Sałat, R. (2023). Multi-Criteria Optimization of Energy and Water Consumption in Fruit- and Vegetable-Processing Plants in Poland. Energies, 16(24), 8118. https://doi.org/10.3390/en16248118