Online Nuclear Magnetic Resonance Analysis of the Effect of Stress Changes on the Porosity and Permeability of Shale Oil Reservoirs

Abstract

:1. Introduction

2. Experimental Samples and Equipment

2.1. Experimental Samples

2.2. Experimental Equipment

3. Experimental Procedure and Method

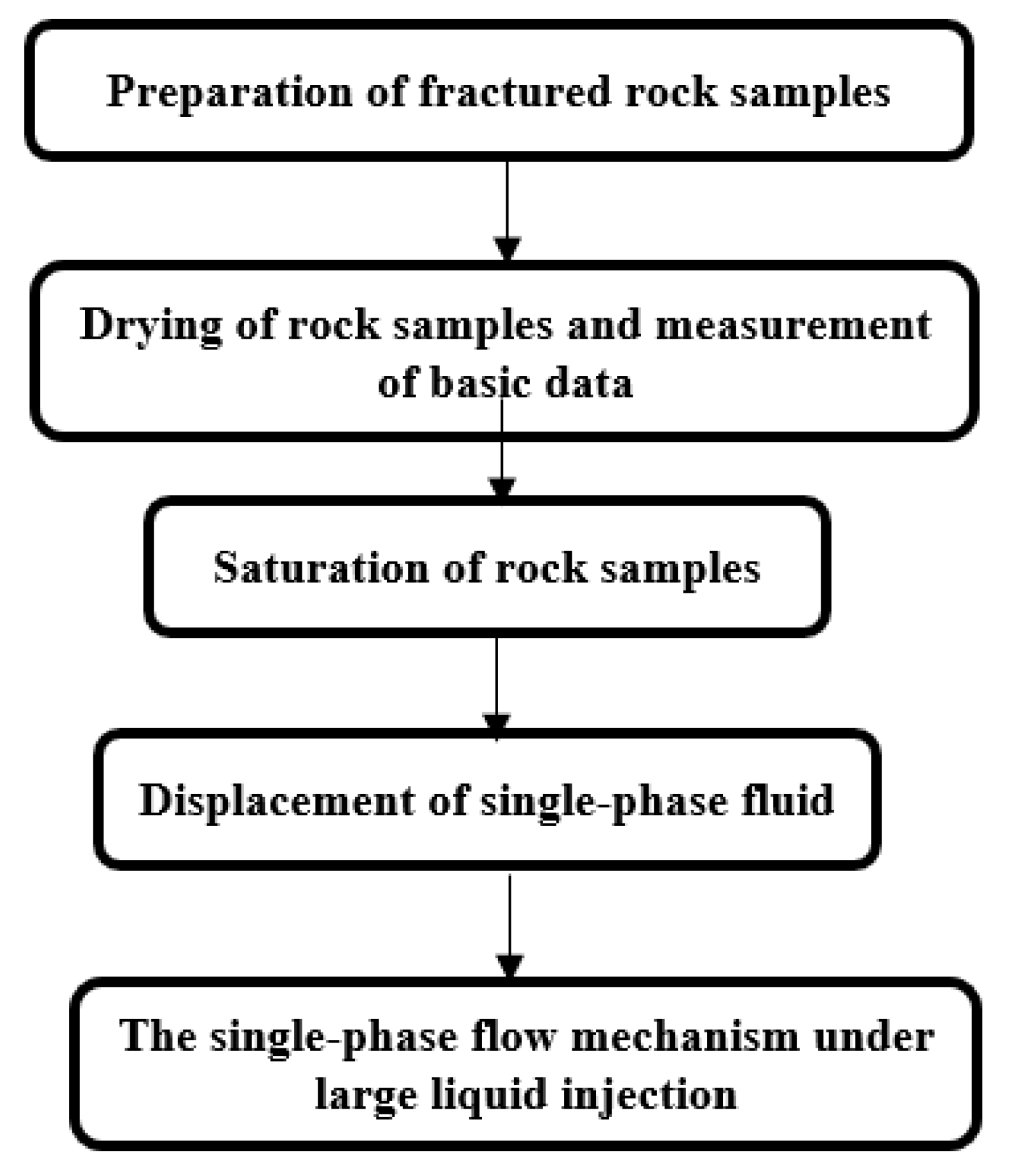

3.1. Experimental Procedure

3.2. Experimental Method

4. Results and Discussion

4.1. The Pore Throat State of Matrix Rock Samples Varies with Pore Pressure

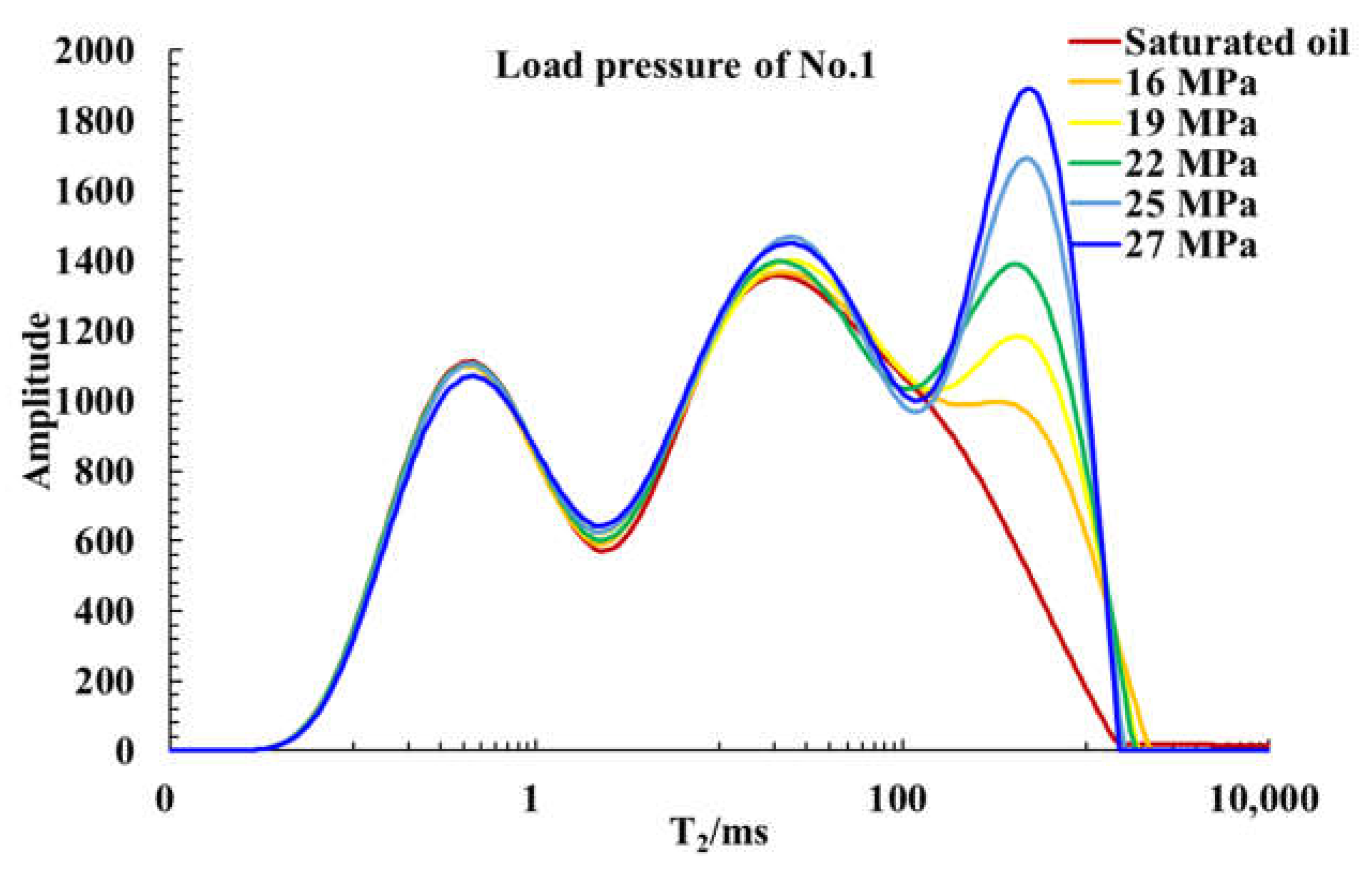

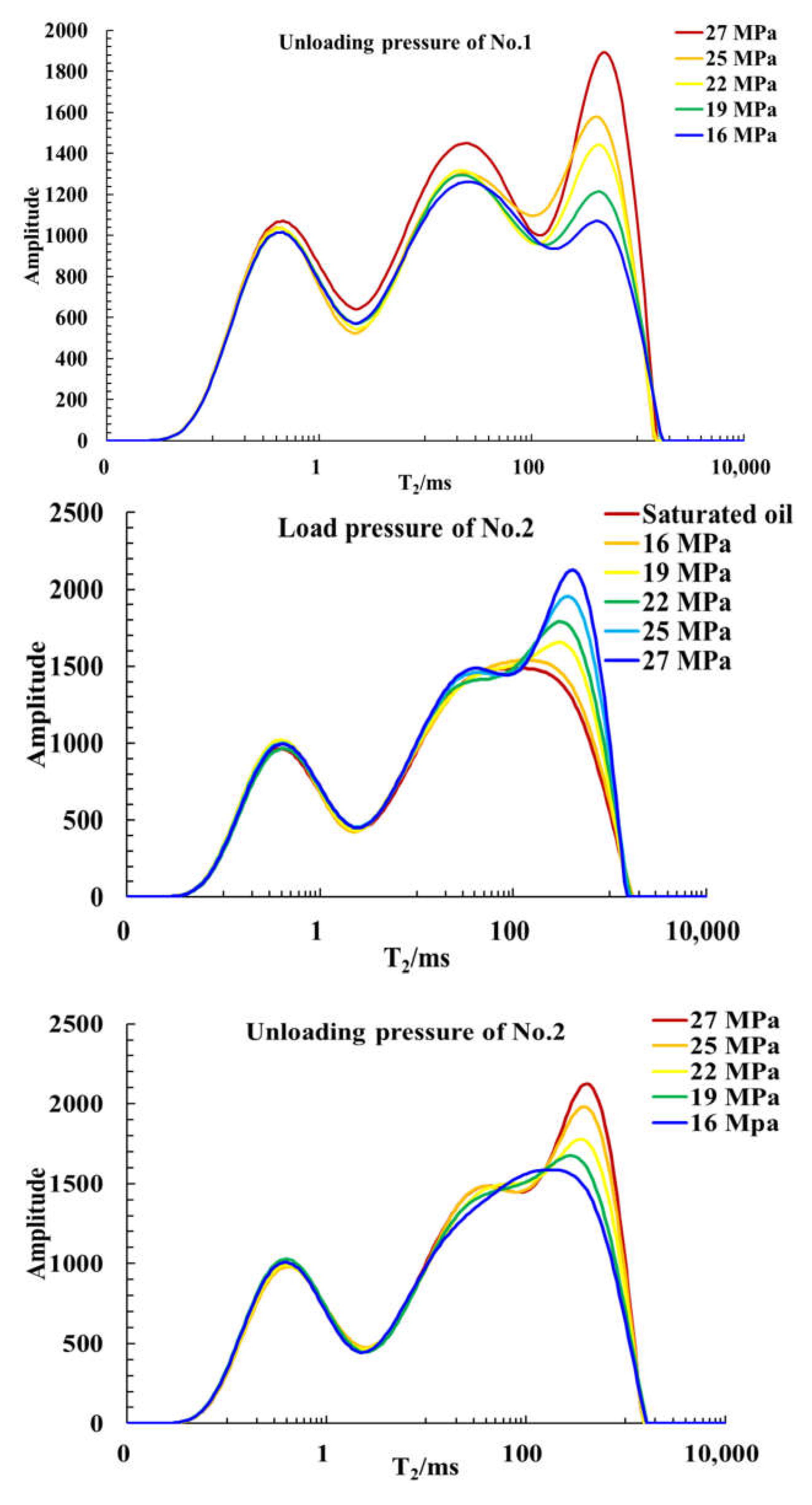

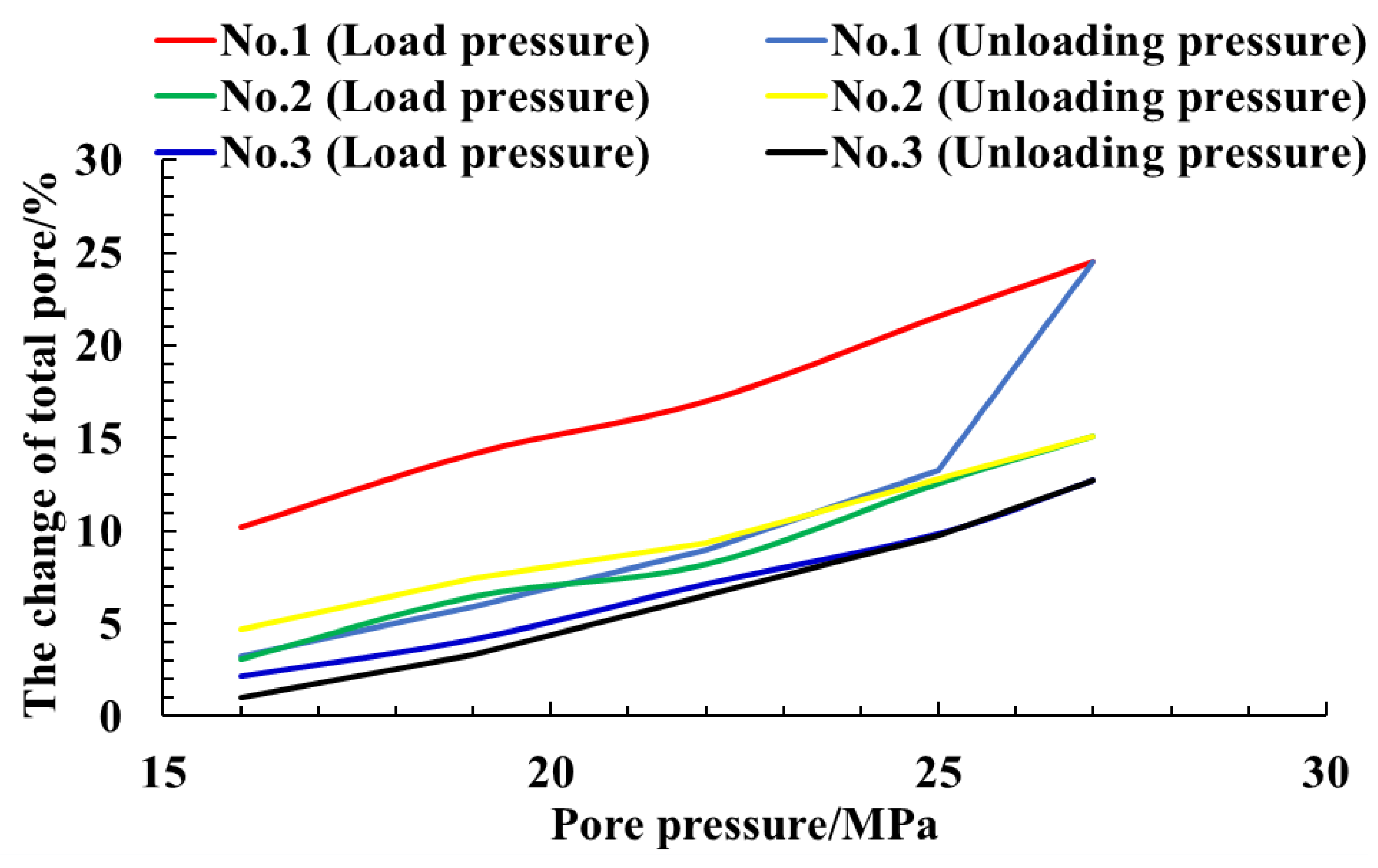

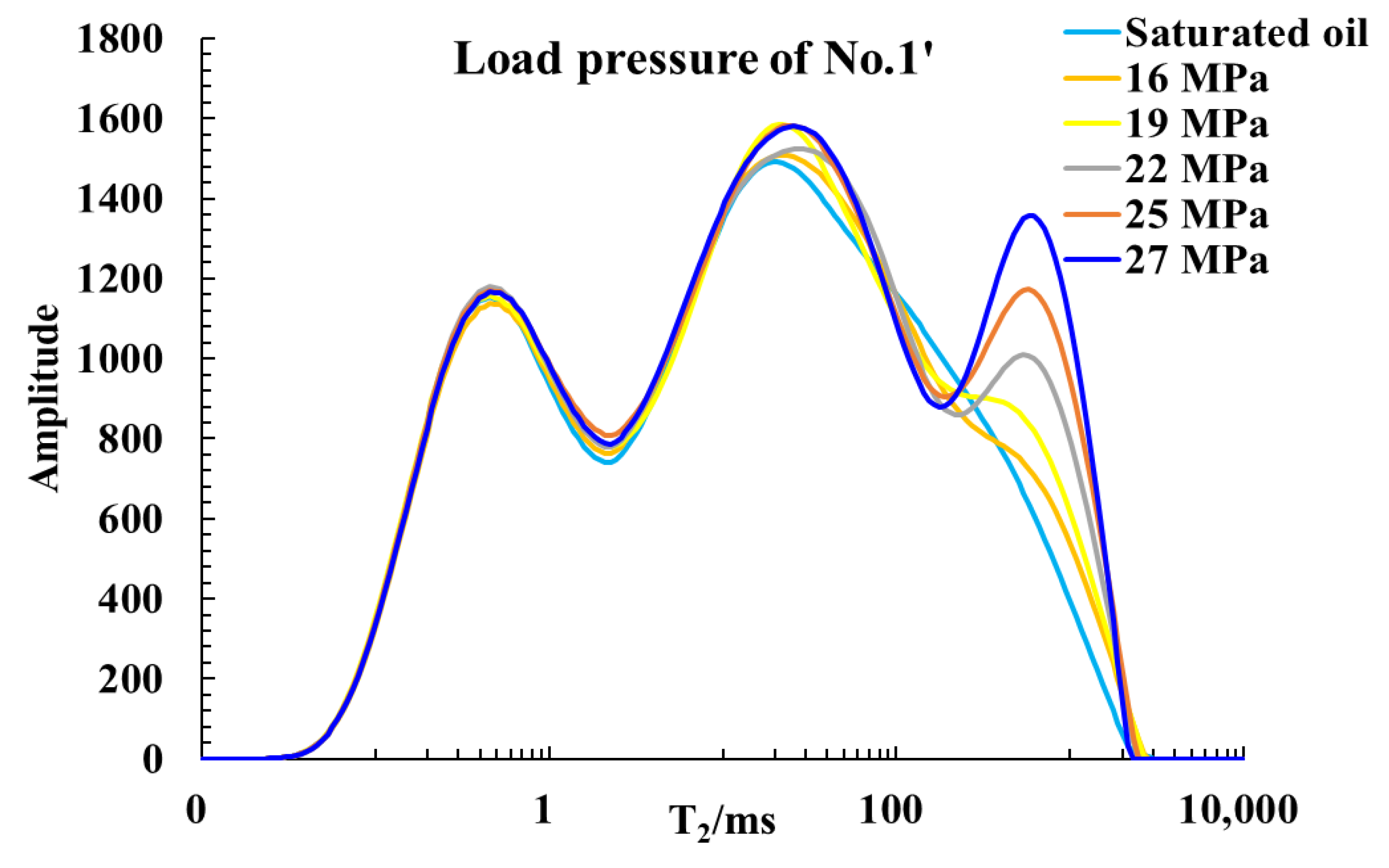

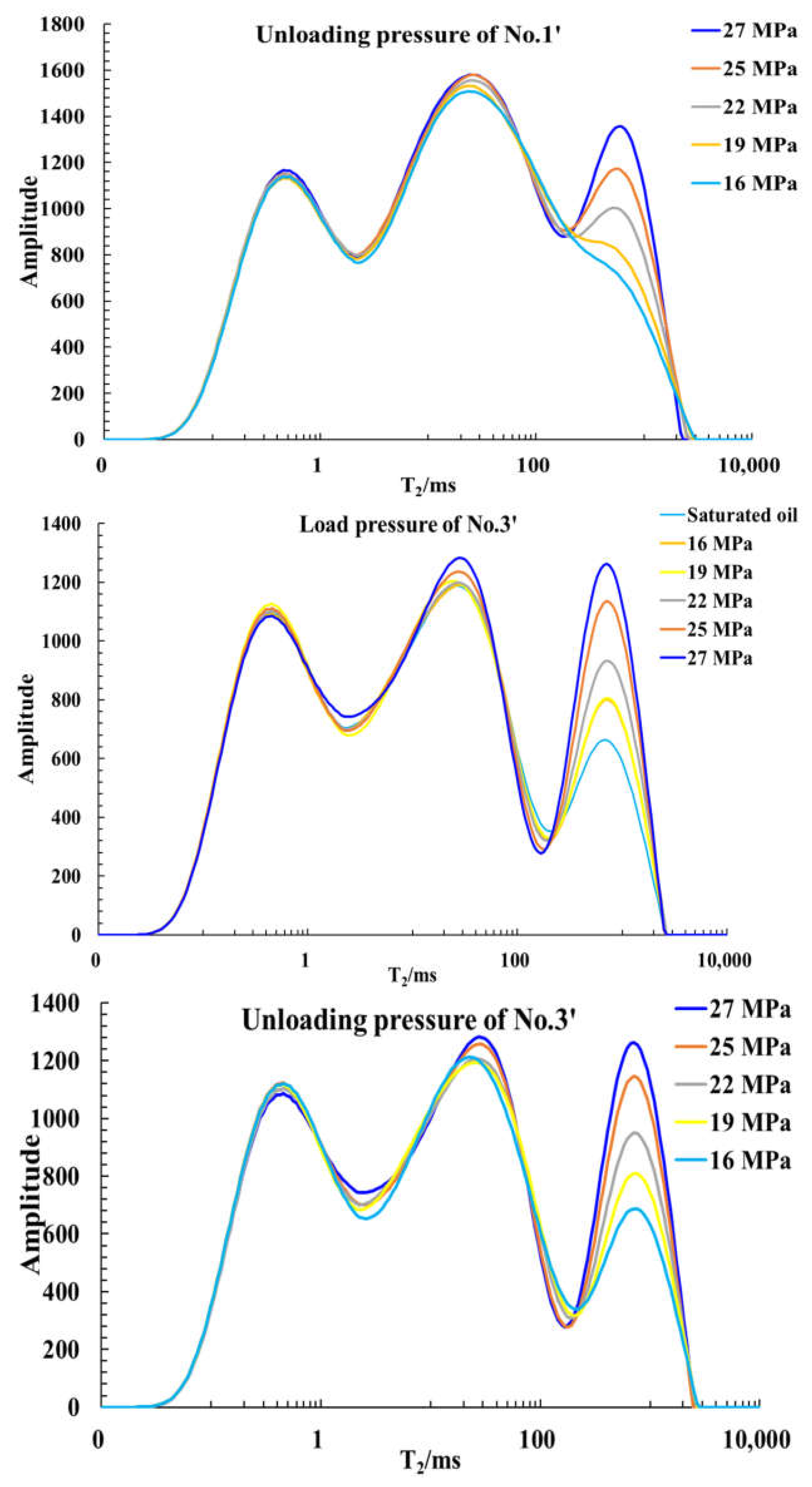

4.2. The Pore Throat State of Fractured Rock Samples Varies with Pore Pressure

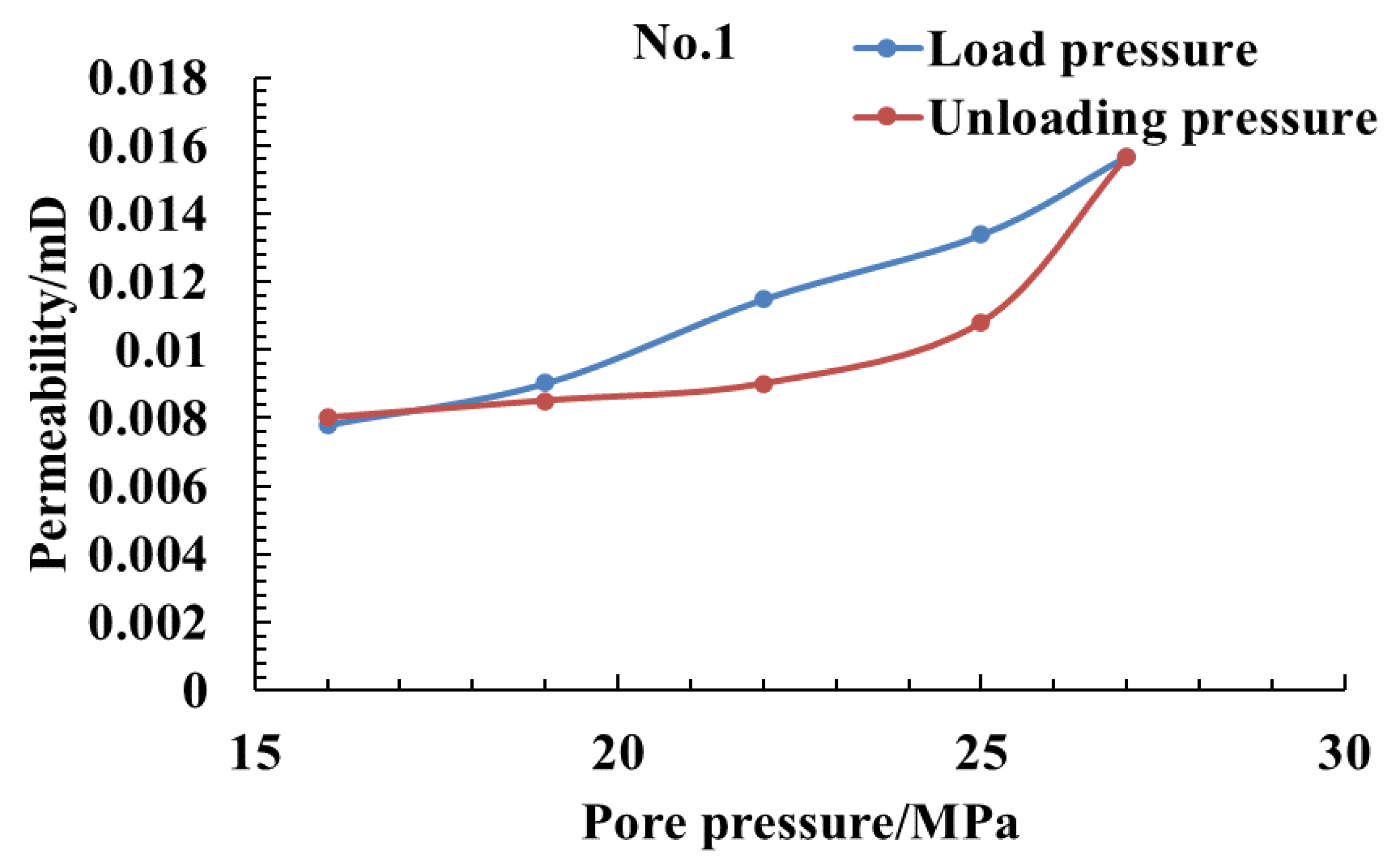

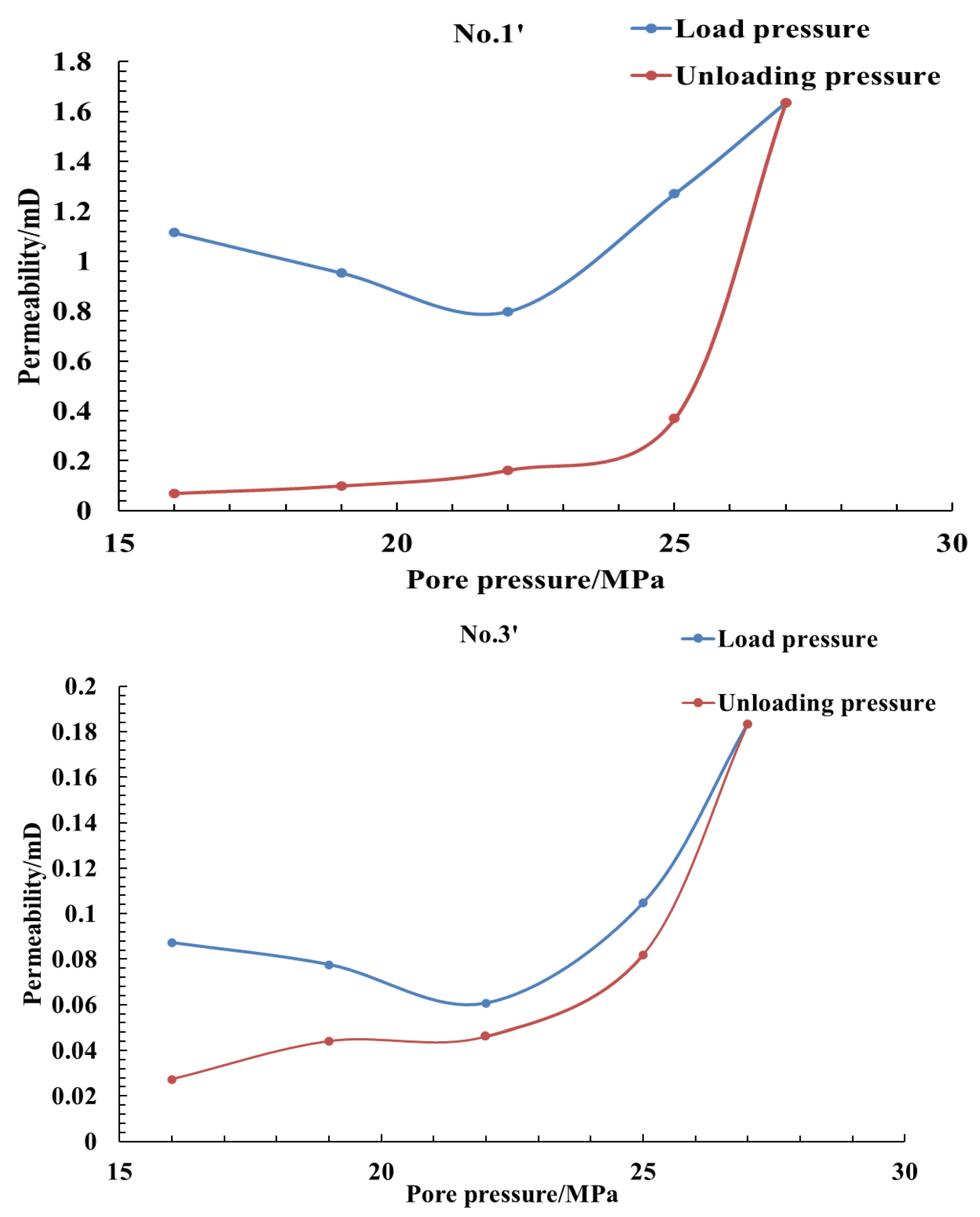

4.3. The Permeability of Matrix and Fractured Samples Varies with Pore Pressure

5. Conclusions

- The IRM and the IRT of matrix rock samples are greater than that of fractured rock samples, indicating that the increase in pore pressure is better for matrix reservoirs. For the matrix reservoir with higher permeability, the less the unloading pressure interferes with the pore. The DRM and DRT of matrix rock samples are greater than that of fractured rock samples. It shows that unloading pressure has little effect on fractured reservoirs.

- The permeability of matrix samples increases with the increase in pore pressure, and the smaller the permeability is, the larger the inflection point of pore pressure with a sudden increase in permeability. Therefore, for the matrix reservoir with low permeability, a large amount of formation energy supplement is an effective means to improve the reservoir permeability. The larger the reservoir permeability, the gentler the downward trend of pore pressure during unloading, and the smaller the range and rate of permeability decline and the interference of unloading pressure on the reservoir. The permeability after pore pressure unloading is slightly higher than that of before the experiment, indicating that no irreversible deformation occurs in the process of pore pressure loading and unloading, and no damage is caused to the reservoir.

- When the pore pressure reached a certain value, the permeability of the fractured rock sample increased rapidly, and the fracture opened in the process of the pore pressure increasing. After the unloading of pore pressure, the fracture closed. The improvement effect of increasing pore pressure is better for the fractured reservoir with low permeability, while the unloading of pore pressure is more damaging for the reservoir with high permeability. Compared with matrix reservoirs, unloading pore pressure is more damaging to fractured reservoirs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yan, W.; Sun, F.; Sun, J.; Golsanami, N. Distribution Model of Fluid Components and Quantitative Calculation of Movable Oil in Inter-Salt Shale Using 2D NMR. Energies 2021, 14, 2447. [Google Scholar] [CrossRef]

- Hu, S.; Tao, S.; Yan, W.; Yang, Z.; Men, G.; Tang, Z.; Xue, J.; Chen, X.; Jia, X.; Jiang, T.; et al. Advances on enrichment law and key technologies of exploration and development of continental tight oil in China. J. Nat. Gas Geosci. 2019, 4, 1083–1093. [Google Scholar]

- Jin, Z.; Zhu, R.; Liang, X.; Shen, Y. Several issues worthy of attention in current lacustrine shale oil exploration and development. Petrol. Explor. Dev. 2021, 48, 1276–1287. [Google Scholar] [CrossRef]

- Dang, H.; Xiao, Q.; Gao, R.; Qi, Z. Characteristics of CO2 displacement for Chang 7 tight reservoir in Yanchang oilfield. J. Shenzhen Univ. 2019, 36, 298–303. [Google Scholar] [CrossRef]

- Jang, I.S. Probabilistic Prediction of Multi-Wells Production Based on Production Characteristics Analysis Using Key Factors in Shale Formations. Energies 2021, 14, 5226. [Google Scholar]

- Zheng, T.; Yang, Z.; Wang, Z.; Dong, C.; He, Y. Carbon dioxide energy storage and stimulation in staged fractured horizontal Wells in tight reservoirs. Sci. Technol. Eng. 2019, 19, 99–104. [Google Scholar]

- Wang, H.; Zhao, W.; He, H.; Feng, J. Characteristics of Tight Oil Reservoirs in Ordos Basin—A Case Study of Chang-7 Member of Longdong Area,Ordos Basin. Unconven. Oil Gas 2019, 6, 42–51. [Google Scholar]

- Hu, S.; Zhu, R.; Wu, S.; Bai, B.; Yang, Z.; Cui, J. Exploration and development of continental tight oil in China. Petrol. Explor. Dev. 2018, 45, 737–748. [Google Scholar] [CrossRef]

- Zhang, J.; Bi, H.; Xu, H.; Zhao, J.L.; Yu, T.X.; Zhao, D.; Geng, Y.G. New progress and reference significance of overseas tight oil exploration and development. Acta Petrol. Sin. 2015, 36, 127–137. [Google Scholar]

- Lan, Y.; Yang, Z.; Wang, P.; Yan, Y.; Zhang, L.; Ran, J. A review of microscopic seepage mechanism for shale gas extracted by supercritical CO2 flooding. Fuel 2019, 238, 412–424. [Google Scholar] [CrossRef]

- Thakur, G. Enhanced Recovery Technologies for Unconventional Oil Reservoirs. J. Petrol. Technol. 2019, 71, 66–69. [Google Scholar] [CrossRef]

- Luo, R.L.; Cheng, L.S.; Peng, J.C. New method of determining relationship between permeability and effective overburden pressure for low-permeability reservoirs. J. China Univ. Petrol. 2007, 31, 87–90. [Google Scholar]

- Xu, X. Stress Sensitivity of Low-permeability Reservoir Containing Micro-fracture and Its Influence on Productivity. Spec. Oil Gas Reserv. 2015, 22, 127–130. [Google Scholar]

- Yu, Z.; Xiong, W.; Gao, S. Stress sensitivity of tight reservoir and its influence on oilfield development. Acta Petrol. Sin. 2007, 28, 95–98. [Google Scholar]

- Li, R.; Li, H.; Yang, Z.; Guo, H.; Gao, T.; Dai, Y.; Meng, H. Experimental study on stress sensitivity of shale reservoir. Chin. Sci. Pap. 2019, 14, 969–974. [Google Scholar]

- Gao, Z.; Qu, X.; Huang, T.; Xue, T.; Cao, P. Stress Sensitivity Analysis of Shale Oil Reservoir in Ordos Basin and Optimization of Horizontal Well Flowback System. Nat. Gas Geosci. 2021, 32, 1867–1873. [Google Scholar]

- Lei, H.; Zheng, Y.; He, J.; Hu, Z. A New Physical Simulation Method for Fluid Flow Characteristics in Shale Reservoirs. Acta Petrol. Sin. 2021, 42, 1346–1356. [Google Scholar]

- Fang, P.L. Study on Fluid solid Coupling Mechanism and Numerical Simulation Method for Tight Oil Development. Ph.D. Thesis, China University of Geosciences, Wuhan, China, 2017. [Google Scholar]

- Chhatre, S.S.; Sinha, S.; Braun, E.M. Effect of Stress, Creep, and Fluid Type on Steady State Permeability Measurements in Tight Liquid Unconventional Reservoirs. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 25–27 August 2014. [Google Scholar]

- Ren, X.; Li, A.; Fu, S. Experimental study on the oil-water relative permeability relationship for tight sandstone considering the nonlinear seepage characteristics. J. Petrol. Sci. Eng. 2018, 161, 409–416. [Google Scholar] [CrossRef]

- Jia, C.J.; Xu, W.Y.; Wang, H.L. Stress dependent permeability and porosity of low-permeability rock. J. Cent. South Univ. 2017, 24, 2396–2405. [Google Scholar] [CrossRef]

- Duan, X.; Hu, Z.; Gu, Z.; Chang, J.; Shen, R.; Sun, W. The online nuclear magnetic resonance detection technology is used to study the production law of shale gas in different occurrence states. Nat. Gas Ind. 2021, 41, 76–83. [Google Scholar]

- Fang, T.; Zhang, L.; Zhang, L.; Liu, N. Study on transport characteristics of tight sandstone gas based on nuclear magnetic resonance technology. Gansu J. Sci. 2017, 4, 22–27. [Google Scholar]

- Liu, G. Characteristics of CO2 huff and puff micropore utilization in fractured tight sandstone reservoir. J. Xi’an Shiyou Univ. 2021, 36, 64–70. [Google Scholar]

- Fu, J.; Li, S.; Niu, X.; Deng, X.; Zhou, X. Geological Characteristics and Exploration Practice of Triassic Chang 7 Shale Oil in Ordos Basin. Petrol. Explor. Dev. 2020, 47, 870–883. [Google Scholar] [CrossRef]

- Gao, B.; Wu, X.; Zhang, Y.; Chen, X.; Bian, R.; Li, Q. Hydrocarbon generation and evolution characteristics of Zhangjiatan oil shale in southern Ordos Basin. Petrol. Exp. Geol. 2022, 44, 24–32. [Google Scholar]

- Huang, Z.; Hao, Y.; Li, S.; Wo, Y.; Sun, D.; Li, M.; Chen, J. Evaluation of oil and gas bearing property and shale oil mobility of shale rock series in Chang 7 Member of Ordos Basin. Geol. China 2020, 47, 210–219. [Google Scholar]

- Gu, Z.; Liu, E.; Wang, X.; Li, R.; Xu, J.; Zhou, B. Development characteristics and exploration potential of shale in the 7th member of Yanchang Formation in the southeast of Ordos Basin. Oil Gas Geol. Rec. Factor 2021, 28, 95–105. [Google Scholar]

- Zheng, Z.; Qi, Z.; Zhang, L.; Yin, J.; Gao, C.; Jiang, C. The shale rock types and reservoir space characteristics of shanxi formation in the dolomite area of ordos basin. J. Northeast Petrol. Univ. 2020, 44, 85–98. [Google Scholar]

- Wan, Y.; Lin, Y.; Ding, Y.; Wang, J.; Li, H.; Xu, G.; Lei, Z.; Chen, H. Study on Brazilian splitting acoustic emission characteristics of layered rock mass. J. Chengdu Univ. Technol. 2021, 48, 714–722. [Google Scholar]

- Wu, S.; Sun, W.; Cheng, Z. Acoustic emission characteristics of brazilian fracturing test of low porosity sandstone under different loading conditions. J. Eng. Sci. 2020, 42, 988–998. [Google Scholar]

- Yu, Y.; Sun, Y.; Gao, R.; Da, L.; Hou, J.; Yang, M. Determination of surface relaxation rate of compact core based on T2 cut-off value. Petrol. Exp. Geol. 2022, 44, 342–349. [Google Scholar]

- Han, C.; Chen, X.; Chen, J.; Yin, X.; Zhang, R.; Geng, Z.; Peng, Y. Progress in Logging Evaluation Technology of Shale Oil in Lucaogou Formation of Santanghu Basin. Xinjiang Petrol. Geol. 2020, 41, 740–747. [Google Scholar]

- Zhou, S.; Liu, H.; Yan, G.; Xue, H.; Guo, W. NMR Study on Movable Fluid and T2 Cut off Value of Marine Shale Reservoirs in South China. Oil Gas Geol. 2016, 37, 612–616. [Google Scholar]

- Wu, M.; Qin, Y.; Wang, X.; Li, G.; Zhu, C.; Zhu, S. Fluid Mobility of Tight Sandstone Reservoirs in China and Its Influencing Factors. J. Jilin Univ. 2021, 51, 35–51. [Google Scholar]

- Kumar, H.H.; Elsworth, D.; Mathews, J.P.; Marone, C. Permeability evolution in sorbing media: Analogies between organic rich shale and coal. Geofluids 2016, 16, 43–55. [Google Scholar] [CrossRef]

- Argüelles, F.J.; Wang, M.; Abeykoon, G.A.; Okuno, R. Enhancement of Water Imbibition in Shales by use of Ketone Solvent. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 19–21 February 2020. [Google Scholar]

- Wang, L.; Zhang, R.; Zhang, N.; Lin, J.; Qin, Y.; Chen, G.; Zhang, G. A high-precision processing method for two-dimensional nuclear magnetic resonance logging data based on component compensation. J. Spectrosc. 2022, 39, 174–183. [Google Scholar]

- Zhou, D.; Shi, Y.; Li, M.; Zhang, Z.; Liu, S. Study on Spontaneous Imbibition Feature of Tight Sandstone Based on NMR Experiment. J. Xi’an Shiyou Univ. 2018, 33, 51–57. [Google Scholar]

- Han, C.; Li, G.; Bie, K.; Yu, D.; Chen, W.; Wu, F. Application of 2D NMR T1-T2 spectrum in fluid identification of complex carbonate reservoir in Fengxi. Well Logging Technol. 2021, 45, 56–61. [Google Scholar]

- Zhang, C. Study on T2cutoff Value of NMR Logging Rock Experiment and Application of Reservoir Evaluation. Master’s Theses, Yangtze University, Jingzhou, China, 2016. [Google Scholar]

| No. | Well | Length/cm | Diameter/cm | Porosity/% | Permeability/mD | Depth/m |

|---|---|---|---|---|---|---|

| 1 | Well Huan 2-1 | 7.29 | 2.531 | 11.95 | 0.058 | 2429.20–2429.40 |

| 2 | Well Huan 2-1 | 7.34 | 2.524 | 11.67 | 0.120 | 2442.80–2443.00 |

| 3 | Well Hua 151-1 | 6.95 | 2.526 | 10.00 | 0.029 | 2336.20–2336.45 |

| 1′ | Well Huan 2-1 | 7.86 | 2.570 | 11.95 | 0.058 | 2429.20–2429.40 |

| 3′ | Well Hua 151-1 | 7.21 | 2.540 | 10.00 | 0.029 | 2336.20–2336.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, L.; Lei, Q.; Yang, Z.; He, Y.; Li, H.; Zhao, G.; Zheng, Z.; Hou, H.; Du, M.; Cheng, L. Online Nuclear Magnetic Resonance Analysis of the Effect of Stress Changes on the Porosity and Permeability of Shale Oil Reservoirs. Energies 2023, 16, 1139. https://doi.org/10.3390/en16031139

Yao L, Lei Q, Yang Z, He Y, Li H, Zhao G, Zheng Z, Hou H, Du M, Cheng L. Online Nuclear Magnetic Resonance Analysis of the Effect of Stress Changes on the Porosity and Permeability of Shale Oil Reservoirs. Energies. 2023; 16(3):1139. https://doi.org/10.3390/en16031139

Chicago/Turabian StyleYao, Lanlan, Qihong Lei, Zhengming Yang, Youan He, Haibo Li, Guoxi Zhao, Zigang Zheng, Haitao Hou, Meng Du, and Liangbing Cheng. 2023. "Online Nuclear Magnetic Resonance Analysis of the Effect of Stress Changes on the Porosity and Permeability of Shale Oil Reservoirs" Energies 16, no. 3: 1139. https://doi.org/10.3390/en16031139