Heat Transfer of Water Flow Boiling in Nanostructured Open Microchannels

Abstract

1. Introduction

2. Experimental Investigation

2.1. Experimental Setup

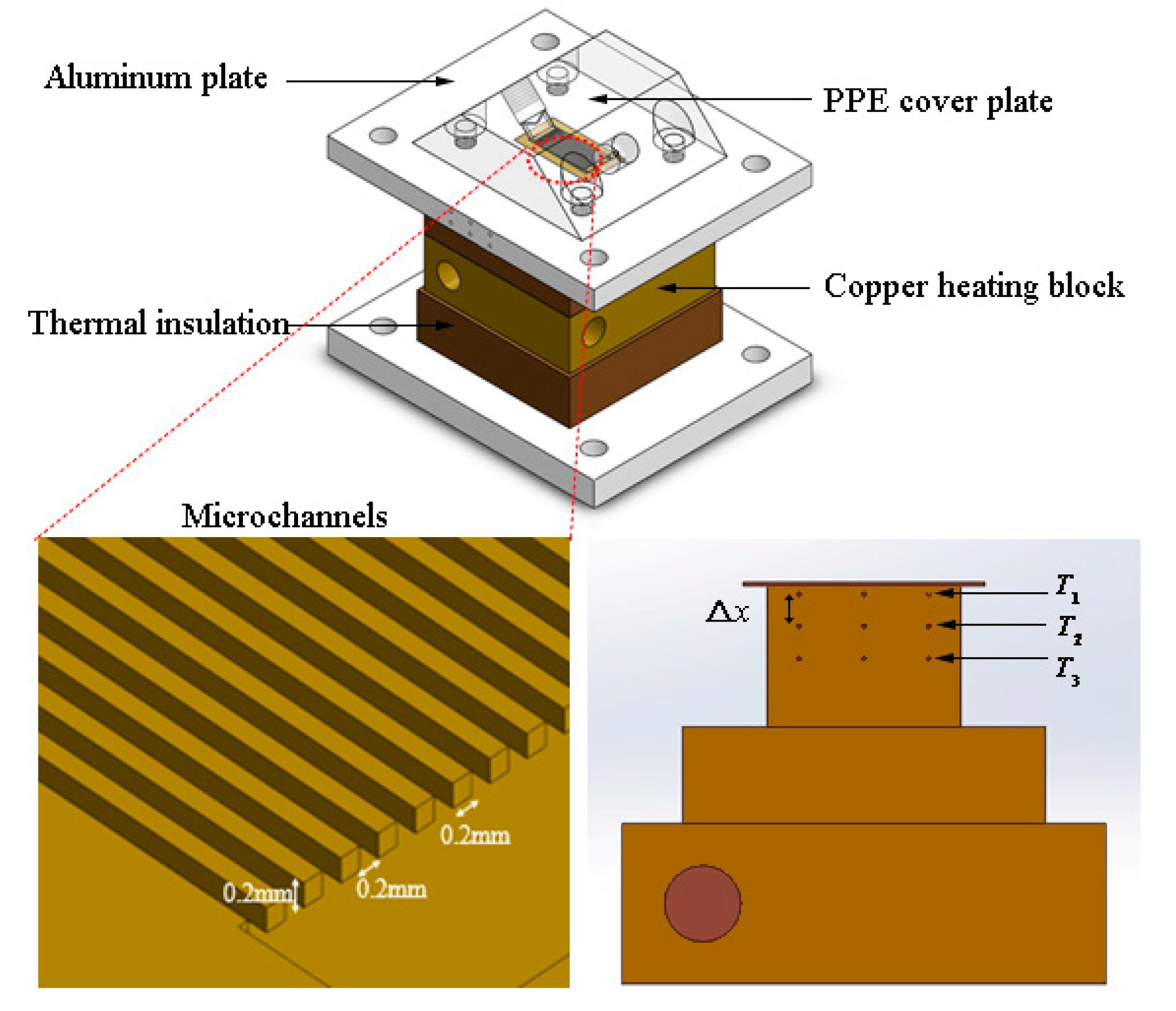

2.2. Test Section

2.3. Experimental Conditions and Surface Structure

2.4. Data Reduction and Uncertainty Analysis

3. Results and Discussion

3.1. Flow Pattern Characteristics

3.2. Boiling Curves

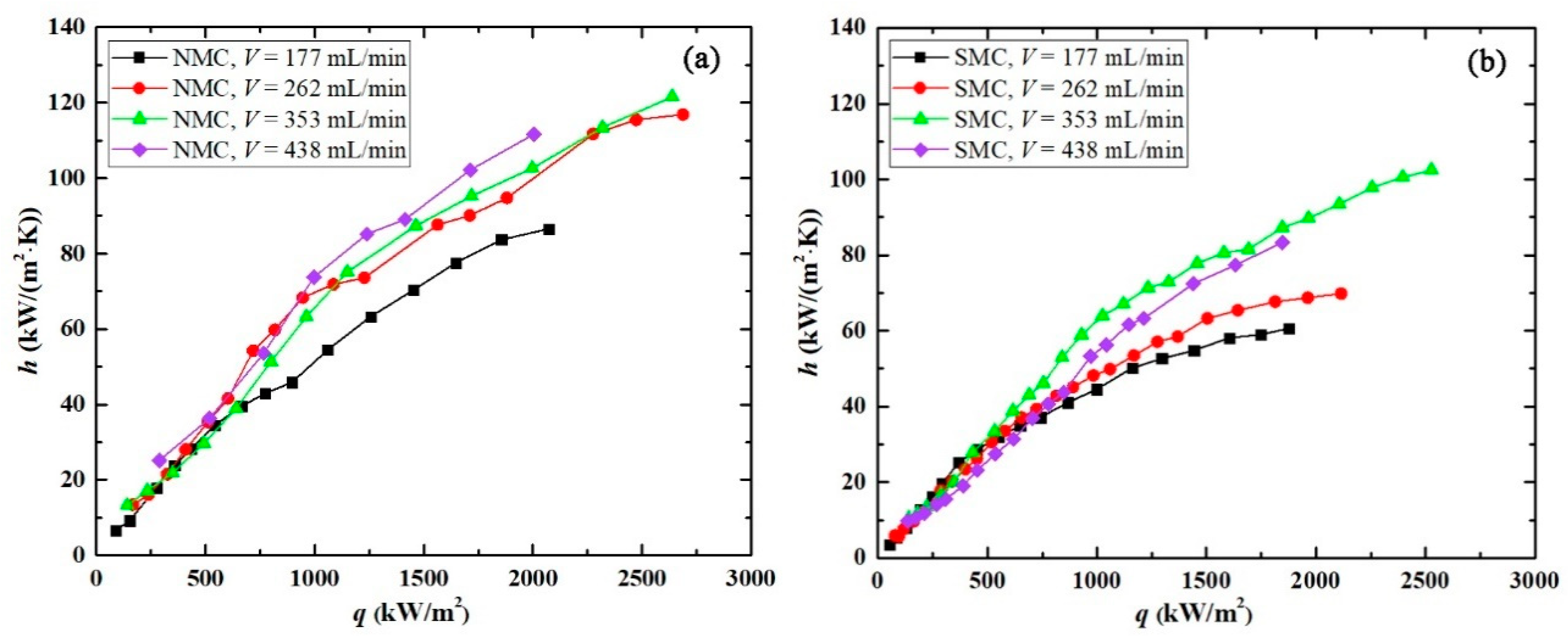

3.3. Heat Transfer Coefficient

4. Conclusions

- As the heat flux increased, the bubbly flow, slug flow, and stratified flow were seen successively in NMC and SMC. The flow pattern transition boundary shifted to a larger heat flux with increasing flow rate, which could be attributed to the decreased bubble nucleation-site density and the reduced bubble growth rate at a larger liquid flow rate.

- The enhanced effect of nanostructures on the NMC’s flow boiling heat dissipation mainly functioned at higher heat flux conditions. The HTC of NMC was slightly higher than that of SMC under low heat fluxes (q < 600 kW/m2) and was unaffected by liquid flow rate. However, under high heat fluxes, the HTC of NMC was about 1.5-times larger than that of SMC, and it increased with an increment in liquid flow rate.

- The heat transfer was controlled by nucleation boiling in bubbly flow and the initial stage of slug flow. During these flow patterns, the nanostructures’ effect on HTC was unnoticeable because of the relatively low heat flux, since the nanoscale cavities provided by the nanostructures required a relatively larger heat flux/wall superheat to be activated as the bubble nucleation sites.

- The nucleation boiling mechanism and convective evaporation mechanism together determined the heat transfer during the later stage of slug flow and stratified flow. The blade-like nanostructures enhanced nucleation boiling via increasing bubble nucleation-site density and bubble departure frequency, improved convective evaporation via enlarging the L–V interface, and suppressing local dryout, jointly resulting in the better heat dissipation performance of NMC under higher heat fluxes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Liu, R.; Zhang, L.; Zhang, X. Applications of Spray Cooling Technology in Aerospace Field; IOP Conference Series: Materials Science and Engineering, 2019; IOP Publishing: Bristol, UK, 2019; p. 12020. [Google Scholar]

- Li, B.; Huang, K.; Yan, Y.; Li, Y.; Twaha, S.; Zhu, J. Heat transfer enhancement of a modularised thermoelectric power generator for passenger vehicles. Appl. Energy 2017, 205, 868–879. [Google Scholar] [CrossRef]

- Piasecka, M.; Strąk, K. Boiling Heat Transfer during Flow in Vertical Mini-Channels with a Modified Heated Surface. Energies 2022, 15, 7050. [Google Scholar] [CrossRef]

- Moreira, D.; Nascimento, V.; Ribatski, G.; Kandlikar, S. Combining liquid inertia and evaporation momentum forces to achieve flow boiling inversion and performance enhancement in asymmetric Dual V-groove microchannels. Int. J. Heat Mass Transf. 2022, 194, 123009. [Google Scholar] [CrossRef]

- Al Siyabi, I.; Khanna, S.; Sundaram, S.; Mallick, T. Experimental and numerical thermal analysis of multi-layered microchannel heat sink for concentrating photovoltaic application. Energies 2018, 12, 122. [Google Scholar] [CrossRef]

- Kalani, A.; Kandlikar, S.G. Flow patterns and heat transfer mechanisms during flow boiling over open microchannels in tapered manifold (OMM). Int. J. Heat Mass Transf. 2015, 89, 494–504. [Google Scholar] [CrossRef]

- Kandlikar, S.G.; Widger, T.; Kalani, A.; Mejia, V. Enhanced flow boiling over open microchannels with uniform and tapered gap manifolds. J. Heat Transf. 2013, 135, 61401. [Google Scholar] [CrossRef]

- Balasubramanian, K.R.; Krishnan, R.A.; Suresh, S. Spatial orientation effects on flow boiling performances in open microchannels heat sink configuration under a wide range of mass fluxes. Exp. Therm. Fluid Sci. 2018, 99, 392–406. [Google Scholar] [CrossRef]

- Qiu, J.; Zhao, Q.; Lu, M.; Zhou, J.; Hu, D.; Qin, H.; Chen, X. Experimental study of flow boiling heat transfer and pressure drop in stepped oblique-finned microchannel heat sink. Case Stud. Therm. Eng. 2022, 30, 101745. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, D.; Qiu, J.; Lu, M.; Zhou, J.; Chen, X. Bubble behaviors and flow boiling characteristics in open microchannels with large aspect ratio. Appl. Therm. Eng. 2022, 213, 118768. [Google Scholar] [CrossRef]

- Fattahi, R.; Saidi, M. Numerical investigation of curved shape fins height effect on heat transfer and flow characteristics in open microchannel heat sink. Int. J. Therm. Sci. 2023, 185, 108060. [Google Scholar] [CrossRef]

- Bhandari, P.; Prajapati, Y.K. Influences of tip clearance on flow and heat transfer characterstics of open type micro pin fin heat sink. Int. J. Therm. Sci. 2022, 179, 107714. [Google Scholar] [CrossRef]

- Suk, L.; Petrosyan, T.; Stevanka, K.; Vlcek, D.; Gejdos, P. Experimental investigation of critical heat flux on different surfaces at low pressure and low flow. Energies 2020, 13, 5205. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, H.; Chen, Y.; Wang, L.; Qu, J.; Wu, M.; Zhou, Z. Boiling heat transfer performance of parallel porous microchannels. Energies 2020, 13, 2970. [Google Scholar] [CrossRef]

- Lin, Y.; Li, J.; Sun, J.; Li, W.; Cao, Y. Onset of Boiling, Heat Transfer, and Flow Patterns of Flow Boiling on the Superhydrophobic Porous Copper Surface in a Microchannel. J. Heat Transf. 2021, 143, 81602. [Google Scholar] [CrossRef]

- Markal, B.; Kul, B.; Avci, M.; Varol, R. Effect of gradually expanding flow passages on flow boiling of micro pin fin heat sinks. Int. J. Heat Mass Transf. 2022, 197, 123355. [Google Scholar] [CrossRef]

- Cho, H.R.; Park, S.C.; Kim, D.; Joo, H.-m.; Yu, D.I. Experimental Study on Pool Boiling on Hydrophilic Micro/Nanotextured Surfaces with Hydrophobic Patterns. Energies 2021, 14, 7543. [Google Scholar] [CrossRef]

- Huang, S.; Wang, L.; Pan, Z.; Zhou, Z. Experimental investigation of a new hybrid structured surface for subcooled flow boiling heat transfer enhancement. Appl. Therm. Eng. 2021, 192, 116929. [Google Scholar] [CrossRef]

- Yang, F.; Dai, X.; Peles, Y.; Cheng, P.; Khan, J.; Li, C. Flow boiling phenomena in a single annular flow regime in microchannels (I): Characterization of flow boiling heat transfer. Int. J. Heat Mass Transf. 2014, 68, 703–715. [Google Scholar] [CrossRef]

- Morshed, A.; Paul, T.C.; Khan, J. Effect of Cu–Al2O3 nanocomposite coating on flow boiling performance of a microchannel. Appl. Therm. Eng. 2013, 51, 1135–1143. [Google Scholar] [CrossRef]

- Wang, S.; Chen, H.-H.; Chen, C.-L. Enhanced flow boiling in silicon nanowire-coated manifold microchannels. Appl. Therm. Eng. 2019, 148, 1043–1057. [Google Scholar] [CrossRef]

- Sharma, D.; Ghosh, D.P.; Saha, S.K.; Raj, R. Thermohydraulic characterization of flow boiling in a nanostructured microchannel heat sink with vapor venting manifold. Int. J. Heat Mass Transf. 2019, 130, 1249–1259. [Google Scholar] [CrossRef]

- Ghosh, D.P.; Sharma, D.; Mohanty, D.; Saha, S.K.; Raj, R. Facile Fabrication of Nanostructured Microchannels for Flow Boiling Heat Transfer Enhancement. Heat Transf. Eng. 2018, 40, 537–548. [Google Scholar] [CrossRef]

- Alam, T.; Li, W.; Chang, W.; Yang, F.; Khan, J.; Li, C. A comparative study of flow boiling HFE-7100 in silicon nanowire and plainwall microchannels. Int. J. Heat Mass Transf. 2018, 124, 829–840. [Google Scholar] [CrossRef]

- Lim, K.; Lee, K.; Ki, H.; Lee, J. Enhancement of flow boiling heat transfer by laser-induced periodic surface structures using femtosecond laser. Int. J. Heat Mass Transf. 2022, 196, 123229. [Google Scholar] [CrossRef]

- Di Sia, G.; Tan, M.K.; Chen, G.M.; Hung, Y.M. Performance enhancement of subcooled flow boiling on graphene nanostructured surfaces with tunable wettability. Case Stud. Therm. Eng. 2021, 27, 101283. [Google Scholar] [CrossRef]

- Yin, L.; Jiang, P.; Xu, R.; Wang, W.; Jia, L. Visualization of flow patterns and bubble behavior during flow boiling in open microchannels. Int. Commun. Heat Mass Transf. 2017, 85, 131–138. [Google Scholar] [CrossRef]

- Yin, L.; Jiang, P.; Xu, R.; Hu, H.; Jia, L. Heat transfer and pressure drop characteristics of water flow boiling in open microchannels. Int. J. Heat Mass Transf. 2019, 137, 204–215. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, W.; Xiang, J.; Liu, C.; Gao, Y.; Li, S.; Ling, W. Development of novel flexible heat pipe with multistage design inspired by structure of human spine. Appl. Therm. Eng. 2020, 175, 115392. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Hsu, Y.Y. On the size range of active nucleation cavities on a heating surface. J. Heat Transf. 1962, 84, 207–213. [Google Scholar] [CrossRef]

| Parameter | Uncertainty |

|---|---|

| Wch, Hch, Lch | ±0.01 mm |

| T(K-type) | ±0.50 °C |

| P | ±0.055% |

| U | ±0.05% |

| I | ±0.2% |

| V | ±0.2% |

| q | ±1.98% |

| Tw | ±2.66% |

| h | ±5.65% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, L.; Yang, Z.; Zhang, K.; Xue, Y.; Dang, C. Heat Transfer of Water Flow Boiling in Nanostructured Open Microchannels. Energies 2023, 16, 1303. https://doi.org/10.3390/en16031303

Yin L, Yang Z, Zhang K, Xue Y, Dang C. Heat Transfer of Water Flow Boiling in Nanostructured Open Microchannels. Energies. 2023; 16(3):1303. https://doi.org/10.3390/en16031303

Chicago/Turabian StyleYin, Liaofei, Zhonglin Yang, Kexin Zhang, Yingli Xue, and Chao Dang. 2023. "Heat Transfer of Water Flow Boiling in Nanostructured Open Microchannels" Energies 16, no. 3: 1303. https://doi.org/10.3390/en16031303

APA StyleYin, L., Yang, Z., Zhang, K., Xue, Y., & Dang, C. (2023). Heat Transfer of Water Flow Boiling in Nanostructured Open Microchannels. Energies, 16(3), 1303. https://doi.org/10.3390/en16031303