Evaluation of Numerical Methods for Predicting the Energy Performance of Windows

Abstract

:1. Introduction

2. Review of Publications Dedicated to Numerical Investigations of Heat Transfer through Windows

2.1. Window Heat Transfer Modelling without Taking into Account Thermal and Solar Radiation

2.2. Window Heat Transfer Modelling including Thermal Radiation and Excluding Incident Solar Radiation

2.3. Window Heat Transfer Modelling in Conditions of Exposure to Incident Solar Radiation

3. Material and Methods

4. Results and Discussion

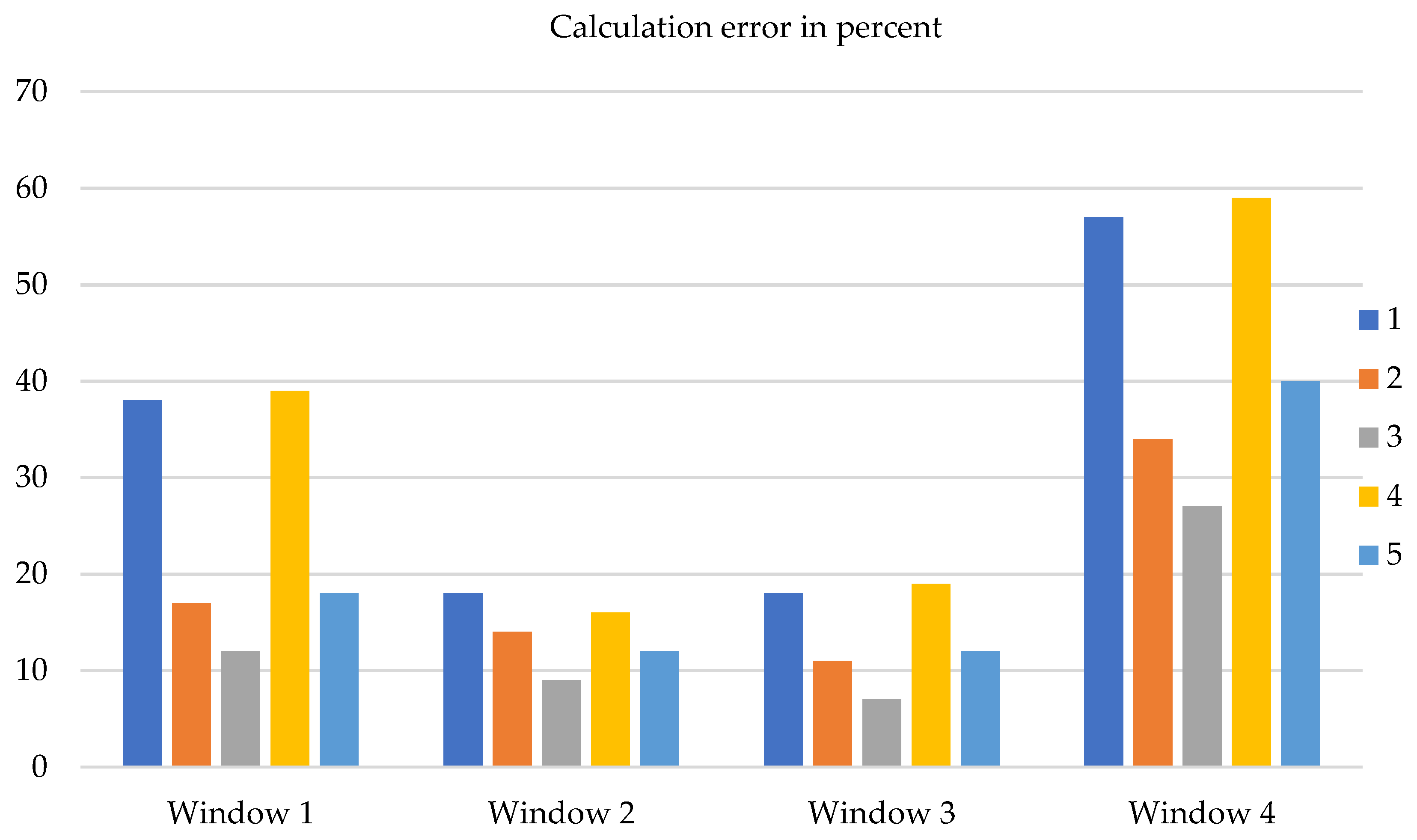

- − for a triple-pane window filled with air: 1.29 W/m2, 1.72 W/m2, and 1.86 W/m2;

- − for a triple-pane window filled with argon: 1.1 W/m2, 1.2 W/m2, and 1.65 W/m2; and

- − for a window with a low-emission coating: 1.34 W/m2, 1.42 W/m2, and 1.68 W/m2.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Pr | Prandtl number |

| Ra | Rayleigh number |

| Nu | Nusselt number |

Abbreviation

| ADI | alternating direction implicite |

| CFD | computational fluid dynamics |

| CW | cumulative wavenumber model |

| DO | discrete ordinates radiation model |

| EAW | energy-active window |

| PCM | phase change materials |

| RANS | Reynolds averaged Navier–Stokes |

| RTE | radiative transport equation |

| S2S | surface-to-surface |

| SHGC | solar heat gain coefficient |

| SOR | successive over-relaxation |

| SST | shear stress transport |

| TDM a | tridiagonal matrix algorithm |

References

- Basok, B.I.; Nakorchevskii, A.I.; Goncharuk, S.M.; Kuzhel, L.N. Experimental Investigations of Heat Transfer Through Multiple Glass Units with Account for the Action of Exterior Factors. J. Eng. Phys. Thermophys. 2017, 90, 88–94. [Google Scholar] [CrossRef]

- Cuce, E.; Riffat, S.B. A state-of-the-art review on innovative glazing technologies. Renew. Sustain. Energy Rev. 2015, 41, 695–714. [Google Scholar] [CrossRef]

- Jelle, B.P.; Hynd, A.; Gustavsen, A.; Arasteh, D.; Goudey, H.; Hart, R. Fenestration of today and tomorrow: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 96, 1–28. [Google Scholar] [CrossRef]

- Wang, Y.; Shukla, A.; Liu, S. A state of art review on methodologies for heat transfer and energy flow characteristics of the active building envelopes. Renew. Sustain. Energy Rev. 2017, 78, 102–1116. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, X.; Jin, X.; Zhou, X.; Shi, X. Towards adoption of building energy simulation and optimization for passive building design: A survey and a review. Energy Build. 2018, 158, 1306–1316. [Google Scholar] [CrossRef]

- Karabay, H.; Arıcı, M. Multiple pane window applications in various climatic regions of Turkey. Energy Build. 2012, 45, 67–71. [Google Scholar] [CrossRef]

- Arıcı, M.; Karabay, H.; Kan, M. Flow and heat transfer in double, triple and quadruple pane windows. Energy Build. 2015, 86, 394–402. [Google Scholar] [CrossRef]

- Gorantla, K.; Shaik, S.; Setty, A.B.T.P. Effects of single, double, triple and quadruple window glazing of various glass materials on heat gain in green energy buildings. Mater. Energy Environ. Eng. 2017, 5, 45–50. [Google Scholar] [CrossRef]

- No, S.T.; Seo, J.S. Analysis of Window Components Affecting U-Value Using Thermal Transmittance Test Results and Multiple Linear Regression Analysis. Adv. Civ. Eng. 2018, 2018, 1780809. [Google Scholar] [CrossRef]

- Arıcı, M.; Karabay, H. Determination of optimum thickness of double-glazed windows for the climatic regions of Turkey. Energy Build. 2010, 42, 1773–1778. [Google Scholar] [CrossRef]

- Gan, G. Thermal transmittance of multiple glazing: Computational fluid dynamics prediction. Appl. Therm. Eng. 2001, 21, 1583–1592. [Google Scholar] [CrossRef]

- Aydın, O. Determination of optimum air-layer thickness in double-pane windows. Energy Build. 2000, 32, 303–308. [Google Scholar] [CrossRef]

- Aydın, O. Conjugate heat transfer analysis of double pane windows. Build. Environ. 2006, 41, 109–116. [Google Scholar] [CrossRef]

- Aguilar-Santana, J.L.; Velasco-Carrasco, M.; Riffat, S. Thermal Transmittance (U-value) Evaluation of Innovative Window Technologies. Future Cities Environ. 2020, 6, 12. [Google Scholar] [CrossRef]

- Park, S.; Song, S.-Y. Evaluation of Alternatives for Improving the Thermal Resistance of Window Glazing Edges. Energies 2019, 12, 244. [Google Scholar] [CrossRef]

- Cuce, E. Accurate and reliable U-value assessment of argon-filled double glazed windows: A numerical and experimental investigation. Energy Build. 2018, 171, 100–106. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E.; Zinzi, M. High Energy-Efficient Windows with Silica Aerogel for Building Refurbishment: Experimental Characterization and Preliminary Simulations in Different Climate Conditions. Buildings 2017, 7, 8. [Google Scholar] [CrossRef]

- Gao, T.; Ihara, T.; Grynning, S.; Jelle, B.P.; Gunnarshaug Lien, A. Perspective of aerogel glazings in energy efficient buildings. Build. Environ. 2016, 95, 405–413. [Google Scholar] [CrossRef]

- Eames, P. Vacuum glazing: Current performance and future prospects. Vacuum 2008, 82, 717–722. [Google Scholar] [CrossRef]

- Fang, Y.; Eames, P.C.; Norton, B.; Hyde, T.J.; Zhao, J.; Wang, J.; Huang, Y. Low emittance coatings and the thermal performance of vacuum glazing. Sol. Energy 2007, 81, 8–12. [Google Scholar] [CrossRef]

- Dalal, R.; Naylor, D.; Roeleveld, D. A CFD study of convection in a double glazed window with an enclosed pleated blind. Energy Build. 2009, 41, 1256–1262. [Google Scholar] [CrossRef]

- Collins, M.; Tasnim, S.; Wright, J. Numerical analysis of convective heat transfer in fenestration with between-the-glass louvered shades. Build Env. 2009, 44, 2185–2192. [Google Scholar] [CrossRef]

- Pavlenko, A.M.; Koshlak, H. Application of thermal and cavitation effects for heat and mass transfer process intensification in multicomponent liquid media. Energies 2021, 14, 7996. [Google Scholar] [CrossRef]

- Koshlak, H.; Pavlenko, A. Method of formation of thermophysical properties of porous materials. Rocz. Ochr. Srodowiska 2019, 21, 1253–1262. [Google Scholar]

- Silva, T.; Vicente, R.; Amaral, C.; Figueiredo, A. Thermal performance of a window shutter containing PCM: Numerical validation and experimental analysis. Appl. Energy 2016, 179, 64–84. [Google Scholar] [CrossRef]

- Souviron, J.; van Moeseke, G.; Khan, A.Z. Analysing the environmental impact of windows: A review. Build. Environ. 2019, 161, 106268. [Google Scholar] [CrossRef]

- Garlisi, C.; Trepci, E.; Li, X.; Al Sakkaf, R.; Al-Ali, K.; Nogueira, R.P.; Zheng, L.; Azar, E.; Palmisano, G. Multilayer thin film structures for multifunctional glass: Self-cleaning, antireflective and energy-saving properties. Appl. Energy 2020, 264, 114697. [Google Scholar] [CrossRef]

- Jørgensen, J.D.; Nielsen, J.H.; Giuliani, L. Thermal resistance of framed windows: Experimental study on the influence of frame shading width. Saf. Sci. 2022, 149, 105683. [Google Scholar] [CrossRef]

- Marinoski, d.l.; Güths, S.; Pereira, F.O.R.; Lamberts, R. Improvement of a measurement system for solar heat gain through fenestrations. Energy Build. 2007, 39, 478–487. [Google Scholar] [CrossRef]

- Arıcı, M.; Kan, M. An investigation of flow and conjugate heat transfer in multiple pane windows with respect to gap width, emissivity and gas filling. Renew. Energy 2015, 75, 249–256. [Google Scholar] [CrossRef]

- Jelle, B.P.; Kalnæs, S.E.; Gao, T. Low-emissivity materials for building applications: A state-of-the-art review and future research perspectives. Energy Build. 2015, 96, 329–356. [Google Scholar] [CrossRef] [Green Version]

- Pavlenko, A.; Usenko, B.; Koshlak, A. Thermal conductivity of the gas in small space. Metall. Min. Ind. 2014, 6, 20–24. [Google Scholar]

- Chaiyapinunt, S.; Phueakphongsuriya, B.; Mongkornsaksit, K.; Khomporn, N. Performance rating of glass windows and glass windows with films in aspect of thermal comfort and heat transmission. Energy Build. 2004, 37, 725–738. [Google Scholar] [CrossRef]

- Xamán, J.; Jiménez-Xamán, C.; Álvarez, G.; Zavala, I.; Hernández-Pérez, I.; Aguilar, J.O. Thermal performance of a double pane window with a solar control coating for warm climate of Mexico. Appl. Therm. Eng. 2016, 106, 257–265. [Google Scholar] [CrossRef]

- Pereira, J.; Gomes, M.G.; Rodrigues, A.M.; Almeida, M. Thermal, luminous and energy performance of solar control films in single-glazed windows: Use of energy performance criteria to support decision making. Energy Build. 2019, 198, 431–443. [Google Scholar] [CrossRef]

- Teixeira, H.; Gomes, M.G.; Rodrigues, A.M.; Pereira, J. Thermal and visual comfort, energy use and environmental performance of glazing systems with solar control films. Build. Env. 2019, 168, 106474. [Google Scholar] [CrossRef]

- Bavaresco, M.V.; Ghisi, E. Influence of user interaction with internal blinds on the energy efficiency of office buildings. Energy Build. 2018, 166, 538–549. [Google Scholar] [CrossRef]

- Jain, S.; Garg, V. A review of open loop control strategies for shades, blinds and integrated lighting by use of real-time daylight prediction methods. Build. Environ 2018, 135, 352–364. [Google Scholar] [CrossRef]

- Bedon, C.; Zhang, X.; Santos, F.; Honfi, D.; Lange, D. Performance of structural glass facades under extreme loads—Design methods, existing research, current issues and trends. Constr. Build. Mater. 2018, 163, 921–937. [Google Scholar] [CrossRef]

- Lahmar, I.; Cannavale, A.; Martellotta, F.; Zemmouri, N. The Impact of Building Orientation and Window-to-Wall Ratio on the Performance of Electrochromic Glazing in Hot Arid Climates: A Parametric Assessment. Buildings 2022, 12, 724. [Google Scholar] [CrossRef]

- Ji, C.; Wu, Z.; Wu, X.; Wang, J.; Jiang, Y. Al-doped VO2 films as smart window coatings: Reduced phase transition temperature and improved thermochromic performance. Sol. Energy Mater. Sol. Cells 2018, 176, 174–180. [Google Scholar] [CrossRef]

- Wu, Y.; Krishnan, P.; Zhang, M.H.; Yu, L.E. Using photocatalytic coating to maintain solar reflectance and lower cooling energy consumption of buildings. Energy Build. 2018, 164, 176–186. [Google Scholar] [CrossRef]

- Fallahi, A.; Haghighat, F.; Elsadi, H. Energy performance assessment of double-skin façade with thermal mass. Energy Build. 2010, 42, 1499–1509. [Google Scholar] [CrossRef]

- Regmi, G.; Velumani, S. Radio frequency (RF) sputtered ZrO2-ZnO-TiO2 coating: An example of multifunctional benefits for thin film solar cells on the flexible substrate. Solar Energy 2023, 249, 301–311. [Google Scholar] [CrossRef]

- Zanghirella, F.; Perino, M.; Serra, V. A numerical model to evaluate the thermal behaviour of active transparent façades. Energy Build. 2011, 43, 1123–1138. [Google Scholar] [CrossRef]

- Koo, S.Y.; Park, S.; Song, J.-H.; Song, S.-Y. Effect of Surface Thermal Resistance on the Simulation Accuracy of the Condensation Risk Assessment for a High-Performance Window. Energies 2018, 11, 382. [Google Scholar] [CrossRef]

- Zhao, X.; Mofid, S.A.; Al Hulayel, M.R.; Saxe, G.W.; Jelle, B.P.; Yang, R. Reduced-scale hot box method for thermal characterization of window insulation materials. Appl. Therm. Eng. 2019, 160, 114026. [Google Scholar] [CrossRef]

- Ghadimi, M.; Ghadamian, H.; Hamidi, A.; Fazelpour, F.; Behghadam, M. Analysis of free and forced convection in airflow windows using numerical simulation of heat transfer. Int. J. Energy Environ. Eng. 2012, 3, 14. [Google Scholar] [CrossRef]

- Vigna, I.; Bianco, L.; Goia, F.; Serra, V. Phase Change Materials in Transparent Building Envelopes: A Strengths, Weakness, Opportunities and Threats (SWOT) Analysis. Energies 2018, 11, 111. [Google Scholar] [CrossRef]

- Li, S.; Zou, K.; Sun, G.; Zhang, X. Simulation research on the dynamic thermal performance of a novel triple-glazed window filled with PCM. Sustain. Cities Soc. 2018, 40, 266–273. [Google Scholar] [CrossRef]

- Wei, L.; Li, G.; Ruan, S.-T.; Qi, H. Dynamic coupled heat transfer and energy conservation performance of multilayer glazing window filled with phase change material in summer day. J. Energy Storage 2022, 49, 104183. [Google Scholar] [CrossRef]

- Musiał, M.; Lichołai, L. The Impact of a Mobile Shading System and a Phase-Change Heat Store on the Thermal Functioning of a Transparent Building Partition. Materials 2021, 14, 2512. [Google Scholar] [CrossRef]

- Lee, R.; Kang, E.; Lee, H.; Yoon, J. Heat Flux and Thermal Characteristics of Electrically Heated Windows: A Case Study. Sustainability 2022, 14, 481. [Google Scholar] [CrossRef]

- Kaboré, M.; Michaux, G.; Le Dréau, J.; Salagnac, P.; Greffet, R. Parametric study of the thermal performance of a sin-gle-family house equipped with an airflow window integrating a heated glazing. In Proceedings of the 16th IBPSA International Conference, Rome, Italy, 2–4 September 2019. [Google Scholar] [CrossRef]

- Nourozi, B.; Ploskić, A.; Chen, Y.; Chiu, J.N.-W.; Wang, Q. Heat transfer model for energy-active windows—An evaluation of efficient reuse of waste heat in buildings. Renew. Energy 2020, 162, 2318–2329. [Google Scholar] [CrossRef]

- Elmalky, A.M.; Araji, M.T. Computational fluid dynamics using finite volume method: A numerical model for Double Skin Façades with renewable energy source in cold climates. J. Build. Eng. 2022, 60, 105231. [Google Scholar] [CrossRef]

- Amaral, A.R.; Rodrigues, E.; Gaspar, A.R.; Gomes, Á. A thermal performance parametric study of window type, orientation, size and shadowing effect. Sustain. Cities Soc. 2016, 26, 456–465. [Google Scholar] [CrossRef]

- Pavlenko, A.; Usenko, B.; Koshlak, A. Analysis of thermal peculiarities of alloying with special properties. Metall. Min. Ind. 2014, 6, 15–19. [Google Scholar]

- Aguilar-Santana, J.L.; Jarimi, H.; Velasco-Carrasco, M. Review on window-glazing technologies and future prospects. Int. J. Low-Carbon Technol. 2020, 15, 112–120. [Google Scholar] [CrossRef]

- De Giorgi, L.; Bertola, V.; Cafaro, E. Thermal convection in double glazed windows with structured gap. Energy Build. 2011, 43, 2034–2038. [Google Scholar] [CrossRef]

- Banionis, K.; Kumžienė, J.; Burlingis, A.; Ramanauskas, J.; Paukštys, V. The Changes in Thermal Transmittance of Window Insulating Glass Units Depending on Outdoor Temperatures in Cold Climate Countries. Energies 2021, 14, 1694. [Google Scholar] [CrossRef]

- Choi, H.; Kang, K.; An, Y.-E.; Lee, Y.; Kim, T. Analysis of Heat Transfer in a Slim Double Skin Façade using CFD Simulation. In Proceedings of the 16th IBPSA International Conference, Rome, Italy, 2–4 September 2019. [Google Scholar] [CrossRef]

- Ismail, K.A.R.; Henríquez, J.R. Two-dimensional model for the double glass naturally ventilated window. Int. J. Heat Mass Transf. 2005, 48, 461–475. [Google Scholar] [CrossRef]

- Ismail, K.A.; Salinas, C.T.; Henriquez, J.R. A comparative study of naturally ventilated and gas filled windows for hot climates. Energy Convers. Manage. 2009, 50, 1691–1703. [Google Scholar] [CrossRef]

- Cho, K.-J.; Cho, D.-W. Solar Heat Gain Coefficient Analysis of a Slim-Type Double Skin Window System: Using an Experimental and a Simulation Method. Energies 2018, 11, 115. [Google Scholar] [CrossRef]

- Pal, S.; Roy, B.; Neogi, S. Heat transfer modelling on windows and glazing under the exposure of solar radiation. Energy Build. 2009, 41, 654–661. [Google Scholar] [CrossRef]

- Demanega, I.; De Michele, G.; Avesani, S.; Pernigotto, G.; Babich, F.; Gasparella, A. CFD and ray tracing to evaluate the thermal performance of Complex Fenestration Systems. In Proceedings of the Building Simulation and Optimization 2018 Conference, Cambridge, UK, 11–12 September 2018; pp. 460–466. [Google Scholar]

- Bhamjee, M.; Nurick, A.; Madyira, D.M. An experimentally validated mathematical and CFD model of a supply air window: Forced and natural flow. Energy Build. 2013, 57, 289–301. [Google Scholar] [CrossRef]

- Najaf Khosravi, S.; Mahdavi, A. A CFD-Based Parametric Thermal Performance Analysis of Supply Air Ventilated Windows. Energies 2021, 14, 2420. [Google Scholar] [CrossRef]

- Chow, T.-T.; Li, C.; Lin, Z. Thermal characteristics of water-flow double-pane window. Int. J. Therm. Sci 2011, 50, 140–148. [Google Scholar] [CrossRef]

- Gosselin, J.R.; Chen, Q. A computational method for calculating heat transfer and airflow through a dual-airflow window. Energy Build. 2008, 40, 452–458. [Google Scholar] [CrossRef]

- Basok, B.I.; Davydenko, B.V.; Isaev, S.A.; Goncharuk, S.M.; Kuzhel, L.N. Numerical modeling of heat transfer through a triple-pane window. J. Eng. Phys. Thermophys. 2016, 89, 1277–1283. [Google Scholar] [CrossRef]

- Ismail, K.A.R.; Salinas, C.T.; Henriquez, J.G. Comparison between PCM filled glass windows and absorbing gas filled windows. Energy Build. 2008, 40, 710–719. [Google Scholar] [CrossRef]

- Ismail, K.A.R.; Henríquez, J.R. Simplified model for a ventilated glass window under forced air flow conditions. Appl. Therm. Eng. 2006, 26, 295–302. [Google Scholar] [CrossRef]

- Skaff, M.C.; Gosselin, L. Summer performance of ventilated windows with absorbing or smart glazings. Sol. Energy 2014, 105, 2–13. [Google Scholar] [CrossRef]

- Zeyninejad Movassag, S.; Zamzamian, K. Numerical investigation on the thermal performance of double glazing air flow window with integrated blinds. Renew. Energy 2020, 148, 852–863. [Google Scholar] [CrossRef]

- Lago, T.G.S.; Ismail, K.A.R.; Lino, F.A.M. Ventilated double glass window with reflective film: Modeling and assessment of performance. Sol. Energy 2019, 185, 72–88. [Google Scholar] [CrossRef]

- Carlos, J.S.; Corvacho, H.; Silva, P.; Gomes, J.C. Modelling and simulation of a ventilated double window. Appl. Therm. Eng. 2011, 31, 93–102. [Google Scholar] [CrossRef]

- Carlos, J.S.; Corvacho, H. Evaluation of the performance indices of a ventilated double window through experimental and analytical procedures: SHGC-values. Energy Build. 2015, 86, 886–897. [Google Scholar] [CrossRef]

- Gosselin, J.R.; Chen, Q. A Dual Airflow Window for Indoor Air Quality Improvement and Energy Conservation in Buildings. HVACR Res. 2008, 14, 359–372. [Google Scholar] [CrossRef]

- Thalfeldt, M.; Kurnitski, J.; Voll, H. Detailed and simplified window model and opening effects on optimal window size and heating need. Energy Build. 2016, 127, 242–251. [Google Scholar] [CrossRef]

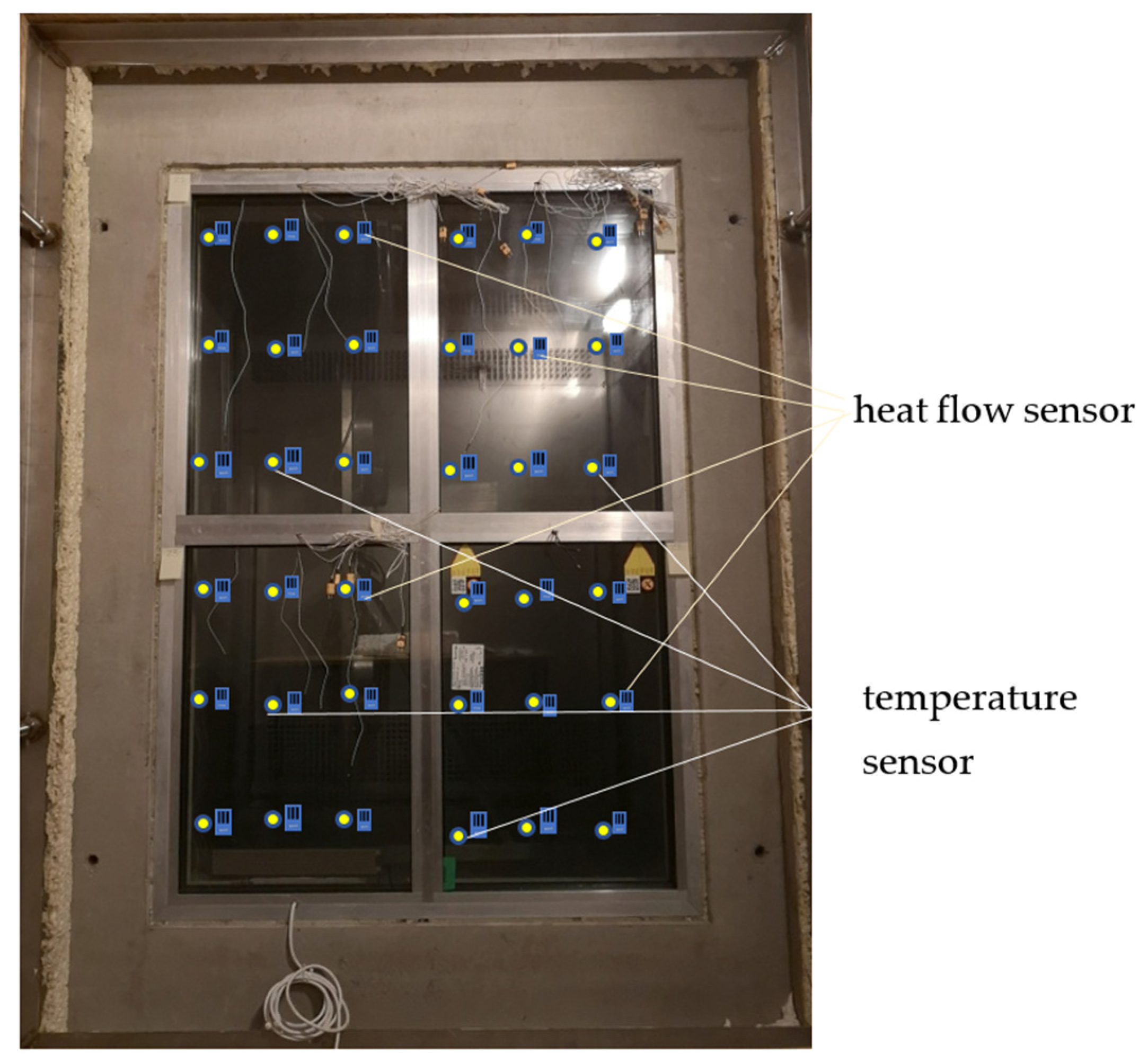

- Basok, B.I.; Davydenko, B.V.; Goncharuk, S.M.; Pavlenko, A.M. Experimental and numerical studies of heat transfer from a double-glazed window with electric heating of its surface. Work. Inst. Electrodyn. Natl. Acad. Sci. Ukr. 2022, 2022, 62. [Google Scholar] [CrossRef]

- Han, J.; Lu, L.; Yang, H. Numerical evaluation of the mixed convective heat transfer in a double-pane window integrated with see-through a-Si PV cells with low-e coatings. Appl. Energy 2011, 87, 3431–3437. [Google Scholar] [CrossRef]

- Lichołai, L.; Musiał, M. Experimental Analysis of the Function of a Window with a Phase Change Heat Accumulator. Materials 2020, 13, 3647. [Google Scholar] [CrossRef]

- LST EN 673:2011; Glass in Building—Determination of Thermal Transmittance (U Value)—Calculation Method. European Committee for Standardization: Brussels, Belgium, 2011.

- ISO 15099; Thermal Performance of Windows, Doors and Shading Devices—Detailed Calculations. International Organization for Standardization: Geneva, Switzerland, 2003.

- Siegel, R.; Howell, J.R. Thermal Radiation Heat Transfer, 2nd ed.; Hemisphere Publishing Corporation: London, UK, 2019; 951p. [Google Scholar]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Gan, G. Prediction of turbulent buoyant flow using an RNG k–ε model. Numer. Heat Transf. Part A Appl. 1998, 33, 169–189. [Google Scholar] [CrossRef]

- Basok, B.; Davydenko, B.; Novikov, V.G.; Pavlenko, A.M.; Novitska, M.P.; Sadko, K.; Goncharuk, S.M. Evaluation of heat transfer rates through transparent dividing structures. Energies 2022, 15, 4910. [Google Scholar] [CrossRef]

- Wright, J.L.; Jin, H.; Hollands, K.G.T.; Naylor, D. Flow visualization of natural convection in a tall, air-filled vertical cavity. Int. J. Heat Mass Transf. 2006, 49, 889–904. [Google Scholar] [CrossRef]

- Chow, T.; Li, V.; Lin, Z. Innovative solar windows for cooling-demand climate. Sol. Energy Mater. Sol. Cells 2010, 94, 212–220. [Google Scholar] [CrossRef]

- Solovjov, V.; Webb, B. A local-spectrum correlated model for radiative transfer in non-uniform gas media. J. Quant. Spectrosc. Radiat. Transf. 2002, 73, 361–373. [Google Scholar] [CrossRef]

- Modest, M. Radiative Heat Transfer; McGraw-Hill: New York, NY, USA, 1993. [Google Scholar]

- Ismail, K.A.R.; Henríquez, J.R. Modeling and simulation of a simple glass window. Sol. Energy Mater. Sol. Cells 2003, 80, 355–374. [Google Scholar] [CrossRef]

- Patankar, S. Numerical Heat Transfer and Fluid Flow; CRC Press: Boca Raton, FL, USA, 1980. [Google Scholar] [CrossRef]

- Oliveti, G.; Arcuri, N.; Bruno, R.; De Simone, M. An accurate calculation model of solar heat gain through glazed surfaces. Energy Build. 2011, 43, 269–274. [Google Scholar] [CrossRef]

- Parra, J.; Guardo, A.; Egusquiza, E.; Alavedra, P. Thermal Performance of Ventilated Double Skin Façades with Venetian Blinds. Energies 2015, 8, 4882–4898. [Google Scholar] [CrossRef]

- Gloriant, F.; Tittelein, P.; Joulin, A.; Lassue, S. Study of the Performances of a Supply-Air Window for Air Renewal Pre-Heating. Energy Procedia 2015, 78, 525–530. [Google Scholar] [CrossRef]

- Ismail, K.A.R.; Salinas, C.S. Non-gray radiative convective conductive modeling of a double glass window with a cavity filled with mixtures of absorbing gases. Int. J. Heat Mass Transf. 2006, 49, 2972–2983. [Google Scholar] [CrossRef]

- Ismail, K.A.R.; Salinas, C.S. Gray radiative conductive 2D modeling using discrete ordinates method with multidimensional spatial scheme and non-uniform grid. Int. J. Therm. Sci. 2006, 45, 706–715. [Google Scholar] [CrossRef]

- Michaux, G.; Greffet, R.; Salagnac, P. Modelling of an airflow window and numerical investigation of its thermal performances by comparison to conventional double and triple-glazed windows. Appl. Energy 2019, 242, 27–45. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.; Xu, X.; Zou, F.-J. Modeling and thermal performance evaluation of a switchable triple glazing exhaust air window. Appl. Therm. Eng. 2016, 92, 8–17. [Google Scholar] [CrossRef]

- Zhang, C.; Gang, W.; Wang, J. Numerical and experimental study on the thermal performance improvement of a triple glazed window by utilizing low-grade exhaust air. Energy 2019, 167, 1132–1143. [Google Scholar] [CrossRef]

- Brzezicki, M. A Systematic Review of the Most Recent Concepts in Smart Windows Technologies with a Focus on Electrochromics. Sustainability 2021, 13, 9604. [Google Scholar] [CrossRef]

- Heidari, N.; Eydgahi, A.; Matin, P. The Effect of Smart Colored Windows on Visual Performance of Buildings. Buildings 2022, 12, 861. [Google Scholar] [CrossRef]

- Aburas, M.; Soebarto, V.; Williamson, T.; Liang, R.; Ebendorff-Heidepriem, H.; Wu, Y. Thermochromic smart window technologies for building application: A review. Appl. Energy 2019, 255, 113522. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, X.; Ming, Y.; Liu, X.; Mahon, D.; Wilson, R.; Liu, H.; Eames, P.; Wu, Y. Energy and daylight performance of a smart window: Window integrated with thermotropic parallel slat-transparent insulation material. Appl. Energy 2021, 293, 116826. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, F.-Y.; Zhao, S.; Xu, Q.; Wang, S.; Luo, D.; Long, Y. Unconventional smart windows: Materials, structures and designs. Nano Energy 2021, 90, 106613. [Google Scholar] [CrossRef]

- Feng, W.; Zou, L.; Gao, G.; Wu, G.; Shen, J.; Li, W. Gasochromic smart window: Optical and thermal properties, energy simulation and feasibility analysis. Sol. Energy Mater. Sol. Cells 2016, 144, 316–323. [Google Scholar] [CrossRef]

- Heiz, B.P.V.; Pan, Z.; Su, L.; Le, S.T.; Wondraczek, L. A large-area smart window with tunable shading and solar-thermal harvesting ability based on remote switching of a magneto-active liquid. Adv. Sustain. Syst 2018, 2, 1870001. [Google Scholar] [CrossRef]

- Hu, Y.; Heiselberg, P.K.; Guo, R. Ventilation cooling/heating performance of a PCM enhanced ventilated window—An experimental study. Energy Build. 2020, 214, 109903. [Google Scholar] [CrossRef]

- Rodriguez-Ake, A.; Xamán, J.; Hernández-López, I.; Sauceda, D.; Carranza-Chávez Francisco, J.; Zavala-Guillén, I. Numerical study and thermal evaluation of a triple glass window under Mexican warm climate conditions. Energy 2022, 239, 122075. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, L.; Su, X.; Luo, Y.; Liu, Z.; Wang, X.; Qiang, S.; Pang, D. Modeling and analyzing the optical and thermal performance of window with transparent insulation slats. Energy Build. 2022, 277, 112567. [Google Scholar] [CrossRef]

- Rabizadeh, M.; Ehsani, M.H.; Shahidi, M.M. ZnO/metal/ZnO (metal = Ag, Pt, Au) films for energy-saving in windows application. Sci. Rep. 2022, 12, 15575. [Google Scholar] [CrossRef]

- Shen, C.; Li, X. Solar heat gain reduction of double glazing window with cooling pipes embedded in venetian blinds by utilizing natural cooling. Energy Build. 2016, 112, 173–183. [Google Scholar] [CrossRef]

| Ref. | Window Type | 1D/2D/3D | Steady or Transient Flow | Aim of the Study | Mathematical Formulation and Numerical Method | Conside-Ring Thermal Radiation | Conside-Ring Solar Radiation |

|---|---|---|---|---|---|---|---|

| [6] | double-, triple- and quadruple-pane windows | 1D | steady | Determination of the optimal number of panes and heat transfer coefficients. | Degree-day method | yes | no |

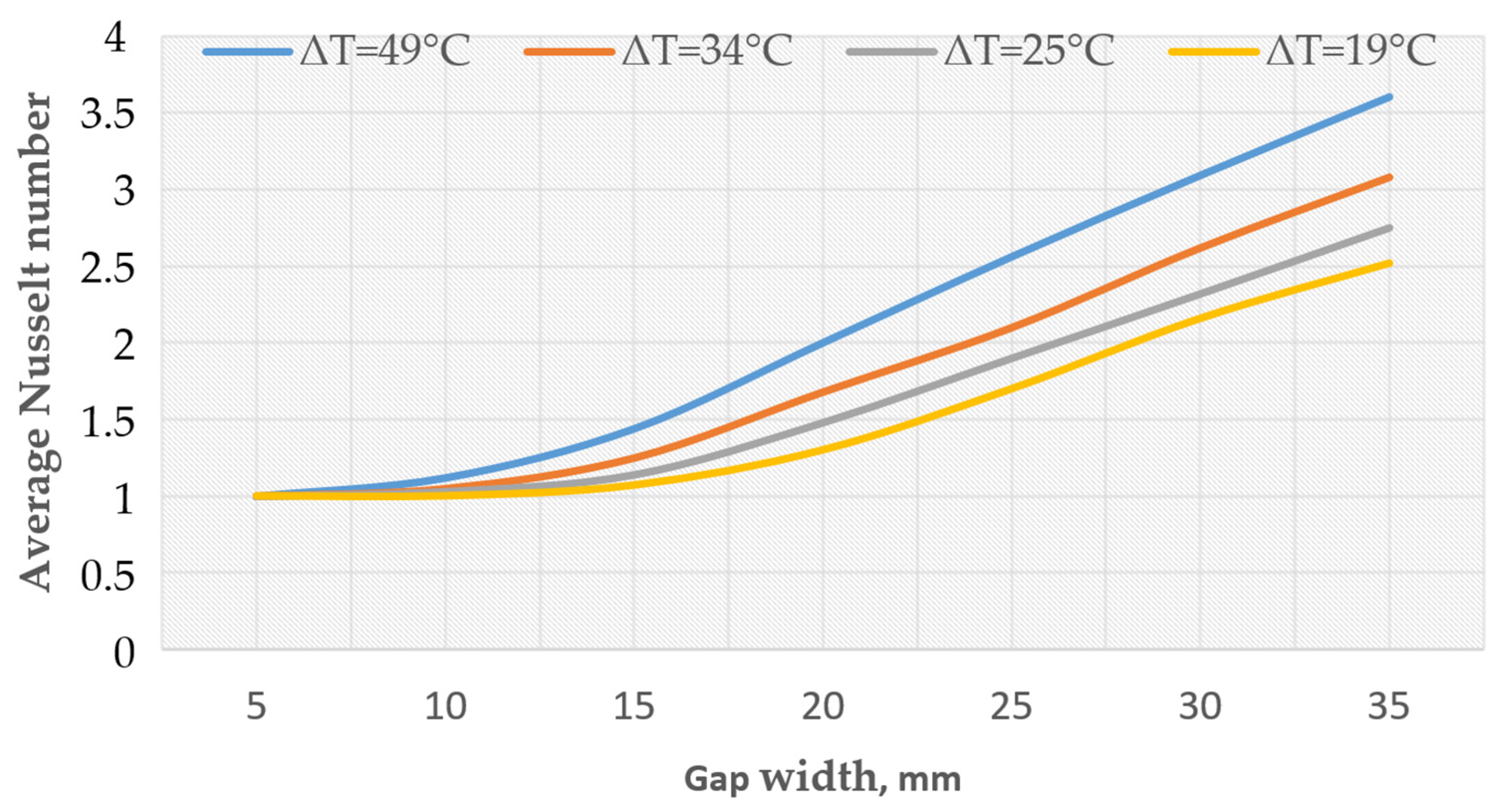

| [7] | double-, triple-, and quadruple-pane windows | 2D | unsteady | Determination of the air flow, the heat transfer, the overall heat transfer coefficient, and the Nusselt number depending on the number of panes, the temperature difference, and the width of the gap. | CFD Second-order upwind scheme S2S radiation model | yes | no |

| [10] | double-pane window | 1D | steady | Determination of the optimal width of the gap in double-pane windows in various climatic zones. | Degree-day method | no | no |

| [11] | double-pane window | 2D | steady | Prediction of the thermal transmittance for varying widths of the air layer at various temperature differences through the window. | CFD Renormalization k–ε turbulence model | yes | no |

| [12] | double-pane window | 2D | steady | Determination of the optimum air layer thickness for different climates. | Finite difference method ADI method | no | no |

| [13] | double-pane window | 2D | steady | Determination of the optimum air layer thickness for different climates and filling, considering a conjugate heat transfer. | Finite difference method ADI method | no | no |

| [21] | double-pane window | 1D/2D | steady | The impact of the Rayleigh number, the enclosure aspect ratio, and the blind geometry on the convective heat transfer. | Control-volume method Second-order upwind scheme | yes | no |

| [30] | double-, triple-, and quadruple-pane windows | 2D | transient | Determination of the overall heat transfer coefficient considering the number of panes, the gap width, and five different emissivity values. | CFD Second-order upwind scheme S2S radiation model | yes | no |

| [34] | double-pane window with and without a solar control coating | 2D | pseudo-transient | Impact of a solar control coating on the convective flux and the radiative flux. | Net radiative method Finite volume method ACM | yes | yes |

| [48] | double-pane airflow windows | 2D | steady | Estimation of the overall forced convective heat transfer. | Second-order upwind scheme Renormalization k–ε turbulence model | yes | no |

| [52] | double- and triple-pane windows | 2D | transient | Impact of a mobile shading system and a phase-change heat store on the thermal performance. | Finite difference method | yes | yes |

| [55] | energy-active window | 2D | steady | Comparison of an energy-active window with a conventional triple-pane one in order to calculate the U-value and select appropriate Nusselt number correlations. | Finite difference method | yes | yes |

| [60] | double-pane window withtransparent fins in the gap | 3D | steady | Investigation of reduction or suppression of the convective motion inside the gap with transparent fins for different Rayleigh numbers and aspect ratio. | CFD | no | no |

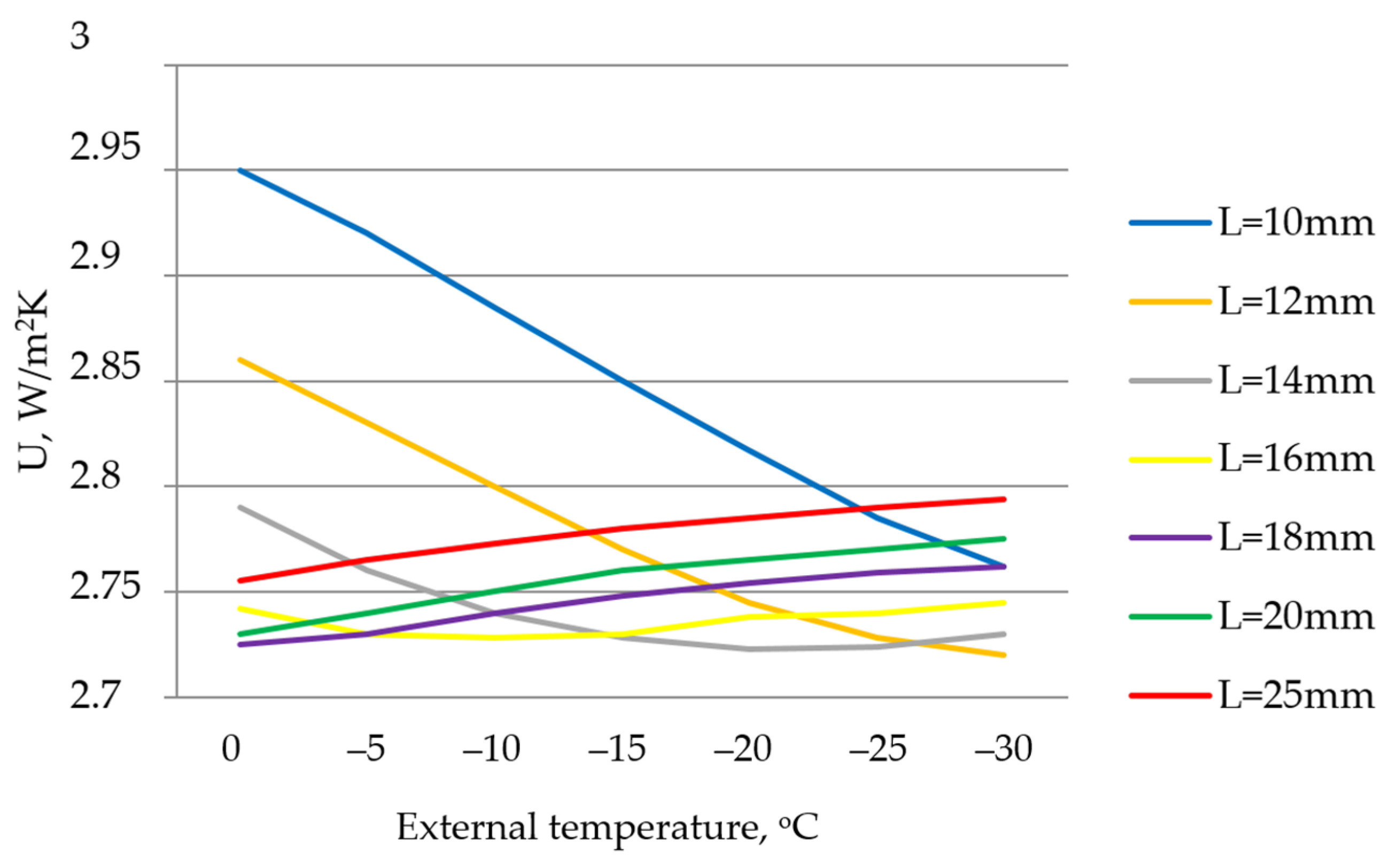

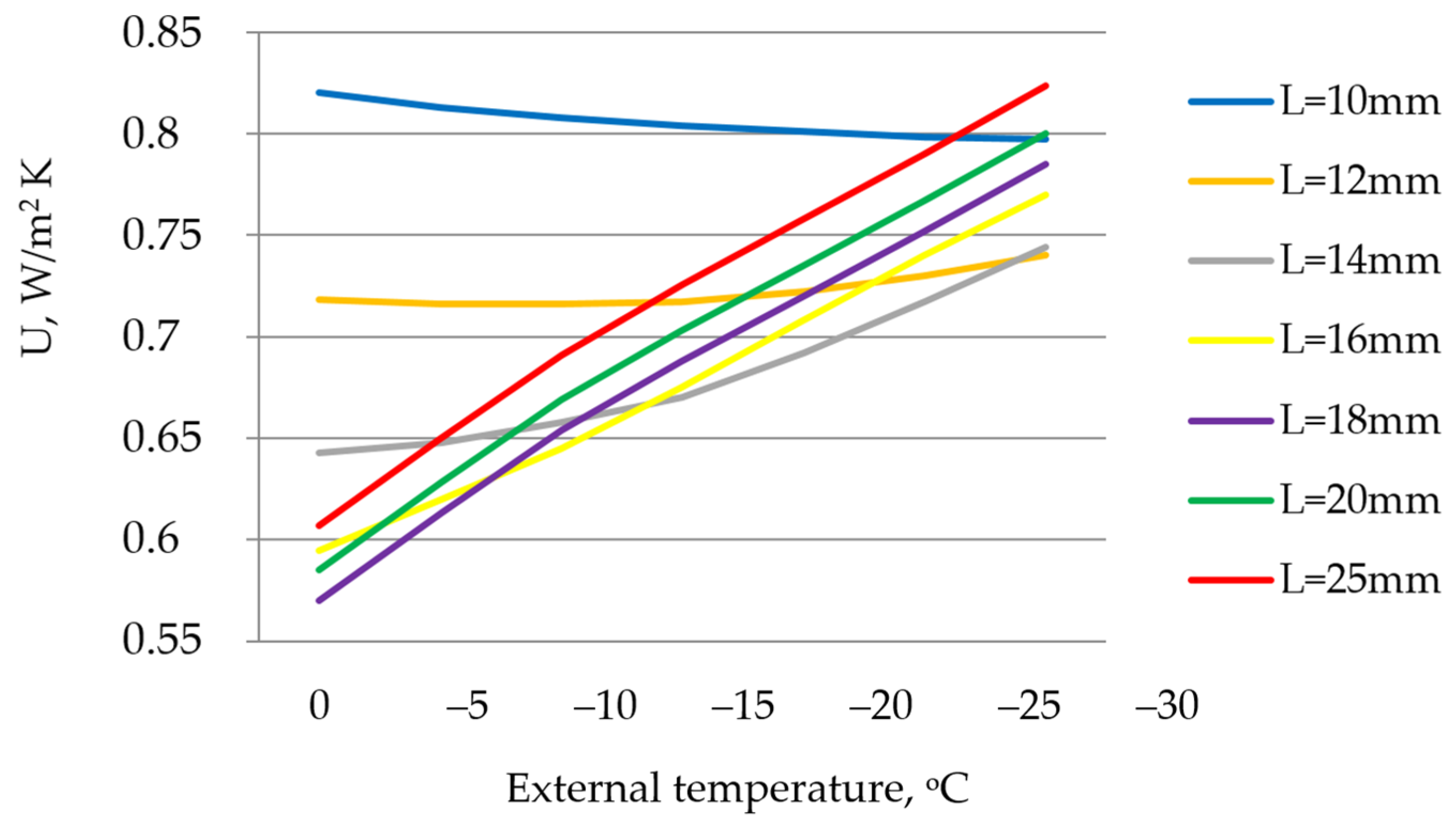

| [61] | double- and triple-pane windows | 1D | steady | Determination of the dependence of the values of thermal transmittance on external temperatures. | Standard EN 673 Standard ISO 15099 | yes | no |

| [62] | slim double skin facade | 2D | steady | Evaluation of the impact of colored or low-emissivity pane to improve the cooling performance. | Renormalization k–ε turbulence model S2S radiation model | yes | yes |

| [63] | double-pane naturally ventilated window | 2D | transient | Determination of the SHGC, the shading coefficient, and the temperature field along and across the gap for different gap widths and incident radiation conditions. | Finite difference method ADI method | yes | yes |

| [64] | double-pane window | 2D | steady | Comparison of the SHGC and the total heat gain coefficient of a double-pane window filled with an absorbing gas, a single-pane window, and a naturally ventilated double-pane window. | CW number model DO method | yes | yes |

| single-pane window | 2D | transient | Finite difference approximation ADI method | yes | yes | ||

| naturally ventilated double-pane window | 2D | transient | ADI method | yes | yes | ||

| [65] | slim-type double skin window system | 3D | steady | Determination of the cavity air temperatures and the SHGC for the closed and open conditions of the window’s external opening. | CFD | yes | yes |

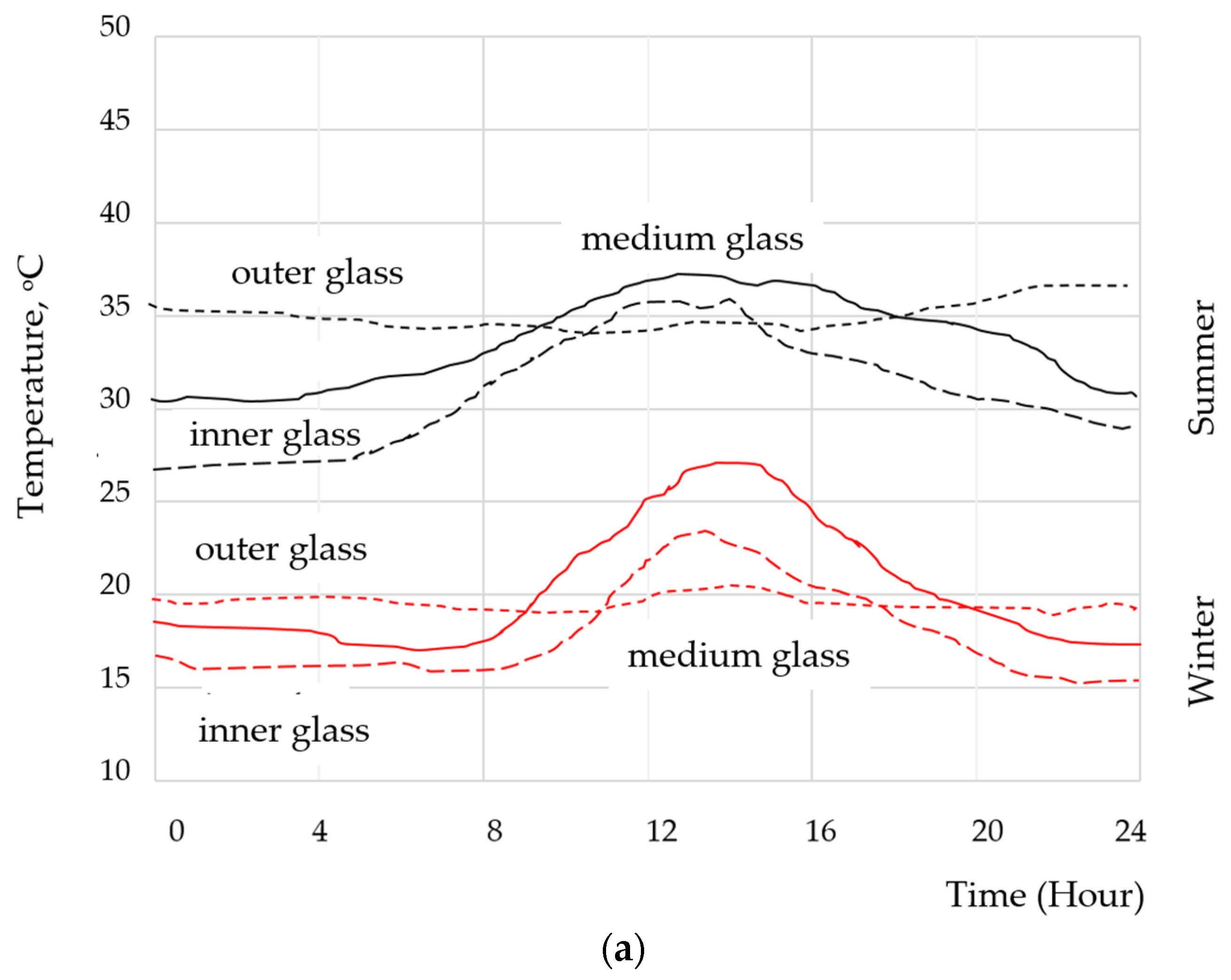

| [66] | single-pane window | 1D | transient | Determination of the amount of global radiation on panes and the corresponding pane surface temperature over the diurnal cycle. | Finite difference method | yes | yes |

| [67] | multi-pane windows | 2D | steady | Investigation of a ray-tracing method compared with the ISO 15099 standard. | CFD + ray-tracing method Standard ISO 15099 | yes | yes |

| [68] | supply air ventilated window | 3D | steady | Investigation of the velocity and the temperature distribution. | CFD Finite volume method Second-order upwind scheme | yes | yes |

| [69] | supply air ventilated windows | 3D | steady | Investigation of the thermal performance and the capacity to preheat ventilation air. | CFD | yes | yes |

| [70] | double-pane window with a controlled flow of water within the gap | 3D | steady | Impact of the water flow velocity, the external and internal temperatures, the incident solar radiation, and the beam angle. | CFD | yes | yes |

| [71] | dual-air flow window | 3D | steady | Investigation a novel method for calculation of air flow through the gap and pane temperatures. | Renormalization k–ε turbulence model S2S radiation model | yes | yes |

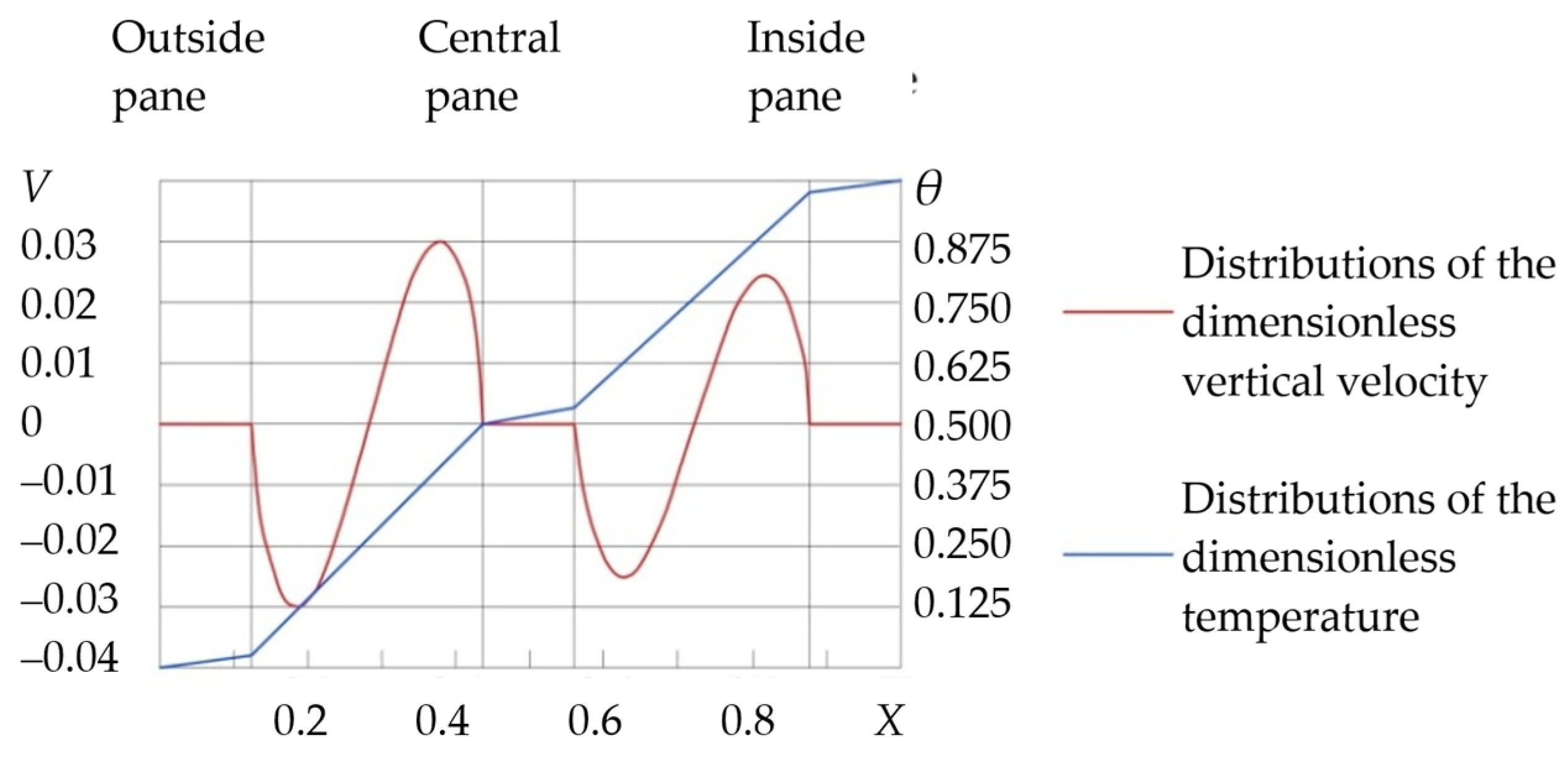

| [72] | triple-pane window | 2D | steady | Determination of the velocity, the pressure, and the temperature fields in the panes and in the gas gap. | Control-volume method | yes | yes |

| [73] | double-pane window | 2D | steady | Comparison of the thermal efficiency of windows filled with an absorbing gas and filled with a PCM. | CW number model | yes | yes |

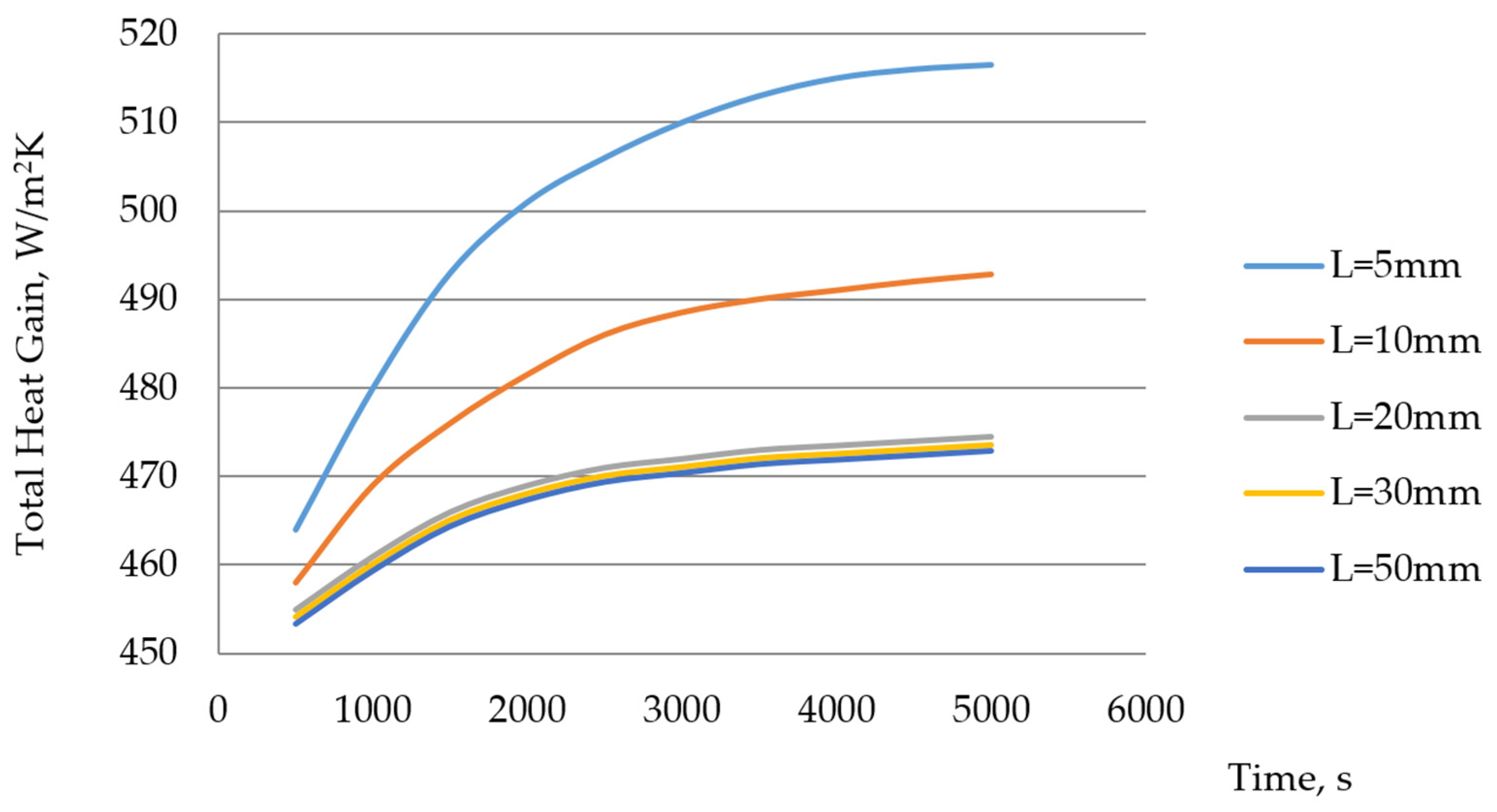

| [74] | double-pane naturally ventilated window | 1D | unsteady | Impact of the gap width and the variation of the forced mass flow rate on the total heat gain and the shading coefficient. | S2S radiation model | yes | yes |

| [75] | ventilated multi-pane windows | 2D | steady | Investigation of the impact of ventilation on different window setup. | CFD Finite volume method S2S radiation model | yes | yes |

| [76] | double-pane air flow window with integrated blinds | 2D | steady | Impact of the tilt angle of the blinds, the gap width, and the areas of inlet and outlet vents on the thermal performance. | k-ω viscous model DO method | yes | yes |

| [77] | ventilated double-pane window | 2D | steady | Impact of a reflective solar control film, the gap width, and the thickness of the glass panes on the thermal performance. | Finite volume method | yes | yes |

| [78] | double-pane ventilated window | 2D | steady | Impact of the airflow rate, the outdoor air temperature, and the solar irradiance on the temperature rise and the useful energy of the delivered air. | CFD Standard ISO 15099 | yes | yes |

| [79] | double-pane ventilated window | 1D | steady | Determination of the SHGC in different operating conditions and for different glass types and different glass to frame ratios. | Standard ISO 15099 | yes | yes |

| [80] | triple-pane dual air flow window | 2D | steady | Impact of solar radiation, wind, mode of operation, airflow rate, and gap width. | CFD Renormalization k–ε turbulence model Second-order upwind scheme | yes | yes |

| [81] | triple-pane window | 2D | steady | Determination of U-value and heat lossses for dirrenent outdoor temperature, window-to-wall ratios, glazing models and number of panes. | Standard ISO 15099 | yes | yes |

| [82] | double-pane window with electric heating | 2D | steady | Analysis of the distribution of heat flows and temperatures. | Finite difference method | yes | no |

| [83] | double-pane window integrated with a photovoltaic system | 2D | steady | Determination of the overall heat transfer coefficient, the temperature distribution, and the flow field for different Rayleigh numbers. | Finite difference method | yes | yes |

| [84] | window with a phase change heat accumulator | 2D | steady | Determination of two complex heat transfer resistances between the external glazing and the PCM accumulator, and between the PCM accumulator and the internal glazing. | Finite difference method | yes | yes |

| Ref. | Glass Type | Operation Mechanism |

|---|---|---|

| [105] | Electrochromic | Response to an electrical voltage or charge |

| [106] | Photochromic | Response to UV light |

| [107] | Thermochromic | Response to temperature |

| [108] | Thermotropic | Response to temperature-dependent light scattering |

| [109] | Mechanochromic | Response to optical properties |

| [110] | Gasochromic | Response to reducing or oxidizing gases |

| [111] | Magnetochromic | Response to magnetic field intensity |

| Model Types | Ref. |

|---|---|

| CFD simulations were performed in many of the cited papers | [7,11,21,30,60,62,65,67,68,69,70,75,78,80,113,114,115,116] |

| The majority of the conducted studies were focused on 2D models | [7,11,12,13,21,30,34,48,52,55,62,63,64,67,72,73,75,76,77,78,80,81,82,83,84,89,99,100,101,113,115] |

| In many of the modeling approaches, the solar radiation was not considered | [6,7,10,11,12,13,21,30] |

| The standard k-ε model or the RNG k-ε turbulence model were implemented for simulations of ventilated windows | [48,62,71,80,98,99,103] |

| In some cases, heat sources were included in the energy equation | [63,64,82,93,100,114] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavlenko, A.M.; Sadko, K. Evaluation of Numerical Methods for Predicting the Energy Performance of Windows. Energies 2023, 16, 1425. https://doi.org/10.3390/en16031425

Pavlenko AM, Sadko K. Evaluation of Numerical Methods for Predicting the Energy Performance of Windows. Energies. 2023; 16(3):1425. https://doi.org/10.3390/en16031425

Chicago/Turabian StylePavlenko, Anatoliy M., and Karolina Sadko. 2023. "Evaluation of Numerical Methods for Predicting the Energy Performance of Windows" Energies 16, no. 3: 1425. https://doi.org/10.3390/en16031425

APA StylePavlenko, A. M., & Sadko, K. (2023). Evaluation of Numerical Methods for Predicting the Energy Performance of Windows. Energies, 16(3), 1425. https://doi.org/10.3390/en16031425