Possibility of Marine Low-Speed Engine Piston Ring Wear Prediction during Real Operational Conditions

Abstract

:1. Introduction

2. Research on Marine Low-Speed Engine Piston Ring Wear Ratio

- Direct measurements of thickness and height of PR using a standard micrometer [8,12,13]. Obtaining these measurements is only possible during a scheduled or unscheduled piston and liner overhaul. The measurements of piston ring wear performed during overhauls do not give information in relation to the lubrication quality; they are also useless for the prediction of PR wear trends and for calculating when catastrophic wear takes place [14,15,16,17]. During the normal operation of an engine, only the methods mentioned below can be considered as applicable between overhauls; this is on the grounds of their simplicity and the ability to perform these measurements within the short time that the vessel is lying in the port.

- Measurement of piston rings and cylinder liner assembly radial wear. Clearance c in the piston ring gaps can be achieved in the dead center of the piston bottom, on the condition that they can be reached through the scavenge ports. These measurements are not easy to perform due to the limited space for taking proper gauging. The results of the measurements obtained in this way can be used for calculating the total wear PR–CL (piston rings–cylinder liner assembly), and for evaluating the partial wear as a consequence of operating for a certain number of hours. The radial wear of PR–CL assembly h is determined from the following Equation (1):

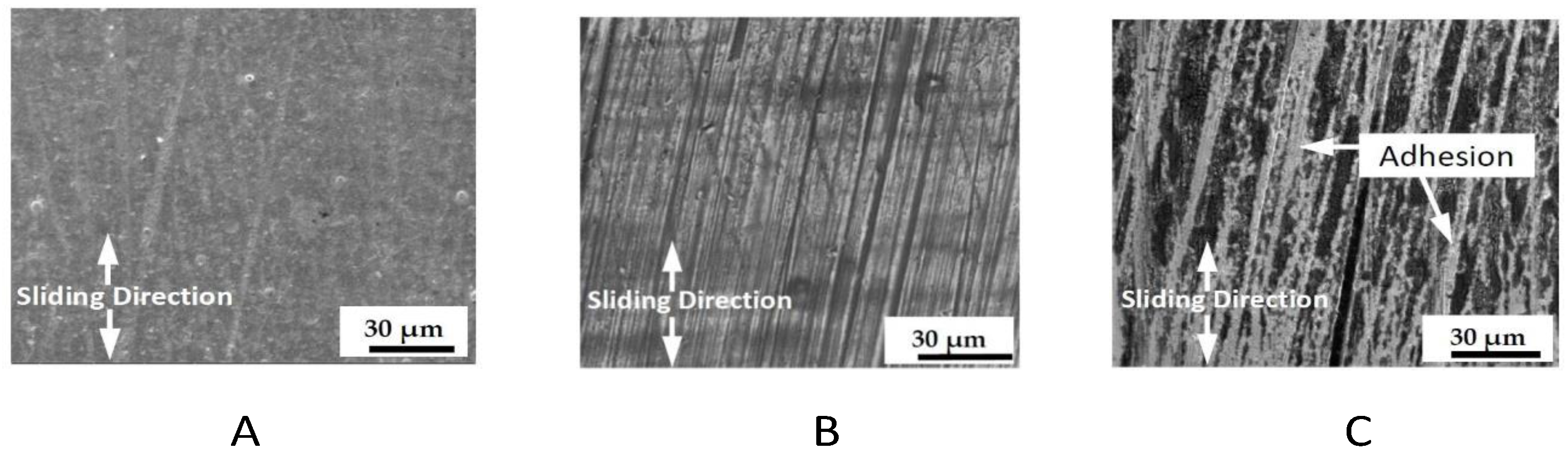

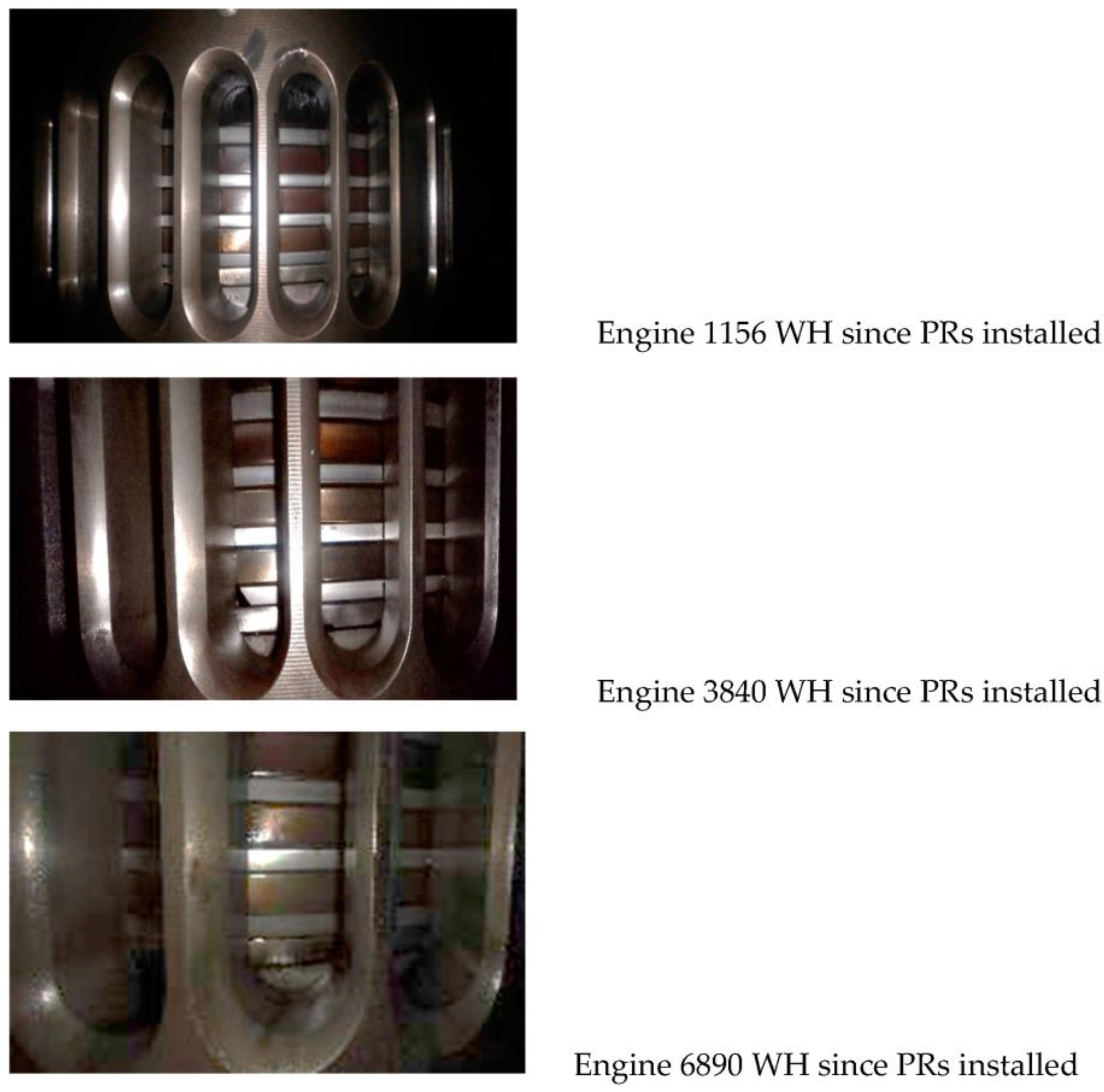

- Direct measurements of PR wear based on PR’s coating surface thickness measurement. The coating of PRs, usually plasma thermal-sprayed coatings of Mo/NiCr/Cr-C, the purpose of which is to improve the tribological properties and increase the wear resistance of PRs, gets worn out upon engine operation. The PRs’ coating thickness can be measured with lepto-scopes, utilizing electromagnetic (induction) methods for non-ferrous layer measurement. These measurements are usually made via scavenge ports. the thickness measurement results of the PR coating can be used as a function of coating wear, depending on the number of working hours the piston rings have been used. The obtained results can be a reliable argument for evaluating the tendencies of their wear and for estimating their service life until the overhaul time is due, and can finally be used to assess the CL–PR lubrication quality. The total wear of the PRs’ coating gives strong information regarding whether the replacement of the piston rings is necessary, because PR resistance to tribological wear becomes significantly lower [9,21,22].

- PR No.1-600 [µm]-Top Ring,

- PR No.2-310 [µm],

- PR No.3-310 [µm],

- PR No.4-310 [µm].

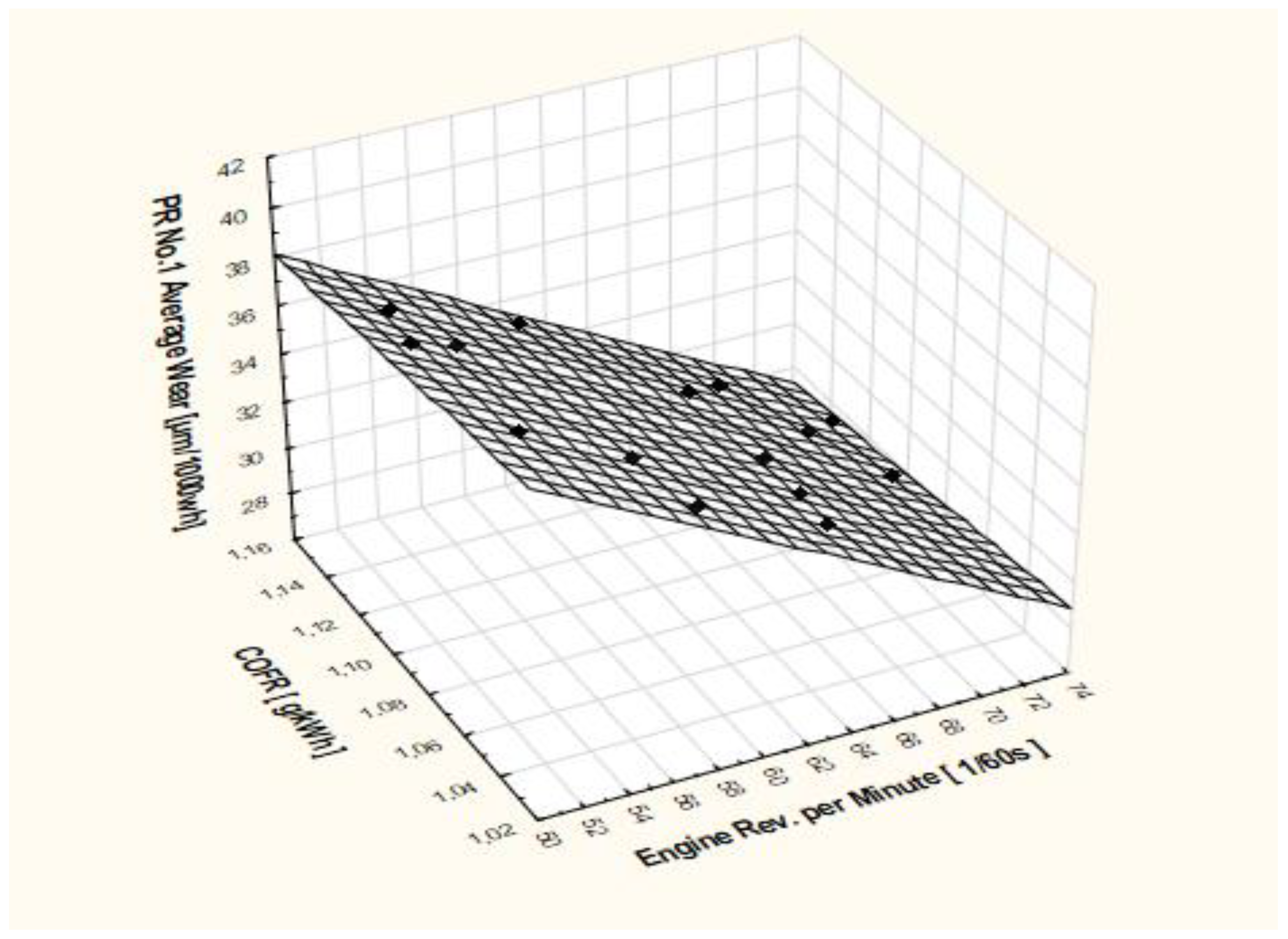

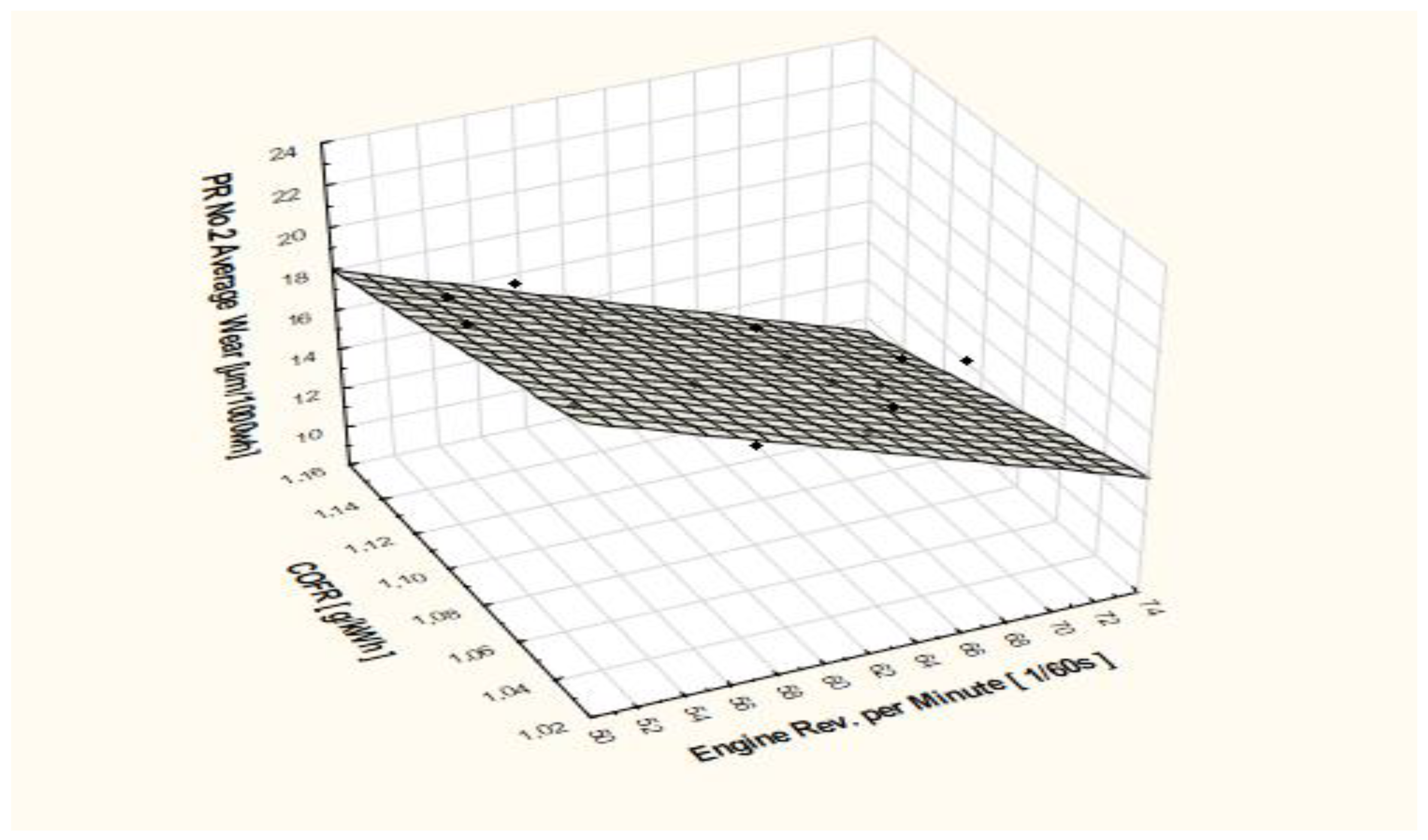

3. Piston Rings Wear Ratio Prediction Models Verification Tests on Engine

4. Discussion

- The wear rates of piston rings tend to increase when the piston speed is kept lower during maneuvering or super slow steaming. Particular attention should be paid when engines are operated at piston speeds of 6.0 m/s or less, due to the lower stability of the oil film on the cylinder liner surface. When an engine is operating in such a condition, using expert knowledge and the authors’ experience, the cylinder lubricating oil feed rate can be increased by 20%. The results of an increased COFR on the PR–CL assembly performance and condition can be confirmed by the inspection of the PRs through the scavenge air ports. If necessary, the COFR can be increased again.

- The presented wear rates prediction models can be utilized, but must be followed by a visual inspection of the piston rings and cylinder liners through scavenge spaces and scavenge ports.

- The values of the PR wear rates obtained by physical measurements can be compared with the values predicted by calculation, using the model described in this paper. The obtained results shown that, by using prediction models, we can make +/− 5% error with the valuation of the PR wear ratio. This value is acceptable for the normal operation of marine low-speed engines.

- The predicted PR wear ratios are useful to estimate the time horizon of reaching the limits of wear when catastrophic wear can take place and when the anti-wear coating disappears.

- Setting up an optimal cylinder oil feed rate should protect the engine against the abnormal wear of the piston rings–cylinder liner assembly, and secure around 15,000–18,000 WH of good engine operation between overhauls of the PR–CL assembly.

- A specifically adjusted cylinder oil feed rate for each engine can reduce the number of cylinder liner pistons and piston ring failures, can reduce the total cylinder oil consumption and reduce the emission of harmful substances into the atmosphere. It increases the reliability of marine engines and overall improves the management of a ship’s marine power plant resources. All the mentioned benefits are related to a reduction in a ship’s operational costs and are directly are related to energy efficiency.

- The idea performed and presented in this research paper aimed to find ways to aid operators in the maintenance of PR wear rates within an acceptable range. In the day-to-day operation of engines, innovation is due; this will be used to create PR wear rate prediction models, evaluate the tendencies of their wear, estimate their service life until the overhaul time is due and, finally, to evaluate the CL–PR lubrication quality. However, we would like to point out that the research was conducted in the real operation of engines used for the propulsion of ships. Many of factors measured were not possible to take.

5. Conclusions

- The presented research was conducted to find user-friendly piston ring wear rate prediction models; this was due to a lack of such aid for operators in the operation of marine low-speed engines in day-to-day operation. This research helps to reduce the costs of engines maintenance, reduce the total cylinder lubricating oil consumption and reduce the emission of noxious substances into the environment. The implementation of these prediction models in marine engines can increase the reliability of marine engines and overall improve the management of ships’ engine department resources.

- Unplanned stops due to the breaking down of the CL–PR assembly and the expenses that cover such events are never desirable, especially not in the shipping industry, where costs are essential for the competitiveness of shipping company. Preventing the mentioned events also has a safety aspect; when at sea, engine power must be fail-safe. The prediction models of the PR wear rates presented in this paper are only one of the aspects able to keep marine low-speed engines reliable and safe. The obtained results can be a reliable argument for evaluating the tendencies of their wear, for estimating their service life until the overhaul time is due and for evaluating the CL–PR lubrication quality.

- The total wear of the PRs’ coatings gives strong information that suggests the replacement of piston rings is absolutely necessary. In normal operating conditions, keeping proper, acceptable PR wear rates depends of many factors, such as the following: engine COFR, engine Load, quality of fuel used for engine operation, quality and timely performance of proper maintenance of all engine components etc. One of important factors to maintain PR wear rates on an acceptable level is the education and motivation of marine engine operators.

- If, during the normal operation of a marine low-speed engine, with certain RPM and COFR, the PR coatings wear rate, calculated using prediction models, are higher than: 40 [µm/1000 WH] for No.1 PR and 20 [µm/1000 WH] for PRs No. 2, 3 and 4, it is strongly recommended that engines operators seriously consider an increase in the COFR. It will help to obtain the required optimal PR wear rates.

- The PR wear rate prediction models presented in this paper are only one of the aspects that make the operation of a marine low-speed engine safe and reliable.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PR | Piston Rings |

| CL | Cylinder Liner |

| PR–CL | Piston Rings and Cylinder Liner assembly |

| CLO | Cylinder Lubricating Oil |

| COFR | Cylinder Oil Feed Rate [g/kWh] |

| MCR | Engine maximum continuous rate [kW] |

| PR WR | Piston Ring Wear Rate Wear Rate [µm/1000 WH] |

| BN | Base Number of Cylinder Lubricating Oil [mg KOH/g] |

| RPM | Revolutions per minute [1/60 s] |

| WH | Working hours. number of hours in operation [h] |

References

- Gu, C.; Wang, R.; Tian, T. Modeling the Fatigue Wear of the Cylinder Liner in Internal Combustion Engines during the Break-In Period and Its Impact on Piston Ring Lubrication. Lubricants 2019, 7, 89. [Google Scholar] [CrossRef]

- Olander, P.; Hollman, P.; Jacobson, S. Piston ring and cylinder liner wear aggravation caused by transition to greener ship transports–Comparison of samples from test rig and field. Wear 2013, 302, 1345–1350. [Google Scholar] [CrossRef]

- Rodríguez, A.L.; Vølund, A.; Klit, P. Modeling of piston ring wear. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 629–638. [Google Scholar] [CrossRef]

- Yuelan, D.; Zhihai, C.; Ping, Z. The Tribological Performance of CrMoN/MoS2 Solid Lubrication Coating on a Piston Ring. Lubricants 2017, 5, 13. [Google Scholar] [CrossRef]

- Yeng, Y.-R. Theoretical Analysis of Piston-Ring Lubrication Part I—Fully Flooded Lubrication. Tribol. Trans. 1992, 35, 696–706. [Google Scholar] [CrossRef]

- Golloch, R.; Kessen, U.; Merker, G.P. Tribological investigations on the piston assembly group of a diesel engine. MTZ Worldw. 2002, 63, 21–24. [Google Scholar] [CrossRef]

- Olander, P.; Eskildsen, S.S.; Fogh, J.W.; Hollman, P.; Jacobson, S. Testing scuffing resistance of materials for marine 2-stroke engines—Difficulties with lab scale testing of a complex phenomenon. Wear 2015, 340–341, 9–18. [Google Scholar] [CrossRef]

- Operation Data and Maintenance Instruction Manual MC Series Engines Edition 2005. B&W Man. Available online: https://seatracker.ru/viewtopic.php?t=1516 (accessed on 1 August 2021).

- Liu, S.; Chen, H.; Shang, B.; Papanikolaou, A. Supporting Predictive Maintenance of a Ship by Analysis of Onboard Measurements. J. Mar. Sci. Eng. 2022, 10, 215. [Google Scholar] [CrossRef]

- Kiriakos, A.; Efthimios, G.P.; Zannis, T.C.; Leligou, H.C. Prediction of a Ship’s Operational Parameters Using Artificial Intelligence Techniques. J. Mar. Sci. Eng. 2021, 9, 681. [Google Scholar] [CrossRef]

- Koszałka, G. Model of Operational Changes in the Combustion Chamber Tightness of a Diesel Engine. Eksploat. I Niezawodn. Maint. Reliab. 2014, 16, 133–139. Available online: https://www.researchgate.net/publication/295603907 (accessed on 10 July 2022).

- Operation Data and Maintenance Instruction Manual MC Series Engines Edition 2010. B&W Man. Available online: https://www.academia.edu/36931905/Instructions_MAN_B_and_W_MC_Engines_OPERATION (accessed on 30 August 2022).

- Operation Data and Maintenance Instruction Manual MC Series Engines Edition 2014. B&W Man. Available online: https://www.academia.edu/30054619/MAN_B_and_W_Diesel?sm=b (accessed on 30 July 2022).

- Chew, F.; McGeary, T. Analysis of Marine Diesel Engine Cylinder Lubricant Drain as a Means of Monitoring Engine Performance—Editor: MAR-TECH. Singapore September 2000. Available online: https://themartechsummit.com/global-virtual-apac (accessed on 22 June 2022).

- Van Doan, D.; Murawski, L. Adjustment of Cylinder Lubricating Oil of Marine Slow-Speed Engines. J. KONES 2017, 24, 113–119. Available online: https://sciendo.com/article/10.5604/01.3001.0010.2803 (accessed on 12 May 2021).

- Wajand, J.A.; Wajand, J.T. Tłokowe Silniki Spalinowe Średnio i Szybkoobrotowe; WNT: Warszawa, Poland, 2005; ISBN 83-204-3054-2. [Google Scholar]

- Kaminski, W. Analytical assessment of selected engine piston drawing out records and records of feed rates. Sci. J. Marit. Univ. Szczec. 2013, 36, 56–60. [Google Scholar]

- McGeary, T.; Chew, F. Paper No.14 Investigation into Abrasiveand Corrosive Wear Mechanisma of Pistons ans Liners in Large Bore 2-Strok Diesel Engine Cylinderse. CIMAC. 2004. Available online: https://www.yumpu.com/en/document/read/39658037/paper-no-14-investigations-into-abrasive-and-flame-marine (accessed on 12 May 2022).

- Piotrowski, I.; Witkowski, K. Okrętowe Silniki Spalinowe, 3rd ed.; Trademar: Gdynia, Poland, 2013; ISBN 978-83-62227-48-8. [Google Scholar]

- Wlodarski, J.K. Tłokowe Silniki Spalinowe-Procesy Tribologiczne; Wyd. Kom i Łącz.: Warszawa, Poland, 1992; ISBN 8320602884. [Google Scholar]

- Chew, F.; McGeary, T. Study of the relationship between cylinder lubricant drain condition and performance parameters of 2-stroke cross-head engines. In Proceedings of the CIMAC Conference on International Council on Combustion Engines, Hamburg, Germany, 7–10 May 2001; paper no. 102. pp. 1–6. [Google Scholar]

- Chun, S.M. Simulation of engine life time related with abnormal oil Consumption. Tribol. Int. 2011, 44, 426–436. [Google Scholar] [CrossRef]

- Kaminski, W. Assessment and analysis of selected main engines cylinder liners and piston rings wear process. In Proceedings of the 17th International Multidisciplinary Scientific Geo Conference SGEM 2017, Vienna, Austria, 27–29 November 2017; ISBN 978-1-5108-4819-1. [Google Scholar] [CrossRef]

- Kaminski, W. Marine Long Stroke Engines Cylinder Liners and Piston Rings wear monitoring using analysis of scavenge drain oil. In Proceedings of the 18th International Multidisciplinary Scientific Geo Conference SGEM 2018, Albena, Bulgaria, 2–8 July 2018. [Google Scholar] [CrossRef]

- CIMAC Guidelines for Lubrication of Two-Stroke Crosshead Diesel Engines. 1997. Available online: https://www.cimac.com/recommendation_15 (accessed on 12 August 2021).

- Vizentin, G.; Vukelic, G.; Murawski, L.; Recho, N.; Orovic, J. Marine Propulsion System Failures—A Review. J. Mar. Sci. Eng. 2020, 8, 662. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, C.; Ma, X.; Wang, Z.; Xu, Y.; Cattley, R. A Multivariate Statistics-Based Approach for Detecting Diesel Engine Faults with Weak Signatures. Energies 2020, 13, 873. [Google Scholar] [CrossRef]

- CIMAC WG8 Recommendation 31 The Lubrication of Two-Stroke Crosshead Diesel Engines. 2017. Available online: https://www.cimac.com/cms (accessed on 12 August 2021).

- Dziubak, T.; Dziubak, S.D. A Study on the Effect of Inlet Air Pollution on the Engine Component Wear and Operation. Energies 2022, 15, 1182. [Google Scholar] [CrossRef]

- Kaminski, W. Marine Long Stroke Engines Piston Rings Wear analysis at real operational conditions. In Proceedings of the 18th International Multidisciplinary Scientific Geo Conference SGEM 2018, Albena, Bulgaria, 2–8 July 2018. [Google Scholar] [CrossRef]

| No. | Engine WH since New PRs Installed [WH] | COFR [g/kWh] | Average Engine RPM [1/60 s] | Average Engine Load [% MCR] | PR No.1 Average Wear Rate [µm/1000 WH] | PR No.2 Average Wear Rate [µm/1000 WH] | PR No.3 and No.4 Average Wear Rate [µm/1000 WH] |

|---|---|---|---|---|---|---|---|

| 1 | 1156 | 1.05 | 52 | 38 | 39 | 20.2 | 14.2 |

| 2 | 2128 | 1.05 | 65.4 | 67 | 32 | 16.8 | 11.9 |

| 3 | 3840 | 1.13 | 67.7 | 73 | 31 | 11.9 | 10.6 |

| 4 | 4520 | 1.13 | 55.6 | 52 | 35.4 | 18.4 | 16.8 |

| 5 | 6890 | 1.13 | 72.0 | 83 | 28 | 9.4 | 12.3 |

| No. | Engine WH since New PRs Installed [WH] | COFR [g/kWh] | Average Engine RPM [1/60 s] | Average Engine Load [% MCR] | PR No.1 Average Wear Rate [µm/1000 WH] | PR No.2 Average Wear Rate [µm/1000 WH] | PR No.3 and No.4 Average Wear Rate [µm/1000 WH] |

|---|---|---|---|---|---|---|---|

| 1 | 4589 | 1.11 | 68 | 80 | 29.3 | 12.3 | 10.1 |

| 2 | 6200 | 1.11 | 52.1 | 38 | 37.8 | 18.9 | 16.9 |

| 3 | 7702 | 1.08 | 67.0 | 77 | 30.5 | 12.6 | 11.8 |

| 4 | 8360 | 1.08 | 71.3 | 83 | 30.2 | 15.1 | 12.1 |

| 5 | 9420 | 1.15 | 60 | 63 | 33.8 | 13.5 | 13.1 |

| No. | Engine WH since New PRs Installed [WH] | COFR [g/kWh] | Average Engine RPM [1/60 s] | Average Engine Load [% MCR] | PR No.1 Average Wear Rate [µm/1000 WH] | PR No.2 Average Wear Rate [µm/1000 WH] | PR No.3 and No.4 Average Wear Rate [µm/1000 WH] |

|---|---|---|---|---|---|---|---|

| 1 | 8300 | 1.12 | 52 | 38 | 38.4 | 19.4 | 17.1 |

| 2 | 9128 | 1.12 | 65.4 | 75 | 32 | 14.8 | 14.3 |

| 3 | 10,625 | 1.09 | 69.3 | 82 | 32.2 | 14.5 | 6.7 |

| 4 | 12,920 | 1.09 | 60.2 | 63 | 32.8 | 15.8 | 14 |

| 5 | 16,713 | 1.04 | 58.7 | 60 | 35.2 | 17.5 | 15.1 |

| Engine WH since New PRs Installed [WH] | Average Engine RPM [1/60 s] | COFR [g/kWh] | Average PR No.1 Wear Rate (Measured–Real) [µm/1000 WH] | Predicted PR No.1 Wear Rate [µm/1000 WH] | ERROR PR No.1 Real–Predicted [%] |

|---|---|---|---|---|---|

| 6023 | 68 | 1.15 | 29.1 | 30.07 | −3.3 |

| 7095 | 59.8 | 1 | 36.2 | 35.38 | 2.3 |

| 8303 | 52.5 | 1.00 | 39.3 | 38.67 | 1.6 |

| 8935 | 56.4 | 1.2 | 35.6 | 34.76 | 3.3 |

| 9438 | 62.2 | 1.15 | 33.1 | 32.68 | 1.3 |

| Engine WH since New PRs Installed [WH] | Average Engine RPM [1/60 s] | COFR [g/kWh] | Average PR No.2 Wear Rate (Measured–Real) [µm/1000 WH] | Predicted PR No.2 Wear Rate [µm/1000 WH] | ERROR PR No.1 Real–Predicted [%] |

|---|---|---|---|---|---|

| 6023 | 68 | 1.15 | 12.3 | 11.78 | 4.2 |

| 7095 | 59.8 | 1 | 18.7 | 19.64 | −5.0 |

| 8303 | 52.5 | 1.00 | 22.6 | 22.27 | 1.5 |

| 8935 | 56.4 | 1.2 | 15.0 | 14.32 | 4.7 |

| 9438 | 62.2 | 1.15 | 13.3 | 13.87 | −4.1 |

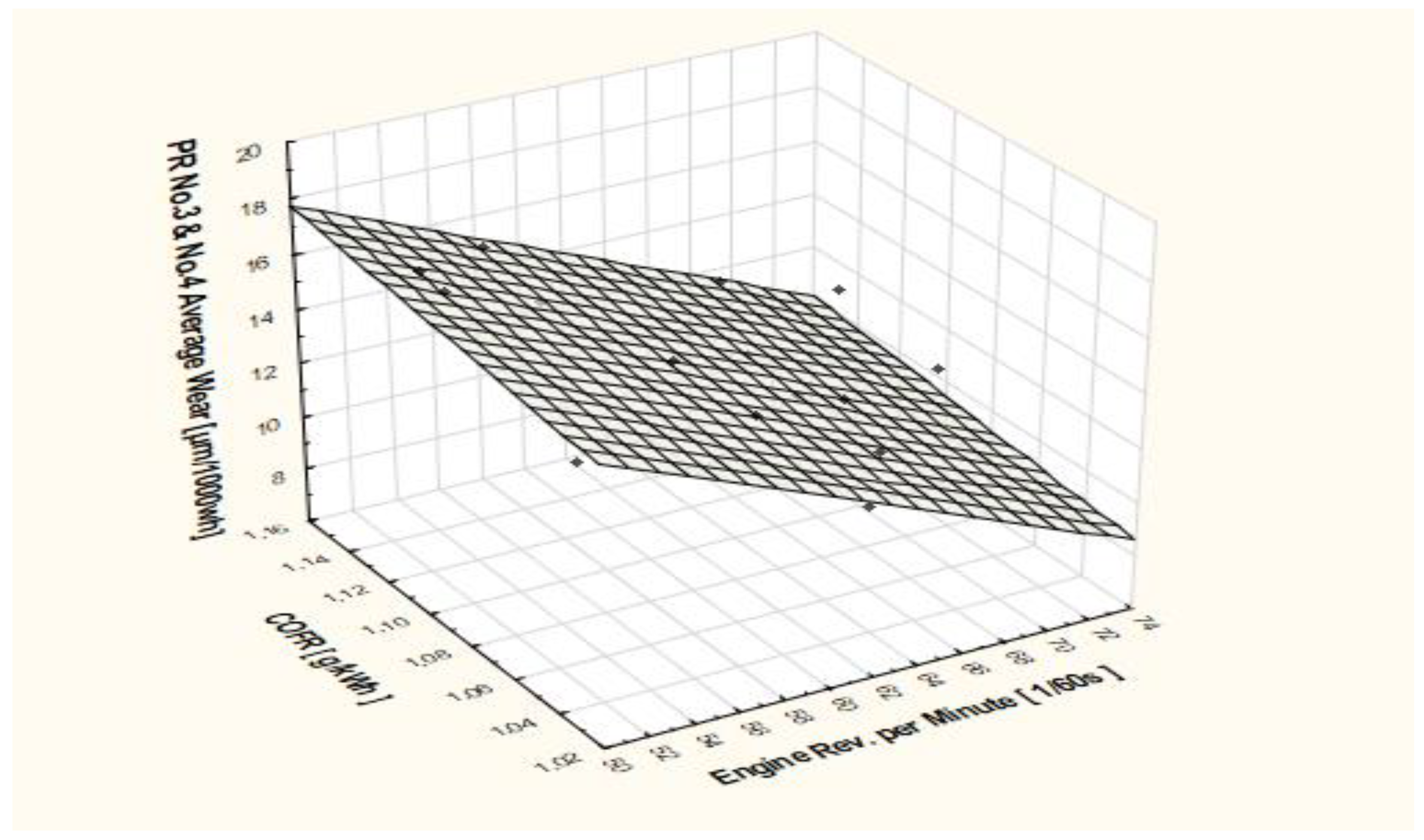

| Engine WH since New PR Installed [WH] | Average Engine RPM [1/60 s] | COFR [g/kWh] | Average PR No. 3 and 4 Wear Rate (Measured–Real) [µm/1000 WH] | Predicted PR No.3 and 4 Wear Rate [µm/1000 WH] | ERROR PR No.3 and 4 Real–Predicted [%] |

|---|---|---|---|---|---|

| 6023 | 68 | 1.15 | 11.2 | 11.73 | −4.5 |

| 7095 | 59.8 | 1 | 12.3 | 12.73 | −3.5 |

| 8303 | 52.5 | 1.00 | 15.5 | 15.07 | 2.8 |

| 8935 | 56.4 | 1.2 | 15.2 | 15.98 | −4.8 |

| 9438 | 62.2 | 1.15 | 13.4 | 13.58 | −1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamiński, W.; Michalska-Pożoga, I. Possibility of Marine Low-Speed Engine Piston Ring Wear Prediction during Real Operational Conditions. Energies 2023, 16, 1433. https://doi.org/10.3390/en16031433

Kamiński W, Michalska-Pożoga I. Possibility of Marine Low-Speed Engine Piston Ring Wear Prediction during Real Operational Conditions. Energies. 2023; 16(3):1433. https://doi.org/10.3390/en16031433

Chicago/Turabian StyleKamiński, Włodzimierz, and Iwona Michalska-Pożoga. 2023. "Possibility of Marine Low-Speed Engine Piston Ring Wear Prediction during Real Operational Conditions" Energies 16, no. 3: 1433. https://doi.org/10.3390/en16031433