1. Introduction

Intensive efforts to search for alternative energy-saving light sources forced by the European Commission regulation of 18 March 2009 resulted in the dynamic development of LED-based lighting technology. Presently, this type of light source is often utilized in lighting technology. LEDs are notably popular light sources for domestic, urban and industrial applications. Indeed, nowadays, LED-based lighting systems in the form of light bulbs or lighting strips are used in the automotive industry, for ambient lighting (including street lighting) and for various types of household lighting.

The main determinants of their popularity are durability, compactness of the structure, relatively low production costs and high energy efficiency during normal operation mode. Considering the problem of energy consumption reduction, the actions taken in this topic are justified. However, the increased number of LED-based light sources in which their circuit topologies are based on the utilization of electronic power components has brought about an enhanced occurrence of diverse transient surges within the power supply network. This is because LED-based light sources require dedicated power electronic drivers. The electronic circuit components included in the composition of such drivers are used to optimize the operating conditions of LED light sources.

The aforementioned drivers comprise rectifiers, bulk capacitors, electronic switching components and inverters operating at increased frequency. As a result, beyond the supply current distortion effect, high-frequency (HF) transient injection into the power supply network, power losses and unfavorable phenomena in the form of voltage and current surges during normal operation and during start-up, are noticed, e.g., [

1,

2,

3].

A wide variety of light sources that exist in today’s market contain filtering systems offering relatively good suppression of HF surges generated by LED drivers. Simple circuits containing a rectifier and filtering capacitors are being withdrawn from the market, and, today, various types of integrated circuits (IC) are most commonly utilized. These ICs secure the desired operating conditions for LEDs. Hence, in order to secure proper operation and to ensure the desired efficiency of these power circuits, they are equipped with additional filtering systems, bulk capacitors or other supplementary circuits. As a result, a complex structure is created in which additional wire resistances, parasitic capacities and inductances may appear and may have an impact on circuit operation, not only during normal operation but during transient states, as well.

In this connection, the problem of generating higher harmonics is not the only issue that arises when using modern lamps based on LEDs. Beyond harmonic propagation, power electronic controlled light sources are characterized by a high inrush current generated during starting-up. Most often, the problem is noticeable when using fixtures that incorporate low-cost drivers without protective circuits that are offered in cost-sensitive markets, and fixtures loaded with a large number of LEDs. In extreme cases, this may be a source of uncontrolled activation of the overload protection circuits and, consequently, power supply disturbances [

4,

5].

Today, there are many controller solutions applied, ranging from the simplest containing rectifiers and filtering circuits to integrated circuits based on various principles of operation and varied complexity levels. Due to the multitude of driver designs available on the market, a diverse impact on the supply power network components and on electric energy quality is expected. The study presented in this paper focuses on two types of popular and market-available universal LED driver solutions and their influence on the overcurrent values generated at switching-on of the power source.

Preliminary observation indicates strong dependence of the inrush current values on the supply voltage parameters. Indeed, at the supply voltage delivery moment, enormous inrush currents are generated. Bearing this in mind, in the frame of the presented study, analysis executed on tested drivers energized by diverse input voltage RMS values at different supply voltage switching-on phases was performed.

The presented document contains a comparative simulation study of two driver types of two alternative principles of operation. The drivers used in the presented study represent, in contrast to the specific designs described in the literature, universal low-cost driver solutions that may be utilized for supplying the various types of LED strips. In the frame of the study, each of the drivers was used for supplying LED strips containing a varied number of LEDs at various supply conditions.

Detailed analysis of the topology of the circuit permits supposition that the wire resistances and parasitic inductances and capacitances can suppress this current surge to a limited level. The cited literature confirms the possibility of the occurrence of such a phenomenon. However, despite this, the inrush current values occurring during switching-on are many times higher than the nominal current recorded at the steady state.

Studies available in the literature on high inrush current value generation usually concern specific LED lamp applications [

6,

7]. Such research works are primarily focused on analyzing the operation of individual light bulb designs containing a fixed number of LEDs in which each of the light bulbs is equipped with its own driver. Herein, the sole variable factor is the number of light bulbs energized through the same power source changes.

A different take on the problem is that of studies concerning the structure of power network topologies analysis and control methods of electrical energy flow in power networks containing various numbers of LED lamps, e.g., [

8]. As a result of these analyses, some solutions to inrush current limitation problems were proposed.

The most commonly recommended approaches to remedying this dilemma are to use specific power network topologies, new converter types [

9,

10,

11] or specifically dedicated transformer designs, e.g., [

12]. Considering the multitude of related publications published in recent years, the problem is therefore still relevant given the widespread use of LED light sources and emerging LED driver designs. In this connection, it is necessary to estimate the influence of various driver circuit constructions on electric energy quality and overcurrent level generation. This can be realized by means of verification experiments of the previously performed simulations, and executed before the product is launched on the market or the target installation is created, e.g., [

13].

The method of testing systems involving preliminary simulations combined with small-scale laboratory tests preceding full-scale experiments is a fundamental method commonly used in any development work. Small-scale tests permit verification of the correctness of the developed mathematical models and allow detection of potential weak points of the analyzed system, e.g., [

14,

15]. This is the basic verification procedure used before a large-scale test installation is launched, and enables avoidance of potential failures and associated repair costs. Accordingly, in existing products, similar analysis permits estimating the behavior of the analyzed product under various operating conditions, e.g., [

16,

17,

18]. A similar line of reasoning was implemented in this paper.

Regarding the problem raised in this paper, typically, in the published studies, simulations were concentrated on the demonstration of the inrush current surges phenomena by creating estimations of the potential overcurrent values and providing generalized proposals of preventive solutions. As a result, many specific minor phenomena typical for individual controller solutions have been often omitted. Among others, these include HF and low-energy current and voltage interferences being the outcome of power electronic component operation. As a result, simulations were based on various levels of simplifications. This could cause inaccuracies in the estimates of the supply voltage and current waveform shapes [

19,

20,

21]. Moreover, the models did not take into consideration the particular characteristic parameters of the utilized circuit elements (e.g., previously mentioned leakage currents of capacitors or parasitic capacities and inductances) or switching surges phenomena.

Indeed, the LED drivers require detailed analysis, reproducing occurrences that previously have been ignored and which can have a significant influence on global simulation results [

22,

23,

24]. Compared to the studies available in the literature [

17,

19,

23,

25], by taking into account the high-frequency, low-energy phenomena, the results of the presented simulations show high efficiency and high reflection of the recorded current and voltage waveforms.

The analysis executed in the frame of the presented study included the detailed development of the aforementioned driver models. This came about using commercially available engineering software. The obtained results were generated by means of simulations of current and voltage waveforms. Subsequently, spectral analysis of the waveforms was verified at the laboratory using a power analyzer. Two scenarios were analyzed. One in the steady state and one at circuit energization. Results achieved at the steady state were used for fine-tuning the models and, consequently, conducting proper inrush current waveform simulation was the main goal of the described study.

The simulations formed the basis of the study of various supply conditions induced during the switching-on voltage phase and at diverse levels of the load current. Finally, a simple, inrush current limiting circuit was implemented in the model, and its inrush current limitation effectiveness was established.

2. LT SPICE Simulation Models Development

For study needs, the commercial LT SPICE engineering software was used. The choice of software was affected by its high popularity and its high effectiveness, as confirmed by countless published studies based on analyses executed using this software.

In the frame of the research, inrush current effects observed for LED drivers and operating on different principles were analyzed. The study is comprised of LT SPICE software simulations performed for various operating conditions, and the results were then experimentally verified. The tested circuits demonstrate typical models of drivers offered within price-sensitive markets. Of note, each of the tested devices may slightly differ from similar market-available constructions in terms of detailed topology and utilized components. Notwithstanding the aforementioned, the presented models demonstrate popular solutions used to power LED strips.

For the developed LT SPICE models, research was conducted in four main stages:

Preliminary measurements comprising current and voltage signals registration at the steady state of the circuit operation;

Simulation models development for steady-state operation representing the base case;

Inrush current registration for drivers energized for various load configurations and supply conditions;

Experimental verification of the simulation results and fine-tuning of the preliminary developed models for transient-state conditions.

The first driver (widely used) is based on the notion of supplying voltage stabilization (VS) and utilizes a Zener diode. The second is an application of the principle of current stabilization (CS) and is realized by incorporating an integrated AL8806 [

26] microcontroller (μC).

The developed model of the first driver (

Figure 1) consists of main blocks: U

in sine voltage source (1), a voltage-controlled switch (2) for simulating the switching-on process, a full-wave rectifier (3) and a voltage stabilization circuit (4).

Additionally, for simulating the inrush current limiter efficiency evaluation, a block called the ICLC (inrush current limiting circuit) was added. Depending on the particular application, the ICLC module may consist of various topologies of the limitation circuit characterized by varied parameters of components utilized for its design. For the tested driver circuits, the same topologies of the applied ICLC were successively used. None of the tested controllers was originally equipped with an ICLC module.

As presented in

Figure 1, the elaborated model additionally consists of two HF current sources I

1 and I

2 (5). These were implemented in the model in order to reflect HF surges produced by the IC driver circuit. Based on previous laboratory measurement results, an additional I

1 current source was implemented and defined by the LT SPICE internal function (1). The amplitude of the I

1 surge current was obtained by means of measurements and fixed at 14.6 mA, where:

Function “White” mimics white noise signal (current in this case) production. It generates random numbers and smoothly transitions between −0.5 and 0.5 values. “Time” is a keyword used in the transient analysis under superior “white” situations and indicates that numbers are generated within the time domain in the assumed simulation time step (0.001 ms).

The I

2 surge signal is a sinusoidal current with an amplitude fixed at 10 mA and a frequency of 5.3 kHz.

Figure 2 presents the complete Fast Fourier Transform (FFT) spectrum of the encountered current surges. HF surges represented in the model by I

1 and I

2 current sources were marked in

Figure 2 by dashed lines. FFT of the voltage waveform indicates that the presence of voltage harmonics is negligible, so it was ignored in the model.

The circuit was supplied via a transformer through a Graetz bridge rectifier. The pulsating voltage at the Graetz bridge output was then filtered using a capacitance C1. In the model, a voltage divider (R1, C2) secures the appropriate voltage value for stabilizing the Zener diode plugged in at the transistor Q1. The function of R1 resistor is to limit the D6 diode current, and voltage at the collector of Q1 transistor. Along with the emitter, it is also a connection terminal for powering the load in the form of a string of LEDs.

D6 Zener diode limits the maximum Q1 transistor current if voltage exceeds 12 V. In this situation, base-emitter voltage is lower than the required 0.7 V level and the transistor is clogged. If the voltage across the Zener diode decreases, Q1 base-emitter voltage is higher than 0.7 and the transistor re-opens again. The specific Q1 transistor operation causes load current pulses. For this reason, in order to smooth the current out, an additional capacitor C3 is used at the driver output terminals. All capacitors used in both driver models take into account leakage current phenomena by implementing additional parallel resistance (values in brackets in capacitance description).

The second driver that utilizes the current stabilization method utilizes an AL8806 IC (

Figure 3). According to the datasheet provided by the manufacturer, “the AL8806 integrated circuit is a step-down DC/DC converter designed to supply LEDs with built-in output open-circuit protection”.

The AL8806 IC is dedicated to drive LEDs supplied by 4.5 V to 40 V AC voltage sources and provides an externally adjustable output current of up to 1.5 A. Depending upon the supply voltage value connected to the VIN pin and the used external components, the IC driver operates at frequencies up to 1 MHz and can provide up to 40 watts of output power.

The IC dimming function may be switched on/off depending on need by applying an external control signal. It additionally includes a standby state circuit with low current consumption. Both functions are available by applying an external control signal to the CTRL pin, according to

Figure 3.

The analysis driver model developed for simulation analysis consists of the following main blocks (

Figure 4): U

in = 12 V sine voltage supply source (1), voltage-controlled switch (2) for simulating the switching-on process, a full-wave rectifier (3), a current stabilization circuit (4) and an inrush current limiting circuit (ICLC).

In order to reproduce the “surge” signals detected at the load current waveforms, low-energy voltage sources (V1, V2) and current signals (I1–I7) were employed in the model within the block (5).

Information on the type of signal, amplitudes and frequencies of the current surge signals were obtained at the measurement stand and were based on measurement results and recorded signals FFT spectrum analysis (

Figure 5).

In contrast to the previously considered voltage stabilization system, a driver equipped with AL8806 IC generates some minor voltage surges with a frequency of a few kHz—as revealed in the FFT spectrum (

Figure 6).

Table 1 contains frequencies and amplitudes of surge pulsations superimposed on the main current and voltage signals, and applied to the model. Here, the frequency spectrum of the “surge signal” comprises a single 10 kHz modulated signal (I

1), a 2 kHz modulation with a 6 kHz index, six (I

2–I

7) sinusoidal current signals and single (I

8) current signal with LT SPICE parameters set at rising time (T

rise), falling time (T

fall) and duration (T

on) at 1 ms and period (T

period) at 3.1 ms. Parameters of the simulated surge signals were collected in

Table 1.

The model I1–I8 current surge signals reflect recognized surges for the registered current waveforms. Similarly, in order to reflect the voltage harmonic components registered for the voltage waveforms, two voltage signals were applied: a single 6 kHz sinusoidal signal (V1) and a 17 kHz modulated voltage signal, a 1.5 kHz modulation with a 5 kHz index, respectively.

For simulation needs, various numbers of NSSW008CT-P1 type LEDs were connected as load. The main criterion for LEDs selection was maximum forward load current at the rated voltage. The diodes were combined into sections connected in parallel, containing 9 diodes, where each branch contained 3 diodes connected in series. As a consequence, the total load current depended on the total number of connected LED sections.

All modeled circuit configurations were energized using a step-down transformer connected through the switch. LT SPICE model parameters of the transformer assumed for simulation needs are listed in

Table 2.

The switching-on process was initiated using a voltage-controlled switch LT SPICE component controlled through the external 12 V DC square impulse. Applying a voltage impulse at the switch terminals caused contacts to close and current to flow through the driver circuits.

3. Numerical Simulation

Depending on the usage of different types of LED drivers, various shapes of the current waveform recorded in stable conditions were expected and assumed as base case simulation results. Therefore, at the first stage of the research, the primary goal of the performed simulations was to reflect the recorded waveforms of the load current registered at the steady state. The calculated current waveforms were the basis for further simulations-inrush current waveforms simulations in this case.

The main purpose of the performed numerical simulations was to estimate the influence of the type of the tested driver’s operating principles on inrush current values occurring during circuit powering. A supplementary goal was to ascertain the type of particular driver’s load type and driver supplying voltage parameters on inrush current values.

The parameters assumed for simulation analysis were collected in

Table 3. The simulation period resulted in preliminary performed measurements that indicated that this is the time sufficient for the stabilization of the driver’s operating conditions.

The preliminary simulations aimed at the precise reflection of the waveforms registered at the steady state. The simulations included voltage and current values, voltage and current distortion levels and harmonic content parameters calculated for various load topologies. As a base case, an LED strip comprising 25 LEDs was assumed as the most common number of LEDs employed in light bulbs recognized as similar applications.

Simulation analysis comprised calculation of current waveforms for the cases:

Steady-state current waveform for a driver based on VS principle of operation and loaded with 25, 100 and 200 LEDs, respectively;

Steady-state current waveform for an AL8806 driver loaded with 25, 100 and 200 LEDs, respectively;

Inrush current for a voltage stabilization driver loaded with 25, 100 and 200 LEDs and varied switching-on phases of supplying voltage;

Inrush current for a current stabilization driver loaded with 25, 100 and 200 LEDs and varied switching-on phases of supplying voltage;

Inrush current waveform calculation for various supplying voltage levels and different switching-on phases;

Estimation of effectiveness of implemented inrush current limitation circuits.

3.1. Base Case Simulation Results and Experimental Verification

The base case comprised voltage and current waveform numerical simulation for each driver loaded with 25, 100 and 200 LEDs, respectively, and working at a steady state. All results obtained by means of simulations were verified at the measurement stand presented in

Figure 7 for the same settings as assumed for simulation analysis. The current and voltage waveforms obtained during simulations and in the frame of measurements were stored in *.csv files for further analysis and were then assessed by applying the Fast Fourier Transform using Matlab software. Harmonic component form factors (FF) verification was realized using a PQM707 analyzer.

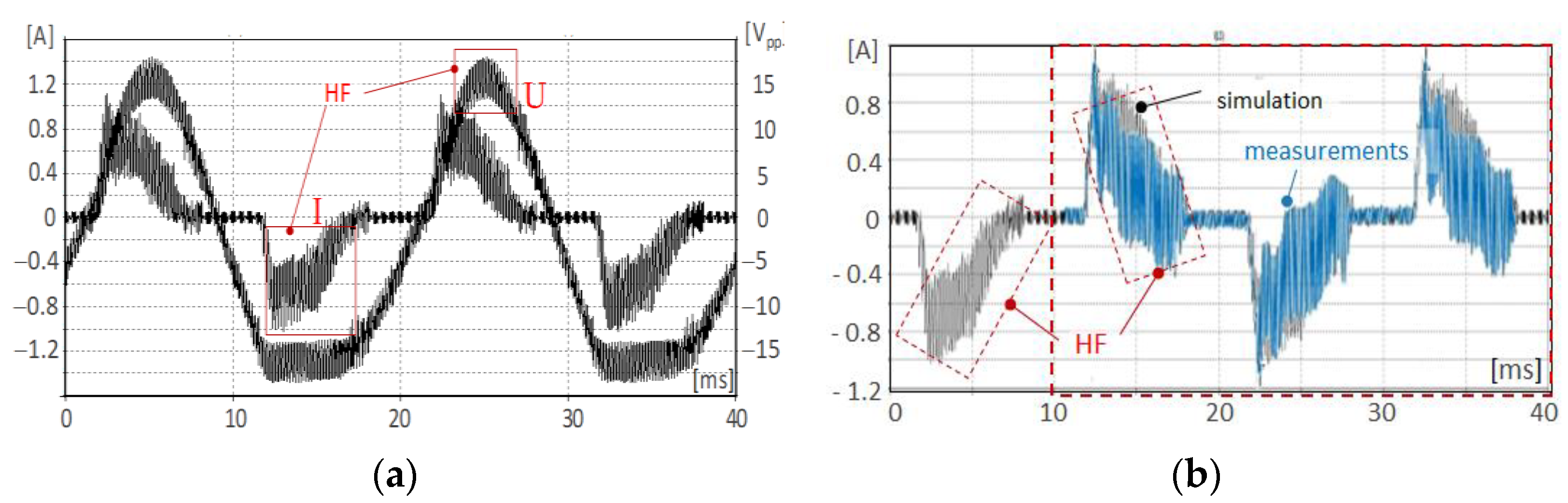

Comparisons of exemplary waveforms obtained for the base case and estimation of steady-state executed simulation correctness are presented in

Figure 8 and

Figure 9 for the VS type driver, and in

Figure 10 and

Figure 11 for the CS type driver.

Analysis of measurement results for the AL 8806 IC-based driver revealed high amplitude (10–13 mA) of high-frequency (5–5.5 kHz) disturbance presence superimposed on the main current waveform.

Taking into account the registered current waveforms distortions, to verify the accuracy of the carried out simulations, additional THD and form factor (FF) analyses comprised of comparisons of results obtained by means of measurements and simulations were implemented.

For each base case, Total Harmonic Distortion factors defined as (2) for current (THD

i) and, by analogy, for voltage (THD

u), as well as form factors defined as (3) for current (FF

i) and, by analogy, for voltage (FF

U), were determined, wherein:

where:

Ik—RMS value of the kth harmonic current,

I

1—RMS value of the current fundamental component.

where:

IRMS—current RMS value,

IAVG—current average value.

Based on the FFT results, the occurrence of harmonic components was compared on the basis of the simulated and measured results.

Figure 12 shows the exemplary simulated (S) and the measured (M) Fourier component distribution and its amplitudes obtained for drivers loaded with 25 LEDs.

THD factors and form factors for current (FF

i) for measured and simulated experimental verification results are collected in

Table 4.

A comprehensive and detailed analysis of results obtained for steady-state by means of simulation and its experimental verification confirms the high degree of similarity of results obtained by simulation in relation to the measurement results. In this connection, the obtained results provide a solid basis for further research consisting of numerical simulation of inrush currents phenomena occurring in circuits energization.

3.2. Inrush Current Simulation Results and Experimental Verification

Experimentally verified driver models operating at steady state were subsequently used for switching-on process simulation performed for various supply voltage parameters and load conditions. Calculations were executed for different levels of RMS input voltage values and different switching-on phases.

For this purpose, a voltage-controlled switch LT SPICE component was incorporated (see

Figure 1 and

Figure 4) into the models. Switches connected at the driver's input were controlled through the square wave voltage impulses for initiating the switching-on process. As this provided the desired moment of switching on of the controlling impulse, it was possible to switch on the supplying voltage of the controller at specific phases of the voltage wave. Simulations were performed for 0°, 45° and 90° of the input voltage phase. The total duration of the simulations was set at 60 ms. This was a time duration considered to be sufficient to reach the steady-state conditions for both drivers.

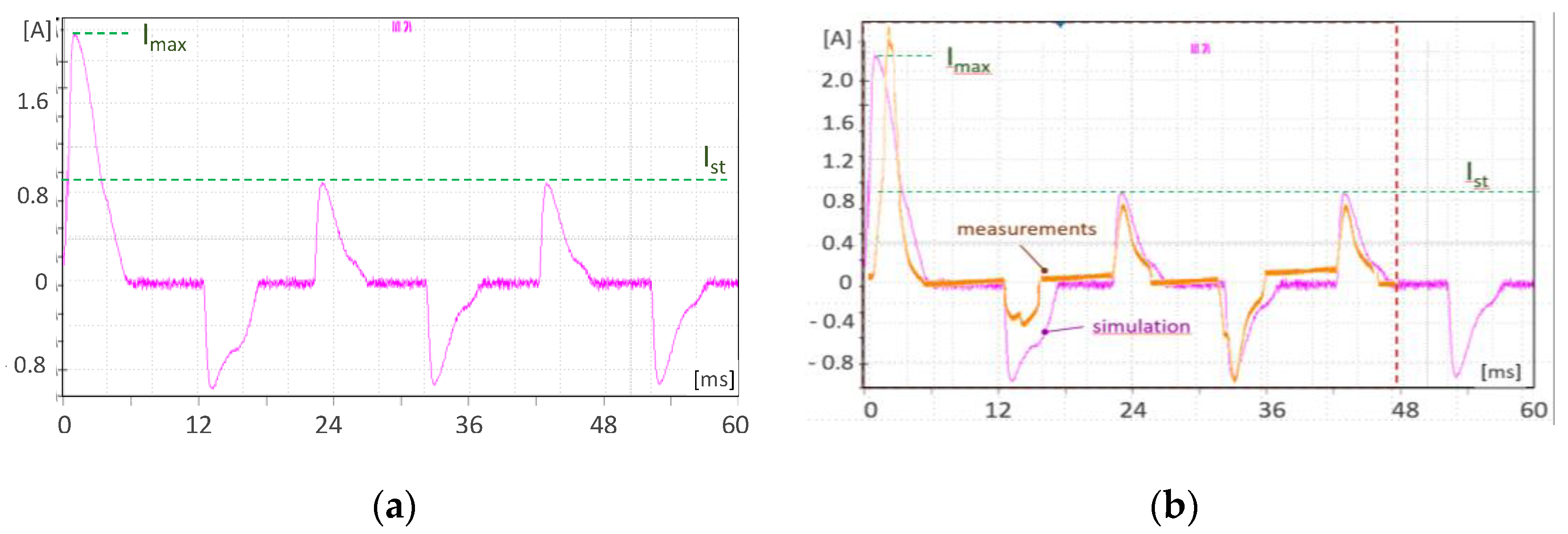

Figure 13 and

Figure 14 show exemplary calculated current waveforms and experimental verifications for VS-based drivers loaded with 25 LEDs and 0°, 45° and 90° of supply voltage phase. In the figures, amplitudes of the calculated inrush current (I

max) and amplitude of steady-state current (I

st) were marked. The calculations presented in

Figure 13 and

Figure 14 were executed for the rated supply voltage.

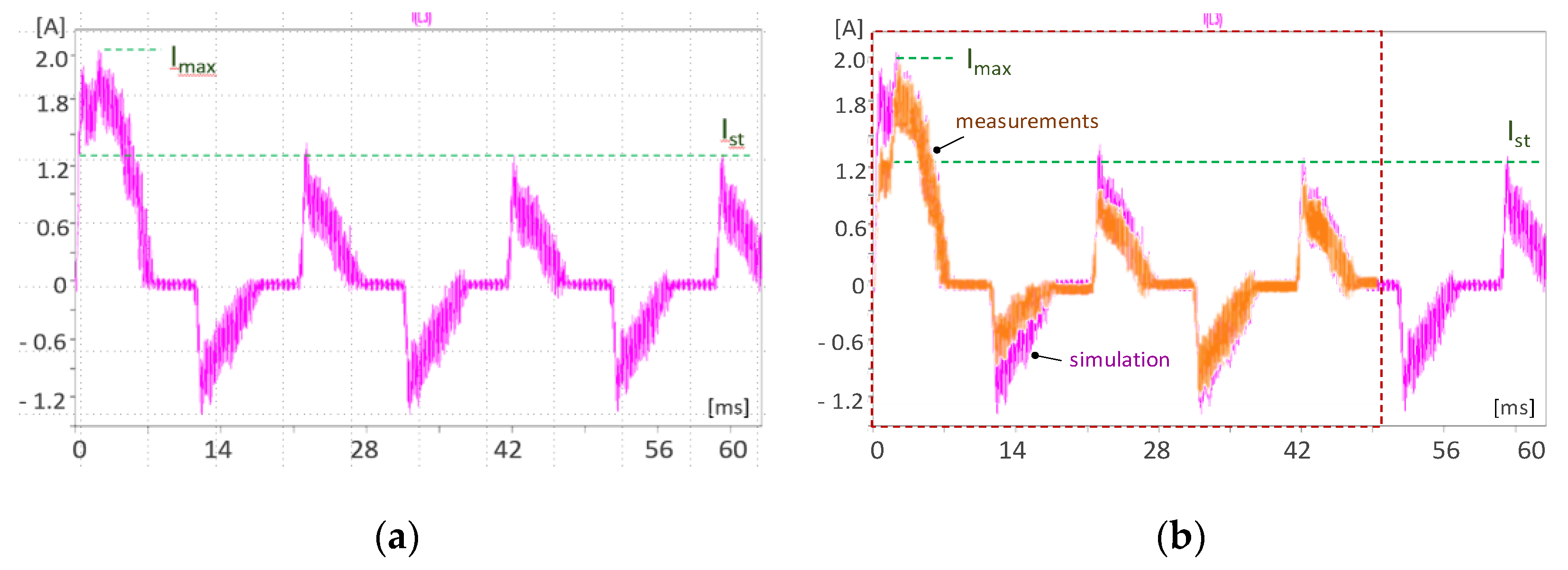

Similarly, calculations of inrush current waveforms for the current stabilization principle of the operation-based driver were executed.

Figure 15 and

Figure 16 present exemplary calculated current waveforms and experimental verifications for CS drivers loaded with 25 LEDs and at 0°, 45° and 90° of the supply voltage phase. The same calculations as presented above were executed for the rated supply voltage in

Figure 15 and

Figure 16.

Depending on the number of LEDs connected as load and the expected increase in load current value inrush current waveforms, simulations for a higher number of LEDs were subsequently executed.

Table 5 lists inrush currents multiplicity related to the amplitude of steady-state current (I

max/I

st) flowing through circuits loaded with various numbers of LEDs and supplied by varied rated voltages (V

n). The estimated multiplicity of inrush current values vs. steady-state current for both driver types at different supply voltage phases are also collected in the table. Due to the high level of HF surges occurring in the current waveforms, for analysis, the amplitudes of the waveforms were taken into account.

Figure 17 presents a summary of the results for both drivers. The solid line represents results obtained for the VS driver at 0°, 45° and 90° of the voltage phase, respectively (e.g., “VS–45” is the result for a stabilized voltage driver for 45° of phase). The dotted line represents the results obtained for a stabilized current (CS) driver under the same conditions.

The analyzed drivers are capable of correct operation at various values of the supply voltage. This feature is very common in market-available drivers. In this connection, changes in the value of the inrush current RMS value as a function of the supply voltage are expected. Graphical comparisons of current values in relation to rated current for VS and CS type drivers for various supply voltages in relation to the rated voltage [V/V

n] and trend lines (dot lines) for each waveform are revealed in

Figure 18.

Depending on the purpose and complexity of the market-offered drivers, some are equipped with circuits limiting the maximum value of the inrush current. The most common inrush current limiting circuits utilized in low-cost solutions are fixed-value resistors or NTC resistors [

27]. The simplest solutions based on fixed-value resistors generate significant power losses during normal operation and limit the permissible level of driver load current. Therefore, they can only be used in the case of a fixed number of diodes used as load. In consequence, they cannot be treated as universal drivers, which were the subject of the performed research. In the case of NTC resistor utilization, limiting circuits are characterized by higher efficiency due to their resistance decrease via the self-heating phenomenon caused by current flow. Alternatively, an inductive choke for current limitation can be applied.

More complex solutions and thus higher price range drivers utilize relays for bypassing the limiting resistors after the start-up process is finished. For high-complexity drivers, electronic control switching-on systems based on MOSFET transistors or triacs are utilized. In the case of the considered drivers, this type of solution is economically unreasonable.

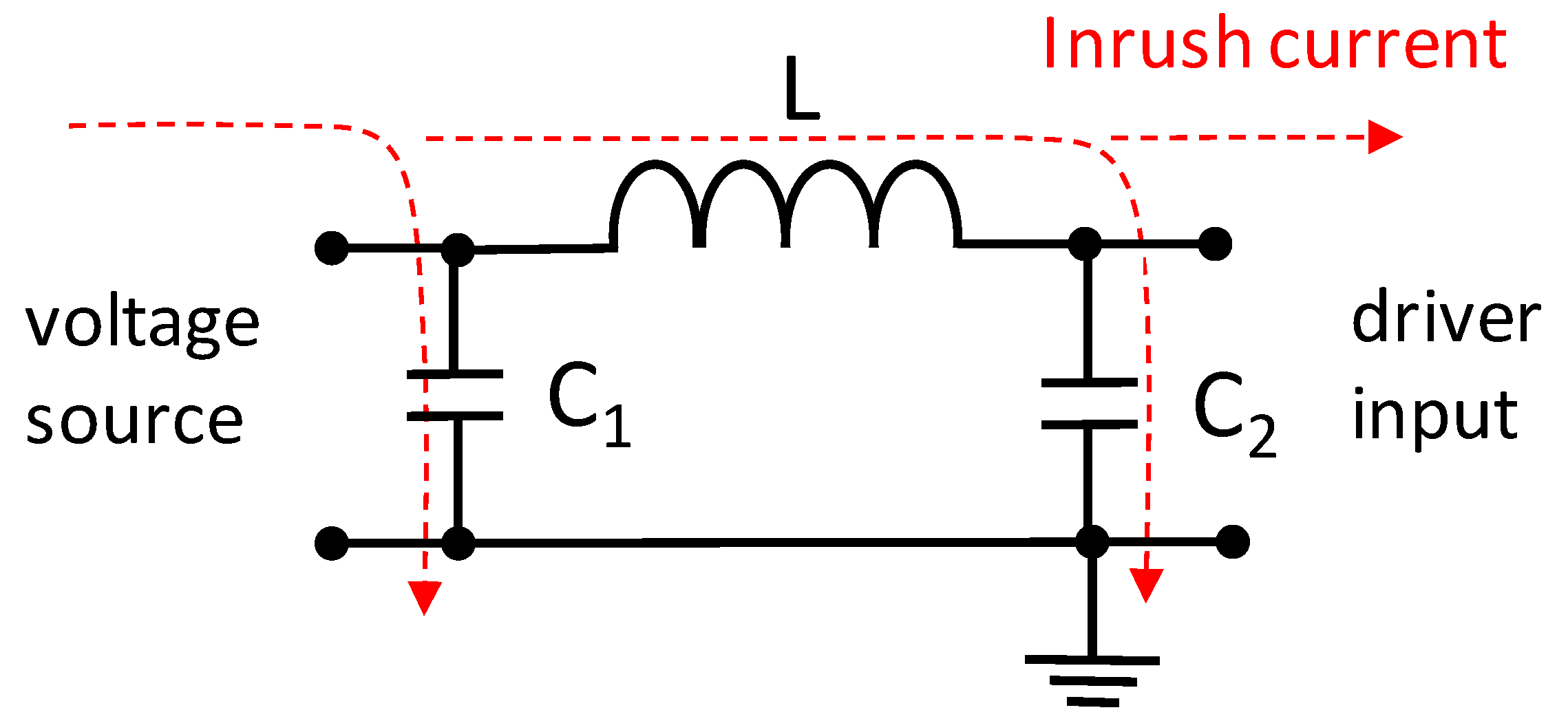

Bearing in mind the above limitations, in the frame of the presented research, an additional simulation case was executed. The simple inrush current limiting circuit, often used in converter applications [

28], was implemented and marked in

Figure 1 and

Figure 2 as the ICLC module. The circuit consists of an inductive element L connected in series and two capacitors connected in parallel to voltage source C

1 and the load C

2. The result is a Pi-filter type circuit in which the inrush current is split between the capacitor C

1 and inductance – capacitance L-C

2 branches (

Figure 19).

Additionally, it was assumed that the minor inductive choke can be based on a solid material magnetic core (not implemented in the model) which, in assumption, can provide an additional dumping effect based on the employment of the eddy currents effect. Simulation results obtained for the worst case (90° input voltage phase) are presented in

Figure 20 and

Table 6. Here, Pi-filter utilization resulted in c.a. 30–40% inrush current reduction.

Parameters of the C1, C2 and L elements should be selected depending on the expected load current, thus, their values depend on load configurations. In the frame of the tests, inductive chokes characterized by inductance from several tens to several hundreds of mH were examined, and capacitances of the order of several dozen microfarads were used. Accordingly, the presented solution may be used as a low-cost approach, but the required inductor values to sufficiently reduce the inrush current may cause too large dimensions. This situation may be unacceptable in the considered application.

4. Summary

The developed LT SPICE software numerical models of LED strips drivers were utilized for simulations related to inrush current phenomena modeling of the situation occurring during actual energization of drivers loaded with various numbers of LEDs. Two types of methods frequently used in practice and representing two different LED strip supply methods for LED-based light sources were compared in view of influence on low-voltage power networks.

All simulation results were verified at the measurement stand. Refinement of the driver models was based on the oscilloscopic measurement results and the measurement results obtained using the power analyzer. The obtained simulation results indicate high similarity and consistency in comparison to recorded current and voltage waveforms.

Nevertheless, in the obtained results, some deviations between the measurement and the simulation results were noticed. The reasons for the observed discrepancies are complex. These can be the result of not taking into account all harmonic components present in the current and voltage waveforms. In our experimental work, for example, the diode models implemented in the driver's structure were characterized by exactly the same parameters, but real components always incorporate manufacturing process inaccuracies. However, in our opinion, the highest impact on the observed deviations resulted from the imprecise estimation of the values of parasitic capacitances and inductances.

The implemented method of HF transients modeling permitted precise reflection of the current waveforms registered at the test stand. Modeling of HF surges by introducing additional current and voltage sources simulating the disturbance was characterized by high efficiency. As a result, the models are effective in simulating LED driver current and voltage waveforms.

The tested VS controllers are more sensitive to changes in load current values, in comparison to the used CS controllers. The tested CS drivers show limited abilities to reduce current flowing during the switching on of the supply source. This may cause a much higher inrush current value presence for a circuit with the same load type, but energized by CS drivers.

An additional study case of current limiting circuits was implemented in the models. The obtained results indicate its effectiveness in reducing the maximum current values observed during circuit energizing. Here, a positive result of incorporating an L-C Pi-type filter application was the observed HF transients dumping effect. The implemented L-C circuit can add the advantage of acting as an input filter reducing conducted EMI interferences.

An effective solution that might be applied for inrush current limitation is voltage phase control. The performed study indicates a high dependency of inrush current in the function of the supply voltage switching-on phase.

As none of the tested drivers comprised an inrush current limitation circuit, this may indicate that the raised problem is very often ignored by the manufacturers of the LED drivers.