1. Introduction

Global warming is becoming the main topic in the discussion tables to define our imminent future in terms of energy saving. Global warming originates mainly from greenhouse gas (GHG) emissions. Among them, carbon dioxide is the most critical man-made greenhouse gas that is constantly referred to. For this reason, total greenhouse gases are measured as carbon dioxide equivalent (CO2-eq), a unit of measurement used to standardize the effects of the various greenhouse gases on the climate. CO2-eq is a metric used to compare the emissions of different greenhouse gases based on their global-warming potential (GWP) by converting the amounts of other gases to the equivalent amount of carbon dioxide with the same global warming potential. Going forward, we will refer only to carbon dioxide (CO2), meaning the equivalent one.

In recent times, there has been discussion in Europe, and beyond of forcing the ecological transition over time by zeroing as soon as possible the CO2 emissions allowed from vehicles. With this objective, the most immediate solution would be the transition to electric mobility at least of the current car fleet. The advantages of pure electric mobility are linked to the possibility of zeroing CO2 emissions, and not only where the vehicles are used. Furthermore, electric vehicles are characterized by very high efficiency compared to traditional ones: this aspect is directly linked to energy saving and less maintenance, which are among the main objectives of the current ecological transition plan.

Given the above, it is worth mentioning that the annual CO

2 impact of road transport alone is 11.9% [

1]; this percentage share is significant, but not so much as to justify the destruction of the automotive industry and all related industries, nor the economic and social expenditure that would result from it. Climate Watch in 2020 reports GHG emissions by sector in [

1].

Figure 1 summarizes GHG emissions for each sub-sector (where energy in buildings refers to heat and electricity). A total of 41.7% of GHG emissions are due to energy in buildings and energy in industry sub-sectors, of which 37% is attributable to the production of electricity. Why? Because fossil fuels produce 60% of the world’s electricity [

2]. The sum of coal, gas, and oil covers the production of 15,000 TWh out of the total 25,000 TWh produced in 2020. The transport sub-sector accounts for only 16.2% of global GHG emissions, and

Figure 2 breaks it down into its main sub-sectors (road, aviation, rail, pipeline, ship). Road transport was responsible for 11.9% of overall GHG emissions in 2020.

According to the authors, the first step should be the decarbonization of electricity generation rather than the electrification of the entire car fleet, which would be affected by CO

2 emissions from electricity production. The IPCC report [

3] shows concrete possibilities to limit the temperature increase to below 2 °C compared to the pre-industrial era. Unfortunately, this appears to be the best we can hope for.

Returning to the road transport sub-sector, 11.9% of global GHG emissions are attributable to it. Road transport is divided into vehicles for the transport of passengers (2/3) and vehicles for the transport of goods (1/3). This analysis focuses only on passenger cars.

Current and future powertrains for passenger cars are Battery Electric Vehicles (BEVs), Hybrid Electric Vehicles (HEVs), Plug-in Electric Vehicles (PEVs), Fuel Cell Vehicles (FCVs) and Internal Combustion Engine Vehicles (ICEVs) powered by gasoline, methane, and alternative fuels (such as green methane, e-fuels, hydrogen, etc.).

The GHG emissions of the engines that equip current and future passenger cars come from both the production phase and the use phase, with different “weights” depending on the type of engine and/or the fuel supplied. The main environmental concerns arising from the production and use stages of these propulsion systems are:

Production of H2: future passenger cars could only be powered by hydrogen. Only green hydrogen obtained by electrolysis from renewable sources can meet future expectations for the reduction of CO2 emissions. The 96% of the hydrogen produced globally is produced using fossil fuels, such as coal, oil, and natural gas, in the reforming process. The production of 1 kg of hydrogen emits 7 to 9 kg of CO2. Despite this, it is the most efficient production process which involves the lowest energy cost.

Presence of REE/critical metals: they are materials with a strong environmental impact. They are used a lot in electric vehicles, but are used much less in conventional vehicles.

Battery production: there are many issues related to the impact of battery production, and they are not limited to CO2 emissions alone.

CO2 emissions related to battery charging: depending on the energy mix of each country, CO2 emissions can be excessively critical.

CO2 exhaust emissions: the greater the size of the thermal engine and the greater the fuel consumption, the greater the carbon dioxide emissions. These decrease by coupling the conventional engine to an electric propulsion system.

It is worth remembering that the sources of electricity are thermal power plants (mainly fueled by natural gas or coal), nuclear power plants, and power plants based on renewable sources. Classical thermoelectric plants have the highest carbon dioxide emissions, especially if they are coal-fired. Nuclear plants have to deal with their reputation as “polluting and unsafe plants” while emitting much less CO2 than other traditional systems; they need public acceptance, especially in Italy. Finally, renewable energy sources are seen as the only “way of salvation” towards a cleaner world, beyond the significant environmental impact associated with the use of rare earths in these plants. Furthermore, it is important to consider the surplus of electricity production needed for the energy transition: electric energy “gaps” are not allowed when large road transport could depend entirely on renewable energy sources.

The authors, after a critical analysis of all the issues mentioned, estimated the forecast of electricity production needed to support the envisioned energy transition. This work and the followed methodology represent the original contribution of the authors. BEVs and FCVs were considered, the former because they need to be recharged, and the latter because the production of hydrogen, especially the green one, involves a huge expenditure of electricity. The electricity required to recharge the PEVs was discarded because the consumptions declared for the vehicle, usually based on the WLTP cycle, do not report the contribution to the traction of the electric motor (only the consumption of the internal combustion engine is declared). Furthermore, each PEV has its own management strategy to define, for each operating condition, the contribution of both electric and thermal traction. This ratio could be computed, making assumptions about the different management strategies, using a vehicle energy model based on energy evaluations; it could allow the energy needs of the wheels to be calculated and divided between the internal combustion engine and the electric motor. The authors are working on such a model and will present the results later.

After the forecast of the increase in electricity demand between now and 2050, it must be considered that it is the common opinion that this electricity surplus can be satisfied by renewable energies, only or largely. According to the authors, electricity from renewable sources deserves a separate discussion; renewable energy sources cannot be depleted, but they cannot provide continuous energy. Their main drawbacks are intermittent power generation and low power density per square meter of the facility. Their intermittence is linked to their dependence on meteorological conditions; their use as energy sources on a large scale poses the problem of “energy holes” when these sources are unproductive.

2. Methodology for Literature Selection

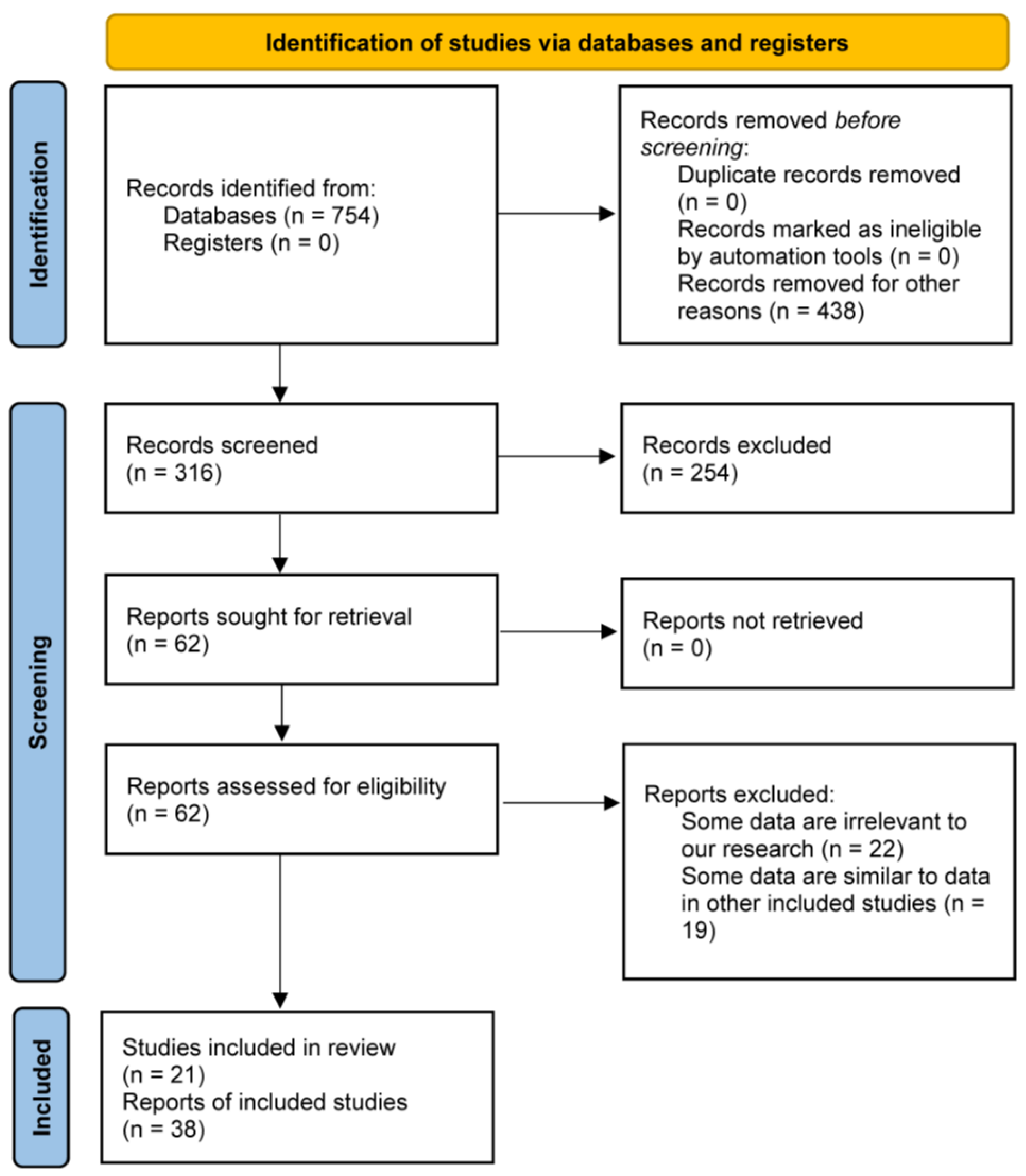

The selection of appropriate literature for this review was made in accordance with the PRISMA 2020 statement [

4].

The literature search included all records in the databases that were available through the end of December 2022. These were subsequently searched within article titles, abstracts, and keywords. The keywords were chosen as follows: GHG emissions; life cycle analysis (assessment); battery electric vehicle(s); carbon intensity in electricity production; electricity mix; automotive batteries; environmental life cycle; e-fuels production; synthetic fuels production; wind power generation; geothermal energy impact (generation); nuclear power (generation); photovoltaic energy (generation); hydropower; solar electric power (generation); lithium batteries; rare earth element content; and copper in electric vehicle(s).

This phase received 316 records, of which 254 records were removed based on the screening of the article title, abstract, and keywords. The remaining records, which were 62, were thoroughly screened. Based on reading the records, 41 records were subsequently removed—22 records were removed due to irrelevance (e.g., studies that did not present results relevant to us), and 19 records were removed due to similarity with other records already included.

The final phase included 38 records, of which only 21 were part of the review paper in the strict sense. The remaining 17 records were useful for estimating the surplus of electricity needed in Italy in 2050 (15) and for citing the PRISMA 2020 statement (2). The flow diagram (

Figure 3) illustrates the flow of information: it maps the number of records identified, included, and excluded [

5].

3. Paper Structure

The contribution is organized into paragraphs that deal with the main relevant topics:

Analysis of GHG emissions, divided into two main sub-paragraphs:

Estimate of the increase in the demand for electricity necessary for the ecological transition in Italy. The authors made an estimate for passenger cars only up to 2050. This represents the main original contribution of the authors.

Renewable sources pose land occupation problems. The main question is whether it is feasible and environmentally sustainable to think that renewable sources can completely replace traditional sources of energy production in the long term;

Rare-earth elements (REE) and critical metals: there are concerns about the sustainability of their mining and production processes. They are all critical to batteries, fuel cells, and renewable energy plants. They are transversal to the focus of the paper. Following a transition to increasingly electric mobility, a substantial increase in battery demand raises serious concerns for REEs.

4. GHG Emissions

The analysis is divided into the use and vehicle production phases.

4.1. Use Stage

In the overall energy assessment, focusing only on GHG emissions from the tailpipes of conventional/hybrid vehicles is simplistic and misleading. It is necessary to take into account the actual GHG emissions in the evaluation of the use phase of both thermal engine vehicles and electric vehicles. Assessing the “direct” environmental impact of the conventional vehicle during its use is simple, while it is less intuitive for a BEV.

4.1.1. Tailpipe Emissions for ICEVs

In this paragraph, only the average CO

2 emissions from vehicle exhausts have been considered because the focus is on the analysis of the most relevant critical issues related to energy transition. Average CO2 emissions depend on the type of vehicle and fuel for cars equipped either exclusively or even with a conventional engine. Average fuel consumption is related to CO

2 emissions. In 2021, the target value for CO

2 emissions from passenger cars was 95 g/km. The average values of the average CO

2 emissions of new passenger cars in Europe, depending on the year, are shown in

Figure 4 [

6].

Figure 4 shows that, after a steady decline until 2016, the average CO

2 emissions of new passenger cars registered in Europe increased between 2017 and 2019. The main reason is the growth of the Sport Utility Vehicles (SUV) segment (increase in overall average weight).

In 2019, the average CO2 emissions of all new cars reached 122.3 gCO2/km. Although this is below the European fleet-wide target of 130 gCO2/km set for 2015–2019, it is well above the 2021 target of 95 gCO2/km. HEVs could help in the process of reducing GHG emissions from engine tailpipes. It is worth noting that, in the case of PEVs, the impact of the GHG emissions emitted during the process of producing the electricity needed to charge the vehicle battery directly from the public grid is neglected. However, this approach is misleading in the overall assessment of GHG emissions, as explained in the following paragraph. The CO2 emissions of the internal combustion engine must be added to those deriving from the production of electricity needed to recharge the PEVs. Taking this element to an extreme, CO2 emissions from BEV use should also be reported based on European average data, at least, to remove the misconception of “zero-emission vehicles”.

4.1.2. GHG Emissions Linked to the Energy Production System

Both PEVs and BEVs need to be charged using electricity: the average GHG emissions for recharging BEVs and PEVs should be evaluated considering the production source of the consumed electricity [

7]. GHG emissions are a function of the electric energy production source and the electric energy consumption per kilometer of the vehicle (measured in kWh/km).

Figure 5 shows the GHG emissions to produce 1 kWh of electricity for some countries in the world [

8]. It should be clear how the environmental impact of a BEV/PEV during its use phase is closely related to the country where the vehicle is most used and its grid mix for electricity generation. In China, where most of the batteries sold worldwide are produced, GHG emissions are more than double those of Europe.

4.2. Production Stage

This sub-paragraph reports the results of the production phase of vehicles, batteries, and fuels (both fossil and synthetic fuels), highlighting the topics of greatest interest.

4.2.1. Life Cycle Assessment (LCA) of Vehicle Production: ICEV and BEV in Comparison

In [

9], the authors provided the results of a comparative environmental assessment of a turbocharged gasoline ICEV and a lithium-ion BEV using the LCA methodology. The impact assessment results showed that BEVs significantly reduce the impact of climate change due to the absence of tailpipe emissions during operation at the point of use. The study of different grid mixes for electricity production showed that this advantage grows significantly as the share of renewable sources increases. On the other hand, the production of BEVs has a more significant environmental impact than ICEVs, mainly due to the extensive use of metals, rare earth metals, and the energy required by specific electric powertrain components, such as the high voltage battery. The other environmental impacts considered, such as acidification, human toxicity, particulate matter, photochemical ozone formation, and resource depletion, were found to be higher for BEVs than for ICEVs. Therefore, the authors stated that the evaluation of electric cars cannot be performed using a single indicator, but should be based on a more complex evaluation approach. The authors in [

9] determined the break-even point for the practical environmental convenience of the electric car. The authors considered three grid mixes for electricity generation: average European, Norwegian, and Polish grid mix.

The last two grid mixes have opposite environmental profiles. The main results, reported in

Table 1, are:

Climate change: the environmental convenience of the electric configuration occurs at a low mileage value (about 45,000 km) compared to the total LC distance (150,000 km). The break-even point for the Norwegian electricity grid mix decreases to around 30,000 km. At the same time, the result is the reverse when considering the Polish grid mix, as no break-even occurs.

Acidification: the BEVs have the break-even point at around 180,000 km, a value higher than that assumed as reference LC mileage (150,000 km).

Photochemical ozone formation shows a similar trend to acidification: effects of ICEV are preferable for any vehicle mileage, except BEVs charged by electricity produced in Norway (break-even point near the end of car life, about 130,000 km).

Human toxicity, particulate matter, and resource depletion: no threshold mileage is detected between ICEV and BEV. The contribution of mileage-independent LC milestones is higher for the electric car for these categories. Considering that the use phase confirms this trend, the results of the ICEV are preferable from an environmental point of view.

Therefore, BEVs have the potential to reduce the impact of climate change compared to ICEVs only if the electricity consumed is produced only from non-fossil energy sources.

4.2.2. GHG Emissions from the Battery Production Process

According to [

8], in 2020, producing 1 kWh of electricity in Europe was equivalent to the emission of 238 g of carbon dioxide into the atmosphere, deriving mainly from non-renewable sources composed of fossil fuels. According to European plans, by 2050, the goal is to produce 1 kWh of electricity with zero-carbon emission. It follows that the environmental impact of battery production is linked to the eco-compatibility of state networks, their renewable/non-renewable energy mix, and the ratio between grams of CO

2 emitted per kilowatt hour produced (gCO

2/kWh). This latter parameter is more critical in the U.S., where, in 2020, 1 kWh was worth about 383 g of CO

2, and it was worse in China, where 1 kWh was equivalent to at least 556 g of CO

2. It was not much better in South Korea: 1 kWh generates 476 g of carbon dioxide, as in Japan, which stood at 470 g (as summarized in

Table 2). To date, Europe accounts for 1% of total battery production, compared with 60% of China, 17% for Japan, and 15% for South Korea (

Table 2).

There is an almost direct proportionality between a battery’s rated capacity (how many kilowatts hour it can store) and its carbon footprint. Therefore, using these values to derive the carbon footprint generated by battery production is reasonable. Excluding batteries, the production of an electric vehicle has an “environmental burden” like the construction of a thermal or hybrid vehicle. The production of a thermal or hybrid powertrain does not generate a carbon footprint comparable to that deriving from the production of a battery for electric vehicles. The electric car becomes an advantage for the ecosystem only when its battery production’s more significant carbon footprint is offset.

In [

10], LCA defined the environmental impact of the battery: with 2.1 million BEVs and PEVs sold in 2019 (2.6% of global car sales), the current world stock of EVs is 7.2 million (around 1% of global car stock). Firstly, for the correct estimation of the energy impact of a battery, it is necessary to calculate its effective mass; the greater the mass of the battery, the greater the energy to be supplied for vehicle mobility.

In [

10], the authors reported the most evaluated characteristics of the battery. An important parameter to evaluate the difference in effective mass between a conventional and an electric vehicle is the specific energy of the battery expressed in Wh/kg. The median value reported in [

10] is 115 Wh/kg; by 2025, this value should be increased to 225 Wh/kg [

11]. The global trend is to improve the characteristics of the battery, i.e., to increase its specific energy (which makes it possible to reduce its weight) and its nominal capacity (which makes it possible to increase its mileage). Computing the energy demand for battery production is not trivial. As reported in [

10], the GHG emissions of the overall battery production have a median value of 120 kgCO

2/kWh

bc (where kWh

bc stands for kWh of battery capacity). Therefore, producing a battery of the same capacity in Europe (currently this production is practically non-existent) would be virtually more sustainable (see

Figure 6): 2.2 tons of CO

2 (1 kWh is 238 g of CO

2), while in the U.S., the calculation would rise to 3.6 tons (where 1 kWh causes the production of 383 g of CO

2), and in Japan and South Korea, the calculation rises to 4.4 tons (1 kWh is worth about 440/446 g).

Therefore, the production of batteries is all the more polluting the “dirtier” the energy used for its production. Furthermore, since several countries have adopted the battery recycling process, it seems useful to add up the GHG emission savings by replacing the raw material and the overall GHG emissions from the recycling process. The overall average savings is 20 kgCO

2/kWh

bc [

10].

Another aspect must be considered in the cost of the environmental impact linked to the ecological transition: the effective use of the vehicle. The average battery life value reported by the manufacturers is around 8–10 years, or an average distance of 180,000 km. Automakers state that a battery must be replaced when its actual capacity drops below 70% of its rated capacity. A traditional vehicle could have a range of around 200,000 km but an effective life of over ten years. The electric battery has a life of 8–10 years regardless of the number of effective recharging processes, i.e., the battery degrades even if not used. Therefore, in the economic and ecological comparison between electric and traditional vehicles, the cost of battery replacement must be considered. For a medium/large vehicle, battery replacement could amount to 25% of the entire cost incurred for the purchase of the vehicle. Therefore, if the life expectancy of the BEVs is more than ten years, the calculated GHG emissions for battery manufacturing must be doubled to consider battery replacement.

4.2.3. GHG Emissions from Fuel Production and Supply Process

This paragraph shows the average value of GHG emissions relating to the production process for petrol, diesel, and hydrogen. The GHG emissions for hydrogen depend on the type of production process, as illustrated in

Table 3 (data source in [

12]).

In

Table 4, GHG emissions were calculated per unit of fuel energy, represented by its lower heating value (LHV). A solution to overcome the problem related to GHG emissions deriving from the production process and supply of fossil fuels is represented by synthetic fuels, in particular e-fuels.

As reported in [

14], traditional energy sources make the energy supply more predictable than renewable energy resources, which have to overcome the challenge of their intermittence (there are periods when it is not possible to harvest energy), which depends on the weather conditions. Therefore, renewable sources are not suitable as a sole source of energy. It is not possible to program a sudden start-up of the traditional energy production systems (a steam power plant takes about 24 h) to deal with unexpected “holes” in the production of energy from renewable sources. The idea could be to make the two plants work together and to use any excess of energy from renewable sources in a different way. Hydrogen and synthetic fuels are chemical energy carriers; the surplus of electricity from renewable sources would produce such fuels. Using these e-fuels in existing conventional or hybrid vehicles represents an excellent opportunity to reduce GHG emissions in the short to medium term. The production of hydrogen and synthetic fuels has the potential to support the defossilization and decarbonization of the transport sector. Waste electricity occurs when renewable supply exceeds grid and end-consumer demand. Germany’s total amount of unused electricity (ghost electricity) was 3.7 TWh in 2016, out of a total electricity demand of 520 TWh per year (0.7%). Forecasts show that this energy surplus could increase to 40 TWh in 2040 (7.7% of the current energy demand). Therefore, hydrogen and synthetic fuels are a viable scenario for 2030. By capturing CO

2 from the air and combining it with green hydrogen (i.e., hydrogen produced by electrolysis using renewable electricity sources), more fuels can be created with zero emissions. Therefore, synthetic fuels produced with excess electricity from renewable sources represent an attractive solution for the decarbonization of mobility and those transport applications that are not suitable for electrification.

In [

15], the authors presented the results of the analysis of all stages of the energy conversion from the source of electricity, i.e., wind, solar, or hydro, to the final application, i.e., a vehicle traveling a certain number of miles. The fuels studied are hydrogen, methane, methanol, dimethyl ether, and diesel. While their production process is analyzed based on the literature, the usage of these fuels was analyzed based on the dynamometer measurement data of various EURO-6b passenger vehicles. This analysis is essential, as the electrification of passenger vehicles may be unsuitable for some applications due to one or more different effects [

16]:

The overall weight may be excessive if the vehicle is to be very light;

The achievement of a high degree of autonomy;

The need for rapid replenishment time.

The authors in [

15] presented a Well-to-Mileage (WtM) comparison based on the fuel type. Finally they derived the energy consumption of a vehicle driving a pre-defined speed profile. The authors derived the energy consumption from a simple vehicle model and used the results as part of the WtM analysis. For each fuel, the following were considered: (i) production/synthesis process; (ii) compression (if necessary, as for hydrogen); (iii) transportation; (iv) refueling process.

Figure 7 and

Figure 8 show the main results of the WtM analysis: the mechanical energy at the vehicle wheels, the chemical energy in the vehicle tank, and the electrical energy for fuel production, storage, and distribution are calculated for conventional as well as hybrid vehicles. The direct use of hydrogen in a fuel cell hybrid vehicle has the lowest electrical energy consumption of the synthetic fuels (

Figure 8), hence the highest WtM efficiency (

Figure 7). Hybridization offers a reduction potential of around 20% for internal combustion engine vehicles, even more for plug-in hybrid vehicles.

5. Estimate of the Surplus Electricity Demand for Passenger Vehicle Mobility—Projection up to 2050

The authors tried to evaluate the increment of demand for electricity to be produced considering the prospect of an increase in electrified (partially or fully electric) passenger vehicles between now and 2050. The presented scenario is based on statistical data. For such a calculation it is necessary to set:

Table 5 shows the current and future percentage diffusion (until 2050) of passenger vehicles by powertrain/fuel type in Italy [

19]. The result is shown in

Figure 10, which shows the forecast of the percentage distribution of vehicles by segment H1, where the term ICE means a traditional vehicle equipped with only a thermal engine and fueled by petrol.

Observing

Figure 10, it should be highlighted that there will be a reduction in ICEVs with a progressive increase in PEVs, BEVs and Fuel Cell Vehicles (FCVs). HEVs will be an important milestone until 2040, and will then be gradually replaced by PEVs, BEVs and FCVs.

- 3.

The declared average energy consumption per kilometer (based on the WLTP cycle), recalculated using the WtM methodology [

15,

20], for each H1 segment. The H1 segments are A, B, C, D, E, F, J, and S.

Table 6,

Table 7,

Table 8,

Table 9,

Table 10 and

Table 11 show the subdivision into segments of each powertrain analyzed (respectively ICEV, HEV, PEV, BEV, FCV), where ICEVs could be powered by both gasoline (

Table 6) or diesel (

Table 7), while FCVs (

Table 11) are powered only by hydrogen.

Table 12 shows the percentage of passenger vehicles belonging to each segment: this distribution is kept constant in the projection analysis up to 2050. Based on these collected data, it is possible to predict by 2050 the distribution of vehicles among the different powertrains and the growing demand for electricity to power the growing number of BEVs and FCVs.

Figure 11 shows the results of the WtM analysis on the single vehicle by powertrain/fuel type and H1 segment; for each segment, the average consumption based on the WLTP cycle is declared. Final average energy consumption is calculated using WtM analysis. In the projection, the hypothesis is to keep the value of the average consumption per segment fixed compared to today, even if it is logical to expect an increase in the efficiency of all types of power units.

- 4.

The average number of kilometers traveled in Italy (approximately 12,000 km).

Therefore, for each powertrain (ICE, HEV, PEV, BEV, FCV fueled by hydrogen only) and fuel, if applicable, the current Italian passenger car market was analyzed on the basis of the European H1 segments [

17,

18]. For each powertrain, fuel, and segment, a characteristic vehicle was chosen and the average consumption declared in the WLTP cycle [

21] was recorded (see

Table 6,

Table 7,

Table 8,

Table 9,

Table 10 and

Table 11). Then the storage, transport, and production energies for each fuel were calculated as in [

15,

20]. Finally, the final energy consumption per kilometer was calculated following the WtM approach [

15].

Following this approach, it is possible to calculate the probable increase in the electricity required by the future on-road fleet. It is necessary to consider the percentage energy weight of the various powertrains that require either recharging of the battery from the electricity grid or the production of green hydrogen (whose energy expenditure is far from negligible).

Figure 12 illustrates the expected percentage surplus of electricity to be produced per year compared to the current electricity production in Italy (289.1 TWh in 2021).

Figure 13 shows the overall values of electricity production expected per year. Therefore, in 2050, the electricity surplus to be produced should be 27.6% higher than the current production in Italy, i.e., 79.7 TWh, for a total electricity production of 368.78 TWh (

Figure 13). In this calculation, the contribution of the electricity needed to recharge the PEVs, as previously assessed, was discarded. Conversely, green hydrogen was considered in the above estimates. Still, the contribution of blue hydrogen and, therefore, of the electricity necessary for its production, must be considered because the ecological transition cannot ignore this production phase. Thinking immediately only of green hydrogen would limit its production and therefore slow down its possible use in the automotive field, as highlighted in [

22]. By replacing green hydrogen with blue hydrogen to power the FCVs, the energy savings would be 4.8 TWh per year in 2030, 22.0 TWh in 2040 and 40.2 TWh in 2050. This saving is due to the more efficient process of producing blue hydrogen derived from methane. In an extreme scenario of BEVs only in 2050, the increase in electricity demand would be 40.02% compared to 2021, while FCVs alone would be 100.64% if powered by green hydrogen. Instead, assuming the use of blue hydrogen in 2050 as fuel for FCVs, the increase in electricity demand would be only 24.06% compared to Italian production in 2021. Considering these limit scenarios, the percentage increase in electricity production by 2050 in Italy is shown in

Figure 14. The use of blue hydrogen would result in considerable energy savings.

These results can be compared with those of Engel et al. [

23]: they estimated that in 2050 there would be an increase in electricity demand for passenger cars of 35.8% in Germany. It should be considered that the current German vehicle fleet is approximately +23% [

24] compared to the Italian one. Engel et al. [

23] predicted a BEV rate of 40% of the total number of passenger cars in 2050, whereas, in the present work, this BEV rate is expected to be less than 25%. However, Engel et al. [

23] did not consider the contribution of electricity required for the production of green hydrogen. Globally, the approaches followed are different, but the results seem to be in line with the different automotive scenarios of the two countries. Seeking a comparison with an Italian scenario, in [

25] the electricity demand forecast for BEVs plus PEVs in 2050 is 35 TWh (with a ratio of 2 to 1 for BEVs), while the electricity demand estimate obtained in this work for the same year is 27.2 TWh for BEVs alone. The results are very close because electricity consumption does not scale linearly between BEVs and PEVs.

Overall, the transition in Italy has not yet taken place since the relationship between fossil fuels and renewables is not favorable to the latter. In Italy, the production of energy from renewable sources in 2020 covered 36% of the national electricity requirement, of which a massive share (41%) was produced with hydroelectric plants. In any case, obtaining from 0 to 50% of renewables is not enough. Obtaining from 50 to 100% is impossible because renewables are highly weather dependent and require large areas dedicated to production sites compared to conventional thermal or nuclear plants (as discussed below). In all the above, the problem of the electricity demand in the hours in which most of the BEV recharge is supposed to take place has been ignored. Furthermore, another aspect usually overlooked by most is the need to distribute the electricity produced. The distribution network includes charging stations but, above all, a distribution network.

For example, in

Figure 15 (data source [

26]), the comparison of the cumulative supply infrastructure investment for BEVs and hydrogen-powered FCVs is depicted. If vehicle penetration increases to 20 million vehicles in the baseline scenario, a battery charging infrastructure would cost around EUR 51 billion, making it more expensive than hydrogen infrastructure, which comes in at around EUR 40 billion.

6. Renewable Energy Sources—Related Issues

Solar and photovoltaic plants have an extremely high impact on the surface occupied compared to traditional energy production plants, both thermal and nuclear. It is legitimate to ask, when global energy production will go towards an increase in the number of installed renewable plants, what is the power per square meter installed. As reported in [

27], solar energy has a potential of about 20 W/m

2 installed for the most efficient ones. How much wind energy, at most, can be generated? Moreover, how efficient will turbines be when more turbines are needed to generate more renewable energy? The researchers found that more turbines generated more electricity only when a few wind turbines were gathered on a wind farm.

In comparison, when they looked at more turbines, they found that wind speeds decreased, and each turbine generated less electricity than expected. Indeed, each turbine draws energy from the wind so that many large-scale operating turbines would reduce the wind speed of the atmospheric flow: this is called the “turbine slowdown effect”. This reduction in wind speed is critical, as it reduces the energy each turbine can extract from the wind. The slowdown effect is not present in solar systems. The maximum yield of wind energy depends on the “scale” of the wind plant. In [

26], the authors estimated an upper production limit of 1.1 W/m

2 for wind systems with a nominal specific installed power of 10 W/m

2 (10% efficiency) and an efficiency of 40% when the nominal specific installed power is between 0.3 and 0.6 W/m

2. Furthermore, some researchers also suggested that there may be changes in the microclimate where large wind farms are installed: this, too, could contribute to the slowdown effect of the turbines.

In comparison, the power per area of nuclear plants is about 1000 W/m2, therefore much higher than that of renewables (20 W/m2 for the most efficient solar plants), about fifty times as much.

Table 13 shows in the first columns the electrical efficiency of electricity generation and the related average GHG emissions [

28,

29,

30]. It must be said that the majority of wind energy emissions come from the production of turbines. For hydroelectric, it is the construction of dams that contributes to GHG emissions. The lowest average value of GHG emissions is for nuclear power plants (in relation to plant production and installation), and the highest is for coal-fired plants. The last two columns of

Table 13 show the LC of land occupation for the production of electricity: it varies according to the reference source.

In

Figure 16, GHG emissions from electricity generation were represented by the first two columns of

Table 13.

Figure 17 compares the production of electricity per square meter of occupied area for different plants: the values shown were calculated considering the average of the last two columns of

Table 13. The highest value of energy production per 1 m

2 of occupied area is for nuclear plants (3636.0 kWh/m

2), while the lowest is for biomass energy crops (3.7 kWh/m

2). Faced with these results, one wonders how it is possible to think of soon replacing nuclear, coal, and gas plants with energy production systems based on renewable sources. Furthermore, keeping the average annual energy produced constant over the years (not at all admissible), the land occupation (minimum for the maximum production of electricity per square meter in

Figure 17) would be unsustainable. Therefore, the issue of renewable sources is linked to their intermittence and considerable concerns about their concrete sustainability.

Consider, for example, the average energy demand in Italy in 2019, which was around 320 TWh. To understand the vast concerns arising from the area occupied by renewable sources, it is possible to calculate the minimum and maximum gross energy that should be produced (from

Table 13). The results are shown in

Table 14: in the case of Photovoltaic (PV) solar plants, having a minimum efficiency of 4% and a maximum of 22%, the installed nominal energy capacity varies between 8000 and 1454.5 TWh (considering 320 TWh as the net energy demand).

The last four columns of

Table 14 report the land occupation and therefore the percentage values of the occupied area for each plant in relation to the Italian surface area. These values should indicate the “size” of these plants, even if the efficiency of these plants is constantly increasing.

For example, for the installation of PV systems with these nominal energy capacity values, the land occupation ranges, as per

Table 14, between 181,200 km

2 and 32,945 km

2, i.e., equal to 60.1% and 10.9% of the total area of Italy. This, according to the authors, should explain why renewable sources for electricity generation will never fully replace conventional power plants, leaving aside the huge concerns about their intermittent energy production.

7. Rare-Earth Elements and Critical Metals: Their Content in Both ICEVs and BEVs

The so-called Rare Earths or Rare-Earth Elements (REE) are seventeen elements, fifteen of the lanthanide family, plus yttrium and scandium. They have certain properties; they exert strong magnetism even at high temperatures. They are therefore indispensable in new or recent generation technological products. Due to their magnetism, rare earths present problems both environmentally and for the health of miners. A total of 97% of the REEs are mined and processed in China, although 38% of REE deposits are located in China. Sixty thousand cubic meters of gaseous waste containing hydrochloric acid are produced for every ton of REE extracted from the earth’s crust, with 200 cubic meters of acids discharged into groundwater and up to 1.4 tons of radioactive waste [

34]. REE and critical metals such as cobalt, lithium, and platinum (all raw materials identified by the European Commission) are indispensable for the ecological transition. They need to be monitored for a low-carbon economy.

The total production of REE nearly doubled between 2010 and 2020, from approximately 133,000 metric tons of rare-earth-oxide (REO) content in 2010 to approximately 240,000 metric tons of REO content in 2020. Total world reserves of REEs are estimated to be around 120 million metric tons [

35].

Once the availability of REEs has been assessed in the world, the main question is: how many REEs are there in a car? It is hard to say. The authors of [

36] estimated that approximately 0.44 kg of rare-earth metals are used in a typical conventional sedan, with approximately 80% of the rare-earth content in magnets. Neodymium is the most widely used rare earth, followed by cerium, which is mainly used in catalytic converters. By comparison, a modern full hybrid electric vehicle with a lithium-ion battery contains about 1 kg of rare-earth elements (of which 73% is neodymium). The conventional vehicle was found to contain approximately 0.44 kg of rare earths (2.23 times less than the full hybrid vehicle), of which 0.4 kg is considered to be an integral part of the vehicle’s operation (including safety components and basic radio/speaker system), and 0.04 kg are classified as vehicle features (e.g., navigation system, DVD player, and power seats). In the permanent magnet engines of hybrid and electric cars, 30% of the magnet consists of neodymium, terbium, and dysprosium. Hence, they are present in both permanent magnets and batteries.

To summarize, the use of REE in modern technology has grown significantly in recent years [

37]. However, “rare earths” are also essential for the “green revolution”; without these minerals, it would be impossible to produce wind turbines, photovoltaic panels, and batteries for electric vehicles. The use of REE increases the efficiency of such devices, while also reducing their weight. For example, gearless wind turbines are the future because they are less prone to breakdowns and need fewer maintenance stops; they need permanent magnets built using REE. Therefore, REEs are the present and the future, and it is difficult to find metals that can replace them. As the size of the batteries increases, thus moving from traditional or hybrid vehicles to fully electric vehicles, the demand for REE increases. As mentioned above, their environmental impact is significant and cannot be traced to the vehicle’s LC. Although their recovery is being tested, the recycling rate does not reach 1% because it is laborious and, therefore, expensive. In addition to REEs, it must be considered that copper is present in a massive way in electric vehicles. Due to its qualities as a conductor of electricity and heat, copper is a crucial metal in the electrification process of the world economy. Lithium, cobalt, manganese, nickel, and copper are called critical metals; they are not REE and not really rare, but they could become “rare” because they are widely used in the automotive industry.

To understand this, some numbers are shown on copper. Seven million electric vehicles (cars and light trucks) are expected to hit U.S. roads by 2025 [

38]. They will represent about 3% of the 258 million vehicles expected to be registered in the United States in 2025. The number of charging ports required to support seven million PEVs in 2025 is 5 million (an EVs/charging ports ratio of 1.4). It will require a significant investment in charging infrastructure. Copper is used in electric vehicles, charging stations, and supporting infrastructure due to the metal’s durability, high conductivity, and efficiency. Considering the copper mass of the vehicles alone (thus neglecting the copper necessary to support infrastructures and recharging stations),

Table 15 shows the copper mass in the different types of vehicles. A BEV vehicle needs 4 to 10 times the mass of copper of a conventional car.

Copper demand from EVs is expected to increase by 1700 kilotons by 2027. Additionally, with concerns about climate change leading to increased investment in renewable energy, the industry’s copper demand could grow faster than expected in the coming years. Will it be able to sustain this further growth? No one can tell.

8. Discussion

Today EVs are believed to be the only solution to global warming. They have undeniable advantages:

There are no local CO2 emissions where EVs are used.

They do not make noise when using the vehicle.

EVs are highly energy efficient due to both the efficiency of the electric drive and the regeneration of vehicle braking/deceleration.

Less maintenance due to high efficiency.

But EVs have many disadvantages, too:

The environmental impact of battery manufacturing does not break even; it is independent of vehicle mileage.

The CO2 emissions linked to its charging depend on the energy mix of the country in which the vehicle is mainly used.

Battery mileage, by date of charge, is very limited.

Recharge time is considerable; by using high power systems it is considerably reduced, but the battery degrades faster.

Finally, a consistent transition of private vehicles to purely electric mobility poses the problem of greater electricity demand compared to the current production and distribution of electric power. To conclude, in accordance with the presented forecast, in 2050, the surplus of electricity to be produced compared to the current production in Italy (year 2021) is equal to +27.6% (1). This value increases if two limit scenarios are considered:

It becomes +40.0% in an extreme scenario in which the entire private car fleet is made up of pure electric vehicles only (2).

It becomes +100.6% assuming that the entire car fleet is made up of fuel cell vehicles powered exclusively by green hydrogen (3).

It is worth noting that renewable energy sources cannot satisfy the expected increase in electricity demand due to their intermittent nature and low specific power. Nor can they be used in the production of electric vehicles and batteries alone. Furthermore, electric vehicles have a life that is not only related to mileage, but rather to the life of the batteries, which degrade even if not used. In order not to throw away the vehicle after the battery has deteriorated, it is necessary to think about its replacement, which has enormous economic and energy costs related to the production and transport phases. Finally, the availability of recharging stations is limited both in Italy and in Europe. The problem is that, even if all the power needed for recharging were available, there would be no distribution infrastructure in the area. The current infrastructure is limited in terms of power because it is designed for different loads than those expected today if there was a substantial transition to electric mobility. The construction of this infrastructure would have an enormous cost because it would be necessary to intervene heavily on the national electricity grid, which, it should be remembered, is mainly connected to underground transport systems.

The environmental impact of electric vehicles is mainly linked to the construction and assembly phases, especially of the battery (the vehicle itself differs little from traditional vehicles). The driving cycle has an impact on battery life, which is the element that degrades fastest in electric vehicles (which require less scheduled maintenance than traditional vehicles). The battery has a maximum number of charges it can be subjected to. The more miles the vehicle travels, the more frequently the battery is recharged and, therefore, the shorter its life. Usually, the actual mileage of a battery is lower than the declared one. The battery life is strongly influenced by the temperature in which it works (the optimal range for its duration should be between 4 °C and 35 °C) and by the driving style. The battery does not tolerate power demand peaks. The ideal battery life would be obtained if it could operate at a fixed point, i.e., with a constant or almost constant power demand. Therefore, the battery is at the heart of the EV impact problem. Its production requires the use of rare or otherwise critical materials for their supply. Their mining is complex, energetically expensive, and has a significant impact on the environment. The energy required for its production (mainly located in China, where massive use is made of coal) is primarily produced today with plants with a high impact in terms of CO2. There are no CO2 emissions during the operating phase of the electric vehicle. During the charging phase, the related amount of CO2 depends on the energy mix of the country in which the vehicle is mainly used; if we think of Europe, the average energy mix is much more favorable than that of China, where the battery is produced. For all these reasons, the most influential factors for CO2 emissions are the extraction of rare/critical materials for battery construction and the related energy mix used.

Finally, it must be said that the cost of EVs in Italy is high compared to traditional vehicles. However, consumers are choosing to pay more despite the many disadvantages of EVs, such as the high cost of home charging and battery swapping. To understand this, it is necessary to consider some aspects of the Italian market:

There have been essential incentives for purchasing electric and hybrid vehicles, which have reduced the cost gap with traditional cars.

For the “electric power” part, annual vehicle taxes have been exempted.

In large cities, anyone buying an electric or hybrid vehicle can drive around downtown and park for free.

On average, Italian families rarely replace the car; it is a durable good. Restrictions on using private vehicles for pollution reasons are increasingly restrictive and are not accompanied by long-term forecasts. Many users prefer to buy a vehicle that gives more certainty of its long-term use, such an EV or an HEV/PEV.

9. Future Directions

Like all predictions, the analysis presented is based on assumptions. This represents the main limitation of the study. The purpose of the research is to indicate the possible increase in electricity demand over time by providing a methodology for approaching the problem.

The future research path, in the authors’ intentions, is made by some steps:

The same methodology can be applied to:

Evaluating the electrical energy needed to produce alternative fuels, such as green methane and e-fuels;

The overall road transport;

Other regions of Europe, for example, to predict future electricity demand and compare the results;

Development of an energy-based model for comparing the energy efficiency of the different powertrains mentioned in this work (ICEV, PEV, HEV, BEV, FCEV) as the load varies. The model is based on the WtM analysis;

Optimization through the energy model of different design solutions of the powertrains. It is carried out by searching for the answer with maximum efficiency.