Economic Analysis of a Pumped Hydroelectric Storage-Integrated Floating PV System in the Day-Ahead Iberian Electricity Market

Abstract

:1. Introduction

- (i)

- Both technologies are clean, renewable energy sources with low greenhouse gas emissions;

- (ii)

- Reduced evaporation of water from reservoirs. The scarcity of clean water is a serious problem that affects all countries. One possible solution is to save water by reducing evaporation from open water surfaces. The assessment of surface water evaporation is complex as it depends on a number of factors such as open water surface, temperature, vapour pressure difference, wind effect, atmospheric pressure and water properties [12]. modules protect the water body from high evaporation and thus save water [13]. Agrawal et al. [12] presented a study on water evaporation in a reservoir with a floating solar installation at the Rajghat dam in the Bundelkhand region of Uttar Pradesh, India. They concluded that the annual reduction in evaporative water losses can be estimated at 1395 (m) per MWp or (L/kWh). Farrar et al. [14] conducted a study on a large reservoir used to irrigate a farm in the Mafraq Governorate in Northern Jordan. They estimated that the installation of a floating system would save 12,700 (m) of water per year. This is equivalent to savings compared to the usual scenario without coverage. Melvin [15] presented a study on the influence of modules on the reduction of water evaporation in reservoirs in Singapore. The study showed that the floating module system on the reservoir had an evaporation rate reduction effect of approximately . Yao et al. [16] presented a technical report on the evaluation of the potential of floating and suspended covers in reducing evaporation from large water reservoirs or dams in South East Queensland (Australia). The report concluded that the annual evaporation reduction efficiency if the dams were fully covered would reach for suspended covers and for floating covers;

- (iii)

- Floating systems do not occupy land. The installation of a plant on fertile land suitable for agricultural use deprives humans of agricultural products for at least 25 years. If the land is not so fertile, it could be used for forestry development [12]. Floating photovoltaic systems free up land occupation which means the land can be used for other purposes;

- (iv)

- Increased electricity generation. modules increase power generation with better cooling systems. The efficiency of floating photovoltaic systems has been addressed by numerous studies. According to some studies, the efficiency gains with floating systems compared to ground-based systems range from to , while others estimate it to be below . According to Liu et al. [17] the performance ratio increases by with systems. Choi [18] verifies that the generation efficiency of a floating system is higher. For Oliveira-Pinto and Stokkermans [19], this efficiency gain ranges from to , depending on the floating solar technology. According to El Hammoumi et al. [13], efficiency increases up to . On the other hand, water surfaces provide large areas free of shading objects, such as trees, decreasing the likelihood of external shading [20];

- (v)

- systems improve water quality in reservoirs. The solar irradiance incident on the water in the reservoirs affects the mixture of substances present in the water, such as nitrogen or phosphorus, causing a decrease in the dissolved oxygen in the water and, as a result, an increase in the amount of algae [21]. This leads to a process known as eutrophication, which particularly occurs in summer. This phenomenon causes water pollution, seriously affecting aquatic life and the environment. A lack of sunlight restricts algae growth, thus reducing eutrophication. Considering floating PV systems prevent solar irradiance from hitting the water, they also restrain photosynthesis, thereby limiting pollution;

- (vi)

- Solar energy storage. The joint use of both technologies means energy can be stored, which addresses the problem of solar energy intermittency [22];

- (vii)

- The prevention of shore erosion. Floating modules hinder the strongest gusts of wind from eroding shorelines.

- (i)

- Uncertainty about the materials used in floating power plants. The degradation of the materials that comprise a floating system is one of the critical factors to consider. It affects the lifetimes of systems and [23]. These materials are always under the effects of water evaporation; therefore, exposure to oxidation and corrosion will always be higher than for terrestrial plants. These phenomena are accentuated when the water is salty [24]. Goswami and Sadhu [25] conducted an experimental study to determine the performance of a module in an system and a ground system. The results showed that the average performance ratio and degradation rate were and , respectively, for the system and and , respectively, for the ground system. There is a high degree of uncertainty at present in the behaviour of elements such as modules or anchors in wet environments;

- (ii)

- Increased initial investment costs. The initial investment costs are currently higher than for ground-based systems [26]. Due to the watery installation environment of systems, flotation and mooring elements are needed for their mounting to avoid displacement caused by wind, waves or water currents. These elements increase the initial budget costs for engineering and material [27]. Obviously, the increase in initial costs is strongly dependent on the exact flotation and mooring equipment used. Oliveira-Pinto and Stokkermans [19] presented a comparative study between two different systems irrespective of location. They showed that the mooring and anchoring systems used resulted in a difference in ;

- (iii)

- A limited tilt angle for PV modules. To avoid the detrimental effects of wind loads, the tilt angle of current float models is low. Depending on the location, this design condition can have a significant negative effect on power generation [28];

- (iv)

- Uncertainty about maintenance costs. Maintenance operations are often more complicated, e.g., require divers. Therefore, maintenance costs may suddenly increase significantly.

- (i)

- Various operating scenarios were analysed based on forecast accuracy in addition to any deviations occurring in the day-ahead market, taking into account the rules of the electricity market and the technical operational limitations of both plants;

- (ii)

- The optimal mode of operation has been identified for each of the scenarios analysed;

- (iii)

- The economic benefit of the optimal mode of operation has been calculated for each of the scenarios analysed.

2. Background

2.1. Iberian Electricity Market

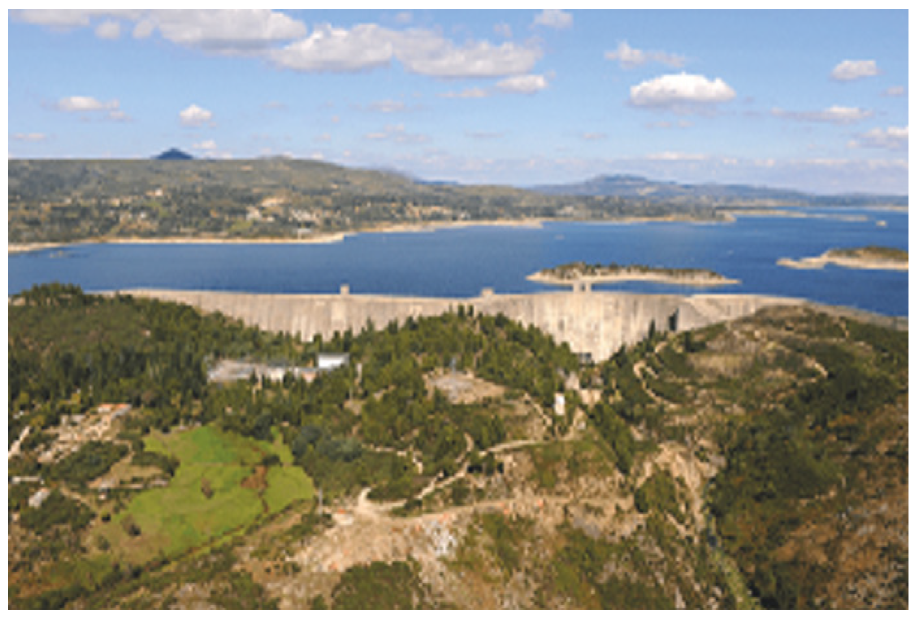

2.2. Pumped Hydroelectric Power Plant

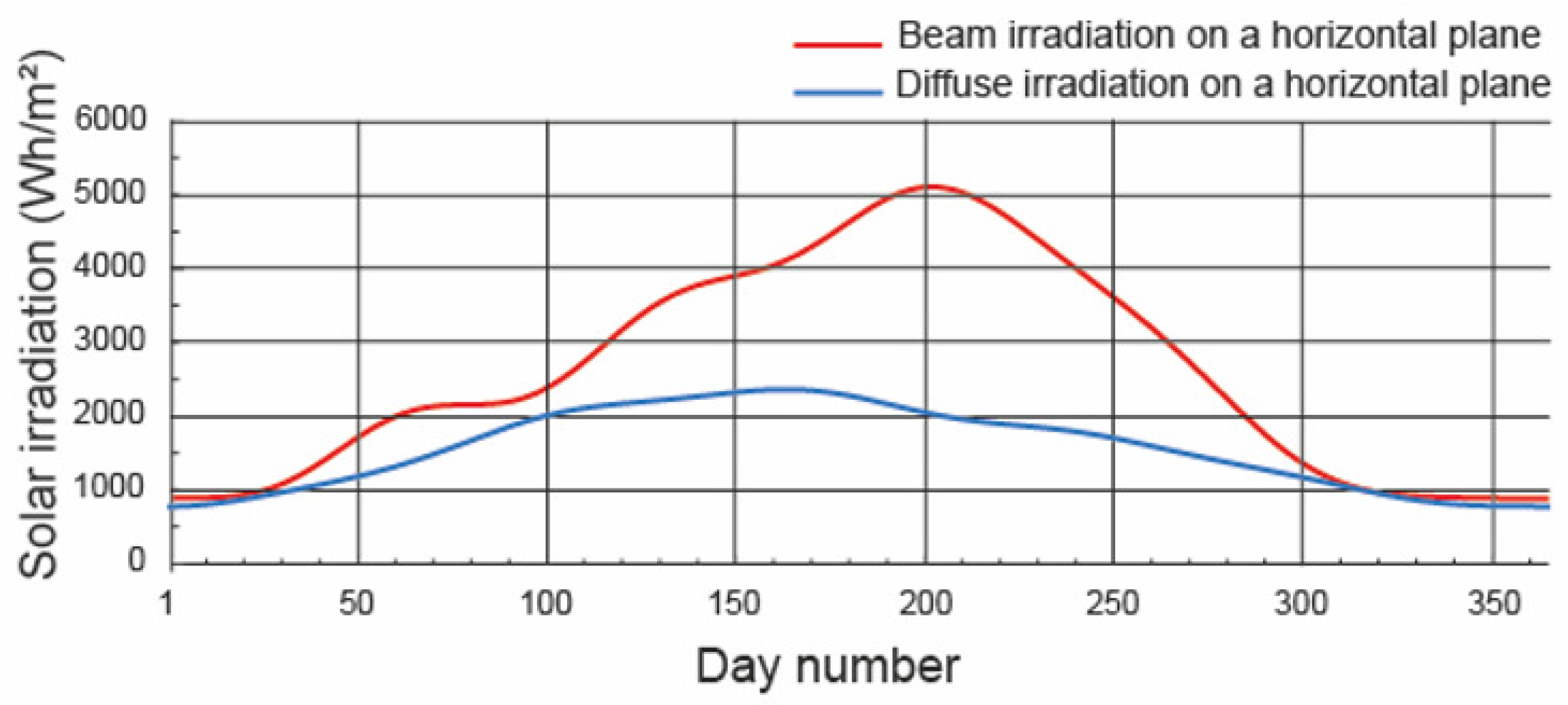

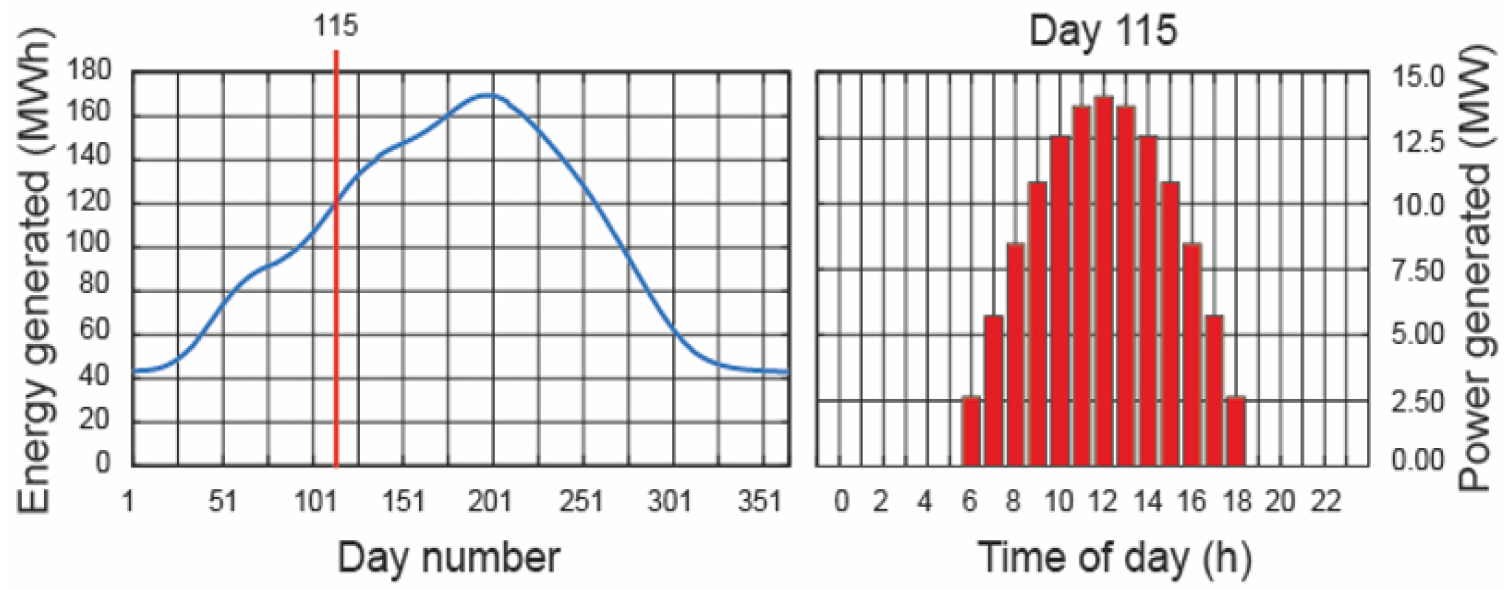

2.3. Floating PV Power Plant

3. Possible Operating Modes of a Floating PV Power Plant Integrated into a Pumped Hydroelectric Power Plant in the Day-Ahead Market

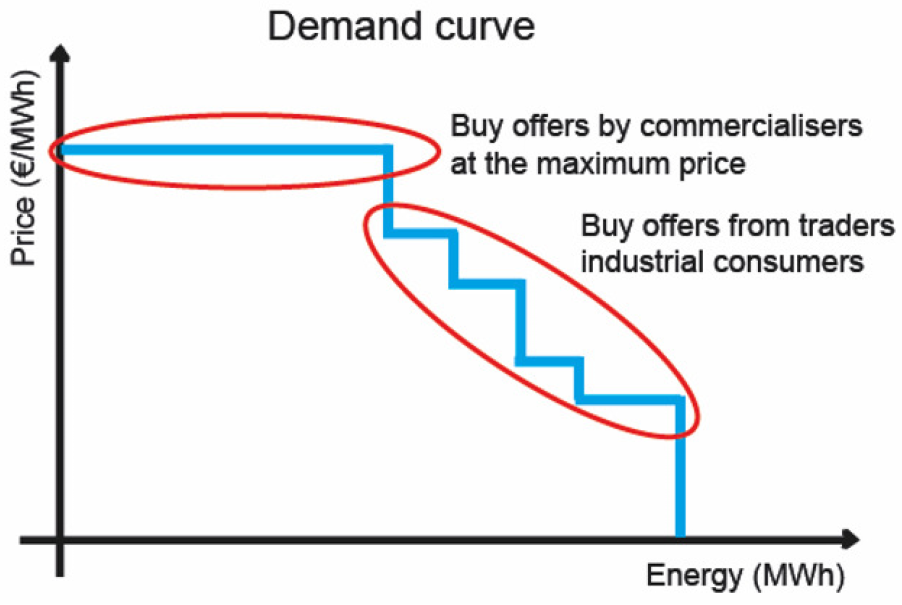

3.1. Supply and Demand Curves of the Day-Ahead Market

3.2. Deviation Management Market

- (i)

- If > 0. It means there is a net need for system balancing, i.e., the net system output is less than scheduled in the market and therefore more energy is needed;

- (ii)

- If < 0, it means that the net production of the system is greater than that which is scheduled in the market and, therefore, there is “surplus” energy.

- (i)

- Deviation in favour. This is in the same direction as the system need. Deviations in favour occur when a power plant produces less energy than scheduled but the < 0 (less energy is produced on a day when there is energy left over in the system) or when the power plant generates more energy than scheduled but the > 0 (more energy is produced on a day when the system needs more energy);

- (ii)

- Deviation against. It goes in the opposite direction to the net system need. Deviations against occur when a power plant generates less energy than scheduled and the > 0 (less energy is produced on a day when the system needs more) or when more energy is generated than scheduled and the < 0 (more energy is produced on a day when the system needs less).

3.3. Settlement of Deviations

- (i)

- If > 0 and the deviation is downward. The downward deviation generates a payment obligation and since it is a deviation against the system, the price that will have to be paid is higher than the market price. Therefore, it is the worst situation for a downward deviation as the power plant is losing money. The cost of the downward deviation in this case is the price premium paid for producing less energy;

- (ii)

- If < 0 and the deviation is downward. The deviation generates a payment obligation, but this time, the price to be paid is equal to the market price since it is in favour of the system. Thus, the power plant does not lose any money, but rather “returns” the money it has been paid for energy it is not producing. This is the best situation for a power plant that commits a downward deviation;

- (iii)

- If > 0 and the deviation is upward. This deviation generates a collection right and in this case it is in favour of the system. This means that the price the power plant will charge for the energy produced will be equal to the market price, which is the best scenario for a power plant in a deviation to upward deviation situation;

- (iv)

- If < 0 and the deviation is upward. Again, the deviation upward generates a collection right, but this time, the price received by the plant will be lower than the market price since it is against the system and it will not pay the same price for energy that is not really “needed”. The cost of the deviation in this case is understood as the money that the plant stops receiving in comparison with the sum to be received if it were selling that energy on another day at the market price.

3.4. Possible Operating Modes

- (i)

- Due to day-ahead market conditions, pumped hydroelectric power plants do not generate power at full capacity 24 h per day. The hours with the highest energy prices are chosen. Thus, water is conserved for use at a later and potentially more valuable time. Therefore, the turbines and their grid transmission lines are used intermittently. For the remaining the hours, they can operate by pumping water. Furthermore, If operating 24 h per day, there would not be enough annual flow through the upper reservoir basin to maintain the average flow required at full power;

- (ii)

- One mode of operation for floating power plants is to sell electricity as it is generated. The natural variability of electricity flows from such power plants creates uncertainty in energy supply;

- (iii)

- Another mode of operation for floating power plants is to store electricity as it is generated by pumping water from the lower reservoir to the upper reservoir. Thus, water is stored for use at a later and potentially more valuable time;

- (iv)

- The latest mode of operation for floating power plants is to simultaneously sell and store electricity as it is generated. In this case, the motor/pump unit is used to pump water from the lower reservoir and increase the hydraulic potential of the upper reservoir using surplus power generation.

4. Case Study Description

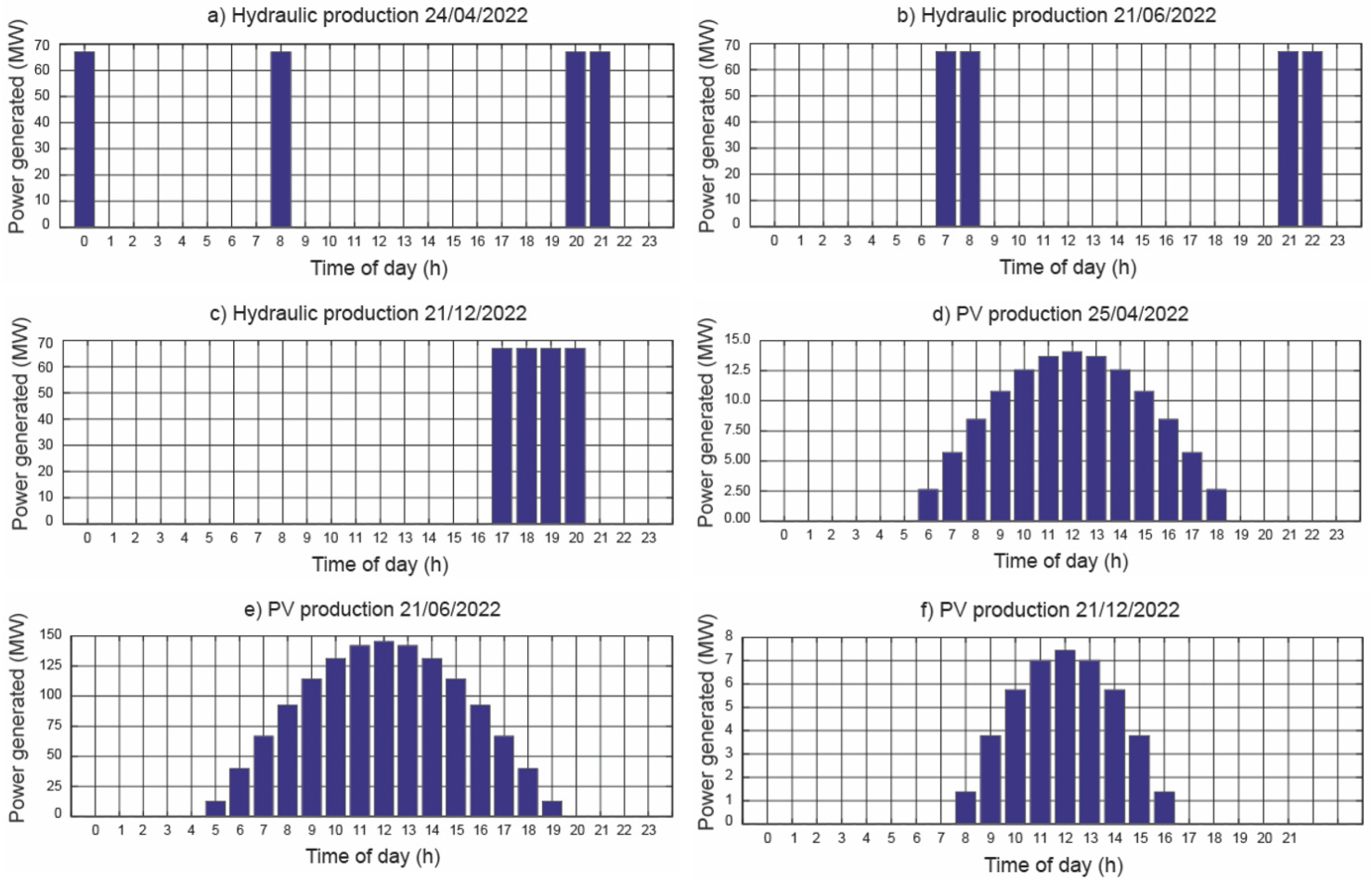

4.1. Hydraulic Production

4.2. Photovoltaic Production

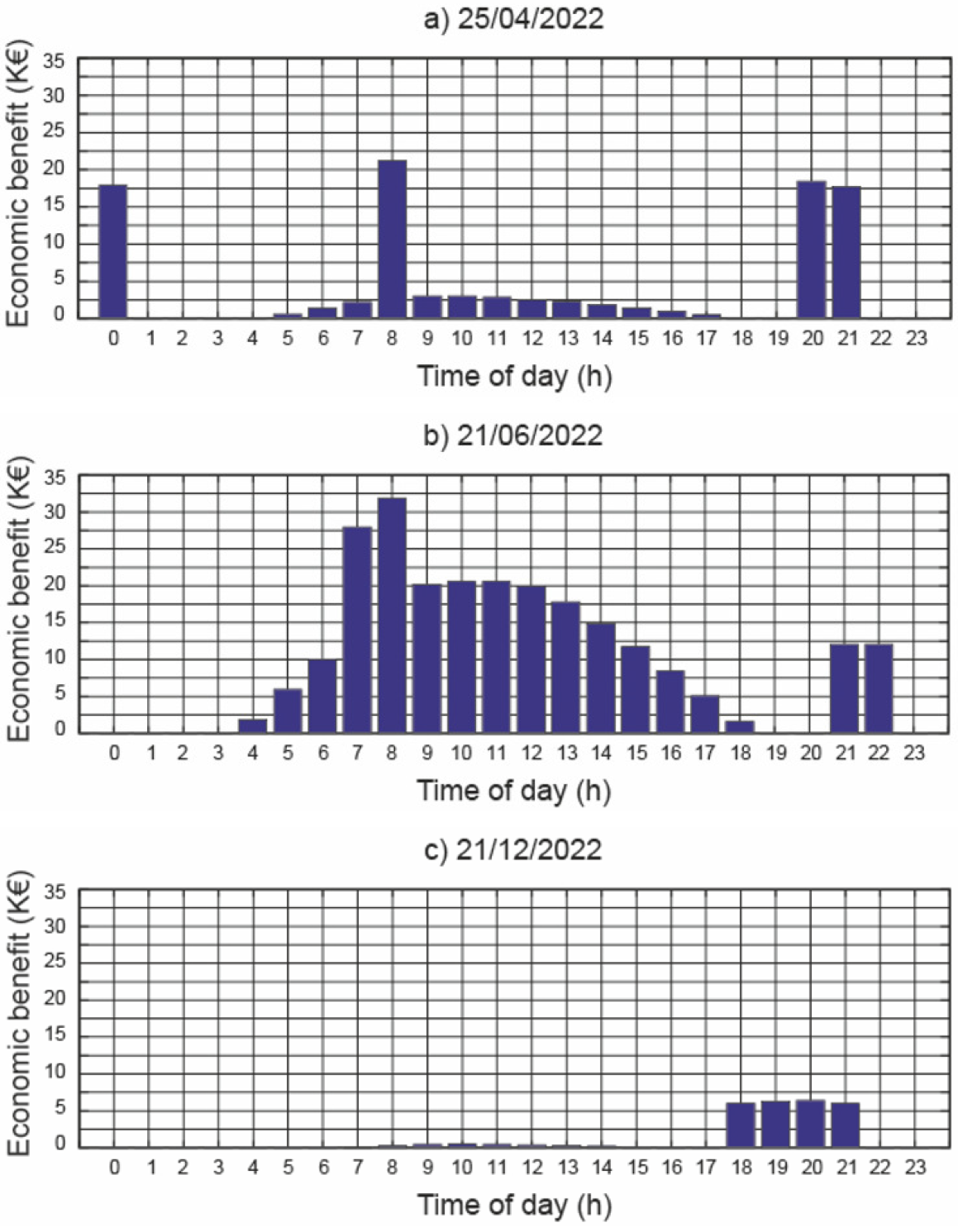

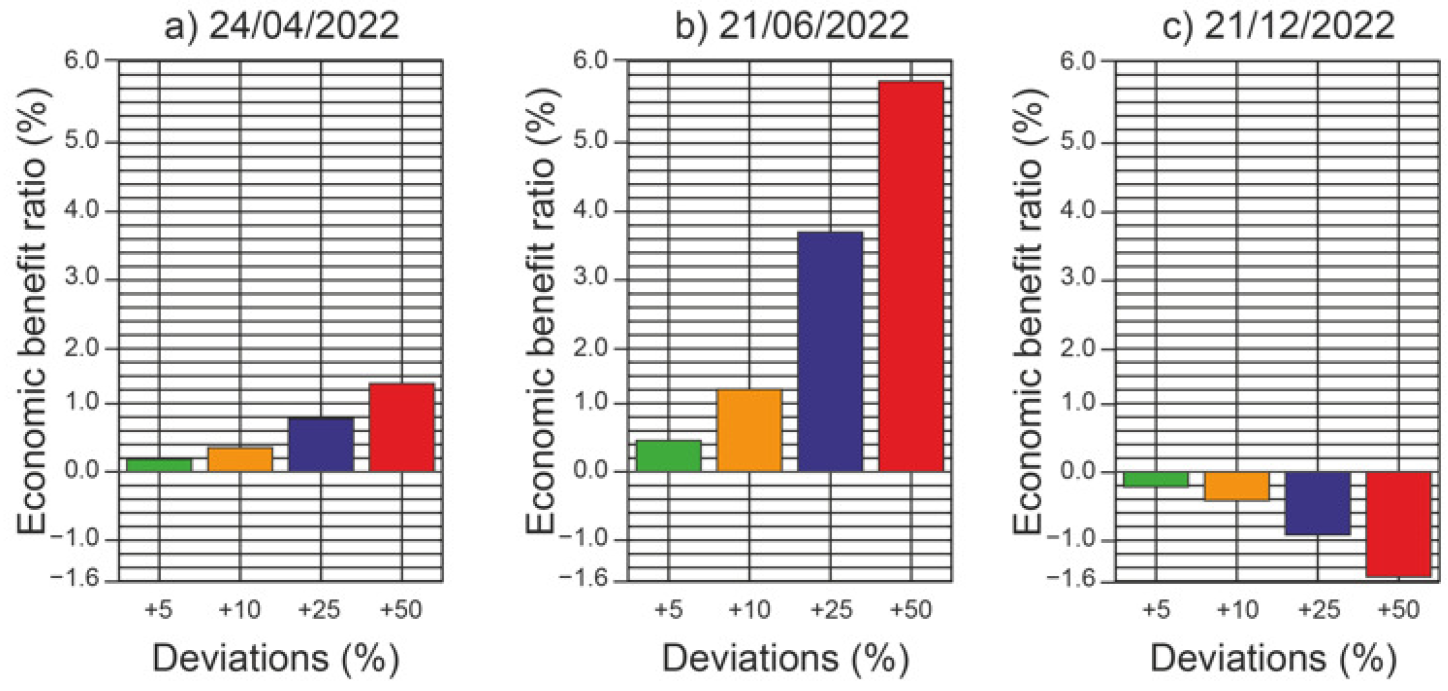

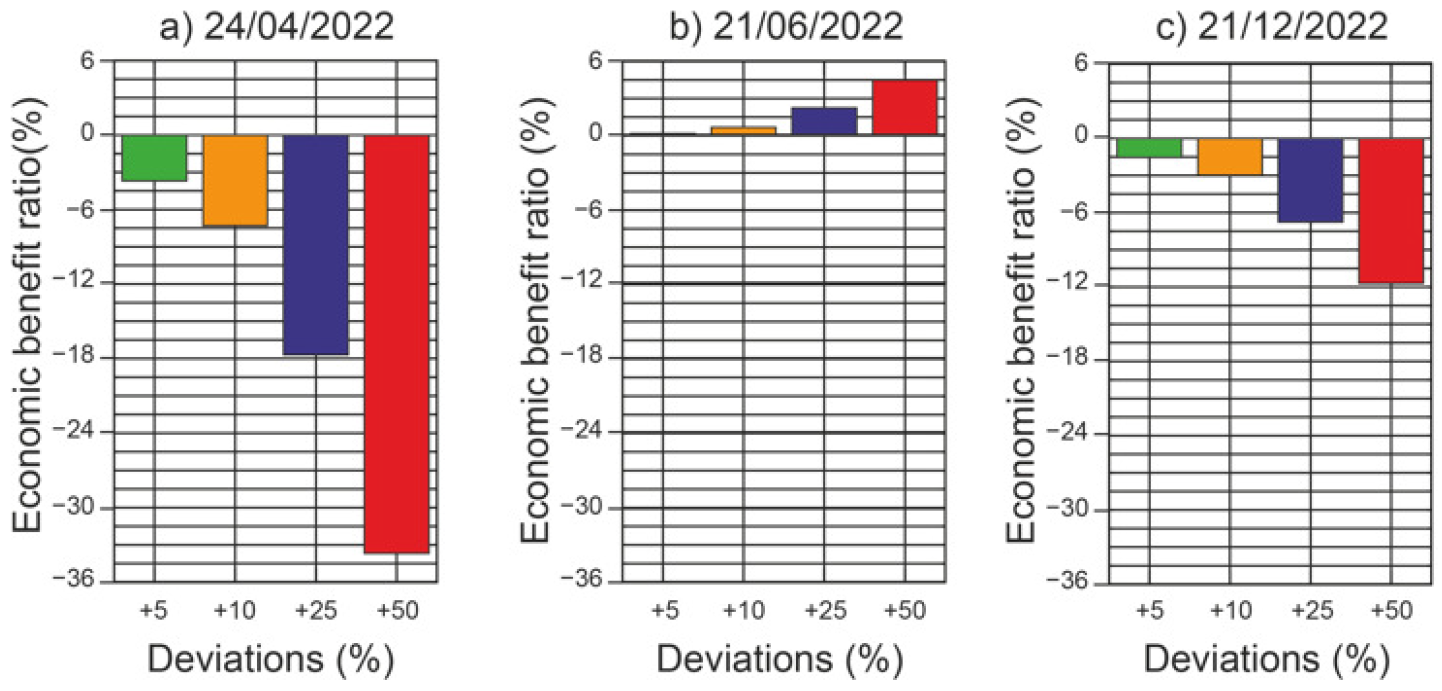

5. Results and Discussions

5.1. Scenario 1

5.2. Scenario 2

5.3. Scenario 3

5.4. Scenario 4

5.5. Scenario 5

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Economic benefit (€) | |

| Economic benefit ratio (%) | |

| g | Acceleration due to gravity (m/s) |

| Adjusted total irradiation on a tilted surface (Wh/m) | |

| Available head (m) | |

| Elevating head (m) | |

| Adjusted beam irradiance on a horizontal surface (W/m) | |

| Adjusted diffuse irradiance on a horizontal surface (W/m) | |

| Adjusted total irradiance on a tilted surface (W/m) | |

| Water pumping coefficient (W·s/m) | |

| Turbine generating coefficient (W·s/m) | |

| Normal operating cell temperature (C) | |

| n | Ordinal of the day (day) |

| Power input of the electric motor (W) | |

| Power output of the electric generator (W) | |

| Power output of the module (W/m) | |

| Power output of the hydro turbine (W) | |

| Turbined flow rate (m/s) | |

| Pumped flow rate (m/s) | |

| T | Solar time (h) |

| Ambient temperature (C) | |

| cell temperature (C) | |

| Reference temperature (C) | |

| Sunrise solar time (h) | |

| Sunset solar time (h) | |

| Solar absorptance of layer (dimensionless) | |

| Tilt angle of photovoltaic module () | |

| Temperature coefficient (1/C) | |

| Azimuth angle of photovoltaic module () | |

| Solar declination () | |

| PV module efficiency (%) | |

| Electric generator efficiency (%) | |

| Motor generator efficiency (%) | |

| Pump efficiency (%) | |

| module efficiency at the reference temperature (%) | |

| Hydro turbine efficiency (%) | |

| Incidence angle () | |

| Zenith angle of the Sun () | |

| Latitude angle () | |

| Total pumping process efficiency (%) | |

| Density of water (kg/m) | |

| Ground reflectance (dimensionless) | |

| Solar transmittance of glazing (dimensionless) | |

| Hour angle () |

References

- Sharm El-Sheikh Climate Change Conference. 6–20 November 2022. Available online: https://unfccc.int/cop27 (accessed on 23 January 2023).

- Bellos, E.; Tzivanidis, C.; Said, Z. A systematic parametric thermal analysis of nanofluid-based parabolic trough solar collectors. Sustain. Energy Technol. Assessments 2020, 39, 100714. [Google Scholar] [CrossRef]

- Gopi, A.; Sharma, P.; Sudhakar, K.; Ngui, W.K.; Kirpichnikova, I.; Cuce, E. Weather impact on solar farm performance: A comparative analysis of machine learning techniques. Sustainability 2023, 15, 439. [Google Scholar] [CrossRef]

- Tuncer, A.D.; Khanlari, A.; Afshari, F.; Sözen, A.; Çiftçi, E.; Kusun, B.; Şahinkesen, İ. Experimental and numerical analysis of a grooved hybrid photovoltaic-thermal solar drying system. Appl. Therm. Eng. 2023, 218, 119288. [Google Scholar] [CrossRef]

- Barbón, A.; Vesperinas, D.; Bayón, L.; García-Mollaghan, D.; Ghodbane, M. Numerical simulation of a solar water disinfection system based on a small-scale linear Fresnel reflector. RSC Adv. 2023, 13, 155–171. [Google Scholar] [CrossRef]

- IRENA. Future of Solar Photovoltaic: Deployment, Investment, Technology, Grid Integration and Socio-Economic Aspects; International Renewable Energy Agency: Masdar City, United Arab Emirates, 2019; Available online: https://irena.org/-/media/Files/IRENA/Agency/Publication/2019/Nov/IRENA_Future_of_Solar_PV_2019.pdf (accessed on 27 December 2022).

- Barbose, G.; Darghouth, N.; O’Shaughnessy, E.; Forrester, S. Tracking the Sun: Pricing and Design Trends for Distributed Photovoltaic Systems in the United States, Edition 2021 ed; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2021. [Google Scholar]

- IRENA. Solar Costs to Fall Further, Powering Global Demand; International Renewable Energy Agency: Masdar City, United Arab Emirates, 2017; Available online: https://www.reuters.com/article/singapore-energy-solar/solar-costs-to-fall-further-powering-global-demand-irena-idINKBN1CS13C (accessed on 27 December 2022).

- Barbón, A.; Fortuny Ayuso, P.; Bayón, L.; Silva, C.A. A comparative study between racking systems for photovoltaic power systems. Renew. Energy 2021, 180, 424–437. [Google Scholar] [CrossRef]

- IEA. Hydroelectricity; International Energy Agency: Paris, France, 2022; Available online: https://www.iea.org/reports/hydroelectricity. (accessed on 23 January 2023).

- Barbour, E.; Grant Wilson, I.A.; Radcliffe, J.; Ding, Y.; Li, Y. A review of pumped hydro energy storage development in significant international electricity markets. Renew. Sustain. Energy Rev. 2016, 61, 421–432. [Google Scholar] [CrossRef]

- Agrawal, K.K.; Jha, S.K.; Mittal, R.K.; Vashishtha, S. Assessment of floating solar PV (FSPV) potential and water conservation: Case study on Rajghat Dam in Uttar Pradesh, India. Energy Sustain. 2022, 66, 287–295. [Google Scholar] [CrossRef]

- El Hammoumi, A.; Chalh, V.; Allouhi, A.; Motahhir, S.; El Ghzizal, A.; Derouich, A. Design and construction of a test bench to investigate the potential of floating PV systems. J. Cleaner Production 2021, 278, 123917. [Google Scholar] [CrossRef]

- Farrar, L.W.; Bahaj, A.S.; James, P.; Anwar, A.; Amdar, N. Floating solar PV to reduce water evaporation in water stressed regions and powering water pumping: Case study Jordan. Energy Convers. Manag. 2022, 260, 115598. [Google Scholar] [CrossRef]

- Melvin, G.K.X. Experimental Study of the Effect of Floating Solar Panels on Reducing Evaporation in Singapore Reservoirs. 2015. Available online: https://cpb-us-w2.wpmucdn.com/blog.nus.edu.sg/dist/b/4438/files/2015/04/FYP-Final-report-14ijhop.pdf (accessed on 27 December 2022).

- Yao, X.; Zhang, H.; Lemckert, C.; Brook, A.; Schouten, P. Evaporation Reduction by Suspended and Floating Covers: Overview, Modelling and Efficiency. Urban Water Security Research Alliance Technical Report No. 28. 2010. Available online: http://www.urbanwateralliance.org.au/publications/uwsra-tr28.pdf (accessed on 27 December 2022).

- Liu, H.; Krishna, V.; Lun Leung, J.; Reindl, T.; Zhao, L. Field experience and performance analysis of floating PV technologies in the tropics. Prog. Photovoltaics: Res. Appl. 2018, 26, 957–967. [Google Scholar] [CrossRef]

- Choi, Y.-K. A study on power generation analysis of floating PV system considering environmental impact. Int. J. Of Software Eng. Its Appl. 2014, 8, 75–84. [Google Scholar] [CrossRef]

- Oliveira-Pinto, S.; Stokkermans, J. Assessment of the potential of different floating solar technologies–Overview and analysis of different case studies. Energy Convers. Manag. 2020, 211, 112747. [Google Scholar] [CrossRef]

- Farfan, J.; Breyer, C. Combining floating solar photovoltaic power plants and hydropower reservoirs: A virtual battery of great global potential. Energy Proccedia 2018, 155, 403–411. [Google Scholar] [CrossRef]

- Sanseverino, I.; Conduto, D.; Pozzoli, L.; Dobricic, S.; Lettieri, T. Algal bloom and its economic impact, European Commission; Joint Research Centre: Brussels, Belgium, 2016. [Google Scholar]

- Aihara, R.; Yokoyama, A.; Nomiyama, F.; Kosugi, N. Optimal operation scheduling of pumped storage hydro power plant in power system with a large penetration of photovoltaic generation using genetic algorithm. In Proceedings of the IEEE Trondheim PowerTech, Trondheim, Norway, 19–23 June 2011. [Google Scholar]

- Aghaei, M.; Fairbrother, A.; Gok, A.; Ahmad, S.; Kazim, S.; Lobato, K.; Oreski, G.; Reinders, A.; Schmitz, J.; Theelen, M.; et al. Review of degradation and failure phenomena in photovoltaic modules. Renew. Sustain. Energy Rev. 2022, 159, 112160. [Google Scholar] [CrossRef]

- Cazzaniga, R.; Cicu, M.; Rosa-Clot, M.; Rosa-Clot, P.; Tina, G.M.; Ventura, C. Floating photovoltaic plants: Performance analysis and design solutions. Renew. Sustain. Energy Rev. 2018, 81, 1730–1741. [Google Scholar] [CrossRef]

- Goswami, A.; Sadhu, P.K. Degradation analysis and the impacts on feasibility study of floating solar photovoltaic systems. Sustain. Energy, Grids Netw. 2021, 26, 100425. [Google Scholar] [CrossRef]

- Teixeira, L.E.; Caux, J.; Beluco, A.; Bertoldo, I.; Louzada, J.A.S.; Eifler, R.C. Feasibility study of a hydro PV hybrid system operating at a dam for water supply in southern Brazil. J. Power And Energy Eng. 2015, 3, 70–83. [Google Scholar] [CrossRef]

- Claus, R.; López, M. Key issues in the design of floating photovoltaic structures for the marine environment. Renew. And Sustainable Energy Rev. 2022, 164, 112502. [Google Scholar] [CrossRef]

- Barbón, A.; Bayón-Cueli, C.; Bayón, L.; Rodríguez-Suanzes, C. Analysis of the tilt and azimuth angles of photovoltaic systems in non-ideal positions for urban applications. Appl. Energy 2022, 305, 117802. [Google Scholar] [CrossRef]

- Zhao, Z.; Yuan, Y.; He, M.; Jurasz, J.; Wang, J.; Egusquiza, M.; Egusquiza, E.; Xu, B.; Chen, D. Stability and efficiency performance of pumped hydro energy storage system for higher flexibility. Renew. Energy 2022, 199, 1482–1494. [Google Scholar] [CrossRef]

- Bakhshaei, P.; Askarzadeh, A.; Arababadi, R. Operation optimization of a grid-connected photovoltaic/pumped hydro storage considering demand response program by an improved crow search algorithm. J. Energy Storage 2021, 44, 103326. [Google Scholar] [CrossRef]

- Al-Masri, H.M.K.; Magableh, S.K.; Abuelrub, A.; Alzaareer, K. Realistic coordination and sizing of a solar array combined with pumped hydro storage system. J. Energy Storage 2021, 41, 102915. [Google Scholar] [CrossRef]

- Shyam, B.; Kanakasabapathy, P. Feasibility of floating solar PV integrated pumped storage system for a grid-connected microgrid under static time of day tariff environment: A case study from India. Renewable Energy 2022, 192, 200–215. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Nayak, P.K. PV-pumped energy storage option for convalescing performance of hydroelectric station under declining precipitation trend. Renew. Energy 2019, 135, 288–302. [Google Scholar] [CrossRef]

- Bayón, L.; Grau, J.M.; Ruiz, M.M.; Suárez, P.M. Mathematical modelling of the combined optimization of a pumped-storage hydro-plant and a wind park. Math. Comput. Model. 2013, 57, 2024–2028. [Google Scholar] [CrossRef]

- Sahu, A.; Yadav, N.; Sudhakar, K. Floating photovoltaic power plant: A review. Renew. Sustain. Energy Rev. 2016, 66, 815–824. [Google Scholar] [CrossRef]

- Barbón, A.; Fortuny Ayuso, P.; Bayón, L.; Fernández-Rubiera, J.A. Predicting beam and diffuse horizontal irradiance using Fourier expansions. Renew. Energy 2020, 154, 46–57. [Google Scholar] [CrossRef]

- WRDC. World Radiation Data Centre. 2022. Available online: http://wrdc.mgo.rssi.ru/ (accessed on 27 December 2022).

- Hottel, H.C. A simple model for estimating the transmittance of direct solar radiation through clear atmosphere. Sol. Energy 1976, 18, 129–134. [Google Scholar] [CrossRef]

- Liu, B.Y.H.; Jordan, R.C. The interrelationship and characteristic distribution of direct, diffuse and total solar radiation. Sol. Energy 1960, 4, 1–19. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; John Wiley & Sons: New York, NY, USA, 2013. [Google Scholar]

- Ghigo, A.; Faraggiana, E.; Sirigu, M.; Mattiazzo, G.; Bracco, G. Design and Analysis of a floating photovoltaic system for offshore installation: The case study of Lampedusa. Energies 2022, 15, 8804. [Google Scholar] [CrossRef]

- Barbón, A.; Ghodbane, M.; Bayón, L.; Said, Z. A general algorithm for the optimization of photovoltaic modules layout on irregular rooftop shapes. J. Clean. Prod. 2022, 365, 132774. [Google Scholar] [CrossRef]

- Barbón, A.; Bayón, L.; Díaz, G.; Silva, C.A. Investigation of the effect of albedo in photovoltaic systems for urban applications: Case study for Spain. Energies 2022, 15, 7905. [Google Scholar] [CrossRef]

- Available online: https://www.isifloating.com/en/solar-flotante-isifloating-by-isigenere-english/ (accessed on 27 December 2022).

- Available online: https://ciel-et-terre.net/solutions/products/ (accessed on 27 December 2022).

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Agathokleous, R.; Panayiotou, G. On-site PV characterization and effect of soiling on their performance. Energy 2013, 51, 439–446. [Google Scholar] [CrossRef]

- Evans, D.L. Simplified method for predicting photovoltaic array output. Sol. Energy 1981, 27, 555–560. [Google Scholar] [CrossRef]

- Kichou, S.; Skandalos, N.; Wolf, P. Floating photovoltaics performance simulation approach. Heliyon 2022, 8, 11896. [Google Scholar] [CrossRef]

- Lawrence Kamuyu, W.C.; Rok Lim, J.; Sub Won, C.; Keun Ahn, H. Prediction model of photovoltaic module temperature for power performance of floating PVs. Energies 2018, 11, 447. [Google Scholar] [CrossRef]

- Mattei, M.; Notton, G.; Cristofari, C.; Muselli, M.; Poggi, P. Calculation of the polycrystalline PV module temperature using a simple method of energy balance. Renew. Energy 2006, 31, 553–567. [Google Scholar] [CrossRef]

- Available online: https://portugal.edp.com/en/alto-rabagao-hydro-power-plant (accessed on 27 December 2022).

- Barbón, A.; Bayón-Cueli, C.; Bayón, L.; Carreira-Fontao, V. A methodology for an optimal design of ground-mounted photovoltaic power plants. Appl. Energy 2022, 314, 118881. [Google Scholar] [CrossRef]

- PVGIS, Joint Research Centre (JRC). 2022. Available online: https://joint-research-centre.ec.europa.eu/pvgis-online-tool_en (accessed on 24 January 2023).

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- ESIOS. Iberian Market Operator, Market Results. 2022. Available online: https://www.esios.ree.es/es/mercados-y-precios (accessed on 27 December 2022).

| Parameter | Deviations | |

|---|---|---|

| To Downward | To Upwards | |

| NNBS > 0 | PDD > MMP | PUD = MMP |

| CDD > 0 | CUD = 0 | |

| NNBS < 0 | PDD = MMP | PUD < MMD |

| CDD = 0 | CUD > 0 | |

(h) | MMP (€) | PUD (€) | PDD (€) |

|---|---|---|---|

| 00:00 | 267.43 | 225.00 | 267.06 |

| 01:00 | 260.61 | 237.00 | 257.88 |

| 02:00 | 248.87 | 246.85 | 246.85 |

| 03:00 | 238.52 | 190.00 | 238.52 |

| 04:00 | 232.61 | 188.07 | 237.14 |

| 05:00 | 230.88 | 190.00 | 240.70 |

| 06:00 | 237.23 | 188.59 | 246.27 |

| 07:00 | 261.87 | 224.00 | 278.72 |

| 08:00 | 272.47 | 214.19 | 310.02 |

| 09:00 | 238.77 | 141.79 | 260.56 |

| 10:00 | 221.75 | 151.95 | 229.13 |

| 11:00 | 204.26 | 141.02 | 214.46 |

| 12:00 | 181.98 | 148.00 | 254.40 |

| 13:00 | 180.1 | 151.96 | 240.5 |

| 14:00 | 173.76 | 171.13 | 178.67 |

| 15:00 | 170.00 | 156.67 | 197.97 |

| 16:00 | 170.56 | 158.98 | 179.62 |

| 17:00 | 180.00 | 153.96 | 153.96 |

| 18:00 | 207.00 | 143.05 | 143.05 |

| 19:00 | 231.76 | 150.08 | 270.52 |

| 20:00 | 275.71 | 202.26 | 220.71 |

| 21:00 | 264.93 | 223.77 | 264.92 |

| 22:00 | 254.00 | 190.74 | 270.53 |

| 23:00 | 232.61 | 172.82 | 268.42 |

(h) | MMP (€) | PUD (€) | PDD (€) |

|---|---|---|---|

| 00:00 | 170.28 | 0 | 0 |

| 01:00 | 150.73 | 0 | 0 |

| 02:00 | 148.00 | 0 | 0 |

| 03:00 | 145.92 | 0 | 0 |

| 04:00 | 148.80 | 0 | 0 |

| 05:00 | 150.06 | 0 | 0 |

| 06:00 | 149.84 | 0 | 0 |

| 07:00 | 175.56 | 0 | 0 |

| 08:00 | 175.56 | 0 | 0 |

| 09:00 | 153.70 | 0 | 0 |

| 10:00 | 145.00 | 0 | 0 |

| 11:00 | 141.22 | 222.22 | 222.22 |

| 12:00 | 140.44 | 0 | 0 |

| 13:00 | 135.73 | 0 | 0 |

| 14:00 | 130.25 | 0 | 0 |

| 15:00 | 127.05 | 0 | 0 |

| 16:00 | 156.36 | 0 | 0 |

| 17:00 | 127.05 | 185.88 | 185.88 |

| 18:00 | 127.05 | 0 | 0 |

| 19:00 | 130.75 | 0 | 0 |

| 20:00 | 146.13 | 0 | 0 |

| 21:00 | 180.03 | 0 | 0 |

| 22:00 | 180.03 | 0 | 0 |

| 23:00 | 146.53 | 0 | 0 |

(h) | MMP (€) | PUD (€) | PDD (€) |

|---|---|---|---|

| 00:00 | 58.78 | 28.35 | 62.26 |

| 01:00 | 50.27 | 21.48 | 58.41 |

| 02:00 | 40.00 | 0.00 | 57.55 |

| 03:00 | 36.83 | 2.29 | 56.75 |

| 04:00 | 36.68 | 0.52 | 58.04 |

| 05:00 | 50.00 | 2.04 | 67.34 |

| 06:00 | 58.17 | 18.31 | 68.21 |

| 07:00 | 64.17 | 34.16 | 67.32 |

| 08:00 | 77.79 | 41.22 | 80.86 |

| 09:00 | 79.00 | 29.76 | 79.33 |

| 10:00 | 68.00 | 24.81 | 70.46 |

| 11:00 | 55.00 | 15.56 | 62.79 |

| 12:00 | 54.00 | 9.61 | 59.19 |

| 13:00 | 53.00 | 0.00 | 57.98 |

| 14:00 | 51.00 | 0.00 | 46.68 |

| 15:00 | 55.00 | 0.00 | 52.38 |

| 16:00 | 70.00 | 13.27 | 68.28 |

| 17:00 | 83.96 | 16.67 | 70.09 |

| 18:00 | 90.00 | 11.51 | 71.53 |

| 19:00 | 93.64 | 3.88 | 3.88 |

| 20:00 | 95.76 | 21.58 | 21.58 |

| 21:00 | 90.00 | 3.14 | 70.72 |

| 22:00 | 68.90 | 0.00 | 66.01 |

| 23:00 | 58.17 | 19.48 | 52.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barbón, A.; Gutiérrez, Á.; Bayón, L.; Bayón-Cueli, C.; Aparicio-Bermejo, J. Economic Analysis of a Pumped Hydroelectric Storage-Integrated Floating PV System in the Day-Ahead Iberian Electricity Market. Energies 2023, 16, 1705. https://doi.org/10.3390/en16041705

Barbón A, Gutiérrez Á, Bayón L, Bayón-Cueli C, Aparicio-Bermejo J. Economic Analysis of a Pumped Hydroelectric Storage-Integrated Floating PV System in the Day-Ahead Iberian Electricity Market. Energies. 2023; 16(4):1705. https://doi.org/10.3390/en16041705

Chicago/Turabian StyleBarbón, Arsenio, Ángel Gutiérrez, Luis Bayón, Covadonga Bayón-Cueli, and Javier Aparicio-Bermejo. 2023. "Economic Analysis of a Pumped Hydroelectric Storage-Integrated Floating PV System in the Day-Ahead Iberian Electricity Market" Energies 16, no. 4: 1705. https://doi.org/10.3390/en16041705