The Contribution of Lean Management—Industry 4.0 Technologies to Improving Energy Efficiency

Abstract

:1. Introduction

2. Literature Review

- Productivity: The ratio of economic output per unit of energy use has been a common metric used to measure relative performance in interrelated economic, energy and environmental issues [33]. Today, it is possible to identify energy-consuming processes, through the production process, and measure energy efficiency [34], since the main factors responsible for energy efficiency in industrial companies are related mainly to production activities [35]. Many analyses have referred to the industrial productivity benefits associated with energy efficiency [36]. Zhang et al. [6] assert the need to adjust the dispersion of labour productivity, optimise energy investment activities, strengthen energy price control mechanisms and energy intensity to improve energy efficiency and energy cost. The configuration of Industry 4.0 technologies and their integration into the production process favours efficient production, improving productivity and efficient use of resources and energy [37]. One example is IoT technology, which enables the control of energy savings [38,39] through intelligent energy analysis. Another example is BDAA, which serves to implement real-time monitoring methods, developing optimisation algorithms, and controlling all devices with precision for flexibility of manufacturing resources to achieve productivity gains [40].

- Manufacturing errors: Saez et al. [31] highlight that efforts to improve the integration of Industry 4.0 technologies into manufacturing operations and reduce manufacturing errors must be part of a holistic approach that considers other aspects, such as energy efficiency [31]. Therefore, companies have incorporated maintenance and production scheduling practices to avoid manufacturing errors and control energy efficiency [41]. In addition, [42] propose the development of models that early error detection can reduce energy consumption by turning machines on/off and pausing their operation.

- Product innovation: Improved energy efficiency and more specifically reduced energy consumption can occur as a side effect of actual product and process innovation activities [43,44,45]. In fact, Liang et al. [46] points out that, at present, enterprises in industrial clusters promote the development of innovative products, processes, and technologies to achieve an energy-saving effect. In addition, green product and process innovation are presented as the economic development pattern of enterprises to conserve generate, transform, and make efficient use of energy [32,35,47]. In this way, it will not only contribute to increasing economic output but will also have an impact on facilitating energy demand management [48].

- Decision-making: Among the quality variables of production processes, uncertainty in decision-making is reduced by monitoring energy, equipment, reliability, real-time quality, and multi-criteria decision-making methods [49,50]. Nowadays, most energy solutions are carried out by genetic algorithms with the help of AVAI technology through energy performance analysis, load prediction, anomaly detection, and consumption pattern recognition to support decision-making [51] and reach optimal solutions. On the other hand, the integration of BDAA with AVAI provides greater operational advantage to enterprises [52] and contributes to decision support, product and process innovation, and risk mitigation.

- Process control: This requires advanced continuous monitoring technologies for smart management of both consumers and producers in relation to energy distribution on different scales: from a single appliance to an entire building or even at the village and city level [53]. Thus, among the most relevant consequences of the adoption at machine level are the implementation of control strategies for the efficient use of components and the minimisation of processing time and non-value tasks, such as reducing the energy demand of machines during idle periods [54]. Monitoring and controlling machines can reduce their energy consumption [31].

- RQ1: What is the influence of Industry 4.0 technologies on the variables usually involved in the quality management of production processes?

- RQ2: What is the influence of Industry 4.0 technologies on energy efficiency?

- RQ3: What is the mediation of quality management of production process variables on energy efficiency in the adoption of Industry 4.0 technologies?

3. Research Methodology

3.1. Sample Frame and Variables

3.2. Qualitative Approach

3.3. Quantitative Approach

4. Results

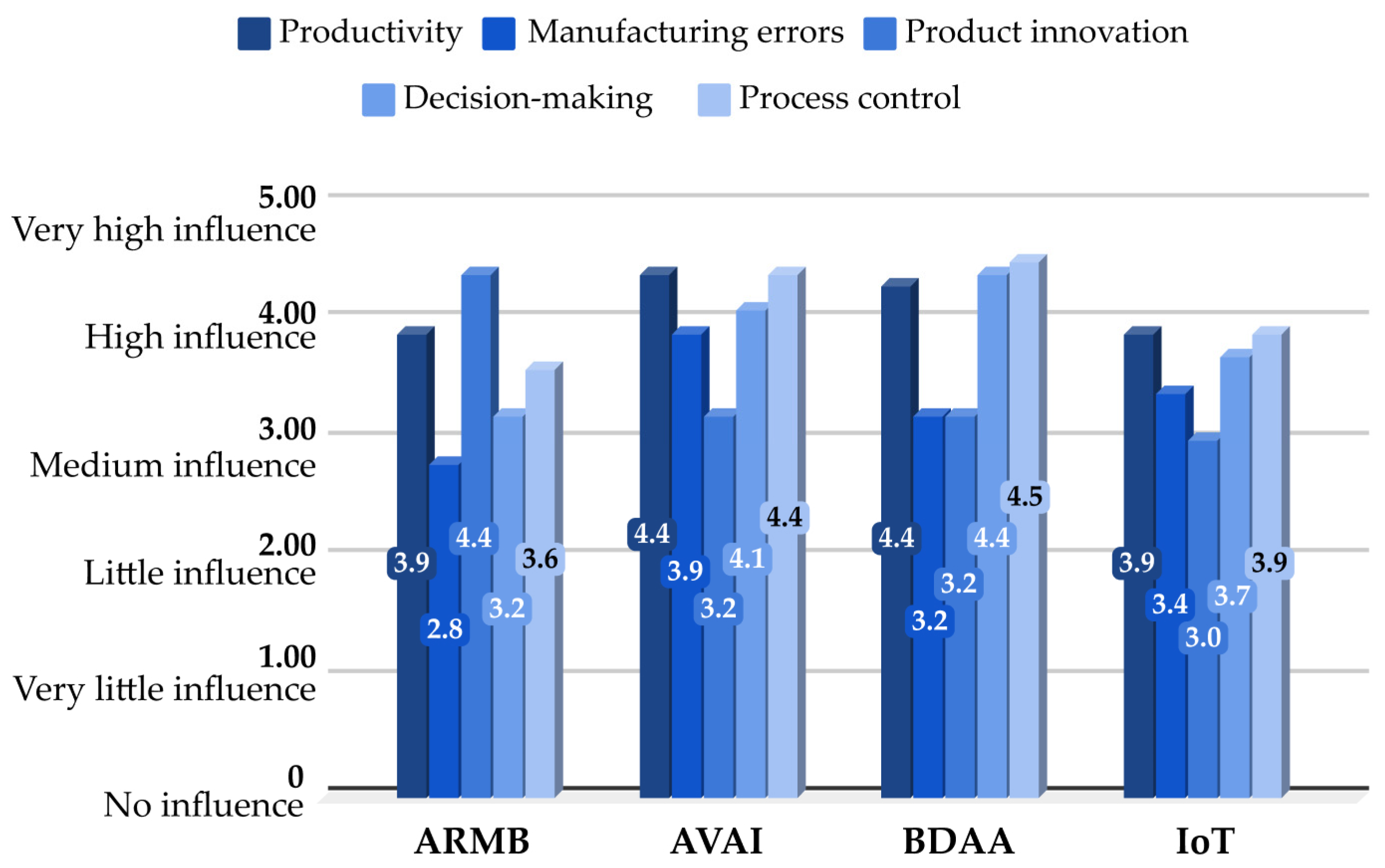

4.1. Influence of the Integration of Industry 4.0 Technologies on the Quality Management of Production Processes

4.2. Influence of the Integration of Industry 4.0 Technologies on Energy Efficiency

4.3. Correlation Analysis between Quality Management of Production Processes Variables and Energy Consumption

4.4. Mediation of Quality Management of Production Processes Variables on the Influence of the Adoption of Industry 4.0 Technologies on Energy Efficiency

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Acronyms

| AMRB | Additive Manufacturing and RoBotics |

| AVAI | Artificial Vision and Artificial Intelligence |

| BDAA | Big Data and Advanced Analytics |

| CE | Circular Economy |

| EEPA | European Enterprise Promotion Awards |

| IoT | Internet of Things |

| OEM | Original Equipment Manufacturer |

| RQ | Research Question |

| WEO | World Energy Outlook |

References

- International Energy Agency o IEA. World Energy Outlook. 2022. Available online: https://www.iea.org/reports/world-energy-outlook-2022/executive-summary (accessed on 16 December 2022).

- United Nations Climate Change. UN Press Release on Climate. Available online: https://www.unep.org/explore-topics/technology/what-we-do/technology-portfolio/technology-portfolio-initiatives (accessed on 22 December 2022).

- European Economic and Social Commission. Fact Sheets on the European Union. Available online: https://www.europarl.europa.eu/factsheets/en/home (accessed on 16 September 2022).

- European Council. Available online: https://www.consilium.europa.eu/en/policies/green-deal/fit-for-55-the-eu-plan-for-a-green-transition/ (accessed on 1 September 2022).

- Herrador, M.; de Jong, W.; Nasu, K.; Granrath, L. Circular economy and zero-carbon strategies between Japan and South Korea: A comparative study. Sci. Total Environ. 2022, 820, 153274. [Google Scholar] [CrossRef]

- Zhang, R.; Fu, Y. Technological progress effects on energy efficiency from the perspective of technological innovation and technology introduction: An empirical study of Guangdong, China. Energy Rep. 2022, 8, 425–437. [Google Scholar] [CrossRef]

- Bleischwitz, R.; Yang, M.; Huang, B.; Xu, X.; Zhou, J.; McDowall, W.; Andrews-Speed, P.; Liu, Z.; Yong, G. The circular economy in China: Achievements, challenges and potential implications for decarbonisation. Resour. Conserv. Recycl. 2022, 183, 106350. [Google Scholar] [CrossRef]

- Huimin, M.; Wu, X.; Yan, L.; Huang, H.; Wu, H.; Xiong, J.; Zhang, J. Strategic plan of “Made in China 2025” and its implementation. In Analyzing the Impacts of Industry 4.0 in Modern Business Environments; Advisory Board; IGI Global: Hershey, PA, USA, 2018; Volume 3, pp. 1–23. [Google Scholar] [CrossRef] [Green Version]

- Baumeister, C.; Korobilis, D.; Lee, T.K. Energy markets and global economic conditions. Rev. Econ. Stat. 2022, 104, 828–844. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Laskurain-Iturbe, I.; Arana-Landín, G.; Landeta-Manzano, B.; Uriarte-Gallastegi, N. Exploring the influence of industry 4.0 technologies on the circular economy. J. Clean. Prod. 2021, 321, 128944. [Google Scholar] [CrossRef]

- World Economic Forum. Global Lighthouse Network: Insights from the Forefront of the Fourth Industrial Revolution. Available online: https://www3.weforum.org/docs/WEF_Global_Lighthouse_Network.pdf (accessed on 12 December 2022).

- European Economic and Social Committee. How the Digital Transformation Can Put Humans at the Centre of Robotics and Automation—Collaboration between Humans and Machines for Better Quality Products and Services Study. Available online: https://www.eesc.europa.eu/sites/default/files/files/qe-01-20-716-en-n.pdf (accessed on 12 December 2022).

- Urban, W.; Łukaszewicz, K.; Krawczyk-Dembicka, E. Application of industry 4.0 to the product development process in project-type production. Energies 2020, 13, 5553. [Google Scholar] [CrossRef]

- Gholami, H.; Hashemi, A.; Lee, J.K.Y.; Abdul-Nour, G.; Salameh, A.A. Scrutinizing state-of-the-art I4. 0 technologies toward sustainable products development under fuzzy environment. J. Clean. Prod. 2022, 377, 134327. [Google Scholar] [CrossRef]

- Neligan, A.; Baumgartner, R.J.; Geissdoerfer, M.; Schöggl, J.P. Circular disruption: Digitalisation as a driver of circular economy business models. Bus. Strategy Environ. 2022, 32, 1–14. [Google Scholar] [CrossRef]

- Harjunkoski, I.; Koziolek, H.; Schulz, D. Industrie 4.0 and international perspective. In Smart Manufacturing: Concepts and Methods; Soroush, M., Baldea, M., Thomas, E., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 59–81. [Google Scholar] [CrossRef]

- Sajadieh, S.M.M.; Son, Y.H.; Noh, S.D. A Conceptual Definition and Future Directions of Urban Smart Factory for Sustainable Manufacturing. Sustainability 2022, 14, 1221. [Google Scholar] [CrossRef]

- Bermeo-Ayerbe, M.A.; Ocampo-Martinez, C.; Diaz-Rozo, J. Data-driven energy prediction modelling for both energy efficiency and maintenance in smart manufacturing systems. Energy 2022, 238, 121691. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Dantas, T.E.; De-Souza, E.D.; Destro, I.R.; Hammes, G.; Rodriguez, C.M.T.; Soares, S.R. How the combination of Circular Economy and Industry 4.0 can contribute towards achieving the Sustainable Development Goals. Sustain. Prod. Consum. 2021, 26, 213–227. [Google Scholar] [CrossRef]

- Zheng, T.; Ardolino, M.; Bacchetti, A.; Perona, M. The applications of Industry 4.0 technologies in manufacturing context: A systematic literature review. Int. J. Prod. Res. 2021, 59, 1922–1954. [Google Scholar] [CrossRef]

- Witkowski, K. Internet of things, big data, industry 4.0—innovative solutions in logistics and supply chains management. Procedia Eng. 2017, 182, 763–769. [Google Scholar] [CrossRef]

- Uriarte-Gallastegi, N.; Landeta-Manzano, B.; Arana-Landin, G.; Laskurain-Iturbe, I. Environmental benefits and weaknesses of additive manufacturing processes in the business sector. Key players influencing the environmental impact of digital manufacturing technologies. DYNA 2020, 95, 587–590. [Google Scholar] [CrossRef]

- Zekić-Sušac, M.; Mitrović, S.; Has, A. Machine learning based system for managing energy efficiency of public sector as an approach towards smart cities. Int. J. Inf. Manag. 2021, 58, 102074. [Google Scholar] [CrossRef]

- Modgil, S.; Sharma, S. Total productive maintenance, total quality management and operational performance: An empirical study of Indian pharmaceutical industry. J. Qual. Maint. Eng. 2016, 22, 353–377. [Google Scholar] [CrossRef]

- Sahoo, S.; Yadav, S. Influences of TPM and TQM practices on performance of engineering product and component manufacturers. In Proceedings of the 17th Global Conference on Sustainable Manufacturing, Sanghai, China, 9 November 2019. [Google Scholar] [CrossRef]

- Boyd, G.A.; Pang, J.X. Estimating the linkage between energy efficiency and productivity. Energy Policy 2000, 28, 289–296. [Google Scholar] [CrossRef]

- De Marchi, V.; Di Maria, E. Sustainability Strategies, Investments in Industry 4.0 and Circular Economy Results. Working Papers, University of Padova, Padova, Italy, 2019. Available online: https://economia.unipd.it/sites/economia.unipd.it/files/20190231_1.pdf (accessed on 19 February 2023).

- Zhang, H.; Chen, S.; Wang, S. Impact of economic growth and labor productivity dispersion on energy intensity in China. Energy 2022, 242, 123004. [Google Scholar] [CrossRef]

- Saez, M.; Barton, K.; Maturana, F.; Tilbury, D.M. Modeling framework to support decision making and control of manufacturing systems considering the relationship between productivity, reliability, quality, and energy consumption. J. Manuf. Syst. 2022, 62, 925–938. [Google Scholar] [CrossRef]

- Huang, Y.C.; Chen, C.T. Exploring institutional pressures, firm green slack, green product innovation and green new product success: Evidence from Taiwan’s high-tech industries. Technol. Forecast. Soc. Chang. 2022, 174, 121196. [Google Scholar] [CrossRef]

- Atalla, T.; Bean, P. Determinants of energy productivity in 39 countries: An empirical investigation. Energy Econ. 2017, 62, 217–229. [Google Scholar] [CrossRef]

- Khraiche, M.; Kutlu, L.; Mao, X. Energy efficiencies of European countries. Appl. Econ. 2022, 54, 2694–2706. [Google Scholar] [CrossRef]

- Paramati, S.R.; Shahzad, U.; Doğan, B. The role of environmental technology for energy demand and energy efficiency: Evidence from OECD countries. Renew. Sustain. Energy Rev. 2022, 153, 111735. [Google Scholar] [CrossRef]

- Chen, H.; Shi, Y.; Xu, M.; Zhao, X. Investment in renewable energy resources, sustainable financial inclusion and energy efficiency: A case of US economy. Resour. Policy 2022, 77, 102680. [Google Scholar] [CrossRef]

- Dyba, W.; De Marchi, V. On the road to Industry 4.0 in manufacturing clusters: The role of business support organisations. Compet. Rev. Int. Bus. J. 2022, 32, 760–776. [Google Scholar] [CrossRef]

- Hossein Motlagh, N.; Mohammadrezaei, M.; Hunt, J.; Zakeri, B. Internet of Things (IoT) and the energy sector. Energies 2020, 13, 494. [Google Scholar] [CrossRef] [Green Version]

- Baidya, S.; Potdar, V.; Ray, P.P.; Nandi, C. Reviewing the opportunities, challenges, and future directions for the digitalization of energy. Energy Res. Soc. Sci. 2021, 81, 102243. [Google Scholar] [CrossRef]

- Da Silva, F.S.T.; da Costa, C.A.; Crovato, C.D.P.; da Rosa Righi, R. Looking at energy through the lens of Industry 4.0: A systematic literature review of concerns and challenges. Comput. Ind. Eng. 2020, 143, 106426. [Google Scholar] [CrossRef]

- Ahmad, T.; Madonski, R.; Zhang, D.; Huang, C.; Mujeeb, A. Data-driven probabilistic machine learning in sustainable smart energy/smart energy systems: Key developments, challenges, and future research opportunities in the context of smart grid paradigm. Renew. Sustain. Energy Rev. 2022, 160, 112128. [Google Scholar] [CrossRef]

- Yang, L.; Liu, Q.; Xia, T.; Ye, C.; Li, J. Preventive Maintenance Strategy Optimization in Manufacturing System Considering Energy Efficiency and Quality Cost. Energies 2022, 15, 8237. [Google Scholar] [CrossRef]

- Gerstlberger, W.; Præst Knudsen, M.; Stampe, I. Sustainable development strategies for product innovation and energy efficiency. Bus. Strategy Environ. 2014, 23, 131–144. [Google Scholar] [CrossRef]

- Da Rosa, F.S.; Lunkes, R.J.; Mendes, A.C. Environmental management accounting and innovation in water and energy reduction. Environ. Monit. Assess. 2020, 192, 621. [Google Scholar] [CrossRef]

- Prokop, V.; Hojnik, J.; Zapletal, D.; Žižmond, E. On the path to sustainable development: The nexus among owner gender diversity, energy management, and firms’ innovation radicalness. Bus. Strategy Environ. 2022, 1–17. [Google Scholar] [CrossRef]

- Liang, Y.; Hao, X. Can the Agglomeration of New Energy Industries Improve Environmental Efficiency? Evidence from China. Sustainability 2022, 14, 8961. [Google Scholar] [CrossRef]

- Song, M.; Wang, S.; Zhang, H. Could environmental regulation and R&D tax incentives affect green product innovation? J. Clean. Prod. 2020, 258, 120849. [Google Scholar] [CrossRef]

- Amin, M.; Zhou, S.; Safi, A. The nexus between consumption-based carbon emissions, trade, eco-innovation, and energy productivity: Empirical evidence from N-11 economies. Environ. Sci. Pollut. Res. 2022, 29, 39239–39248. [Google Scholar] [CrossRef]

- Telukdarie, A.; Buhulaiga, E.; Bag, S.; Gupta, S.; Luo, Z. Industry 4.0 implementation for multinationals. Process Saf. Environ. Prot. 2018, 118, 316–329. [Google Scholar] [CrossRef]

- Liang, Y.; Ju, Y.; Martínez, L.; Dong, P.; Wang, A. A multi-granular linguistic distribution-based group decision making method for renewable energy technology selection. Appl. Soft Comput. 2022, 116, 108379. [Google Scholar] [CrossRef]

- Chen, X.; Geyer, P. Machine assistance in energy-efficient building design: A predictive framework toward dynamic interaction with human decision-making under uncertainty. Appl. Energy 2022, 307, 118240. [Google Scholar] [CrossRef]

- Razavi Hajiagha, S.H.; Amoozad Mahdiraji, H.; Moradi, S.; Garza-Reyes, J.A.; Alaei, S. Unveiling the relation between the challenges and benefits of operational excellence and industry 4.0: A hybrid fuzzy decision-making approach. TQM J. 2022. [Google Scholar] [CrossRef]

- Iqbal, N.; Kim, D.H. Iot task management mechanism based on predictive optimization for efficient energy consumption in smart residential buildings. Energy Build. 2022, 257, 111762. [Google Scholar] [CrossRef]

- Frigerio, N.; Matta, A.; Lin, Z. Pareto Front Analysis of Buffer-based Energy Efficient Control for Machines in Serial Flow Lines. In Proceedings of the IEEE 21st Mediterranean Electrotechnical Conference (MELECON), Palermo, Italy, 14–16 June 2022. [Google Scholar] [CrossRef]

- European Commission. European Enterprise Promotion Awards. 2019. Available online: https://single-market-economy.ec.europa.eu/smes/supporting-entrepreneurship/european-enterprise-promotion-awards_en (accessed on 18 July 2022).

- Cambra-Fierro, J. Análisis de las Relaciones Proveedor-Cliente en el Contexto de los Mercados Industriales: Un Estudio Empírico en las Denominaciones de Origen (DO) Vinícolas de Aragón. Ph.D. Thesis, Universidad de Zaragoza, Zaragoza, Spain, 2004. [Google Scholar]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research and Applications: Design and Methods, 6th ed.; Sage: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Gummesson, E. Qualitative research in management: Addressing complexity, context and persona. Manag. Decis. 2006, 44, 167–179. [Google Scholar] [CrossRef]

- Patton, M.Q. Qualitative Research Evaluation Methods: Integrating Theory and Practice, 4th ed.; Sage: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Glaser, B.G.; Strauss, A.L. Strategies for qualitative research. In Discovery of Grounded Theory, 1st ed.; Routledge: London, UK, 2017; pp. 3–6. [Google Scholar] [CrossRef]

- Miles, M.B.; Huberman, A.M.; Saldana, J. Qualitative Data Analysis: A Methods Sourcebook, 3rd ed.; Sage: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Cohen, P.; West, S.G.; Aiken, L.S. Applied Multiple Regression/Correlation Analysis for the Behavioral Sciences; Psychology Press: London, UK, 2014. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Organ, D.W. Self-reports in organizational research: Problems and prospects. J. Manag. 1986, 12, 531–544. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Structural Equation Models with Unobservable Variables and Measurement error: Algebra and Statistics. J. Mark. Res. 1981, 18, 382–388. [Google Scholar] [CrossRef]

- Robinson, J.P. Criteria for Scale Selection and Evaluation. In Measures of Personality and Social Psychological Attitudes, 1st ed.; Academic Press: New York, NY, USA, 1991; pp. 1–16. [Google Scholar]

- Mason, C.H.; Perreault, W.D., Jr. Collinearity, power, and interpretation of multiple regression analysis. J. Mark. Res. 1991, 28, 268–280. [Google Scholar] [CrossRef]

- Binda, N.U.; Balbastre-Benavent, F. Investigación cuantitativa e investigación cualitativa: Buscando las ventajas de las diferentes metodologías de investigación. Rev. Cienc. Económicas 2013, 31, 179–187. [Google Scholar] [CrossRef]

- Khedhaouria, A.; Jamal, A. Sourcing knowledge for innovation: Knowledge reuse and creation in project teams. J. Knowl. Manag. 2015, 19, 932–948. [Google Scholar] [CrossRef]

- Awan, U.; Arnold, M.G.; Gölgeci, I. Enhancing green product and process innovation: Towards an integrative framework of knowledge acquisition and environmental investment. Bus. Strategy Environ. 2021, 30, 1283–1295. [Google Scholar] [CrossRef]

- Campbell, T.; Williams, C.; Ivanova, O.; Garrett, B. Could 3D Printing Change the World? Technologies, Potential, and Implications of Additive Manufacturing, 1st ed.; Atlantic Council: Washington, DC, USA, 2011; Volume 3. [Google Scholar]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef] [Green Version]

- Oettmeier, K.; Hofmann, E. Additive manufacturing technology adoption: An empirical analysis of general and supply chain-related determinants. J. Bus. Econ. 2017, 87, 97–124. [Google Scholar] [CrossRef]

- Prause, G.; Atari, S. On sustainable production networks for industry 4.0. Entrep. Sustain. Issues 2017, 4, 421–431. [Google Scholar] [CrossRef]

- Kellens, K.; Baumers, M.; Gutowski, T.G.; Flanagan, W.; Lifset, R.; Duflou, J.R. Environmental dimensions of additive manufacturing: Mapping application domains and their environmental implications. J. Ind. Ecol. 2017, 21 (Suppl. S1), S49–S68. [Google Scholar] [CrossRef] [Green Version]

- Rejeski, D.; Zhao, F.; Huang, Y. Research needs and recommendations on environmental implications of additive manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Pavlo, S.; Fabio, C.; Hakim, B.; Mauricio, C. 3D-Printing Based Distributed Plastic Recycling: A Conceptual Model for Closed-Loop Supply Chain Design. In Proceedings of the IEEE International Conference on Engineering, Technology and Innovation, Stuttgart, Germany, 17–20 June 2018. [Google Scholar] [CrossRef]

- Sauerwein, M.; Doubrovski, E.L. Local and recyclable materials for additive manufacturing: 3D printing with mussel shells. Mater. Today Commun. 2018, 15, 214–217. [Google Scholar] [CrossRef]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused particle fabrication 3-D printing: Recycled materials’ optimization and mechanical properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef] [Green Version]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recycle bot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef] [Green Version]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Bahrin, M.A.K.; Othman, M.F.; Azli, N.H.N.; Talib, M.F. Industry 4.0: A review on industrial automation and robotic. J. Teknol. 2016, 78, 137–143. [Google Scholar] [CrossRef] [Green Version]

- Waibel, M.W.; Steenkamp, L.P.; Moloko, N.; Oosthuizen, G.A. Investigating the effects of smart production systems on sustainability elements. Procedia Manuf. 2017, 8, 731–737. [Google Scholar] [CrossRef]

| [Ref.] Authors (Year) | Research Gap | Methodology-Data | Main Contributions |

|---|---|---|---|

| [23] Witkowski (2017) | Innovation in production logistics with Industry 4.0 technologies | Analysis of 900 strategic, inter-company and high value innovation projects from Europe, USA and China | Industry 4.0 technologies contribute to technical and technological product innovation. |

| [20] Kamble et al. (2018) | Sustainability of Industry 4.0 technologies based on process integration, process control, innovation and product quality | Literature review of 85 papers | Industry 4.0 contributes to sustainable benefits, process safety, energy efficiency and productivity, energy generation and distribution. |

| [40] da Silva et al. (2020) | Industry 4.0 technologies for improving productivity, smart factory performance and production, self-decision, and machine control | Literature review of 2519 papers | The combination of Industry 4.0 technologies and cloud computing are necessary to process data related to consumption, savings, and energy efficiency. |

| [14] Urban et al. (2020) | Possibilities of applying Industry 4.0 concepts and tools to the product development process. | Single case study | Innovations based on AR/VR technologies optimize energy efficiency up to 30%. |

| [38] Hossein et al. (2020) | Industry 4.0 solutions in the energy sector: Energy supply, transmission, distribution, and energy demand. | Literature review of 168 papers | The IoT in the energy supply chain and the advantages of IoT-based energy management systems increase energy efficiency. |

| [44] da Rosa et al. (2020) | Product and process innovation in reducing energy consumption. | Analysis of 116,962 companies from 55 sectors. | Innovative products and process innovation leads to a reduction in energy consumption. |

| [21] Dantas et al. (2021) | Analysis of CE and Industry 4.0 technologies in the contribution to the implementation of sustainable practices of the 2030 Agenda | Literature review of 50 papers | Better process control increases flexibility, production agility and, in turn, organisational agility. |

| [11] Laskurain-Iturbe et al. (2021) | Influence of Industry 4.0 technologies on the circular economy | Multiple case study of 27 projects of Industry 4.0 technologies | Industry 4.0 technologies offer companies solutions to reduce consumption of energy.Important differences between the potential impacts of each technology. |

| [25] Zekić-Sušac et al. (2021) | Integration of BD and machine learning into an intelligent system for energy efficiency management | Study of 17,000 public buildings | The combination of AI, BD and IoT show potential for smart energy management and energy efficiency. |

| [48] Amin et al. (2022) | Energy consumption, energy productivity and eco-innovation | Data available from 1995 to 2019 | The use of advanced technology increases energy productivity and in turn reduces consumption. |

| [51] Chen et al. (2022) | Reducing uncertainty in decision making, reduce uncertainty and achieve energy efficiency. | 19,725,379-energy performance of buildings data records. | Increased use of machines based on predictive processes contributes to less uncertainty at the start of energy efficient design. |

| [52] Hajiagha et al. (2022) | Benefits of Industry 4.0 technologies for decision making | 12 experts participated with the DEMATEL (Decision Making Trial and Evaluation Laboratory) methodology. | Industry 4.0 technologies contribute to operational excellence, continuously improving processes to achieve optimal performance, and improving the energy efficiency of equipment and machinery. |

| [34] Khraiche et al. (2022) | Energy efficiency policies and targets. | Study of 44 countries in Europe from 1990 to 2015 | Between 1999 and 2015, most European countries experienced a reduction in energy efficiency as the adoption of technology involved |

| [16] Neligan et al. (2022) | Digitization as a potential force towards the circularity of products and more energy efficient | Multiple case study: 599 manufacturing companies and 296 industrial service providers. | Companies improve resource efficiency at different stages of a product’s life cycle by: driving innovation, digitisation and circularity together with financial analysis. |

| [18] Sajadieh et al. (2022) | Manufacturing paradigm of smart factory technologies and urban manufacturing | Multiple case study: 9 smart factories. | Conceptual definition of urban smart factory (SF): A human-centric factory with four pillars: personalization, sustainability, resilience, and SF. |

| Technology—Industry 4.0 Project | Source of Evidence † |

| AMRB 1―Design and manufacture of complex metal parts for the automotive industry. | I(1)/V(2)/D(15) |

| AMRB 2―Obtain 3D models of a very specific piece used in an oil refinery. | I(3)/V(0)/D(7) |

| AMRB 3―Development of thermoplastic automotive components. | I(1)/V(1)/D(7) |

| AMRB 4―3D printing software that corrects anisotropy. | I(1)/V(1)/D(4) |

| AMRB 5―Development of new AM tools for industrial processes and metallic aeronautical components assembly. | I(1)/V(0)/D(3) |

| AMRB 6―Manufacture of prototypes for its geometric, dimensional, mechanical and structural validation. | I(2)/V(0)/D(6) |

| AMRB 7―Metal AM in manufacturing process. | I(1)/V(1)/D(7) |

| AMRB 8―Surface treatments to avoid light transmission losses in optical measuring equipment in aggressive environments. | I(2)/V(1)/D(3) |

| AMRB 9―Technological scouting on AM technologies. | I(1)/V(1)/D(7) |

| AMRB 10―Design and manufacture of 3D metal printers based on SLM technology. | I(2)/V(1)/D(5) |

| AMRB 11―Design, manufacture and produce custom, trustworthy & connected 3D printers. | I(2)/V(0)/D(6) |

| AVAI 1―Robot for predictive maintenance improvement in automotive sector. | I(1)/V(2)/D(4) |

| AVAI 2―Development and construction of an AV prototype for non-contact measurement of sheet thickness in areas susceptible to stretch-type defects. | I(1)/V(2)/D(7) |

| AVAI 3―Sheet metal quality control in assembly process. | I(2)/V(1)/D(14) |

| AVAI 4―Development of an automatic and continuous arrow measurement system with artificial vision. | I(3)/V(1)/D(7) |

| AVAI 5―Process compliance control in manual position. | I(2)/V(0)/D(10) |

| AVAI 6―AI algorithms to reduce energy consumption of industrial plants. | I(2)/V(0)/D(5) |

| AVAI 7―Recognition of broken machines using sound. | I(1)/V(0)/D(6) |

| AVAI 8―Digital transformation into business opportunities. | I(1)/V(0)/D(5) |

| AVAI 9―Improve the energy management in buildings with high savings and comfort levels. | I(2)/V(0)/D(3) |

| AVAI 10―AI prototyping for non-contact measurement of sheet thickness in areas susceptible to stretch-type defects | I(1)/V(1)/D(6) |

| AVAI 11―Sheet metal quality control in assembly process. | I(3)/V(1)/D(4) |

| AVAI 12―Development of an automatic and continuous arrow measurement system with artificial vision. | I(2)/V(1)/D(5) |

| AVAI 13―Process compliance control in manual position. | I(2)/V(1)/D(6) |

| AVAI 14―AI algorithms to reduce energy consumption of industrial plants. | I(1)/V(1)/D(6) |

| AVAI 15―Intelligent reading of consumption meters, for the extraction of different fields of interest from an image through mobile devices. | I(3)/V(1)/D(7) |

| AVAI 16―AI-powered HMI and assistant to augment workers in the digital factory. | I(2)/V(0)/D(6) |

| AVAI 17―Industrial AI solutions for transforming process data into value. | I(3)/V(2)/D(5) |

| AVAI 18―Replacing manned helicopters with long-range drones. | I(2)/V(1)/D(4) |

| AVAI 19―Build a predictive machine failure analytics model based on the Halerium tool. | I(2)/V(2)/D(7) |

| AVAI 20―Data analysis via AI algorithms in converters for preventive maintenance, sizing of components, calculating operational limit | I(1)/V(0)/D(3) |

| AVAI 21―Robotic process automation through the development and design of interfaces based on AI. | I(3)/V(0)/D(7) |

| AVAI 22―Simplify complex processes and automate what required humans with help of natural language processing and AI. | I(2)/V(2)/D(6) |

| AVAI 23―Personal data anonymization software based on AI. | I(1)/V(1)/D(3) |

| AVAI 24―Digitising the most distributed infrastructure on earth, power lines. | I(3)/V(0)/D(4) |

| BDAA 1―Help automotive companies to make smart decisions based on their own data. | I(3)/V(2)/D(7) |

| BDAA 2―Identify patterns of behaviour in telecom operator’s mobile customers in order to optimize investments in its network. | I(2)/V(1)/D(4) |

| BDAA 3―Big data and machine learning to chrome plated processes at auto parts manufacturer. | I(3)/V(0)/D(5) |

| BDAA 4―Optimize manufacturing processes at airplane engines manufacturer. | I(2)/V(0)/D(7) |

| BDAA 5―Data analytics project aimed at creating value for operator’s customers. | I(3)/V(2)/D(6) |

| BDAA 6―Analysis of the vegetation around electrical infrastructure using nanosatellites images. | I(2)/V(0)/D(3) |

| BDAA 7―Special programming of the Berckhoff automation tool in order to acquire the capacity of introduce owned models. | I(1)/V(2)/D(6) |

| BDAA 8―Warehouse management optimization. | I(2)/V(2)/D(5) |

| BDAA 9―Validation of approximation through neural networks to Recovery Time Objective in process units. | I(1)/V(1)/D(5) |

| BDAA 10―Modelling and optimization of manufacturing processes based on advanced analytical techniques. | I(3)/V(0)/D(4) |

| BDAA 11―Sensorization pilot project to validate the potential and maturity of the technology. | I(1)/V(0)/D(3) |

| BDAA 12―Transform data captured from multiple sources (SCADA, ERP, BI) into valuable information for decision making. | I(3)/V(0)/D(6) |

| BDAA 13―Asset health information platform for early detection of component defects that cause failures. | I(2)/V(1)/D(3) |

| BDAA 14―Implementation of an intelligent system for production planning. | I(1)/V(0)/D(5) |

| BDAA 15―Software platform to connect safely machines, data and analysis for operating efficiency. | I(2)/V(0)/D(5) |

| BDAA 16―Implementation of a technological infrastructure that allows relating process parameters with results in the product. | I(1)/V(2)/D(4) |

| IOT 1―Operational intelligence for wind turbines, met masts, solar plants and IoT devices. | I(1)/V(0)/D(6) |

| IOT 2―Help clients build their own devices by connecting them with sensors and wireless communicators. | I(1)/V(1)/D (6) |

| IOT 3―Oil circuit monitoring solution for compressors and hydraulic systems (lifting table) in automotive sector. | I(3)/V(2)/D(4) |

| IOT 4―Cloud platform to monitor and control company processes. | I(1)/V(1)/D(3) |

| IOT 5―Predictive maintenance of infrastructures based on a scalable assistance system. | I(3)/V(1)/D(6) |

| IOT 6―Project focused on the asset management field. | I(3)/V(0)/D(5) |

| IOT 7―Optimising preventive maintenance of a cable-processing machine. | I (2)/V(1)/D(6) |

| IOT 8―Connection, control and management of the forming machinery area and its possible connection with the current ERP. | I(2)/V(0)/D(7) |

| IOT 9―Automatic output record of measurement equipment and tools from the warehouse with RFID technology. | I(1)/V(1)/D(5) |

| IOT 10―Workers’ safety system, capable of detecting falls. Risk assessment of different jobs. | I(2)/V(2)/D(4) |

| IOT 11―Ergonomic evaluation in real time. | I(3)/V(1)/D(3) |

| IOT 12―Monitoring of production cells in industrial plants. | I(2)/V(1)/D(7) |

| IOT 13―Management of the push bench gearboxes for controlling aspects like the assembly of them in the bench or the tones laminated by each one. | I(2)/V(2)/D(5) |

| IOT 14―Industrial asset tracking and forklift fleet analytics. | I(2)/V(1)/D(3) |

| IOT 15―Development of software solution for automation systems. | I(1)/V(2)/D(6) |

| IOT 16―VCSim simulation tool in a set of distributed and interconnected parts. | I(2)/V(0)/D(7) |

| IOT 17―Indoor geolocation and analysis of industrial assets. | I(2)/V(2)/D(4) |

| IOT 18―Monitoring any parameter in energy-intensive industry easily and costly-effectively using waste heat as a source of energy. | I(3)/V(0)/D(4) |

| IOT 19―Surface treatments to avoid light transmission losses in optical measuring equipment in aggressive environments. | I(3)/V(0)/D(4) |

| IOT 20―Implementation of corporate electric mobility solutions. | I(1)/V(1)/D(6) |

| IOT 21―Process automation & asset digitalization through RFID. | I(1)/V(1)/D(4) |

| Group | Variable | Type | Scale |

|---|---|---|---|

| Industry 4.0 Technologies | AMRB | Dummy | 0 = No 1 = Yes |

| AVAI | |||

| BDAA | |||

| IoT | |||

| Quality management of production processes | Productivity Manufacturing errors Product innovation Decision-making Process control | Likert | 0 = No influence 1 = Very little influence 2 = Little influence 3 = Medium influence 4 = High influence 5 = Very high influence |

| Energy efficiency | Energy efficiency | Likert | 0 = No influence 1 = Improv. less than 5% 2 = Improv. between 5–10% 3 = Improv. between 15–20% 4 = Improv. between 20–25% 5 = Improv. more than 25% |

| Research Phase | ||||

|---|---|---|---|---|

| Design | Case Selection | Data Collection | Data Analysis | |

| Reliability | Develop case study protocols based on the literature. | Selection based on theoretical sampling (Yin, 2017). | Provide the script to all interviewees prior to the interview. | Third-party review of the processes followed in the research process (Lincoln and Guba, 1985). |

| Develop a case study database (with all available documents: interview transcripts, archives, etc.) (Lincoln and Guba, 1985). | ||||

| Internal validity | Establish the theoretical framework prior to data analysis (Eisenhardt, 1989; Yin, 2017). | Sampling criteria in the case study protocol (Yin, 2017). | Records of factors that could serve as alternative explanations (Miles et al., 2018) | Pattern matching (matching patterns identified in the work of other authors) (Miles et al., 2018). |

| Triangulation techniques: multiple sources of evidence and data collection methods (Lincoln and Guba, 1985). | ||||

| Construct validity | The use of multiple sources of evidence: interviews, documents, artefacts and others, to protect against researcher bias (Flick, 1992; Peräkylä, 1997). | N/A | Peer review of transcripts and drafts (LeCompte and Goetz, 1982). | Chain of evidence (verbatim transcripts of interviews and notes from company observations to cross-check data from particular sources of evidence) (Griggs 1987; Hirschman, 1986). |

| Let key informants and other supporting researchers review the data analysis and the draft report findings (Yin, 2017). | ||||

| External validity | Justification for the selection of case studies. | Description of business cases and contextual factors of the case study (Yin, 2017). | N/A | Not Applicable |

| Defining the scope and limits at the research design stage (Marshall and Rossman, 1989). | ||||

| Productivity | Manufacturing Errors | Product Innovation | Decision Making | Process Control | ||

|---|---|---|---|---|---|---|

| Energy efficiency | Index | 0.249 | 0.229 | −0.060 | 0.314 | 0.371 |

| Sig. | 0.035 | 0.053 | 0.617 | 0.007 | 0.001 |

| Step | Model Information | AMRB | AVAI | BDAA | Product Innovation | Decision-Making | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R2 | F | Sig. | Error | β | Sig. | β | Sig. | β | Sig. | β | Sig. | Β | Sig. | |

| 1st | 0.623 | 40.674 | <0.001 | 2.13 | 0.343 | <0.001 | 0.536 | <0.001 | 0.483 | <0.001 | - | - | - | - |

| 2nd | 0.838 | 75.221 | <0.001 | 1.4 | 0.096 | 0.122 | 0.056 | 0.425 | 0.073 | 0.258 | 0.064 | 0.607 | 0.761 | <0.001 |

| 1st Step | ||||||||||

| Tech. | Model Information | Industry 4.0 Technology | Product Innovation | Decision-Making | ||||||

| R2 | F | Sig. | Error | β | Sig. | β | Sig. | Β | Sig. | |

| AMRB | 0.118 | 9.484 | 0.003 | 3.29 | 0.343 | 0.003 | - | - | - | - |

| AVAI | 0.277 | 28.617 | <0.001 | 2.95 | 0.536 | 0.001 | - | - | - | - |

| BDAA | 0.234 | 21.650 | <0.001 | 3.06 | 0.483 | 0.001 | - | - | - | - |

| IoT | 0.217 | 19.734 | <0.001 | 3.09 | 0.466 | 0.001 | - | - | - | - |

| 2nd Step | ||||||||||

| AMRB | 0.837 | 126.041 | <0.001 | 1.39 | 0.070 | 0.215 | 0.085 | 0.483 | 0.819 | <0.001 |

| AVAI | 0.835 | 122.747 | <0.001 | 1.41 | −0.040 | 0.945 | 0.155 | 0.158 | 0.779 | <0.001 |

| BDAA | 0.836 | 123.629 | <0.001 | 1.41 | 0.036 | 0.650 | 0.160 | 0.145 | 0.754 | <0.001 |

| IoT | 0.836 | 123.322 | <0.001 | 1.41 | 0.029 | 0.601 | 0.152 | 0.163 | 0.765 | <0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arana-Landín, G.; Uriarte-Gallastegi, N.; Landeta-Manzano, B.; Laskurain-Iturbe, I. The Contribution of Lean Management—Industry 4.0 Technologies to Improving Energy Efficiency. Energies 2023, 16, 2124. https://doi.org/10.3390/en16052124

Arana-Landín G, Uriarte-Gallastegi N, Landeta-Manzano B, Laskurain-Iturbe I. The Contribution of Lean Management—Industry 4.0 Technologies to Improving Energy Efficiency. Energies. 2023; 16(5):2124. https://doi.org/10.3390/en16052124

Chicago/Turabian StyleArana-Landín, Germán, Naiara Uriarte-Gallastegi, Beñat Landeta-Manzano, and Iker Laskurain-Iturbe. 2023. "The Contribution of Lean Management—Industry 4.0 Technologies to Improving Energy Efficiency" Energies 16, no. 5: 2124. https://doi.org/10.3390/en16052124