Energy Costs Reduction for Dispersion Using a Jet-Slot Type Milk Homogenizer

Abstract

:1. Introduction

- −

- The presence of contact of milk emulsion with air, which leads to foaming, i.e., worsening the quality of the finished product;

- −

- The implementation of the supply of the fat phase through channels of small diameter, which reduces the indicators of the reliability of the disperser.

- −

- The ability to feed cream to the high-speed flow of skim milk in the form of a jet of small diameter, which will allow the flow to effectively act on the cream, ensuring the destruction of fat globules to the values justified by the requirements of regulatory documentation;

- −

- The possibility of increasing productivity by increasing the volume of cream entering the homogenizer, which is achieved by changing the area of the slot channels (which also prevents equipment failure associated with rapid obliteration of the internal surfaces at the point of fat phase supply).

- −

- To find analytical dependences that link the power and specific energy consumption with the productivity of the homogenizer, the diameter of the annular gap, the fat content of normalized milk and cream, and the speed of cream supply;

- −

- To determine the effect on the energy consumption of the fat content of normalized milk and cream and to find a rational value of the fat content of cream used during normalization and homogenization in a jet-slot homogenizer of milk;

- −

- To develop a methodology and conduct experimental studies on the dependence of the developed homogenizer power on its performance, to check the adequacy of the analytically obtained data.

2. Materials and Methods

- −

- The excess pressure of the supply of skim milk (1–3 MPa);

- −

- The width of the annular gap (0.1–0.9 mm);

- −

- The speed of cream (5–110 m/s);

- −

- The fat content of cream (10–50%).

- −

- The duration of the experiment which was determined by a stopwatch SOPR-2a-2-010 (Russian Federation), with an absolute error of no more than 0.2 s;

- −

- The weight of milk which was determined on an electronic scale SCL-150 (Taiwan), with an absolute error of no more than 5 mg;

- −

- The temperature of the skim phase and cream which was determined by a thermometer with an interchangeable cone, with an absolute error of no more than 0.5 °C.

- −

- The power using a McBrain VA318 electrical measuring wattmeter with an absolute error of 0.1 V.

3. Results

3.1. Results of Analytical Studies of Power and Specific Energy Consumption in a Jet-Slot Milk Homogenizer

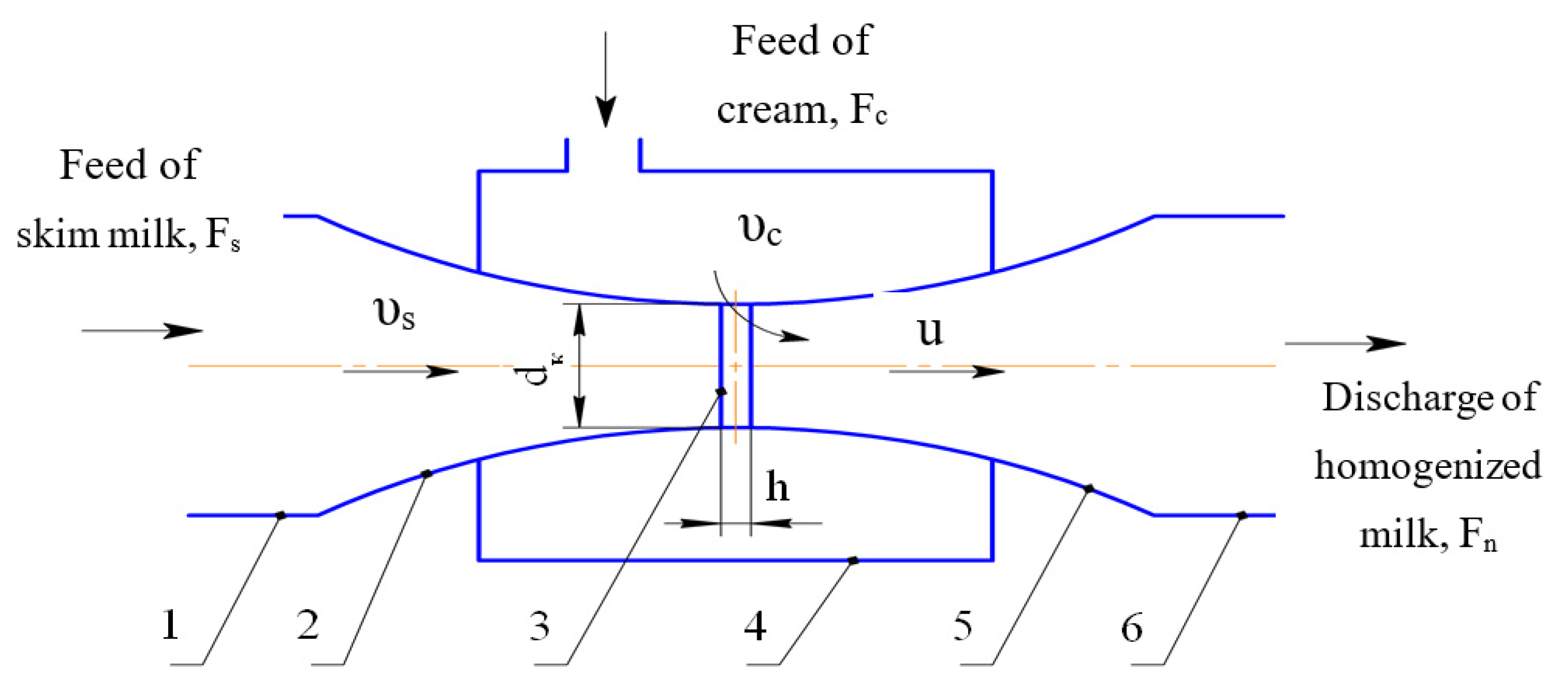

- μs, μc—respectively, the flow rates of the confusor at the place of the largest narrowing and the annular gap at the place where the cream is fed;

- dk—diameter of the confusor at the point of greatest narrowing, mm.

3.2. Experimental Study of Power in a Jet-Slot Homogenizer of Milk

4. Discussion

- −

- To determine the optimal parameters of the developed homogenizer: a high degree of dispersion with minimal energy consumption;

- −

- To establish the effects of obliteration and experimentally determine the real coefficient of consumption of the annular gap. After conducting such studies, it will be possible to develop technical documentation for the introduction of the experimental homogenizer into production.

5. Conclusions

- Analytical dependences have been found that relate the power and specific energy consumption to the performance of the homogenizer, the diameter of the annular gap, the fat content of normalized milk and cream, and the rate of cream supply. These dependences are the basis for creating the theory of jet dispersion of microemulsions. The theoretical significance of the obtained results lies in the improvement of the theory of hydrodynamic dispersion of milk emulsions.

- The rational value of the fat content of the cream used for homogenization is analytically substantiated. The nature of the obtained analytical dependences indicates a significant increase in the energy consumption of dispersion when using cream with a fat content of less than 20%, which is associated with an increase in the volume of cream fed through the annular gap during the normalization-homogenization of milk. To minimize the specific energy consumption of the process, their fat content should be higher than 20%. In the experimental homogenizer, it is possible to carry out the process of fat normalization simultaneously with homogenization. In this case, the fat content of cream can be less than 20% when producing milk with a fat content of less than 2%.

- Experimental studies had been conducted, the results of which confirm the adequacy of the data obtained in the course of analytical studies. Thus, the deviations of the power indicators of the developed jet-slot homogenizer of milk differ from the data obtained in the course of analytical studies by not more than 10%. Thus, the developed analytical dependences can be used to calculate industrial samples of jet milk homogenizers. The practical significance of the conducted research consists of substantiating the possibility of a 5–7-fold reduction in energy costs when implementing a jet-slot homogenizer of milk at enterprises in the milk processing industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fialkova, E.A. Gomogenizatsiya. Novyj Vzglyad; Monografiya-spravochnik. SPb.; GIORD: St. Petersburg, Russia, 2006; p. 392. [Google Scholar]

- Dhankhar, P. Homogenization fundamentals. IOSR J. Eng. 2014, 4, 1–8. [Google Scholar] [CrossRef]

- Innings, F.; Trägårdh, C. Visualization of the drop deformation and break-up process in a high pressure homogenizer. Chem. Eng. Technol. 2005, 28, 882–891. [Google Scholar] [CrossRef]

- Huppertz, T. Homogenization of Milk Other Types of Homogenizer (High-Speed Mixing, Ultrasonics, Microfluidizers, Membrane Emulsification). In Encyclopedia of Dairy Sciences, 2nd ed.; Academic Press: Cambridge, MA, USA, 2011; pp. 761–764. [Google Scholar] [CrossRef]

- Tartar, L. The General Theory of Homogenization; Lecture Notes; Springer: Berlin/Heidelberg, Germany, 2009; p. 470. [Google Scholar]

- Samoichuk, K.; Zahorko, N.; Oleksiienko, V.; Petrychenko, S. Generalization of Factors of Milk Homogenization. In Modern Development Paths of Agricultural Production; Springer: Cham, Switzerland, 2019; pp. 192–198. [Google Scholar] [CrossRef]

- Samojchuk, K.O.; Koval’ov, O.O. Mekhanizmi disperguvannya zhirovikh kul’ok v struminnomu gomogenizatori moloka. Nauk. Pr. ONAKhT 2016, 80, 103–107. [Google Scholar] [CrossRef]

- Ciron, C.I.E.; Gee, V.L.; Kelly, A.L.; Auty, M.A.E. Comparison of the effects of high-pressure microfluidization and conventional homogenization of milk on particle size, water retention and texture of non-fat and low-fat yoghurts. Int. Dairy J. 2010, 20, 314–320. [Google Scholar] [CrossRef]

- Jiang, B.; Shi, Y.; Lin, G.; Kong, D.; Du, J. Nanoemulsion prepared by homogenizer: The CFD model research. J. Food Eng. 2019, 241, 105–115. [Google Scholar] [CrossRef]

- Håkansson, A.; Fuchs, L.; Innings, F.; Revstedt, J.; Trägårdh, C.; Bergenståhl, B. Velocity measurements of turbulent two-phase flow in a high-pressure homogenizer model. Chem. Eng. Commun. 2013, 200, 93–114. [Google Scholar] [CrossRef]

- Erbil, H.Y. Evaporation of pure liquid sessile and spherical suspended drops: A review. Adv. Colloid Interface Sci. Elsevier B.V. 2012, 170, 6786. [Google Scholar] [CrossRef]

- Vladisavljevic, G.; Al Nuumani, R.; Nabavi, S. Microfluidic production of multiple emulsions. Micromachines 2017, 8, 75. [Google Scholar] [CrossRef]

- Yong, A.P.; Islam, M.A.; Hasan, N. The Effect of pH and High-Pressure Homogenization on Droplet Size. Sigma J. Eng. Nat. Sci. 2017, 35, 1–22. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Li, F.; Li, L.; Ge, X.; Zhang, S.; Qiu, T. Scale-up of microreactor: Effects of hydrodynamic diameter on liquid–liquid flow and mass transfer. Chem. Eng. Sci. 2020, 226, 115838. [Google Scholar] [CrossRef]

- Valencia-Flores, D.C.; Hernández-Herrero, M.; Guamis, B.; Ferragut, V. Comparing the Effects of Ultra-High-Pressure Homogenization and Conventional Thermal Treatments on the Microbiological, Physical, and Chemical Quality of Almond Beverages. J. Food Sci. 2013, 78, 199–205. [Google Scholar] [CrossRef] [PubMed]

- Minakov, A.; Rudyak, V.; Gavrilov, A.; Dekterev, A. Smeshenie v mikromiksere T—Tipa pri umerennykh chislakh Rejnol’dsa. Teplofiz. I Ajeromekhanika 2012, 19, 577–587. [Google Scholar]

- Fonte, C.P.; Fletcher, D.F.; Guichardon, P.; Aubin, J. Simulation of micromixing in a T-mixer under laminar flow conditions. Chem. Eng. Sci. 2020, 222, 115706. [Google Scholar] [CrossRef]

- Cao, Z.; Wu, Z.; Sattari Najafabadi, M.; Sunden, B. Liquid-Liquid Flow Patterns in Microchannels. In Proceedings of the ASME 2017 Heat Transfer Summer Conference, Bellevue, WA, USA, 9–12 July 2017; pp. 1–9. [Google Scholar]

- Roudgar, M.; Brunazzi, E.; Galletti, C.; Mauri, R. Numerical study of split T-micromixers. Chem. Eng. Technol. 2012, 35, 1291–1299. [Google Scholar] [CrossRef]

- Di Marzo, L.; Cree, P.; Barbano, D.M. Prediction of fat globule particle size in homogenized milk using Fourier transform mid-infrared spectra. J. Dairy Sci. 2016, 99, 8549–8560. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Minakov, A.; Yagodnitsina, A.; Lobasov, A.; Rudyak, V.; Bilsky, A. Study of fluid flow in micromixer with symmetrical and asymmetrical inlet conditions. Houille Blanche 2013, 5, 12–21. [Google Scholar] [CrossRef]

- Foroughi, H.; Kawaji, M. Viscous oil-water flows in a microchannel initially saturated with oil: Flow patterns and pressure drop characteristics. Int. J. Multiph. Flow 2011, 37, 1147–1155. [Google Scholar] [CrossRef]

- Dreher, S.; Kockmann, N.; Woias, P. Characterization of Laminar Transient Flow Regimes and Mixing in T-shaped Micromixers. Heat Transf. Eng. 2009, 30, 91–100. [Google Scholar] [CrossRef]

- Lobasov, A.; Minakov, A.; Rudyak, V. Izuchenie rezhimov smesheniya zhidkosti i nanozhidkosti v T-obraznom mikromiksere. Inzhenerno Fiz. Zhurnal 2018, 91, 133–145. [Google Scholar]

- Camarri, S. T-shaped micromixers aligned in a row: Characterization of the engulfment regime. Eng. Acta Mechanica 2022, 233, 1987–2077. [Google Scholar] [CrossRef]

- Yagodnitsyna, A.; Kovalev, A.; Bilsky, A. Flow patterns of immiscible liquid-liquid flow in a rectangular microchannel with T-junction. Chem. Eng. J. 2016, 303, 547–554. [Google Scholar] [CrossRef]

- Darekar, M.; Singh, K.K.; Mukhopadhyay, S.; Shenoy, K.T. Liquid-Liquid Two-Phase Flow Patterns in Y-Junction Microchannels. Ind. Eng. Chem. Res. 2017, 56, 12215–12226. [Google Scholar] [CrossRef]

- Fani, A.; Camarri, S.; Salvetti, M. Investigation of the steady engulfment regime in a three-dimensional T-mixer. Phys. Fluids 2013, 25, 64–102. [Google Scholar] [CrossRef] [Green Version]

- Lobasov, A.S.; Minakov, A.V. Analyzing mixing quality in a T-shaped micromixer for different fluids properties through numerical simulation. Chemical Eng. Process. 2018, 124, 11–23. [Google Scholar] [CrossRef] [Green Version]

- Hussong, J.; Lindken, R.; Pourquie, M.; Westerweel, J. Numerical study on the flow physics of a T-shaped micro mixer. In Proceedings of the IUTAM Symposium on Advances in Micro- and Nanofluidics, Dresden, Germany, 6–8 September 2007; Springer: Berlin/Heidelberg, Germany, 2009; pp. 191–205. [Google Scholar] [CrossRef]

- Haponiuk, E.; Zander, L.; Probola, G. Effect of the homogenization process on the rheological properties of food emulsions. Pol. J. Nat. Sci. 2015, 30, 149–158. [Google Scholar]

- Rayner, M.; Dejmek, P. Engineering Aspects of Emulsification and Homogenization in the Food Industry; CRC Press, Taylor & Francis Group: London, UK, 2015; p. 322. ISBN 9781466580435. [Google Scholar] [CrossRef]

- Morales, J.; Watts, A.; McConville, J. Mechanical particle-size reduction techniques. AAPS Adv. Pharm. Sci. Ser. 2016, 22, 165–213. [Google Scholar] [CrossRef]

- Liao, Y.X.; Lucas, D. A literature review of theoretical models for drop and bubble breakup in turbulent dispersions. Chem. Eng. Sci. 2009, 64, 3389–3406. [Google Scholar] [CrossRef]

- Deynichenko, G.; Yudina, T.; Levchenko, L.; Palianychka, N.; Verkholantseva, V.; Dmytrevskyi, D.; Chervonyi, V. Parameter optimization of milk pulsation homogenizer. J. Hyg. Eng. Des. 2018, 24, 63–67. [Google Scholar]

- Hussain, H.; Truong, T.; Bansal, N.; Bhandari, B. The Effect of Manipulating Fat Globule Size on the Stability and Rheological Properties of Dairy Creams. Food Biophys. 2017, 12, 1–10. [Google Scholar] [CrossRef]

- Mohammadi, V.; Ghasemi-Varnamkhasti, M.; Ebrahimi, R.; Abbasvali, M. Ultrasonic techniques for the milk production industry. Meas. J. Int. Meas. Confed. MSRMD 2014, 58, 93–102. [Google Scholar] [CrossRef]

- Postelmans, A.; Aernouts, B.; Jordens, J.; Van Gerven, T.; Saeys, W. Milk homogenization monitoring: Fat globule size estimation from scattering spectra of milk. Innov. Food Sci. Emerg. Technol. 2020, 60, 102311. [Google Scholar] [CrossRef]

- Samojchuk, K.O.; Koval’ov, O.O.; Lubko, D.V. Modelyuvannya parametriv struminnogo gomogenizatora moloka shchilinnogo tipu. Pr. TDATU 2018, 18, 286–292. Available online: http://elar.tsatu.edu.ua/handle/123456789/7185 (accessed on 28 January 2023).

- Movchan, S.; Dereza, O.; Mazilin, S.; Dereza, S. Study of Hydromechanical Parameters Part of the Water Solutions Household in Running Flows. In Modern Development Paths of Agricultural Production: Trends and Innovations; Springer: Cham, Switzerland, 2019; pp. 145–160. [Google Scholar] [CrossRef]

- Palyanychka, N.; Verkholantseva, V.; Yanakov, V. Experimental investigations of the parameters of the jet milk homogenizer with separate cream supply. Technol. Audit. Prod. Reserves 2017, 3, 33–39. [Google Scholar] [CrossRef] [Green Version]

- Zhuravel, D.; Viunyk, O.; Milko, D.; Bondar, A.; Sukhenko, Y.; Sukhenko, V. Research on milk homogenization in the stream homogenizer with separate cream feeding. Potravin. Slovak J. Food Sci. 2020, 14, 142–148. [Google Scholar] [CrossRef]

- Samojchuk, K.O.; Koval’ov, O.O.; Borokhov, I.V.; Palyanichka, N.O. Analitichni doslidzhennya energetichnikh pokaznikiv i parametriv yakosti struminno-shchil’ovogo gomogenizatora moloka. Pr. TDATU 2019, 19, 3–18. [Google Scholar] [CrossRef]

- Samojchuk, K.O.; Koval’ov, O.O.; Palyanichka, N.O.; Kolodij, O.S.; Lebid’, M.R. Eksperimental’ni doslidzhennya parametriv struminnogo gomogenizatora moloka z rozdil’noyu podacheyu vershkiv shchil’ovogo tipu. Pr. TDATU 2019, 19, 117–129. [Google Scholar] [CrossRef]

- Samoichuk, K.; Kovalyov, A.; Oleksiienko, V.; Palianychka, N.; Dmytrevskyi, D.; Chervonyi, V.; Horielkov, D.; Zolotukhina, I.; Slashcheva, A. Determining the quality of milk fat dispersion in a jet-slot milk homogenizer. East. Eur. J. Enterp. Technol. 2020, 5, 16–24. [Google Scholar] [CrossRef]

- Samoichuk, A.; Kovalyov, V.; Oleksiienko, N.; Palianychka, D.; Dmytrevskyi, V.; Chervonyi, D.; Horielkov, I.; Zolotukhina, A.; Slashcheva, A. Elaboration of the research method for milk dispersion in the jet slot type homogenizer. EUREKA Life Sci. 2020, 5, 51–59. [Google Scholar] [CrossRef]

- Ansari, M.A.; Kim, K.Y.; Kim, S.M. Numerical study of the effect on mixing of the position of fluidstream interfaces in a rectangular microchannel. Int. J. Microsyst. Technol. 2010, 16, 1757–1763. [Google Scholar] [CrossRef]

- Voloshina, A.; Panchenko, A.; Panchenko, I.; Titova, O.; Zasiadko, A. Uluchshenie vykhodnykh kharakteristik planetarnykh gidravlicheskikh mashin. IOP Conf. Ser. Mater. Sci. Eng. 2019, 708, 012038. [Google Scholar] [CrossRef]

- ISO 9622:2013; Milk and Liquid Milk Products. ISO Standards: Geneva, Switzerland, 2013.

- ISO 707:2013; Milk and milk products. Guidance on Sampling. ISO Standards: Geneva, Switzerland, 2013.

- Yanga, B.; Zhua, Z.; Gaoa, M.; Yana, X.; Zhua, X.; Guo, W. A portable detector on main compositions of raw and homogenized milk. Comput. Electron. Agric. 2020, 177, 105668. [Google Scholar] [CrossRef]

- Panchenko, A.; Voloshina, A.; Kiurchev, S.; Titova, O.; Onopreychuk, D.; Stefanov, V.; Safoniuk, I.; Pashchenko, V.; Radionov, H.; Golubok, M. Razrabotka universal’noj modeli mekhatronnoj sistemy s gidravlicheskim privodom. East. Eur. J. Enterp. Technol. 2018, 7, 51–60. [Google Scholar] [CrossRef] [Green Version]

- Kiurchev, S.; Leshchij, R. Method of calculation of an industrial model of jet-slot milk homogenizer. Teka Q. J. Agri Food Ind. 2020, 19, 23–30. [Google Scholar]

- Bulgakov, V.; Kuvachov, V.; Olt, J. Theoretical study on power performance of agricultural gantry systems. Ann. DAAAM Proc. Int. DAAAM Symp. 2019, 30, 167–175. [Google Scholar]

- Čėsna, J.; Medvedskyi, O.; Postol, Y.; Kukharets, V.; Zayets, M.; Hrudovij, R.; Pantsyr, Y.; Zarajczyk, J.; Daniel, Z. Simulation of Design Parameters of a Milking Cup with An Extended Service Life. Agric. Eng. 2022, 26, 243–252. [Google Scholar] [CrossRef]

- Faichuk, O.; Voliak, L.; Hutsol, T.; Glowacki, S.; Pantsyr, Y.; Slobodian, S.; Szeląg-Sikora, A.; Gródek-Szostak, Z. European Green Deal: Threats Assessment for Agri-Food Exporting Countries to the EU. Sustainability 2022, 14, 3712. [Google Scholar] [CrossRef]

- Labenko, O.; Sobchenko, T.; Cupiał, M.; Mudryk, K.; Kocira, A.; Pavlenko-Didur, K.; Klymenko, O.; Neuberger, P. Project Environment and Outlook within the Scope of Technologically Integrated European Green Deal in EU and Ukraine. Sustainability 2022, 14, 8759. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samoichuk, K.; Kovalyov, A.; Fuchadzhy, N.; Hutsol, T.; Jurczyk, M.; Pająk, T.; Banaś, M.; Bezaltychna, O.; Shevtsova, A. Energy Costs Reduction for Dispersion Using a Jet-Slot Type Milk Homogenizer. Energies 2023, 16, 2211. https://doi.org/10.3390/en16052211

Samoichuk K, Kovalyov A, Fuchadzhy N, Hutsol T, Jurczyk M, Pająk T, Banaś M, Bezaltychna O, Shevtsova A. Energy Costs Reduction for Dispersion Using a Jet-Slot Type Milk Homogenizer. Energies. 2023; 16(5):2211. https://doi.org/10.3390/en16052211

Chicago/Turabian StyleSamoichuk, Kyrylo, Alexandr Kovalyov, Natalia Fuchadzhy, Taras Hutsol, Michał Jurczyk, Tadeusz Pająk, Marian Banaś, Olena Bezaltychna, and Alona Shevtsova. 2023. "Energy Costs Reduction for Dispersion Using a Jet-Slot Type Milk Homogenizer" Energies 16, no. 5: 2211. https://doi.org/10.3390/en16052211