Abstract

Process heating is the activity with the most energy consumption in the industrial sector. Solar heating (SH) systems are a promising alternative to provide renewable thermal energy to industrial processes. However, factors such as high investment costs and area limitations in industrial facilities hinder their utilization; therefore, hybrid systems that combine two different solar thermal or photovoltaic technologies where each technology operates under conditions that allow a higher overall performance than conventional configurations have been proposed. In this review, we discuss the limitations of conventional SH systems and the potential of hybrid configurations to overcome them. First, the current literature about conventional and hybrid systems is presented. Then, the application of common performance indicators to evaluate hybrid configurations is analyzed. Finally, the limitation, advantages, and potential applications of conventional and hybrid systems are discussed. This work shows that conventional systems are the most promising alternatives in low and high-temperature industrial applications. At the same time, in medium and processes, hybrid configurations have great potential to increase the performance of SH systems and help to boost their adoption in the industrial sector. There are few studies about hybrid systems in industrial applications, and further research is required to determine their potential.

1. Introduction

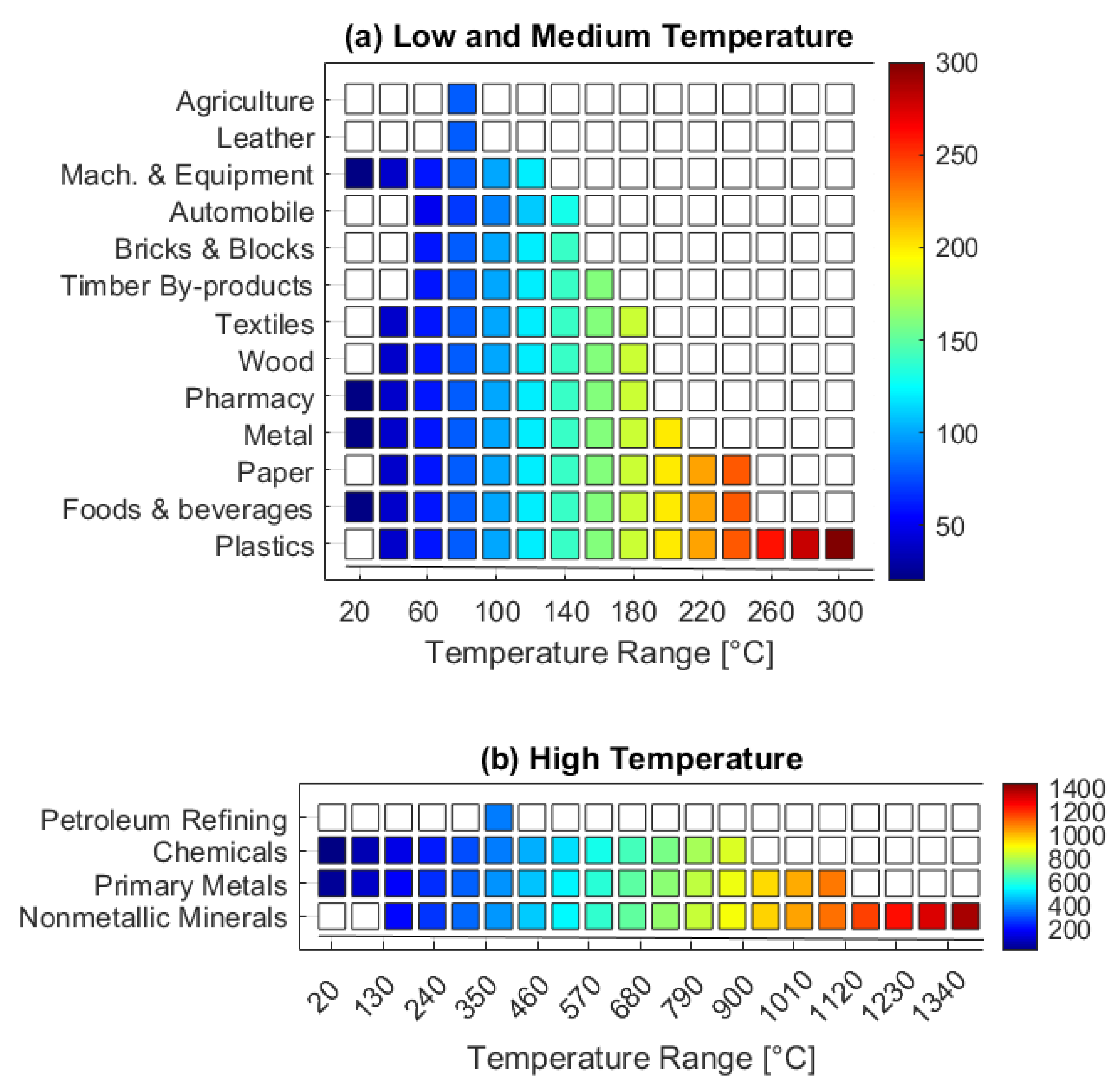

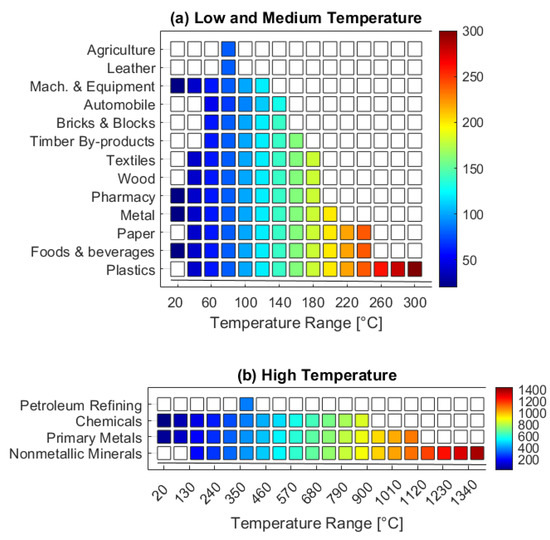

Global warming has become one of the main concerns of most countries worldwide. To mitigate climate change, it is necessary to replace fossil fuels with renewable energy sources that help to decrease the greenhouse gas (GHG) emissions produced by human action. In the frame of the Paris agreement [1], many countries have set goals for their energy infrastructure development to limit the global average temperature increase to 1.5 °C above pre-industrial levels. In this sense, the European Union countries set the goal of reducing their GHG emissions by at least 55% below 1990 levels by 2030, while developing countries such as India have also set important GHG emissions reduction targets [2,3]. To achieve those goals and allow the development of a net-zero emissions energy infrastructure, renewable energy technologies play a primary role [4]. In 2021 industrial activity was responsible for 38% of total final energy consumption in the world, and it is expected that the energy demand in this sector will continue to grow in the following years [5]. Within industrial energy consumption, two-thirds of the energy demand is for heat generation [6]. Among renewable energy sources, solar energy is one of the most promising alternatives [4]. Solar conversion systems are able to transform solar energy into thermal energy, electricity, or both. These technologies have been evaluated in a wide range of applications such as power generation [7,8,9], seawater desalination [10,11,12], cooling processes [13], district heating [14,15], and industrial heating [16,17,18], among others. Solar heat for industrial processes (SHIP) systems are able to supply thermal energy to industrial processes with low-temperature (below 80 °C), medium-temperature (between 80 °C and 250 °C), and high-temperature (above 250 °C) requirements [18,19,20]. SHIP systems have become one of the most promising alternatives to meet part of the heat demand of industrial activity with a renewable energy source [21].

Solar heating technologies have shown to be economically competitive with fossil alternatives in industrial applications, especially in high solar levels locations [22,23,24,25], and the number of SHIP plants increased by almost 9% in 2021 [21]. In the same way, photovoltaic (PV) systems are the dominant solar technology in the electricity sector [26]. However, PV cells have lower energy conversion efficiency than solar thermal technologies. Depending on the operating conditions and technology used, more than three times larger area of PV modules could be required to provide the same amount of energy as an ST system [24,27]. This fact represents a challenge for the utilization of PV systems in industrial heating applications. On the other hand, electric-driven heat pumps (HP) are a promising technology to improve the energy efficiency in heating processes and reduce emissions [28,29]. HPs are combined with solar energy systems to improve the energy performance of the system and provide a more effective solar heating (SH) alternative [30].

However, despite the huge potential of SH technologies in 2021, only 0.17% of the worldwide installed area of SH systems were of SHIP plants [21]. This relatively small implementation of solar heating systems in industrial applications is due to many factors that prevent the large-scale utilization of SHIP plants worldwide. Among the main obstacles to the proliferation of SHIP plants are the high investment costs of solar systems, the variability of the solar resource, and the limited available area in industrial facilities for solar field installation [31,32]. For this reason, it is necessary to improve the design of conventional solar heating systems to increase their technical viability and economic performance.

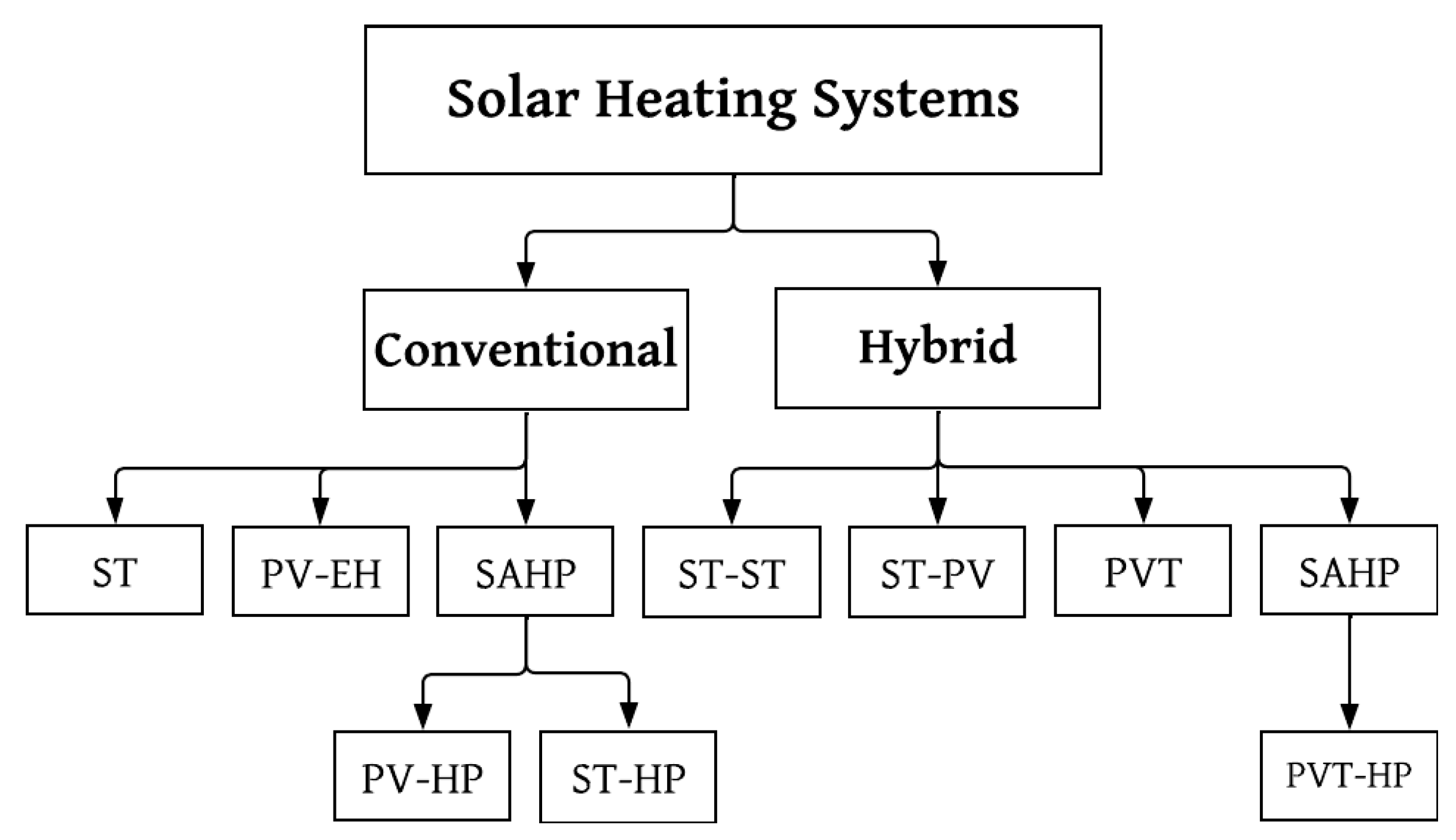

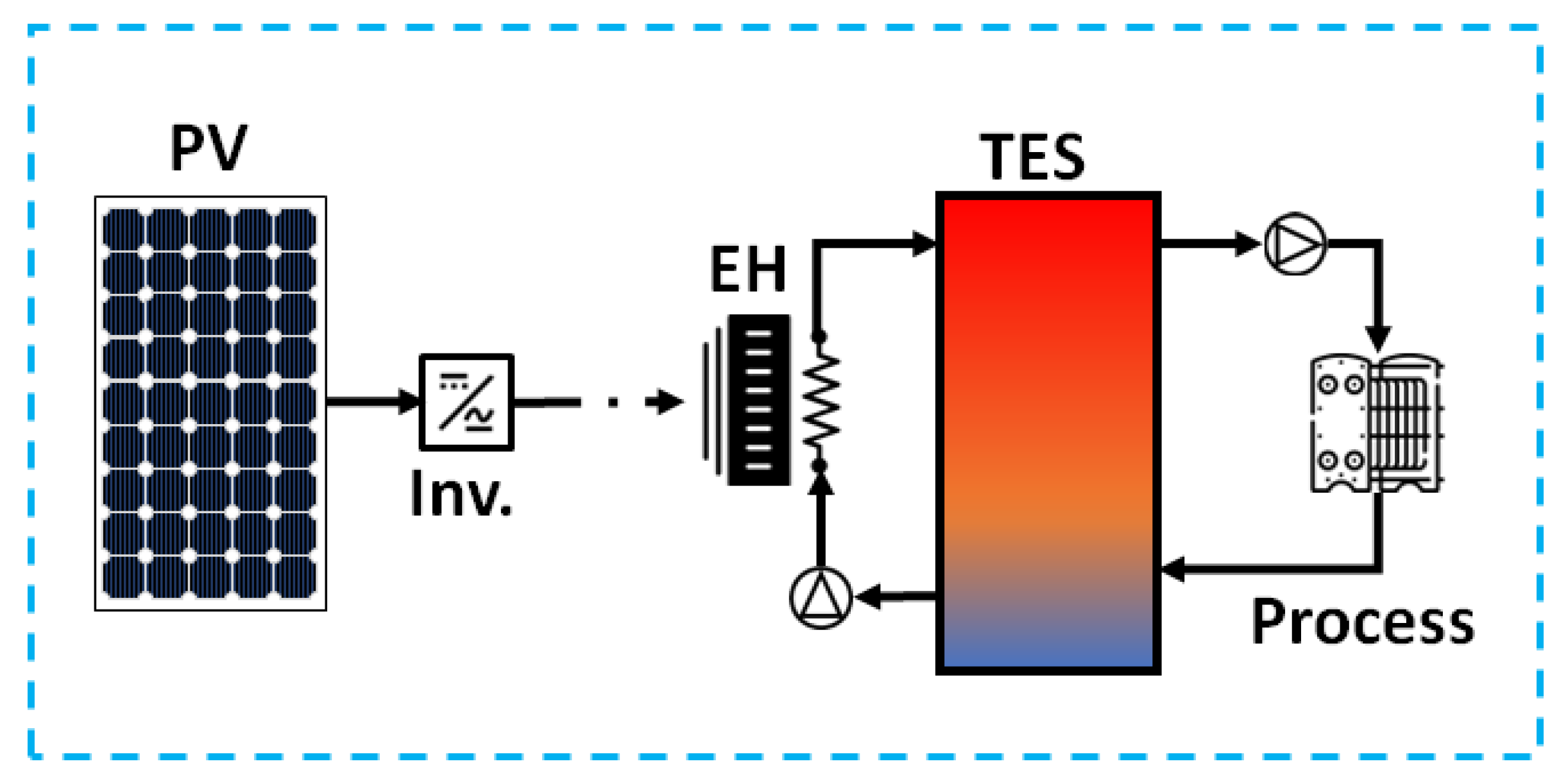

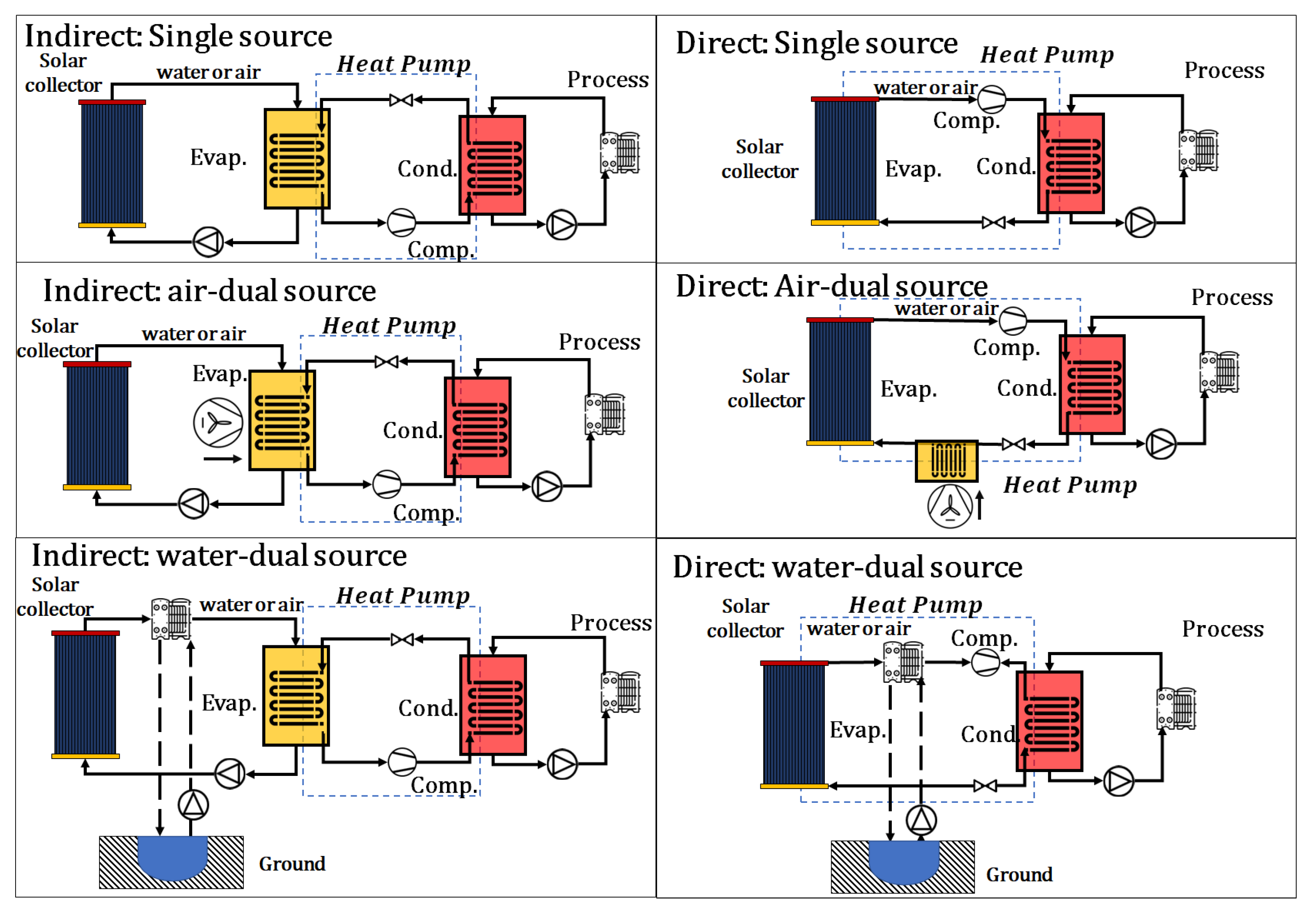

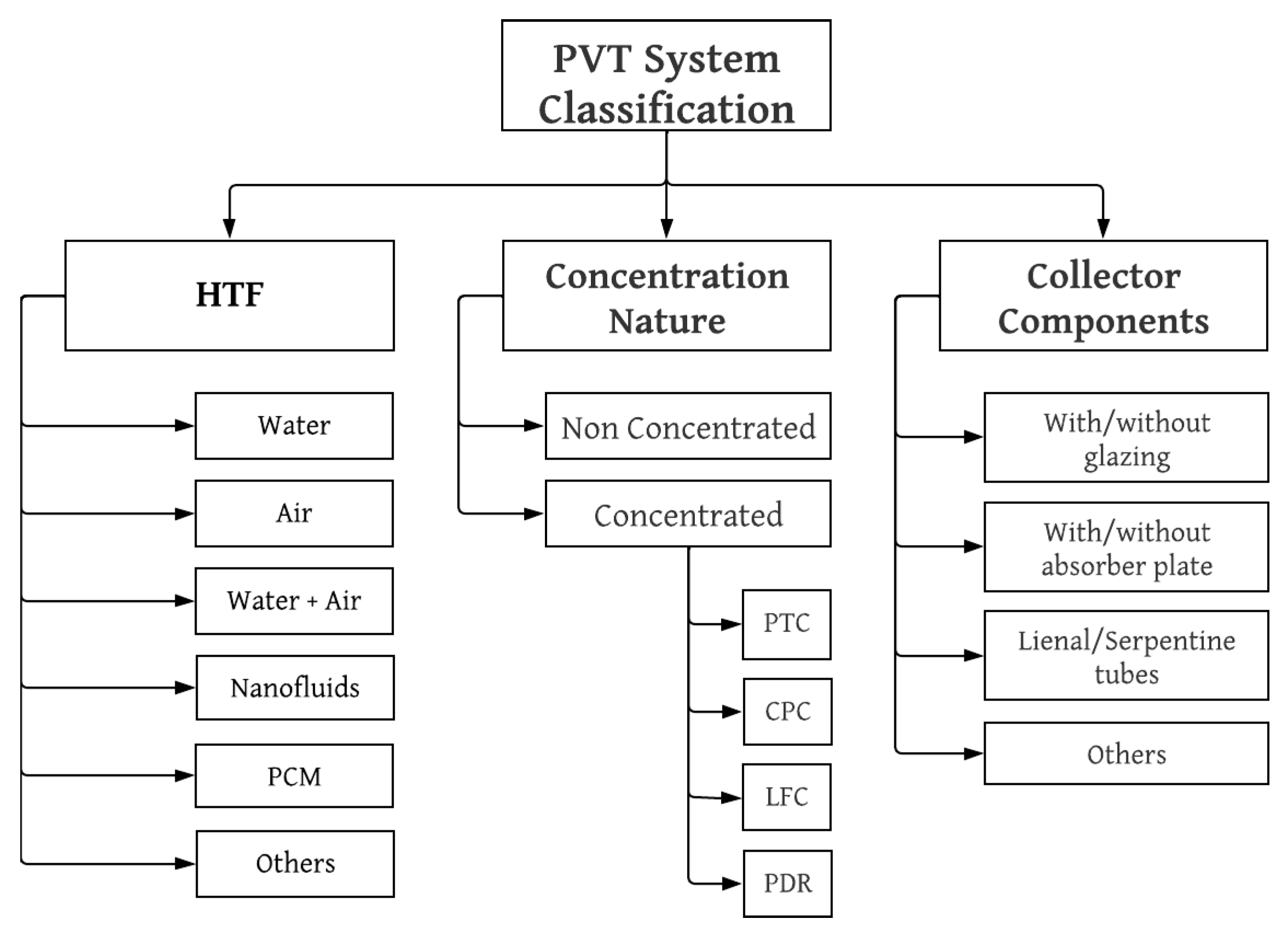

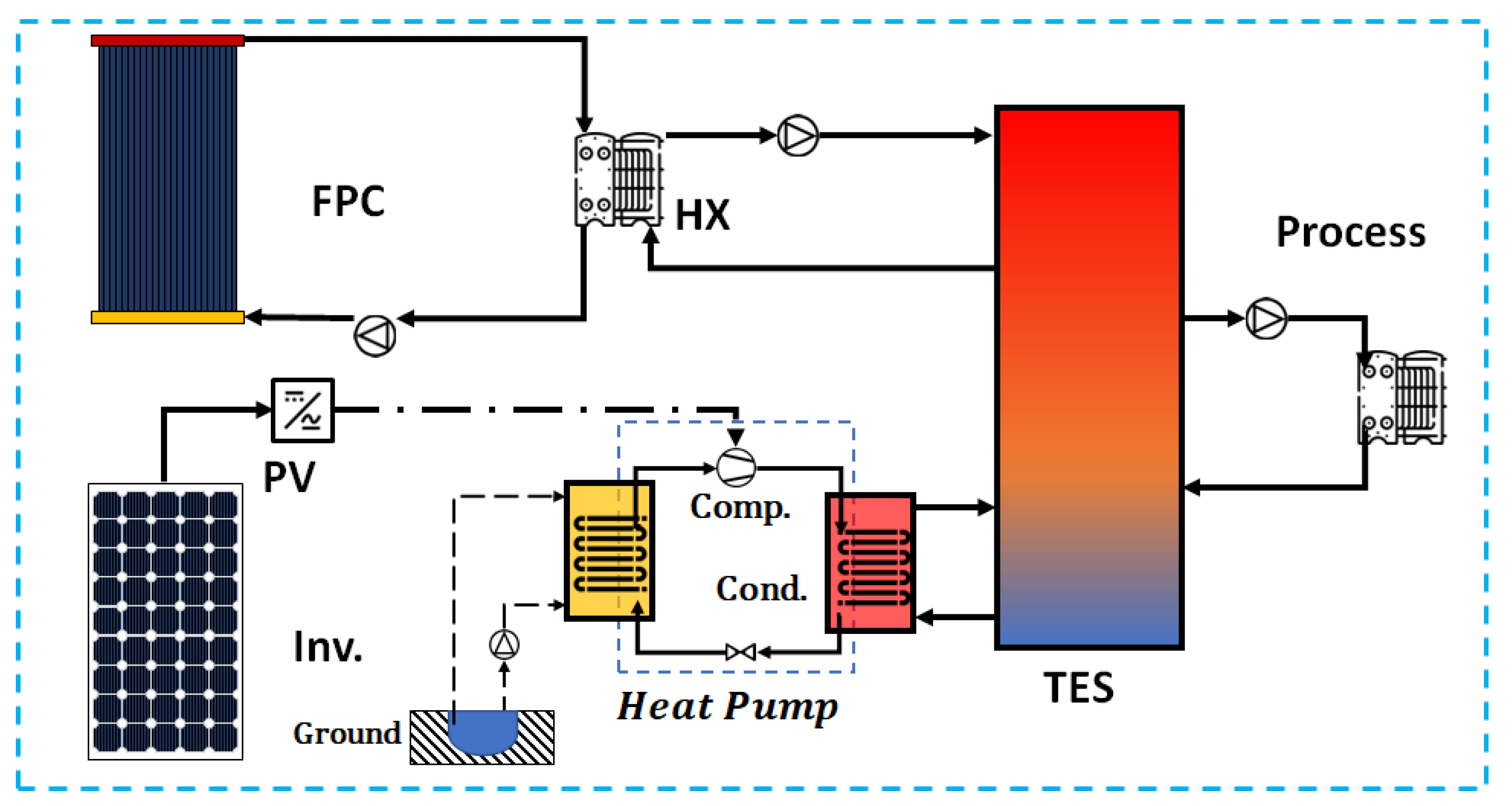

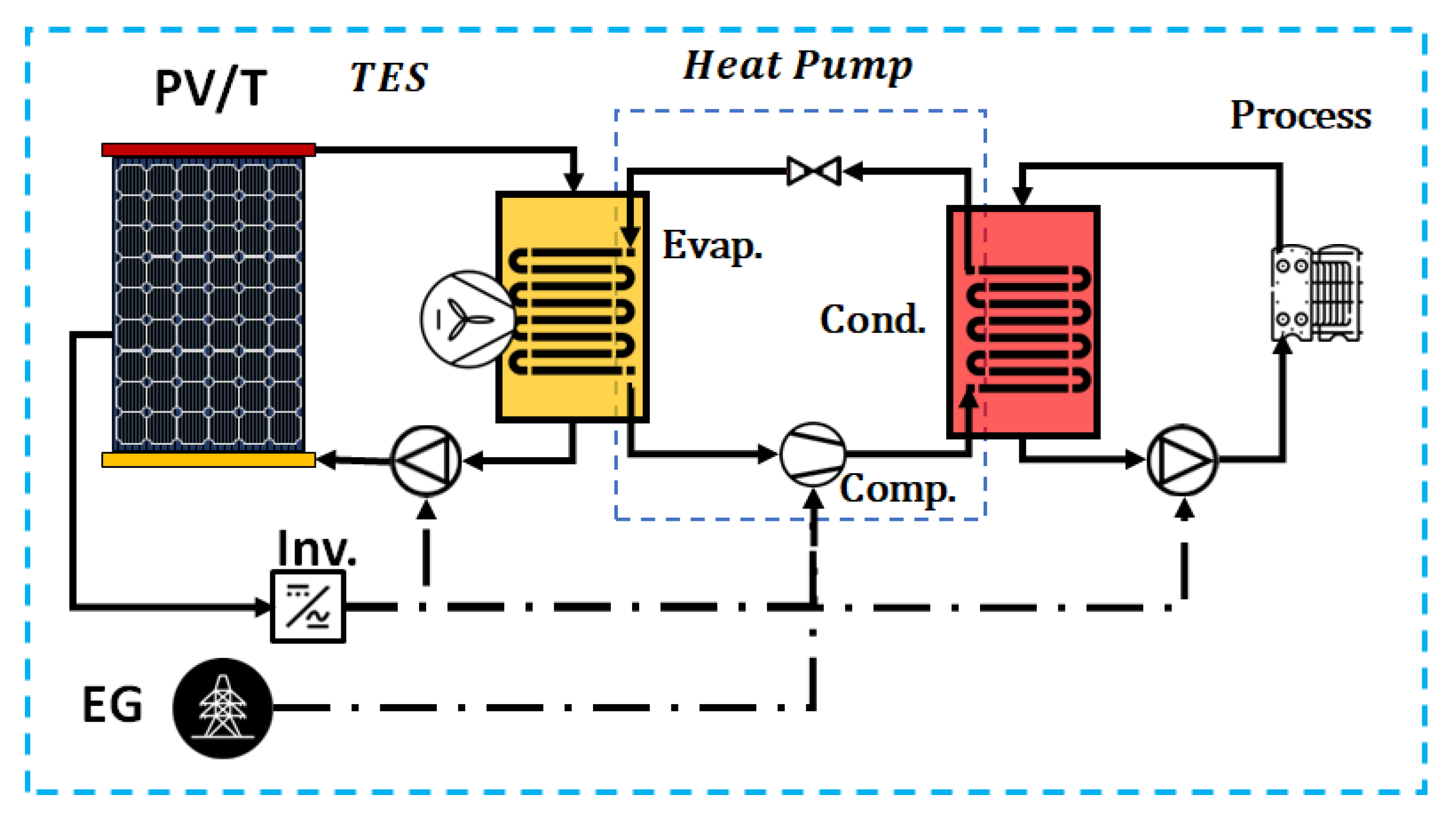

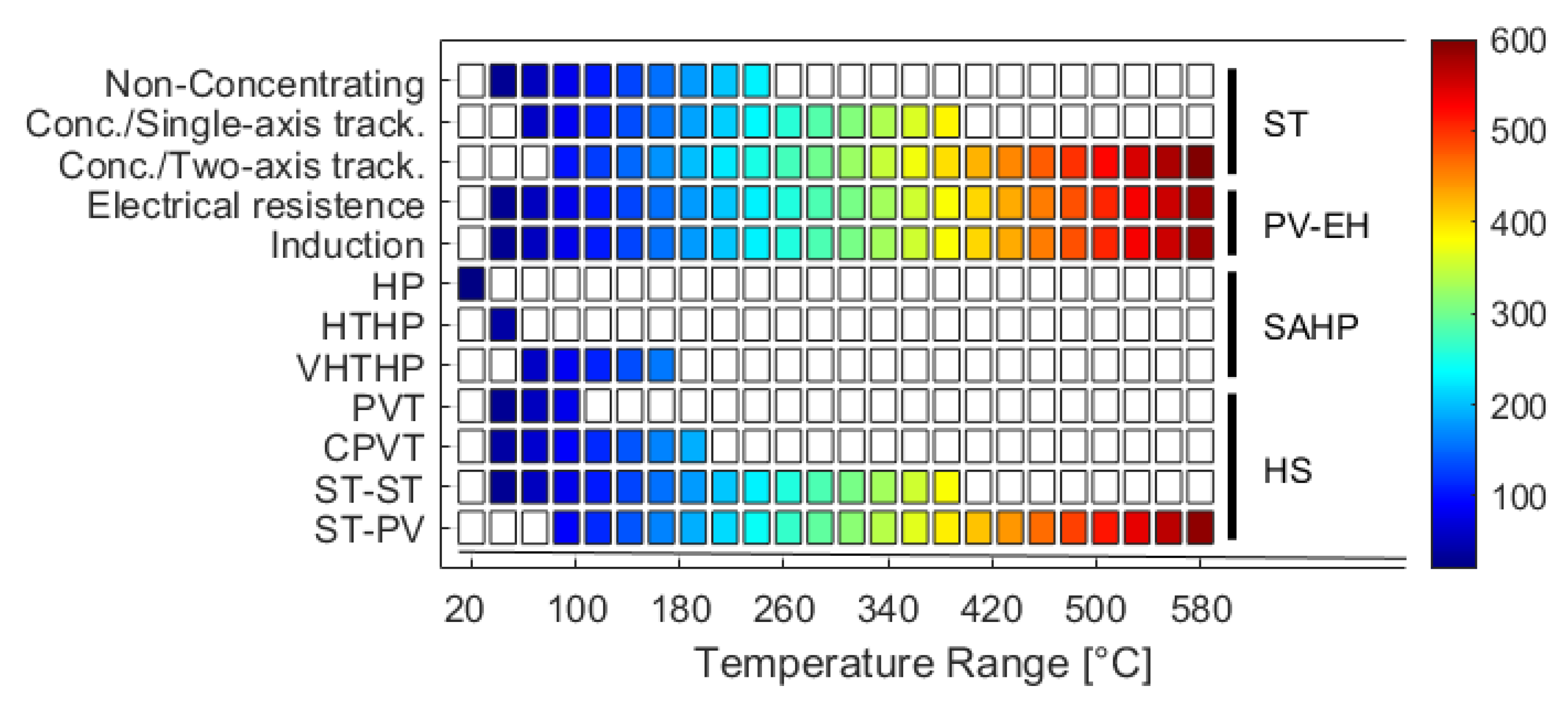

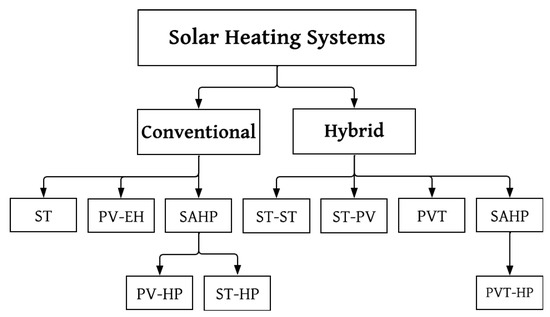

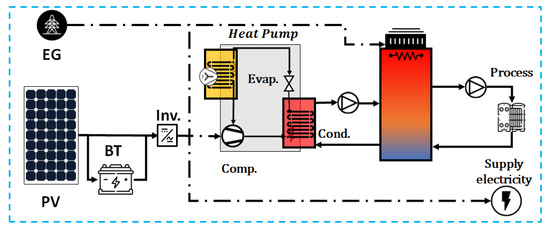

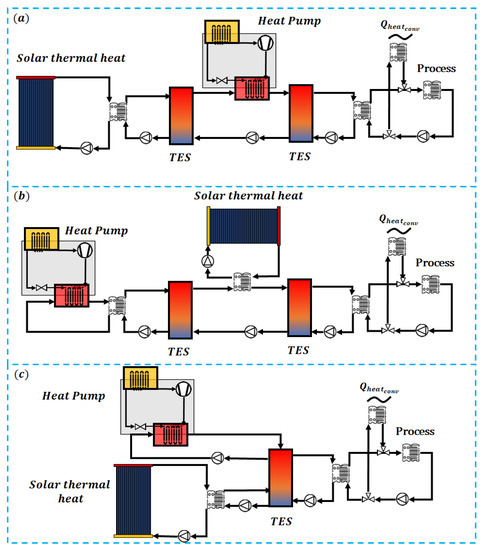

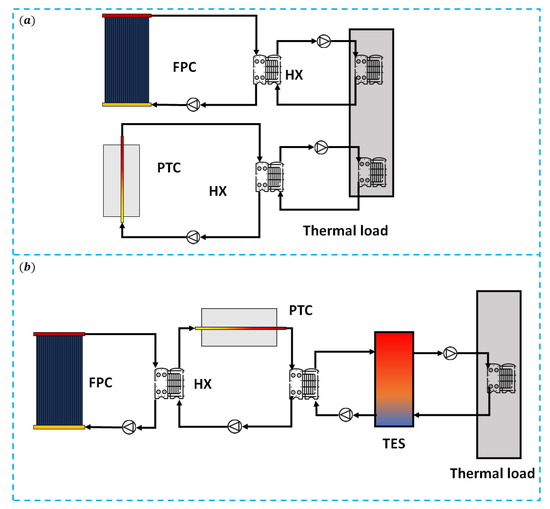

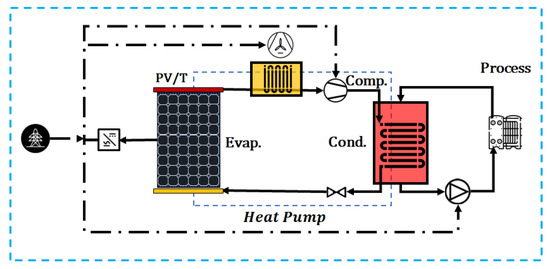

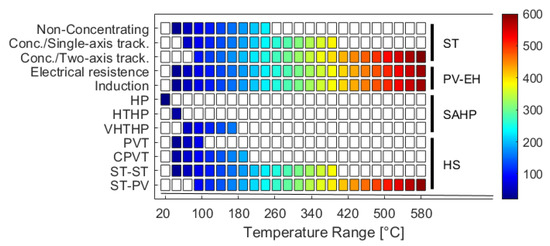

Conventional SH systems include solar thermal (ST) collectors, PV with electric heating devices or PV-electric heating (PV-EH), PV-assisted heat pump (PV-HP), and solar thermal-assisted heat pump (ST-HP) systems. These technologies have particular technical and economic advantages and restrictions that give them different application scenarios. Several studies have proposed different hybrid configurations that combine two conventional technologies to take advantage of the benefits of each system to create hybrid heating systems (HS) with better overall performance than the conventional alternatives. These hybrid systems can combine two technologies in the same device, as in the case of photovoltaic-thermal collectors (PVT) [33], or combine individual technologies in the same system with serial or parallel configurations, as in the case of hybrid systems with two different technologies of ST collectors (ST-ST HS) [34,35], hybrid systems with ST collectors and PV-EH systems (ST-PV HS) [36,37], and solar hybrid assisted heat pumps (SHAHP) [38,39]. The conventional and hybrid solar heating systems are shown in Figure 1.

Figure 1.

Solar heating systems (conventional and hybrid systems).

Different studies have analyzed the implementation of HSs, most of them for domestic consumers [34,40,41]. However, the potential and limitations of the different conventional and HSs have not been directly compared, and it is necessary to identify the conditions where each technology alternative has greater potential for industrial application than the other configurations [37,42,43].

This review discusses the limitations of conventional technologies and how hybrid configurations can help to overcome those barriers to boost the implementation of solar heating systems in industrial applications. Further, limitations of the current literature about hybrid heating systems and potential applications are identified. Section 1 introduces the motivation and objectives of this review article. Section 2 presents the most common conventional solar heating systems. Section 3 describes different solar hybrid systems and analyzes the current literature about those configurations. Section 4 shows the solar radiation and time interval characteristics of the analyzed studies. Section 5 reported the solar thermal plants operating for SHIP applications worldwide. Section 6 discusses the evaluation of hybrid systems with the main key performance indicators used for conventional technologies. Section 7 discusses the limitations, advantages, and potential applications in the industrial sector of conventional and hybrid systems. Finally, Section 8 presents the conclusions of this article.

The aim of the present work is to analyze the potential of hybrid configurations of PV and ST technologies to improve the performance of solar alternatives in industrial heating applications. The promising combinations of PV and ST technologies, the limitations of conventional and hybrid configurations, the scenarios where HS can allow to overcome the limitations of conventional systems and the importance of different performance indicators to find the best technological combination are analyzed. Further research needs to provide a better understanding of the full potential of solar hybrid configurations are also presented. This work is also a contribution for solar heating project developers allowing them to propose better technological solutions that help to encourage the solar systems proliferation in industrial heating applications.

2. Conventional Solar Heating Technologies and Heat Pumps

2.1. Solar Thermal Collectors (ST Collectors)

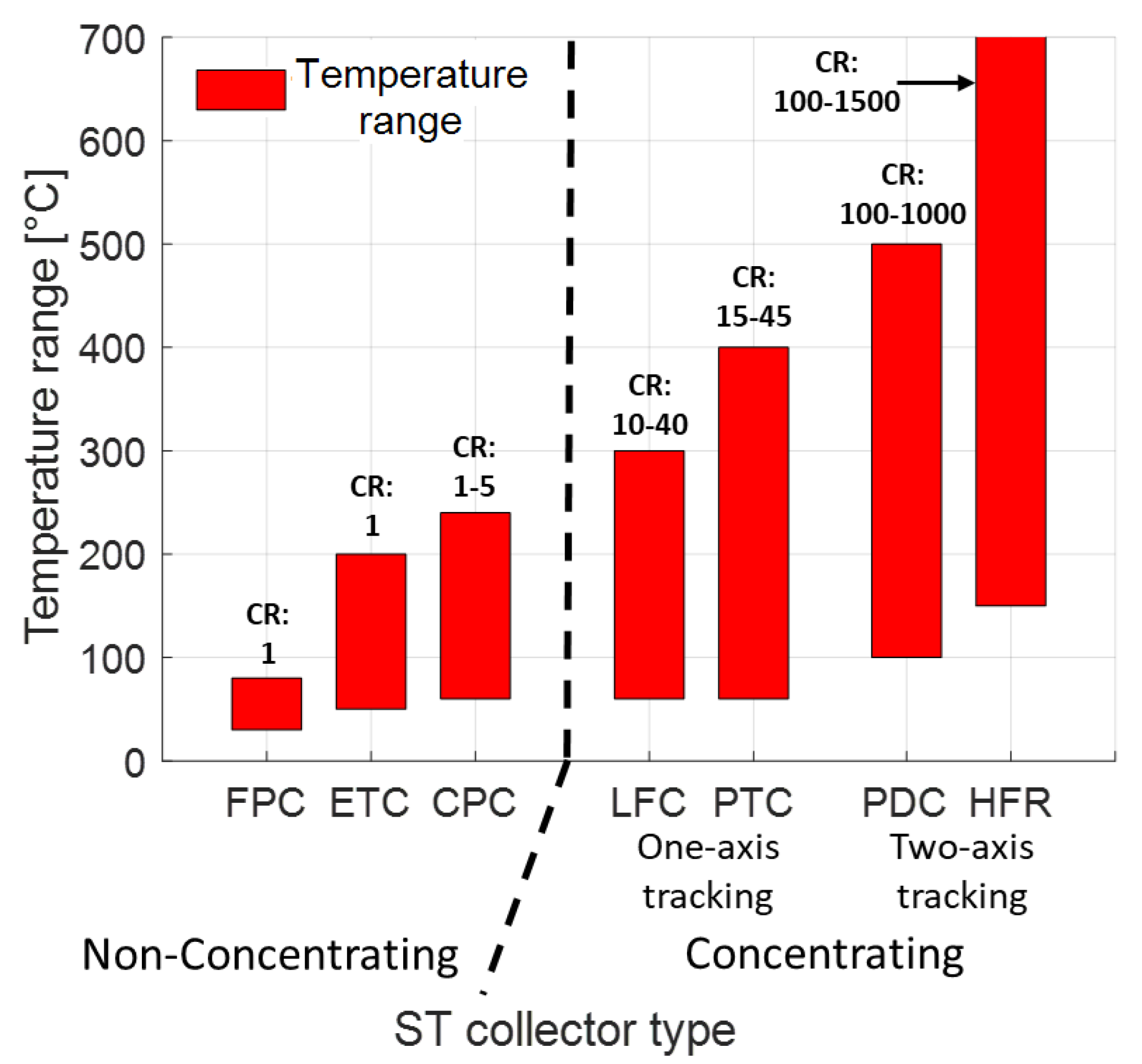

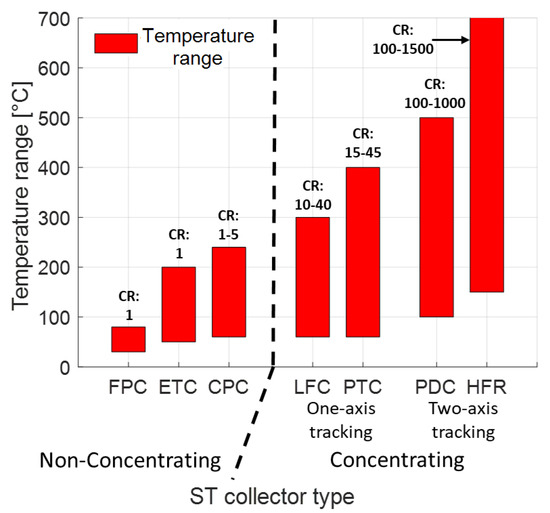

The most common solar technology for heating applications is the ST collector. These devices transform solar radiation into thermal energy. The energy absorbed is transmitted to a heat transfer fluid (HTF), which can be used to store energy in a thermal energy storage (TES) or to provide heat to a domestic or industrial application [44,45]. ST collectors are often classified based on their concentration nature into two kinds (Figure 2): Non-concentrating and concentrating collectors [17,18,44,45]. Non-concentrating collectors do not concentrate solar radiation or have low concentration ratios (CR) up to 5 [46]. These collectors generally do not have solar tracking and are set at fixed tilt and orientation angles that maximize their annual energy production [32,44]. The foremost non-concentrating collectors are the flat plate collector (FPC), evacuated tube collector (ETC), and stationary compound parabolic collector (CPC) [47]. On the other hand, concentrating collectors reflect the beam radiation incident on a reflective surface onto a smaller collecting surface [17,48]. Normally, concentrating collectors have solar tracking, and depending on the collector type could be one or two-axis tracking [46]. The most common concentrating collectors with one-axis tracking are linear Fresnel collectors (LFC) and parabolic trough collectors (PTC). With two-axis tracking, the most common are the parabolic dish concentrator (PDC), and heliostat field reflector (HFR) [20,47,49]. The common CR and temperature ranges of ST collectors are shown in Figure 2.

Figure 2.

Features of main solar thermal collectors (HFR systems can reach temperatures up to 2000 °C). Own figure based on [17,20,45,46].

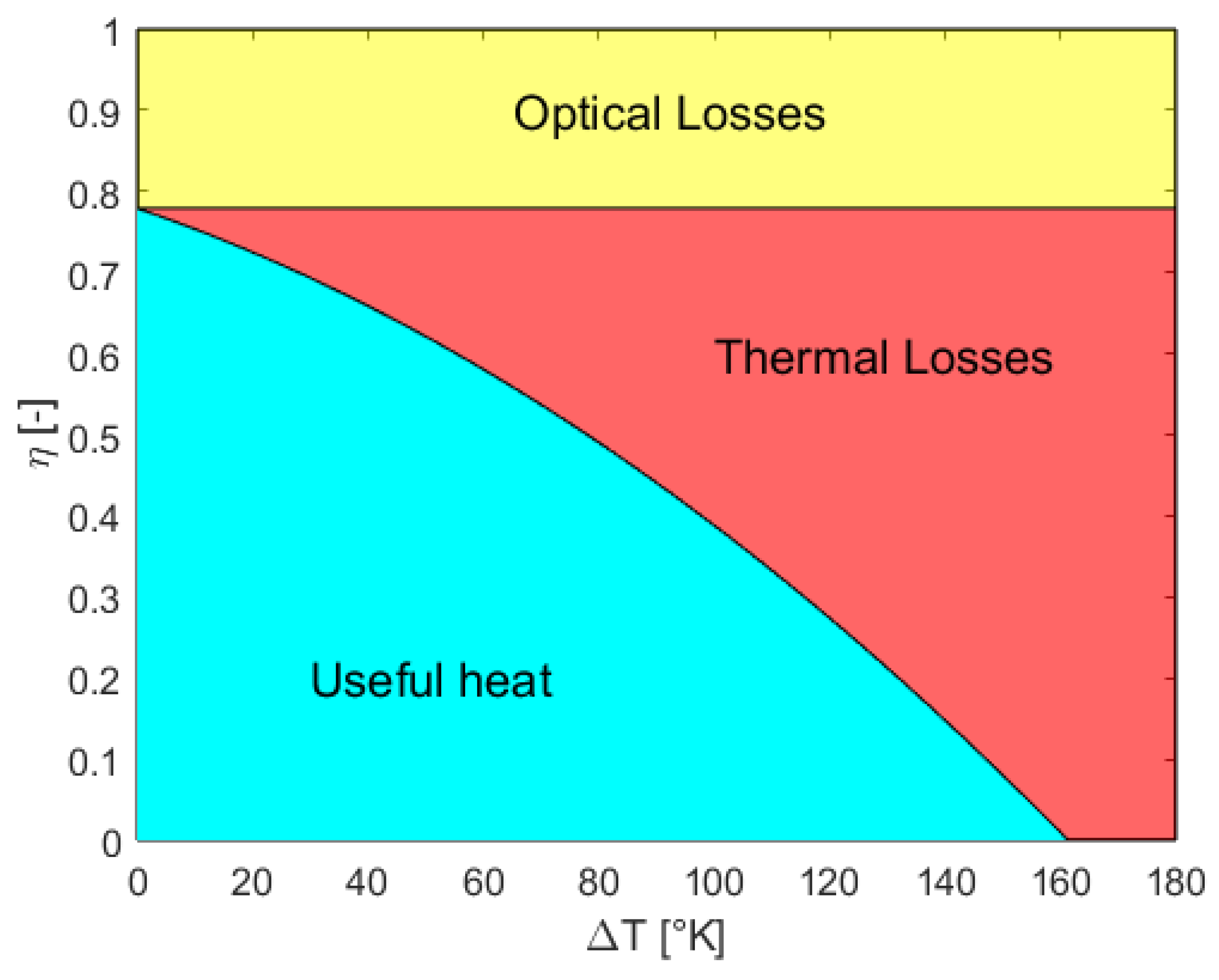

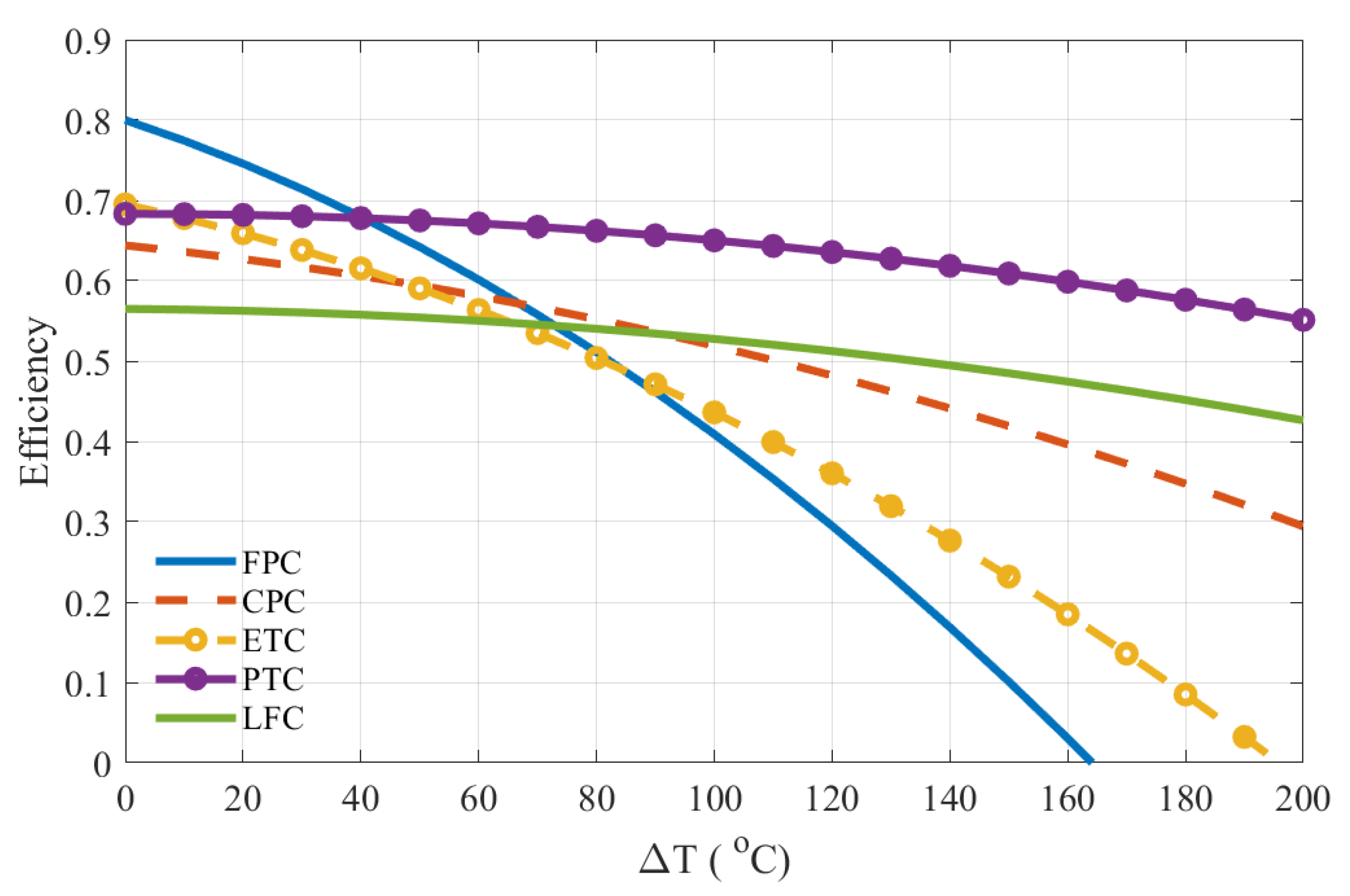

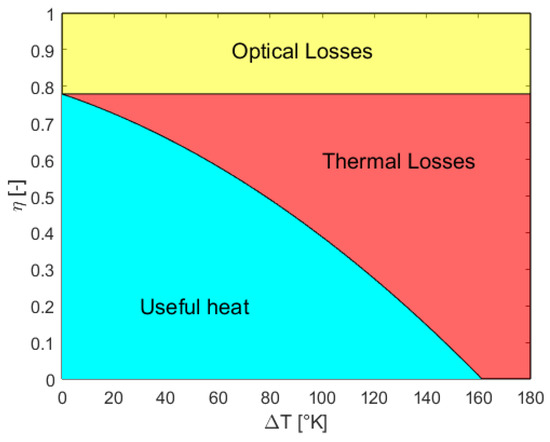

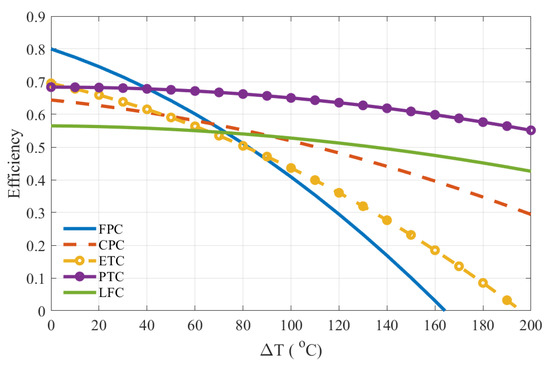

The efficiency of ST collector is affected by the optical and thermal losses (Figure 3) [47]. The optical losses are due to the geometrical and optical (reflectivity, absorptivity and transmissivity) parameters of the collector. Thermal losses are due to heat transfer by conduction, convection, and radiation from the collector to the environment, and depend on the temperature difference between the components of the ST collector and its surroundings [47,50,51]. As is shown in Figure 4, FPCs have higher optical efficiency than other collectors but are also more affected by thermal losses. On the other hand, concentrating collectors such as PTCs have lower optical efficiencies, but their thermal loss coefficients are also lower, giving them better thermal performance in higher operating temperatures [44]. The need for a tracking system makes concentrating systems more expensive than non-concentrating [17,46,52]. Therefore, in low-temperature applications, the combination of better efficiency and lower costs makes non-concentrating technologies the preferred alternative. In medium-temperature and high-temperature processes, concentrating collectors have shown better economic performance [17].

Figure 3.

Effect of optical and thermal losses in the efficiency of an ST collector. The x-axis shows the temperature difference between the average operating temperature of the ST collector and the ambient air. The efficiency curve considers the lost coefficients of the FPC HEAT-boost 35/10 [53]. Own figure based on [47].

Figure 4.

ST collectors efficiency as a function of the difference between the average temperature of the collector and the ambient temperature (own figure based on the ISO 9806 steady-state collector model [47] and the loss coefficients of commercial ST collectors [54,55,56]; W/m and °C).

In recent years, many researchers have studied the integration of solar heating systems in the industrial sector. Some of them evaluate the utilization of a non-concentrating collector technology in low-temperature processes. Karki et al. [32] proposed a methodology to evaluate the economic feasibility of FPC systems for heating low-temperature industrial processes with small and medium demands. The f-chart and modified f-chat methods were used to estimate the energy production of the solar systems. Eleven locations around the world were evaluated. It was considered a cleaning process in the dairy industry. The results showed that the economic feasibility of the solar system is mainly sensitive to variations in the costs of the combustible of the auxiliary fossil heating system and the cost of the FPCs. Variations in other parameters, such as the cost of the auxiliary boiler and discount rate, have lower effects on the economic performance of the system. The authors show that reaching one hundred percent of solar fraction (SF) is not economically feasible. The study concludes that the integration of FPC systems in low-temperature industrial processes is already possible in many locations around the world, but they remain scarce due to the lack of information on scenarios of applicability and tools for the project feasibility analysis. Venkatramanan et al. [57] developed a methodology for the design of ETC systems for air heating in industrial processes. A case study in India was evaluated. Results showed that the ETC field allowed the reduction in carbon dioxide emissions by tons per year. The authors concluded that ETC systems can provide solar heat to industrial processes with temperatures between 80 and 120 °C. Barbosa et al. [58] studied the economic and environmental performance of a water heating system with FPC for a textile industry located in northeast Brazil. Results showed that the system is economically and environmentally feasible, with an economic return times greater than the capital invested.

In other studies, different ST collector technologies are compared in low-temperature applications as in the case of the work carried out by Farjana et al. [59] who evaluated the utilization of FPC and ETC systems to provide solar heat to lead mining facilities in seven countries around the world. Results showed that the ETC systems allowed higher SF and energy efficiency than FPC, reaching SFs of over in four of the seven countries evaluated. Life cycle assessment showed that the integration of solar technologies helps to mitigate the ambient impact of the mining facility, with improvements in indicators such as global warming emissions, terrestrial ecotoxicity, and human non-carcinogenic toxicity. Ismail et al. [19] reviewed the existing literature on ST systems for low-temperature processes in the food industry. The study found that by 2020, there were more than 41 MWth of solar thermal installed capacity in low-temperature processes in the food industry worldwide. The authors found that FPC, ETC and PTC are already economically competitive with fossil alternatives in this application in many locations around the world. The most commonly used technology was FPCs. The dairy industry had the largest number of solar systems in processes such as pre-hating, cleaning, sterilization, and pasteurization. The authors determined that to promote the use of solar systems in the food industry more economic incentives should be applied especially in developing countries. Quiñones et al. [22] analyzed the integration of solar thermal energy in the Chilean copper industry. The process considered was electro-winning, and 14 locations in the country were evaluated. The economic, energetic, and environmental performance of FPC, ETC, and PTC were analyzed and compared. The study showed that economic payback periods of 8 years with SFs up to could be reached. Solar alternatives can be competitive with diesel boilers when the cost of the diesel is higher than 32 USD/MWh. The authors concluded that the integration of solar heat in the Chilean copper industry is economically feasible. Further, the technology with the best economic potential was the FPC, but if a scenario of cost reduction is considered, the PTC could be the best alternative due to the high levels of direct normal irradiation (DNI) in northern Chile.

On the other hand, other studies have focused on the analysis of concentrating systems principally in medium-temperature processes. Baba et al. [23] evaluated the economic performance of LFCs to meet saturated or overheated steam demand in industrial processes with temperatures up to 200 °C. The payback period of the LFC system is compared with boilers systems with heavy fuel, diesel, natural gas, or biomass. A case study in Morocco is analyzed as a base scenario, and sensitivity analysis to DNI levels is made considering the radiation of locations in Egypt, Spain, Italy, and Mali. Results showed that the LFC can compete with all the fossil and biomass alternatives evaluated. The LFC system reaches a payback period of 4.4 years in the heavy fuel boiler scenario. The operation and maintenance cost of the biomass boiler was 13% higher than the LFC system. DNI sensibility analysis showed that payback periods are highly dependent on DNI levels. The authors conclude that LFC systems can be used to partially replace existing fossil systems in industrial facilities with competitive payback periods. Immonen et al. [60] evaluated the integration of a PTC system with an optimized operating scheme in an industrial process. A case study with two integration points with a maximum integration temperature of 390 °C was considered. The location of the industrial plant was Salt Lake City, USA. The results showed that the optimized strategy denominated flexible heat integration allows an increase in the solar fraction of 13% and a decrease of 10.4% in the levelized cost of heat (LCOH) compared to a PTC plant with a conventional control strategy. Compared to a natural gas boiler, the solar system allows a 17.4% reduction in harmful emissions. The authors determined that the PTC system is economically competitive with the natural gas boiler and the optimized operating strategy improves the performance of the system, especially in moments with lower DNI levels available. Holler et al. [25] evaluated the economic feasibility of a PTC system to provide solar heat to produce steam at 180 °C for a fruit juice production facility in Germany. The system reached a solar fraction of up to 23% without TES with LCOH values around 57 €/MWh. The authors found that solar heating with PTC is also economically attractive in locations with annual DNI levels as low as 900 kWh/m.

2.2. Photovoltaic-Electric Heating (PV-EH)

In a PV-EH system, a PV field is coupled to an electric heating element to provide solar heat to a domestic or industrial application [24,27]. Traditionally, ST collectors have been preferred over PV due to their cost and efficiency in heating applications [61]. PV systems transform sunlight into electricity using PV modules composed of semiconductors such as silicon or cadmium tellurium. The electricity generated by a solar cell is influenced by many factors such as cell size and material, irradiance, environmental conditions, etc. [62]. There are several types of solar cells depending on their manufacturing process, which involve different efficiencies and costs. PV-EH systems commonly use electric resistance or induction devices to transform electricity into heat and can reach temperatures up to 2000 °C [63,64,65]. These systems have gained popularity in recent years in domestic applications such as water or space heating, while in industrial processes few studies have been carried out [24].

The energy performance of PV-EH systems with two approaches of power regulation: fixed load resistance of the direct current resistive heating element and maximum power point tracking was compared by Matuska et al. [27]. Both alternatives were evaluated for a domestic water application. An integration temperature of 45 °C with a maximum temperature of 85 °C in the TES were considered. The researchers found that maximum power point tracking can improve the energy performance of the PV-EH system between 20% to 35% over the fixed load resistance approach. The energy efficiency of the system reaches values up to 15% under European weather conditions. The authors also compared the efficiency of the PV-EH system with an ST collector alternative with FPC. Results showed that the efficiency of the ST collector was three times higher than the PV-EH alternative for the same operating and radiation conditions.

Clift et al. [66] evaluated the utilization of the excess electricity produced by a PV system that feeds a residential building to heat a water TES by an EH device. The heated water was used to meet the hot water requirements of the building. An improved control strategy was implemented to maximize hot water production. Results showed that an adequate control strategy is crucial to increase the performance of the system. The PV-EH system was able to provide 84.8% of the hot water requirements of the building. Authors deduce that the energy performance of the PV-EH system rivals the best ST heaters on the market.

Some studies have evaluated the utilization of PV-EH systems in industrial applications. Pérez-Aparicio et al. [61] compare economically and environmentally three ST collector technologies CPC, LFC and PTC with two alternatives of PV heating systems: a PV-EH system and a PV-EH combined with a HP. A case study of an industrial process with a temperature of 200 °C was evaluated. In the case of the system with HP, the HP system is used to pre-heat the thermal fluid up to a temperature of 60 °C. The comparison between ST collectors and PV alternatives is made in terms of ratios of levelized cost of energy and GHG emissions. These metrics are presented as a function of the life cycle cost and system efficiency ratios. Results allow visualizing with which combinations of cost and efficiency ratios the ST system offers better energy or environmental performance than the PV alternatives. The study found that ST alternatives are preferred over PV to meet solar heat in most of the range of life cycle costs and energy efficiencies evaluated. However, some scenarios exist where the PV has better performance than ST systems and this range is wider when the HP is included. The authors conclude that if the PV cost reduction continues in the coming years, PV-EH will compete with ST collectors in industrial heating applications in a wider range of scenarios.

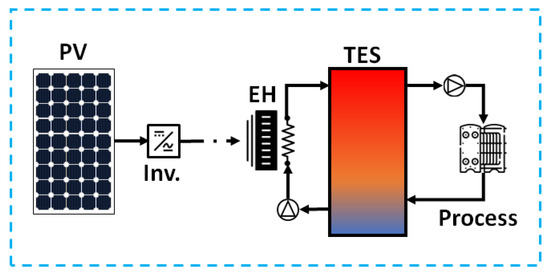

Meyers et al. carried out two studies [24,67] where they presented a methodology to determine which technology (ST or PV-EH) provide solar heat to industrial processes with the lowest cost. Different scenarios of process temperatures, load profiles, solar radiation, costs, ST technologies, and land acquisition costs were considered. The ST collectors analyzed were FPC, ETC, and PTC. Process temperatures from 50 °C to 170 °C were analyzed. The layout of the PV-EH with TES was the same of the ST system. A representation of the PV-EH system is shown in Figure 5. Results show that ST technologies have better economic performance in low-temperature processes in most of the locations evaluated. The PV-EH is the best alternative mainly in process with temperatures over 100 °C in locations with medium and low levels of DNI. PV-EH systems have the advantage that their thermal energy efficiency is almost independent of the temperature of the process. This means that the heat generation cost gap between ST and PV resistance decreases as the process temperature increases. The authors stated that if ST collectors costs do not decrease in the next years and PV costs continue to reduce, PV-EH will become the lowest-cost solar alternative for process heating in most European countries.

Figure 5.

Scheme of PV-EH system. Own figure based on [24].

2.3. Photovoltaic-Assisted Heat Pumps (PV-HP)

HP is a thermal machine that allows the transfer of energy between two systems through a thermodynamic cycle of expansion/compression. Conventional HPs are composed of an evaporator, a compressor, a condenser, and an expansion valve. The coefficient of performance (COP) describes how effective the HP is in converting the energy consumed into useful energy. The COP is defined as the ratio between the amount of energy provided and the electrical energy consumed by the HP. Typically, HPs transfer heat from the environment (ambient air or groundwater) using a refrigerant gas for the internal compression cycle. Based on the medium from which the HP receives energy and the medium to which the HP transfers its heat production most common HPs are air-to-air heat pumps (AAHP), air-to-water heat pumps (AWHP), and water-to-water heat pumps (WWHP) [68,69]. On the other hand, based on the heat sink temperature HPs can be categorized as HP for sink temperatures up to 80 °C, high-temperature heat pump (HTHP) for sink temperatures up to 100 °C, and very high-temperature heat pump (VHTHP) for sink temperatures up to 160 °C [70]. HPs are most frequently used in the residential sector and for low-temperature industrial heat processes, such as the milk pasteurization processes in the dairy industry [71]. While HTHP and VHTHP are usually used in waste heat recovery processes in the industrial or district sector, where the waste heat available is used as an energy source for the HP, being capable of reaching a COP greater than 5 with heat sink temperatures between 80 to 125 °C [28,70,72,73]. Commercially available HPs can reach temperatures up to 150 °C, experimental prototypes can reach almost 160 °C, and numerical studies have found that innovative HPs could be technical and economically able to provide temperatures up to 280 °C [29]. The energy performance of HPs is affected by the temperature lift (difference between source and sink temperatures). COP of high-temperature commercial equipment varies between 2.4 and 5.8 for temperature lifts of 95 and 40 °C, respectively [28].

On the other hand, the simulation of the thermodynamic behavior of HP is generally carried out by applying various regression methods, combining their resolution with thermodynamic equations to close the energy balance. The methods mainly rely on coefficients of performance obtained from a regression of experimental data or supplied by the manufacturer. In this sense, the efficiency of the resolution model depends on the quality of the data set for the regression process, the kind of application, and the number of input variables. Compared with experimental data, the methods with greater precision are multivariate polynomial models and neural networks [74,75].

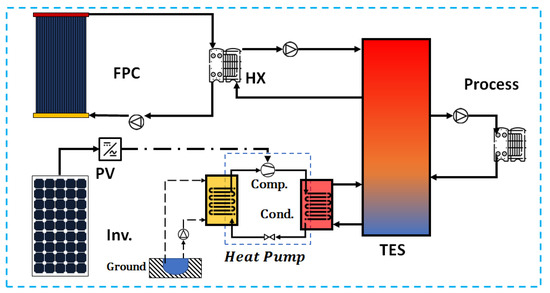

Combining solar technologies with heat pumps can improve the individual energy performance of both systems for heat generation. These configurations are known as solar-assisted heat pumps (SAHP) and have gained particular interest in research in recent decades. ST, PV, and PVT systems can be used in SAHPs to provide electricity, heat, or both to the HP [30,76].

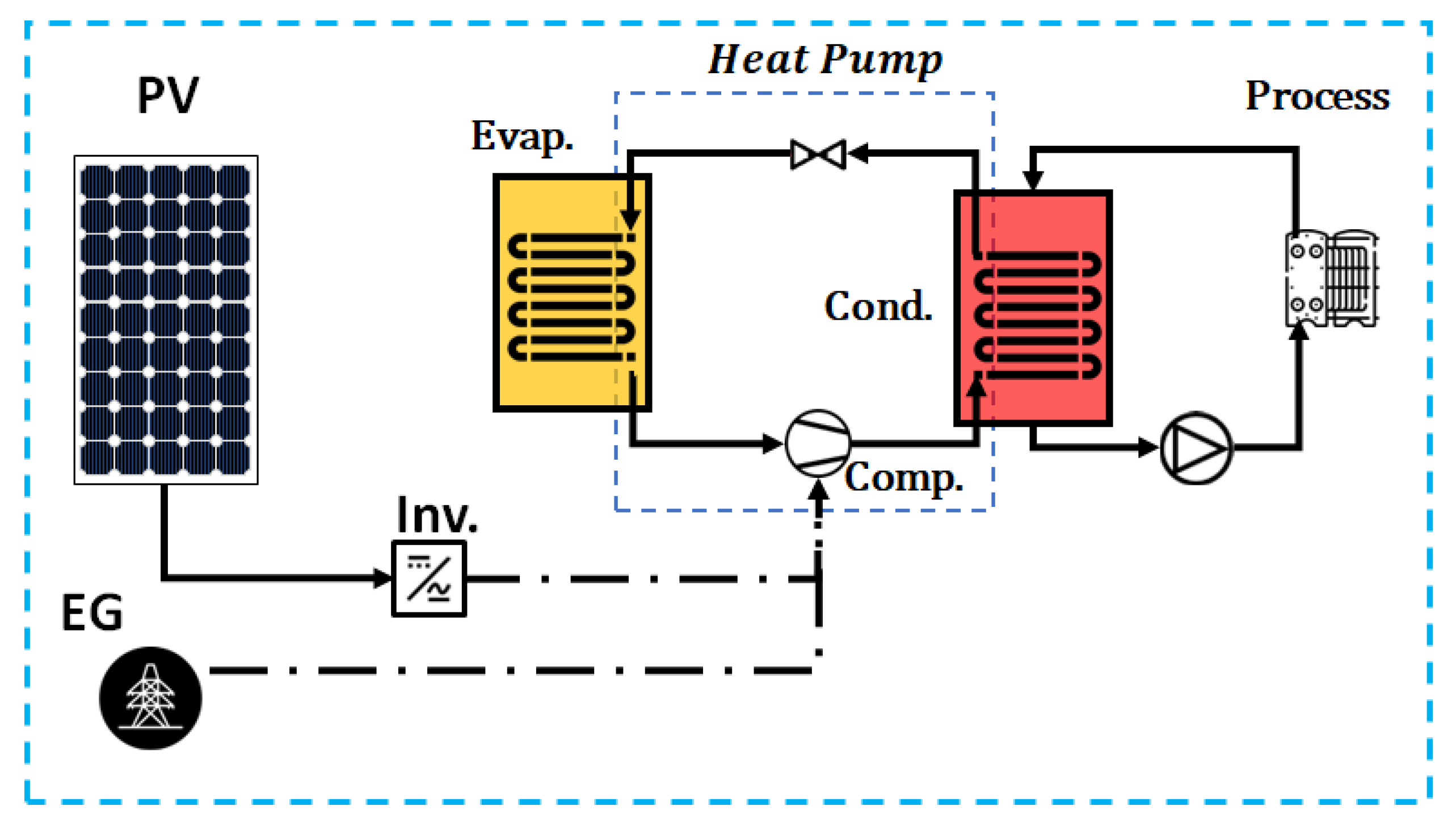

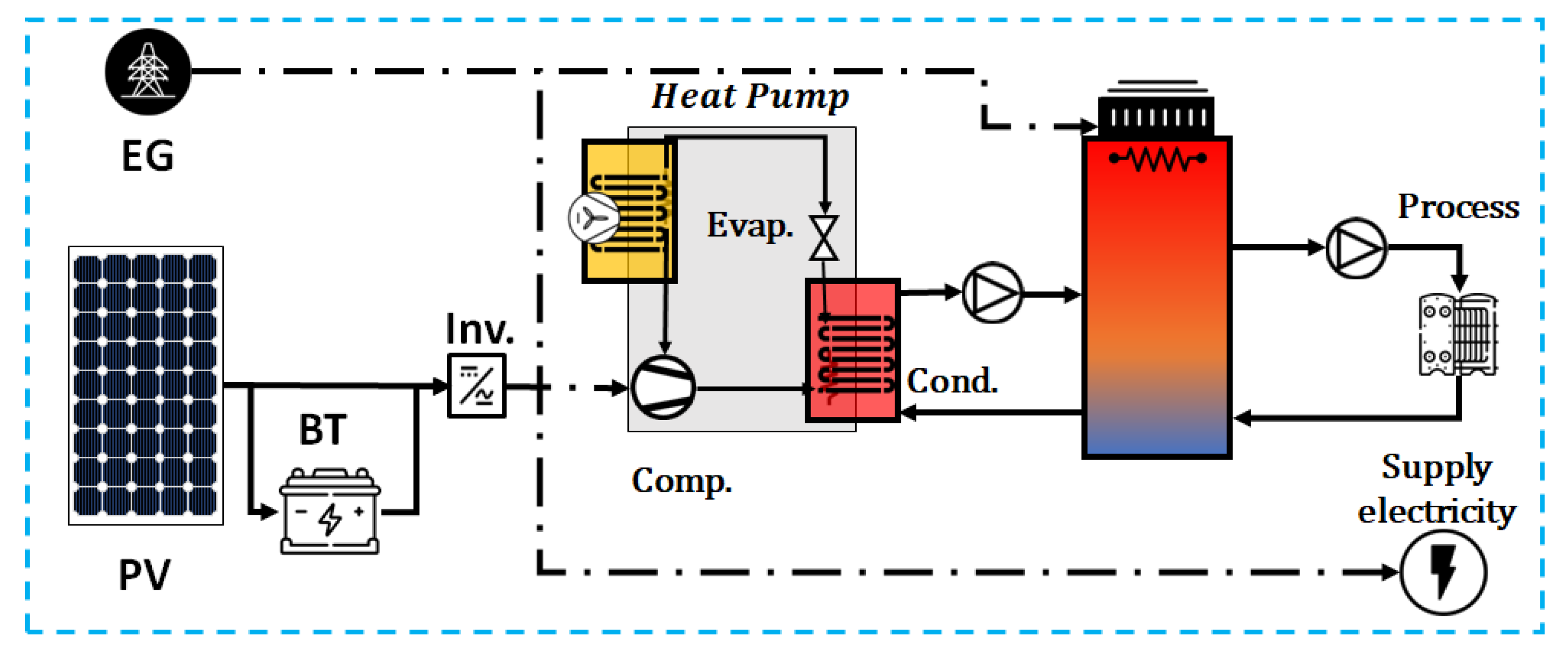

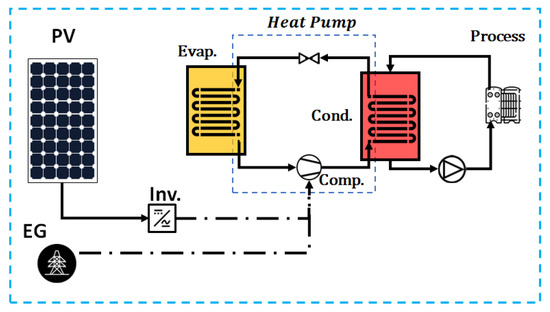

The use of PV-HP consists of feeding the electrical demand of the HP compressor with the electricity produced by the PV module (Figure 6). The use of this class of configurations has increased drastically in recent years due to the decrease in PV module costs and the high efficiency of the HPs [20]. The use of AWHP combined with PV modules (PV-AWHP) has been widely described for domestic applications. This kind of system has shown benefits such as lower initial investment cost and ease of installation compared to ST systems, with investment payback periods of less than three years [77,78]. In addition, when considering the integration of a TES, the PV-AWHP system can allow important energy savings when an adequate control strategy is used [79]. In this sense, the performance of the PV-AWHP highly depends on the operation with an appropriate control strategy adapted to the weather and energy demand characteristics.

Figure 6.

Basic scheme of a PV-HP system.

Coppiterrs D. et al. [80] carried out an exergetic analysis in domestic applications comparing a PV-AWHP system connected to a thermal storage tank with electrical resistance-like energy backup (TESER), as shown in Figure 7. The PV-AWHP-TESER system is compared to a system with PV batteries for electricity supply and a gas boiler for heating processes. The PV-AWHP-TESER system shows greater robustness in the design optimization concerning the variability in calculating the levelized cost of energy (LCOE). However, the analysis may be influenced by the costs of the electricity market, making it necessary for future research to evaluate electricity consumption rates.

Figure 7.

Scheme of an AWHP connected to a thermal storage tank with electrical resistance like energy backup (TESER). Own figure based on [80].

The performance of PV-AWHP and WWHP combined with PV modules (PV-WWHP) systems providing space heating and hot water in domestic applications is analyzed by [81]. A sensitivity analysis of the cost–benefit ratio considering a multi-family house in Austria is realized. Results show that the utilization of PV-HP systems can reduce GHG emissions by 45–60% compared with a gas boiler system. The authors exposed that with an increase of 17% in the cost of gas the PV-HP became economically viable without any subsidy. In another study, Peña-Bello A. et al. [82] developed an open-source algorithm to evaluate the behavior of PV-AWHP-TES systems with the help of the electrical network for space heating and domestic hot water (DHW) supply in Geneva. The study concludes that using TES reduces the levelized cost of electricity (LCOE), reaching a range between 0.55–0.71 $/kWhele. However, due to the economic sensitivity of local electricity rates, the use of PV batteries is more effective than TES systems in increasing the self-sufficiency of AWHP.

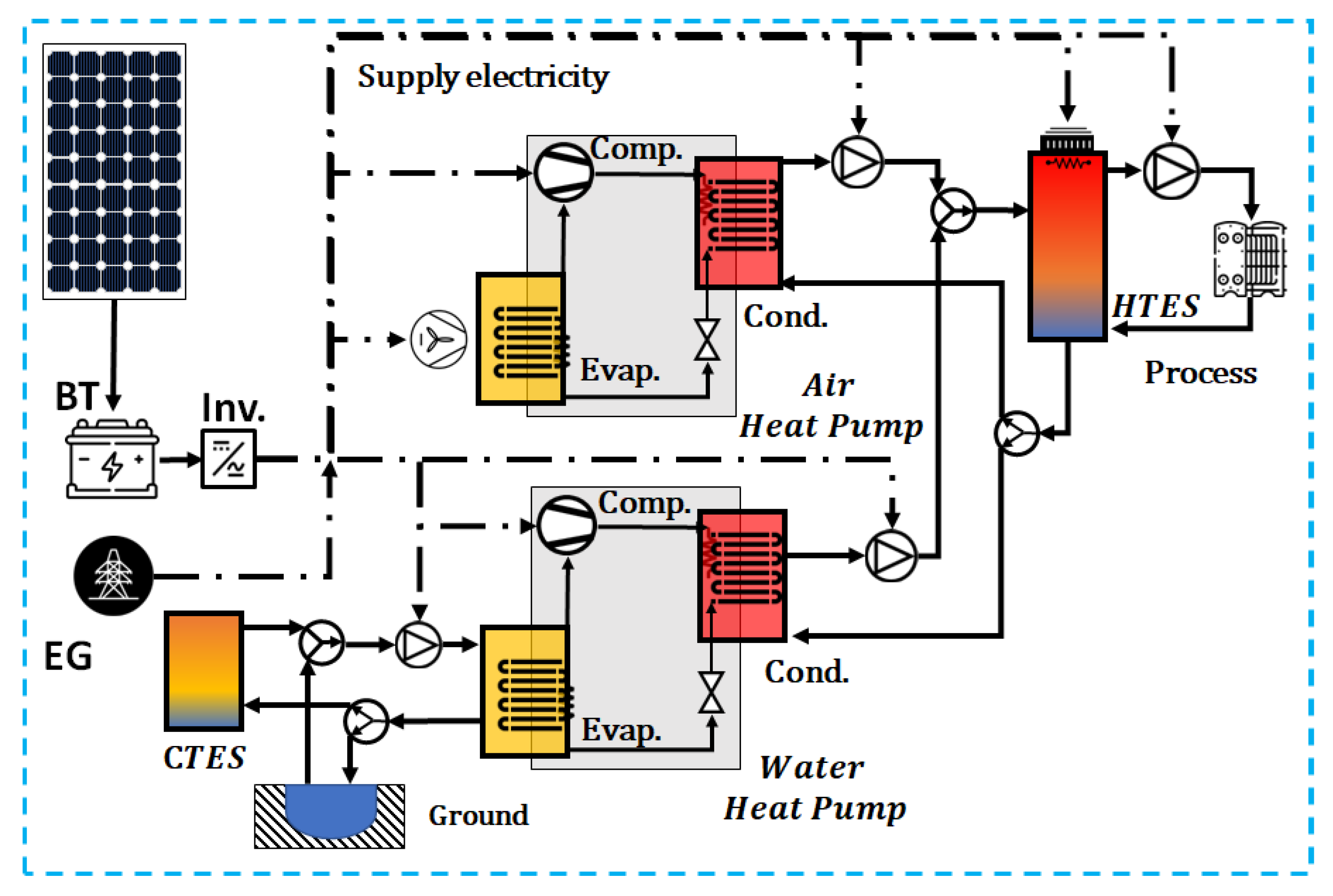

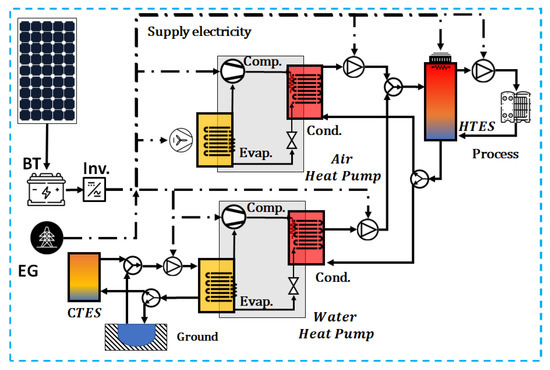

In climates with temperatures below 0 °C, ground source WWHP (GSWWHP) systems tend to have better performance. Chwieduk et al. [83] found that a PV-GSWWHP system can provide space heating and DHW during the winter season to a familiar residency in Warsaw, Poland, achieving energy savings of 1.53 MWh and 1.35 MWh with the PV-GSWWHP system with and without batteries, respectively. However, the analysis does not consider the PV production in seasonal periods without heat demand. In this sense, Biglarian et al. [84] evaluated a PV-GSWWHP system without PV batteries where the surplus electricity is distributed for the internal consumption of the house. The system reached a life cycle cost (LCC) of $9.6 with a payback period of fewer than four years and net savings of 29.2 tCO considering 20 years of system lifetime. However, using GSWWHP has the drawback that when the energy subtraction from the ground source exceeds its energy recovery the temperature of the ground source can decrease which affects the GSWWHP performance. Frequently, this problem is resolved by adding a complementary EH system forming a GSWWHP-EH system. In this sense, a study in Changsha, China, evaluated combining a PV-GSWWHP system with an AWHP as an auxiliary heating device (Figure 8). The performance of the PV-GSWWHP-AWHP was compared with a PV-GSWWHP-EH system. Results showed that the PV-GSWWHP-AWHP allows an electricity consumption 42% lower than the PV-GSWWHP-EH system and an increase in the global system COP of 135% [85].

Figure 8.

Scheme of the PV-WWHP-AWHP system. Own figure based on [85].

In industrial applications, there are fewer studies than in the domestic sector. One of the studies that evaluate an industrial application is the work carried out by Ahrens et al. [86], who studied a dairy in Bergen, Norway, where is used an ammonia HP (HP-NH) and a high-temperature hybrid absorption/compressor HP (HACHP) for milk processes, building space heating and DHW. The HPs use waste heat as an energy source. Results showed that the inclusion of the HPs in replace of gas boilers allowed a 37.9% of energy saving, reductions in GHG emissions between 23.2% and 91.7% and a heat recovery rate of 95%. The authors found that the energy contribution of the PV field is low related to the total energy demand due to the limited roof area available, and the waste heat recovery is more relevant to reduce energy consumption.

The results obtained in the domestic and industrial sectors have led to projections with HP to be applied as alternatives to the current options that use GLP or electric heaters. The study developed by [87] evaluates the different coupling options in Switzerland, focusing on single-family housing, multi-family housing, commercial buildings, and the industry with PV-HP with batteries of lithium ions as a sensible technology to reach the maximum potential in 2050. The projection considering the Swiss scenario estimates a potential total share of PV between 65% and 89%. In which the PV reaches 100% (9.4 GWP) of its potential in the industry and 91% (7.4 GWP) in commercial buildings.

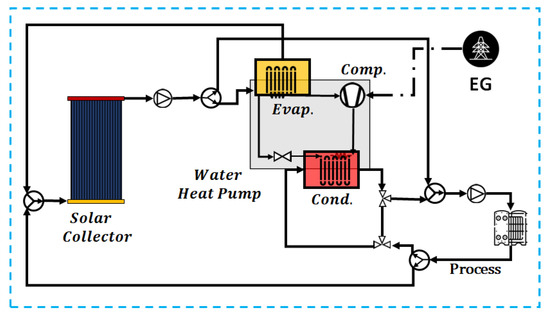

2.4. Solar Thermal-Assisted Heat Pump (ST-HP)

In an ST-HP system, the ST collectors are used as heat source for the HP. In the ST-HP configuration, the solar technology can improve the efficiency in the operation of the HP providing heat at higher temperatures than other alternative heat sources such as ambient air. Due to this fact, the ST-HP configuration can be advantageous compared to PV-HP systems, where the solar technology does not produce any improvement in the compression cycle operation efficiency of the HP [30]. In ST-HP systems, the solar source can be combined with alternative non-fossil heat sources such as ambient air, ground, or waste heat [88]. For domestic applications, the most-used alternative heat sources in ST-HP systems are ambient air and ground [76,89], while for industrial applications waste heat is commonly evaluated as an alternative heat source [90,91]. Systems that combine solar and air ambient heat sources are known as solar thermal-assisted air source HP [89], and systems that combine solar and ground are known as solar thermal-assisted ground source HP [92].

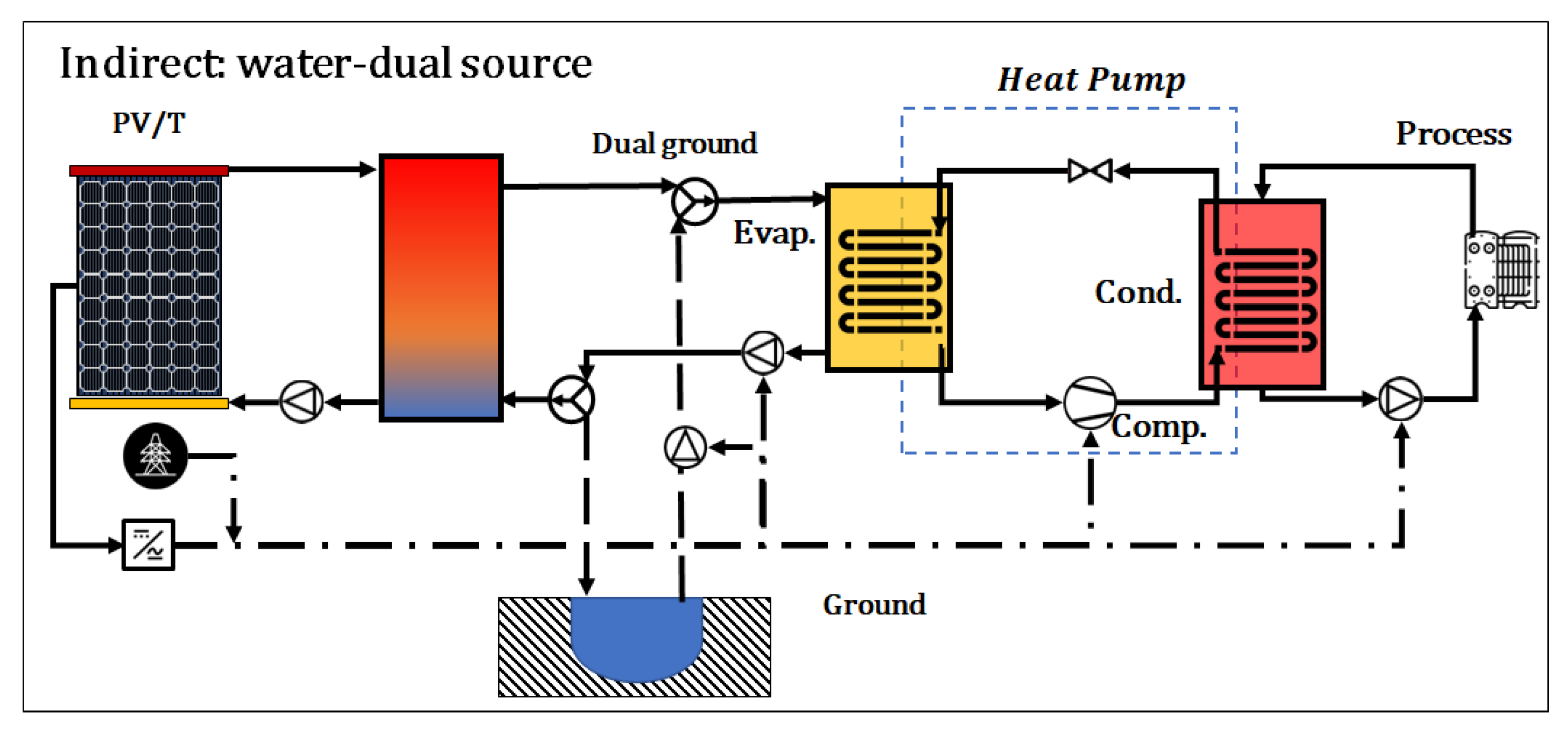

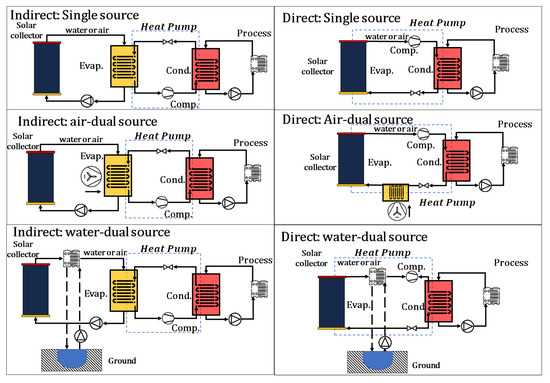

The arrangement of the components of an ST-HP system can vary widely depending on the ST technology, the alternative energy source used and the integration scheme to the desired facility. Further, ST-HP configurations constantly become more complex to achieve greater energy efficiencies [30]. There are many ways to classify the ST-HP systems by their configuration. Based on the generation method, ST-HP can be classified as direct expansion (DX) and indirect expansion (IDX) ST-HP systems [89,93]. In the DX connection, the ST collector and the HP are joined in one system, where the ST collector acts as the evaporator of the HP. On the other hand, in IDX connection, the ST field supplies heat to the evaporator of the HP by a heat exchanger [30,76,89,94,95,96,97]. In addition, based on the existence or not of an auxiliary heat source, DX and IDX can be subclassified as single-source and dual-source systems. The schemes of ST-HP considering both classifications is shown in Figure 9. ST-HP can also be integrated by reversible HPs, where the ST collector can function as an evaporator or condenser depending on thermal needs, changing its operating mode to provide cold or heat [30]. However, in this section, the focus is on heat systems and configurations related to heating applications.

Figure 9.

Classification of heat pump configuration according to the generation method.

In industrial applications, systems with single source DX configurations have been investigated on an experimental scale in food drying processes [98,99,100].The DX has shown better performance than the IDX configuration in systems with small ST areas [30] and with medium and low levels of solar radiation [95]. Nevertheless, in systems with larger areas of collectors, the larger volumes of refrigerant required, the complexity in the adequate control of the compression cycle and the maintenance difficulties of the system difficulties affect the technical and economic viability of the implementation of DX configurations in applications with industrial scale [30,94,97].

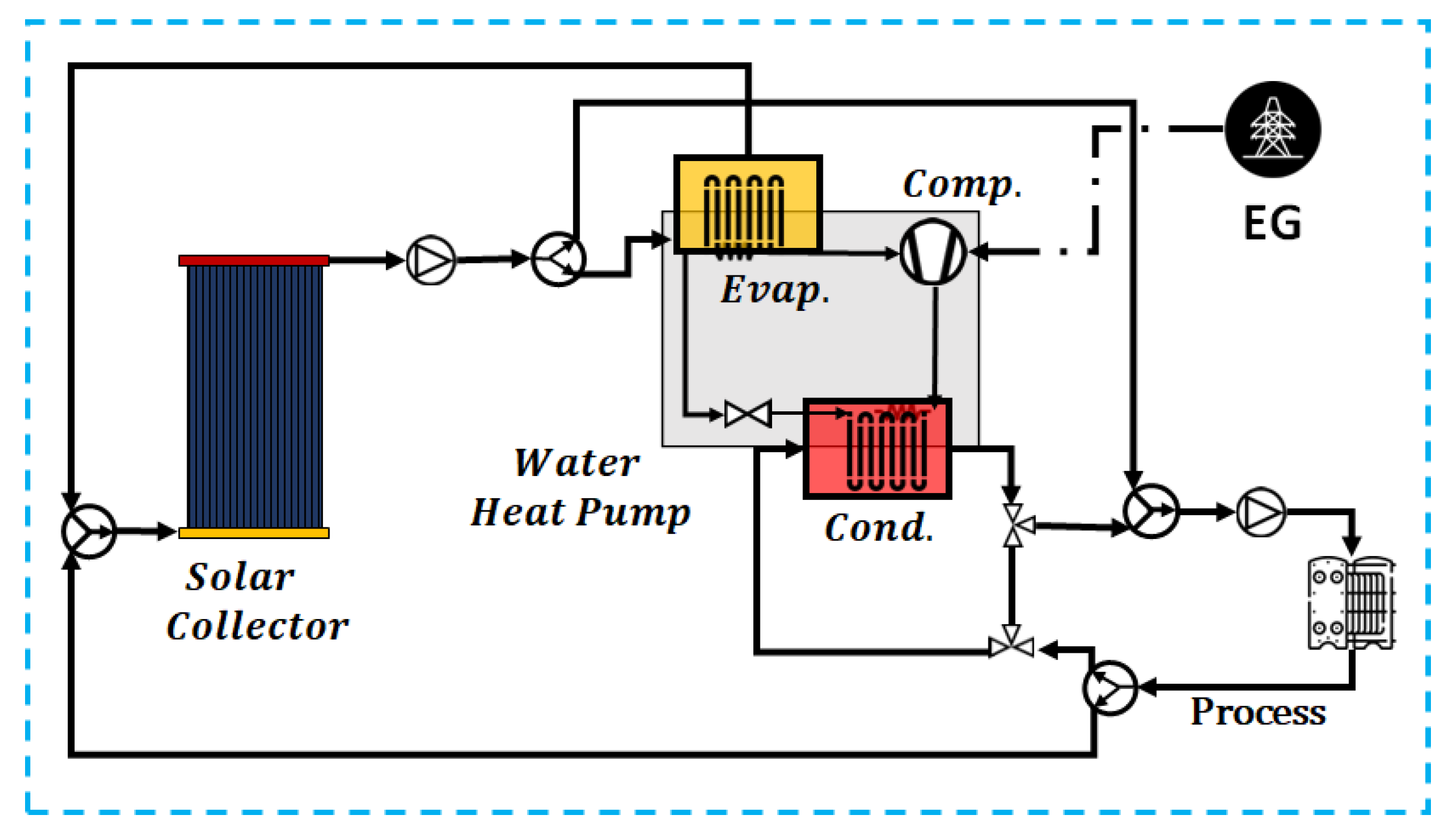

Exist a special case of single IDX configuration where the ST field can supply heat to the HP or direct to the process heat load (Figure 10). In this configuration, when the outlet temperature of the ST field is concordant with the heating load requirements, solar heat is supplied directly for the demand. On the contrary, when the temperature is not adequate solar heat is delivered to the cold side of the HP [30,94].

Figure 10.

Single IDX-ST-HP (ST collector can supply heat to the HP or direct to the process heat load). Own figure based on [30].

One of the main limitations of single source systems is that the restriction of the evaporator to operate just with the ST collectors reduces the flexibility in the operation of the system and makes it more sensible to the solar energy variability [30]. In this sense, dual-source configurations could provide a solution to this problem. In dual-source systems, the solar and the alternative heat source (ambient air, ground, or waste heat) can provide energy simultaneously to the HP or can operate with only one of the heat sources when the other cannot supply an adequate temperature for the evaporator of the HP. The use of dual sources can improve the performance of the HP allowing more available energy and operating temperature in the evaporator of the HP. This class of systems also prevents frost in the evaporator when the temperatures tend to be very low [101]. The dual-source arrangement has shown to be the configuration with the widest range of operation conditions, ensuring better efficiency and reliability under different meteorological conditions and load requirements. However, the implementation of this configuration is justified when there is available an adequate alternative energy source to the process requirements and it can provide enough amount of energy to justify the additional cost of the system [30,95,96].

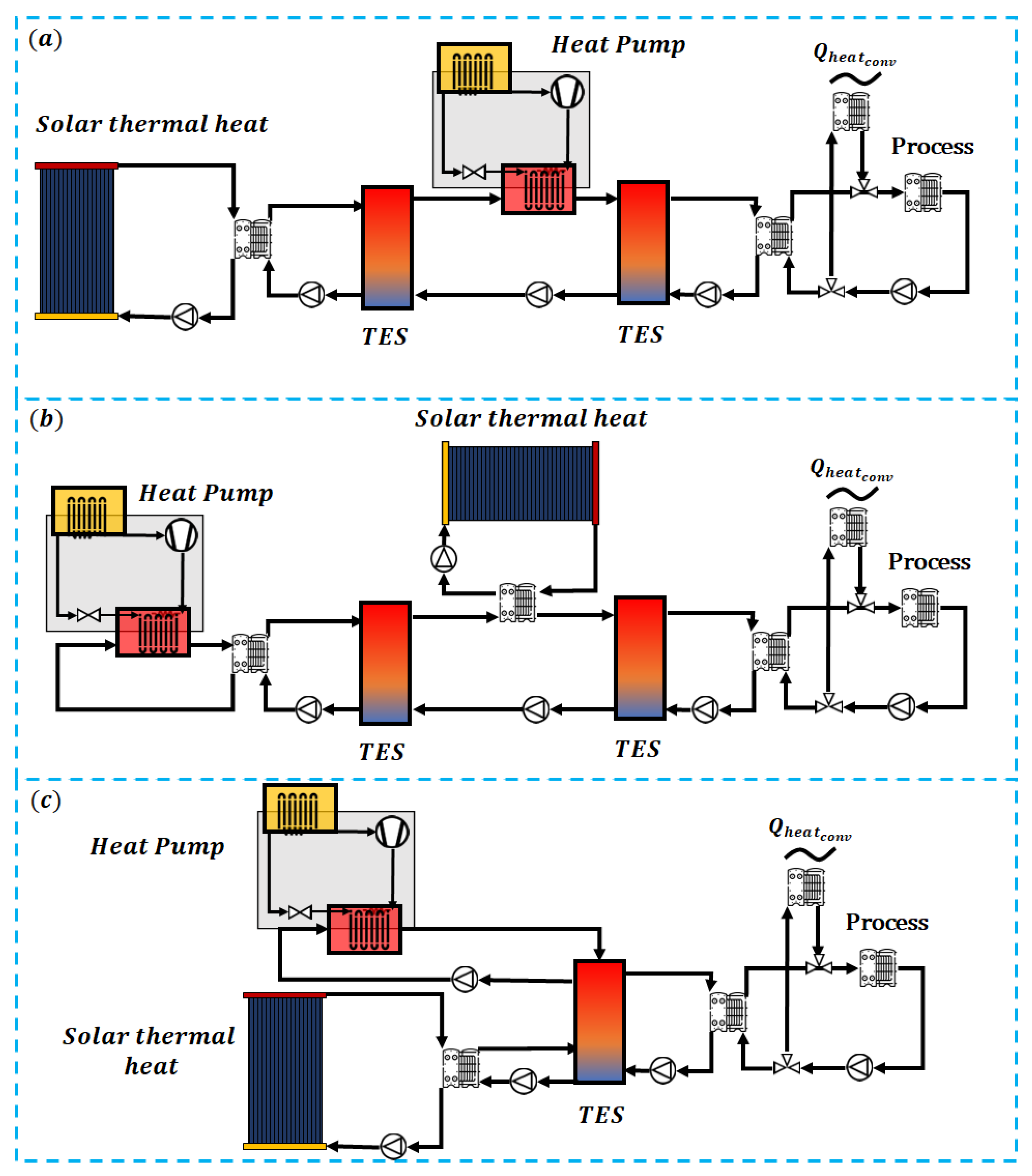

On the other hand, some researchers have evaluated configurations that combine an ST field with conventional HPs. In these cases, the HP only operates with an alternative heat source such as ambient air, ground or waste heat. Considering the integration scheme of both systems with the load demand, these systems are generally classified as serial or parallel [88,89,90]. In serial configurations, the ST field is connected to the condenser of the HP (Figure 11a,b) [89,90]. In this case, both the ST field and the HP supply energy to the same stream. Depending on the temperature of the alternative heat source, the ST field or the HP acts as a pre-heater. In the first case, the ST field can operate at a lower temperature which increases the efficiency of the collector. The second case allows using an alternative heat source with a temperature not high enough to be compatible with the industrial process requirements [90].

Figure 11.

(a) Configuration with independent ST field and conventional HP connected in series (ST field as pre-heater); (b) configuration with independent ST field and conventional HP connected in series (HP as pre-heater); (c) configuration with independent ST field and conventional HP connected in parallel (HP as pre-heater). Own figure based on [90].

In the parallel configuration (Figure 11c), the ST field and the HP supply energy to the heating load separately. Commercially, the parallel configuration is widely used for domestic applications [68], nevertheless for the optimal implementation of this system arrangement, both energy sources must be able to reach the temperature needed by the industrial process, making difficult the application of this configuration when there is not an adequate alternative energy source [90].

3. Hybrid Solar Heating Systems (HS)

Solar HSs have been proposed to improve the performance of conventional solar systems and overcome their individual limitations. HSs combine two types of solar thermal technologies or solar thermal with PV systems. Both technologies can be combined in the same device as in the case of a PVT [33], or combine different individual technologies in the same system. In this case, we can have solar thermal–solar thermal hybrid systems (ST-ST HS), which combine two technologies of ST [34,35]; solar thermal–photovoltaic heating hybrid systems (ST-PV HS), which combines an ST technology with a PV-EH system [36,37]; and solar hybrid assisted heat pumps (SHAHP). HSs have the potential to become an important tool to provide solar thermal energy to industrial processes in a more optimal way [42].

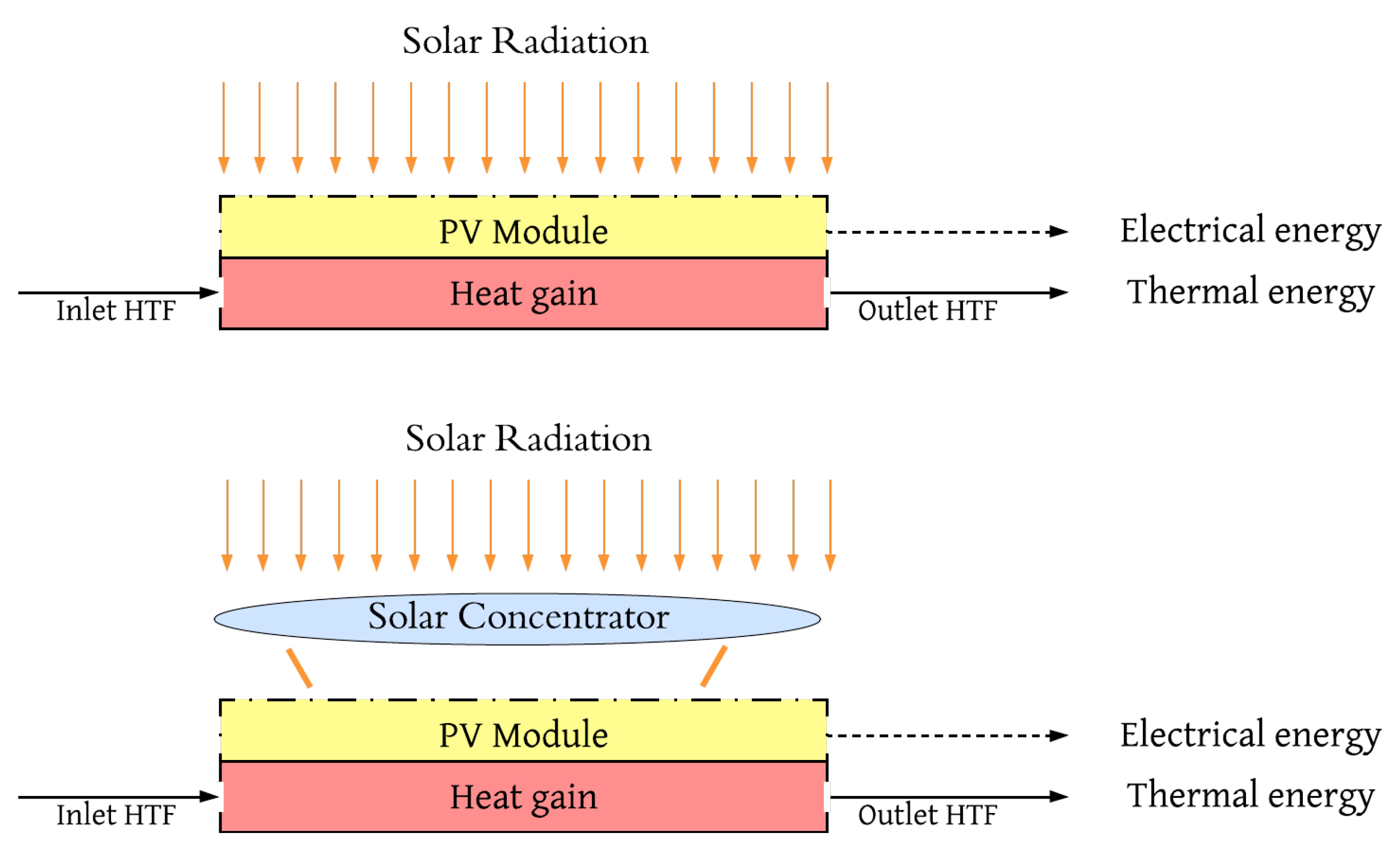

3.1. Photovoltaic-Thermal Collector (PVT Collector)

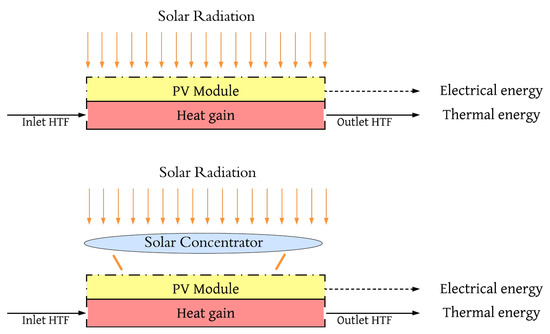

A PVT collector is a device that combines PV modules with heat transfer elements, which can operate with HTFs such as water, air, and nanofluids. This combination creates a device that converts solar radiation into electricity and heat at the same time. The heat is extracted from the PV cells, reducing their temperature increase and efficiency decline [102,103]. This is an important advantage over conventional PV modules, due to the fact that conventional PV systems cannot convert the entire spectrum of solar radiation into electricity and the unused solar energy is dissipated in form of heat in the solar cell. This heat causes temperature increases and heat losses in the solar PV system, thus reducing its performance [104]. Most common PVT systems are of flat type, but they can also use concentrating technologies such as compound parabolic concentrators, cylindrical parabolic, linear Fresnel reflectors, Fresnel lenses, or dish concentrators. These systems are known as concentrating photovoltaic thermal (CPVT) [102,105,106,107,108]. The schemes of a PVT and CPVT are shown in Figure 12.

Figure 12.

Schemes of a PVT and CPVT.

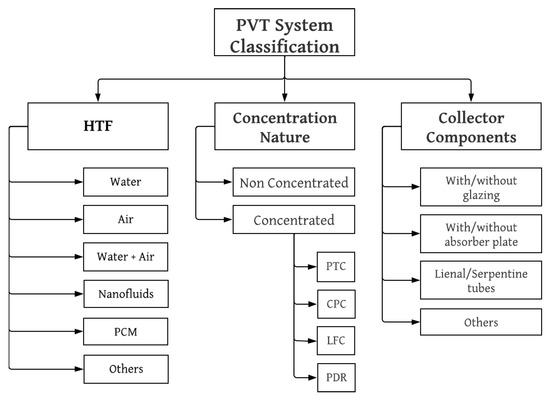

Joshi et al. [104] classified the PVT systems according to the heat extraction medium, final applications, and type of collector, among others. We can see a simplification of that classification in Figure 13. Based on the HTF used in the PVT systems, the most common PVT types are PVT-water and PVT-air [104,109]. PVT-water systems present overall efficiencies between 40 and 65%, while the overall efficiencies of PVT-air are between 40 and 50% [109]. On the other hand, CPVT systems can reach higher electrical and thermal performance than PVT systems. The overall efficiency range of CPVT systems with cylindrical parabolic and linear Fresnel reflectors can reach values of 70% and 60% respectively, with a higher outlet temperature of the HTF than conventional PVTs. This gives CPVT a wider range of possible applications [106].

Figure 13.

PVT system classification. Own figure based on [104].

PVT-water is a well-developed technology, with multiple uses and higher efficiency and heat capacity than PVT-air types. However, these systems present some disadvantages as high costs, oxidation/corrosion of the absorber, difficulty of maintenance, freezing of water in cold climates, leakage problems, high weight/area ratio, and more pump energy demand. PVT-air systems are also a well-developed technology, with less risk of corrosion, simpler, and better for space heating in cold regions. However, PVT-air systems are limited by the lower heat capacity of the air than water and have shown a lower number of potential applications [104,109,110,111]. On the other hand, CPVT technologies allow higher thermal efficiencies at higher temperatures than conventional PVTs, and they are able to produce the same electrical energy with a lower number of solar cells. Nevertheless, these systems are more complex, present more risk of overheating, are highly dependent on direct radiation levels, and require expensive components to resist the high operation temperatures [105,106,109,112].

PVT and CPVT systems have shown potential in applications such as domestic water heating, desalination, space heating, space cooling, distillation, pool heating, solar drying, and water heating for industrial process [33,104,109,113]. Mittelman et al. [114] analyzed a large-scale multiple-effect evaporation desalination (MEED) system coupled with a CPVT field. The heat production of the CPVT system was used for the desalination process which required a temperature of 90 °C, and the electrical production was sold to the grid. Results showed that the CPVT + MEED is competitive with other solar-driven desalination alternatives and with conventional reverse osmosis desalination when the grid cost of electricity is high enough.

Among PVT studies in industrial applications is the work developed by Kalogirou et al. [102], who analyzed the utilization of PVT systems for supplying the electric and heat demand of an industrial facility. The study considered two possible temperatures (60 °C and 80 °C) for a water-heating process in three locations (Nicosia, Athens and Madison). The authors compared the performance of two alternatives of PV cells technologies for the PVT system polycrystalline silicon (pc-SI) and amorphous silicon (a-SI). Results showed that the electricity production was higher with the pc-Si alternative, but the a-SI allowed a slightly higher thermal solar fraction. The PVT alternative produces 25% less electricity than a conventional PV system, but the PVT can cover an important part of the heat demand. Although the lower electric efficiency of the a-SI alternative, it had the best economic performance due to its lower cost and higher thermal production. In another study, Tiwari et al. [115] analyzed a PVT-air integrated to a solar drying system. Results show that among the advantages of this technology is the reduction in drying time, which implies an increase in production, with payback periods of 1–5 years, being twice as cheap as an electric dryer and more flexible in terms of temperature control. Other advantages are long service life and low maintenance.

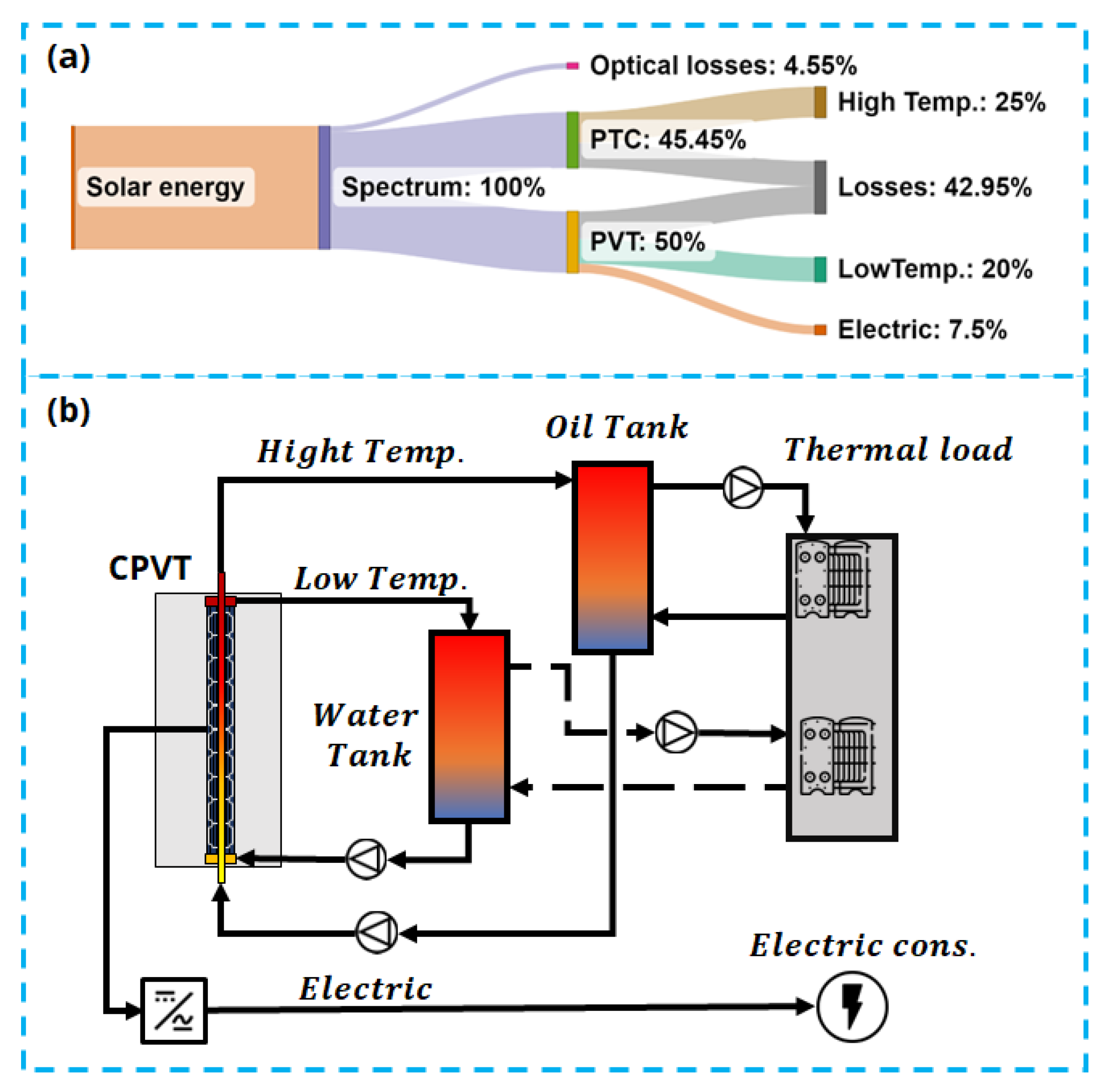

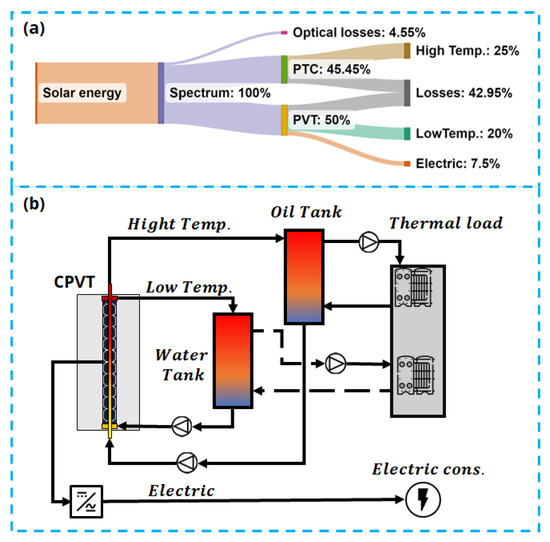

Wang et al. [116] proposed an innovative CPVT system that combines a spectral-splitting PTC with a PVT collector. In this case, the spectrum splitter in the PTC absorber reflects the range of the solar spectrum useful for PV electricity generation. The other part of the spectrum is absorbed for the PTC to produce heat. This system is studied for a dairy farm facility in Bari, Italy. The PTC heat is utilized to meet the demand of steam at 240 °C and the heat produced by the PVT is used for water heating at 70 °C. The electricity is used to supply the pumping requirements and the electrical demand of the industrial facility, any excess is sold to the grid. A Sankey flow and a scheme of the system are shown in Figure 14). The spectral-splitting CPVT system was able to cover 52%, 40%, and 14% of the steam, hot water, and electricity demands, respectively. The steam generated reached an average temperature of 204 °C, and the heat produced by the PVT had an average temperature of 40 °C. Results showed that the efficiency of the PVT system is improved allowing a lower operating temperature for the PV cell while simultaneously the system can provide high-temperature heat. The authors concluded that for the system become economically competitive with fossil alternatives, the cost of the spectral splitter should decrease.

Figure 14.

Spectral-splitting-PTC-PVT: (a) Sankey flow. (b) Scheme of the plant. Own figure based on [116].

The performance of CPVT systems was compared with a side-by-side independent PV and ST system (PV + ST) by Diego Cabral et al. [112], who carried out an experimental study of an innovative CPVT with two alternatives of compound parabolic concentrator geometries. The CPVT and the PV + ST systems had the same total area. Locations in Cairo and Athens were considered for the study and operating temperatures of 45 °C, 55 °C, and 65 °C. The CPVT had an annual yield 10% and 4.4% higher than the PV + ST system in Cairo and Athens, respectively, at the operating temperature of 45 °C. For the temperature of 65 °C the annual yield was 7.2% and 15.3% lower than the PV + ST system for the Cairo and Athens cases, respectively. The results showed that in low-temperature operation the CPTV can reach higher energy performance than the PV + ST system, but in the highest evaluated temperature the PV + ST system has better energy production than the CPTV. The observed trend was that as the temperature increases the difference in the energy production between both alternatives increases. The authors concluded that the cost of the CPVT has to decrease and its overall efficiency increase to become competitive with the PV + ST alternative.

Within the industrial sector, the applications where PVT and CPVT systems have shown greater potential are agroindustrial, drying, water distillation, textile, and food production processes [41,105,112,115,117,118,119]. PVT systems are recommended mainly in low-temperature processes such as greenhouse space heating, water pre-heating, and drying of agricultural products. CPVTs can also be used in that applications, but additional are able to provide heat to process with medium-temperature requirements such as water heating or steam generation. The largest share of PVT plants operating worldwide is for domestic applications, while in the industrial sector, PVTs are little used [21,117]. Most of the existing systems in industrial processes have a prototype scale in applications such as agroindustrial production [118,119].

3.2. Solar Thermal–Solar Thermal Hybrid System (ST-ST HS)

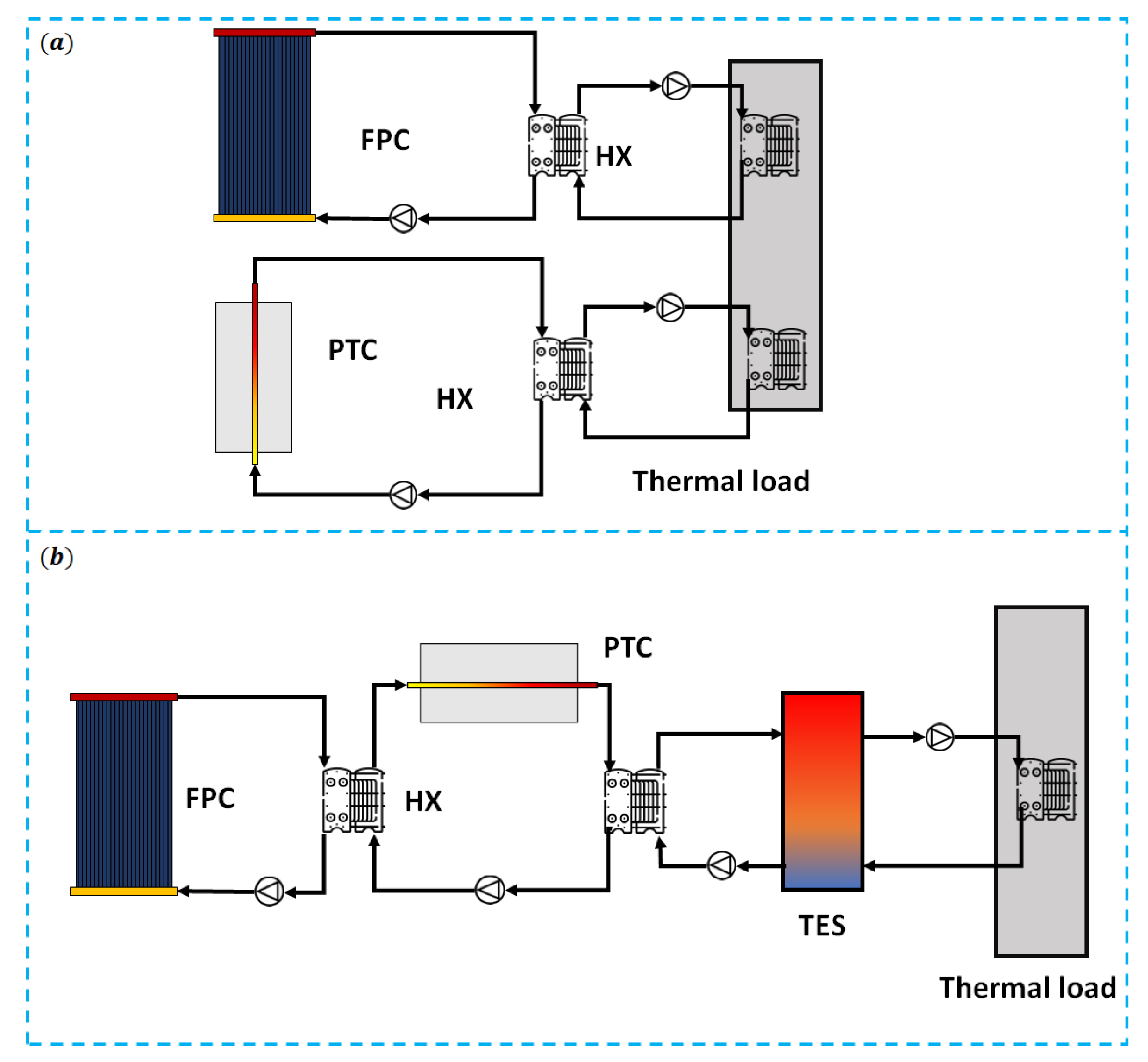

ST-ST HSs combine two types of solar thermal collectors in a parallel (Figure 15a) [35] or serial (Figure 15b) [34,120] configuration.

Figure 15.

(a) ST-ST HS with parallel configuration; (b) ST-ST HS with serial configuration.

In a parallel configuration, both solar thermal technologies supply heat independently. Madiouli et al. [35] studied experimentally the performance of a single slope solar still assisted by an FPC and a PTC HS that provide heat in a parallel configuration, the system also had a package glass ball layer that worked as a thermal storage material. Results showed an increase of up to 203% in water production compared to conventional single-slope solar still. However, the system assisted by the hybrid solar field shows a price per liter of water produced of 0.22 $/L, while the price of the conventional system was 0.067 $/L [35].

In ST-ST HSs with serial configuration, one of the solar fields acts as a pre-heater, increasing the temperature of the thermal fluid to an intermediate temperature; then, the other solar field heats the fluid up to the integration temperature. Since low-temperature collectors such as FPC could be significantly cheaper than collectors for higher temperatures such as PTC or LFC, one of the potential advantages of this configuration is that it could reduce the cost of the solar heating system related to a conventional alternative, through the use of a cheaper technology to pre-heat the HTF to an intermediate temperature, which reduces the required area of more expensive high-temperature collectors [120]. One example of the successful implementation of ST-ST HSs with serial configuration could be seen in Taars, Denmark, where an ST-ST HS with a total area of 10,000 m for district water heating has been operating since 2015. This system combines in series by a heat exchanger an FPC solar field with a PTC solar field. In the Taars plant, FPCs field pre-heats the return water flow from 40 °C to 70 °C and then the PTCs field heats up the flow to 95 °C. This plant provides 22.2% of the total annual heat demand [34].

The performance and optimization of the Taars plant have been analyzed in different studies. In [34,40], the energy behavior of the Taars plant is analyzed from operating measurements and numerical modeling. The results showed that the FPC field in the hybrid system produces 15% more energy per area than an FPC-only plant. Further, it was seen that the hybrid system could have significantly higher energy production on summer days compared to an FPC-only plant due to the good performance of PTCs on days with high levels of DNI. The authors concluded that the performance of the plant could be improved with the appropriate dimensioning of both solar fields and thermal storage. In [43], a mono-objective optimization methodology is implemented to find the best sizing of the FPC and PTC fields. Maximum energy output and LCOH were considered as the objective functions. When the maximum energy output is considered, the optimal solar field is completely composed of PTCs. On the other hand, when LCOE is taken as the objective function, the optimal solar field is composed of a mix of FPCs and PTCs. Results show that the FPC-PTC HS can have an LCOH between 5% and 9% lower than a conventional natural gas boiler system. The authors concluded that ST-ST HS could have great potential for other heating applications, and they also highlighted that the utilization of other technologies such as LFC, ETC, and CPC in these hybrid configurations should be studied. In another study, Perers et al. found that with an increase of 50% in the price of the PTCs the hybrid configuration is no more economically feasible for the Taars plant scenario [121].

The use of ST-ST HSs to supply solar heat to industrial processes with higher temperatures than district heating applications has been studied in [42,120]. In these studies, the authors propose an ST-ST HS with FPCs and PTCs as one promising hybrid configuration for industrial applications. The study considers that the FPCs pre-heat a glycol–water mixture up to an intermediate temperature of 90 °C, and the PTCs use water in a pressurized system for applications up to 150 °C or thermal oil for applications up to 300 °C to reach the process integration temperature. This system was evaluated numerically considering an industrial process with an integration temperature of 300 °C in Lancaster, California. A parametric study of the effect of the thermal storage size on the total annual energy production was made. The total thermal energy generation varied from 14,262 MWh for 0 h of storage to 35,255 MWh for 12 h, with a total hybrid field area of 3542 m. The result showed the feasibility of the implementation of ST-ST HS in industrial heating process applications and their potential to improve the economic performance of conventional solar heating systems. The authors determined that the correct dimensioning and temperature control of this hybrid system is more complex than in FPC-only or PTC-only plants, and there are no design standards or pre-feasibility analysis tools for this type of system [42,120].

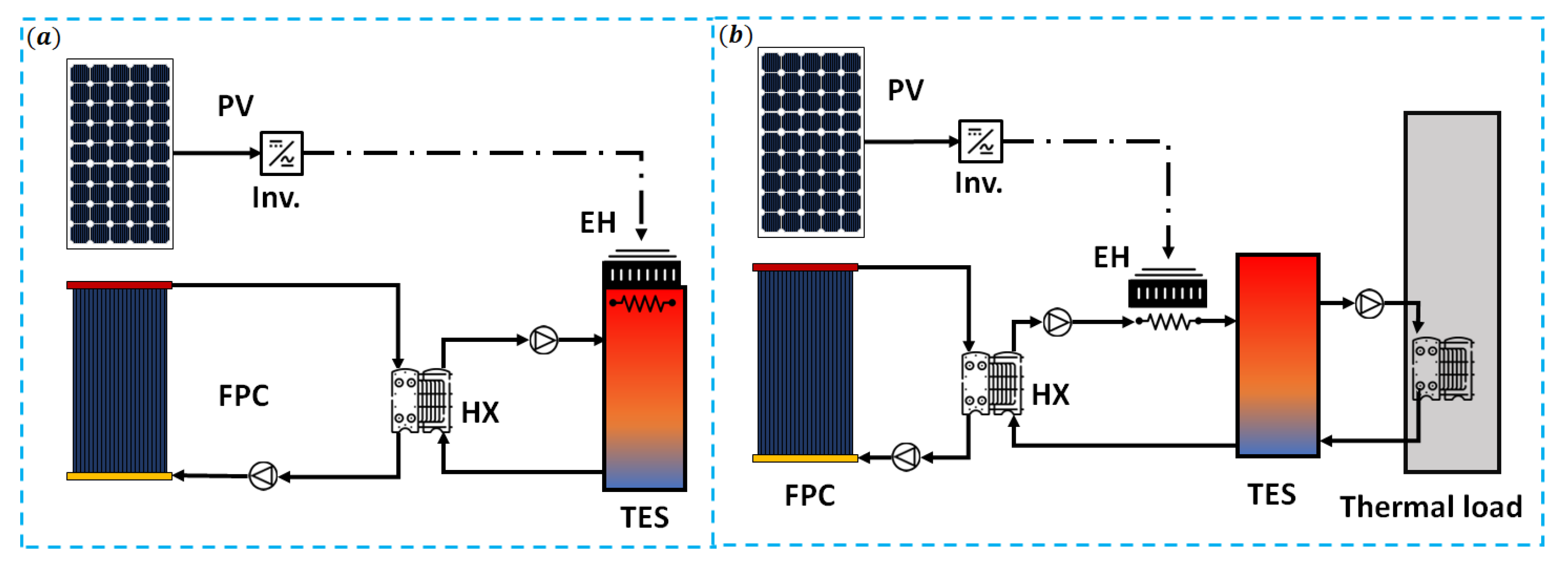

3.3. Solar Thermal–Photovoltaic Heating Hybrid System (ST-PV HS)

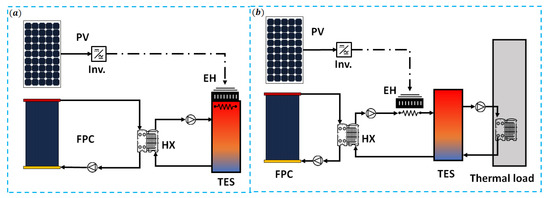

ST-PV HSs combine ST collectors with PV-electric heating systems to provide thermal energy. Both technologies in an ST-PV HS can be arranged in parallel (Figure 16a) or in series (Figure 16b).

Figure 16.

(a) ST-PV-HS with parallel configuration; (b) ST-PV-HS with serial configuration.

In the parallel configuration, as in the case of ST-ST HSs, both technologies supply energy independently of each other. This configuration could be easily applied in systems with ST collectors and a TES with an internal PV-fed EH device to heat the HTF inside the TES. Some studies have evaluated a variation of this configuration using a HP as heating element instead of an induction or Joule effect device. This configuration was studied in a domestic application by Dermentzis et al. [122] who evaluated a system composed by an PV-WWHP in parallel with an ST collector, three ventilation units, and heat recovery for air conditioning of multi-family houses in Austria. The scheme of the system is shown in Figure 17. Results showed that the system allows saving 49% of electric consumption (27% of the consumption of HP and 22% for auxiliary systems). However, the required control system to achieve optimal operation could increase the installation cost and operational complexity. In another study, Bany Mousa et al. [37] study a hybrid system that combines an LFC solar field with a PV-HP system to supply heat to an industrial sterilization process at 134 °C. Mono-objective, bi-objective, and tri-objective optimization was used to find the optimum combination of technologies. Solar fraction, LCOH, and GHG emissions payback time were considered as optimization variables. The system was evaluated considering twelve locations around the world. Results show that compared to the LFC-only or PV-HP-only configurations, the ST-PV HS can enhance the solar fraction, LCOH, and GHG emissions payback time by up to 9.6%, 4.4%, and 6.8%, respectively. The optimum mixture of technologies depends largely on the objective function considered, radiation characteristics in the location evaluated, and the cost ratio between technologies.

Figure 17.

ST-PV-HP scheme. Own figure based on [122].

On the other hand, when the ST-PV HS is arranged with serial configuration, the fluid is first pre-heated by an ST field and then a PV-heater system boosts the HTF temperature to reach the value required at the integration point. This configuration allows taking advantage of the high efficiency of ST technology at low-temperature operation and the low cost of the PV systems. Sturm et al. [36] studied an ST-PV HS with serial configuration to supply heat to a soy sauce industrial production in Beijing, China. The hybrid system was composed of FPCs and PV-electric heating systems. Two integration points in the production chain were analyzed, one with an integration temperature of 90 °C and the other of 152 °C. The ST-PV HS performance was compared to FPC-only and PV-heater-only systems. For the FPC-only alternative in the point with the higher temperature, a vacuum FPC was considered. Concentrate collector was not considered due to the low levels of DNI in Beijing. Results showed that for the lower temperature integration point, the best configuration was the FPC-only system. For the higher temperature integration point, the best alternative was the ST-PV HS with an LCOH 10% lower than the PV-only system and the ST-only had the worse economic performance. The authors concluded that ST-PV HSs could be a competitive alternative in medium and high-temperature industrial process applications in locations with medium and low DNI levels.

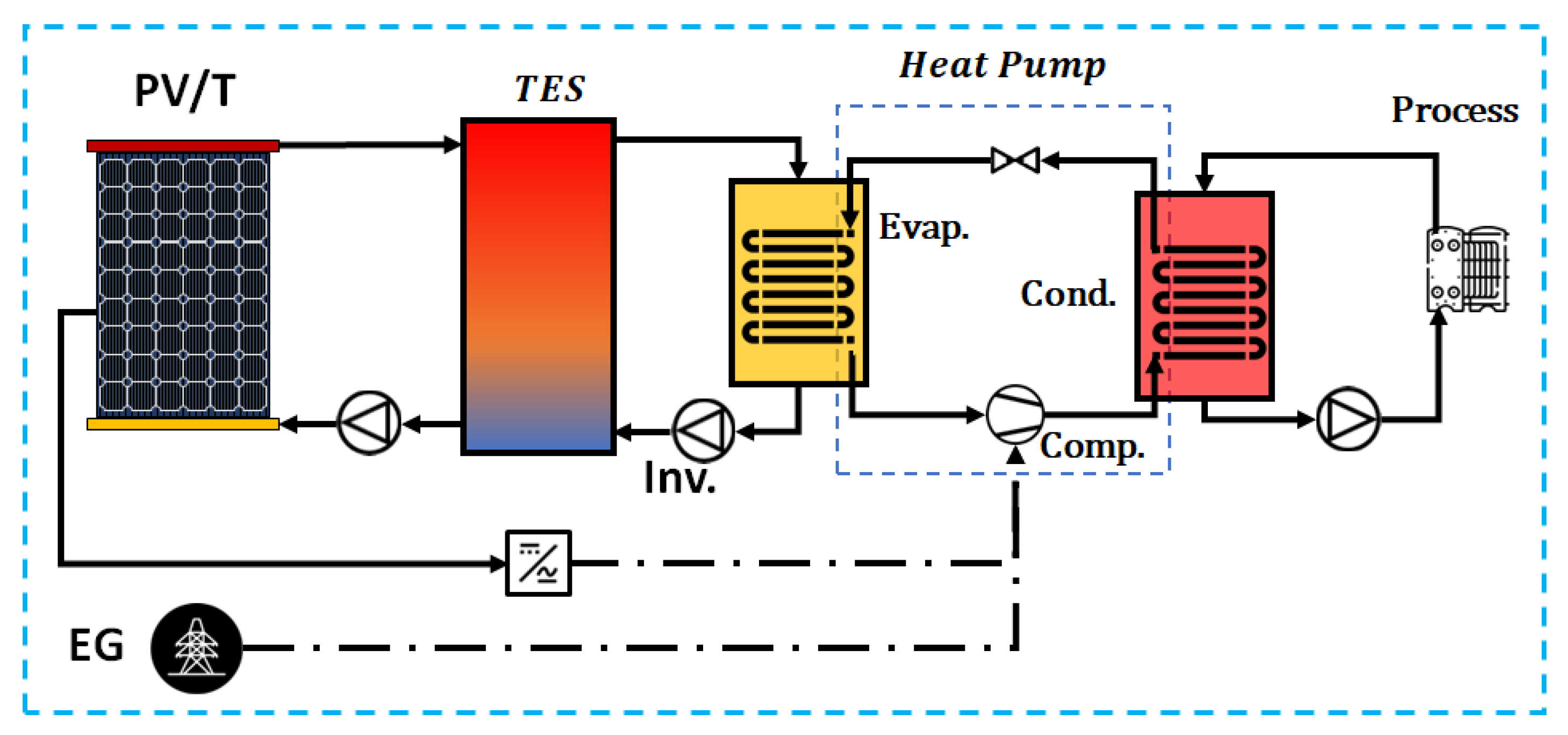

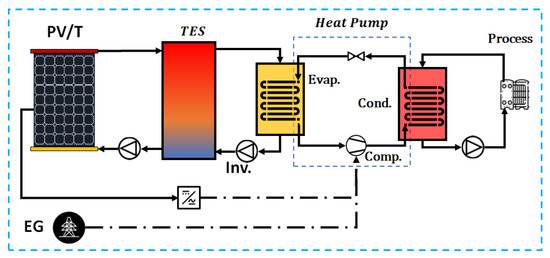

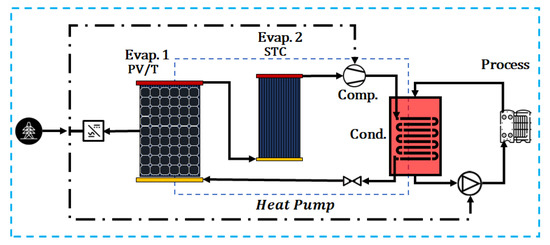

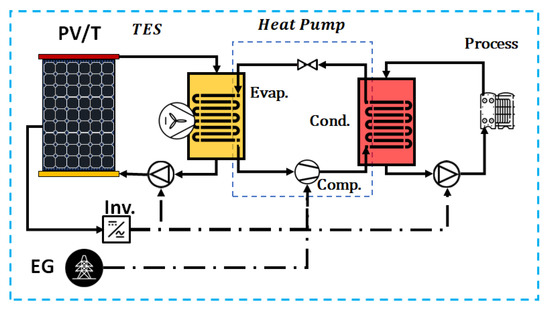

3.4. PVT–Assisted HP Systems (PVT-HP Systems)

PVT-HP systems integrate PVT fields with HPs. These systems are an alternative to the systems presented in the ST-HP and PV-HP sections. In a PVT-HP system, the solar technology can simultaneously provide electricity and heat to the HP allowing higher solar coverture of the energy requirements of the HP. This capacity gives the PVT-HP configuration more significant technical advantages and application prospects than individual PV-only and ST-only SAHP alternatives. Their main advantages are the capacity of simultaneously increase the efficiency of the PV system and improve the efficiency of the HP by adding heat to the evaporator. Although PVT-HP systems tend to reduce the solar heat gain compared to an ST-HP, the PVT-HP can increase the overall efficiency of the system due to the electrical generation of the PV module [123,124]. PVT-HP systems can be categorized based on the generation method and the disposition of their main components with the same classification presented in the ST-HP section. As in the case of ST-HP configurations, PVT-HP can also be integrated by reversible HPs heating and cooling applications [125,126,127]. Nevertheless, in this section, the focus is only on heating systems.

In general, the integration of a PVT system increases the operational complexity of an HP due to the requirement of flow and temperature control compared to a conventional PV-HP system. This is related to the influence of meteorological conditions on the heat and electricity supply to the HP, which influences the performance of the HP and makes it necessary to establish adequate control and optimization strategies. Normally, using PVT-HP with high solar radiation increases the COP because the temperature and evaporation pressure of the refrigerant increase, thanks to the higher operating temperature of the PVT. Consequently, the compressor consumes less electricity to complete the thermodynamic cycle, but the higher temperature in the PVT decreases the electrical and thermal efficiencies due to the increase in the operating temperature of the PV cell and larger temperature differences with the environment. In contrast, the increase in ambient temperature improves the COP and the thermal efficiency but reduces the electrical performance of the PV. In contrast, the increase in ambient temperature improves the COP and the thermal efficiency but reduces the electrical performance of the PV. This causes that by increasing the area of the PVT system, it is possible to improve the COP, due to the lower electrical consumption. However, the general efficiency of the system is reduced [39,128,129,130].

Many studies have evaluated the utilization of single-source PVT-HP systems mainly in domestic applications. Some of these studies have evaluated DX configurations as the work carried out by Zhou et al. [130], who carry out the analysis of a DX-PVT-HP for heating a room. The ambient temperature ranges between 6–15 °C, the temperature of the PV cell between 15–36 °C, the PVT system supplies heat to maintain a water tank at 40 °C, which provides heat to the room to maintain the temperature at 20 °C. At the optimum operating point, it was obtained electrical and thermal efficiencies of 14.5% and 59.7%, respectively, and a COP of 5.2. However, it was not carried out a techno-economic analysis. Jiang et al. [131] evaluated the utilization of a DX-PVT-HP for an aerobic composting process with a required operating temperature of 60 °C. The reached COP was 4.6 with 600 W/m of solar irradiance and an external temperature of 20 °C. The thermal and electrical efficiencies were 34.9% and 13.2%. In another study, Li et al. [129], carry out an outdoor test rig at Yanshan University (China) with a PVT-HP system. The single-source DX-PVT-HP system operates with a complementary system with solar thermal and air source supply when the levels of solar radiation are low. The simulation shows that the COP of the system oscillated between 2 (winter) and 4 (summer) throughout the year depending on the environmental variables (ambient temperature and solar radiation). The maximum temperature of PV cells was 64, 71, and 75 °C in winter, transitory seasons and summer, respectively. The temperature of entry to the condenser in winter, transitory season, and summer is 10, 15, and 20 degrees, respectively, while at the output of the condenser was 37.4, 44.5, and 49.1 °C. Economic feasibility analysis shows that the initial cost of the PVT-HP system is 71.1% higher than the traditional air source HP (ASHP) system. However, the 15-year operation and maintenance cost is 36.0% lower than the traditional system. Therefore, the lifecycle cost of the PVT-HP system is approximately 29.6% lower than that of the ASHP system.

Other studies have analyzed IDX configurations, among those works is the carried out by Qu et al. [38], who evaluated the exergetic, economic, and environmental behavior of PV-AWHP and PVT-WWHP systems in a residential house for DHW and electricity production in Shanghai, China. The configuration consists of a PVT-WWHP system with an indirect single source configuration, as shown in Figure 18. The PVT-WWHP system obtained an improvement of 25.3% in electrical conversion efficiency and decreased its COP to 3.71, equivalent to a reduction of 1.3% compared to the PV-AWHP system, obtaining an emission saving of 0.62 and 0.50 for the PVT-WWHP and PV-WWHP systems, respectively. Although the exergy loss showed a 75% decrease compared to the PV-AWHP, the payback period increased by six years for the PVT-WWHP system due to its high initial investment. On the other hand, Cui et al. [132], evaluated the economic performance of using a single source PVT-WWHP for space heating and DHW applying the Monte Carlo method. The results show that it is possible to achieve a 4-year payback with an net present value (NPV) of £38,990.

Figure 18.

Scheme of PVT system with indirect simple source WWHP. Own figure based on [38].

Del Amo et al. [133] evaluated a PVT-WWHP system to provide heat to an academic building at the University of Zaragoza (Spain) with seasonal storage with temperatures up to 85 °C. The results of the study showed the technical and economic feasibility of the PVT-HP system due to the economic savings related to the grid electricity and gas costs (the reference values of LCOE and LCOH were 14.58 and 4.90 cent€/kWh, respectively). Although the seasonal storage implies an increase in the initial investment, the optimization of the volume of the tank increases the solar coverage and improves the thermal performance of the PVT system, due to the reduction in the working temperature of the PVT collector. This improvement implies an advantage in buildings with roof space limitations.

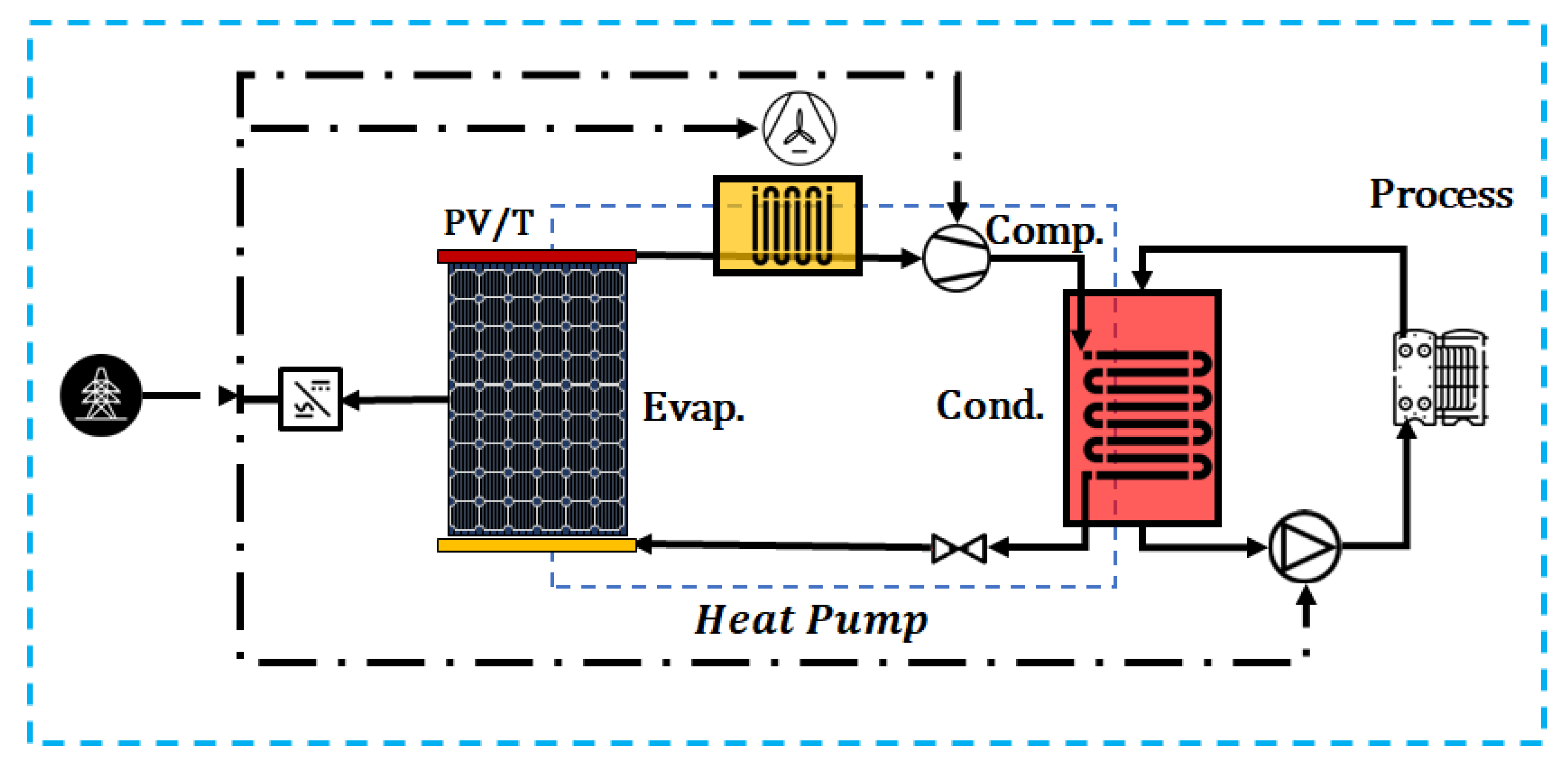

Dual-source PVT-HP systems have also been studied in many research works, most of them in domestic applications. As in the case of dual-source ST-HP systems, in dual-source PVT systems, the most common auxiliary heat sources used in domestic applications are ambient air and ground. DX air-dual source PVT-HP systems (Figure 19) have been evaluated in [123,124]. Results showed that these systems can have better performance than ASHPs, especially at low ambient temperatures. Regarding DX air-dual source ST-HP systems, the PVT-HP configuration tends to decrease the solar heat gain but can increase the overall efficiency of the system due to the electrical generation of the PVT collector. In another study, Yao et al. [39] analyzed the performance of a DX air-dual source PVT-HP system with a build-in PCM (phase change material) thermal heat storage (PCM-TES) in a residential application. The system provides thermal energy for water heating at 40 °C and underfloor heating at 31 °C to keep indoor temperature. The optimal performance of the system reached 17.77% and 55.76% of electrical and thermal efficiency, respectively, and a COP of 5.79. The initial cost of the PVT-HP with PCM-TES system was much higher than a conventional air conditioning system and got a payback of 4 years.

Figure 19.

Scheme of a DX air-dual source PVT-HP system.

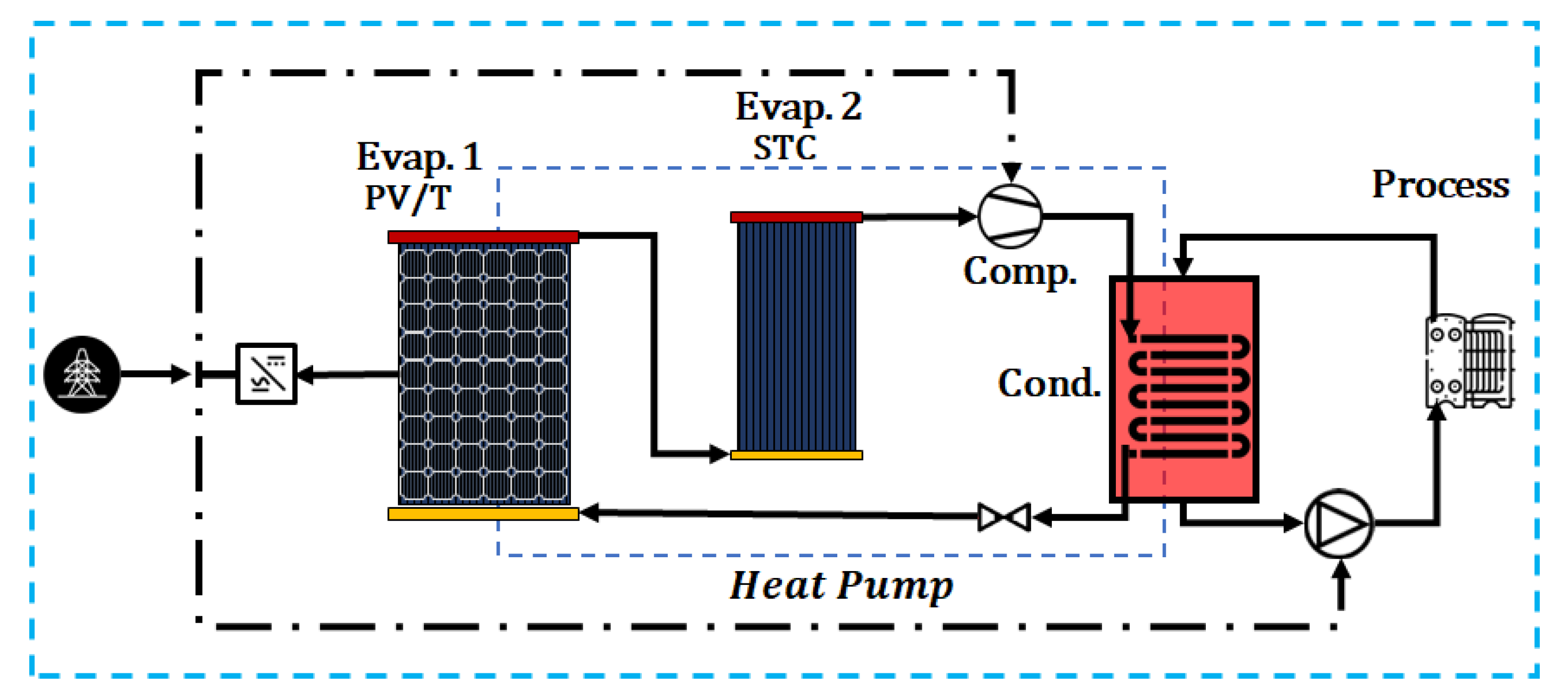

A particular case of DX dual-source PVT-HP system was evaluated by Abbas et al. [134], who produced a configuration with a PVT and two ST evaporators connected in series (PVT-ST-HP) as is shown in Figure 20. The system was experimentally evaluated obtaining an average COP of 6.11 with a maximum COP of 7.1, with an efficiency of the PV system and thermal of 14% and 67%, respectively. Consequently, the thermal efficiency of the direct dual source PVT-HP system increases between 10% and 15% compared to an ST-HP system.

Figure 20.

Scheme of PVT-ST system with direct dual water source HP. Own figure based on [134].

On the other hand, many studies also analyze IDX dual-source PVT-HP systems. Systems with ambient air as the auxiliary heat source were evaluated by authors such as Zhang et al. [135], the results of their study showed that the IDX air-dual source PVT-HP systems reduced the energy consumption by 13.1% compared to an ASHP. In addition, the lower operating temperature of the PV cells in the PVT collector increases electrical production by 14.7%. In another study, [136] found that an IDX air-dual source PVT-HP system can achieve an electrical and thermal efficiency of 16.6% and 30.28%, with values of COP between 3 and 5.2. Wang et al. [137], evaluated an IDX air-dual source PVT-HP with a reversible HP (Figure 21). The system had four operating conditions depending on the annual heat and cold demand for air conditioning in the residential building spaces. Due to the inclusion of thermal storage and the optimization of energy dispatch, the system achieves emissions savings of 1.85 per year and a payback period of 3.86 years.

Figure 21.

Scheme of PVT system with indirect dual air source HP.

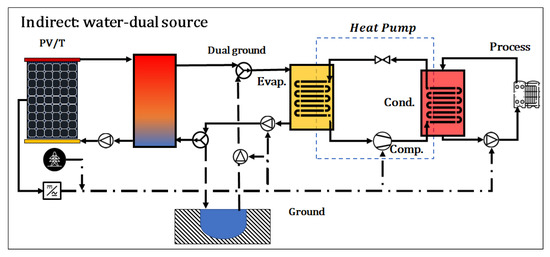

IDX dual source PVT-HP systems with ground source have also been evaluated. These systems have shown the capacity to provide higher source temperatures than ambient air source alternatives during winter, allowing to remain COP values between 2 and 5 [138]. A reversible IDX ground-dual source WWHP (Figure 22) was experimentally evaluated in [139]. The system reached COP values of 6.9 and 8.3 during summer and winter, respectively. However, the payback was 19 years without government subsidies and based on an economic sensitivity analysis, when grants are included, the payback was reduced to 15 years.

Figure 22.

Scheme of PVT system with indirect dual ground source HP.

Among the industrial applications where PVT-HP systems have been more studied are agroindustrial production and food processing. These studies have been focused mainly on drying processes. Most of the analyses have been carried out numerically or with experimental prototypes. The use of these systems on an industrial scale has been little analyzed [140,141,142,143].

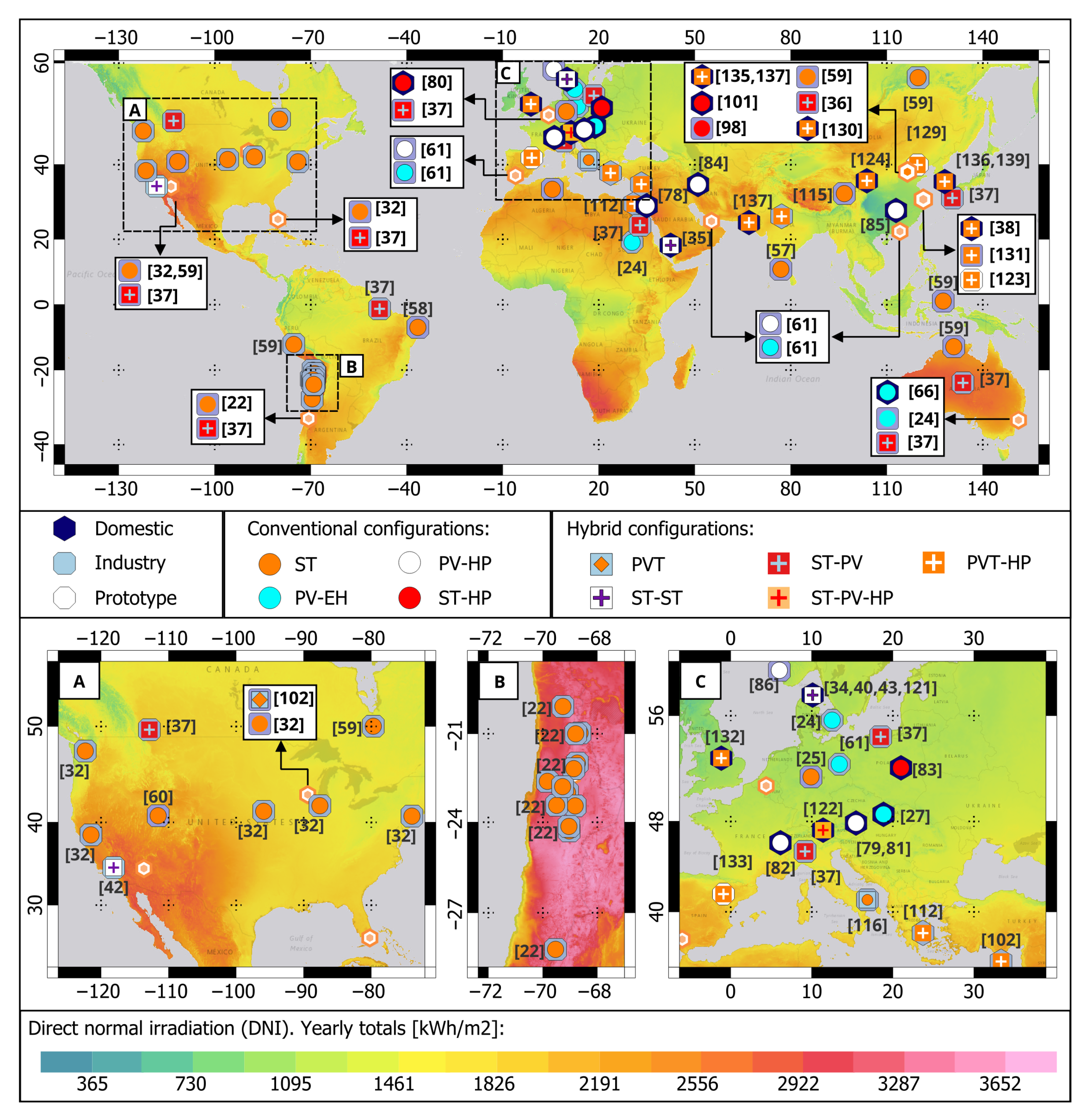

4. Solar Radiation and Time Interval Characteristics of the Analyzed Studies

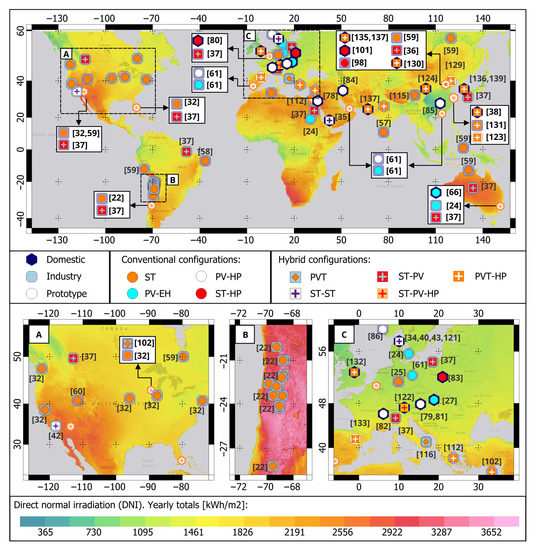

Figure 23 shows the annual DNI levels in the locations evaluated in the studies annalized in this work. In general, it can see that most of the conventional and hybrid configurations have been evaluated under different solar radiation levels. ST collector is the technology evaluated under more variety of radiation levels, even in the northern region of Chile, which has the highest annual radiation levels in the world. In the case of hybrid and SAHP systems, many of the studies have been carried out in locations with medium and low radiation levels in Europe and Asia.

Figure 23.

Annual radiation levels in the locations evaluated in the studies of conventional and HSs. Own figure based on [144]: DNI yearly total levels.

On the other hand, regarding the period of the studies analyzed, most of them consider time series of meteorological data with a length of one year, which allows the representation of the annual behavior of the studied systems. Only the experimental works presented in Table 1 have analysis periods shorter than one year.

Table 1.

Summary of time evaluated in experimental applications.

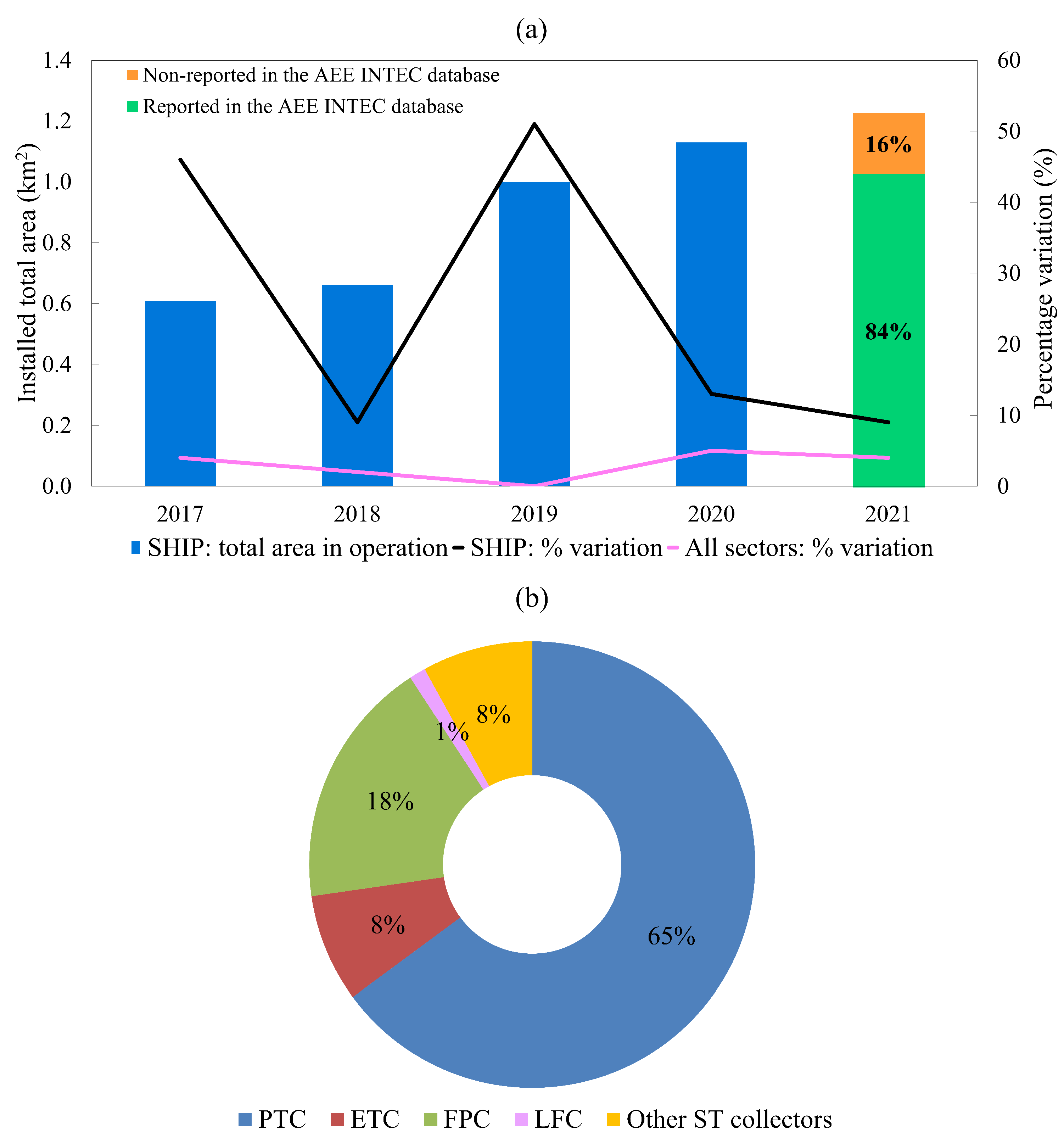

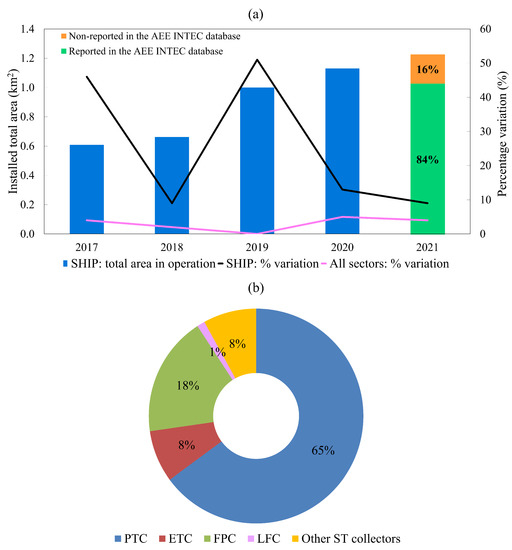

5. ST Plants for SHIP Applications Installed Worldwide

The Solar Heating and Cooling Program of the International Energy Agency (SHC IEA) reports each year the solar heating capacity in the principal markets worldwide [21]. In that report, only ST collectors and PVT are considered. This fact shows that other conventional or hybrid systems have not yet gained significant participation in the global solar heat market. In Figure 24a, the bars show in the left y-axis the total area of operating ST systems in SHIP applications worldwide from 2017 to 2021, and the black and pink lines show in the right y-axis the total area percentage variation of ST plants in SHIP and all sectors applications, respectively. More detailed information about the technical characteristic of 84% of the total area of SHIP plants reported can be found in a database developed by AEE INTEC [145]. It can see that the total area of ST systems operating in SHIP applications increased each year from 2017 to 2021. Additionally, the figure also shows that the annual percentage increase in SHIP applications is higher than the increase in the overall solar heating market. This fact indicates that in recent years, the relative importance of ST technologies in the industrial sector has been growing faster than in the domestic and commercial sectors. On the other hand, Figure 24b, shows the technological percentage distribution of the SHIP plants available in the AEE INTEC database. It can be seen that PTC is the technology with the larger operating area, followed by FPC and ETC. It is important to clarify that there are a higher number of FPC operating plants, while PTC is in third place.

Figure 24.

SHIP operating plants total area worldwide: (a) evolution of operating plants per year and percentage variation; (b) technological percentage distribution reported in 2021 [21,145,146,147,148,149].

6. Performance Indicators for Conventional and Hybrid Systems

To evaluate the performance of solar heating systems and the usefulness of their integration into industrial processes are needed metrics that allow quantifying how well the systems meet the desired requirements. These metrics are commonly known as key performance indicators (KPI), which allow comparing the performance of different energy systems. Most used KPIs in solar heating systems evaluate their energetic, economic, environmental, or exergetic performance and help to select the best technology alternative and optimal design [150,151,152]. Compared to the case of conventional solar heating systems, the application KPIs in hybrid configuration has special considerations due to the combination of different technologies and the possibility of simultaneously producing two forms of energy.

6.1. Energetic Performance Indicators

Two of the main energy indicators used in solar energy systems are the system energy efficiency () and the solar fraction (SF). shows how well the system converts the solar energy incident in the collector field into useful energy (in the form of heat or electricity) [17,45]. On the other hand, SF quantifies how much of the energy demand is met by the solar system. In HSs, each solar field presents different values of according to the efficient nature and operating temperature of each technology. Further, the combination of the two technologies could require additional complementary components such as heat exchangers and piping, which implies greater thermal losses than a conventional system. Meanwhile, in the case of SAHPs, high temperatures in the evaporator improve the efficiency of the HP, but also, the energy performance of ST collectors and PVTs declines with the increase in the operating temperature. This implies that an adequate trade-off between HP and solar technology efficiencies should exist to ensure the best energy performance of the system. The SF is also related to , due to that a higher value of also allows a large SF for a system with the same field area of solar collectors.

For a better quality in the comparison of the energy performance of different energy solar systems, it is important to consider that electricity and heat have distinct energy grades. This fact is particularly relevant in conventional and hybrid configurations with the capacity to simultaneously produce electric and thermal energy because it requires the utilization of different amounts of primary energy to obtain useful thermal or electric energy from fossil sources [153,154,155]. One useful metric that considers the different energy grades of electricity and heat is the primary energy-saving efficiency () [153,156]. This metric considers the electric and thermal energy output in terms of the same primary energy source, allowing the evaluation (in terms of primary energy) of the efficiency of the system in the conversion of the incident solar radiation into useful energy [156]. Another useful indicator related to the primary energy performance of the system is the primary energy saving (PES). The PES is the ratio between the primary energy saved by the renewable energy system and the primary energy consumed by an equivalent fossil system that provides the same energy requirements [71,157]. This indicator allows the evaluation of the relative reduction in the primary energy consumption of the solar system (including electric and thermal energy) related to the primary energy consumption of a fossil energy alternative.

Reaching the highest possible overall efficiency and primary energy saving of the HS required optimizing the technology combination, interaction way between both technologies, temperature operation, and control strategy. To be competitive with conventional systems, hybrid configurations should be able to provide more quantity of energy per area than individual technologies, which is of great importance in most industrial applications, where exist limitations of available area for the installation of solar collectors. In the same sense, to minimize the possible environmental impact and be more competitive with other renewable energy alternatives, HSs should be able to provide a greater primary energy-saving performance.

6.2. Economic Performance Indicators

Economic competitiveness is a crucial factor for the proliferation of solar thermal energy technologies in the industrial sector [32]. Many economic indicators are used to evaluate the economic performance of energy systems. Among these indicators, one of the most widely used to compare solar systems with other energy alternatives is the LCOE and its variations when is applied to electrical and thermal energy (LCOE and LCOH, respectively) [17,158,159,160,161]. This metric shows the cost per produced or saved energy by the system in the lifetime of the project [158]. The LCOE considers the costs related to the project such as initial investment, subsidies, or incentives, and operating and maintenance costs in the whole lifetime of the project. Other indicators also used to evaluate the economic performance of solar systems are the net present value (NPV) [22,58], internal rate of return (IRR) [22,58], payback period (PBP) [91,162], and life cycle cost (LCC) [89,92]. The NPV represents the present value of the difference between the revenues and costs in the lifetime of the project. This indicator allows investors to determine if the project will produce a positive cash flow balance that allows the recovery of the invested capital [58,162]. The IRR is the value of the discount rate that produces a NPV equal to zero. The PBP shows the period of time required to recover the capital invested. Finally, the LCC is the present value of the sum of the capital invested and operating, maintenance, and replacement costs during the whole life of the project.