Review of Porous Ceramics for Hot Gas Cleanup of Biomass Syngas Using Catalytic Ceramic Filters to Produce Green Hydrogen/Fuels/Chemicals

Abstract

1. Introduction

2. Ceramic Filters

2.1. Mechanisms of Filtration

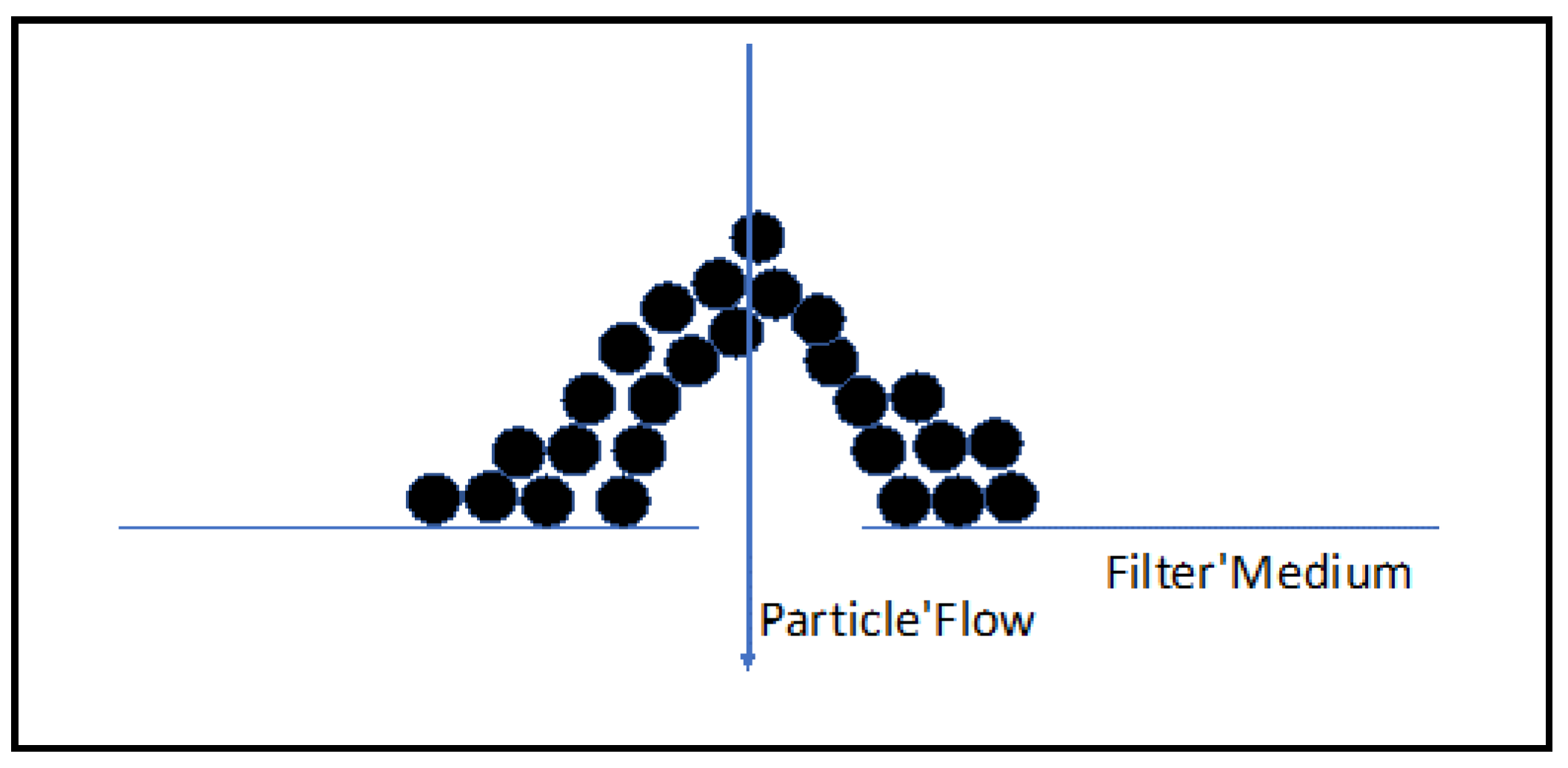

2.1.1. Straining

2.1.2. Filtration

2.2. Formation of Filter Cake and Associated Problems

2.3. Regeneration Techniques to Control Cake Buildup

2.3.1. Back Pulsing

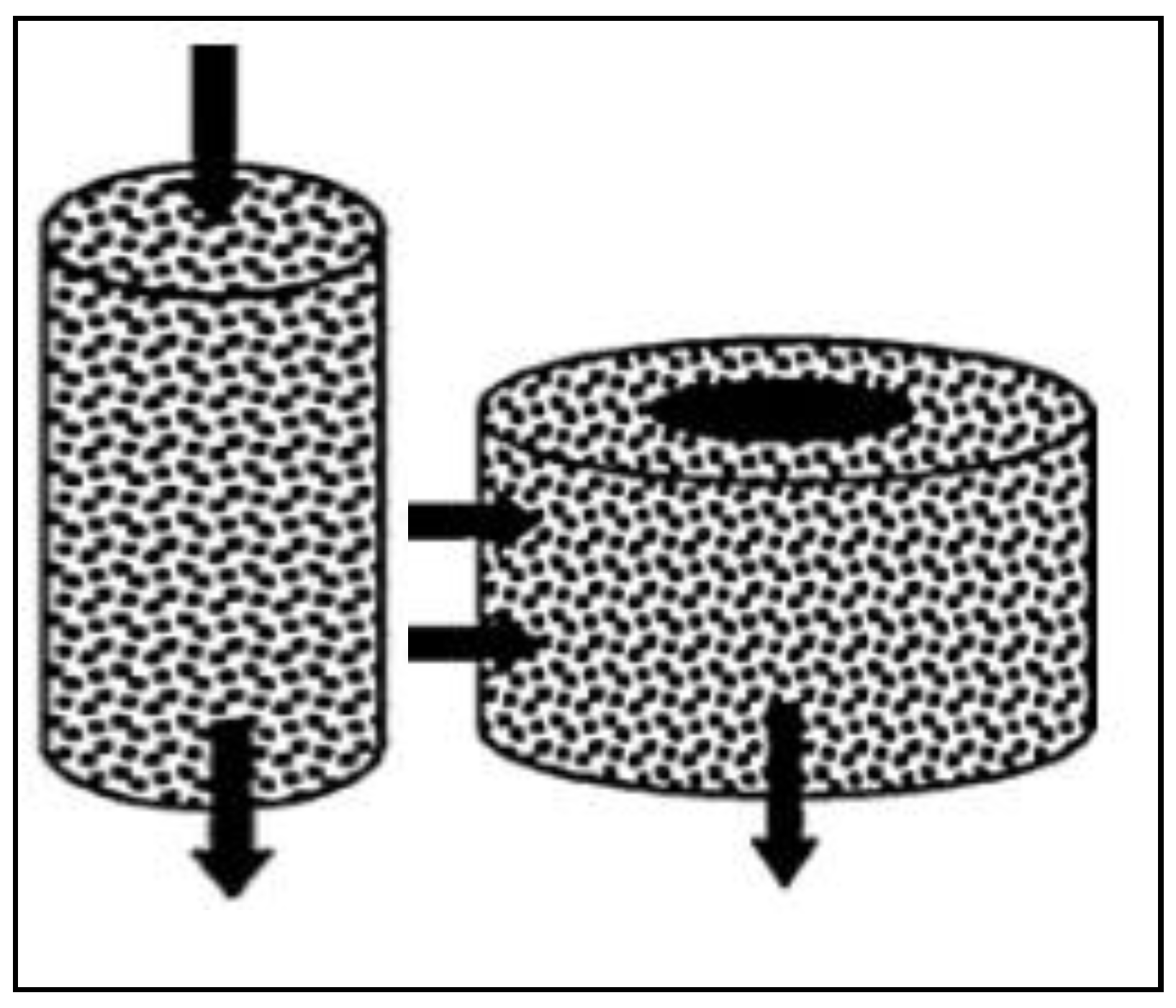

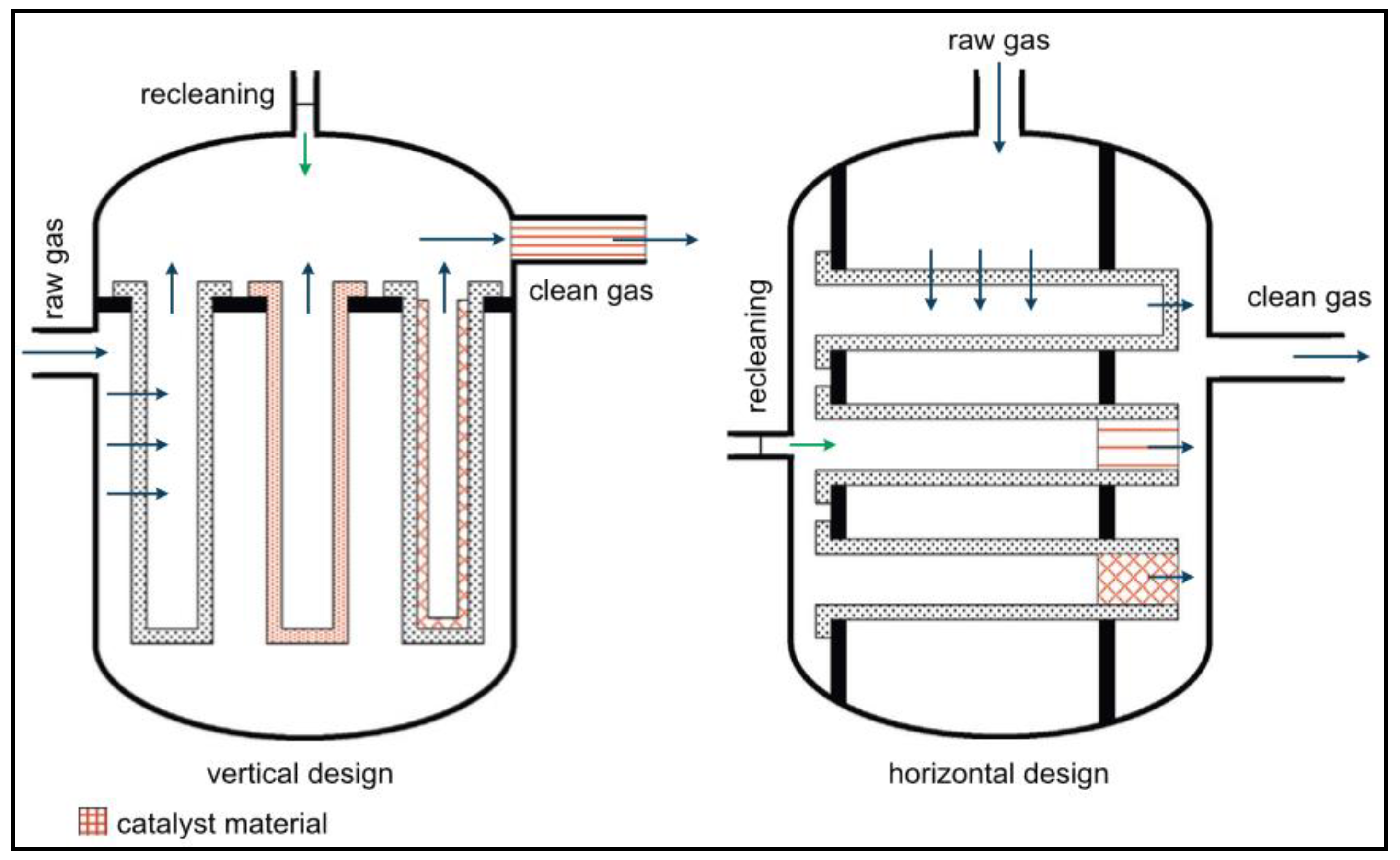

2.3.2. Design Configurations

3. Common Industrial Filtration Applications

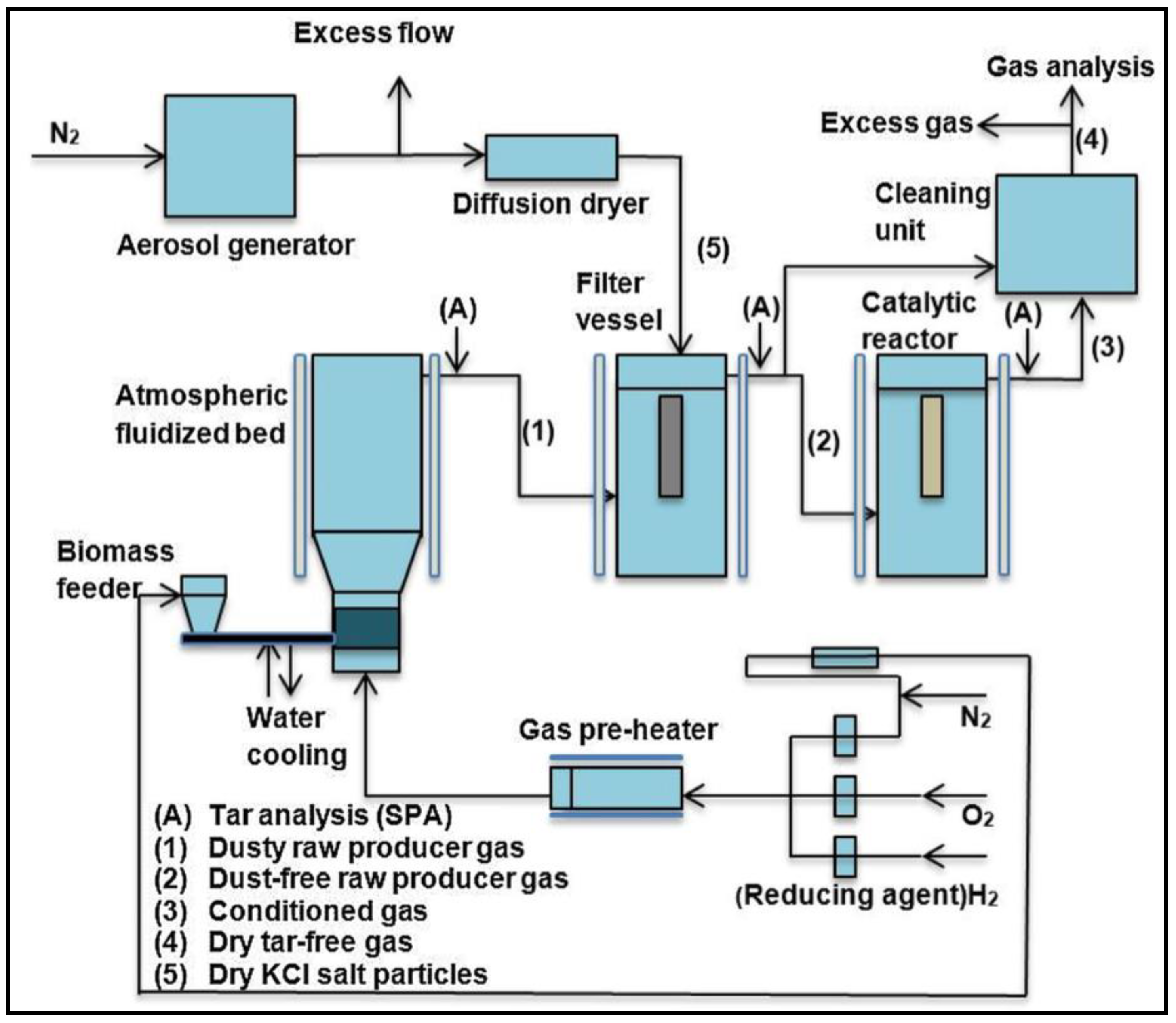

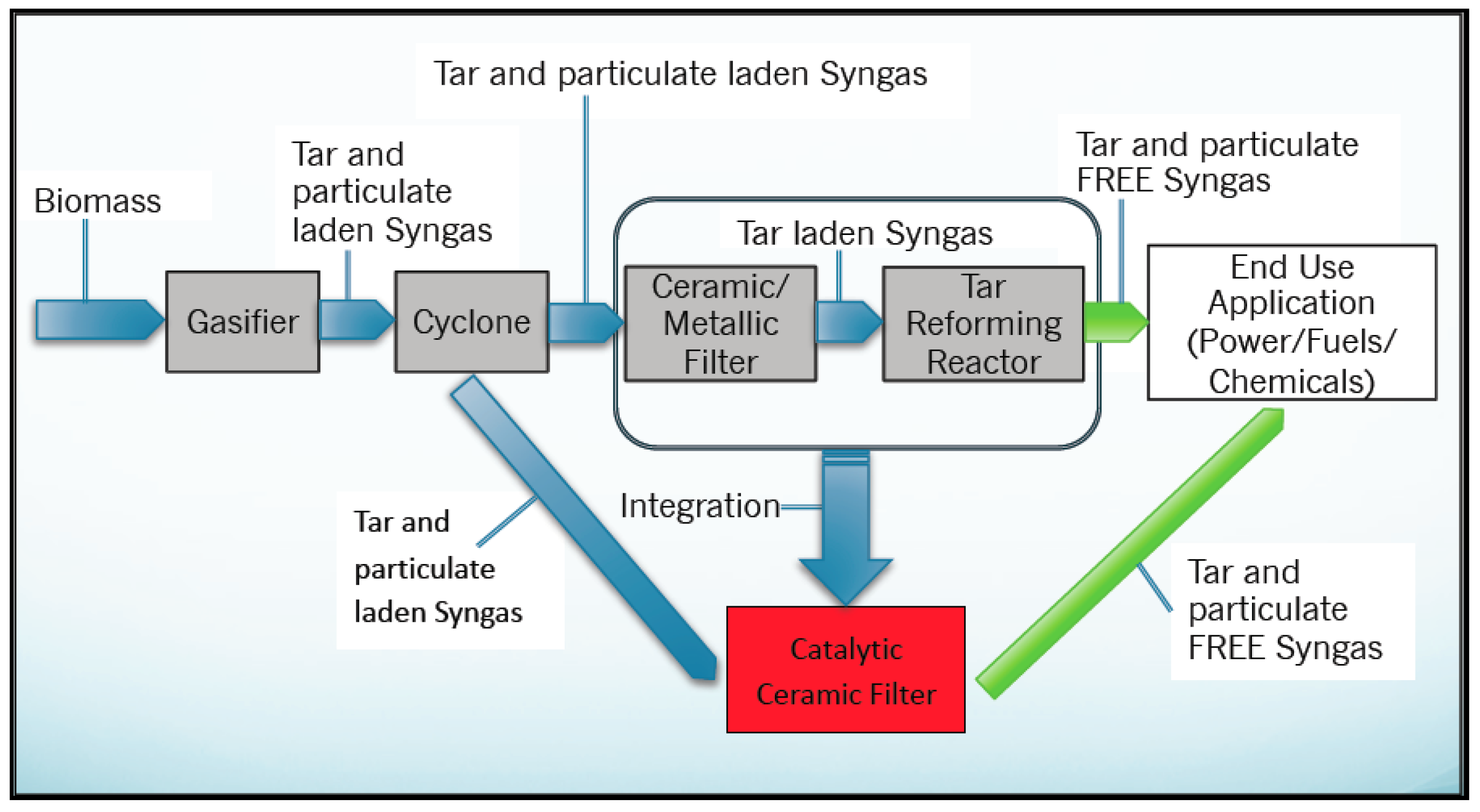

3.1. Biomass Conversion

3.2. Mixed Feedstock Conversion

3.3. Municipal Solid Waste (MSW) and Hazardous Waste (HW) Conversion

4. Ceramic as Catalyst Support

- High surface area and porosity,

- Ability to maintain mechanical integrity at the elevated temperatures required for reaction, and

- Uniform pore size and structure for selectivity of product.

4.1. Reduction and Oxidation of Pollutants

4.1.1. Nitrogen Oxides (NOx) Reduction

4.1.2. Volatile Organic Compounds (VOCs) Oxidation

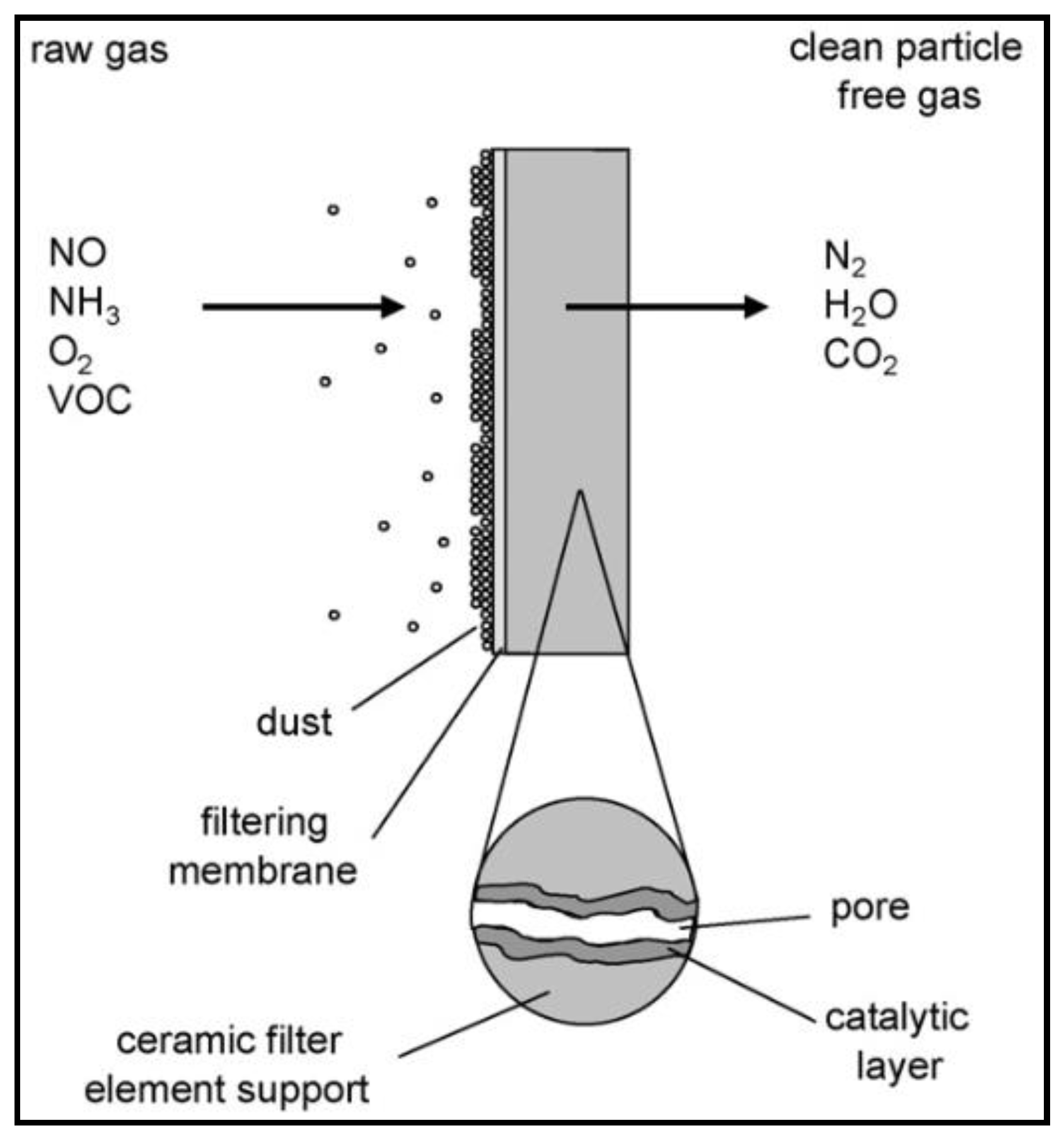

4.1.3. Integrated Catalytic Reduction/Oxidation and Filtration

4.1.4. NOx Reduction Simulations and Recent Advances

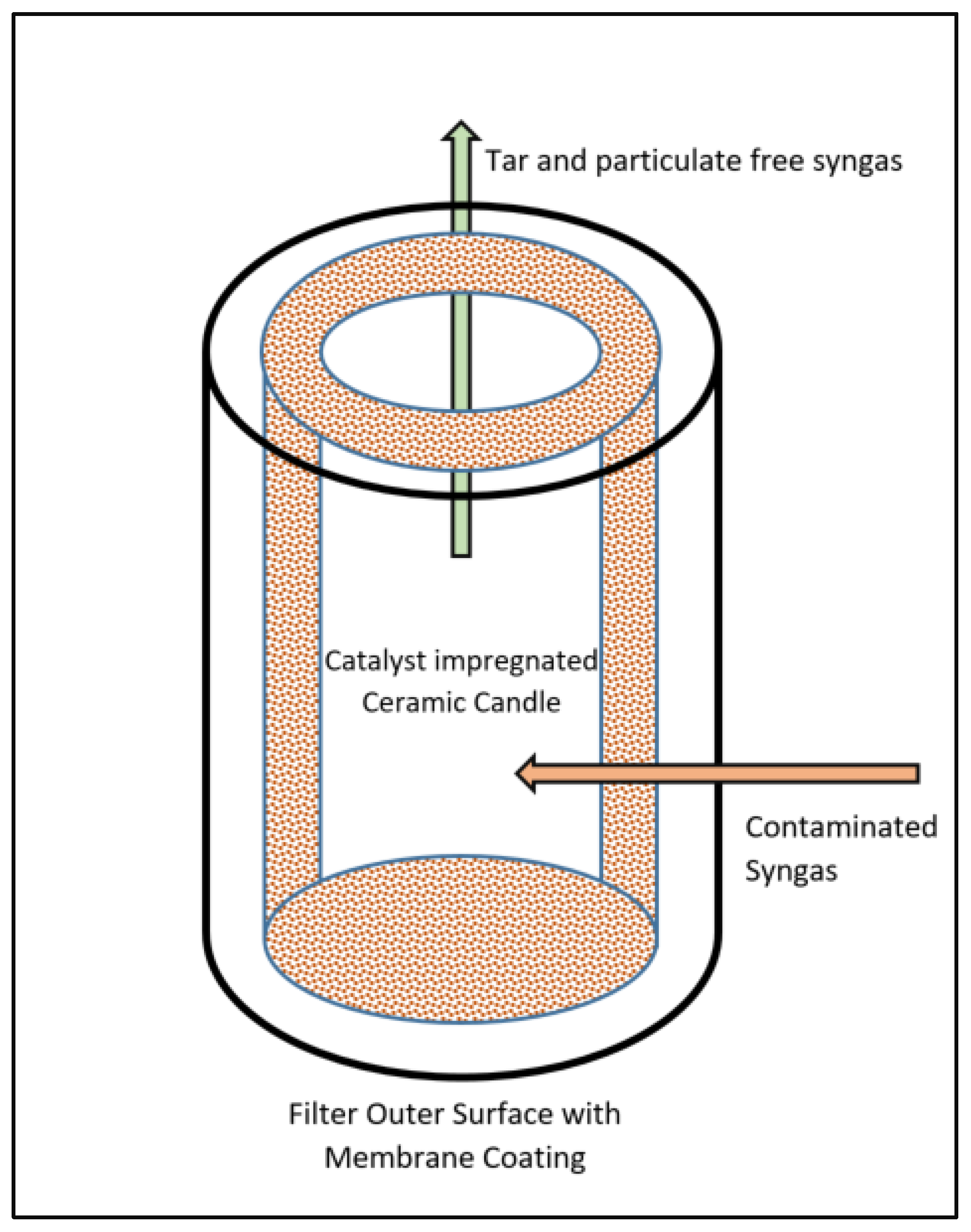

4.2. Tar Reforming

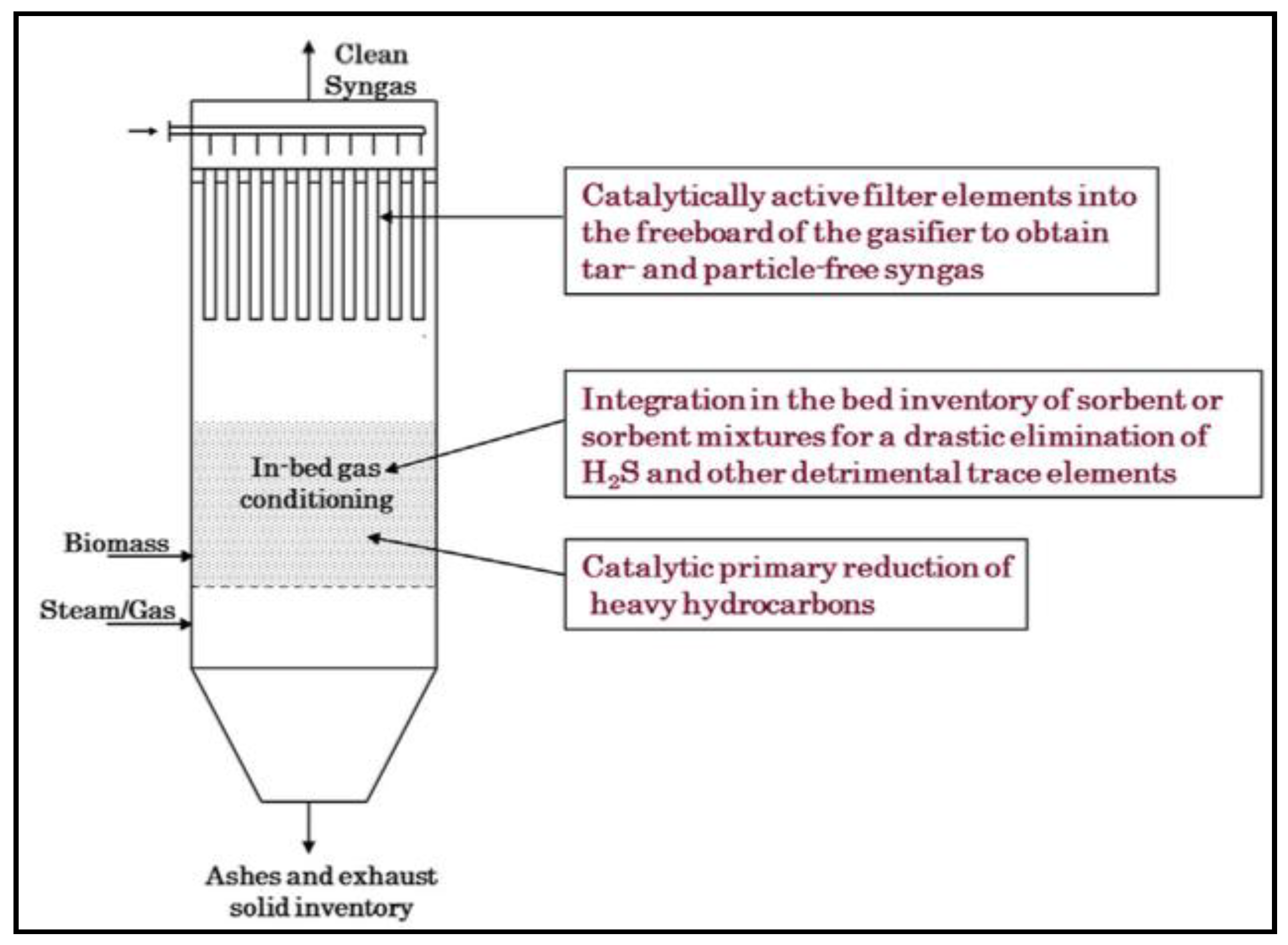

4.2.1. In-Situ Tar Reforming

4.2.2. Ex-Situ Tar Reforming

Ceramic Discs

Ceramic Monolith

Ceramic Foams

4.2.3. Ceramic Support Summary

4.2.4. Tar Reforming Filter Simulations

5. Conclusions and Future Perspectives

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CNM | carbon nanomaterials |

| CPSI | cells per square inch |

| DPF | diesel particulate filter |

| IGCC | integrated gasification combined cycle |

| MSW | municipal solid waste |

| NOx | nitrogen oxides |

| PAH | polycyclic aromatic hydrocarbon |

| PFBC | pressurized fluidized bed combustion |

| PM | particulate matter |

| SOFC | solid oxide fuel cells |

| SCR | selective catalytic reduction |

| SOx | sulfur oxides |

| VOC | volatile organic compound |

References

- Department of Energy. Biden-Harris Administration Announces Historic $7 Billion Funding Opportunity to Jump-Start America’s Clean Hydrogen Economy; Department of Energy, Ed.; Department of Energy: Washington, DC, USA, 2022.

- Ochu, E.; Braverman, S.; Smith, G.; Friedman, J. Hydrogen Fact Sheet: Production of Low-Carbon Hydrogen; Columbia University: New York, NY, USA, 2021. [Google Scholar]

- Ruth, M. Hydrogen Production Cost Estimate Using Biomass Gasification: Independent Review; National Renewable Energy Laboratory: Golden, CO, USA, 2011.

- Alptekin, F.M.; Celiktas, M.S. Review on Catalytic Biomass Gasification for Hydrogen Production as a Sustainable Energy Form and Social, Technological, Economic, Environmental, and Political Analysis of Catalysts. ACS Omega 2022, 7, 24918–24941. [Google Scholar] [CrossRef] [PubMed]

- Bridgewater, A.V. The technical and economic feasibility of biomass gasification for power generation. Fuel 1995, 74, 631–653. [Google Scholar] [CrossRef]

- Milne, T.A.; Abatzoglou, N.; Evans, R.J. Biomass Gasifier “Tars”: Their Nature, Formation, and Conversion; NREL/TP-570-25357; National Renewable Energy Laboratory: Golden, CO, USA, 1998.

- Dayton, D. A Review of the Literature on Catalytic Biomass Tar Destruction; National Renewable Energy Laboratory: Golden, CO, USA, 2002.

- Biomass Conversion: Challenges for Federal Research and Commercialization; Report Published by Biomass Research and Development Board; Biomass Research and Development Board: Golden, CO, USA, 2011.

- Turn, S.Q.; Kinoshita, C.M.; Ishimura, D.M.; Hiraki, T.T.; Zhou, J.; Masutani, S.M. An Experimental Investigation of Alkali Removal from Biomass Producer Gas Using a Fixed Bed of Solid Sorbent. Ind. Eng. Chem. Res. 2001, 40, 1960–1967. [Google Scholar] [CrossRef]

- Woolcock, P.J.; Brown, R.C. A review of cleaning technologies for biomass-derived syngas. Biomass Bioenergy 2013, 52, 54–84. [Google Scholar] [CrossRef]

- Lind, T.; Hokkinen, J.; Jokiniemi, J.K.; Saarikoski, S.; Hillamo, R. Electrostatic Precipitator Collection Efficiency and Trace Element Emissions from Co-Combustion of Biomass and Recovered Fuel in Fluidized-Bed Combustion. Environ. Sci. Technol. 2003, 37, 2842–2846. [Google Scholar] [CrossRef]

- Aravind, P.V.; de Jong, W. Evaluation of high temperature gas cleaning options for biomass gasification product gas for Solid Oxide Fuel Cells. Prog. Energy Combust. Sci. 2012, 38, 737–764. [Google Scholar] [CrossRef]

- Sharma, S.D.; Dolan, M.; Park, D.; Morpeth, L.; Ilyushechkin, A.; McLennan, K.; Harris, D.J.; Thambimuthu, K.V. A critical review of syngas cleaning technologies—Fundamental limitations and practical problems. Powder Technol. 2008, 180, 115–121. [Google Scholar] [CrossRef]

- Rhyner, U. Reactive Hot Gas Filter for Biomass Gasification. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2013. [Google Scholar] [CrossRef]

- Mertzis, D.; Koufodimos, G.; Kavvadas, I.; Samaras, Z. Applying modern automotive technology on small scale gasification systems for CHP production: A compact hot gas filtration system. Biomass Bioenergy 2017, 101, 9–20. [Google Scholar] [CrossRef]

- Heidenreich, S. Hot gas filtration—A review. Fuel 2013, 104, 83–94. [Google Scholar] [CrossRef]

- Corporation, P. Gas Filtration Intro; Pall Corporation: Port Washington, NY, USA, 2008. [Google Scholar]

- Ding, W.; Shi, Y.; Kessel, F.; Koch, D.; Bauer, T. Characterization of corrosion resistance of C/C–SiC composite in molten chloride mixture MgCl2/NaCl/KCl at 700 °C. npj Mater. Degrad. 2019, 3, 42. [Google Scholar] [CrossRef]

- Jha, S.; Sekellick, R.S.; Rubow, K.L. Sintered Metal Hot Gas Filters. In Proceedings of the 4th International Symposium Gas Cleaning at High Temperatures, Karlsruhe, Germany, 22–24 September 1999. [Google Scholar]

- Adler, J. Ceramic Diesel Particulate Filters. Int. J. Appl. Ceram. Technol. 2005, 2, 429–439. [Google Scholar] [CrossRef]

- Heidenreich, S. Ceramic membranes: High filtration area packing densities improve membrane performance. Filtr. Sep. 2011, 48, 25–27. [Google Scholar] [CrossRef]

- Cummer, K.; Brown, R. Ancillary equipment for biomass gasification. Biomass Bioenergy 2002, 23, 113–128. [Google Scholar] [CrossRef]

- Heidenreich, S. Chapter Eleven—Hot Gas Filters. In Progress in Filtration and Separation; Tarleton, S., Ed.; Academic Press: Oxford, UK, 2015; pp. 499–525. [Google Scholar] [CrossRef]

- Gómez-Martín, A.; Orihuela, M.P.; Becerra, J.A.; Martínez-Fernández, J.; Ramírez-Rico, J. Permeability and mechanical integrity of porous biomorphic SiC ceramics for application as hot-gas filters. Mater. Des. 2016, 107, 450–460. [Google Scholar] [CrossRef]

- Roewer, G.; Herzog, U.; Trommer, K.; Müller, E.; Frühauf, S. Silicon Carbide—A Survey of Synthetic Approaches, Properties and Applications. In High Performance Non-Oxide Ceramics I; Jansen, M., Ed.; Springer Berlin Heidelberg: Berlin/Heidelberg, Germany, 2002; pp. 59–135. [Google Scholar]

- Schaafhausen, S.; Yazhenskikh, E.; Heidenreich, S.; Müller, M. Corrosion of silicon carbide hot gas filter candles in gasification environment. J. Eur. Ceram. Soc. 2014, 34, 575–588. [Google Scholar] [CrossRef]

- Schaafhausen, S.; Yazhenskikh, E.; Walch, A.; Heidenreich, S.; Müller, M. Corrosion of alumina and mullite hot gas filter candles in gasification environment. J. Eur. Ceram. Soc. 2013, 33, 3301–3312. [Google Scholar] [CrossRef]

- Yalamaç, E.; Trapani, A.; Akkurt, S. Sintering and microstructural investigation of gamma–alpha alumina powders. Eng. Sci. Technol. Int. J. 2014, 17, 2–7. [Google Scholar] [CrossRef]

- Environmental, U. Characterisation and Estimation of Dioxin and Furan Emissions from Waste Incineration Facilities; UNILABS: Sydney, Australia, 2001; p. 93. [Google Scholar]

- Fukushima, M.; Yoshizawa, Y.-i. Fabrication and morphology control of highly porous mullite thermal insulators prepared by gelation freezing route. J. Eur. Ceram. Soc. 2016, 36, 2947–2953. [Google Scholar] [CrossRef]

- Cagliostro, D.E.; Hsu, M.-T.S. Method for Waterproofing Ceramic Materials. U.S. Patent US5814397A, 29 September 1998. p. 7. [Google Scholar]

- Heidenreich, S.; Haag, W.; Salinger, M. Next generation of ceramic hot gas filter with safety fuses integrated in venturi ejectors. Fuel 2013, 108, 19–23. [Google Scholar] [CrossRef]

- Newby, R.A.; Bruck, G.J.; Alvin, M.A.; Lippert, T.E. Optimization of Advanced Filter Systems; Westinghouse Science and Technology Center: Pittsburg, PA, USA, 1998. [Google Scholar] [CrossRef]

- Das, I.; De, G.; Hupa, L.; Vallittu, P.K. Porous SiO2 nanofiber grafted novel bioactive glass-ceramic coating: A structural scaffold for uniform apatite precipitation and oriented cell proliferation on inert implant. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 62, 206–214. [Google Scholar] [CrossRef]

- Silva, L.H.d.; Lima, E.d.; Miranda, R.B.d.P.; Favero, S.S.; Lohbauer, U.; Cesar, P.F. Dental ceramics: A review of new materials and processing methods. Braz. Oral Res. 2017, 31, 58. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Baba, T.; Jiang, H.; Liu, C.; Guan, Y.; Elleuch, O.; Kuech, T.; Morgan, D.; Idrobo, J.C.; et al. Radiation-induced segregation in a ceramic. Nat. Mater. 2020, 19, 992–998. [Google Scholar] [CrossRef] [PubMed]

- Goldstein, L.; Hedman, B.; Knowles, D.; Freedman, S.I.; Woods, R.; Schweizer, T. Gas-Fired Distributed Energy Resource Technology Characterizations; National Renewable Energy Laboratory: Golden, CO, USA, 2003. [CrossRef]

- Gao, N.; Li, A.; Quan, C.; Qu, Y.; Mao, L. Characteristics of Hydrogen-Rich Gas Production of Biomass Gasification with Porous Ceramic Reforming. Int. J. Hydrogen Energy 2012, 37, 9610–9618. [Google Scholar] [CrossRef]

- Gao, N.; Liu, S.; Han, Y.; Xing, C.; Li, A. Steam reforming of biomass tar for hydrogen production over NiO/ceramic foam catalyst. Int. J. Hydrogen Energy 2015, 40, 7983–7990. [Google Scholar] [CrossRef]

- Gao, N.; Wang, X.; Li, A.; Wu, C.; Yin, Z. Hydrogen production from catalytic steam reforming of benzene as tar model compound of biomass gasification. Fuel Process. Technol. 2016, 148, 380–387. [Google Scholar] [CrossRef]

- Hwang, K.-R.; Cho, S.-H.; Ihm, S.-K.; Lee, C.-B.; Park, J.-S. Catalytic Active Filter for Water-Gas Shift Reaction. J. Chem. Eng. Jpn. 2009, 42, s199–s203. [Google Scholar] [CrossRef]

- Shiva Kumar, S.; Himabindu, V. Hydrogen production by PEM water electrolysis—A review. Mater. Sci. Energy Technol. 2019, 2, 442–454. [Google Scholar] [CrossRef]

- Guan, G.; Kaewpanha, M.; Hao, X.; Abudula, A. Catalytic steam reforming of biomass tar: Prospects and challenges. Renew. Sustain. Energy Rev. 2016, 58, 450–461. [Google Scholar] [CrossRef]

- Li, D.; Tamura, M.; Nakagawa, Y.; Tomishige, K. Metal catalysts for steam reforming of tar derived from the gasification of lignocellulosic biomass. Bioresour. Technol. 2015, 178, 53–64. [Google Scholar] [CrossRef]

- Zhang, W.; Qi, S.; Pantaleo, G.; Liotta, L.F. WO3–V2O5 Active Oxides for NOx SCR by NH3: Preparation Methods, Catalysts’ Composition, and Deactivation Mechanism—A Review. Catalysts 2019, 9, 527. [Google Scholar] [CrossRef]

- Brummer, V.; Teng, S.Y.; Jecha, D.; Skryja, P.; Vavrcikova, V.; Stehlik, P. Contribution to cleaner production from the point of view of VOC emissions abatement: A review. J. Clean. Prod. 2022, 361, 132112. [Google Scholar] [CrossRef]

- Hutten, I.M. Chapter 2—Filtration Mechanisms and Theory. In Handbook of Nonwoven Filter Media; Hutten, I.M., Ed.; Butterworth-Heinemann: Oxford, UK, 2007; pp. 29–70. [Google Scholar] [CrossRef]

- Seville, J.; Chuah, T.G.; Sibanda, V.; Knight, P. Gas cleaning at high temperatures using rigid ceramic filters. Adv. Powder Technol. 2003, 14, 657–672. [Google Scholar] [CrossRef]

- Smid, J.; Hsiau, S.S.; Peng, C.Y.; Lee, H.T. Hot gas cleanup: Pilot testing of moving bed filters. Filtr. Sep. 2006, 43, 21–24. [Google Scholar] [CrossRef]

- Saracco, G.; Specchia, V. Catalytic Ceramic Filters for Flue Gas Cleaning. 2. Catalytic Performance and Modeling Thereof. Ind. Eng. Chem. Res. 1995, 34, 1480–1487. [Google Scholar] [CrossRef]

- Ripperger, S.; Gösele, W.; Alt, C.; Loewe, T. Filtration, 1. Fundamentals. Ullmann’s Encycl. Ind. Chem. 2013, 1–38. [Google Scholar] [CrossRef]

- Radjai, F.; Hund, D.; Antonyuk, S.; Ripperger, S.; Nezamabadi, S.; Luding, S.; Delenne, J.Y. Simulation of Bridging at the Static Surface Filtration by CFD-DEM Coupling. EPJ Web Conf. 2017, 140, 09033. [Google Scholar] [CrossRef]

- Wakeman, R. The influence of particle properties on filtration. Sep. Purif. Technol. 2007, 58, 234–241. [Google Scholar] [CrossRef]

- Courson, C.; Gallucci, K. 8—Gas cleaning for waste applications (syngas cleaning for catalytic synthetic natural gas synthesis). In Substitute Natural Gas from Waste; Materazzi, M., Foscolo, P.U., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 161–220. [Google Scholar] [CrossRef]

- Heidenreich, S.; Scheibner, B. Hot gas filtration with ceramic filters: Experiences and new developments. Filtrat 2002, 39, 22–25. [Google Scholar]

- Sasatsu, H.; Keiichi, K.; Misawa, N.; Iritani, J. Hot Gas Particulate Cleaning Technology Applied for PFBC/IGFC, The Ceramic Tube Filter (CTF) and Metal Filter. In Proceedings of the 5th International Symposium on Gas Cleaning at High Temperature, Morgantown, WV, USA, 17–20 September 2002. [Google Scholar]

- Larsen, D.A.; Bacchi, D.P.; Connors, T.F.; Collins, E.L., III. Method of Producing Monolithic Ceramic Cross-Flow Filter. U.S. Patent US 5716559A, 10 February 1998. [Google Scholar]

- Beattie, C.J.C.; Withers, C.J. Applications of Low Density Ceramic Filters for Gas Cleaning at High Temperatures. In Gas Cleaning at High Temperatures; Clift, R., Seville, J.P.K., Eds.; Springer Netherlands: Dordrecht, The Netherlands, 1993; pp. 173–189. [Google Scholar]

- Leibold, H.; Dirks, F.; Rüdinger, V. Particulate emissions from a LLW incinerator and off-gas cleaning with a new type of ceramic candle filter. Waste Manag. 1989, 9, 87–94. [Google Scholar] [CrossRef]

- Hackel, M.; Schaub, G.; Nacken, M.; Heidenreich, S. Kinetics of reduction and oxidation reactions for application in catalytic gas–particle-filters. Powder Technol. 2008, 180, 239–244. [Google Scholar] [CrossRef]

- Roddy, D.J.; Manson-Whitton, C. 5.10—Biomass Gasification and Pyrolysis. In Comprehensive Renewable Energy; Sayigh, A., Ed.; Elsevier: Oxford, UK, 2012; pp. 133–153. [Google Scholar]

- Döring, N.; Meyer, J.; Kasper, G. Effect of filtration velocity variations on the NOx conversion of catalytically impregnated filter elements. Powder Technol. 2008, 180, 203–209. [Google Scholar] [CrossRef]

- Heidenreich, S.; Nacken, M.; Hackel, M.; Schaub, G. Catalytic filter elements for combined particle separation and nitrogen oxides removal from gas streams. Powder Technol. 2008, 180, 86–90. [Google Scholar] [CrossRef]

- Zürcher, S.; Hackel, M.; Schaub, G. Kinetics of Selective Catalytic NOx Reduction in a Novel Gas-Particle Filter Reactor (Catalytic Filter Element and Sponge Insert). Ind. Eng. Chem. Res. 2008, 47, 1435–1442. [Google Scholar] [CrossRef]

- Phule, A.; Kim, J.; Choi, J. Development of high performance catalytic filter of V2O5-WO3/TiO2 supported-SiC for NOX reduction. Powder Technol. 2018, 327, 282–290. [Google Scholar] [CrossRef]

- Zhao, H.; Xiong, G.; Baron, G. Pore-wall modified metal/ceramic catalytic membranes prepared by the sol-gel method. Stud. Surf. Sci. Catal. 1998, 118, 717–724. [Google Scholar] [CrossRef]

- Ha, J.-W.; Choi, J. The Effect of SO2 and H2O on the NO Reduction of V2O5 -WO3/TiO2/SiC Catalytic Filter. Korean Chem. Eng. Res. 2014, 52, 688–693. [Google Scholar] [CrossRef]

- Kim, Y.; Choi, J.; Scott, J.; Chiang, K.; Amal, R. Preparation of high porous Pt-V2O5-WO3/TiO2/SiC filter for simultaneous removal of NO and particulates. Powder Technol. 2008, 180, 79–85. [Google Scholar] [CrossRef]

- Kim, Y.G.; Choi, J.H.; Yu, L.; Bak, Y.C. Modification of V2O5-WO3/TiO2 Catalysts Supported on SiC Filter for NO Reduction at Low Temperature. Solid State Phenom. 2007, 124–126, 1713–1716. [Google Scholar] [CrossRef]

- Lopez, G.; Santamaria, L.; Lemonidou, A.; Zhang, S.; Wu, C.; Sipra, A.T.; Gao, N. Hydrogen generation from biomass by pyrolysis. Nat. Rev. Methods Prim. 2022, 2, 20. [Google Scholar] [CrossRef]

- Vuppaladadiyam, A.K.; Vuppaladadiyam, S.S.V.; Awasthi, A.; Sahoo, A.; Rehman, S.; Pant, K.K.; Murugavelh, S.; Huang, Q.; Anthony, E.; Fennel, P.; et al. Biomass pyrolysis: A review on recent advancements and green hydrogen production. Bioresour. Technol. 2022, 364, 128087. [Google Scholar] [CrossRef]

- Choi, J.-H.; Kim, S.-K.; Bak, Y.-C. The reactivity of V2O5-WO3-TiO2 catalyst supported on a ceramic filter candle for selective reduction of NO. Korean J. Chem. Eng. 2001, 18, 719–724. [Google Scholar] [CrossRef]

- Choi, J.-H.; Kim, S.-K.; Ha, S.-J.; Park, Y.-O. The preparation of V2O5/TiO2 catalyst supported on the ceramic filter candle for selective reduction of NO. Korean J. Chem. Eng. 2001, 18, 456–462. [Google Scholar] [CrossRef]

- An, W.; Zhang, Q.; Chuang, K.T.; Sanger, A.R. A Hydrophobic Pt/Fluorinated Carbon Catalyst for Reaction of NO with NH3. Ind. Eng. Chem. Res. 2002, 41, 27–31. [Google Scholar] [CrossRef]

- Grossale, A.; Nova, I.; Tronconi, E.; Chatterjee, D.; Weibel, M. The chemistry of the NO/NO2–NH3 “fast” SCR reaction over Fe-ZSM5 investigated by transient reaction analysis. J. Catal. 2008, 256, 312–322. [Google Scholar] [CrossRef]

- Zürcher, S.; Schaub, G. Foams as Structured Packing for the Catalytic Gas Conversion in Gas-Particle Filters. 2007, 79. Available online: https://publikationen.bibliothek.kit.edu/1000050239 (accessed on 1 December 2021).

- Zürcher, S.; Pabst, K.; Schaub, G. Ceramic foams as structured catalyst inserts in gas–particle filters for gas reactions—Effect of backmixing. Appl. Catal. A Gen. 2009, 357, 85–92. [Google Scholar] [CrossRef]

- Dong, G.-j.; Zhao, Y.; Zhang, Y.-f. Preparation and performance of V-Wreparation and performance of V-W/x(Mn-Ce-Ti)/y(Cu-Ce-Ti)/cordierite catalyst by impregnation method in sequence for SCR reaction with urea. J. Fuel Chem. Technol. 2014, 42, 1093–1101. [Google Scholar] [CrossRef]

- U.S. EPA (Ed.) Report on the Environment, Volatile Organic Compound Emissions; U.S. EPA: Washington, DC, USA, 2018; p. 5.

- Cybulski, A.; Moulijn, J.A. Structured Catalysts and Reactors, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2005; p. 856. [Google Scholar]

- Nacken, M.; Heidenreich, S.; Hackel, M.; Schaub, G. Catalytic activation of ceramic filter elements for combined particle separation, NOx removal and VOC total oxidation. Appl. Catal. B Environ. 2007, 70, 370–376. [Google Scholar] [CrossRef]

- Schoubye, P.; Jensen, J.R. Catalytic Activated Ceramic Dust Filter—A New Technology for Combined Removal of Dust, NOx, dioxin, VOCs and Acids from Off Gases; Haldor Topsoe, Ed.; Haldor Topsoe: Lyngby, Denmark, 2006. [Google Scholar]

- Moss, K.D. Ceramic Filter Systems. In Ceramic Industry; 2012; Available online: http://www.ceramicindustry.com/articles/92599-ceramic-filter-systems/ (accessed on 15 December 2021).

- Gravley, R. NOx Treatment by Selctive Catalytic Reduction with Catalytic Ceramic Filter Elements; Tri-Mer Corporation: Owosso, MI, USA, 2014. [Google Scholar]

- Saracco, G.; Specchia, V. Catalytic filters for the abatement of volatile organic compounds. Chem. Eng. Sci. 2000, 55, 897–908. [Google Scholar] [CrossRef]

- Choi, J.; Mun, S.; Kim, S.; Hong, M.; Lee, J. Simultaneous Removal of Particulates and NOx Using Catalyst Impregnated Fibrous Ceramic Filters; University of North Texas Digital Library: Denton, TX, USA, 2002; Available online: https://digital.library.unt.edu/ark:/67531/metadc781611/ (accessed on 15 December 2021).

- The World Bank. Pollution Prevention and Abatement Handbook, 1998; The World Bank: Washington, DC, USA, 1999; p. 471. [Google Scholar] [CrossRef]

- Simeone, E.; Siedlecki, M.; Nacken, M.; Heidenreich, S.; Jong, W. High temperature gas filtration with ceramic candles and ashes characterisation during steam–oxygen blown gasification of biomass. Fuel 2013, 108, 99–111. [Google Scholar] [CrossRef]

- Tan, Z.; Niu, G.; Qi, Q.; Zhou, M.; Wu, B.; Yao, W. Ultralow Emission of Dust, SOx, HCl, and NOx Using a Ceramic Catalytic Filter Tube. Energy Fuels 2020, 34, 4173–4182. [Google Scholar] [CrossRef]

- Nair, B.N.; Yamaguchi, T.; Okubo, T.; Suematsu, H.; Keizer, K.; Nakao, S.-I. Sol-gel synthesis of molecular sieving silica membranes. J. Membr. Sci. 1997, 135, 237–243. [Google Scholar] [CrossRef]

- Li, A.; Zhao, H.; Gu, J.; Xiong, G. Preparation of γ-Al2O3 composite membrane and examination of membrane defects. Sci. China-Chem. 1997, 40, 31–36. [Google Scholar] [CrossRef]

- Lu, M.; Xiong, G.; Zhao, H.; Cui, W.; Gu, J.; Bauser, H. Dehydration of 1-butanol over γ-Al2O3 catalytic membrane. Catal. Today 1995, 25, 339–344. [Google Scholar] [CrossRef]

- Masuda, T.; Asanuma, T.; Shouji, M.; Mukai, S.R.; Kawase, M.; Hashimoto, K. Methanol to olefins using ZSM-5 zeolite catalyst membrane reactor. Chem. Eng. Sci. 2003, 58, 649–656. [Google Scholar] [CrossRef]

- Balachandran, U.; Lee, T.H.; Dorris, S.E. Hydrogen production by water dissociation using mixed conducting dense ceramic membranes. Int. J. Hydrogen Energy 2007, 32, 451–456. [Google Scholar] [CrossRef]

- Tsodikov, M.V.; Fedotov, A.S.; Antonov, D.O.; Uvarov, V.I.; Bychkov, V.Y.; Luck, F.C. Hydrogen and syngas production by dry reforming of fermentation products on porous ceramic membrane-catalytic converters. Int. J. Hydrogen Energy 2016, 41, 2424–2431. [Google Scholar] [CrossRef]

- U.S. EPA. Nitrogen Oxides (NOx), Why and How They Are Controlled; U.S. EPA, Ed.; Clean Air Technology Center: Research Triangle Park, NC, USA, 1999; p. 57.

- Nahavandi, M. Selective Catalytic Reduction of Nitric Oxide by Ammonia over V2O5/TiO2 in a Hollow Cylindrical Catalyst under Enhancing Effect of Electrohydrodynamics: A Kinetic Modeling Study. Ind. Eng. Chem. Res. 2014, 53, 12673–12688. [Google Scholar] [CrossRef]

- Nova, I.; Lietti, L.; Tronconi, E.; Forzatti, P. Dynamics of SCR reaction over a TiO2-supported vanadia–tungsta commercial catalyst. Catal. Today 2000, 60, 73–82. [Google Scholar] [CrossRef]

- Ashok, J.; Dewangan, N.; Das, S.; Hongmanorom, P.; Wai, M.H.; Tomishige, K.; Kawi, S. Recent progress in the development of catalysts for steam reforming of biomass tar model reaction. Fuel Process. Technol. 2020, 199, 106252. [Google Scholar] [CrossRef]

- Coll, R.; Salvadó, J.; Farriol, X.; Montané, D. Steam reforming model compounds of biomass gasification tars: Conversion at different operating conditions and tendency towards coke formation. Fuel Process. Technol. 2001, 74, 19–31. [Google Scholar] [CrossRef]

- Kinoshita, C.M.; Wang, Y.; Zhou, J. Tar formation under different biomass gasification conditions. J. Anal. Appl. Pyrolysis 1994, 29, 169–181. [Google Scholar] [CrossRef]

- Ciferno, J.P.; Marano, J.P. Benchmarking Biomass Gasification Technologies for Fuels, Chemicals and Hydrogen Production; National Energy Technology Laboratory, US Department of Energy: Albany, OR, USA, 2002.

- Park, S.J.; Son, S.H.; Kook, J.W.; Ra, H.W.; Yoon, S.J.; Mun, T.-Y.; Moon, J.H.; Yoon, S.M.; Kim, J.H.; Kim, Y.K.; et al. Gasification operational characteristics of 20-tons-Per-Day rice husk fluidized-bed reactor. Renew. Energy 2021, 169, 788–798. [Google Scholar] [CrossRef]

- Balas, M.; Lisy, M.; Zdenek, A.; Pospisil, J. Wet scrubber for cleaning of syngas from biomass gasification. Adv. Environ. Sci. Dev. Chem. 2014, 195–201. Available online: https://www.researchgate.net/publication/303170096_Wet_scrubber_for_cleaning_of_syngas_from_biomass_gasification (accessed on 15 December 2021).

- Zhang, Z.; Liu, L.; Shen, B.; Wu, C. Preparation, modification and development of Ni-based catalysts for catalytic reforming of tar produced from biomass gasification. Renew. Sustain. Energy Rev. 2018, 94, 1086–1109. [Google Scholar] [CrossRef]

- Orío, A.; Corella, J.; Narváez, I. Performance of Different Dolomites on Hot Raw Gas Cleaning from Biomass Gasification with Air. Ind. Eng. Chem. Res. 1997, 36, 3800–3808. [Google Scholar] [CrossRef]

- Corella, J.; Orío, A.; Aznar, P. Biomass Gasification with Air in Fluidized Bed: Reforming of the Gas Composition with Commercial Steam Reforming Catalysts. Ind. Eng. Chem. Res. 1998, 37, 4617–4624. [Google Scholar] [CrossRef]

- Kumar, A.; Jones, D.; Hanna, M. Thermochemical Biomass Gasification: A Review of the Current Status of the Technology. Energies 2009, 2, 556–581. [Google Scholar] [CrossRef]

- Aouad, S.; Labaki, M.; Ojala, S.; Seelam, P.; Turpeinen, E.; Gennequin, C.; Estephane, J.; Aad, E.A. A Review on the Dry Reforming Processes for Hydrogen Production: Catalytic Materials and Technologies. Catal. Mater. Hydrog. Prod. Electro Oxid. React. Front. Ceram. 2018, 2, 60–128. [Google Scholar] [CrossRef]

- Straczewski, G.; Koutera, K.; Gerhards, U.; Garbev, K.; Leibold, H. Development of catalytic ceramic filter candles for tar conversion. Fuel Commun. 2021, 7, 100021. [Google Scholar] [CrossRef]

- Buchireddy, P.R.; Bricka, R.M.; Rodriguez, J.; Holmes, W. Biomass Gasification: Catalytic Removal of Tars over Zeolites and Nickel Supported Zeolites. Energy Fuels 2010, 24, 2707–2715. [Google Scholar] [CrossRef]

- Simell, P.; Ståhlberg, P.; Kurkela, E.; Albrecht, J.; Deutsch, S.; Sjöström, K. Provisional protocol for the sampling and anlaysis of tar and particulates in the gas from large-scale biomass gasifiers. Version 1998. Biomass Bioenergy 2000, 18, 19–38. [Google Scholar] [CrossRef]

- Abu El-Rub, Z.; Bramer, E.A.; Brem, G. Review of Catalysts for Tar Elimination in Biomass Gasification Processes. Ind. Eng. Chem. Res. 2004, 43, 6911–6919. [Google Scholar] [CrossRef]

- Delgado, J.; Aznar, M.P.; Corella, J. Calcined Dolomite, Magnesite, and Calcite for Cleaning Hot Gas from a Fluidized Bed Biomass Gasifier with Steam: Life and Usefulness. Ind. Eng. Chem. Res. 1996, 35, 3637–3643. [Google Scholar] [CrossRef]

- Wang, T.; Chang, J.; Lv, P.; Zhu, J. Novel Catalyst for Cracking of Biomass Tar. Energy Fuels 2005, 19, 22–27. [Google Scholar] [CrossRef]

- Garcia, L.; Sanchez, J.L.; Salvador, M.L.; Bilbao, R.; Arauzo, J. Assessment of Coprecipitated Nickel-Alumina Catalysts for Pyrolysis of Biomass. In Developments in Thermochemical Biomass Conversion: Volume 1/Volume 2; Bridgwater, A.V., Boocock, D.G.B., Eds.; Springer Netherlands: Dordrecht, The Netherlands, 1997; pp. 1158–1169. [Google Scholar]

- Majdi, H.S.; Saud, A.N.; Saud, S.N. Modeling the Physical Properties of Gamma Alumina Catalyst Carrier Based on an Artificial Neural Network. Materials 2019, 12, 1752. [Google Scholar] [CrossRef]

- Shen, Y.; Yoshikawa, K. Recent progresses in catalytic tar elimination during biomass gasification or pyrolysis—A review. Renew. Sustain. Energy Rev. 2013, 21, 371–392. [Google Scholar] [CrossRef]

- Świerczyński, D.; Libs, S.; Courson, C.; Kiennemann, A. Steam reforming of tar from a biomass gasification process over Ni/olivine catalyst using toluene as a model compound. Appl. Catal. B Environ. 2007, 74, 211–222. [Google Scholar] [CrossRef]

- Bartholomew, C.H. Mechanisms of catalyst deactivation. Appl. Catal. A Gen. 2001, 212, 17–60. [Google Scholar] [CrossRef]

- Gao, X.; Wang, Z.; Ashok, J.; Kawi, S. A comprehensive review of anti-coking, anti-poisoning and anti-sintering catalysts for biomass tar reforming reaction. Chem. Eng. Sci. X 2020, 7, 100065. [Google Scholar] [CrossRef]

- Uchida, H.; Harada, M.R. Hydrogen Energy Engineering Applications and Products; Academic Press: Cambridge, MA, USA, 2019; pp. 201–220. [Google Scholar] [CrossRef]

- Argyle, M.; Bartholomew, C. Heterogeneous Catalyst Deactivation and Regeneration: A Review. Catalysts 2015, 5, 145–269. [Google Scholar] [CrossRef]

- Rostrup-Nielsen, J.R. Industrial relevance of coking. Catal. Today 1997, 37, 225–232. [Google Scholar] [CrossRef]

- Wen, W.Y.; Cain, E. Catalytic pyrolysis of a coal tar in a fixed-bed reactor. Ind. Eng. Chem. Process Des. Dev. 1984, 23, 627–637. [Google Scholar] [CrossRef]

- Moud, P.H.; Andersson, K.J.; Lanza, R.; Engvall, K. Equilibrium potassium coverage and its effect on a Ni tar reforming catalyst in alkali- and sulfur-laden biomass gasification gases. Appl. Catal. B Environ. 2016, 190, 137–146. [Google Scholar] [CrossRef]

- Tuomi, S.; Kurkela, E.; Simell, P.; Reinikainen, M. Behaviour of tars on the filter in high temperature filtration of biomass-based gasification gas. Fuel 2015, 139, 220–231. [Google Scholar] [CrossRef]

- Nacken, M.; Ma, L.; Engelen, K.; Heidenreich, S.; Baron, G.V. Development of a Tar Reforming Catalyst for Integration in a Ceramic Filter Element and Use in Hot Gas Cleaning. Ind. Eng. Chem. Res. 2007, 46, 1945–1951. [Google Scholar] [CrossRef]

- Nacken, M.; Ma, L.; Heidenreich, S.; Baron, G.V. Performance of a catalytically activated ceramic hot gas filter for catalytic tar removal from biomass gasification gas. Appl. Catal. B Environ. 2009, 88, 292–298. [Google Scholar] [CrossRef]

- Simeone, E.; Hölsken, E.; Nacken, M.; Heidenreich, S.; De Jong, W. Study of the Behaviour of a Catalytic Ceramic Candle Filter in a Lab-Scale Unit at High Temperatures. Int. J. Chem. React. Eng. 2010, 8. [Google Scholar] [CrossRef]

- Engelen, K.; Zhang, Y.; Baron, G. Development of a Catalytic Candle Filter for One-Step Tar and Particle Removal in Biomass Gasification Gas. Int. J. Chem. React. Eng. 2003, 1. [Google Scholar] [CrossRef]

- Fantini, M.; Nacken, M.; Heidenreich, S.; Siedlecki, M.; Fornasari, G.; Benito, P.; Leite, M.; Jong, W. Bagasse Gasification in a 100 kWth Steam-Oxygen Blown Circulating Fluidized Bed Gasifier with Catalytic and Non-Catalytic Upgrading of the Syngas Using Ceramic Filters; WIT Transactions on Ecology and the Environment: Billerica, MA, USA, 2014; Volume 190, pp. 1079–1090. [Google Scholar] [CrossRef]

- Lang, L.; Yang, W.; Xie, J.; Yin, X.; Wu, C.; Lin, J.Y.S. Oxidative filtration for flyash & tar removal from 1.0 MWth fixed-bed biomass air gasification. Biomass Bioenergy 2019, 122, 145–155. [Google Scholar] [CrossRef]

- Gao, N.; Li, A.; Quan, C.; Gao, F. Hydrogen-rich gas production from biomass steam gasification in an updraft fixed-bed gasifier combined with a porous ceramic reformer. Int. J. Hydrogen Energy 2008, 33, 5430–5438. [Google Scholar] [CrossRef]

- Abu El-Rub, Z. Biomass Char as an In-Situ Catalyst for tar Removal in Gasification Systems. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2008. [Google Scholar]

- Shen, Y.; Fu, Y. Advances in in situ and ex situ tar reforming with biochar catalysts for clean energy production. Sustain. Energy Fuels 2018, 2, 326–344. [Google Scholar] [CrossRef]

- Heidenreich, S.; Foscolo, P.U. New concepts in biomass gasification. Prog. Energy Combust. Sci. 2015, 46, 72–95. [Google Scholar] [CrossRef]

- de Diego, L.F.; García-Labiano, F.; Gayán, P.; Abad, A.; Mendiara, T.; Adánez, J.; Nacken, M.; Heidenreich, S. Tar abatement for clean syngas production during biomass gasification in a dual fluidized bed. Fuel Process. Technol. 2016, 152, 116–123. [Google Scholar] [CrossRef]

- Rapagnà, S.; Gallucci, K.; Di Marcello, M.; Muriel, M.; Foscolo, P.; Nacken, M.; Heidenreich, S. Tar Reforming and Particulate Abatement by Means of Catalytic Ceramic Candles Placed in the Freeboard of Fluidized Bed Biomass Gasifiers. In Proceedings of the 2nd International Conference on Green Process Engineering, Venice, Italy, 14–17 June 2009. [Google Scholar]

- Rapagnà, S.; Gallucci, K.; Di Marcello, M.; Foscolo, P.; Nacken, M.; Heidenreich, S. In Situ Catalytic Ceramic Candle Filtration for Tar Reforming and Particulate Abatement in a Fluidized-Bed Biomass Gasifier. Energy Fuels 2009, 23, 3804–3809. [Google Scholar] [CrossRef]

- Rapagna, S.; Gallucci, K.; Di Marcello, M.; Matt, M.; Nacken, M.; Heidenreich, S.; Foscolo, P.U. Gas cleaning, gas conditioning and tar abatement by means of a catalytic filter candle in a biomass fluidized-bed gasifier. Bioresour Technol. 2010, 101, 7134–7141. [Google Scholar] [CrossRef]

- Rapagnà, S.; Spinelli, G. Air-steam biomass gasification in a fluidised bed reactor in presence of ceramic filters. Chem. Eng. 2015, 43, 397–402. [Google Scholar] [CrossRef]

- D’Orazio, A.; Rapagnà, S.; Foscolo, P.U.; Gallucci, K.; Nacken, M.; Heidenreich, S.; Di Carlo, A.; Dell’Era, A. Gas conditioning in H2 rich syngas production by biomass steam gasification: Experimental comparison between three innovative ceramic filter candles. Int. J. Hydrogen Energy 2015, 40, 7282–7290. [Google Scholar] [CrossRef]

- Rapagna, S.; Gallucci, K.; Foscolo, P.U. Olivine, dolomite and ceramic filters in one vessel to produce clean gas from biomass. Waste Manag. 2018, 71, 792–800. [Google Scholar] [CrossRef]

- Rapagnà, S.; D’Orazio, A.; Gallucci, K.; Foscolo, P.; Nacken, M.; Heidenreich, S. Hydrogen Rich Gas from Catalytic Steam Gasification of Biomass in a Fluidized Bed Containing Catalytic Filters. Chem. Eng. Trans. 2014, 37, 157–162. [Google Scholar] [CrossRef]

- Rapagnà, S.; Gallucci, K.; Di Marcello, M.; Foscolo, P.; Nacken, M.; Heidenreich, S.; Muriel, M. Modified Alumina Oxide Hot Gas Filter for Catalytic Fluidized Bed Gasification. In Proceedings of the 19th European Biomass Conference and Exhibition, Berlin, Germany, 6–10 June 2011; 2011; pp. 1071–1074. [Google Scholar]

- Rapagnà, S.; Gallucci, K.; Di Marcello, M.; Muriel, M.; Foscolo, P.; Nacken, M.; Heidenreich, S. Characterisation of Tar produced in the Gasification of Biomass with in situ Catalytic Reforming. Int. J. Chem. React. Eng. 2010, 8. [Google Scholar] [CrossRef]

- Rapagnà, S.; Mazziotti di Celso, G.; Di Marcello, M.; Nacken, M.; Heidenreich, S.; Foscolo, P.U. Catalytic ceramic candles to improve the quality of hot biomass gasification products. In Proceedings of the 16th European Biomass Conference and Exhibition, Valencia, Spain, 2–6 June 2008; pp. 963–966. [Google Scholar]

- Nacken, M.; Ma, L.; Heidenreich, S.; Baron, G. Catalytic Activity in Naphthalene Reforming of Two Types of Catalytic Filters for Hot Gas Cleaning of Biomass-Derived Syngas. Ind. Eng. Chem. Res. 2010, 49, 5536–5542. [Google Scholar] [CrossRef]

- Rapagnà, S.; Gallucci, K.; Di Marcello, M.; Foscolo, P.U.; Nacken, M.; Heidenreich, S.; Matt, M. First Al2O3 based catalytic filter candles operating in the fluidized bed gasifier freeboard. Fuel 2012, 97, 718–724. [Google Scholar] [CrossRef]

- García-Labiano, F.; Gayán, P.; de Diego, L.F.; Abad, A.; Mendiara, T.; Adánez, J.; Nacken, M.; Heidenreich, S. Tar abatement in a fixed bed catalytic filter candle during biomass gasification in a dual fluidized bed. Appl. Catal. B Environ. 2016, 188, 198–206. [Google Scholar] [CrossRef]

- Savuto, E.; Di Carlo, A.; Steele, A.; Heidenreich, S.; Gallucci, K.; Rapagnà, S. Syngas conditioning by ceramic filter candles filled with catalyst pellets and placed inside the freeboard of a fluidized bed steam gasifier. Fuel Process. Technol. 2019, 191, 44–53. [Google Scholar] [CrossRef]

- Nacken, M.; Baron, G.V.; Heidenreich, S.; Rapagnà, S.; D’Orazio, A.; Gallucci, K.; Denayer, J.F.M.; Foscolo, P.U. New DeTar catalytic filter with integrated catalytic ceramic foam: Catalytic activity under model and real bio syngas conditions. Fuel Process. Technol. 2015, 134, 98–106. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An overview of advances in biomass gasification. Energy Environ. Sci. 2016, 9, 2939–2977. [Google Scholar] [CrossRef]

- Engelen, K.; Zhang, Y.; Draelants, D.J.; Baron, G.V. A novel catalytic filter for tar removal from biomass gasification gas: Improvement of the catalytic activity in presence of H2S. Chem. Eng. Sci. 2003, 58, 665–670. [Google Scholar] [CrossRef]

- Ma, L.; Verelst, H.; Baron, G.V. Integrated high temperature gas cleaning: Tar removal in biomass gasification with a catalytic filter. Catal. Today 2005, 105, 729–734. [Google Scholar] [CrossRef]

- Zhao, H.; Draelants, D.J.; Baron, G.V. Performance of a Nickel-Activated Candle Filter for Naphthalene Cracking in Synthetic Biomass Gasification Gas. Ind. Eng. Chem. Res. 2000, 39, 3195–3201. [Google Scholar] [CrossRef]

- Zhao, H.; Draelants, D.J.; Baron, G.V. Preparation and characterisation of nickel-modified ceramic filters. Catal. Today 2000, 56, 229–237. [Google Scholar] [CrossRef]

- Draelants, D.J.; Zhang, Y.; Zhao, H.; Baron, G.V. Preparation of nickel-modified ceramic filters by the urea precipitation method for tar removal from biomass gasification gas. In Studies in Surface Science and Catalysis; Gaigneaux, E., De Vos, D.E., Grange, P., Jacobs, P.A., Martens, J.A., Ruiz, P., Poncelet, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2002; Volume 143, pp. 159–165. [Google Scholar]

- Zhang, Y.; Draelants, D.J.; Engelen, K.; Baron, G.V. Development of nickel-activated catalytic filters for tar removal in H2S-containing biomass gasification gas. J. Chem. Technol. Biotechnol. 2003, 78, 265–268. [Google Scholar] [CrossRef]

- Draelants, D.; Zhao, H.; Baron, G. Preparation of Catalytic Filters by the Urea Method and Its Application for Benzene Cracking in H2S-Containing Biomass Gasification Gas. Ind. Eng. Chem. Res. 2001, 40, 3309–3316. [Google Scholar] [CrossRef]

- Draelants, D.; Zhao, H.B.; Baron, G. Catalytic conversion of tars in biomass gasification fuel gases with nickel-activated ceramic filters. Stud. Surf. Sci. Catal. 2000, 130, 1595–1600. [Google Scholar] [CrossRef]

- Zhang, Y.; Draelants, D.; Engelen, K.; Baron, G. Improvement of Sulphur Resistance of a Nickel-modified Catalytic Filter for Tar Removal from Biomass Gasification Gas; University of North Texas Libraries: Denton, TX, USA, 2002. [Google Scholar]

- Ma, L.; Baron, G.V. Mixed zirconia–alumina supports for Ni/MgO based catalytic filters for biomass fuel gas cleaning. Powder Technol. 2008, 180, 21–29. [Google Scholar] [CrossRef]

- Tuna, Ö.; Simsek, E.B.; Sarıoğlan, A. A new approach for integrated system of biomass gasification combined reforming and desulfurization processes consisting of Ni/Al2O3 and Cu-Zn2TiO4 heterostructure ceramic filters. Chem. Eng. Process.—Process Intensif. 2021, 165, 108433. [Google Scholar] [CrossRef]

- Espinosa, R.B. Structured Catalysts and Reactors for Three Phase Catalytic Reactions. Ph.D. Dissertation, University of Twente, Enschede, The Netherlands, 2016. [Google Scholar]

- Giroux, T.; Hwang, S.; Liu, Y.; Ruettinger, W.; Shore, L. Monolithic structures as alternatives to particulate catalysts for the reforming of hydrocarbons for hydrogen generation. Appl. Catal. B Environ. 2005, 56, 95–110. [Google Scholar] [CrossRef]

- Quan, C.; Gao, N.; Chunfei, W. Utilization of NiO/porous ceramic monolithic catalyst for upgrading biomass fuel gas. J. Energy Inst. 2017, 91, 331–338. [Google Scholar] [CrossRef]

- Rhyner, U.; Edinger, P.; Schildhauer, T.J.; Biollaz, S.M.A. Experimental study on high temperature catalytic conversion of tars and organic sulfur compounds. Int. J. Hydrogen Energy 2014, 39, 4926–4937. [Google Scholar] [CrossRef]

- Pfeifer, C.; Hofbauer, H. Development of catalytic tar decomposition downstream from a dual fluidized bed biomass steam gasifier. Powder Technol. 2008, 180, 9–16. [Google Scholar] [CrossRef]

- Simell, P.; Kurkela, E.; Ståhlberg, P.; Hepola, J. Catalytic hot gas cleaning of gasification gas. Catal. Today 1996, 27, 55–62. [Google Scholar] [CrossRef]

- Toledo, J.M.; Corella, J.; Molina, G. Catalytic Hot Gas Cleaning with Monoliths in Biomass Gasification in Fluidized Beds. 4. Performance of an Advanced, Second-Generation, Two-Layers-Based Monolithic Reactor. Ind. Eng. Chem. Res. 2006, 45, 1389–1396. [Google Scholar] [CrossRef]

- Balzarotti, R.; Italiano, C.; Pino, L.; Cristiani, C.; Vita, A. Ni/CeO2-thin ceramic layer depositions on ceramic monoliths for syngas production by Oxy Steam Reforming of biogas. Fuel Process. Technol. 2016, 149, 40–48. [Google Scholar] [CrossRef]

- Gao, N.; Han, Y.; Quan, C.; Wu, C. Promoting hydrogen-rich syngas production from catalytic reforming of biomass pyrolysis oil on nanosized nickel-ceramic catalysts. Appl. Therm. Eng. 2017, 125, 297–305. [Google Scholar] [CrossRef]

- Gao, N.; Han, Y.; Quan, C. Study on steam reforming of coal tar over Ni Co/ceramic foam catalyst for hydrogen production: Effect of Ni/Co ratio. Int. J. Hydrogen Energy 2018, 43, 22170–22186. [Google Scholar] [CrossRef]

- Nacken, M.; Ma, L.; Heidenreich, S.; Verpoort, F.; Baron, G.V. Development of a catalytic ceramic foam for efficient tar reforming of a catalytic filter for hot gas cleaning of biomass-derived syngas. Appl. Catal. B Environ. 2012, 125, 111–119. [Google Scholar] [CrossRef]

- Twigg, M.V.; Richardson, J.T. Theory and Applications of Ceramic Foam Catalysts. Chem. Eng. Res. Des. 2002, 80, 183–189. [Google Scholar] [CrossRef]

- Twigg, M.V.; Richardson, J.T. Fundamentals and Applications of Structured Ceramic Foam Catalysts. Ind. Eng. Chem. Res. 2007, 46, 4166–4177. [Google Scholar] [CrossRef]

- Rhyner, U.; Edinger, P.; Schildhauer, T.J.; Biollaz, S.M.A. Applied kinetics for modeling of reactive hot gas filters. Appl. Energy 2014, 113, 766–780. [Google Scholar] [CrossRef]

- Palma, V.; Ruocco, C.; Ricca, A. Ceramic foams coated with Pt Ni/CeO2ZrO2 for bioethanol steam reforming. Int. J. Hydrogen Energy 2016, 41, 11526–11536. [Google Scholar] [CrossRef]

- Kapteijn, F.; Moulijn, J.A. Structured catalysts and reactors—Perspectives for demanding applications. Catal. Today 2020, 383, 5–14. [Google Scholar] [CrossRef]

- Savuto, E.; Di Carlo, A.; Gallucci, K.; Stendardo, S.; Rapagnà, S. 3D-CFD simulation of catalytic filter candles for particulate abatement and tar and methane steam reforming inside the freeboard of a gasifier. Chem. Eng. J. 2019, 377, 120290. [Google Scholar] [CrossRef]

- Savuto, E.; Di Carlo, A.; Bocci, E.; D’Orazio, A.; Villarini, M.; Carlini, M.; Foscolo, P.U. Development of a CFD model for the simulation of tar and methane steam reforming through a ceramic catalytic filter. Int. J. Hydrogen Energy 2015, 40, 7991–8004. [Google Scholar] [CrossRef]

| Device | Collection Efficiency (%) | Pressure Drop (kPa) | Flow Capacity | Energy Required |

|---|---|---|---|---|

| Cyclones | 90–95 (>PM5) | 7.5–27.5 | Very High | Moderate |

| Granular Filters | >99 | 6–10 | High | Moderate |

| Electrostatic Precipitators | >99 | 0.3–0.6 | Low | High |

| Rigid Barrier Filters | >99.5 | 5–25 | High | Low |

| Contaminant | IC Engine | Gas Turbine | Methanol Synthesis | Fischer–Tropsch Synthesis | SOFC |

|---|---|---|---|---|---|

| PM | 15 mg/m3 (PM10) | 30 mg/m3 | 0.02 mg/m3 | 0.02 mg/m3 | 3 mg/m3 |

| Tar | 15 mg/m3 | 100 mg/m3 | 0.1 mg/m3 | 0.1 mg/m3 | 5 mg/m3 |

| Sulfur (H2S, COS) | 50 mg/m3 | 20 mg/m3 | 0.1 mg/m3 | 0.1 mg/m3 | 4 mg/m3 |

| Nitrogen (NH3, HCN) | 10 mg/m3 | 50 mg/m3 | 0.1 mg/m3 | 0.02 mg/m3 | 2 mg/m3 |

| Alkali | 0.02 mg/m3 | 0.02 mg/m3 | 0.1 mg/m3 | 0.01 mg/m3 | 3 mg/m3 |

| Halides | 15 mg/m3 | 1 mg/m3 | 0.001 mg/m3 | 0.01 mg/m3 | 50 mg/m3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peck, D.; Zappi, M.; Gang, D.; Guillory, J.; Hernandez, R.; Buchireddy, P. Review of Porous Ceramics for Hot Gas Cleanup of Biomass Syngas Using Catalytic Ceramic Filters to Produce Green Hydrogen/Fuels/Chemicals. Energies 2023, 16, 2334. https://doi.org/10.3390/en16052334

Peck D, Zappi M, Gang D, Guillory J, Hernandez R, Buchireddy P. Review of Porous Ceramics for Hot Gas Cleanup of Biomass Syngas Using Catalytic Ceramic Filters to Produce Green Hydrogen/Fuels/Chemicals. Energies. 2023; 16(5):2334. https://doi.org/10.3390/en16052334

Chicago/Turabian StylePeck, Devin, Mark Zappi, Daniel Gang, John Guillory, Rafael Hernandez, and Prashanth Buchireddy. 2023. "Review of Porous Ceramics for Hot Gas Cleanup of Biomass Syngas Using Catalytic Ceramic Filters to Produce Green Hydrogen/Fuels/Chemicals" Energies 16, no. 5: 2334. https://doi.org/10.3390/en16052334

APA StylePeck, D., Zappi, M., Gang, D., Guillory, J., Hernandez, R., & Buchireddy, P. (2023). Review of Porous Ceramics for Hot Gas Cleanup of Biomass Syngas Using Catalytic Ceramic Filters to Produce Green Hydrogen/Fuels/Chemicals. Energies, 16(5), 2334. https://doi.org/10.3390/en16052334