Abstract

This study is a systematic review of research on heat transfer analysis in cavities and aims to provide a comprehensive understanding of flow and heat transfer performance in various kinds of cavities with or without the presence of fins, obstacles, cylinders, and baffles. The study also examines the effects of different forces, such as magnetic force, buoyancy force, and thermophoresis effect on heat transfer in cavities. This study also focuses on different types of fluids, such as air, water, nanofluids, and hybrid nanofluids in cavities. Moreover, this review deals with aspects of flow and heat transfer phenomena for only single-phase flows. It discusses various validation techniques used in numerical studies and the different types and sizes of mesh used by researchers. The study is a comprehensive review of 297 research articles, mostly published since 2000, and covers the current progress in the area of heat transfer analysis in cavities. The literature review in this study shows that cavities with obstacles such as fins and rotating cylinders have a significant impact on enhancing heat transfer. Additionally, it is found that the use of nanofluids and hybrid nanofluids has a greater effect on enhancing heat transfer. Lastly, the study suggests future research directions in the field of heat transfer in cavities. This study’s findings have significant implications for a range of areas, including electronic cooling, energy storage systems, solar thermal technologies, and nuclear reactor systems.

1. Introduction

The study highlights that enclosed cavities have a broad area of uses, such as electronic cooling, energy storage systems, solar thermal technologies, and nuclear reactor systems. The study has considered various shapes of cavities, including square, rectangular, triangular, trapezoidal, semicircular, hexagonal, U-shaped, etc. Different types of boundary conditions are applied to the walls of the cavities, which affect the flow and thermal behavior inside the cavities. The study considers temperature, heat flux, adiabatic, and isothermal as thermal boundary conditions, such as. On the other hand, the hydraulic boundary conditions considered are fixed, moving, and elastic. Some authors have also applied magnetic field strength to enhance heat transfer or alter buoyancy effects. Different types of fluids have been used in the cavity, including pure water, air, nanofluids, phase change material, porous media, and non-Newtonian fluid.

The main mechanisms of heat transfer in enclosed cavities are natural, forced, or mixed convection. The driving force for natural convection is mainly the buoyancy force (according to Boussinesq approximation), which is caused by the change in fluid density resulting from the applied temperature difference [1,2]. Research has shown that the buoyancy force can destabilize the flow inside the enclosure, but the application of a magnetic field can stabilize it [3]. In addition, the addition of nanoparticles to the liquid inside the cavity can improve its thermal conductivity, heat capacity, and density [4]. Alqaed et al. [5] studied the use of Al2O3/H2O nanofluid with an applied magnetic field. They proved that the presence of nanoparticles contributed to the fluid properties and improved heat transfer. The magnetic field also imposed a specific force (Lorentz force), which opposes the flow inside the cavity and reduces the heat transfer rate. Hatami [6] demonstrated that the presence of fins inside the cavity leads to an increase in vortices (increased mixing) which in turn leads to an enhancement of the rate of heat transfer. The interplay between the magnetic and buoyancy of a hybrid nanofluid Cu-Al2O3 inside a cavity leads to a decrease in flow velocity and reduced heat transfer rate [7]. Similar trends in the effect of nanofluid have been observed in different-shaped enclosures such as hexagonal [8], U-shaped [9], and trapezoidal cavities [10].

The moving boundary imposes a shear force on the fluid surface, which can lead to the generation of recirculating eddies that closes the wall of the cavity. The direction of the moving boundary can affect the strength of the shear force and the characteristics of the eddies that are formed. Additionally, for low values of Prandtl numbers, the effects of the moving boundary on the flow can be more pronounced [11]. Adding nanoparticles to a fluid can have a similar effect to that of fixed boundaries in that the fluid’s thermal conductivity enhances, and the rate of heat transfer rises. That’s because nanoparticles can enhance a fluid’s thermal conductivity and improve the rate of heat transfer. Additionally, if the fluid has been subjected to a magnetic field, the presence of the nanoparticles can lead to the generation of Lorentz force that acts in the vertical direction of the magnetic field. This force can suppress circulation and reduce the heat transfer rate. This effect is observed when the nanoparticles are magnetic nanoparticles and the intensity of the magnetic field is raised [12].

The main objective of this work is to conduct a comprehensive literature review of the hydraulic and thermal behaviors inside a cavity. The focus will be on studying the effects of different shapes of the cavity, various applied boundary conditions, and different types of working fluids. The study will compare the effects of using various types of fluids such as air, water, nanofluids, non-Newtonian fluid, etc. The study will also aim to predict correlations for the Nusselt number for different ranges of Rayleigh and Reynolds numbers at different imposed boundary conditions.

The primary conclusion of this literature review is that not many studies have been conducted on phase change materials (PCMs) in cavities, and it is not the focus of our review. Additionally, few studies have considered the use of LES and DNS models to model turbulent flow in cavities. It is also suggested that optimization should be conducted to predict the optimum shape of the cavity. Finally, more studies are needed to investigate the behavior of cavities filled with different types of fluids, such as two immiscible fluids, which can include the interaction between two different regions inside the same enclosure, such as the development of a couple of thermal boundary layer with different fluids separated by different types of partition.

Aim of the Study

A configurative systematic review process is adopted for this study to review the following:

- Model geometry, flow domain, type, CFD modeling, parameters, and meshing.

- Different types of validations are used by researchers.

- Heat transfer behavior for different flow conditions, geometries, boundary conditions, and the presence of different obstacles inside cavities.

2. Methodology

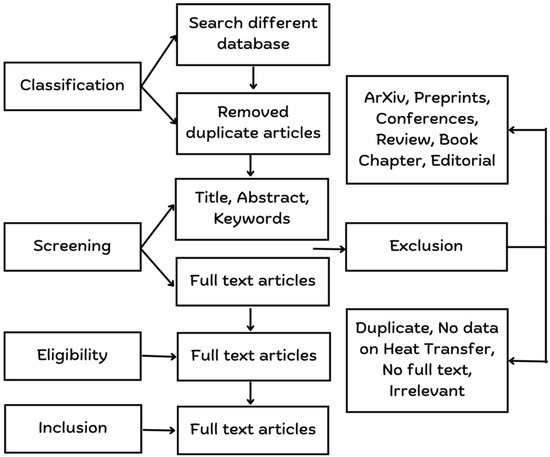

The present review employs a configurative systematic review approach to report on the heat transfer analysis inside different shapes of cavities. A flow chart of the process is provided in Figure 1. The study used various databases such as ScienceDirect, SAGE, ResearchGate, Google Scholar, and Web of Science to conduct the literature search. The search was conducted using key terms such as “Heat transfer”, “Rectangular cavity”, “Square cavity”, “Trapezoidal cavity”, “Triangular cavity”, “Hexagonal cavity”, “Octagonal cavity”, “T-shaped cavity”, “U-shaped cavity”, “C-shaped cavity”, “V-shaped cavity”, “H-shaped cavity”, “Arc-shaped cavity”, “L-shaped cavity”, “M-shaped cavity”, and “Cavity or enclosure”. The article-searching process began on 1 March 2022 and ended on 30 November 2022. One restriction was imposed during the search process, which was that the articles must be written in English.

Figure 1.

Flow chart of the study selection process.

In addition to the language restriction, the review also excluded articles that were published in ArXiv and Preprints, including conference and review articles. Book chapters, editorials, duplicate articles, articles with no data on heat transfer, articles with no full text available, and other irrelevant articles were also excluded. The authors also reviewed all the references that are connected to their research. Eligible articles were selected by two authors (G.S. & A.A.) who worked independently, screened all the articles, checked the title and abstract as well as assessed the full text. If there was any disagreement regarding the selection, a third author (S.C.S.) discussed the issues that occurred between the first two authors and then resolved the problem. Two authors (G.S. & A.A.) collected some information from the appropriate studies: author’s last name, published year, CFD tools, flow domain or shape of the domain, dimension of the study, algorithms used to solve the problem, parameters and their ranges, type of flow, name of nanofluids or hybrid nanofluids, nanofluids thermo-physical properties, validation data, and results on heat transfer analysis. A total of 2732 articles were considered, 1257 articles were removed because of duplication, 905 articles were removed for other exclusion criteria, and 570 articles were considered which were related to heat transfer analysis inside cavities. After careful screening of the title and abstract, a total of 315 articles were considered for screening of the full text. Finally, 297 articles were selected for the present review study.

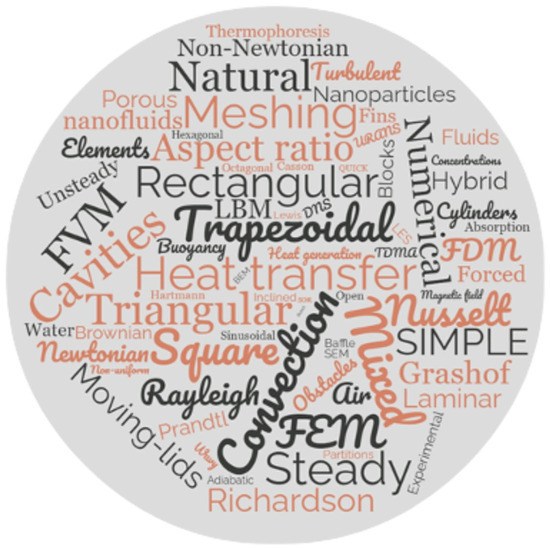

The word cloud map in Figure 2 shows the most frequently used words in the abstracts of the selected articles. It appears that the main topics of these articles are natural convection and mixed convection, steady flow, and heat transfer. These articles also focus on numerical experiments, using air and nanofluids as working fluids and utilizing FVM and FEM as numerical methods. The average rate of heat transfer is often presented as a function of the Nusselt number in relation to the Richardson number and Rayleigh number.

Figure 2.

Word Cloud Map.

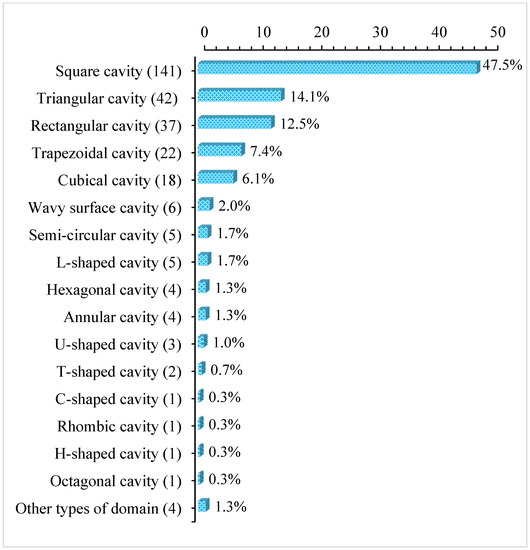

Figure 3 shows that square cavities are the most studied among the different types of cavities, accounting for 47.5% of the total number of articles. The second most studied are triangular cavities, with 14.1% of the articles. Rectangular cavities (12.5%), trapezoidal cavities (7.4%), and cubical cavities (6.1%) are also studied in a significant number of articles. The other types of cavities are studied at much lower percentages, with T-shaped (0.7%) and U-shaped (1%) cavities being the least studied. 2.5% of articles deal with other types of cavities. Square cavities have a wide range of practical applications in various fields, such as aerospace, mechanical engineering, energy, and electronics. They have many advantages, for example, in heat transfer, fluid flow, and electromagnetic waves, and therefore are widely used in many engineering systems and devices. The high percentage of research articles focused on square cavities suggests that they are an important area of study in the field.

Figure 3.

Percentage of different types of cavities.

3. Physical Domain and Mathematical Modelling

3.1. Physical Domain

Many researchers have published a large number of articles over the years to study the hydraulic and thermal performances inside enclosures with various shapes such as square, rectangular, triangular, hexagonal, octagonal, trapezoidal, T-shaped, U-shaped, L-shaped, M-shaped, V-shaped, H-shaped, I-shaped, C-shaped, arc-shaped, and other modified geometries. These studies often introduce obstacles such as fins, cylinders, blocks, rotating blades, etc., inside these physical domains to further complicate the flow patterns and potentially enhance or degrade heat transfer rates Table 1 provides more information about this research.

3.2. Governing Equations

The Navier-Stokes equations describe the motion of a fluid and are widely used in engineering and physics to model different fluid flow phenomena. The equations consist of three main components: the continuity equation, which describes the conservation of mass, the momentum equation, which describes the forces that were applied to the fluid; and the energy equation, which describes the transfer of thermal energy. These equations can be applied to a wide range of fluid types and flow conditions, including incompressible, steady and unsteady flows, Newtonian and non-Newtonian fluids, laminar and turbulent flows, and fluids with different physical properties, such as air, water, and nanofluids. The geometry of the system can also be two or three-dimensional. Solving the Navier-Stokes equations is a challenging task and requires advanced mathematical techniques. In addition to the commonly studied body forces such as gravity and electromagnetic forces, other types of body forces can also play a role in various physical systems. These can include buoyancy forces, Brownian motion of particles, thermophoresis effect, heat generation or absorption, radiation, and the porous medium effect described by the Forchheimer-Brinkman model. These forces can have significant effects on the behavior of the system and must be taken into account when studying and modeling the system. Considering all the assumptions, the three-dimensional Navier-Stokes equation can be presented in the dimensional form (Versteeg [13]):

Continuity equation:

-momentum equation:

-momentum equation:

-momentum equation:

Energy equation:

Here, are the velocities, is the pressure, and t is the time. are the Cartesian coordinate systems, is the temperature, is density, is dynamic viscosity, is gravitational acceleration, is the angle, and is the thermal expansion coefficient respectively.

Complex geometries are often encountered in physical systems, and numerical methods are often used to solve the system of equations that govern these systems. Some common numerical techniques used include the finite difference method, finite volume method, finite element method, lattice Boltzmann method, wavelet-based methods such as Coiflet wavelet-homotopy method, fourth-order compact formulation, dual reciprocity boundary element method, spectral element method, large eddy simulation, direct numerical simulation, radial basis function-based partition of unity method, and Improved element-free Galerkin–reduced integration penalty method. These methods can be used to solve a wide range of problems and have been applied in various fields, such as fluid dynamics, heat transfer, and solid mechanics. The problem of heat transfer analysis inside cavities can also be solved using commercial and open-source computational fluid dynamics (CFD) codes or software. Some examples of commonly used commercial CFD codes include COMSOL Multiphysics, ANSYS Fluent, and ADINA Multiphysics. There are also open-source options, such as FlexPDE and OpenFOAM that can be used to solve such problems. These codes and software can be used to perform a wide range of simulations, including heat transfer, fluid flow, and solid mechanics. They are widely used in various fields such as aerospace, automotive, and mechanical engineering and often include a range of features and capabilities such as pre-processing, solving, and post-processing.

3.3. Meshing

In order to solve the system of equations that govern a physical system, the physical domain must be discretized into a smaller number of elements or cells. This process is known as meshing. The Navier-Stokes equations are then solved on these elements or cells to determine the complex flow and thermal field nature. The accuracy of the results largely relies on the number of cells used in the mesh, and smaller cells are preferred to obtain higher accuracy. However, there is a trade-off between the accuracy and computational resources required. It is necessary to find a balance between the computational time and cost and the desired accuracy of the solution.

Researchers have used a variety of meshing techniques to discretize the physical domain and solve the Navier-Stokes equations. These include uniform or non-uniform meshing with rectangular or orthogonal grids, tetrahedral meshing, and non-uniform meshing with triangular grids or clustered grids. The choice of meshing technique depends on the complexity of the geometry, the level of accuracy required, and the computational resources available. It is observed that many researchers have used structured meshes as opposed to unstructured meshes. This is because structured meshes are typically less computationally expensive and require less time for simulation. Additionally, most of the researchers carry out grid-independent tests (GIT) to ensure that the solution does not depend on the grid size. GIT is a vital part of numerical simulations, and it is important that researchers present a clear and detailed discussion of GIT. However, it is also seen that some researchers did not present a clear and detailed discussion on GIT.

A lack of comparison between the performance of uniform meshes and dense non-uniform or fine meshes on flow and temperature fields is often missing in the literature. This can make it difficult for readers to understand the effects of mesh resolution on the solution and the accuracy of the simulation. Comparing the results of simulations using different meshes is an important part of any numerical study, and it is known as a mesh independence study. This is particularly important for complex flow features and can help readers to understand or revisit the study. By comparing the performance of uniform meshes and dense non-uniform or fine meshes, one can determine the optimal mesh resolution for a specific problem and also identify the errors and uncertainties associated with the simulation. Therefore, a clear presentation of the mesh independence study is important for future readers to understand the study and to replicate the simulations.

Table 1.

(a): Research performed from 1989 to 2013. (b) The research was performed from 2014 to 2019. (c): Research performed from 2020 to 2023.

Table 1.

(a): Research performed from 1989 to 2013. (b) The research was performed from 2014 to 2019. (c): Research performed from 2020 to 2023.

| (a) | |||||

| Ref. | CFD Methods and Algorithms | Flow Domain | Dimension, Type of Flow | Parameters and Ranges | Meshing |

| Wee et al. [2] | Experimental, FDM, DADI | Rectangular cavity | 2D, unsteady, laminar | 2 105 ≤ GrT ≤ 2 106, 10 ≤ GrC ≤ 2 105, 2 104 ≤ Ra ≤ 1.47 106 | - |

| Moallemi & Jjang [11] | FVM, SIMPLIER | Lid-driven square cavity | 2D, steady, laminar, non-Newtonian | 102 ≤ Re ≤ 2200, 0.01 ≤ Pr ≤ 50, 0.01 ≤ Ri ≤ 10 | Non-uniform grid, 42 42 |

| Sasaguchi et al. [14] | Grid generation | Rectangular cavity with cylinders | 2D, unsteady, laminar | N/A | Uniform mesh, 31 101, 31 121 |

| Al-Amiri et al. [15] | FEM | Lid-driven cavity with wavy wall | 2D, steady, laminar, mixed convection | Pr = 0.71, 1, Gr = 104, 0.1 ≤ Ri ≤ 10, 0 ≤ Am ≤ 0.075, 0 ≤ ≤ 3, Re = 500 | - |

| Saha et al. [16] | FEM | Inclined rectangular enclosure | 2D, natural convection, steady, laminar | Pr = 0.71, 103 ≤ Gr ≤ 106, 0.5 ≤ A ≤ 1.0, 0 ≤ ≤ 30 | Non-uniform, six nodded 6394 elements |

| Saha et al. [17] | FVM | Triangular cavity | 2D, natural convection | Pr = 0.71, Gr = 1.33 106, 0.5 ≤ A ≤ 1.0 | 360 90, 720 160, 270 90 for A = 0.2, 0.5, 1.0 |

| Tiwari & Das [18] | FVM, SIMPLE, QUICK, TDMA | Double lid-driven square cavity | 2D, unsteady | Pr = 6.2, 0.1 ≤ Ri ≤ 10, 103 ≤ Ra ≤ 106, 0 ≤ ≤ 0.2, Cu-water nanofluid | Uniform grid, 61 61 |

| Saha et al. [19] | FEM | Inclined sinusoidal enclosure | 2D, steady, natural convection, laminar | Pr = 0.71, 103 ≤ Gr ≤ 106, 0 ≤ ≤ 45 | Non-uniform grid, 5240 elements |

| Varol et al. [20] | FDM | Triangular cavity | 2D, natural convection | 0.25 ≤ A ≤ 1.0, 102 ≤ Ra ≤ 103 | Uniform grid, 61 61 |

| Chen & Cheng [21] | FVM, SOR | Lid-driven triangular cavity | 2D, mixed convection, unsteady, laminar | Pr = 0.71, Re = 100, Gr = 5 105 | 41 41 |

| Noor et al. [22] | FDM, QUICK, RK-4, SOLA | Double lid-driven square cavity | 2D, unsteady, laminar | Pr = 0.71, 10 ≤ Re ≤ 103, 1 ≤ ≤ 5 | Clustered grid, 125 125 |

| Ouertatani et al. [23] | FVM, QUICK. CDS, RBSOR | Double lid-driven cubic cavity | 3D, mixed convection, unsteady, laminar | Pr = 0.71, 102 ≤ Re ≤ 103, 10−3 Ri ≤ 10 | 64 64 64 |

| Basak et al. [24] | FEM | Triangular porous cavities | 2D, natural convection, steady | 10−5 ≤ Da ≤ 10−1, 0.015 ≤ Pr ≤ 103, 103 ≤ Ra ≤ 5105 | 20 20–28 28 bi-quadratic elements |

| Lei & O’Neill [25] | FVM, SIMPLE, CDS, SUR | Square cavity with different corners | 2D, unsteady, natural convection | Pr = 6.62, 0 ≤ Ra ≤ 108 | 16,000 cells |

| Saha [26] | FEM | Sinusoidal corrugated enclosure | 2D, steady | Pr = 0.71, 103 ≤ Gr ≤ 106, 0 ≤ Ha ≤ 102 | Non-uniform grid, 4928 elements |

| Saha et al. [27] | FEM | Octagonal enclosure | 2D, natural convection, steady, laminar | Pr = 0.71, 7, 20, 50, 103 ≤ Ra ≤ 106 | Non-uniform, 10,466 elements |

| Saha et al. [28] | FVM, QUICK, SIMPLE | Triangular enclosure | 2D, natural convection, unsteady | Pr = 0.72, 104 ≤ Ra ≤ 7.2 106, A = 0.2, 0.5, 1.0 | 270 90, 320 80, 360 90 for A = 1, 0.5 & 0.2 |

| Saha et al. [29] | FVM, QUICK, SIMPLE | Triangular enclosure | 2D, natural convection, unsteady | Pr = 0.72, 7.2 103 ≤ Ra ≤ 1.5 106, A = 0.2, 0.5, 1.0 | 270 90, 320 80, 360 90 for A = 1, 0.5 & 0.2 |

| Saha et al. [30] | FVM, QUICK, SIMPLE | Triangular enclosure | 2D, natural convection, unsteady | Pr = 0.72, 5 ≤ Ra ≤ 1.5 107, A = 0.2, 0.5, 1.0 | 360 120, 320 90, 360 90 for A = 1, 0.5 & 0.2 |

| Sivasankaran et al. [31] | FVM, UDS, CDS, SOR | Lid-driven square cavity | 2D, unsteady, laminar, mixed convection | Pr = 0.71, 0 ≤ Am ≤ 1, 0 ≤ ≤ , 0.1 ≤ Ri ≤ 102, 102 ≤ Re ≤ 103 | Uniform grid, 81 81 |

| Sivakumar et al. [32] | FVM, SIMPLE, QUICK. CDS | Lid-driven square cavity | 2D, mixed convection, unsteady, laminar | Pr = 0.71, 102 ≤ Re ≤ 103, 102 ≤ Gr ≤ 106, 10−2 ≤ Ri ≤ 102 | Uniform grid, 81 81 |

| Al-Amiri & Khanafer [33] | ADINA, FSI, FEM, ALE | Lid-driven square cavity | 2D, steady, laminar | Pr = 0.71, 102 ≤ Re, Gr ≤ 103 | Non-uniform mesh, 120 120 |

| Cheng [34] | Compact formulation, SOR, ADI | Lid-driven square cavity | 2D, mixed convection | 10 ≤ Re ≤ 2200, 100 ≤ Gr ≤ 4.86 106, 10−2 ≤ Pr ≤ 50, 10−2 ≤ Ri ≤ 102 | 256 256 |

| Nasrin & Parvin [35] | FEM, TFM | Lid-driven square cavity with wavy wall | 2D, laminar, steady, mixed convection | 30 ≤ Re ≤ 300, 0 ≤ Ha ≤ 50, Pr = 0.71, Ra = 104 | Non-uniform, 37,123 nodes, 5604 elements |

| Saha [36] | FVM, QUICK | Triangular cavity | 2D, unsteady, natural convection | 0.2 ≤ A ≤ 1.0, 5 ≤ Pr ≤ 100, Ra = 107 | - |

| Saha [37] | FVM, SIMPLE, QUICK | Triangular cavity | 2D, unsteady, natural convection | 0.2 ≤ A ≤ 1.0, 5 ≤ Pr ≤ 100, 5 106 ≤ Ra ≤ 108 | - |

| Yu et al. [38] | Fluent, FVM, QUICK, SIMPLE | Square cavity | 2D, unsteady, natural convection | 104 ≤ Ra ≤ 106, 0 ≤ ≤ 0.04, CuO–H2O nanofluid | 100 100 |

| Al-Farhany & Turan [39] | FVM, SIMPLER | Inclined rectangular porous cavity | 2D, unsteady, natural convection | 0 ≤ ϕ ≤ 85, 0.1 ≤ Le ≤ 10, −5 ≤ N ≤ 5, Pr = 4.5, Ra = 5 × 106 | - |

| Arani et al. [40] | FVM, SIMPLIER, TDMA, CDS, UDS | Lid-driven square cavity | 2D, mixed convection, laminar, steady | 10−3 ≤ Ri ≤ 10, 0 ≤ ≤ 0.1, Gr = 102, Re = 102 Cu–H2O nanofluid | Uniform grid. 80 80 |

| Basak et al. [41] | FEM | Porous triangular cavities | 2D, natural convection, steady | Pr = 0.025, 1000, 10−5 ≤ Da ≤ 10−3, Ra = 5 105 | 28 28 bi-quadratic elements |

| Chamkha & Abu-Nada [42] | FVM, CDS, UDS, SOR, SUR | Double lid-driven square cavity | 2D, mixed convection, steady, laminar | 0.001 ≤ Ri ≤ 10, 0 ≤ ≤ 0.1, H2O-Al2O3 nanofluid | Uniform grid, 81 81 |

| Nasrin & Parvin [43] | FEM | Trapezoidal cavity | 2D, free convection, steady, laminar | Ra = 105, = 0.05, 0.65 ≤ A ≤ 2, 1.47 ≤ Pr ≤ 8.81, Cu–H2O nanofluid | 40,295 nodes, 10,936 elements |

| Raji et al. [44] | FVM, SIMPLIER | Square cavity with blocks | 2D, natural convection, laminar, steady | 103 ≤ Ra ≤ 108, Pr = 0.71 | 254 254 |

| Saha & Gu [45] | FVM | Triangular enclosure | 2D, natural convection, unsteady | Pr = 0.7, Ra = 105, A = 0.5 | Triangular grid, 8143 nodes |

| Saha & Gu [46] | FVM | Triangular enclosure | 2D, natural convection, unsteady | Pr = 0.72, 5.0 104 ≤ Ra ≤ 106, A = 0.5 | - |

| Teamah & El-Maghlany [47] | FVM, CDS, GS, TDMA | Square cavity | 2D, steady, laminar | 103 ≤ Ra ≤ 107, 0 ≤ Ha ≤ 60, 0 ≤ ≤ 0.06, −10 ≤ q ≤ 10, Pr = 6.2, H2O based Al2O, Cu, TiO2 nanofluids | 60 60 |

| Ahmed et al. [48] | Collocated FVM, UDS, CDS, TDMA | Inclined lid-driven square cavity | 2D, mixed convection, laminar, steady | 10−2 ≤ Ri ≤ 102, 0 ≤ ≤ 1.0, 0 ≤ Ha ≤ 100, 0 ≤ ≤ 90 | Uniform grid. 81 81 |

| Bhardwaj & Dalal [49] | FDM, QUICK, SOR, CDS | Porous triangular cavity | 2D, natural convection, laminar | 103 ≤ Ra ≤ 106, 10−4 ≤ Da ≤ 10−2, Am = 0.05 | Orthogonal mesh, 41 41 |

| Cho et al. [50] | FVM, SIMPLEC, TDMA | Lid-driven cavity with wavy surfaces | 2D, mixed convection, laminar, steady | 0 ≤ ≤ 0.1, 10−2 ≤ Ri ≤ 103, 101 ≤ Gr ≤ 104, 0 ≤ ≤ 0.2, Pr = 6.2, H2O based Cu, Al2O3, TiO2 nanofluids | 101 201 |

| Elsherbiny & Ragab [51] | - | Inclined rectangular cavities | 2D, laminar, natural convection | 102 ≤ Ra ≤ 106, 0.5 ≤ A ≤ 5, 0 ≤ ≤ 180 | Uniform mesh, 42 42 |

| Huelsz & Rechtman [52] | LBM | Inclined square cavity | 2D, natural convection, laminar, unsteady | Pr = 0.71, −180 ≤ ≤ 180, 103 ≤ Ra ≤ 106 | 103 103 |

| Khanafer & Aithal [53] | ADINA, FEM, NR | Lid-driven square cavity with cylinder | 2D, steady, laminar, mixed convection | Pr = 0.7, 104 ≤ Gr ≤ 106, 0.01 ≤ Ri ≤ 10, Re = 102 | Non-uniform grid, 19,520 nodes |

| Ramakrishna et al. [54] | FEM | Trapezoidal cavities | 2D, free convection, laminar | 30 ≤ ≤ 90, Pr = 0.015, 7.2, 103 ≤ Ra ≤ 105 | 28 28 bi-quadratic elements |

| Sivasankaran et al. [55] | FVM, UDS, CDS | Inclined lid-driven square cavity | 2D, unsteady, laminar, mixed convection | Pr = 0.71, 0.01 ≤ Ri ≤ 102, 0 ≤ ≤ 90 | 81 81 |

| (b) | |||||

| Ref. | CFD Methods and Algorithms | Flow Domain | Dimension, Type of Flow | Parameters and Ranges | Meshing |

| Sathitamoorthy & Chamkha [56] | FEM | Square cavity with thin partition | 2D, natural convection, steady | Pr = 0.7, 100, 103 ≤ Rah ≤ 105 | 20 20 elements, 41 41 grid points |

| Abu-Nada & Chamkha [57] | FVM, SOR, SUR, UDS | Lid-driven square cavity with wavy wall | 2D, mixed convection, laminar, steady | Pr = 6.57, 0.01 ≤ Ri ≤ 102, 0 ≤ ≤ 0.09, H2O-CuO nanofluid | Uniform grid, 81 81 |

| Ait-Taleb et al. [58] | FDM, SIMPLE, TDMA | Rectangular cavities with tiles | 2D, steady, laminar | 8.7 103 ≤ Rah ≤ 1.8 105, 4.1 105 ≤ RaH ≤ 1.23 107, Pr = 0.71 | Non-uniform mesh, 80 40 |

| Cheng & Liu [59] | Ansys Fluent, FVM, SOR, ADI | Lid-driven square and rectangular cavities | 2D, unsteady | Pr = 0.71, 10−2 ≤ Ri ≤ 102, 0.2 ≤ A ≤ 5, 0 ≤ ≤ 90, Re = 102 | Uniform grid, 640 128, 128 128, 128 640 |

| Cho [60] | FVM, SIMPLE, TDMA | Square cavity with wavy wall | 2D, natural convection, laminar, steady | 103 ≤ Ra ≤ 106, 0 ≤ ≤ 0.04, Pr = 6.2, H2O-Al2O3 nanofluid | 101 201 |

| Kalteh et al. [61] | FDM, CDS, SUR | Lid-driven square cavity with block | 2D, steady, mixed convection | Gr = 102, 0.000625 ≤ Ri ≤ 4, 0 ≤ ≤ 0.05, H2O based Al2O3, TiO2, Ag, CuO nanofluids | Regular grid, 80 80 |

| Khanafer [62] | ADINA, FEM, FSI, ALE | Lid-driven square cavity | 2D, steady, laminar, mixed convection | Pr = 0.7, 102 ≤ Gr ≤ 104, 10−4 ≤ Ri ≤ 1.0, 102 ≤ Re ≤ 103 | Non-uniform, 120 120 |

| Muthtamilselvan & Doh [63] | FVM, SIMPLE, QUICK, TDMA | Lid-driven square cavity | 2D, steady, mixed convection | 0 ≤ Rai ≤ 105, Pr = 6.2, 10−2 ≤ Ri ≤ 10, 0 ≤ ≤ 0.06, Cu-H2O nanofluid | Uniform grid, 41 41 |

| Ramakrishna et al. [64] | FEM | Porous trapezoidal cavity | 2D, natural convection, laminar, steady | 10−5 ≤ Da ≤ 10−3, 30 ≤ ≤ 90, Pr = 0.015, 103 | 28 28 bi-quadratic elements |

| Ray & Chatterjee [65] | Fluent, FVM | Lid-driven square cavity | 2D, steady, mixed convection | 0.1 ≤ Ri ≤ 10, 0 ≤ Ha ≤ 50, 0 ≤ J ≤ 5, Re = 102, Pr = 0.71 | Non-uniform, 56,126 mixed elements |

| Saha & Gu [66] | Fluent, FVM | Triangular cavity | 2D, unsteady, natural convection | Pr = 0.72, 105 ≤ Ra ≤ 108, A = 0.2, 0.5, 1.0 | Non-uniform grid, 400 100 |

| Xu & Saha [67] | FVM, SIMPLE, QUICK | Square cavity with fin | 2D, unsteady, natural convection | Pr = 0.71, 105 ≤ Ra ≤ 109 | Non-uniform grid, 198 198 |

| Cui et al. [68] | Fluent, FVM, SIMPLE, QUICK | Triangular cavity | 3D, natural convection, unsteady | A = 0.5, Pr = 6.98, Ra = 2.08 106 | Non-uniform grid, 100 66 45 |

| Elsherbiny & Ismail [69] | FDM, TDMA, CDS | Inclined rectangular cavities | 2D, laminar, steady | Pr = 0.71, 0 ≤ ≤ 180, 103 ≤ Ra ≤ 106, A = 1, 5, 10 | Uniform grid, 42 42 |

| Elsherbiny & Ragab [51] | - | Inclined rectangular cavities | 2D, laminar, natural convection | Pr = 0.71, 0 ≤ ≤ 180, 102 ≤ Ra ≤ 106 | Uniform mesh, 42 42 |

| Groşan et al. [70] | FDM, CDS | Porous square cavity | 2D, steady, natural convection | Ra = 10, 100, Le = 1, 10, H2O, aluminum foam, carbon nanotubes | 227 227 |

| Moumni et al. [71] | FVM, AB, QUICK, CDS, Euler, RBSOR | Double lid-driven square cavity | 2D, unsteady, laminar | 1 ≤ Re ≤ 102, Pr = 6.2, 10−2 ≤ Ri ≤ 20, 0 ≤ ≤ 0.2, H2O based Cu, Ag, Al2O3, TiO2 nanofluids | Uniform grid, 120 120 |

| Saha & Gu [72] | Fluent, FVM, QUICK | Triangular enclosure | 2D, natural convection, steady, unsteady | 105 ≤ Ra ≤ 106, Pr = 0.72, A = 0.2, 0.5, 1.0 | Non-uniform grid |

| Sheremet & Pop [73] | FDM, CDS, SOR | Lid-driven square cavity | 2D, unsteady, laminar, mixed convection | Re = 102, Pr = 6.26, 10 ≤ Gr ≤ 105, 10 ≤ Le ≤ 104, N, Nb, Nt = 0.1 to 0.4 | Uniform grid, 400 400 |

| Sojoudi et al. [74] | Fluent, FVM | Triangular cavity | 2D, natural convection, unsteady | 103 ≤ Ra ≤ 106, 0.2 ≤ A ≤ 1, Pr = 0.72 | 15,700 triangular elements |

| Armaghani et al. [75] | FVM, SIMPLE | L-shaped cavity with baffle | 2D, steady, natural convection | Pr = 0.71, 104 ≤ Ra ≤ 106, 0.1 ≤ A ≤ 0.7, 0 ≤ Bf ≤ 0.3, 0 ≤ ≤ 0.04, Al2O3-H2O nanofluid | Uniform grid, 100 100 |

| Jmai et al. [76] | FVM, QUICK, SOR, multigrid | Double lid-driven square cavity | 2D, unsteady, laminar, mixed convection | 10−2 ≤ Ri ≤ 102, 0 ≤ ≤ 0.1, Cu–H2O nanofluid | Non-uniform grid, 64 64 |

| Kareem et al. [77] | Fluent, URANS, LES, FVM, SIMPLE | Cubic lid-driven cavity | 3D, unsteady, mixed convection, turbulent | Re = 5000, 10,000, 15,000 and 30,000 | Structured, non-uniform, 1,699,200 grids |

| Kareem et al. [78] | FVM, UDS, SIMPLE | Lid-driven trapezoidal cavity | 2D, mixed convection | 0 ≤ ≤ 0.04, 0.1 ≤ Ri ≤ 10, 102 ≤ Re ≤ 1200, 0 ≤ ≤ 60, 0.5 ≤ A ≤ 2, H2O based Al2O3, CuO, SiO2, TiO2 nanofluids | Unstructured, non-uniform 5470 grids |

| Mamourian et al. [79] | FVM, SIMPLE | Lid-driven square cavity | 2D, steady, laminar, Mixed convection | 10−2 ≤ Ri ≤ 102, 0 ≤ ≤ 0.1, Gr = 102, Am = 0.25, Cu–H2O nanofluid | Structured non-uniform, 101 201 |

| Mejri et al. [80] | LBM | Triangular cavity | 2D, natural convection, laminar | 103 ≤ Ra ≤ 106, 0 ≤ ≤ 315, Ma = 0.1 | - |

| Rahmati et al. [81] | LBM | Double lid-driven cavity | 2D, mixed convection, laminar, steady | Gr = 100, Pr = 6.57, 10−2 ≤ Ri ≤ 102, 0 ≤ ≤ 0.06, Cu-H2O nanofluid | 100 100 |

| Rashad et al. [12] | FVM, ADI, SIMPLE, UDS, CDS | Lid-driven square cavity | 2D, mixed convection, laminar | 0 ≤ Ha ≤ 100, 10−3 ≤ Ri ≤ 10, 0 ≤ ≤ 0.01, Cu-H2O nanofluid | Uniform grid, 81 81 |

| Selimefendigil & Öztop [82] | FEM, ALE | Lid-driven inclined square cavity | 2D, steady | 10−2 ≤ Ri ≤ 102, 0 ≤ ≤ 0.05, 103 ≤ Rai ≤ 106, 0 ≤ Ha ≤ 50, 0 ≤ ≤ 90, 5 102 ≤ E ≤ 106, CuO-H2O nanofluid | Non-uniform mesh, 10,916 nodes |

| Selimefendigil & Öztop [83] | FEM, FSI, ALE | Triangular cavity | 2D, natural convection, steady | 104 ≤ Ra ≤ 106, 104 ≤ Rai ≤ 107, 0 ≤ Ha ≤ 40, 0 ≤ ≤ 90, Pr = 7.1, 5 102 ≤ E ≤ 105 | - |

| Selimefendigil et al. [84] | FEM, NR | Lid-driven square cavity | 2D, Mixed convection | 10−2 ≤ Ri ≤ 102, 0 ≤ Ha ≤ 50, 0 ≤ ≤ 90, 0 ≤ ≤ 0.05, CuO-H2O nanofluid | Non-uniform,. 17,408 elements |

| Sojoudi et al. [85] | FVM, QUICK, SIMPLE | Triangular cavity | 2D, unsteady, natural convection | 103 ≤ Ra ≤ 106, 0.2 ≤ A ≤ 1.0, Pr = 0.72 | 15,600 triangular elements |

| Sojoudi et al. [86] | FVM, QUICK, SIMPLE | Triangular cavity | 2D, unsteady, natural convection | 103 ≤ Ra ≤ 106, 0.2 ≤ A ≤ 1.0, Pr = 0.71 | 360 75, 360 90, 360 120 for A = 0.2, 0.5, 1 |

| Aparna & Seetharamu [87] | FEM | Porous trapezoidal cavity | 2D, natural convection | 100 ≤ Ra ≤ 2000 | 41 41 |

| Alsabery et al. [88] | COMSOL, FEM | Trapezoidal cavity | 2D, unsteady, non-Newtonian, laminar | 104 ≤ Ra ≤ 106, 0 ≤ ≤ 0.2, 0.1 ≤ Pr ≤ 103, 0 ≤ ≤ 21.8, H2O based TiO2, Cu, Al2O3, Ag nanofluids | Non-uniform, 4690 elements |

| Al-Weheibi et al. [89] | COMSOL, FEM | Trapezoidal enclosure | 2D, natural convection, unsteady, laminar | 103 ≤ Ra ≤ 106, 0 ≤ ≤ 0.1, 0.25 ≤ A ≤ 1.0 | 6-noded 403,388 elements, 204,436 grids |

| Balla et al. [90] | FEM | Inclined porous square cavity | 2D, free convection, laminar | 0.01 ≤ ≤ 0.3, 101 ≤ Ra ≤ 103, 0 ≤ M ≤ 10, 0 ≤ ≤ 90, H2O based TiO2, Cu, Al2O3, SiO2 nanofluids | 6-noded triangular grid, 5000 elements, 2601 nodes |

| Cui et al. [91] | FVM | Prismatic enclosure | 3D, unsteady, natural convection | 100 ≤ Ra ≤ 106, Pr = 0.71 | Non-uniform grid, 100 66 45 |

| Das et al. [92] | FEM | Square & triangular cavities | 2D, steady, laminar | Pr = 0.7, 103 ≤ Ra ≤ 105 | 34 34 biquadratic elements |

| Gangawane [93] | Fluent, FVM, SIMPLE, QUICK | Lid-driven cavity with triangular block | 2D, steady, laminar, mixed convection | 1 ≤ Re ≤ 103, 0 ≤ Gr ≤ 105, Pr = 1, 50, 102, b = 10%, 20%, 30% | Unstructured, non-uniform, 26,318 nodes, 9126 elements |

| Ghalambaz et al. [94] | FEM, FSI, ALE | Square cavity with oscillating elastic fin | 2D, natural convection, laminar, unsteady | Pr = 0.7, 104 ≤ Ra ≤ 107, 10−3 ≤ Am ≤ 0.1, 1 ≤ Tr ≤ 103, 108 ≤ E ≤ 1013 | 27,131 domain elements, 1022 boundary elements |

| Gibanov et al. [95] | FDM | Lid-driven square cavity with block | 2D, steady, laminar, mixed convection | 10−2 ≤ Ri ≤ 10, 0 ≤ ≤ 0.05, Re = 102, Pr = 6.82, Al2O3-H2O nanofluid | Uniform grid, 200 200 |

| Gibanov et al. [96] | FDM | Lid-driven inclined square cavity | 2D, unsteady, mixed convection | Ri =1, Re = 102, Pr = 6.26, Da = 10−7, 10−3, 0 ≤ Ha ≤ 102, 0 ≤ ≤ 0.05, 0 ≤ ≤ , ferrofluid | Uniform grid, 200 200 |

| Hammami et al. [97] | FVM, QUICK, RBSOR | Double lid-driven cubic cavity with cylinder | 3D, unsteady | 102 ≤ Re ≤ 1500, Pr | Staggered grid non-uniform, 80 80 80 |

| Hatami [6] | FEM, FlexPDE | Rectangular cavity with heated fins | 2D, steady | 0.03 ≤ ≤ 0.09, H2O based TiO2, Al2O3 nanofluids | - |

| Hatami et al. [98] | FEM, RSM, FlexPDE | Lid-driven T-shaped porous cavity | 2D, steady, mixed convection | Ri = 0.1, Re = 50, Da = 0.001, H2O based TiO2, Cu, Al2O3 nanofluids | - |

| Hussain et al. [99] | FEM, GE, CN | Double lid-driven square cavity | 2D, steady, mixed convection | 1 ≤ Re102, 0 ≤ ≤ 45, 0.01 ≤ Ri ≤ 10, 0 ≤ ≤ 0.04, Al2O3-H2O nanofluid | Uniform grid, 65,536 elements |

| Javed et al. [100] | FEM | Trapezoidal porous cavities | 2D, free convection, steady | Pr = 6.2, 10−5 ≤ Da ≤ 10−3, 105 ≤ Ra ≤ 107, 0 ≤ Ha ≤ 60, 0 ≤ ≤ 0.03, Cu-H2O nanofluid | 6 noded 704 elements, 1000 grids |

| Kareem & Gao [101] | Fluent, LES, URANS, SIMPLEC, QUICK | Lid-driven cubic cavity with cylinder | 3D, unsteady, mixed convection, turbulent | Pr, Re = 5000, 10,000, 15,000, 30,000, 0 ≤ ≤ 10 | Structured, non-uniform cells, 929,160 elements |

| Khanafer & Aithal [102] | ADINA, FEM | Lid-driven square cavity with cylinder | 2D, steady, laminar, mixed convection | 0.01 ≤ Ri ≤ 10, Re = 100, −10 ≤ ≤ 10 | 150 150 |

| Khatamifar et al. [103] | DNS, SIMPLE, QUICK | Rectangular cavity with partition | 2D, natural convection, unsteady | 105 ≤ Ra ≤ 109, Pr = 0.71, 0.05 ≤ Tp ≤ 0.2 | Non-uniform mesh, 300 250 |

| Mojumder et al. [104] | FEM | Lid-driven L-shaped cavity | 2D, mixed convection, laminar, steady | 1 ≤ Re ≤ 100, 103 ≤ Gr ≤ 105, 10−5 ≤ Da ≤ 10−3, Pr = 6.2 | Triangular mesh, 4452 elements |

| Selimefendigil et al. [105] | FEM, ALE, FSI | Lid-driven square cavity | 2D, steady | 0.01 ≤ Ri ≤ 5, 0 ≤ Ha ≤ 50, 102 ≤ Re ≤ 103, CuO-H2O nanofluid | Triangular elements, 17,224 grids |

| Selimefendigil et al. [106] | FEM, ALE, NR | Lid-driven Trapezoidal cavity with cylinder | 3D, steady, laminar, mixed convection | 0.5 ≤ Ri ≤ 50, 0 ≤ ≤ 20, 0 ≤ ≤ 0.04, 103 ≤ E ≤ 105, CuO-H2O nanofluid | Tetrahedral elements |

| Selimefendigil & Öztop [107] | FEM, FSI, ALE | Lid-driven triangular cavity | 2D, mixed convection, steady | 0.05 ≤ Ri ≤ 50, 0 ≤ ≤ 0.04, Pr = 6.8, 104 ≤ RaI ≤ 108, 500 ≤ E ≤ 105, H2O–CuO nanofluid | Non-uniform grid, 26,306 elements |

| Sheremet et al. [108] | FDM | Triangular cavities | 2D, natural convection | Pr = 0.7, 104 ≤ Ra ≤ 2 105, 102 ≤ Le ≤ 104, 0 ≤ N ≤ 5, Nb = Nt = 0.1 | Uniform grid, 300 150 |

| Yu et al. [3] | FDM, UCS, TVD, RK | Rectangular cavity | 2D, unsteady, laminar | Pr = 0.025, A = 2, 0 ≤ Ha ≤ 50, 0 ≤ Le ≤ 20 | Uniform grid, 41 81 |

| Aghakhani et al. [109] | FDLBM | C-shaped cavity | 2D, laminar, non-Newtonian | 103 ≤ Ra ≤ 105, 0 ≤ Ha ≤ 40, 0.2 ≤ A ≤ 0.6 | 160 160 |

| Astanina et al. [110] | FDM | Lid-driven square porous cavity | 2D, steady, mixed convection | 0.01 ≤ Ri ≤ 10, 0 ≤ ≤ 0.04, 10−7 ≤ Da ≤ 10−3, Da2 = 10−5, Re = 102, Pr = 6.82, H2O–Al2O3 nanofluid | Uniform grid, 200 200 |

| Alsabery et al. [111] | FEM, FEA, NR | Double lid-driven square cavity with block | 2D, steady, laminar, mixed convection | 1 ≤ Re ≤ 500, 10−2 ≤ Ri ≤ 102, 0 ≤ ≤ 0.04, Pr = 4.623, Le = 3.5 105, Sc = 3.55 104, H2O–Al2O3 nanofluid | Uniform triangular grid, 12,232 grids |

| Balootaki et al. [112] | LBM-BGK | Lid-driven rectangular cavity with block | 2D, mixed convection | 10−2 ≤ Ri ≤ 50, Re = 100, Pr = 0.7 | 450 150 |

| Bhowmick et al. [113] | FEM, SIMPLE, QUICK | V-shaped cavity | 2D, natural convection | 2.26 105 ≤ Ra ≤ 2.26 109, 0.1 ≤ A ≤ 1.0, Pr = 6.63 | Non-uniform, 800 150 |

| Cho [114] | FVM, TDMA, SIMPLE | Lid-driven cavity with wavy surface | 2D, steady, laminar, mixed convection | 10−2 ≤ Ri ≤ 102, 0 ≤ ≤ 0.04, 1 ≤ Re ≤ 200, Pr = 6.2, 0 ≤ Am ≤ 0.6, H2O–Cu nanofluid | 101 1001 |

| Gangawane et al. [115] | Fluent, FVM, SIMPLE, QUICK | Lid-driven square cavity with block | 2D, steady, laminar, mixed convection | Ri= 0.01, 1, 10, Pr= 1, 1 ≤ Re ≤ 103 | Unstructured, 17,874 nodes, 17,598 elements |

| Gibanov et al. [116] | FDM | Lid-driven square cavity | 2D, mixed convection, laminar, unsteady | 10−2 ≤ Ri ≤ 10, 0 ≤ ≤ 0.05, 1.0 ≤ K ≤ 20.0, Re = 100, Pr = 6.82, H2O–Al2O3 nanofluid | Uniform grid, 100 100 |

| Hussain et al. [117] | FEM, CN, GE | Double lid-driven square cavity | 2D, laminar, unsteady, mixed convection | 0 ≤ ≤ 0.04, 10−2 ≤ Ri ≤ 10, 0 ≤ Ha ≤ 102, 0 ≤ ≤ 90, H2O–Al2O3 nanofluid | Non-uniform triangular grid, 65,536 elements |

| Javed & Siddiqui [118] | FEM | Square cavity with square blockage | 2D, free convection, steady, laminar | 105 ≤ Ra ≤ 107, Pr = 0.062, 0 ≤ ≤ 0.06, 0 ≤ Ha ≤ 60, H2O–Cobalt ferrofluid | Non-uniform, 6-noded 1776 elements |

| Karbasifar et al. [119] | SIMPLEC | Lid-driven cubic cavity with cylinder | 3D, laminar, steady, mixed convection | 10−2 ≤ Ri ≤ 102, = 0, 0.1%, 0.2%, = 0, 15, 45, H2O–Al2O3 nanofluid | - |

| Kareem & Gao [120] | Fluent, URANS, SIMPLEC, QUICK | Lid-driven Cubical cavity with cylinder | 3D, mixed convection, unsteady, turbulent | 5000 ≤ Re ≤ 104, −5 ≤ Ω ≤ 5, SiO2-H2O nanofluid | 929,160 grids |

| Mikhailenko et al. [121] | FDM, CDS, Thomas, SOR | Rotating square cavity with obstacle | 2D, laminar, unsteady | Pr = 0.7, Ra = 105, 0 ≤ ≤ 180, 0 ≤ Ta ≤ 106, 0.1 ≤ Os ≤ 1.0, 0.0 ≤ ε ≤ 0.9 | 101 101 |

| Oglakkaya & Bozkaya [122] | DRBEM | Lid-driven square cavity | 2D, mixed convection, unsteady, laminar | Pr = 0.71, Re = 102, Am = 0.05, Ha = 0, 25, 50, 0 ≤ ≤ 90, J = 0, 1, 3, 5, 103 ≤ Ra ≤ 105 | 400 grids |

| Razera et al. [123] | Fluent, FVM, SIMPLEC | Lid-driven square cavity | 2D, steady, laminar, mixed convection | 101 ≤ Re ≤ 103, 103 ≤ Ra ≤ 106, Pr = 0.71 | Non-uniform, 33,248 volumes |

| Selimefendigil & Öztop [124] | FEM, COBYLA | Lid-driven trapezoidal cavity | 2D, mixed convection | 0.01 ≤ Ri ≤ 25, 0 ≤ Ha ≤ 40, 0 ≤ ≤ 90, 0 ≤ ≤ 0.03, H2O–Al2O3 nanofluid | 6282, 4685 and 3691 elements for different |

| Sheikholeslami [125] | LBM | Lid-driven square cavity with hot sphere | 3D, forced convection | 10−3 ≤ Da ≤ 102, 30 ≤ Re ≤ 180, 0 ≤ Ha ≤ 40, H2O–Al2O3 nanofluid | 81 81 81 |

| Sheremet et al. [126] | FDM | Porous square vented cavity | 2D, mixed convection, unsteady | 104 ≤ Ra ≤ 106, Nb = Nt = 10−6, 10−5 ≤ Da ≤ 10−2, 50 ≤ Re ≤ 300, Pr = 6.82, Le = 103, N = 1, H2O–Al2O3 nanofluid | Uniform grid, 201 201 |

| Taghizadeh & Asaditaheri [127] | OpenFOAM, FVM. SIMPLE | Lid-driven square cavity with cylinder | 2D, laminar, mixed convection | 0.01 ≤ Ri ≤ 10, 10−5 ≤ Da ≤ 10−2, 0 ≤ ≤ 90, Re = 100, Pr = 0.7 | Non-uniform, 11,200 |

| Zhai et al. [128] | FVM, SIMPLE, QUICK | Triangular Roof | 2D, unsteady, natural convection | 104 ≤ Ra ≤ 107, 0.1 ≤ A ≤ 1.0, Pr = 0.71 | Non-uniform mesh, 600 600 |

| Zhou et al. [129] | LBM, OpenMP | Double lid-driven cubic cavity | 3D, mixed convection, laminar, unsteady | 0.1 ≤ Ri ≤ 102, 0 ≤ ≤ 0.04, H2O–Al2O3 nanofluid | 101 101 101 |

| Alnaqi et al. [130] | FDM | Square cavity with a fin | 2D, laminar, steady | 0 ≤ Ha ≤ 60, 103 ≤ Ra ≤ 106, 0 ≤ Rd ≤ 3, 0 ≤ ≤ 0.06, H2O–Al2O3 nanofluid | Uniform grid. 120 120 |

| Al-Rashed et al. [131] | FVM, SIMPLEC | Inclined lid-driven cubical cavity | 3D, steady, mixed convection, laminar | Re, Gr, Pr, 1 ≤ Ri ≤ 102, 0 ≤ ≤ 45, H2O–Al2O3 nanofluid | - |

| Barnoon et al. [132] | FVM, SIMPLE | Lid-driven square cavity with cylinders | 2D, steady, laminar, mixed convection | 0 ≤ Ha ≤ 30, 1 ≤ Ri ≤ 102, 0 ≤ ≤ 90, 0.01 ≤ ≤ 0.03, H2O–Al2O3 nanofluid | Non-uniform grid, 19,297 elements |

| Bhowmick et al. [133] | Fluent, FVM, SIMPLE | V-shaped triangular cavity | 2D, natural convection, unsteady | 1 ≤ Ra ≤ 108, A = 0.5, Pr = 0.71 | 800 150 |

| Cho [134] | FVM, SIMPLE, TDMA | Lid-driven cavity with wavy wall | 2D, laminar, mixed convection | 1 ≤ Re ≤ 300, 0 ≤ Ha ≤ 50, 10−2 ≤ Re ≤ 102, 0 ≤ Am ≤ 0.7, 0 ≤ ≤ 0.04, 0 ≤ ≤ 360, Cu-H2O nanofluid | Non-uniform grid, 101 1001 |

| Cui et al. [135] | FVM | Prismatic enclosure | 3D, unsteady, natural convection | 100 ≤ Ra ≤ 107, Pr = 0.71, 0.1 ≤ A ≤ 1.5 | Non-uniform mesh, 138 42 51 |

| Hadavand et al. [136] | FVM, SIMPLEC | Lid-driven sim-circular cavity | 2D, mixed convection, laminar, steady | 1 ≤ Ri ≤ 10, = −90 to 90, 0 ≤ ≤ 0.06, Ag-H2O nanofluid | Unorganized triangular grid, 44,896 grids |

| Hamid et al. [137] | FEM | Trapezoidal cavity | 2D, steady, non-Newtonian, natural convection, laminar | 104 ≤ Ra ≤ 105.5, Pr = 20 | - |

| Jiang & Zhou [4] | FVM, QUICK, CDS, PISO | Rectangular cavity | 2D, steady, laminar | 0 ≤ ≤ 0.25, dp = 13, 36, 50 nm, distilled H2O-Al2O3, PGW-ZnO nanofluids | Non-uniform orthogonal grid, 200 50 |

| Karatas & Derbentli [138] | Experimental research | Rectangular cavity | 3D, unsteady | 4.5 103 ≤ Rai ≤ 1.13 108, A = 1, 2.09, 3, 4, 5, 6 | - |

| Lamarti et al. [139] | LBM | Lid-driven square cavity | 2D, mixed convection, laminar | Pr = 0.71, 102 ≤ Re ≤ 103, 102 ≤ Gr ≤ 106, 1 ≤ ≤ 5 | 100 100 |

| Louaraychi et al. [140] | FVM, SIMPLER, TDMA | Double lid-driven rectangular cavity | 2D, unsteady, mixed convection | 1 ≤ Ra ≤ 107, 0.1 ≤ Pe ≤ 500, A = 24 | Uniform grid, 381 121 |

| Mohebbi et al. [141] | LBM | Γ-shaped enclosure with obstacle | 2D, natural convection, steady, laminar | 103 ≤ Ra ≤ 106, 0 ≤ ≤ 0.05, 0.2 ≤ A ≤ 0.6, Al2O3-H2O nanofluid | 100 100 |

| Selimefendigil & Öztop [142] | FEM, ALE, NR | Lid-driven L-shaped cavity | 2D, steady, mixed convection | 0.03 ≤ Ri ≤ 30, 0 ≤ ≤ 180, 104 ≤ RaI ≤ 106, 0 ≤ Ha ≤ 50, CuO-H2O nanofluid | Non-uniform, 19,112 elements |

| (c) | |||||

| Ref. | CFD Methods and Algorithms | Flow Domain | Dimension, Type of Flow | Parameters and Ranges | Meshing |

| Abu-Hamdeh et al. [143] | FVM, SIMPLE, CDS, UDS, TDMA | Lid-driven porous square open cavity | 2D, mixed convection, steady | 102 ≤ Re ≤ 103, 10−3 ≤ Da ≤ 0.1, 103 ≤ Gr ≤ 105 | Staggered grid, 48 48 |

| Afrand et al. [144] | SIMPLE | Triangular cavity | 2D, free convection, laminar, steady | 104 ≤ Ra ≤ 106, 0 ≤ Ha ≤ 40, 0 ≤ ≤ 90, 0 ≤ ≤ 0.06, Al2O3-H2O nanofluid | Staggered grid |

| Alsabery et al. [145] | FEM | Lid-driven square cavity | 2D, mixed convection, steady, laminar | 1 ≤ Re ≤ 500, 0.01 ≤ Ri ≤ 100, 0 ≤ Ha ≤ 50, 0 ≤ ≤ 0.04, Al2O3-H2O nanofluid | Triangular grid, 6402 elements |

| Alsabery et al. [146] | FEM | Lid-driven cubic cavity with cylinder | 3D, mixed convection, steady | Re = 10, 100, Pr = 4.623, 10−2 ≤ Ri ≤ 102, 0 ≤ ≤ 0.04, Le = 3.5 105, Sc = 3.55 104, Al2O3-H2O nanofluid | Non-uniform triangular grid, 175,778 elements |

| Bilal et al. [147] | FEM | Triangular cavity with cylinder | 2D, laminar, steady, free convection | 103 ≤ Ra ≤ 106, 0.2 ≤ Pr ≤ 7 | Hybrid grid |

| Cho [148] | FVM, SIMPLE, TDMA | Square cavity with wavy walls | 2D, natural convection, steady, laminar | Pr = 6.2, 102 ≤ Ra ≤ 106, 10−6 ≤ Da ≤ 10−2, 0 ≤ ≤ 0.04, Cu-H2O nanofluid | 101 1001 |

| Ganesh et al. [149] | FEM | Square Cavity with different obstacles | 2D, steady, laminar | 103 ≤ Ra ≤ 106, 0 ≤ ≤ 0.08, 103 ≤ RaE ≤ 106, 103 ≤ RaI ≤ 105 Al2O3-H2O/Ethylene Glycol nanofluid | Circular: 6979 elements, Square: 21,916 elements, Triangular: 19,431 elements |

| Haq et al. [150] | FEM | Lid-driven hexagonal cavity with obstacle | 2D, steady | 200 ≤ Re ≤ 500, Pr = 6.2, 10−6 ≤ Ri ≤ 1, 0 ≤ Ha ≤ 20, SWCNT-H2O nanofluid | Non-uniform triangular elements |

| Khan et al. [151] | FEM | Porous trapezoidal cavity | 2D | Pr = 6.2, 102 ≤ Ha ≤ 104, 104 ≤ Ra ≤ 105, 0 ≤ ≤ 0.2%, Fe3O4-H2O ferrofluid | - |

| Li et al. [152] | FDLBM | Triangular enclosure | 2D, laminar, non-Newtonian, steady | 103 ≤ Ra ≤ 105, 0 ≤ Ha ≤ 60, 0 ≤ ≤ 90 | 160 160 or 19,600 nodes |

| Liu & Huang [153] | DNS, QUICK, SIMPLE, CDS | Rectangular cavities with or without fins | 2D, unsteady, turbulent | 1.15 108 ≤ Ra ≤ 3.68 109 | Non-uniform grid, 400 360 cells |

| Rammane et al. [154] | TS, MLS, NR, HO-MFA | Lid-driven square cavity | 2D, steady | 102 ≤ Re ≤ 2 104 | Mesh free |

| Saha et al. [155] | FVM, SIMPLE, QUICK | Triangular enclosure | 2D, unsteady, natural convection | Pr = 0.72, 105 ≤ Ra ≤ 109, 0.2 ≤ A ≤ 1.0 | 380 80, 380 100, 380 160 for A = 0.2, 0.5, 1 |

| Selimefendigil & Öztop [156] | FVM, QUICK, SIMPLE | U-shaped corrugated cavity | 2D, forced convection, laminar, steady | 102 ≤ Re ≤ 103, 0 ≤ Ha ≤ 50, 10−4 ≤ Da ≤ 5 10−2, CNT-H2O nanofluid | Non-uniform grid, 38,874 grids |

| Soomro et al. [157] | FEM | Lid-driven Triangular cavity with obstacle | 2D, mixed convection, laminar, steady | 200 ≤ Re ≤ 600, 0.01 ≤ Ri ≤ 1, 0 ≤ Ha ≤ 20, Pr = 6.2 | Around 5000 nodes |

| Thiers et al. [158] | SEM, NeK5000, GMRES | Rectangular cavity | 2D, unsteady | A = 4, Pr = 0.71, Ra = 9 107 | 183 169 |

| Aljabair et al. [159] | FDM, CDS, UDS, SOR | Sinusoidal lid-driven cavity | 2D, mixed convection, laminar | 1 ≤ Re ≤ 1000, 0 ≤ Ra ≤ 107, 0 ≤ ≤ 0.07, Cu-H2O nanofluid | 41 41 |

| Alsabery et al. [160] | FEM | Wavy lid-driven square cavity | 2D, laminar, steady, mixed convection | 0.01 ≤ Ri ≤ 10, Re = 100, 0 ≤ ≤ 0.04, H2O/Cu-Al2O3 hybrid nanofluid | - |

| Çolak et al. [161] | OpenFOAM, FVM, SIMPLE | Lid-driven cavity with porous block | 2D, mixed convection, steady | 10−1 ≤ Ri ≤ 10, Gr = 105, 10−7 ≤ Da ≤ 10−1, Pr = 6.2 | Uniform grid, 201 201 |

| Eshaghi et al. [162] | FEM | H-shaped cavity with a baffle inside | 2D, natural convection, laminar | 104 ≤ Ra ≤ 106, 2 ≤ Le ≤ 8, 1 ≤ N ≤ 3, −60 ≤ . ≤ 60, Cu-Al2O3-H2O hybrid nanofluid | - |

| Fayz-Al-Asad et al. [163] | FEM | Triangular cavity | 2D, natural convection, steady | Pr = 0.71, 104 ≤ Ra ≤ 106 | 6718 elements, 13,112 nodes |

| Hasnaoui et al. [164] | LBM, MRT, BGK | Rectangular cavity | 2D, biry mixture | Sr = −0.5, 0, 0.5, 0 ≤ Ra ≤ 80, Pr = 0.71, A = 2, Le = 2 | 120 240 |

| Hussain et al. [165] | FEM | Double lid-driven cavity with fins | 2D, laminar, steady | 0 ≤ Ha ≤ 100, 0 ≤ ≤ 90, 0.01 ≤ Ri ≤ 1, Pr = 6.2, Re = 100, = 0.02, Cu-H2O nanofluid | 33,177 grids |

| Hoston et al. [166] | IEFG–RIPM | Lid-driven square cavity | 2D, steady | Re = 10,000, 15,000, 20,000, 25,000, 30,000 and 35,000 | 150 150 (Refined at cavity walls) |

| Ibrahim & Hirpho [167] | COMSOL, FEM | Trapezoidal cavity | 2D, mixed convection, laminar | Ha = 0, 50, Ri = 0.1, 1, 10, Re = 100, Am = 0.25, 0.5, 1 | 91 91 |

| Ikram et al. [168] | FEM, ALE | Hexagonal cavity with rotating modulator | 2D, forced convection, unsteady, laminar | Pr = 0.71, 102 ≤ Re ≤ 103, 103 ≤ Bi ≤ 104, 103 ≤ Ra ≤ 107 | Non-uniform, 48,548 elements |

| Joe & Perumal [169] | OpenFOAM, FVM | Rectangular cavity containing cylinders | 2D, unsteady | Pr = 0.72, Re = 1600 | Unstructured triangular cells |

| Mondal & Mahapatra [170] | FDM, BiCGStab | Trapezoidal cavity | 2D, mixed convection, steady, laminar | Pr = 6.2, N = 5, 0.5 ≤ A ≤ 2, 10−2 ≤ Ri ≤ 102, 102 ≤ Re ≤ 103, 45 ≤ ≤ 90, 0 ≤ ≤ 0.5, 20 ≤ Ha ≤ 40, 1 ≤ Le ≤ 2, Al2O3-H2O nanofluid | 81 81 |

| Mebarek-Oudina et al. [171] | FEM | Trapezoidal porous cavity with zigzag wall | 2D, laminar, steady | 0 ≤ Ha ≤ 100, 0 ≤ ≤ 90, 103 ≤ Ra ≤ 105, 0 ≤ ≤ 0.08, Cu-Al2O3/H2O hybrid nanofluid | Triangular grid, 20,296 elements |

| Saha et al. [172] | FVM | Rectangular cavity with baffles | 2D, laminar, steady | 50 ≤ Re ≤ 250 Ri = 0, 2, 4 | 45 51 |

| Saha et al. [173] | FVM, SIMPLE, QUICK | Triangular cavity | 2D, natural convection | Pr = 0.72, 103 ≤ Ra ≤ 106, A = 0.2, 0.5, 1.0 | 360 75, 360 90, 360 120 for A = 0.2, 0.5, 1 |

| Shah et al. [174] | FEM, NR | Lid-driven trapezoidal cavity with obstacle | 2D, mixed convection, steady, laminar | 10−2 ≤ Ri ≤ 10, 0.1 ≤ Le ≤ 10, 300 ≤ Re ≤ 500, −10 ≤ N ≤ 10, Pr = 0.71 | Non-uniform, approx. 3200 elements |

| Shahid et al. [175] | MRT-LBM | Triangular lid driven cavity | 2D, mixed convection, unsteady | Pr = 0.71, 1, 7, 10−2 ≤ Ri ≤ 102, 104 ≤ Gr ≤ 107 | - |

| Shahid et al. [176] | MRT-LBM | Lid-driven rectangular cavity with obtacles | 2D, mixed convection, laminar | Pr = 0.71, 1, 7, 10−2 ≤ Ri ≤ 102, 103 ≤ Gr ≤ 106, A = 0.2, 0.5, 2, 5 | Not clearly mentioned for different A |

| Shekaramiz et al. [177] | OpenFOAM, FVM, SIMPLE | Wavy triangular cavity | 2D, free convection, steady | 5 103 ≤ Ra ≤ 2 105, Pr = 4.6, 0 ≤ Ha ≤ 50, 0 ≤ ≤ 90, = 2%, H2O-Fe3O4 nanofluid | 16,000 and 12,000 nodes |

| Tizakast et al. [178] | FVM, SIMPLER | Lid-driven rectangular cavity | 2D, laminar, unsteady, non-Newtonian | RaT ≤ 5 106, Pe ≤ 103, 10−3 ≤ Le ≤ 103, 10−3 ≤ N ≤ 103, 0.6 ≤ n ≤ 1.4 | Uniform grid, A = 24:381 121 |

| Velkennedy et al. [179] | FDM, ADI, CDS | Rectangular vented cavity | 2D, laminar, unsteady | 103 ≤ Ra ≤ 106, Pr = 0.71 | 181 121 |

| Xiong et al. [180] | FEM | Lid-driven triangular cavity | 2D, mixed convection | Pr = 6.2, 0 ≤ Ha ≤ 40, 0 ≤ Re ≤ 103, 0.01 ≤ Ri ≤ 2 | Uniform triangular mesh |

| Abbas et al. [181] | FEM | Square cavity with obstacles | 2D, steady, laminar | 0 ≤ ≤ 0.04, 10 ≤ Ha ≤ 40, 103 ≤ Ra ≤ 107, Cu-H2O nanofluid | 59,173 elements |

| Ahmed et al. [182] | Coiflet wavelet-homotopy method | Lid-driven square porous cavity | 2D, unsteady | Pr = 6.2, 10 ≤ Ri ≤ 102, 10−4 ≤ Da ≤ 10−1, 3 ≤ Le ≤ 106, Al2O3-Cu/H2O hybrid nanofluid | - |

| Alam et al. [8] | FEM | Semi-circular cavity | 2D, unsteady, semi-circular cavity, free convection | Pr = 23.0, 6.84, 1 ≤ dp ≤ 10, 0 ≤ ≤ 0.05, 0 ≤ Ha ≤ 100, 104 ≤ RaT ≤ 106, ZnO, Fe3O4, Co, Al2O3, Ag nanoparticles, H2O & kerosene as base fluids | 15,817 elements |

| Ali et al. [183] | Comsol, FEM | Lid-driven square cavity | 2D, mixed convection, steady | Re = 1, 10, 102, Ha = 0, 10, 25, = 0, 1%, 5%, Pr = 6.2, Gr = 102, Al2O3-H2O nanofluid | Non-uniform, 30,550 nodes, 60,036 elements |

| Alqaed et al. [5] | FVM, SIMPLE | Rectangular cavity with triangular blades | 2D, steady, laminar | 103 ≤ Ra ≤ 105, 0 ≤ Ha ≤ 30, = 0.3, Al2O3-H2O nanofluid | 150 450 |

| Acharya & Chamkha [184] | FEM | Hexagonal cavity with parallel fins | 2D, laminar, steady | 103 ≤ Ra ≤ 105, 0 ≤ Ha ≤ 100, 0 ≤ ≤ 0.04, Pr = 6.2, Al2O3-H2O nanofluid | Non-uniform, 34,502 elements |

| Batool et al. [185] | FVM, SIMPLE | Lid-driven square cavity | 2D, steady, laminar | 100 ≤ Re ≤ 400, micropolar nanofluids | Staggered grid |

| Charqui et al. [186] | FVM, SIMPLE, TDMA | Tall partitioned cavity | 2D, natural convection, laminar | Pr = 0.71, 7, A = 40 | Uniform mesh, 80 200 |

| Cui et al. [187] | FVM, SIMPLE | Triangular cavity | 3D, natural convection, unsteady | Pr = 0.7, 102 ≤ Ra ≤ 107, 0.1 ≤ A ≤ 1.5 | Non-uniform mesh, 141 41 51 |

| Dahani et al. [188] | LBM, MRT, BGK operator | Double lid-driven square cavity | 2D, unsteady | 0 ≤ ≤ 180, Re = 102, 10−2 ≤ Ri ≤ 102, 102 ≤ Gr ≤ 106, Pr = 0.71 | Uniform grid, 160 160 |

| Esfe et al. [9] | Fluent, FVM, SIMPLE | U-shaped porous enclosure | 2D, steady | 103 ≤ Ra ≤ 105, 0 ≤ ≤ 0.03, Al2O3-H2O nanofluid | Approx 1600 cells |

| Geridonmez & Oztop [10] | Rbf-Pum | Right Isosceles triangular cavity | 2D, natural convection, steady, laminar | 0 ≤ Ha ≤ 100, 0.25 ≤ A ≤ 1, Pr = 6.07, Ra = 105, 0 ≤ ≤ 0.02, Al2O3-Cu/H2O nanofluid | 1,842,025 & 1,741,596 nodes |

| Hirpho & Ibrahim [189] | FEM | Trapezoidal enclosure | 2D, mixed convection, non-Newtonian, steady, laminar | 10−1 ≤ Ri ≤ 102, Re = 100, Pr = 20, 0 ≤ ≤ 0.02, Al2O3-Cu/H2O hybrid nanofluid | 201 201 |

| Khalil et al. [190] | Fluent, FVM, RSM | Porous trapezoidal cavity with wavy wall | 2D, steady | 0 ≤ Ha ≤ 40, 0 ≤ Am ≤ 20, 5 102 ≤ Ra ≤ 2.4 104 | 320 320 |

| Liu [191] | CDS, SIMPLE, QUICK | Rectangular cavity with fins | 2D, free convection, unsteady | 0 ≤ ≤ 40, Ra = 1.84 109 | 360 400 |

| Noor et al. [192] | FEM | Lid-driven trapezoidal cavity with obstacle | 2D, forced convection, steady | 102 ≤ Re ≤ 700, 10−3 ≤ Ri ≤ 10, 0 ≤ Ha ≤ 102 | Trangular grid, 4622 nodes. 8929 elements |

| Nouraei et al. [193] | FVM, SIMPLE | Semi-circular vented cavity | 2D, mixed convection, laminar, steady | 10 ≤ Re ≤ 100, 0 ≤ ≤ 0.06, Cu-H2O nanofluid | 52,000 grids |

| Polasanapalli & Anupindi [194] | LBM | Concentric circular annular cavity | 2D, mixed convection, unsteady | 104 ≤ Ra ≤ 106, 0 ≤ Re ≤ 104, Pr = 0.71, 0 ≤ ≤ 360, 10−3 ≤ Ri ≤ 103 | 120 120, 180 180 |

| Prince et al. [195] | COMSOL, FEM | Trapezoidal cavity with different surface | 2D, natural convection | Pr = 0.716, 103 ≤ Ra ≤ 106, Materials: Pinewood, plexiglas, dry concrete, glass fiber | Rectangle: 6112, Triangle: 10,191, Sinusoidal: 5993 elements |

| Rahaman et al. [196] | Fluent, FVM, CDS, SIMPLE | Trapezoidal cavity | 2D, unsteady, natural convection | Pr = 0.71, 100 ≤ Ra ≤ 108, A = 0.5 | Non-uniform, 300 100 |

| Roy et al. [197] | FEM | Square enclosure with blocks | 2D, unsteady, natural convection | Pr = 6.2, 0 ≤ Rd ≤ 3, 0 ≤ ≤ 0.09, 104 ≤ Ra ≤ 106, 0 ≤ Ha ≤ 60, Cu- Al2O3/H2O hybrid nanofluid | Triangular 65,740 elements |

| Shah et al. [198] | FEM, NR | Lid-driven corrugated porous cavity | 2D, mixed convection, laminar, steady | 102 ≤ Re ≤ 400, 0 ≤ ≤ 0.05, 10−5 ≤ Da ≤ 10−1, Pr = 6.2, 10−2 ≤ Ri ≤ 100, CuO-H2O nanofluid | Approx 8000 elements |

| Tizakast et al. [199] | FVM, SIMPLE | Lid-driven Rectangular cavity | 2D, unsteady non-Newtonian, laminar | 2 ≤ A ≤ 30, 102 ≤ RaT ≤ 107, 10−3 ≤ Le ≤ 103, 0.1 ≤ Pe ≤ 104 | - |

| Xia et al. [200] | UPWIND | T-shaped lid-driven cavity | 2D, mixed convection | 0 ≤ ≤ 0.03, 0.1 ≤ Re ≤ 10, 0.2 ≤ A ≤ 0.4, Al2O3-H2O nanofluid | Uniform mesh, 250,000 cells |

| Zarei et al. [201] | FVM, SIMPLE | Square cavity with wavy walls | 2D, steady | Ra = 104, 0 ≤ Am ≤ 0.15, 0 ≤ ≤ 0.04, Cu-H2O nanofluid | 135,008 triangular cells |

| Zhang et al. [202] | FVM, SIMPLE | Semi-elliptic lid-driven cavity | 2D, mixed convection, steady, laminar | 0 ≤ ≤ 0.06, Gr = 5 104, 15 104, 25 104, 4 105, 10−1 ≤ Ri ≤ 10, Pr = 6.2, Ag-H2O nanofluid | 43,905 triangular grids |

| Akhter et al. [7] | FEM | square cavity with cylinder | 2D, steady | 104 ≤ Ra ≤ 5 106, Pr = 6.2, 0 ≤ ≤ 0.05, 0 ≤ Ha ≤ 102, Cu-Al2O3/H2O hybrid nanofluid | 24,961 nodes, 49,188 elements |

| He et al. [203] | Experimental, FVM, SIMPLE | Cubic cavity | 3D | 0 ≤ B ≤ 133, 0 ≤ ≤ 0.03, 6.9 105 ≤ Ram ≤ 11.6 105, Fe3O4-Paraffin nanofluid | 50 50 50 |

| Ikram et al. [204] | FEM, ALE | Hexagonal cavity with rotating modulator | 2D, forced convection, unsteady, laminar | Pr = 0.71, 102 ≤ Re ≤ 103, 104 ≤ Ra ≤ 106, Bi = 104 | 49,874, 50,672 and 52,601 elements |

| Ouri et al. [205] | Comsol, FEM, ANFIS | L-shaped cavity with rotating cylinder | 2D, unsteady | 200 ≤ Re ≤ 103, 102 ≤ Rew ≤ 103, 0 ≤ Ha ≤ 40, 0 ≤ ≤ 0.02, Ag-MgO/H2O hybrid nanofluid | Non-uniform triangular 65,216 elements |

| Sayed et al. [206] | FVM, LES, URANS | Cubical cavity | 3D, unsteady | Ra = 109, Pr = 0.71, Prt = 0.9 | 166,375 cells |

4. Validations

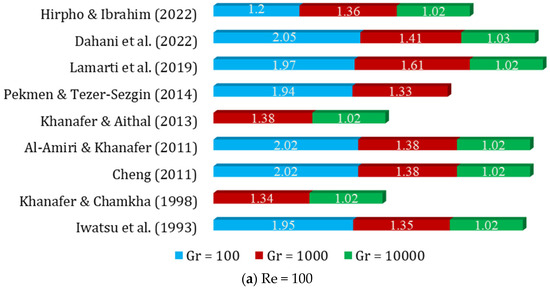

In computational fluid dynamics (CFD), validation is an important aspect of research. It is the process of comparing the numerical results with experimental, benchmark, or numerical results to assess the accuracy of the simulation. Validation is important for several reasons: it helps to ensure that the numerical model is implemented correctly and that the solution is not affected by any errors or bugs in the code; it also allows researchers to compare their results with other studies, and it gives an idea about the accuracy of the numerical model compared with real-world data. One common way to validate CFD simulations is to compare the numerical results with experimental data. This can be conducted by comparing the velocity, temperature, and pressure fields obtained from the simulation with measurements taken in a laboratory experiment. The percentage difference between the numerical and experimental results is used as a measure of the accuracy of the simulation. A percentage difference of less than 5% is generally considered to be a good match between the numerical and experimental results. The above-mentioned studies used different types of validations, and details of some of these are presented below. Providing detailed information about the validation process in a study is important for ensuring the accuracy of the numerical results and for providing a useful resource for future research. Moreover, according to the authors’ knowledge, no such details are available in previous studies. By presenting the details of their validation studies, the authors are providing a valuable resource for future researchers. This information can be used to compare the results of new studies with previous work and to assess the accuracy of new simulations. Additionally, the figures (Figure 4, Figure 5, Figure 6, Figure 7, Figure 8, Figure 9 and Figure 10) likely provide a visual representation of the validation results, making it easier for readers to understand and interpret the data.

Figure 4.

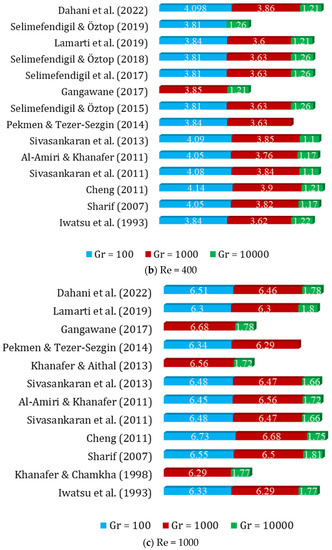

Variation of Nuavg with different Gr for Pr = 0.71 (Case: Mixed convection flow inside a square lid-driven cavity) [31,33,34,53,55,93,105,106,124,139,142,188,189,207,208,209,210,211].

Figure 5.

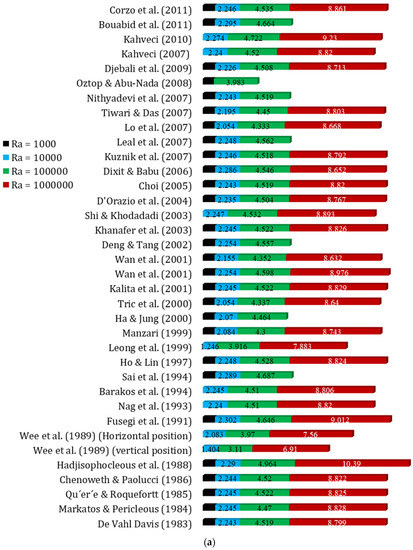

(a,b): Variation of Nuavg with different Ra for Pr = 0.71 (Case: Natural convection flow in a square cavity) [2,7,9,18,52,71,75,79,89,94,99,103,149,162,163,179,212,213,214,215,216,217,218,219,220,221,222,223,224,225,226,227,228,229,230,231,232,233,234,235,236,237,238,239,240,241,242,243,244,245,246,247,248,249,250,251,252,253,254,255,256,257,258,259,260,261,262,263,264,265,266,267].

Figure 6.

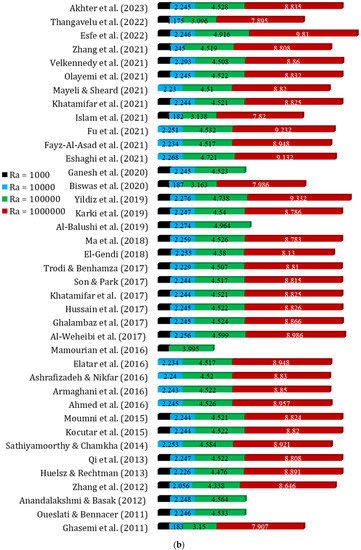

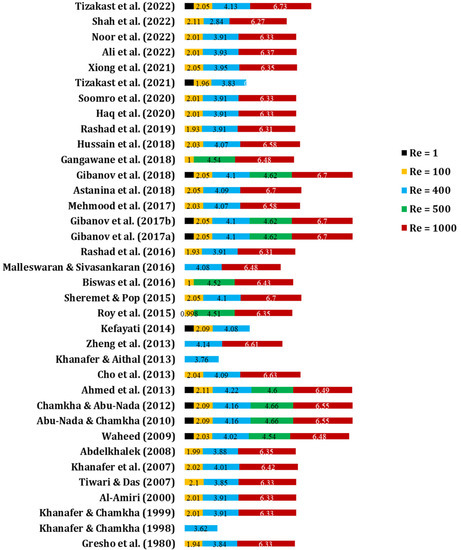

Variation of Nuavg with different Re for Pr = 0.71 and Gr = 102 (Case: Mixed convection flow in a square lid-driven cavity) [12,18,42,48,50,53,73,95,96,110,115,116,117,150,157,178,180,183,192,198,199,208,268,269,270,271,272,273,274,275,276,277,278].

Figure 7.

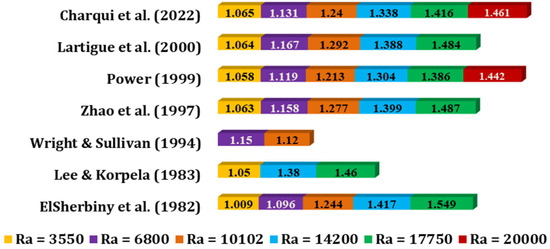

Variation of Nuavg with different Ra for A = 40 [186,279,280,281,282,283,284].

Figure 8.

Variation of for Ra = 103 (Case: Porous square cavity) [20,285,286,287,288].

Figure 9.

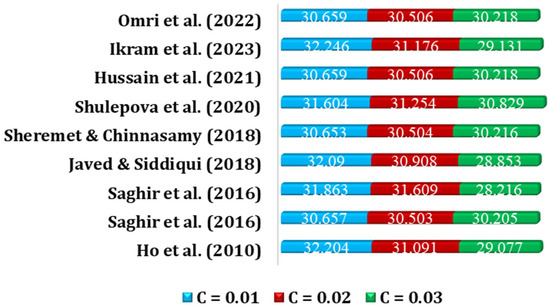

Variation of for different nanoparticles concentration (C) of Al2O3 nanofluid [118,165,204,289,290,291,292,293].

Figure 10.

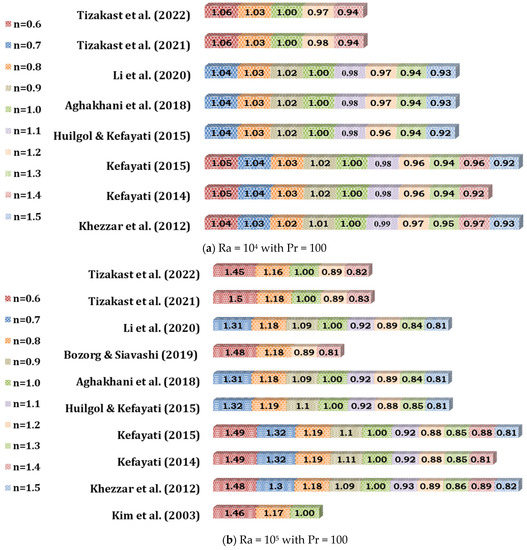

Variation of relative average Nusselt number for different Ra (Case: Non-Newtonian Power-law Fluids) with Pr = 100 [109,152,178,199,218,273,294,295,296,297].

For a square lid-driven cavity with mixed convection flow, the variation of the average Nusselt number with different Gr for a fixed Pr of 0.71 was studied through numerical simulations or experiments. In the case of mixed convection, as the Gr increases, the Nuavg is expected to decrease. This is due to the lid-driven motion of the cavity. Details of the results are presented in Figure 4.

Based on the validation data presented in Figure 4a–c, the following correlations (Equations (6)–(8)) are proposed. It is worth noting that all these correlations exhibit a maximum percentage error of less than 10%, which indicates a strong relationship between the provided data and the proposed equations.

In a square cavity with natural convection flow, the variation of Nuavg with different Ra for a fixed Pr of 0.71 is studied throughout the literature. We know as Ra increases, the strength of natural convection increases, and the Nuavg increases. However, the relationship between Nuavg and Ra can be complex, as the flow pattern and heat transfer mechanisms in the cavity can vary with changing Ra. In general, for a square cavity with natural convection flow and Pr = 0.71, the variation of the Nuavg with Ra can be explained by different values of Ra. For low Ra < 104, the heat transfer is dominated by conductive heat transfer, and Nuavg is relatively constant and low. However, for intermediate Ra (104 < Ra < 108), the heat transfer is dominated by a combination of conduction and convection, and Nuavg increases rapidly with Ra due to the onset of natural convection. Such findings are explained in Figure 5.

Based on the results displayed in Figure 5a,b, a novel correlation is introduced for the computation of Nuavg, which is presented below. The correlation (Equation (9)) exhibits a high level of consistency with the aforementioned findings, with an error range of 1.4% to less than 10%. In a few instances, the maximum error is found to be approximately 13%, but this is attributed to the researcher’s recording of low Nuavg values.

As shown in Figure 6, for a fixed Pr = 0.71 and low Gr = 100 in mixed convection flow in a square lid-driven cavity, Nuavg always increases with increasing Re. This is because at low Gr, the buoyancy forces are weak, and the flow is dominated by the lid-driven motion. As Re increases, the flow becomes more vigorous, resulting in increased mixing and enhanced heat transfer.

Based on the findings depicted in Figure 6, a novel correlation for computing Nuavg is introduced and presented below. The proposed correlation (Equation (10)) exhibits a strong association with the provided data, with a minimum and maximum error of 0.01% and 7.30%, respectively. However, for some of the given data, a higher percentage of error is observed, which is not attributable to the correlation, but rather is due to poorly recorded research data obtained by the researcher.

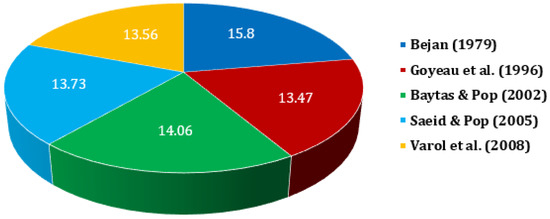

We know that an increase in the aspect ratio leads to an increase in the heat transfer rate. This is because an increase in the aspect ratio leads to an increase in the surface area available for heat transfer. As a result, there is more area for the fluid to exchange heat with the solid surfaces, leading to a higher heat transfer rate. Additionally, an increase in the aspect ratio can also promote greater fluid mixing and circulation, which further enhances the heat transfer rate. We also know that Nuavg increases with increasing Ra for a porous square cavity case. At low Ra, the flow is dominated by conduction, and the heat transfer is primarily governed by thermal conduction. As Ra increases, the buoyancy forces become more significant, resulting in increased flow circulation and mixing. This enhanced mixing leads to an increase in the heat transfer rate and Nuavg. Such findings are presented in Figure 7 and Figure 8, that is observed by a different researcher.

Based on the results depicted in Figure 7, a new correlation for determining Nuavg is proposed and put forward. The correlation (Equation (11)) demonstrates a high level of accuracy, with a minimum error of 0.08% and a maximum error of 9.93%. These findings suggest that the correlation has significant potential for future use.

Figure 9 presents the variation of Nuavg with different nanoparticle concentrations (C) for Al2O3 nanofluid. It is observed that Nuavg slightly decreases with the increase in C. The decrease in Nuavg with increasing C may be due to several factors, such as the nanoparticles may aggregate at high concentrations, leading to a decrease in effective surface area and, thus, a decrease in convective heat transfer.

Based on the outcomes presented in Figure 9, a new correlation is suggested for computing Nuavg. This correlation (Equation (12)) demonstrates a robust concurrence with the results of earlier studies, with an error range of 0.01% to a maximum of 5.41%.

Figure 10 shows that the Nuavg increases with increasing Ra for a fixed Pr = 100, which indicates an enhancement of convective heat transfer. However, the rate of increase depends on the power-law index n. It is also seen that Nuavg slightly increases with the increase in n. It indicates that the non-Newtonian behavior of the fluid has a small effect on the convective heat transfer in the fluid.

Based on the data depicted in Figure 10, two correlations (Equations (13) and (14)) are proposed with minimum and maximum errors of 0.06% and 3.41%, and 0.01% and 7.69%, respectively. These correlations demonstrate excellent agreement with the provided data.

5. Heat Transfer Analysis

According to the above-mentioned literature, the flow behavior inside the cavities can be classified into the following categories: effect of the applied boundary conditions to walls such as temperature difference, localized heat sources, magnetic field, or inlet flow to the cavity through a specific port(s). The other types of cavities use internal fins or cylinders to drive the flow inside the cavity. Some of the above-mentioned references (Given in Table 1) are discussed below:

5.1. Square Cavity

In the study by Abbas et al. [181], the effect of using Cu-water nanofluid on heat transfer enhancement was investigated inside a square cavity, using two circular heated obstacles and applying a constant magnetic field. They found that Nuavg improved with the rise of Ra up to a certain point and then showed a negligible variation. However, for lower values of Ra, Nu decreased with Ha. Additionally, the increase in nanoparticle concentration resulted in a decrease in the heat transfer rate for each value of Ha. The study also found that the increase in magnetic field intensity led to a decrease in the rate of heat transfer because of the high sensitivity of Cu nanoparticles to the applied magnetic field. In the study by Roy et al. [197], the flow behavior inside a square cavity filled with MHD hybrid Cu-Al2O3/H2O nanofluid was investigated. A cold elliptical block and a hot square block were inserted inside the cavity, and all four walls were set at the same temperature as the elliptical object. The results of the study confirmed that the local Nu increased with Ra and decreased with an applied magnetic field. Additionally, the presence of nanoparticles enhanced the heat transfer rate. The study also found that Ha had a stronger effect on local and average Nu at high values of Ra. Furthermore, high Rd led to an improvement in the rate of heat transfer. In the study by Zarei et al. [201], the flow of a Cu-H2O nanofluid inside a square cavity with a wavy left wall and straight other walls was investigated, with a uniform heat flux applied to the left vertical wall and a constant temperature on the right vertical wall, while the other boundaries were adiabatic. They found that increasing the nanoparticles concentration and decreasing the wavelength and amplitude of the wavy wall led to an increase in Nuavg. In the study by Akhter et al. [7], the flow of a hybrid nanofluid Cu-Al2O3/H2O inside a square cavity was investigated. A heat-conductive circular solid was placed at the center of the cavity. The bottom and top boundaries of the cavity were partially heated and cooled, respectively. Their results confirmed that the heat transfer was enhanced with the Ra and decreased with the Ha. They also found that the thermal performance increased linearly with an increase in χ. For the nanoparticles volume fraction of 1% and 5%, there was an increase in heat transfer by 47.74% and 106.78%, respectively, as compared to the base fluid.

5.2. Rectangular Cavity

The study by Wee et al. [2] found that the rate of heat transfer in a rectangular cavity full of air is significantly higher when the cavity is in a vertical position with upwards transfer compared to a horizontal position with the downward transfer. Al-Farhany & Turan [39] found that using a rectangular porous cavity with left and right boundaries at various temperatures and insulated top and bottom walls, the flow inside the cavity was driven by buoyancy, and the results showed that the highest Nuavg occurred at zero inclination for high Ra, while for low Ra, the maximum Nuavg was found at 60 degrees inclination. Additionally, the results showed that as the aspect ratio and Le increase, Nuavg decreases and Sh increases. Elsherbiny & Ragab [51] studied an inclined rectangular cavity with a hot spot at the bottom wall and insulated surfaces. They found that as the aspect ratio increases, Nuavg decreases, and when the local heat source position was at the middle or quarter position of the bottom wall, the maximum Nuavg occurred at specific aspect ratio values. Moreover, they found that Nuavg increases with increasing tilt angle (φ) from 0 to 75 degrees, then starts to decrease until 150 degrees and remains constant up to 180 degrees. Elsherbiny & Ismail [69] studied an oblique rectangular cavity with two local heat sources at the bottom wall and insulated surfaces. They found that Nuavg increases until φ’s reaches 60 degrees and then starts to decrease until it reaches a minimum value at 180 degrees. They also found that at a tilt angle of 150 degrees, the effect of Ra on Nuavg is very low, and at 180 degrees, Nuavg becomes independent of Ra. Additionally, they observed that Nuavg decreases by 23% when the aspect ratio reaches 10. Hatami [6] numerically investigated the free convection and flow of nanofluids in a rectangular cavity with two heated fins installed on the cold lower and upper walls while the vertical walls were insulated. They found that Nuavg was higher for higher volume fractions of Al2O3 and similarly for lower volume fractions of TiO2. Additionally, they observed that Nuavg increases as the height of the fins increases. Yu et al. [3] studied numerically the effect of the magnetic field and electric source on the flow characteristics and heat and mass transfer of electrically conducting fluid inside a rectangular cavity. It was found that with the increase in the density of the magnetic field, the oscillatory flow became more stable, and heat transfer by convection and mass transfer was reduced. Moreover, it was also found that the magnetic field had no effect on Nuavg, which only varied with dimensionless heat generation or absorption coefficient, while Sh remained equal to one.

Jiang and Zhou’s [4] study examined the impact of nanofluids on surface tension in a rectangular cavity. They applied a temperature difference across the vertical walls and a free surface on the upper surface. They found that for distilled water-Al2O3 nanofluid, a rise in nanoparticles volume fraction led to convective flow being dominated by the fluid’s thermophysical properties and the surface tension temperature coefficient. For PGW-ZnO nanofluid, an increase in nanoparticle concentration resulted in convective flow being mainly controlled by the surface tension temperature coefficient. Karatas and Derbentli’s [138] study investigated free convection flow in a partially heated rectangular cavity with various aspect ratios. They kept the temperature of the vertical cold boundary constant, and the temperature of the hot boundary was a time-periodic temperature. They observed that Nuavg increased from 2.64 to 16.44 as the aspect ratio decreased from 6 to 1. Thiers et al. [158] explored the impact of local thermal disturbances (one on the cold side and the other on the hot side) on the flow instability in a rectangular enclosure with an aspect ratio of 4.0. They considered the left boundary as a hot boundary, while right boundary as a cold boundary, and the top and bottom walls as adiabatic. Their research showed that the highest heat transfer enhancement occurred when the local disturbance area was located at Lh= 0.7 and/or Lc = 0.3. Hasnaoui et al. [164] studied thermo-solutal convection in a rectangular cavity. They found that the flow became unstable for Sr = 0 and −0.5 and remained unstable until R = 20. They also observed that the rate of heat transfer was strongly impacted by thermo-diffusion in the range of R, leading to instabilities. Alqaed et al. [5] performed a numerical simulation to study the natural convection heat transfer and entropy generation of alumina-water nanofluid flow in a rectangular cavity. They installed two hot triangular blades on the bottom wall, and the two sidewalls were adiabatic, whereas the upper wall was set at a low temperature and the bottom wall was set at a high temperature. They found that a rise in Ra led to an increase in Nuavg and entropy generation, but it decreased Be, and the increment in Ha also led to reducing Be for higher Ra. They reported that the maximum values of Nuavg, entropy generation, and Be occurred at a cavity inclination of 30 degrees. Liu [191] examined the convection heat transfer behavior inside a rectangular cavity with an adiabatic fin fixed on each of the side walls. The top and bottom boundaries were adiabatic, while the left boundary was cold, and the right boundary was hot. The study found that Nuavg increased by 5% for the finned cavity as compared to the non-finned one. Additionally, Nuavg for both cases increased with the angle of inclination until 5 degrees and then decreased.

Sasaguchi et al. [14] studied the heat transfer analysis numerically in a rectangular cavity containing water. All boundaries were insulated and cold (−10 °C), including the internal presence of single or double cylinder inside the cavity. The study found that the solidification speed for a single cylinder was faster than double cylinders for a temperature equal to 0 °C, while the solidification was faster for the double cylinders for a temperature higher than 4 °C. Liu & Huang [153] investigated the effect of adding thin fins to the middle of the high and low-temperature walls of a rectangular cavity, with the top and bottom walls being considered as insulated walls. They applied a linear temperature distribution to the hot and cold side walls. The study found that the effect of the adiabatic horizontal thin fin led to a change in the convective flow attached to the middle of the sidewall. Nuavg correlated well with Ra0.25 for all three thermal heating conditions examined. However, when the slope of the applied linear temperature distribution was negative to both the right and left walls, Nuavg was lower than the other two heating conditions.

Joe and Perumal [169] studied the influences of rotating cylinders on the mixing and distribution of temperature within a rectangular cavity. They found that the best results were obtained when the cylinders were close to the middle line and rotated in the same direction. This resulted in improved mixing and a more uniform temperature distribution. Saha et al. [172] studied free convection flow inside a rectangular cavity with isothermally heated baffles. They concluded that the flow velocity and heat transfer interaction efficiency were highest for the case of plane baffles, where fluid was blended more effectively as the length of the baffles increased. They also found that the maximum value of Nuavg was achieved at Re = 250 for plane baffles. Additionally, they found that the heating efficiency increased with Re and Ri and decreased as the length of the baffles increased. Velkennedy et al. [179] investigated the air-flow behavior inside a ventilated rectangular cavity with two outlets and one inlet. The inlet vent was positioned on the bottom of the right wall, and the outlets were put on the top wall. Both vertical walls were considered hot walls, and the bottom wall was adiabatic. They found that the rate of heat transfer to the right wall was reduced at the upper part of the cavity due to the introduction of a cold partition. However, they also found that the heat transfer rate increased significantly with the introduction of the cold partition for lower Ra, and this difference was reduced for higher Ra. Ait-Taleb et al. [58] studied the flow behavior inside a building block that generally contains three air cavities in the horizontal orientation and two in the vertical orientation. They found that by keeping the temperatures of the upper and lower walls the cold outside and hot inside, respectively, the hollow block with two air cells deep in the vertical direction allowed for a significant reduction in heat transfer between the inside and outside of the building. Charqui et al. [186] numerically investigated the heat transfer and free convection flow inside a tall thin partitioned cavity, where the left and right parts were filled with air and water, respectively. They found that even though the partition was thin, air and water behaved differently. The temperature of the inside wall had less effect by solar flux than the heat flux through the partition. The wall opposite to sunlight was kept at 20 degrees Celsius, and the temperature of the other surface was varied between 0 degrees Celsius to 50 degrees Celsius. The other surfaces were assumed to be adiabatic.

5.3. Other Cavity Types