Experimental Thermal Behavior of Fibrous Structures for High-Performance Heat Resistant Fire Curtains

Abstract

1. Introduction

2. Materials and Methods

2.1. Passive Fire Protection—Classification Criteria

2.2. Test Materials

2.3. Test Facilities

2.3.1. Test Facility for Fire Resistance and Thermal Insulation

2.3.2. Test Facility for Smoke Production and Flaming Particles

2.3.3. Test Facility for Ignitability

3. Results

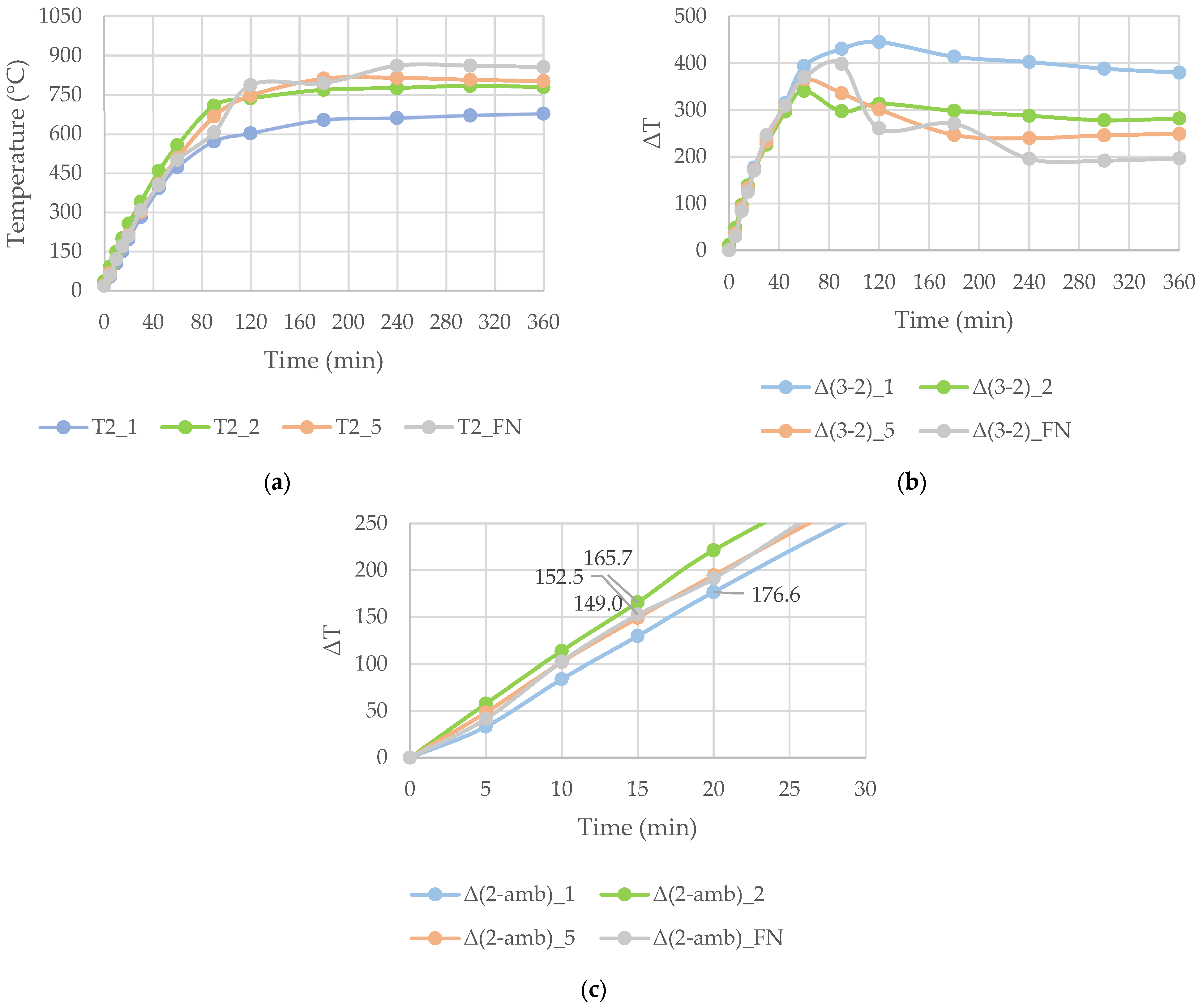

3.1. Fire Resistance and Thermal Insulation Tests

3.1.1. Uncoated Samples

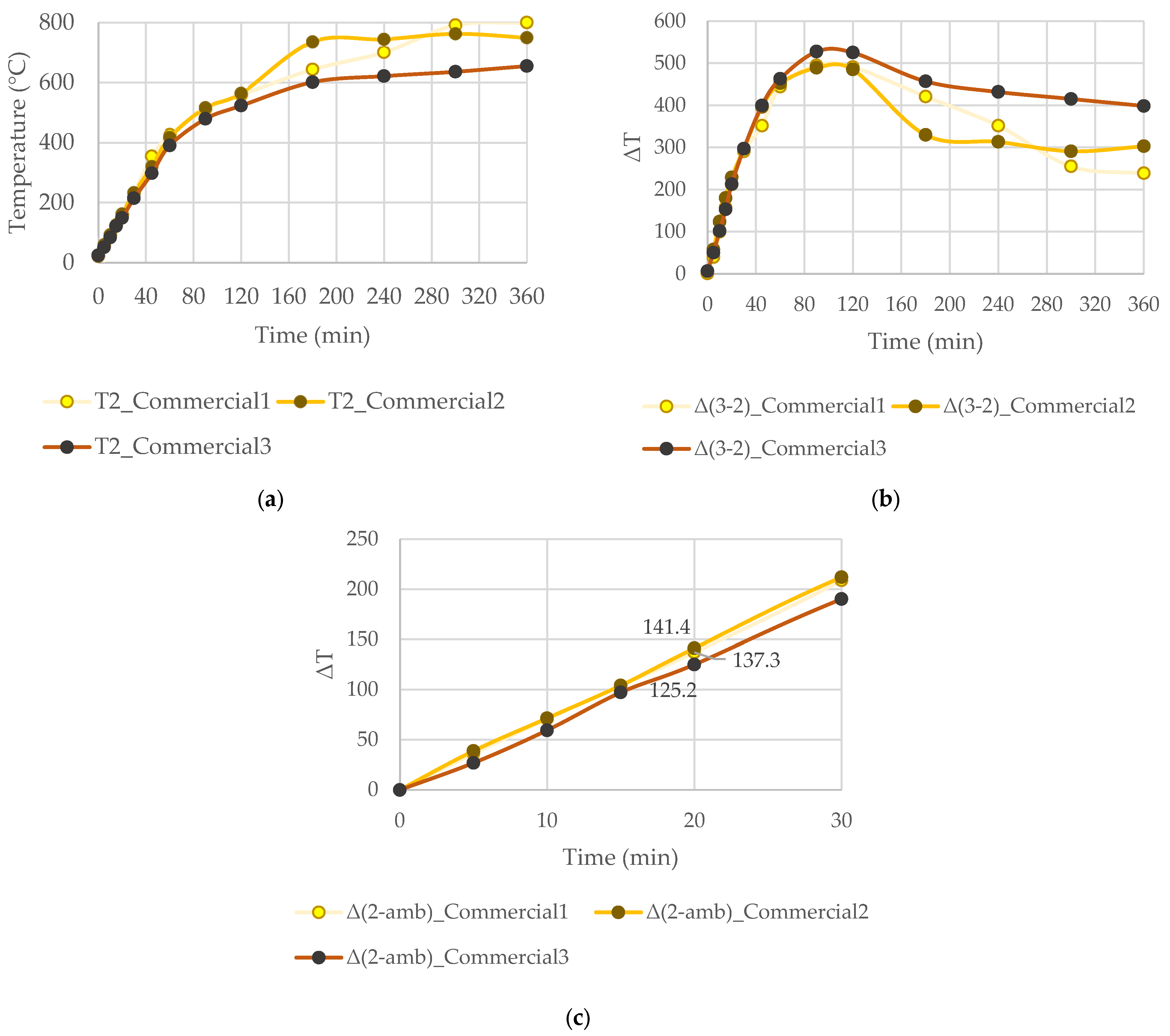

3.1.2. Coated Samples

3.1.3. Commercial Samples

3.2. Ignitability Tests

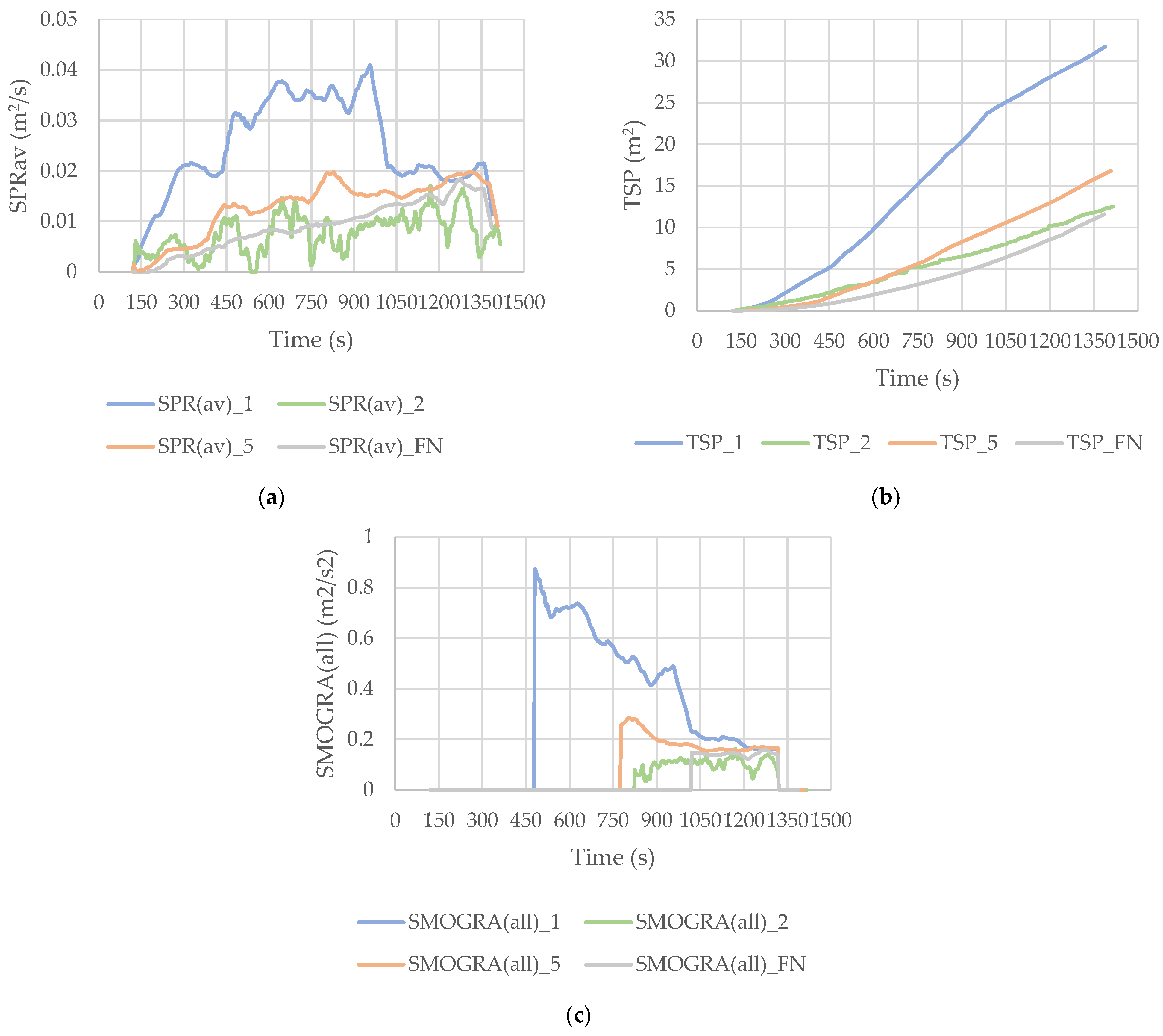

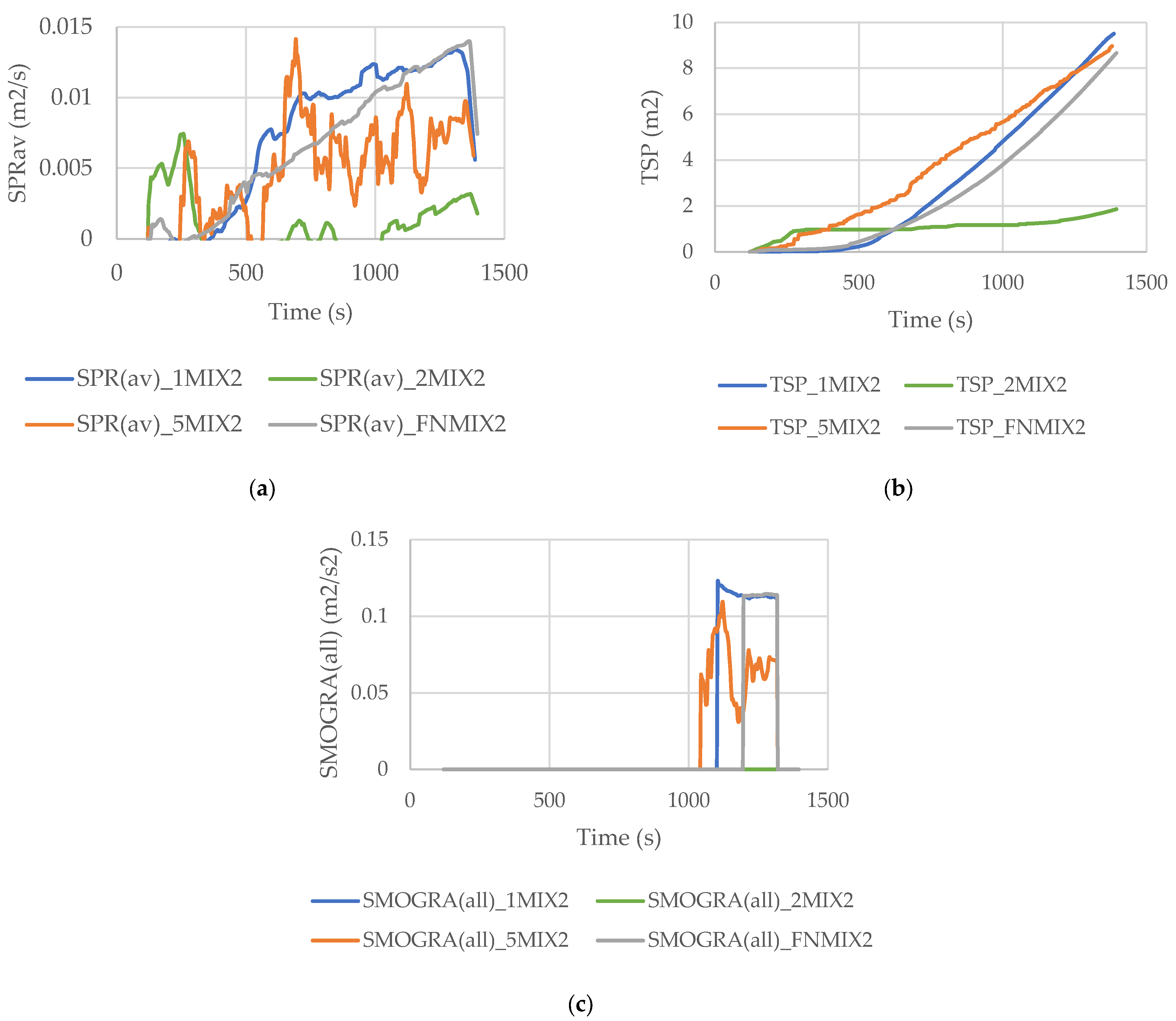

3.3. Test Results for Smoke Production and Flamming Particles/Droplets

3.3.1. Uncoated Samples

3.3.2. Coated Samples

4. Discussions and Comparisons

4.1. Discussions of Results

4.1.1. Fire Resistance and Thermal Insulation

- Uncoated samples:

- Coated samples:

- Coating performance:

- Commercial samples:

- Overall analysis:

4.1.2. Ignitability

4.1.3. Smoke Production and Flaming Particles/Droplets

4.2. Comparative Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Brushlinsky, N.; Sokolov, S.; Hall, J.; Wagner, P. World Fire Statistics—Report No 10 Second Edition; World Fire Statistics: Ljubljana, Slovenia, 2005. [Google Scholar]

- Mróz, K.; Hager, I.; Korniejenko, K. Material Solutions for Passive Fire Protection of Buildings and Structures and Their Performances Testing. Procedia Eng. 2016, 151, 284–291. [Google Scholar] [CrossRef]

- Kilinc, F.S. Handbook of Fire Resistant Textiles; Woodhead Pub: Cambridge, UK, 2013. [Google Scholar]

- Nedryshkin, O.; Gravit, M.; Lyapin, A.; Voronin, V. Overview of fire curtains in construction. MATEC Web Conf. 2016, 86, 04052. [Google Scholar] [CrossRef]

- Nikitina, M.; Ustinov, A.; Kiseleva, V.; Babikov, I. New fire retardant compositions for fire-resistant automatic curtains. MATEC Web Conf. 2018, 245, 11004. [Google Scholar] [CrossRef]

- Horrocks, A.R. Technical fibres for heat and flame protection. In Handbook of Technical Textiles: Technical Textile Applications; Woodhead Pub: Cambridge, UK, 2016; pp. 237–270. [Google Scholar]

- BS EN 13501-1:2007+A1:2009; Fire Classification of Construction Products and Building Elements—Part 1: Classification Using Data from Reaction to Fire Tests. British Standards Institution: London, UK, 2009.

- BS 476-20:1987; Fire Tests on Building Materials and Structures—Part 20: Method for Determination of the Fire Resistance of Elements of Construction (General Principles). British Standards Institution: London, UK, 1987.

- BS EN 1634-3:2001; Fire Resistance Tests for Door and Shutter Assemblies—Part 3: Smoke Control Doors and Shutters. British Standards Institution: London, UK, 2001.

- BS EN 1634-1:2014+A1:2018; Fire Resistance and Smoke Control Tests for Door and Shutter Assemblies, Openable Windows and Elements of Building Hardware—Part 1: Fire Resistance Test for Door and Shutter Assemblies and Openable Windows. British Standards Institution: London, UK, 2018; p. 38.

- BS EN 13501-2:2003; Fire Classification of Construction Products and Building Elements—Part 2: Classification Using Data from Fire Resistance Tests, Excluding Ventilation Services. British Standards Institution: London, UK, 2003.

- DIN EN 1363-1:2012; Fire Resistance Tests—Part 1: General Requirements. British Standards Institution: London, UK, 2012.

- BS EN 13823:2010+A1:2014; Reaction to Fire Tests for Building Products—Building Products Excluding Floorings Exposed to the Thermal Attack by a Single Burning Item. British Standards Institution: London, UK, 2014.

- ANSI/UL 94:2014; Tests for Flammability of Plastic Materials for Parts in Devices and Appliances. American National Standards Institute: New York, NY, USA, 2014.

- BS EN 13501-4:2007+A1:2009; Fire Classification of Construction Products and Building Elements—Part 4: Classification Using Data from Fire Resistance Tests on Components of Smoke Control Systems. British Standards Institution: London, UK, 2009.

- EN ISO 1182:2020; Reaction to Fire Tests for Products—Non-Combustibility Test. International Organization for Standardization: Geneva, Switzerland, 2020.

- EN ISO 1716:2018; Reaction to Fire Tests for Products—Determination of the Gross Heat of Combustion (Calorific Value). International Organization for Standardization: Geneva, Switzerland, 2018.

- BS EN ISO 11925-2:2010; Reaction to Fire Tests—Ignitability of Products Subjected to Direct Impingement of Flame—Part 2: Single-Flame Source Test. British Standards Institution: London, UK, 2010.

- Li, X.; Yang, Z.; Yao, J.; Zhang, Y. Organic Nano-Montmorillonite for Simultaneously Improving the Flame Retardancy, Thermal Stability, and Mechanical Properties of Intumescent Flame-Retardant Silicone Rubber Composites. J. Macromol. Sci. Part B 2015, 54, 1282–1296. [Google Scholar] [CrossRef]

- Giessmann, A. Foulard technology and impregnation or double-side coating without edge coating. Coating 2008, 41, 2–5. [Google Scholar]

- Bhat, T.; Chevali, V.; Liu, X.; Feih, S.; Mouritz, A.P. Fire performance of basalt fibre composites under tensile loading. In Proceedings of the 16th European Conference on Composite Materials, ECCM 2014, Seville, Spain, 22–26 June 2014. [Google Scholar]

- Benichou, N.; Sultan, M. Fire Resistance of Lightweight Wood-Framed Assemblies: State-of-the-Art Report; Institute for Research in Construction: Ottawa, ON, Canada, 1999. [Google Scholar]

| Function | Criterion | Classification Symbol | Classification Standard | Test Standard | |

|---|---|---|---|---|---|

| Reaction to fire | Fire behavior | Fire contribution | A1–A2–B–C–D–E–F | EN 13501-1 | EN ISO 1182 EN ISO 1716 |

| Flame spread | EN ISO 11925-2 EN 13823 | ||||

| Ignitability | EN ISO 11925-2 | ||||

| Smoke production | s1–s2–s3 | EN 13823 | |||

| Flaming particles/droplets production | d0–d1–d2 | EN 13823 EN ISO 11925-2 | |||

| Fire resistance | Loadbearing capacity | R | EN 13501-2 | EN 1634-1 | |

| Integrity | E | ||||

| Thermal insulation | I | ||||

| Radiation | W | ||||

| Smoke control | Smoke leakage | Sa Sm | EN 13501-4 | EN 1634-3 | |

| Stability | D DH | EN 1634-1 | |||

| Sample | 1 | 2 | 5 | FN | 1MIX2 | 2MIX2 | 5MIX2 | FNMIX2 | |

|---|---|---|---|---|---|---|---|---|---|

| Choice | |||||||||

| Fibrous structure type | 2D-Basket weave | 2D-Basket weave | 2D-Basket weave | 3D near-net-shape | 2D-Basket weave | 2D-Basket weave | 2D-Basket weave | 3D near-net-shape | |

| Warp material | GF | GF | GF | GF | GF | GF | GF | GF | |

| Weft material | GF | BF | GF (50%) + BF (50%) | GF | GF | BF | GF (50%) + BF (50%) | GF | |

| Active material | - | - | - | SMM | - | - | - | SMM | |

| Coating applied | - | - | - | - | MIX2 | MIX2 | MIX2 | MIX2 | |

| Designation | Polymer Matrix | Inorganic Additives |

|---|---|---|

| MIX2 | WPU | Nanoclay (2–5%) + Alumina 0.3 μm (25/75) |

| Commercial Sample Designation | Fibrous Structure Type | Fabric Materials | Coating |

|---|---|---|---|

| Commercial1 | 2D Woven fabric | GF | No |

| Commercial2 | 2D Woven fabric | GF + SF | No |

| Commercial3 | 2D Woven fabric | GF + SF | Yes |

| Sample | 1 | 2 | 5 | FN | 1MIX2 | 2MIX2 | 5MIX2 | FNMIX2 | |

|---|---|---|---|---|---|---|---|---|---|

| Parameter | |||||||||

| Exposure time (s) | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | |

| Ignition of the sample | No | No | No | No | No | No | No | No | |

| Cotton ignition | No | No | No | No | No | No | No | No | |

| Flaming particles/droplets | No | No | No | No | No | No | No | No | |

| Time to reach the top (s) | - | - | - | - | - | - | - | 8 | |

| 1 | 2 | 5 | FN | 1MIX2 | 2MIX2 | 5MIX5 | FNMIX2 |

|---|---|---|---|---|---|---|---|

| 5.020 | 3.508 | 3.708 | 3.528 | 6.803 | 6.633 | 6.138 | 4.145 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cunha, D.; Fangueiro, R.; Bessa, J.; Paiva, C.; Ribeiro, D.; Silva, E.; Silveira, D.; Soares, D.; Vilarinho, C. Experimental Thermal Behavior of Fibrous Structures for High-Performance Heat Resistant Fire Curtains. Energies 2023, 16, 2426. https://doi.org/10.3390/en16052426

Cunha D, Fangueiro R, Bessa J, Paiva C, Ribeiro D, Silva E, Silveira D, Soares D, Vilarinho C. Experimental Thermal Behavior of Fibrous Structures for High-Performance Heat Resistant Fire Curtains. Energies. 2023; 16(5):2426. https://doi.org/10.3390/en16052426

Chicago/Turabian StyleCunha, Diogo, Raul Fangueiro, João Bessa, Conceição Paiva, Daniel Ribeiro, Elisabete Silva, Dionísio Silveira, Delfim Soares, and Cândida Vilarinho. 2023. "Experimental Thermal Behavior of Fibrous Structures for High-Performance Heat Resistant Fire Curtains" Energies 16, no. 5: 2426. https://doi.org/10.3390/en16052426

APA StyleCunha, D., Fangueiro, R., Bessa, J., Paiva, C., Ribeiro, D., Silva, E., Silveira, D., Soares, D., & Vilarinho, C. (2023). Experimental Thermal Behavior of Fibrous Structures for High-Performance Heat Resistant Fire Curtains. Energies, 16(5), 2426. https://doi.org/10.3390/en16052426