Methods of Measurement of Die Temperature of Semiconductor Elements: A Review

Abstract

:1. Introduction

2. Methods of Measurement of Die Temperature of Semiconductor Elements

2.1. Electrical Methods for Measuring Die Temperature

2.1.1. Description

- pulsed mode (switching methods);

- continuous mode (non-switching methods) [26].

- forward voltage VF;

- threshold voltage Vth;

- bipolar transistor current gain;

- other (e.g., resistance of the drain–source channel of the transistor RDS as a TSP).

2.1.2. Forward Voltage of the Diode as a TSP

2.1.3. Threshold Voltage of Field Effect Transistor as a TSP

2.1.4. Bipolar Transistor Current Gain as a TSP

2.1.5. Other Used TSPs

2.1.6. Summary of Electrical Methods

2.2. Contact Methods of Measurement of Die Temperature

2.2.1. Description of Contact Methods

- thermocouple;

- liquid crystals;

- thermographic phosphor;

- thermistor and thermoresistor.

2.2.2. Thermocouple

2.2.3. Liquid Crystal

2.2.4. Thermographic Phosphors

2.2.5. Thermistor and Thermoresistor

2.2.6. Summary of Contact Methods

2.3. Non-Contact Methods of Measurement of Die Temperature

2.3.1. Description

- a pyrometer or thermal imaging camera;

- thermoreflectance—a change in the value of the reflection coefficient;

- luminescence.

2.3.2. Thermographic and Pyrometric Measurement of Die Temperature

- the material from which the observed surface is made;

- the condition of the die (e.g., clean, dirty, scratched);

- the observation angle;

- the temperature of the die surface observed [69].

- microbolometer;

- detector based on Strained Layer Superlattice (SLS).

2.3.3. Thermoreflectance

2.3.4. Luminescence

2.3.5. Summary of Non-Contact Methods

3. Determination of Die Temperature Based on the Case Temperature

3.1. Die–Case Thermal Resistance

3.2. Finite Element Method

3.2.1. Natural Convection

3.2.2. Forced Convection

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Joglekar, C.; Mortimer, B.; Ponci, F.; Monti, A.; De Doncker, R.W. SST-Based Grid Reinforcement for Electromobility Integration in Distribution Grids. Energies 2022, 15, 3202. [Google Scholar] [CrossRef]

- Alghaythi, M.L.; O’Connell, R.M.; Islam, N.E.; Guerrero, J.M. A multiphase-interleaved high step-up DC-DC boost converter with voltage multiplier and reduced voltage stress on semiconductors for renewable energy systems. In Proceedings of the IEEE Power & Energy Society Innovative Smart Grid Technologies Conference (ISGT), Washington, DC, USA, 17–20 February 2020. [Google Scholar] [CrossRef]

- Nikolic, M.V.; Milovanovic, V.; Vasiljevic, Z.Z.; Stamenkovic, Z. Semiconductor Gas Sensors: Materials, Technology, Design, and Application. Sensors 2020, 20, 6694. [Google Scholar] [CrossRef] [PubMed]

- Bhalerao, S.R.; Lupo, D.; Berger, P.R. Flexible, solution-processed, indium oxide (In2O3) thin film transistors (TFT) and circuits for internet-of-things (IoT). Mater. Sci. Semicond. Process. 2022, 139, 106354. [Google Scholar] [CrossRef]

- Kalsoom, T.; Ramzan, N.; Ahmed, S.; Ur-Rehman, M. Advances in Sensor Technologies in the Era of Smart Factory and Industry 4.0. Sensors 2020, 20, 6783. [Google Scholar] [CrossRef]

- Sasaki, M.; Ikeda, M.; Asada, K. A Temperature Sensor With an Inaccuracy of −1/+0.8 °C Using 90-nm 1-V CMOS for Online Thermal Monitoring of VLSI Circuits. IEEE Trans. Semicond. Manuf. 2008, 21, 201–208. [Google Scholar] [CrossRef]

- Sun, L.; Shi, Z.; Wang, H.; Zhang, K.; Dastan, D.; Sun, K.; Fan, R. Ultrahigh discharge efficiency and improved energy density in rationally designed bilayer polyetherimide–BaTiO 3/P (VDF-HFP) composites. J. Mater. Chem. A 2020, 8, 5750–5757. [Google Scholar] [CrossRef]

- Minh, Q.N.; Nguyen, V.-H.; Quy, V.K.; Ngoc, L.A.; Chehri, A.; Jeon, G. Edge Computing for IoT-Enabled Smart Grid: The Future of Energy. Energies 2022, 15, 6140. [Google Scholar] [CrossRef]

- Martins, L.S.; Guimarães, L.F.; Junior, A.B.B.; Tenório, J.A.S.; Espinosa, D.C.R. Electric car battery: An overview on global demand, recycling and future approaches towards sustainability. J. Environ. Manag. 2021, 295, 113091. [Google Scholar] [CrossRef]

- Bu, Z.; Zhang, X.; Hu, Y.; Chen, Z.; Lin, S.; Li, W.; Xiao, C.; Pei, Y. A record thermoelectric efficiency in tellurium-free modules for low-grade waste heat recovery. Nat. Commun. 2022, 13, 237. [Google Scholar] [CrossRef]

- Jacques, S.; Diack, P.M.; Batut, N.; Leroy, R.; Gonthier, L. Rise time and dwell time impact on Triac solder joints lifetime during power cycling. In Proceedings of the 27th International Conference on Microelectronics Proceedings, Nis, Serbia, 16–19 May 2010. [Google Scholar] [CrossRef]

- Recommendations for Board Assembly of Infineon Transistor Outline Type Packages. Available online: https://www.infineon.com/dgdl/InfineonRecommendations_for_Board_Assembly_TO-P-v03_00-EN.pdf?fileId=5546d462580663ef0158069840880338 (accessed on 5 December 2022).

- Bhol, K.; Jena, B.; Nanda, U. Silicon nanowire GAA-MOSFET: A workhorse in nanotechnology for future semiconductor devices. Silicon 2022, 14, 3163–3171. [Google Scholar] [CrossRef]

- Ramkumar, M.S.; Priya, R.; Rajakumari, R.F.; Valsalan, P.; Chakravarthi, M.K.; Latha, G.; Mathupriya, S.; Rajan, K. Review and Evaluation of Power Devices and Semiconductor Materials Based on Si, SiC, and Ga-N. J. Nanomater. 2022, 2022, 8648284. [Google Scholar] [CrossRef]

- Hashimoto, T.; Letts, E.R.; Key, D. Progress in Near-Equilibrium Ammonothermal (NEAT) Growth of GaN Substrates for GaN-on-GaN Semiconductor Devices. Crystals 2022, 12, 1085. [Google Scholar] [CrossRef]

- Niu, H. A review of power cycle driven fatigue, aging, and failure modes for semiconductor power modules. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017. [Google Scholar] [CrossRef]

- Nol Chen, J.; Zhang, X. Prediction of thermal conductivity and phonon spectral of silicon material with pores for semiconductor device. Phys. B Condens. Matter 2021, 614, 413034. [Google Scholar] [CrossRef]

- Moore, A.L.; Shi, L. Emerging challenges and materials for thermal management of electronics. Mater. Today 2014, 17, 163–174. [Google Scholar] [CrossRef]

- Górecki, K.; Posobkiewicz, K. Cooling Systems of Power Semiconductor Devices—A Review. Energies 2022, 15, 4566. [Google Scholar] [CrossRef]

- Balda, J.C.; Mantooth, A. Power-Semiconductor Devices and Components for New Power Converter Developments: A key enabler for ultrahigh efficiency power electronics. IEEE Power Electron. Mag. 2016, 3, 53–56. [Google Scholar] [CrossRef]

- Bercu, N.; Lazar, M.; Simonetti, O.; Adam, P.M.; Brouillard, M.; Giraudet, L. KPFM-Raman Spectroscopy Coupled Technique for the Characterization of Wide Bandgap Semiconductor Devices. Mater. Sci. Forum 2022, 1062, 330–334. [Google Scholar] [CrossRef]

- Avenas, Y.; Dupont, L.; Khatir, Z. Temperature measurement of power semiconductor devices by thermo-sensitive electrical parameters—A review. IEEE Trans. Power Electron. 2011, 27, 3081–3092. [Google Scholar] [CrossRef] [Green Version]

- Abad, B.; Borca-Tasciuc, D.A.; Martin-Gonzalez, M.S. Non-contact methods for thermal properties measurement. Renew. Sustain. Energy Rev. 2017, 76, 1348–1370. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, S.; Lu, G.Q.; Mei, Y.H. Reliability Behavior of A Resin-Free Nanosilver Paste at Ultra-Low Temperature of 180 °C. Power Electron. Devices Compon. 2022, 3, 100014. [Google Scholar] [CrossRef]

- JESD 51-53. Available online: https://www.jedec.org (accessed on 5 December 2022).

- Blackburn, D.L. A Review of Thermal Characterization of Power Transistors. In Proceedings of the 4th Annual IEEE Semiconductor Thermal and Temperature Measurement Symposium, San Diego, CA, USA, 6 August 2002. [Google Scholar] [CrossRef]

- Baliga, J. Modern Power Devices; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 1987. Available online: https://www.osti.gov/biblio/6719122 (accessed on 5 December 2022).

- Poppe, A.; Farkas, G.; Gaál, L.; Hantos, G.; Hegedüs, J.; Rencz, M. Multi-Domain Modelling of LEDs for Supporting Virtual Prototyping of Luminaires. Energies 2019, 12, 1909. [Google Scholar] [CrossRef] [Green Version]

- Khatir, Z. Junction Temperature Investigations Based on a General Semi-analytical Formulation of Forward Voltage of Power Diodes. IEEE Trans. Electron Devices 2012, 59, 1716–1722. [Google Scholar] [CrossRef]

- Sun, Q.J.; Gao, X.; Wang, S.D. Understanding temperature dependence of threshold voltage in pentacene thin film transistors. J. Appl. Phys. 2013, 113, 194506. [Google Scholar] [CrossRef]

- Yang, E.S.; Yang, Y.F.; Hsu, C.C.; Ou, H.J.; Lo, H.N. Temperature dependence of current gain of GaInP/GaAs heterojunction and heterostructure-emitter bipolar transistors. IEEE Trans. Electron Devices 1999, 46, 320–323. [Google Scholar] [CrossRef] [Green Version]

- Threshold Voltahe Data Analysis. Available online: https://electronics.stackexchange.com/questions/333725/threshold-voltage-data-analysis (accessed on 5 December 2022).

- Barlini, D.; Ciappa, M.; Mermet-Guyennet, M.; Fichtner, W. Measurement of the transient junction temperature in MOSFET devices under operating conditions. Microelectron. Reliab. 2007, 47, 1707–1712. [Google Scholar] [CrossRef]

- Koenig, A.; Plum, T.; Fidler, P.; De Doncker, R. On-line Junction Ternperature Measurernent of CoolMOS Devices, Power Electronics and Drive Systems. In Proceedings of the 7th International Conference on Power Electronics and Drive Systems, Bangkok, Thailand, 27–30 November 2007. [Google Scholar] [CrossRef]

- Yan, D.; Ma, D.B. A Monolithic GaN Power IC With On-Chip Gate Driving, Level Shifting, and Temperature Sensing, Achieving Direct 48-V/1-V DC–DC Conversion. IEEE J. Solid State Circuits 2022, 57, 3865–3876. [Google Scholar] [CrossRef]

- Lv, Y.; Yin, S.; Liu, Y.; Li, Z.; Li, P.; Sun, X.; Chen, J.; Yang, Z.; Yuan, J. Continuously Geometric Phase Modulation by using a reflective liquid crystal structure. Opt. Commun. 2022, 509, 127847. [Google Scholar] [CrossRef]

- Soldati, A.; Delmonte, N.; Cova, P.; Concari, C. Device-Sensor Assembly FEA Modeling to Support Kalman-Filter-Based Junction Temperature Monitoring. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 1736–1747. [Google Scholar] [CrossRef]

- Salem, T.E.; Ibitayo, D.; Geil, B.R. A Technique for Die Surface Temperature Measurement of High-Voltage Power Electronic Components using Coated Thermocouple Probes. In Proceedings of the 2006 IEEE Instrumentation and Measurement Technology Conference Proceedings, Sorrento, Italy, 24–27 April 2006. [Google Scholar] [CrossRef]

- Weil, E.D.; Levchik, S. A review of current flame retardant systems for epoxy resins. J. Fire Sci. 2004, 22, 25–40. [Google Scholar] [CrossRef]

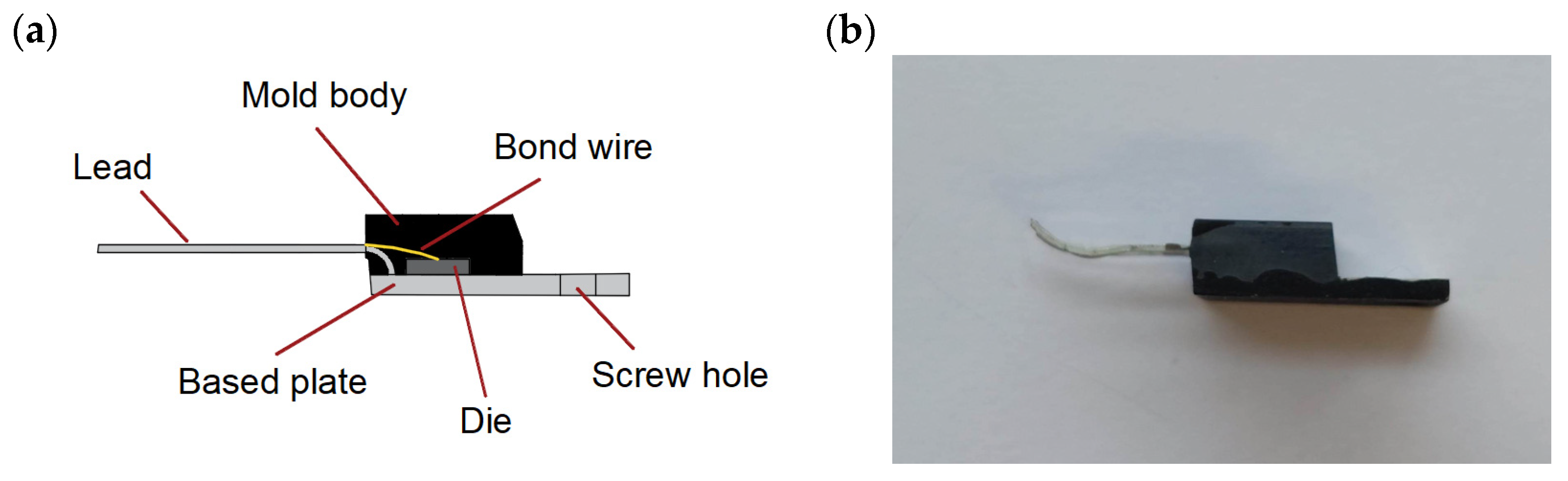

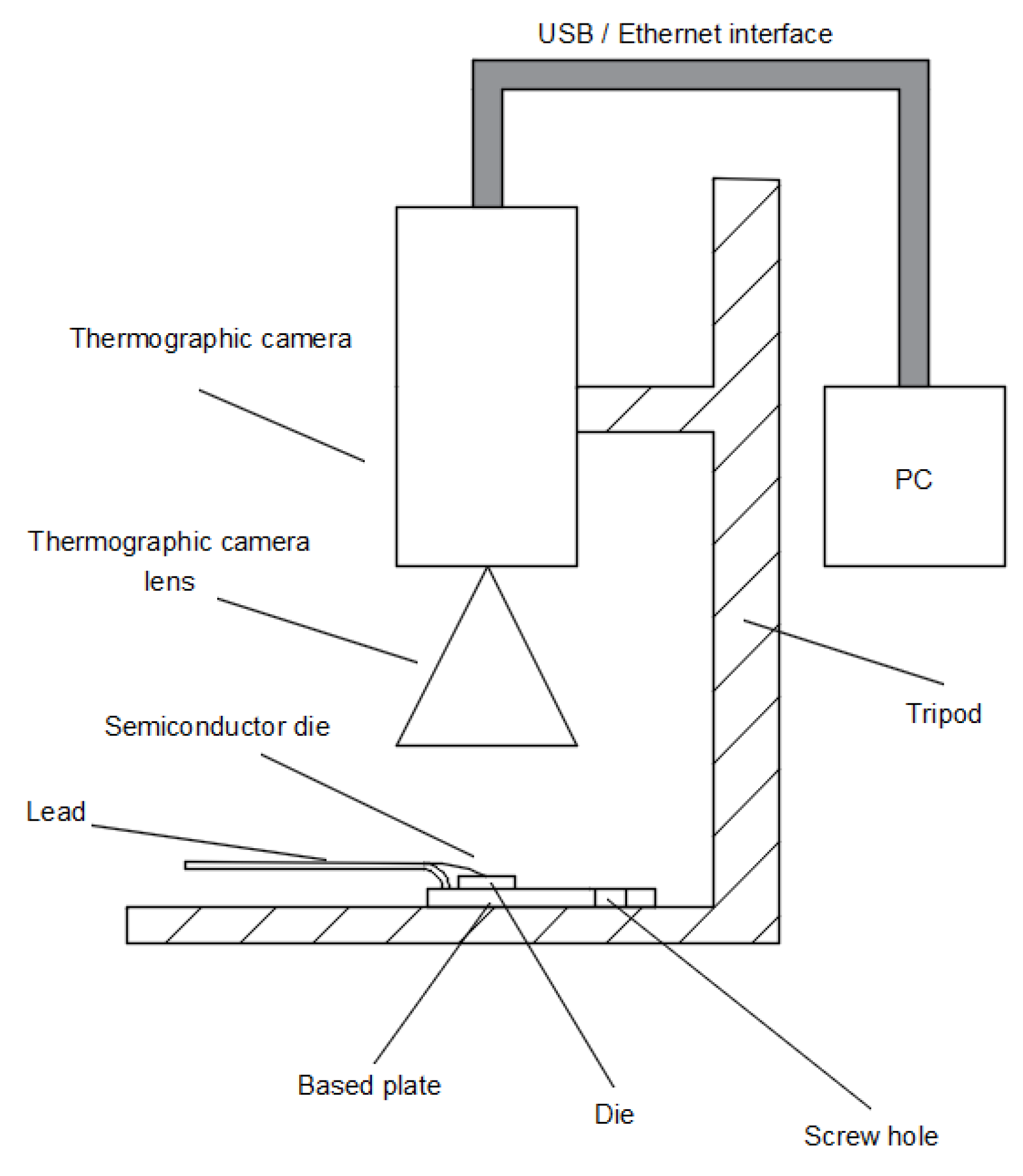

- Dziarski, K.; Hulewicz, A.; Dombek, G.; Drużyński, Ł. Indirect Thermographic Temperature Measurement of a Power-Rectifying Diode Die. Energies 2022, 15, 3203. [Google Scholar] [CrossRef]

- Jeon, J.G.; Kim, H.J.; Shin, G.; Han, Y.; Kim, J.H.; Lee, J.H.; Lee, J.; Lim, H.; Ha, S.; Bae, M.; et al. High-Precision Ionic Thermocouples Fabricated Using Potassium Ferri/Ferrocyanide and Iron Perchlorate. Adv. Electron. Mater. 2022, 8, 2100693. [Google Scholar] [CrossRef]

- Lima, H.V.; Campidelli, A.F.; Maia, A.A.; Abrão, A.M. Temperature assessment when milling AISI D2 cold work die steel using tool-chip thermocouple, implanted thermocouple and finite element simulation. Appl. Therm. Eng. 2018, 143, 532–541. [Google Scholar] [CrossRef]

- Srodit, G.; Szabon, J.; Janossy, I.; Azekely, V. High Resolution Thermal Mapping of Microcircuits Using Nematic Liquid Crystals. Solid State Electron. 1981, 24, 1127–1133. [Google Scholar] [CrossRef]

- Popov, V.M.; Klimenko, A.S.; Pokanevich, A.P.; Gavrilyuk, I.I.; Moshel, N.V. Liquid-crystal thermography of hot spots on electronic components. Russ. Microelectron. 2007, 36, 392–401. [Google Scholar] [CrossRef]

- Park, J.H.; Lee, C.C. A new configuration of nematic liquid crystal thermography with applications to GaN-based devices. IEEE Trans. Instrum. Meas. 2006, 55, 273–279. [Google Scholar] [CrossRef]

- Fleuren, E.M. A Very Sensitive and Simple Analytic Technique Using Nematic Liquid Crystals. In Proceedings of the 21st Annual International Reliability Physics Symposium, Phoenix, AZ, USA; 1983; pp. 148–149. [Google Scholar]

- Lee, C.C.; Park, J. Temperature measurement of visible light-emitting diodes using nematic liquid crystal thermography with laser illumination. IEEE Photonics Technol. Lett. 2004, 16, 1706–1708. [Google Scholar] [CrossRef]

- Burgess, D.; Tan, R. Improved Sensitivity for Hot Spot Detection Using Liquid Crystal. In Proceedings of the 22nd Annual Reliability Physics Symposium, Las Vegas, NV, USA, 3–5 April 1984; pp. 119–121. [Google Scholar] [CrossRef]

- Hiatt, J.A. A Method for Detection of Hot Spots on Semiconductors Using Liquid Crystals. In Proceeding of the 19th Annual Reliability Physics Symposium, Orlando, FL, USA, 7–9 April 1981; pp. 130–133. [Google Scholar] [CrossRef]

- Aldén, M.; Omrane, A.; Richter, M.; Särner, G. Thermographic phosphors for thermometry: A survey of combustion applications. Prog. Energy Combust. Sci. 2011, 37, 422–461. [Google Scholar] [CrossRef]

- Brübach, J.; Pflitsch, C.; Dreizler, A.; Atakan, B. On surface temperature measurements with thermographic phosphors: A review. Prog. Energy Combust. Sci. 2013, 39, 37–60. [Google Scholar] [CrossRef]

- A Simple Thermistor Design for Industrial Temperature Measurement. Available online: http://repository.futminna.edu.ng:8080/jspui/handle/123456789/10291 (accessed on 5 December 2022).

- SIMOTICS GP/SD/DP/XP Low-Voltage Motors—1LE1 Platform Release for Sale and Delivery: Product Has Been Extended to Include Pt1000 Resistance Thermometer. Available online: https://support.industry.siemens.com/cs/document/109741861/simotics-gp-sd-dp-xp-low-voltage-motors-%E2%80%93-1le1-platform-release-for-sale-and-delivery-product-has-been-extended-to-include-pt1000-resistance-thermometer-?dti=0&lc=en-AT (accessed on 5 December 2022).

- Emaikwu, N.; Catalini, D.; Muehlbauer, J.; Hwang, Y.; Takeuchi, I.; Radermacher, R. Experimental investigation of a staggered-tube active elastocaloric regenerator. Int. J. Refrig. 2022. [Google Scholar] [CrossRef]

- Yen Kee, Y.; Asako, Y.; Lit Ken, T.; Che Sidik, N.A. Uncertainty of Temperature measured by Thermocouple. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 68, 54–62. [Google Scholar] [CrossRef]

- Moller, S.; Resagk, C.; Cierpka, C. On the application of neural networks for temperature field measurements using thermochromic liquid crystals. Exp. Fluids 2020, 61, 111. [Google Scholar] [CrossRef] [Green Version]

- Cai, T.; Li, Y.; Guo, S.; Peng, D.; Zhao, X.; Liu, Y. Pressure effect on phosphor thermometry using Mg4FGeO6:Mn. Meas. Sci. Technol. 2019, 30, 027001. [Google Scholar] [CrossRef]

- Platinum Temperature Sensor PT1000-55—Data Sheet. Available online: https://www.tme.eu/Document/67cf717905f835bc5efcdcd56ca3a8e2/Pt1000-550_EN.pdf (accessed on 18 January 2023).

- Temperature Sensors Pt100/Pt1000 Series—Technical Data. Available online: http://www.image.micros.com.pl/_dane_techniczne_auto/cz%20pt1000-4x32b%20ii.pdf (accessed on 18 January 2023).

- Thermistor Thermal Resolution—PDF. Available online: https://www.pdffiller.com/jsfiller-desk11/?requestHash=0ad693dd27755969522e5d1dd32d20714f957bf6b310e8966402229ae42ecc79&projectId=1193607408&loader=tips&MEDIUM_PDFJS=true&PAGE_REARRANGE_V2_MVP=true&isPageRearrangeV2MVP=true#1fe3cca8891a4c83b3a27c2c60c28ffe (accessed on 18 January 2023).

- NTC Thermistors—Application Note. Available online: https://www.vishay.com/docs/29053/ntcappnote.pdf (accessed on 18 January 2023).

- Hulewicz, A.; Dziarski, K.; Dombek, G. The Solution for the Thermographic Measurement of the Temperature of a Small Object. Sensors 2021, 21, 5000. [Google Scholar] [CrossRef]

- Minkina, W.; Dudzik, S. Infrared Thermography: Errors and Uncertainties; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Legierski, J.; Wiecek, B. Steady state analysis of cooling electronic circuits using heat pipes. IEEE Trans. Compon. Packag. Technol. 2001, 24, 549–553. [Google Scholar] [CrossRef]

- Dziarski, K.; Hulewicz, A.; Dombek, G. Lack of Thermogram Sharpness as Component of Thermographic Temperature Measurement Uncertainty Budget. Sensors 2021, 21, 4013. [Google Scholar] [CrossRef]

- Felczak, M.; Więcek, B.; De Mey, G. Optimal placement of electronic devices in forced convective cooling conditions. Microelectron. Reliab. 2009, 49, 1537–1545. [Google Scholar] [CrossRef]

- Santamaría-Holek, I.; Pérez-Madrid, A. Scaling Planck’s law: A unified approach to the Casimir effect and radiative heat-conductance in nanogaps. Nanoscale Horiz. 2022, 7, 526–532. [Google Scholar] [CrossRef]

- Zampoli, V.; Jordan, P.M. Second-sound phenomena in type II conductors with Stefan–Boltzmann source. Mech. Res. Commun. 2022, 126, 103998. [Google Scholar] [CrossRef]

- Litwa, M. Influence of angle of view on temperature measurements using thermovision camera. IEEE Sens. J. 2010, 10, 1552–1554. [Google Scholar] [CrossRef]

- Ajmera, S.K.; Syllaios, A.J.; Tyber, G.S.; Taylor, M.F.; Hollingsworth, R.E. Amorphous silicon thin-films for uncooled infrared microbolometer sensors. In Proceedings of the Infrared Technology and Applications XXXVI, Orlando, FL, USA, 5–9 April 2010. [Google Scholar] [CrossRef]

- Yadav, P.K.; Yadav, I.; Ajitha, B.; Rajasekar, A.; Gupta, S. Reddy, Advancements of Uncooled Infrared Microbolometer Materials: A Review. Sens. Actuators A Phys. 2022, 342, 113611. [Google Scholar] [CrossRef]

- Dufour, D.; Le Noc, L.; Tremblay, B.; Tremblay, M.N.; Généreux, F.; Terroux, M.; Vachon, C.; Wheatley, M.J.; Johnston, J.M.; Wotton, M.; et al. Bi-Spectral Microbolometer Sensor for Wildfire Measurement. Sensors 2021, 21, 3690. [Google Scholar] [CrossRef] [PubMed]

- Optris Xi 400. Available online: https://www.optris.global/optris-xi-400?gclid=Cj0KCQiAyracBhDoARIsACGFcS6QywUcVtRWJEML-YW59PMjbauQd65cIBKpFHuxnjYOj37Mq3LMuGsaAmvKEALw_wcB (accessed on 5 December 2022).

- Gurga, A.R.; Nosho, B.Z.; Terterian, S.; Wang, S.; Rajavel, R.D. Dual-band MWIR/LWIR focal plane arrays based on III-V strained-layer superlattices. In Proceedings of the Infrared Technology and Applications XLIV, Orlando, FL, USA, 15–19 April 2018. [Google Scholar] [CrossRef]

- The Advantages of LWIR SLS Thermal Cameras. Available online: http://www.flirmedia.com/MMC/THG/Brochures/RND_077/RND_077_US.pdf (accessed on 5 December 2022).

- Zaccara, M.; Edelman, J.B.; Cardone, G. A general procedure for infrared thermography heat transfer measurements in hypersonic wind tunnels. Int. J. Heat Mass Transf. 2020, 163, 120419–120435. [Google Scholar] [CrossRef]

- Altenburg, S.J.; Straße, A.; Gumenyuk, A.; Maierhofer, C. In-situ monitoring of a laser metal deposition (LMD) process: Comparison of MWIR, SWIR and high-speed NIR thermography. Quant. InfraRed Thermogr. J. 2020, 19, 97–114. [Google Scholar] [CrossRef]

- Yoon, S.T.; Park, J.C. An experimental study on the evaluation of temperature uniformity on the surface of a blackbody using infrared cameras. Quant. InfraRed Thermogr. J. 2021, 19, 172–186. [Google Scholar] [CrossRef]

- Schuss, C.; Remes, K.; Leppänen, K.; Saarela, J.; Fabritius, T.; Eichberger, B.; Rahkonen, T. Detecting Defects in Photovoltaic Cells and Panels with the Help of Time-Resolved Thermography under Outdoor Environmental Conditions. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Chakraborty, B.; Sinha, B.K. Process-integrated steel ladle monitoring, based on infrared imagin—A robust approach to avoid ladle breakout. Quant. InfraRed Thermogr. J. 2020, 17, 169–191. [Google Scholar] [CrossRef]

- Tomoyuki, T. Coaxiality Evaluation of Coaxial Imaging System with Concentric Silicon–Glass Hybrid Lens for Thermal and Color Imaging. Sensors 2020, 20, 5753. [Google Scholar] [CrossRef]

- Wollack, J.E.; Cataldo, G.; Miller, K.H.; Quijada, A.M. Infrared properties of high-purity silicon. Opt. Lett. 2020, 45, 4935–4938. [Google Scholar] [CrossRef]

- Dziarski, K. Selection of the Observation Angle in Thermography Temperature Measurements with the Use of a Macro Lens. In Proceedings of the 13th International Conference on Measurement, Bratislava, Slovakia, 17–19 May 2021. [Google Scholar] [CrossRef]

- Dziarski, K.; Hulewicz, A. Effect of unsharpness on the result of thermovision diagnostics of electronic components. In Proceedings of the 15th Quantitative InfraRed Thermography Conference, Porto, Portugal, 6–10 July 2020. [Google Scholar] [CrossRef]

- Minkina, W.; Klecha, D. Atmospheric transmission coefficient modelling in the infrared for thermovision measurement. J. Sens. Sens. Syst. 2016, 5, 17–23. [Google Scholar] [CrossRef] [Green Version]

- Dziarski, K.; Hulewicz, A. Uncertainty of Thermographic Temperature Measurement of Electric Units Contained in Switchgear. Pomiary Autom. Robot. 2021, 25, 31–36. [Google Scholar] [CrossRef]

- Wang, D.; Zheng, L.; Si, W.; Yang, H.; Gao, Y. Thermal Analysis of High-Power Light-Emitting Diode Using Thermoreflectance Thermography. In Proceedings of the 2021 22nd International Conference on Electronic Packaging Technology (ICEPT), Xiamen, China, 14–17 September 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Thermo-Reflectance Thermography for Submicron Temperature Measurements. Available online: https://www.electronics-cooling.com/2008/02/thermo-reflectance-thermography-for-submicron-temperature-measurements/ (accessed on 18 January 2023).

- Blackburn, D.L. Temperature measurements of semiconductor devices—A review. In Proceedings of the Twentieth Annual IEEE Semiconductor Thermal Measurement and Management Symposium (IEEE Cat. No.04CH37545), San Jose, CA, USA, 11 March 2004; pp. 70–80. [Google Scholar] [CrossRef]

- González-Aguilera, D.; Rodriguez-Gonzalvez, P.; Armesto, J.; Lagüela, S. Novel approach to 3D thermography and energy efficiency evaluation. Energy Build. 2012, 54, 436–443. [Google Scholar] [CrossRef]

- Sensors, S. Infrared Camera Accuracy and Uncertainty in Plain Language. Available online: https://www.fierceelectronics.com/components/infrared-camera-accuracy-and-uncertainty-plain-language (accessed on 18 January 2023).

- Pyrometer Testing and Heat Measurements. Available online: https://www.govinfo.gov/content/pkg/GOVPUB-C13-37e7fd57919420ec99a37e4d43a952f3/pdf/GOVPUB-C13-37e7fd57919420ec99a37e4d43a952f3.pdf (accessed on 18 January 2023).

- Koskelo, E.; Radunskaya, A.; Hudgings, J. Using noise to stochastically enhance the resolution of charge coupled device based thermoreflectance imaging. J. Appl. Phys. 2020, 128, 104502. [Google Scholar] [CrossRef]

- Wang, J.; Xie, Z.; Che, X. Development of a Novel Pyrometer by Eliminating the Uncertainty of Emissivity Using Reflector with Two Apertures in Medium Plate Rolling Process. Actuators 2022, 11, 188. [Google Scholar] [CrossRef]

- Infrared Camera Accuracy and Uncertainty in Plain Language. Available online: https://www.flir.com/discover/rd-science/infrared-camera-accuracy-and-uncertainty-in-plain-language/ (accessed on 18 January 2023).

- Kopeć, M.; Więcek, B. AC temperature estimation of power electronic devices using 1D thermal modeling and IR thermography measurements. In Proceedings of the 15th Quantitative InfraRed Thermography Conference, Porto, Portugal, 20–23 September 2020; Available online: https://qirt.gel.ulaval.ca/archives/qirt2020/papers/161.pdf (accessed on 18 January 2023).

- Incropera, F.; De Witt, D. Introduction to Heat Transfer; Wiley: New York, NY, USA, 1985; Available online: https://scirp.org/reference/referencespapers.aspx?referenceid=1503886 (accessed on 5 December 2022).

- JESD 51-14. Available online: https://www.jedec.org/standards-documents, (accessed on 11 February 2023).

- Schweitzer, D.; Pape, H.; Chen, L.; Kutscherauer, R.; Walder, M. Transient dual interface measurement—A new JEDEC standard for the measurement of the junction-to-case thermal resistance. In Proceedings of the 2011 27th Annual IEEE Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 20–24 March 2011; pp. 222–229. [Google Scholar] [CrossRef]

- Schweitzer, D.; Pape, H.; Chen, L. Transient measurement of the junction-to-case thermal resistance using structure functions: Chances and limits. In Proceedings of the 2008 Twenty-Fourth Annual IEEE Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 16–20 March 2008. [Google Scholar] [CrossRef]

- Górecki, K.; Ptak, P. New Method of Measurements Transient Thermal Impedance and Radial Power of Power LEDs. IEEE Trans. Instrum. Meas. 2020, 69, 1. [Google Scholar] [CrossRef]

- Górecki, P.; Górecki, K.; Kisiel, R.; Myśliwiec, M. Thermal Parameters of Monocrystalline GaN Schottky Diodes. IEEE Trans. Electron Devices 2019, 66, 5. [Google Scholar] [CrossRef]

- Górecki, K.; Zarębski, J.; Górecki, P.; Ptak, P. Compact thermal models of semiconductor devices: A Review. Int. J. Electron. Telecommun. 2019, 65, 151–158. [Google Scholar] [CrossRef]

- Górecki, P.; Górecki, K. Measurements and Computations of Internal Temperatures of the IGBT and the Diode Situated in the Common Case. Electronics 2021, 10, 210. [Google Scholar] [CrossRef]

- Górecki, P.; Wojciechowski, D. Accurate Computation of IGBT Junction Temperature in PLECS. IEEE Trans. Electron. Devices 2020, 67, 7. [Google Scholar] [CrossRef]

- Devloo, P.R.B.; Bravo, C.M.A.A.; Rylo, E.C. Systematic and generic construction of shape functions for p-adaptive meshes of multidimensional finite elements. Comput. Methods Appl. Mech. Eng. 2009, 198, 1716–1725. [Google Scholar] [CrossRef]

- Staton, D.A.; Cavagnino, A. Convection heat transfer and flow calculations suitable for electric machines thermal models. IEEE Trans. Ind. Electron. 2008, 55, 3509–3516. [Google Scholar] [CrossRef] [Green Version]

- Ghahfarokhi, P.S. Determination of Forced Convection Coefficient over a Flat Side of Coil. In Proceedings of the 2017 IEEE 58th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 12–13 October 2017. [Google Scholar] [CrossRef]

- Aminu, Y.; Ballikaya, S. Thermal resistance analysis of trapezoidal concentrated photovoltaic–Thermoelectric systems. Energy Convers. Manag. 2021, 250, 114908. [Google Scholar] [CrossRef]

- Garcia-Gutierrez, L.M.; Hernández-Jiménez, F.; Cano-Pleite, E.; Soria-Verdugo, A. Experimental evaluation of the convection heat transfer coefficient of large particles moving freely in a fluidized bed reactor. Int. J. Heat Mass Transf. 2020, 153, 119612. [Google Scholar] [CrossRef]

- Omer, K.; Butcher, C.; Worswick, M. Characterization of heat transfer coefficient for non-isothermal elevated temperature forming of metal alloys. Int. J. Mater. Form. 2020, 13, 177–201. [Google Scholar] [CrossRef]

- Flir E-Series Thermographic Cameras. Available online: https://www.flirmedia.com/MMC/THG/Brochures/IND_002/IND_002_EN.pdf (accessed on 18 January 2023).

- Flir a8580 Thermographic Camera. Available online: https://www.flir.com/products/a8580-sls/ (accessed on 18 January 2023).

- Flir x6980 Thermographic Camera. Available online: https://www.flir.com/products/x6980-sls/?vertical=rd+science&segment=solutions (accessed on 18 January 2023).

| Methods | Thermal Resolution | Uncertainty | Advantage | Disadvantage |

|---|---|---|---|---|

| Thermocouple | 0.5 °C [54] | 0.42 °C [55] | High resolution | Electric shock, difficulty of temperature measurement of semiconductor die during semiconductor operation |

| Liquid Crystal | A few degrees Celsius [56] | nd | Possible temperature mapping | |

| Thermographic Phosphor | 0.1 °C 1 [57] | nd | Possible temperature mapping | |

| Thermoresistor | 0.01 °C [58] | 1.8 °C [59] | High resolution | |

| Thermistor | ~1 °C [60] | 2.0 °C [61] | High resolution |

| Methods | Thermal Resolution | Accuracy | Advantage | Disadvantage |

|---|---|---|---|---|

| Thermographic | 0.1 [90] | 1 °C [91,92] | High resolution, possible temperature mapping | High cost of thermographic camera, strong environmental impact |

| Pyrometric | 0.1 [93] | 2 °C [94] | High resolution, possible temperature mapping | Strong environmental impact |

| Thermoreflectance | 0.01 [95] | Nd | No risk of electric shock, high resolution | Difficult to use outside laboratory |

| Luminescence | 1.0 [96] | Nd | No risk of electric shock, high resolution | Experimental method |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dziarski, K.; Hulewicz, A.; Kuwałek, P.; Wiczyński, G. Methods of Measurement of Die Temperature of Semiconductor Elements: A Review. Energies 2023, 16, 2559. https://doi.org/10.3390/en16062559

Dziarski K, Hulewicz A, Kuwałek P, Wiczyński G. Methods of Measurement of Die Temperature of Semiconductor Elements: A Review. Energies. 2023; 16(6):2559. https://doi.org/10.3390/en16062559

Chicago/Turabian StyleDziarski, Krzysztof, Arkadiusz Hulewicz, Piotr Kuwałek, and Grzegorz Wiczyński. 2023. "Methods of Measurement of Die Temperature of Semiconductor Elements: A Review" Energies 16, no. 6: 2559. https://doi.org/10.3390/en16062559

APA StyleDziarski, K., Hulewicz, A., Kuwałek, P., & Wiczyński, G. (2023). Methods of Measurement of Die Temperature of Semiconductor Elements: A Review. Energies, 16(6), 2559. https://doi.org/10.3390/en16062559