Three-Pond Model with Fuzzy Inference System-Based Water Level Regulation Scheme for Run-of-River Hydropower Plant

Abstract

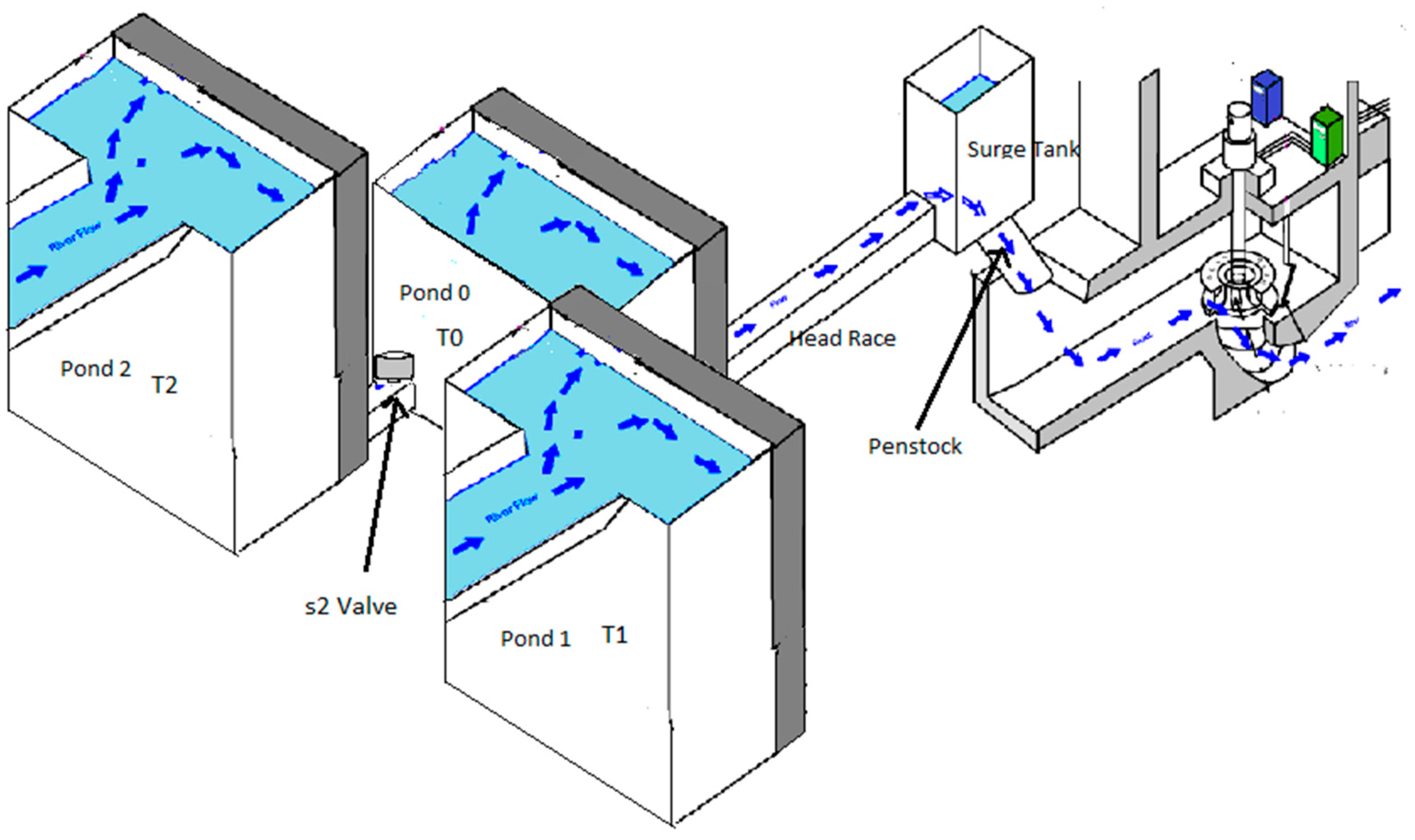

:1. Introduction

- New Three-Pond Model instead of traditional single-pond model.

- Formulation of its control system

- The proposed system is more robust against disturbances when compared to a traditional system.

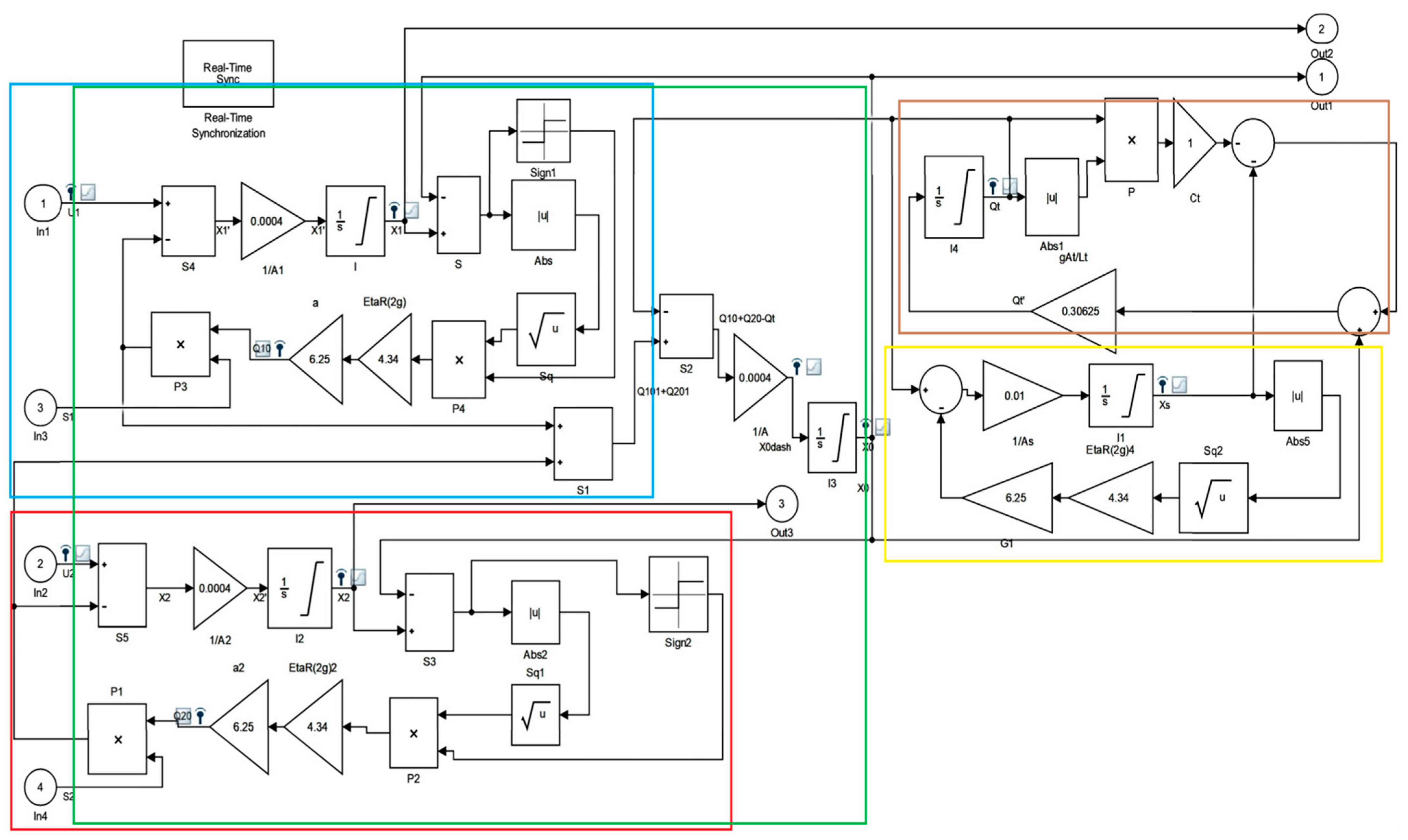

2. System Model

3. Control Design

Fuzzy Control

| Algorithm 1. Simplified pseudo code for Fuzzy System 1 controlling levels of Pond 1 and 0. |

| 1: Start 2: Take required pond levels 3:Check level of pond 1 and 0 4: IF (Pond levels are lower than required level) Increase the value of inflow U1 and Hold valve S1 5: ELSE IF (The pond level is greater the required level) 6:Stop the inflow U1 and increase the position of S1 7: ELSE IF (The ponds levels are same as required level) 8: Decreased U1 and S1 until inflow and outflow is balanced 9: Hold the position of U1 and S1 10: END IF 11: Repeat steps 1 to 10 12: Stop |

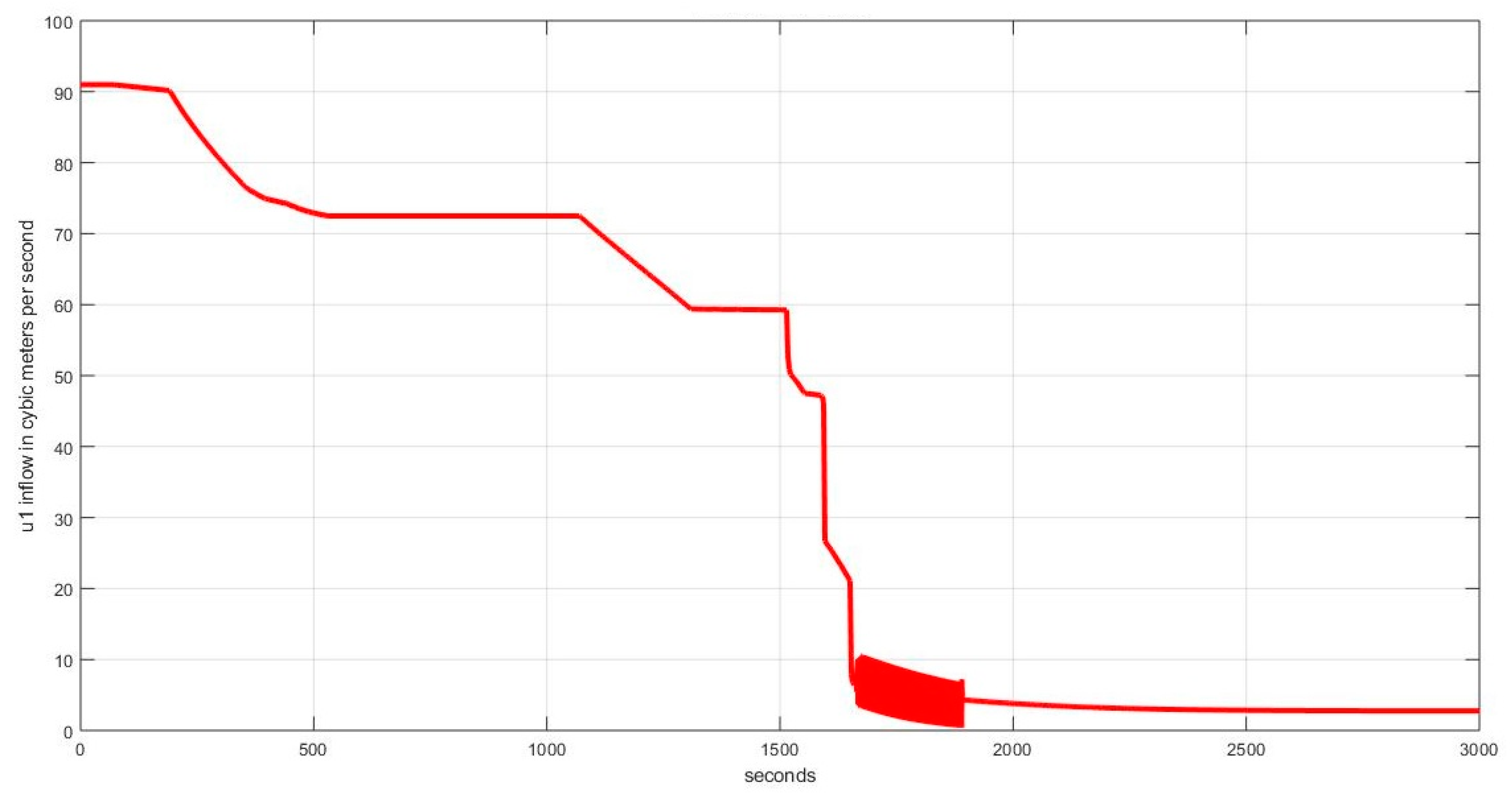

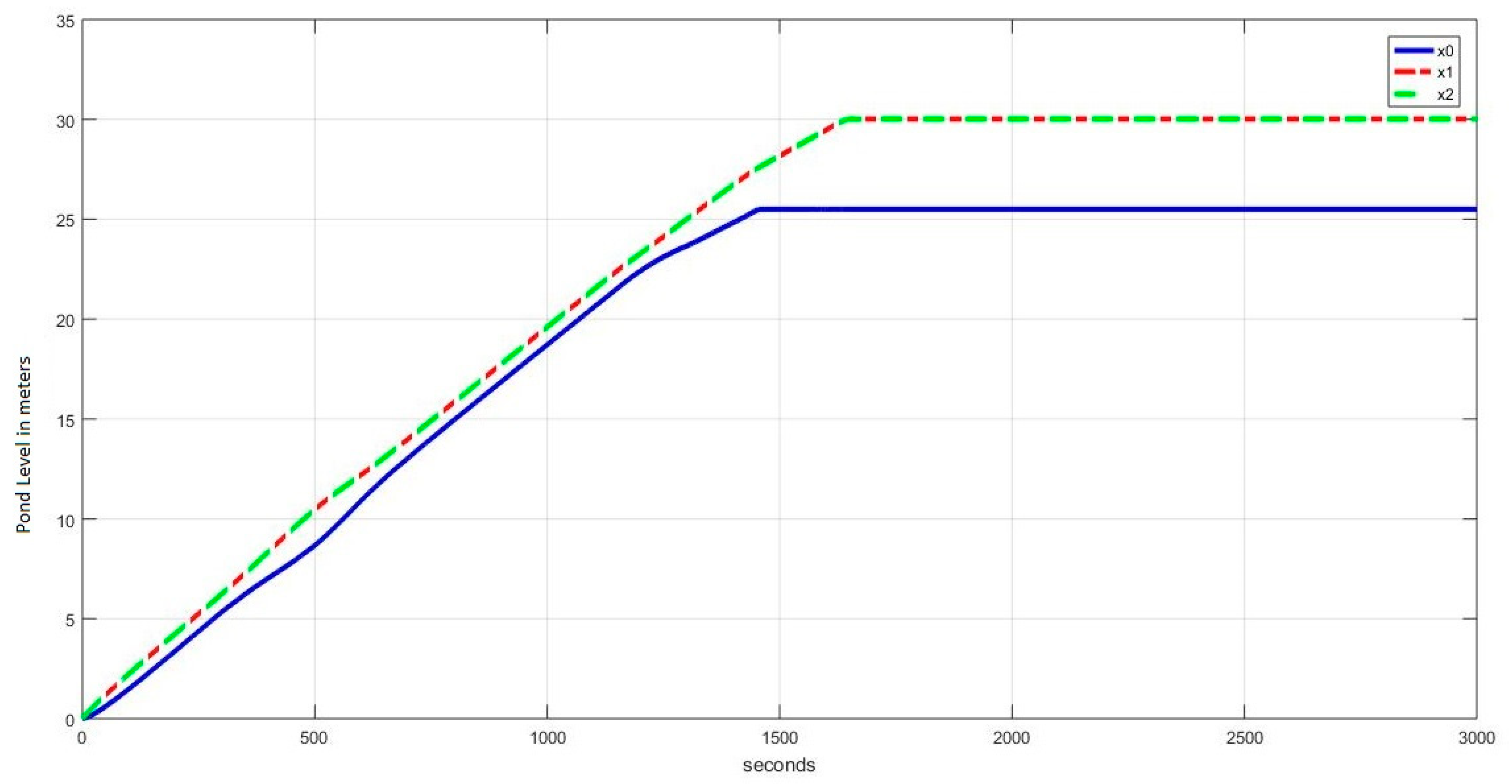

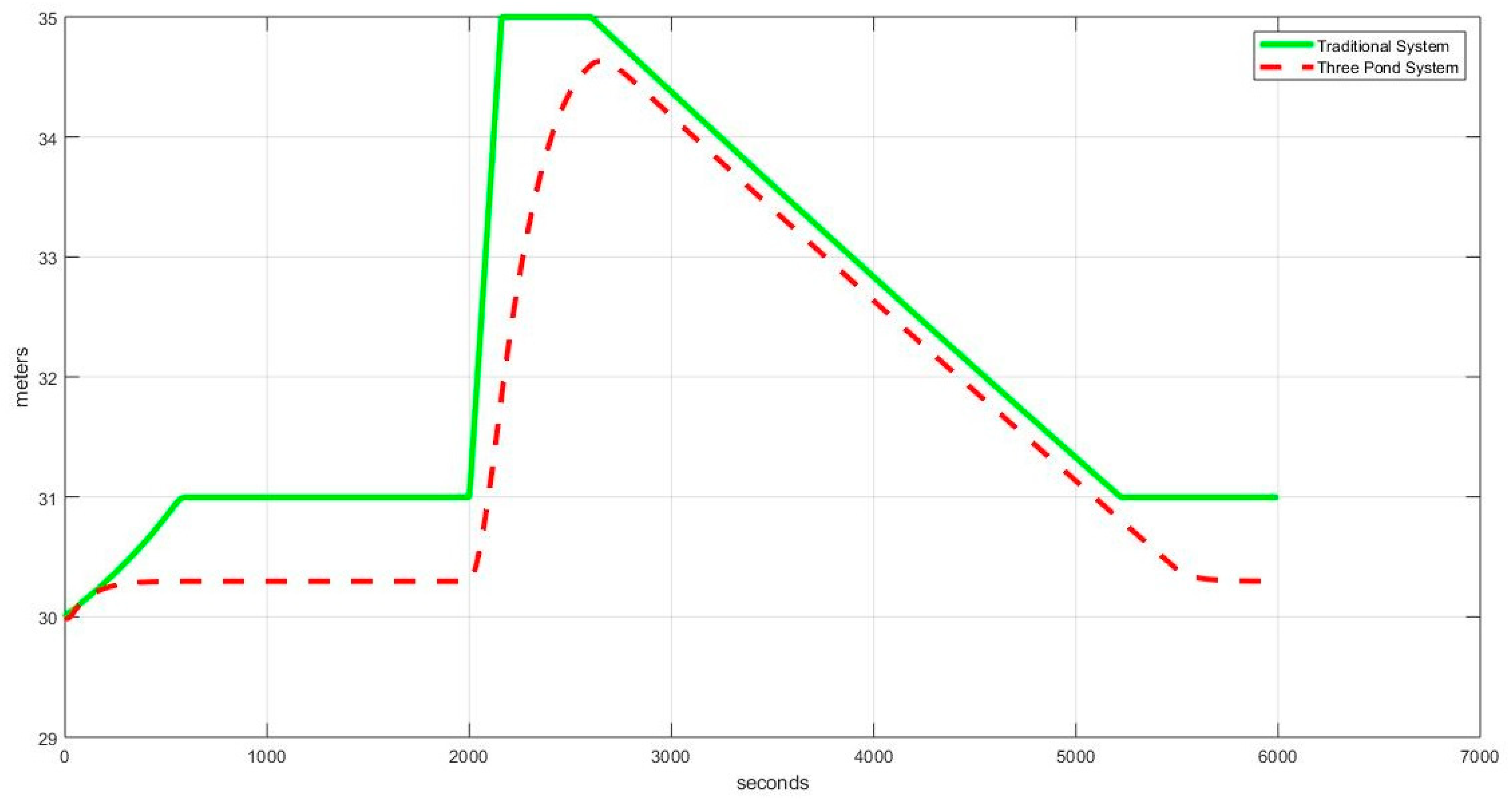

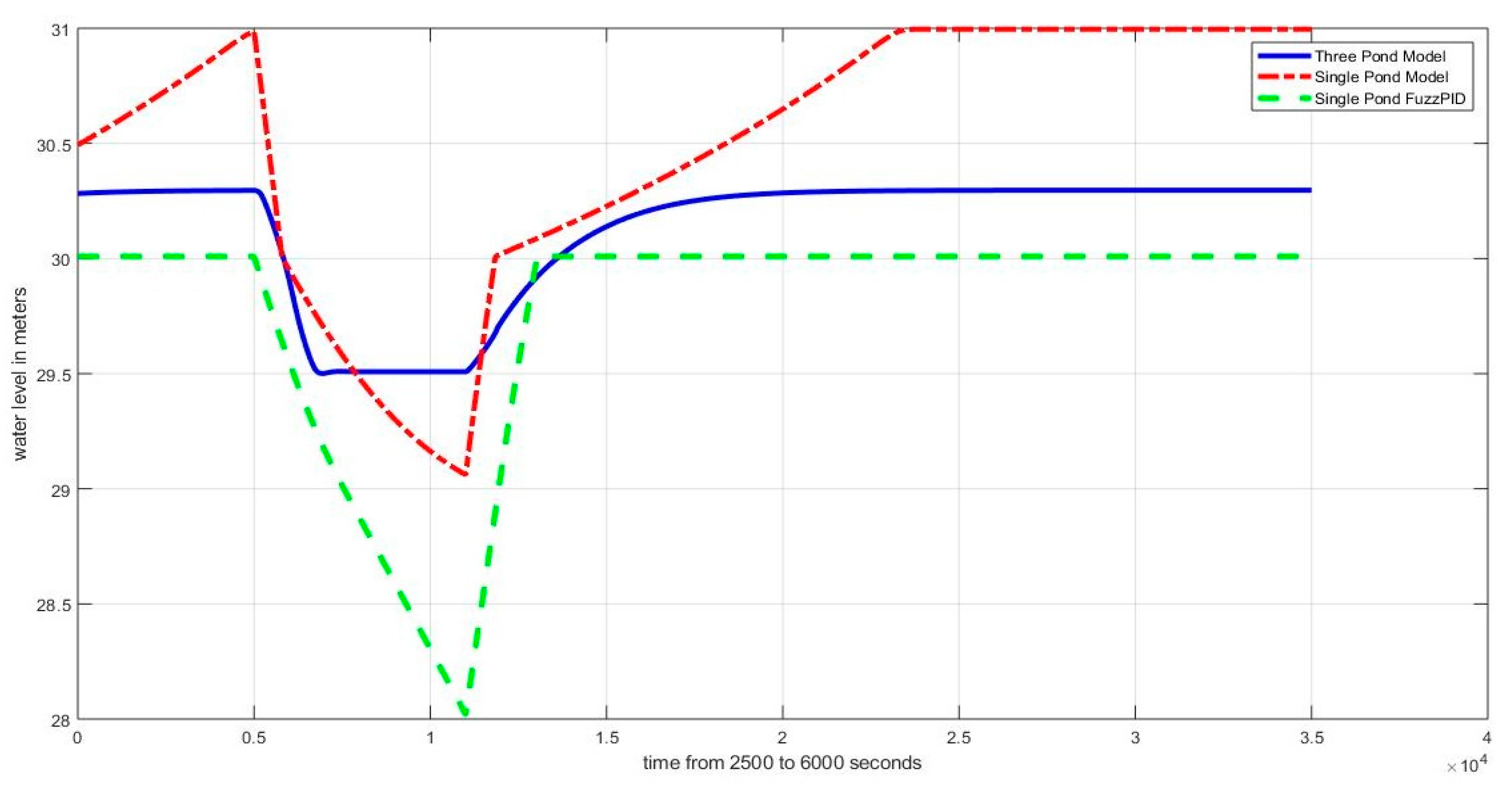

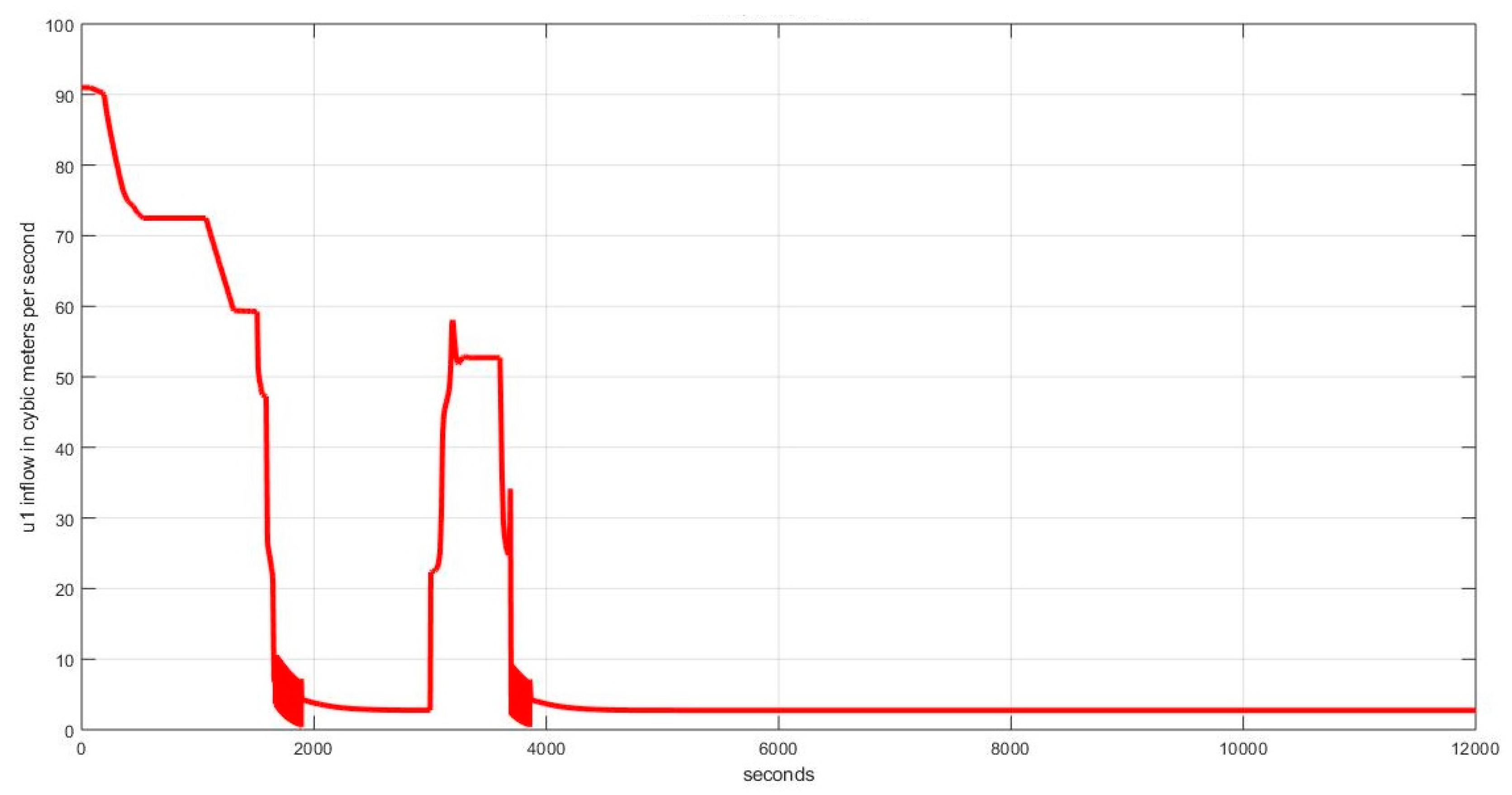

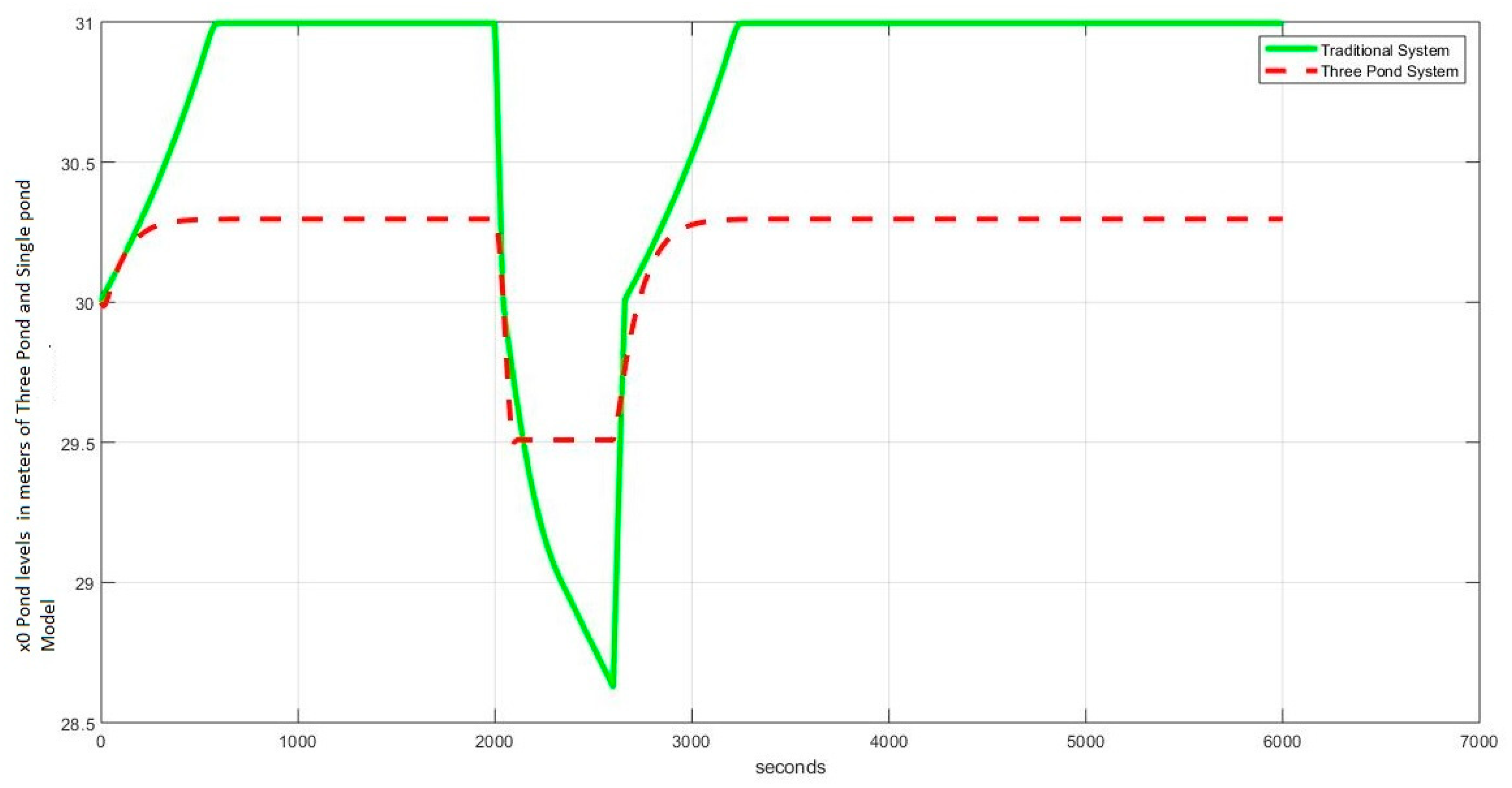

4. Results and Discussion

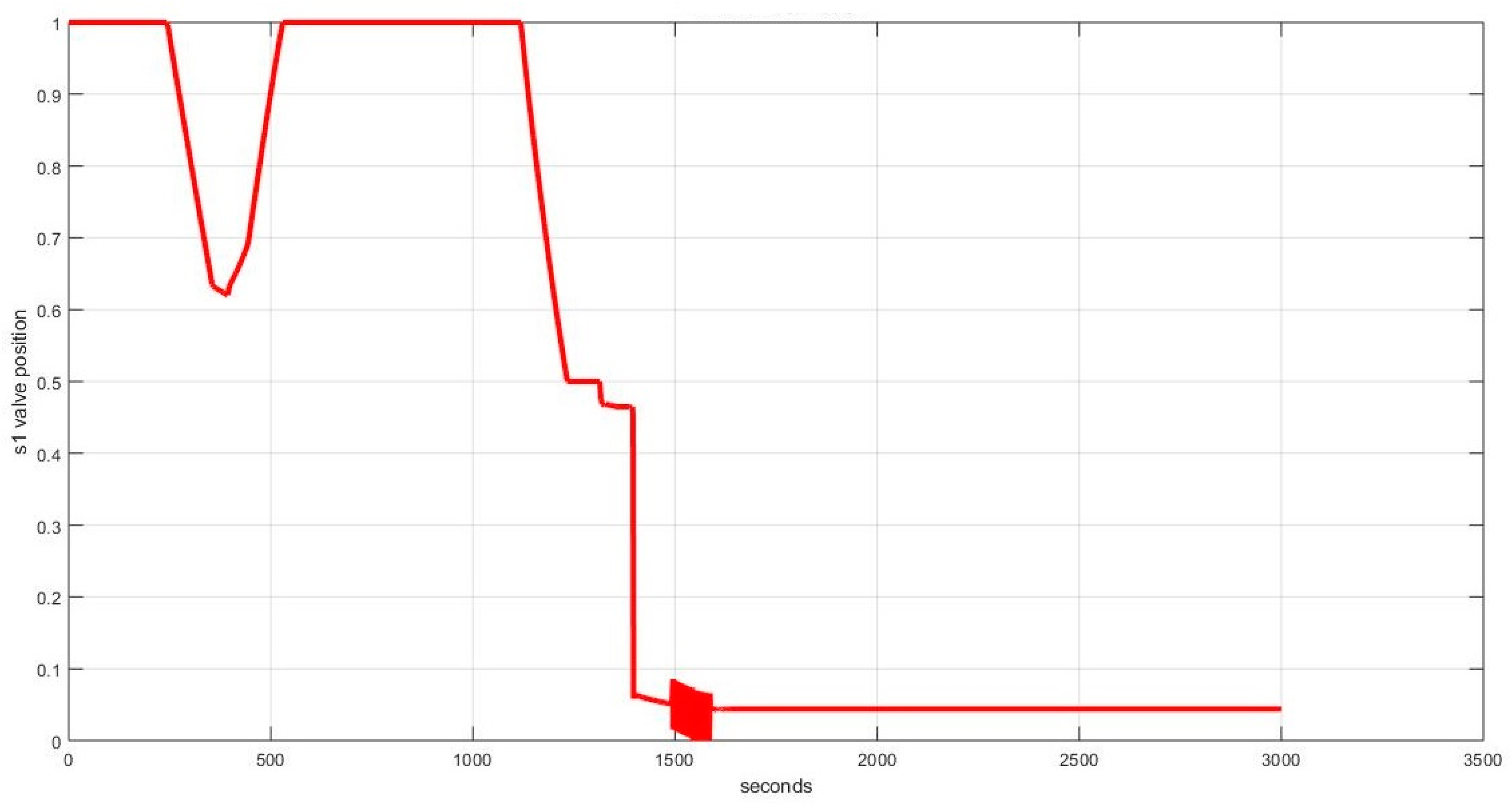

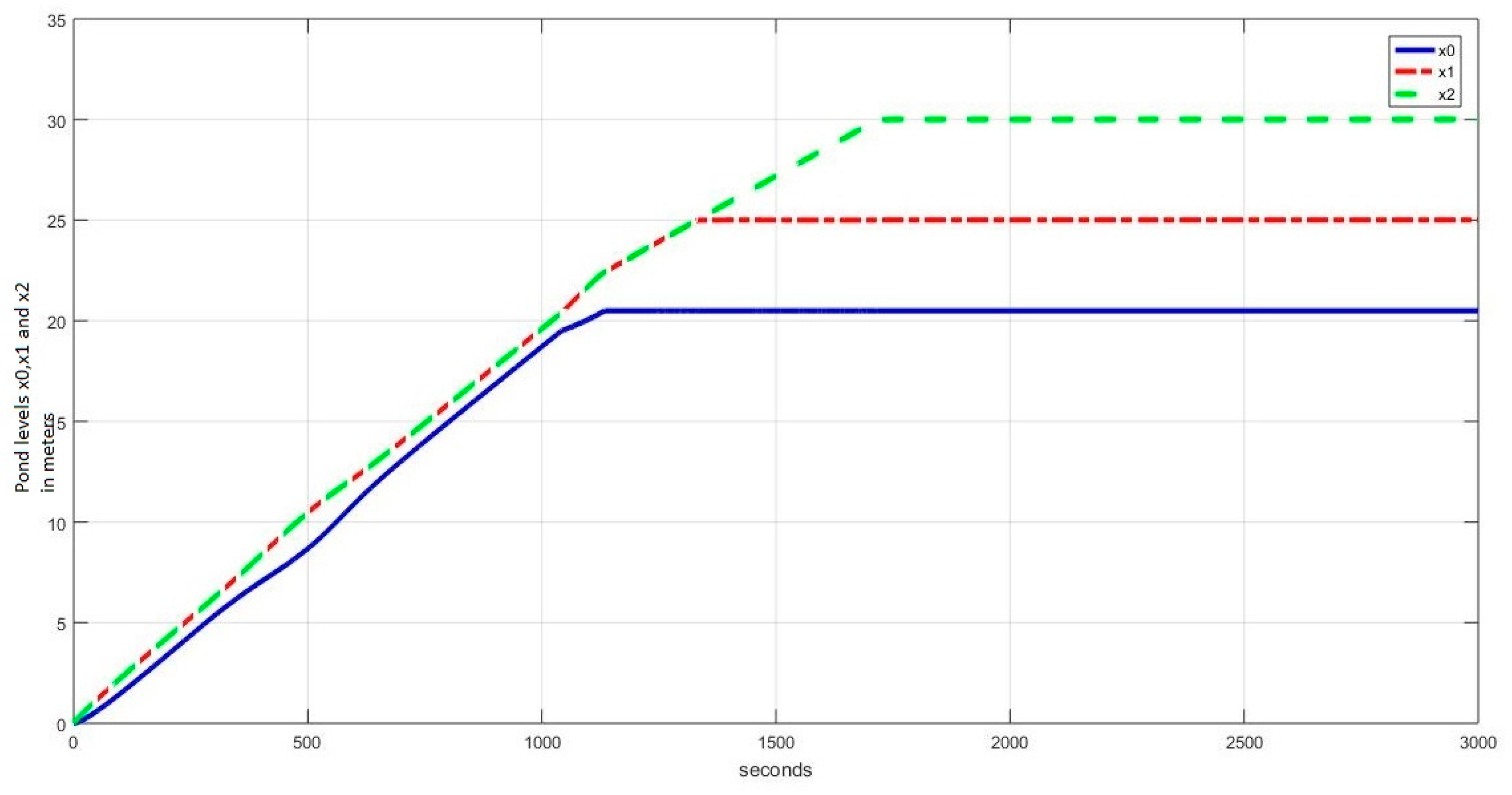

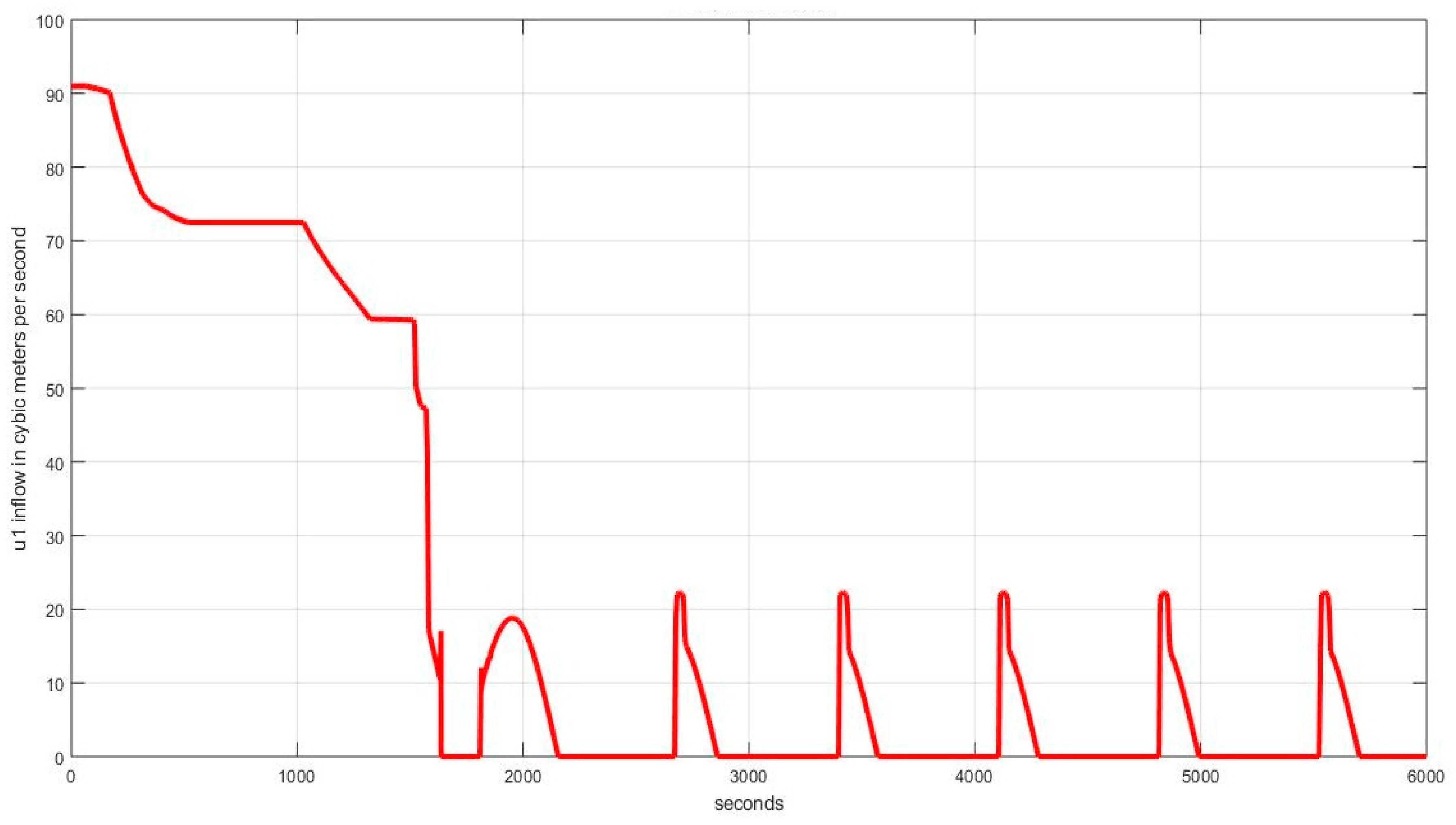

4.1. Level Regulation

4.1.1. Case I: (, , )

4.1.2. Case II: (, , )

4.1.3. Case III: (, , )

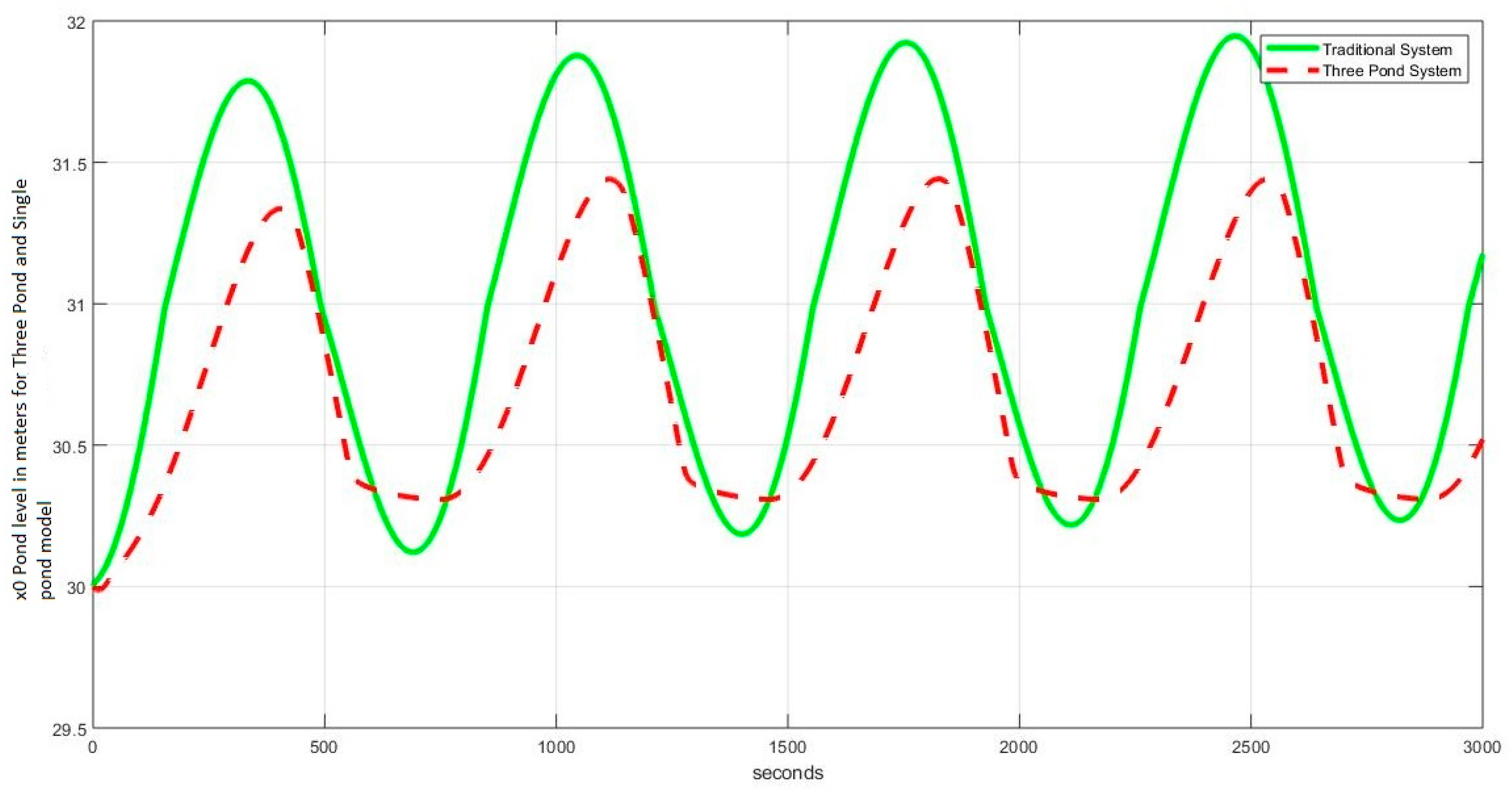

4.2. Robustness Analysis

4.2.1. Case Ia: Sinusoidal Disturbance (Three-Pond System vs. Single-Pond System)

4.2.2. Case Ib: Sinusoidal Disturbance (Three-Pond System vs. Single-Pond System, Half Capacity)

4.2.3. Case IIa: White Noise Disturbance (Three-Pond System vs. Single-Pond System)

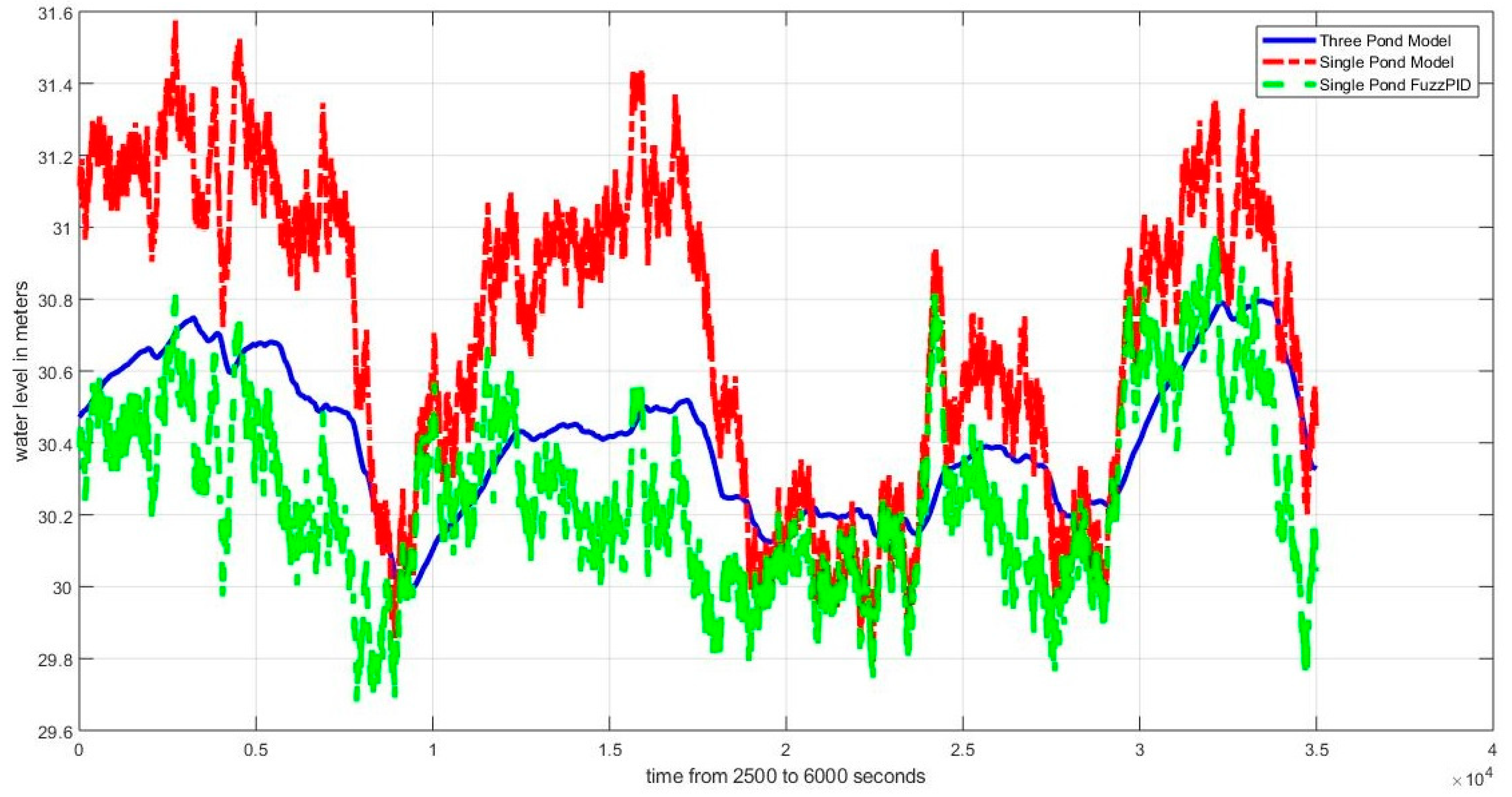

4.2.4. Case IIb: White Noise Disturbance (Three-Pond System vs. Single-Pond System, Half Capacity Case)

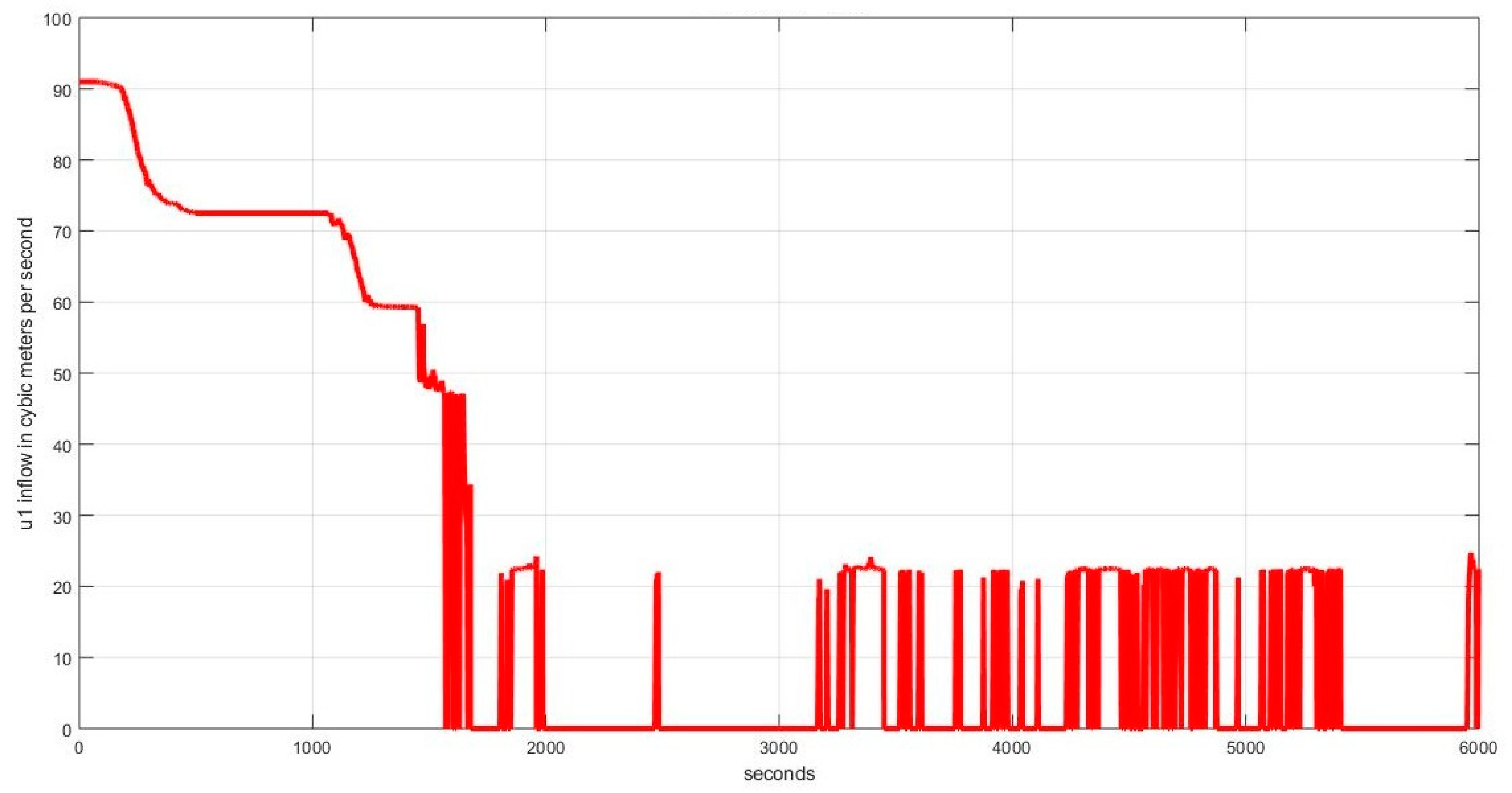

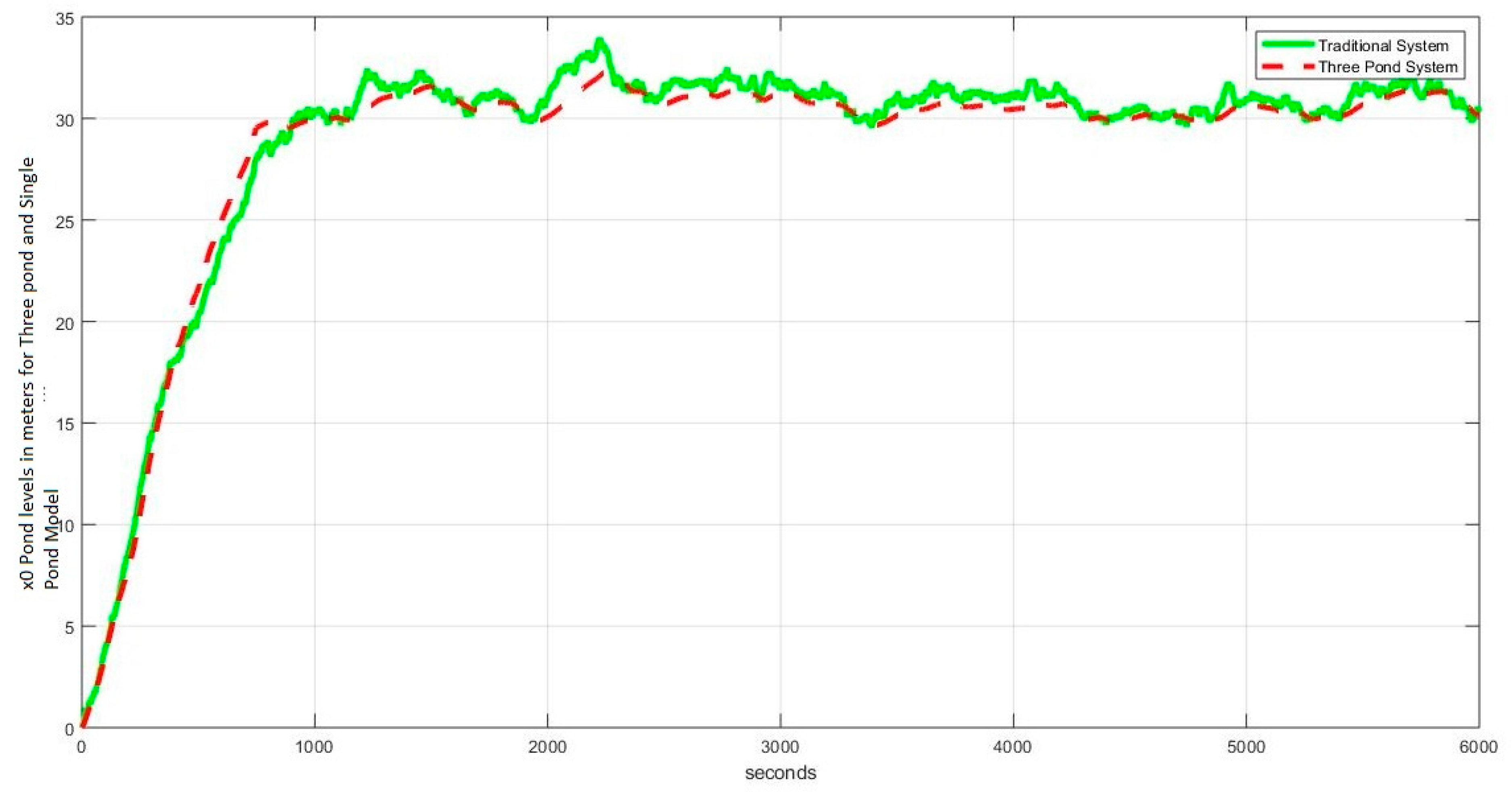

4.2.5. Case IIIa Positive Surge Disturbance (Three-Pond System vs. Single-Pond System)

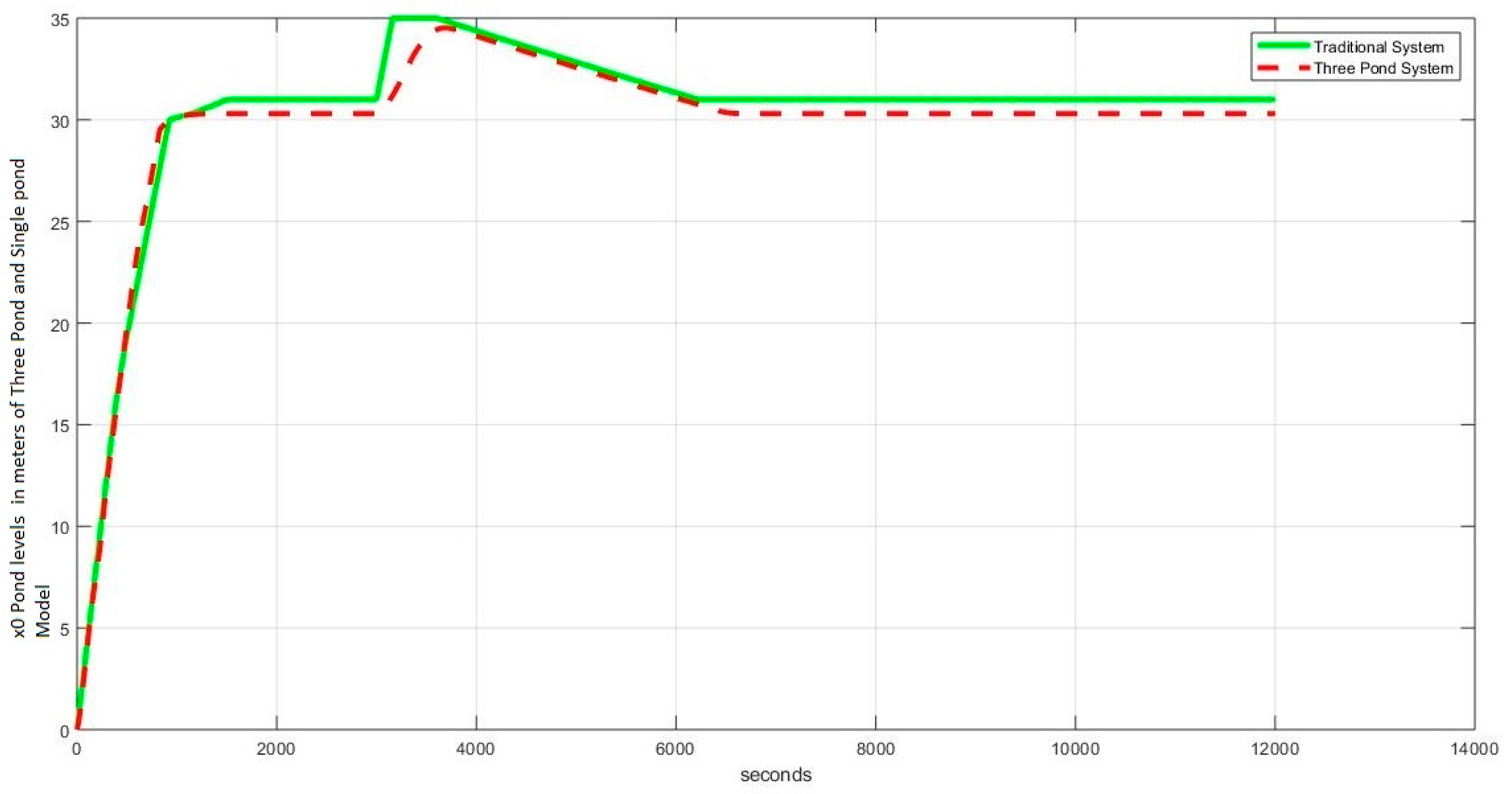

4.2.6. Case IIIb Positive Surge (Three-Pond System vs. Single-Pond System (Half Capacity)

4.2.7. Case IVa Negative Surge (Three-Pond System vs. Single-Pond System)

4.2.8. Case IVb Negative Surge (Three-Pond System vs. Single-Pond System, Half Capacity)

4.3. Observations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Demirbaş, A. Global Renewable Energy Resources. Energy Sources 2006, 28, 779–792. [Google Scholar] [CrossRef]

- Gupta, G.; Bogdan, P. Distributed placement of power generation resources in uncertain environments. In Proceedings of the 2017 ACM/IEEE 8th International Conference on Cyber-Physical Systems (ICCPS), Pittsburgh, PA, USA, 18–21 April 2017; Volume 9, pp. 71–79. [Google Scholar] [CrossRef]

- Jose, S.I.; Fraile-Ardanuy, J.; Perez, J.I.; Wilhelmi, J.R.; Sanchez, J.A. Control of a run of river small hydro power plant. In Proceedings of the 2007 International Conference on Power Engineering, Energy and Electrical Drives, Setubal, Portugal, 12–14 July 2007; pp. 672–677. Available online: https://ieeexplore.ieee.org/abstract/document/4380132/ (accessed on 8 March 2023).

- Omkar, Y.; Kishor, N.; Fraile-Ardanuy, J.; Mohanty, S.R.; Pérez, J.I.; Sarasúa, J.I. Pond head level control in a run-of-river hydro power plant using fuzzy controller. In Proceedings of the 2011 16th International Conference on Intelligent System Applications to Power Systems, Hersonissos, Greece, 25–28 September 2011; pp. 1–5. Available online: https://ieeexplore.ieee.org/abstract/document/6082177/ (accessed on 8 March 2023).

- Chen, G.; Weiming, B.; Cheng, Z. The design of A.G.C. program adapted for the run-off-river hydropower plant. In International Conference on Power System Technology; IEEE: New York, NY, USA, 2002; Volume 4, pp. 2308–2312. Available online: https://ieeexplore.ieee.org/abstract/document/1047196 (accessed on 8 March 2023).

- Lakhdar, B.; Bacha, S.; Roye, D.; Rekioua, T. Experimental validation of direct power control of variable speed micro-hydropower plant. In Proceedings of the IECON 2012-38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 995–1000. Available online: https://ieeexplore.ieee.org/abstract/document/6388585/ (accessed on 8 March 2023).

- Jinho, K.; Gevorgian, V.; Luo, Y.; Mohanpurkar, M.; Koritarov, V.; Hovsapian, R.; Muljadi, E. Supercapacitor to provide ancillary services with control coordination. IEEE Trans. Ind. Appl. 2019, 55, 5119–5127. Available online: https://ieeexplore.ieee.org/abstract/document/8744562/ (accessed on 8 September 2020).

- Isara, B.; Premrudeepreechacharn, S. Development of expert system for fault diagnosis of an 8-MW bulb turbine downstream irrigation hydro power plant. In Proceedings of the 2017 6th International Youth Conference on Energy (IYCE), Budapest, Hungary, 21–24 June 2017; pp. 1–6. Available online: https://ieeexplore.ieee.org/abstract/document/8003740/ (accessed on 8 September 2020).

- Jiheng, J.; Qiao, Y.; Lu, Z. The probabilistic production simulation for renewable energy power system considering the operation of cascade hydropower stations. In Proceedings of the 2018 International Conference on Power System Technology (POWERCON), Guangzhou, China, 6–8 November 2018; pp. 331–338. [Google Scholar]

- Molina, M.G.; Pacas, M. Improved power conditioning system of micro-hydro power plant for distributed generation applications. In Proceedings of the 2010 IEEE International Conference on Industrial Technology, Vi a del Mar, Chile, 14–17 March 2010; pp. 1733–1738. [Google Scholar]

- Alberto, T.; Luise, F.; Raffin, P.; Degano, M. Traditional hydropower plant revamping based on a variable-speed surface permanent-magnet high-torque-density generator. In Proceedings of the 2011 International Conference on Clean Electrical Power (ICCEP), Ischia, Italy, 14–16 June 2011; pp. 350–356. Available online: https://ieeexplore.ieee.org/abstract/document/6036335/ (accessed on 8 March 2023).

- Gabriela, H.-G. Predictive control for balancing wind generation variability using run-of-river power plants. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–29 July 2011; pp. 1–8. [Google Scholar]

- Dariusz, B.; Węgiel, T. Small hydropower plant with integrated turbine-generators working at variable speed. IEEE Trans. Energy Convers. 2003, 28, 452–459. [Google Scholar]

- Saeed, S.; Asghar, R.; Mehmood, F.; Saleem, H.; Azeem, B.; Ullah, Z. Evaluating a Hybrid Circuit Topology for Fault-Ride through in DFIG-Based Wind Turbines. Sensors 2022, 22, 9314. [Google Scholar] [CrossRef] [PubMed]

- Camelia, A.; Mircescu, D.; Aştilean, A.; Ghiran, O. Fluid Stochastic Petri Nets based Modelling and simulation of Micro Hydro Power stations behaviour. In Proceedings of the 2014 IEEE International Conference on Automation, Quality and Testing, Robotics, Cluj-Napoca, Romania, 22–24 May 2014; pp. 1–6. [Google Scholar]

- Huiting, X.; Liu, W.; Wang, L.; Li, M.; Zhang, J. Optimal sizing of small hydro power plants in consideration of voltage control. In Proceedings of the 2015 International Symposium on Smart Electric Distribution Systems and Technologies (EDST), Vienna, Austria, 8–11 September 2015; pp. 165–172. [Google Scholar]

- Azeem, B.; Ullah, Z.; Rehman, F.; Ali, S.M.; Haider, A.; Saeed, S.; Hussain, I.; Mehmood, C.; Khan, B. Levenberg-Marquardt SMC control of grid-tied Doubly Fed Induction Generator (DFIG) using FRT schemes under symmetrical fault. In Proceedings of the 1st International Conference on Power, Energy and Smart Grid (ICPESG), Mirpur Azad Kashmir, Pakistan, 9–10 April 2018; pp. 1–6. [Google Scholar]

- Amjad, S.M.; Shah, S.H.A.; Habib, U. Establishment of hydroelectric microgrids, need of the time to resolve energy shortage problems. In Proceedings of the 2017 3rd International Conference on Power Generation Systems and Renewable Energy Technologies (PGSRET), Johor Bahru, Malaysia, 4–6 April 2017; pp. 16–21. Available online: https://ieeexplore.ieee.org/abstract/document/8251794/ (accessed on 8 March 2023).

- Dariusz, B. Small hydropower plant as a supplier for the primary energy consumer. In Proceedings of the 2015 16th International Scientific Conference on Electric Power Engineering (E.P.E.), KoutynadDesnou, Czech Republic, 20–22 May 2015; pp. 148–151. [Google Scholar]

- Luiz, D.A.; Saboia, A.L.; Andrade, R.M. An exact multi-plant hydro power production function for mid/long term hydrothermal coordination. In Proceedings of the 2016 Power Systems Computation Conference (PSCC), Genoa, Italy, 20–24 June 2016; pp. 1–7. [Google Scholar]

- Yue, C.; Liu, F.; Wei, W.; Mei, S.; Chang, N. Robust unit commitment for large-scale wind generation and run-off-river hydropower. CSEE J. Power Energy Syst. 2016, 2, 66–75. [Google Scholar]

- Liu, Y.; Zhou, J.; Chang, C.; Lu, P.; Wang, C.; Tayyab, M. Short-term joint optimization of cascade hydropower stations on daily power load curve. In Proceedings of the 2016 IEEE International Conference on Knowledge Engineering and Applications (ICKEA), Singapore, 28–30 September 2016; pp. 236–240. [Google Scholar]

- Qiang, F.; Wen, X.; Lin, C.; Peng, W.; Zhang, Y. Research on influence factors analysis and countermeasures of improving prediction accuracy of run-of-river small hydropower. In Proceedings of the 2017 2nd International Conference on Power and Renewable Energy (ICPRE), Chengdu, China, 20–23 September 2017; pp. 548–552. [Google Scholar]

- Dejan, P.; Stokelj, T.; Golob, R. Selecting input variables for hpp reservoir water inflow forecasting using mutual information. In Proceedings of the 2001 PowerTech, Porto, Portugal, 10–13 September 2001; Volume 2. [Google Scholar]

- Martins, L.S.A.; Soares, S. Insights on short-term hydropower scheduling: On the representation of water continuity equations. In Proceedings of the 2016 Power Systems Computation Conference (PSCC), Genoa, Italy, 20–24 June 2016; pp. 1–6. [Google Scholar]

- Ullah, K.; Basit, A.; Ullah, Z.; Aslam, S.; Herodotou, H. Automatic Generation Control Strategies in Conventional and Modern Power Systems: A Comprehensive Overview. Energies 2021, 14, 2376. [Google Scholar] [CrossRef]

- Anuradha, W.; Lai, L.L. Small hydro power plant analysis and development. In Proceedings of the 2011 4th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies (DRPT), Weihai, China, 6–9 July 2011; pp. 25–30. [Google Scholar]

- Karol, O. Impact of carbon financing on the development of small scale run of river hydropower plants in Malaysia during the period 2008–2012. In Proceedings of the 2013 48th International Universities’ Power Engineering Conference (UPEC), Dublin, Ireland, 2–5 September 2013; pp. 1–4. [Google Scholar]

- Ellen, M.R.N.; Cruz, J.C.D.; Amado, T. Water Quality Analysis: Ecological Integrity Conformance of Run-of-River Hydropower Plants. In Proceedings of the 2018 IEEE 10th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Baguio City, Philippines, 29 November–2 December2018; pp. 1–4. [Google Scholar]

- Ullah, K.; Basit, A.; Ullah, Z.; Albogamy, F.R.; Hafeez, G. Automatic Generation Control in Modern Power Systems with Wind Power and Electric Vehicles. Energies 2022, 15, 1771. [Google Scholar] [CrossRef]

- Ullah, K.; Basit, A.; Ullah, Z.; Asghar, R.; Aslam, S.; Yafoz, A. Line Overload Alleviations in Wind Energy Integrated Power Systems Using Automatic Generation Control. Sustainability 2022, 14, 11810. [Google Scholar] [CrossRef]

- Qiang, F.; Lin, C.; Wen, X.; Wen, P.; Chen, Y. Research on application of run-of-river small Hydropower Station group short-term power forecast system in Guizhou Power Grid. In Proceedings of the 2016 IEEE International Conference on Power and Renewable Energy (ICPRE), Shanghai, China, 21–23 October 2016; pp. 328–334. [Google Scholar]

- Karthik, D.; Chelliah, T.R.; Khare, D. Sustainable operation of small hydropower schemes in changing climatic conditions. In Proceedings of the 2017 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Bangalore, India, 8–10 November 2017; pp. 1–6. [Google Scholar]

- Azrulhisham, E.A.; ArifAzri, M. Application of LISST instrument for suspended sediment and erosive wear prediction in run-of-river hydropower plants. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 20–22 February 2018; pp. 886–891. [Google Scholar]

- Fang, F.; Karki, R. Reliability Implications of Riverflow Variations in Planning Hydropower Systems. In Proceedings of the 2018 IEEE Conference on Technologies for Sustainability (SusTech), Long Beach, CA, USA, 11–13 November 2018; pp. 1–6. [Google Scholar]

- Wang, Y.; Wu, N.; Tang, T.; Wang, Y.; Cai, Q. Small run-of-river hydropower dams and associated water regulation filter benthic diatom traits and affect functional diversity. Sci. Total Environ. 2022, 813, 152566. [Google Scholar] [CrossRef]

- Colin, S.; Oladosu, G. Environmental design of low-head run-of-river hydropower in the United States: A review of facility design models. Renew. Sustain. Energy Rev. 2022, 160, 112312. [Google Scholar]

- Bernardes, J., Jr.; Santos, M.; Abreu, T.; Prado Jr, L.; Miranda, D.; Julio, R.; Viana, P.; Fonseca, M.; Bortoni, E.; Bastos, G.S. Hydropower Operation Optimization Using Machine Learning: A Systematic Review. AI 2022, 3, 78–99. [Google Scholar] [CrossRef]

- Mariusz, O. Directions and Extent of Flows Changes in Warta River Basin (Poland) in the Context of the Efficiency of Run-of-River Hydropower Plants and the Perspectives for Their Future Development. Energies 2022, 15, 439. [Google Scholar]

- Paul, A.; Tostado-Véliz, M.; Jurado, F. A novel methodology for comprehensive planning of battery storage systems. J. Energy Storage 2021, 37, 102456. [Google Scholar]

- Jure, J.D.; Dolanc, G.; Pregelj, B. Utilization of Excess Water Accumulation for Green Hydrogen Production in a Run-of-River Hydropower Plant. Renew. Energy 2022, 195, 780–794. [Google Scholar]

- Arai, R.; Toyoda, Y.; Kazama, S. Streamflow maps for run-of-river hydropower developments in Japan. J. Hydrol. 2022, 607, 127512. [Google Scholar] [CrossRef]

- Omni Calculator. Available online: https://www.omnicalculator.com/physics/coefficient-of-discharge#:~:text=The%20discharge%20coefficient%20is%20the%20ratio%20of%20actual%20discharge%20to,velocity%20coefficient%20and%20contraction%20coefficient (accessed on 1 March 2023).

- Saeed, A.; Shahzad, E.; Aslam, L.; Qureshi, I.M.; Khan, A.U.; Iqbal, M. New Paradigm for Water Level Regulation using Three Pond Model with Fuzzy Inference System for Run of River Hydropower Plant. arXiv 2020, arXiv:201113131. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saeed, A.; Shahzad, E.; Khan, A.U.; Waseem, A.; Iqbal, M.; Ullah, K.; Aslam, S. Three-Pond Model with Fuzzy Inference System-Based Water Level Regulation Scheme for Run-of-River Hydropower Plant. Energies 2023, 16, 2678. https://doi.org/10.3390/en16062678

Saeed A, Shahzad E, Khan AU, Waseem A, Iqbal M, Ullah K, Aslam S. Three-Pond Model with Fuzzy Inference System-Based Water Level Regulation Scheme for Run-of-River Hydropower Plant. Energies. 2023; 16(6):2678. https://doi.org/10.3390/en16062678

Chicago/Turabian StyleSaeed, Ahmad, Ebrahim Shahzad, Adnan Umar Khan, Athar Waseem, Muhammad Iqbal, Kaleem Ullah, and Sheraz Aslam. 2023. "Three-Pond Model with Fuzzy Inference System-Based Water Level Regulation Scheme for Run-of-River Hydropower Plant" Energies 16, no. 6: 2678. https://doi.org/10.3390/en16062678

APA StyleSaeed, A., Shahzad, E., Khan, A. U., Waseem, A., Iqbal, M., Ullah, K., & Aslam, S. (2023). Three-Pond Model with Fuzzy Inference System-Based Water Level Regulation Scheme for Run-of-River Hydropower Plant. Energies, 16(6), 2678. https://doi.org/10.3390/en16062678