Evaluating the Effect of Ammonia Co-Firing on the Performance of a Pulverized Coal-Fired Utility Boiler

Abstract

:1. Introduction

2. Method for Evaluating Boiler Performance

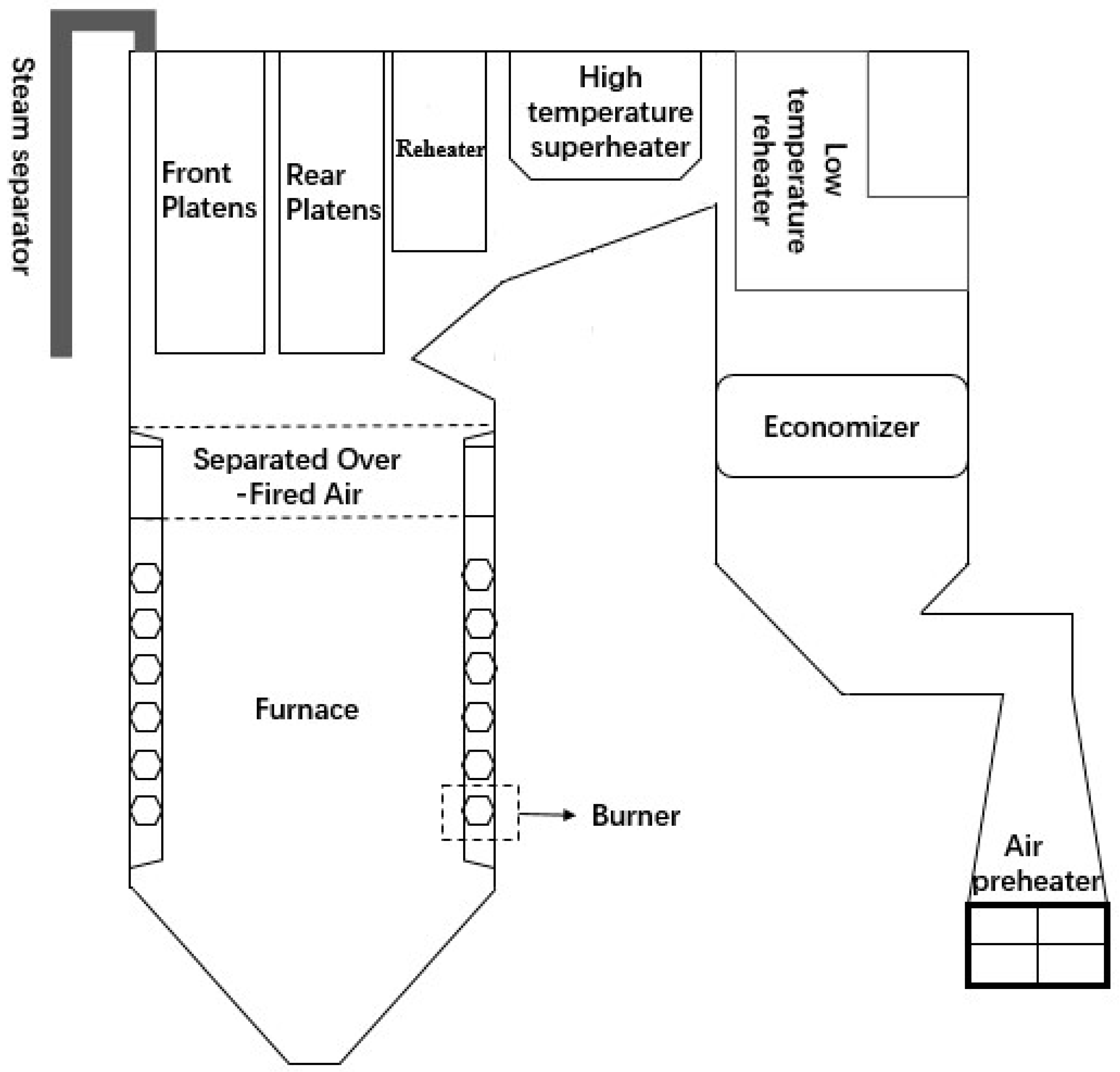

2.1. Overview of the Existing Pulverized Coal-Fired Utility Boiler

2.2. Thermal Calculation Analysis of Boiler Performance

2.3. Co-Firing Gaseous Fuels with Pulverized Coal

3. Results and Discussion

3.1. Effects of Ammonia Co-Firing on the Boiler Performance

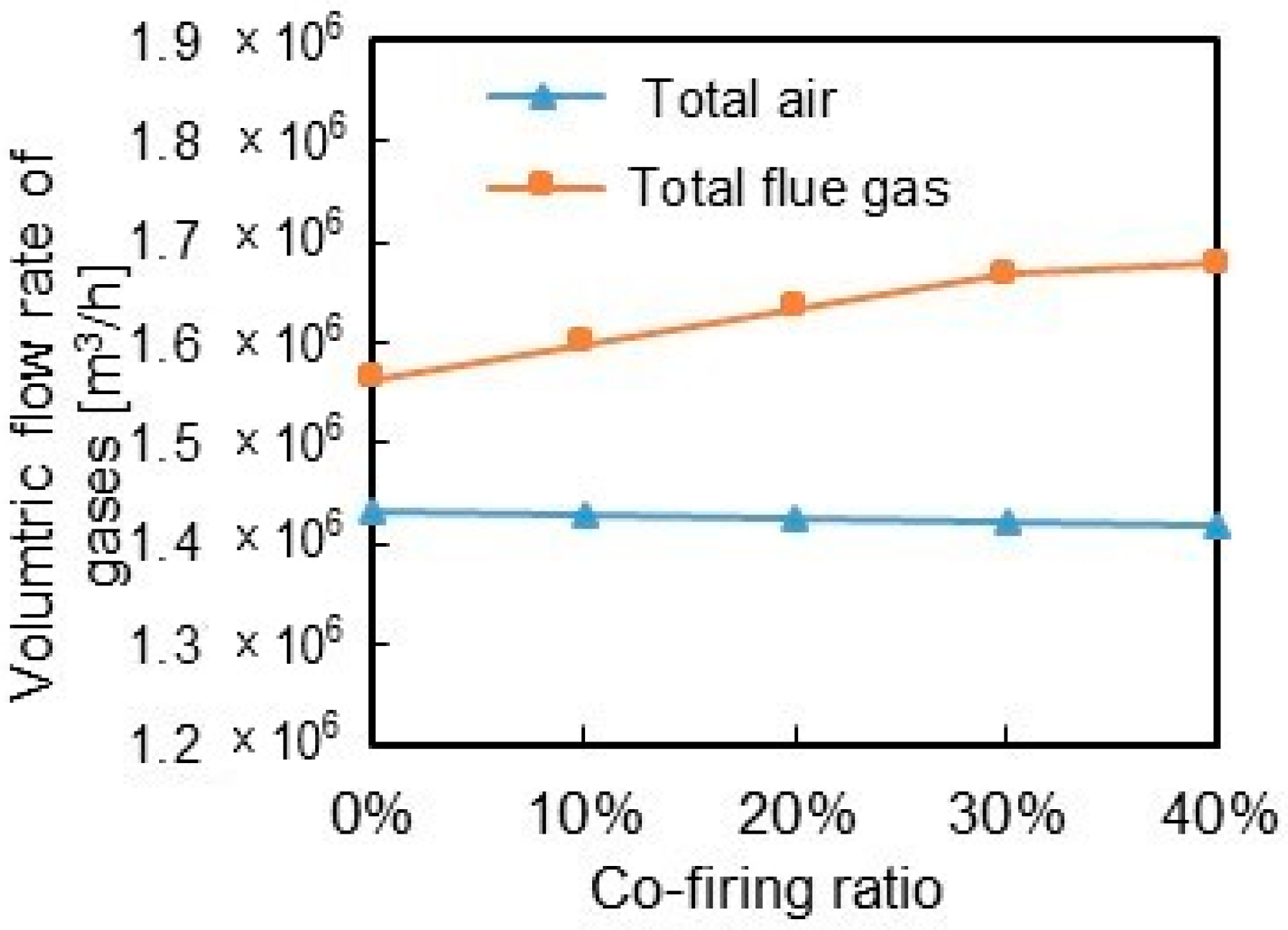

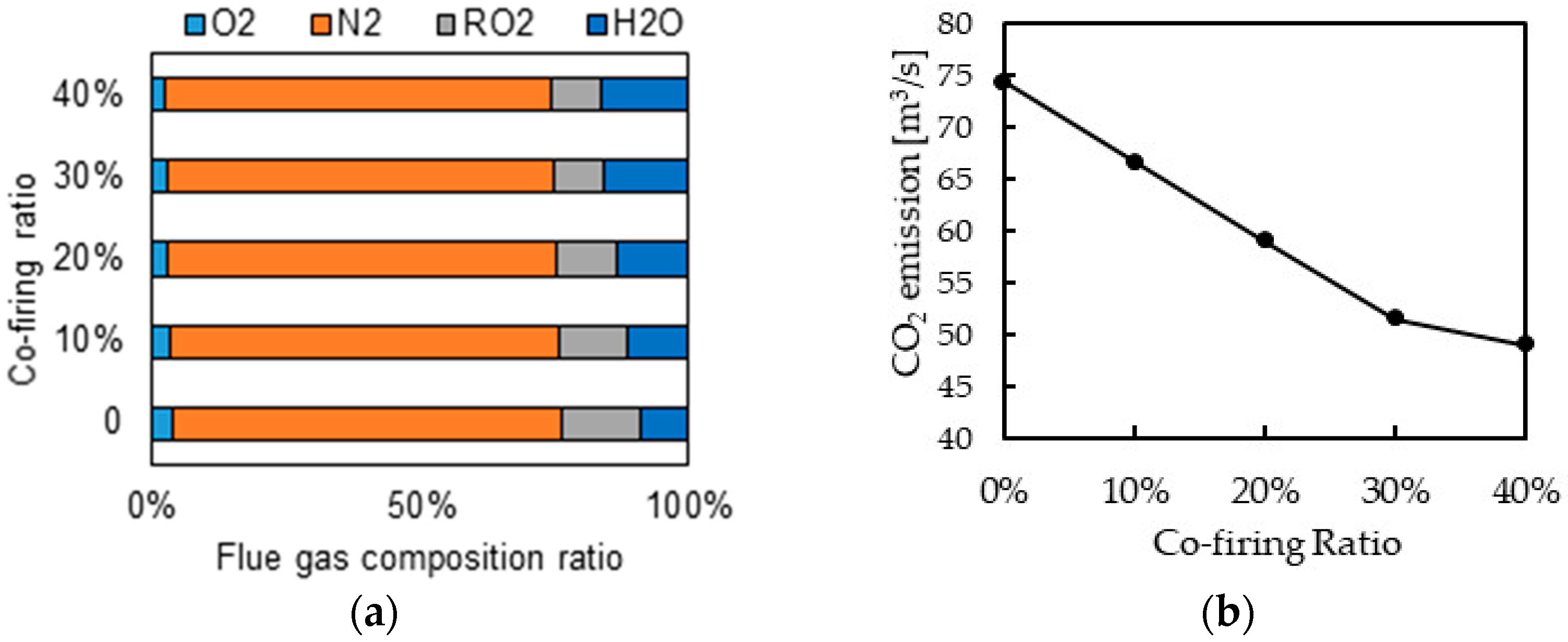

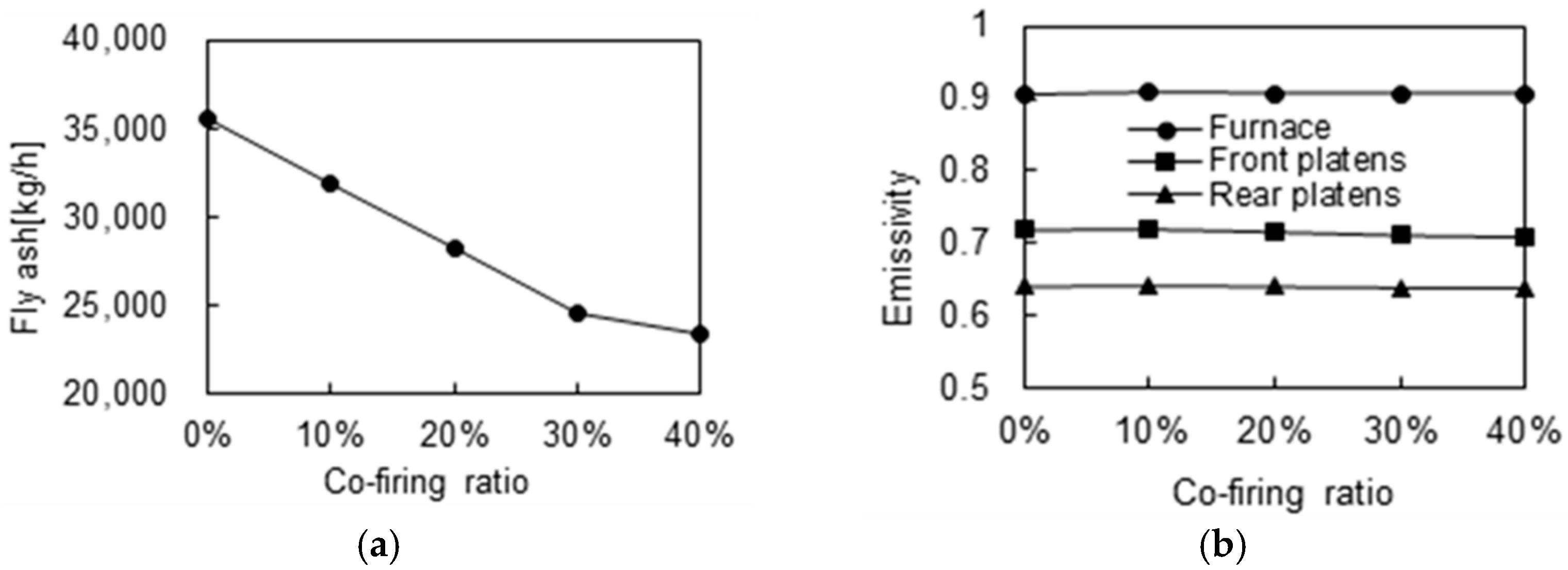

3.1.1. Flue Gas Properties

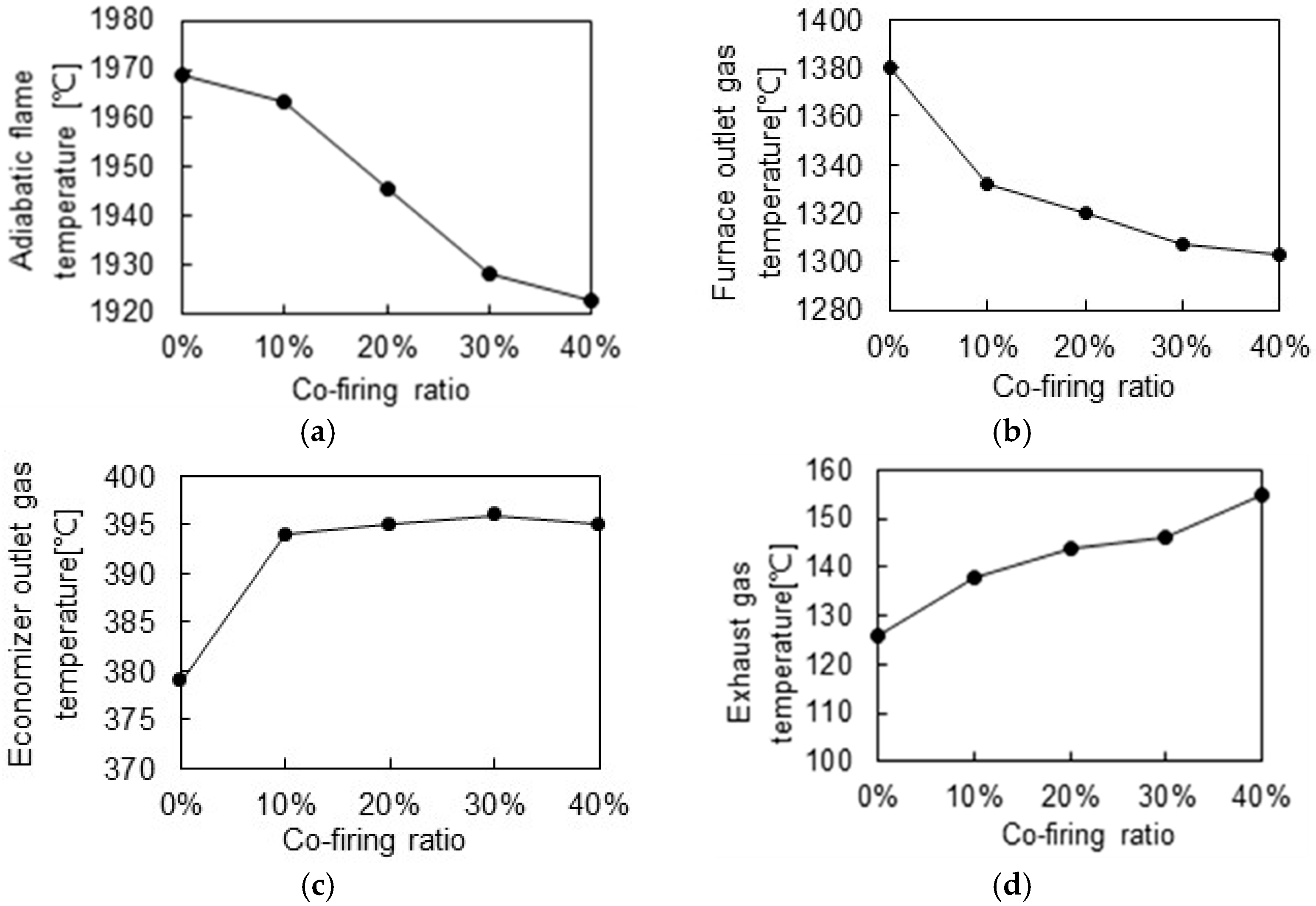

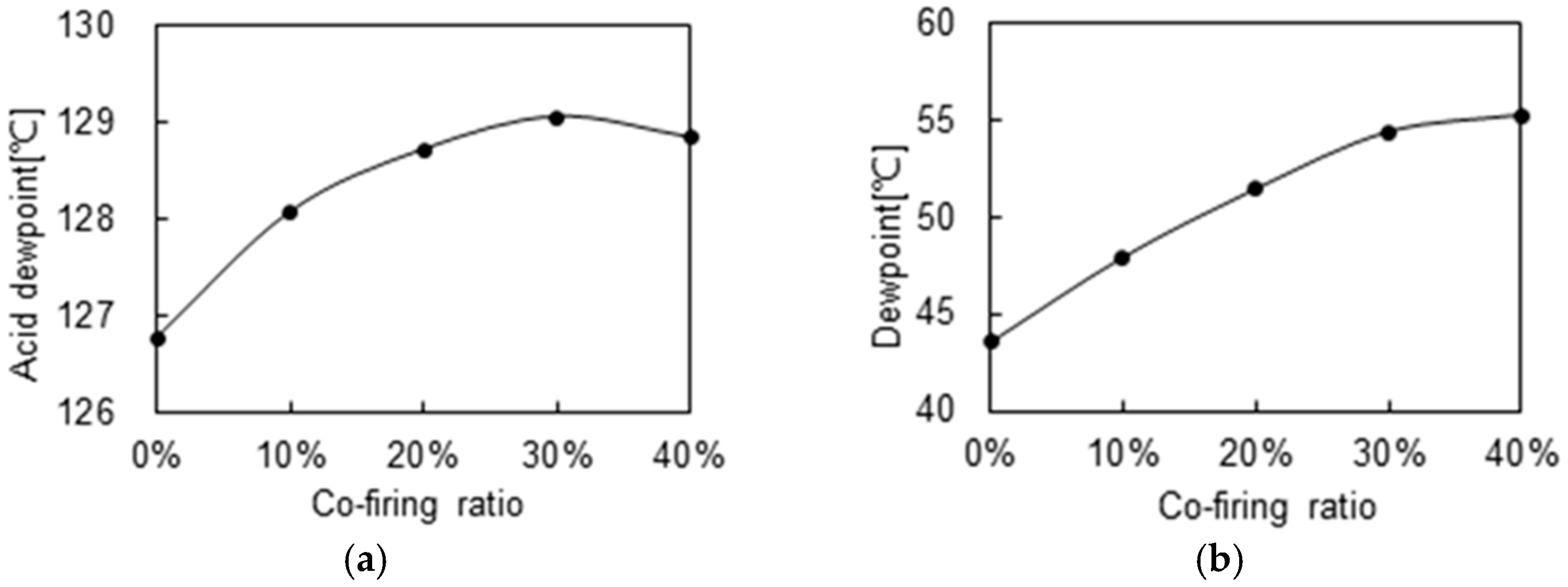

3.1.2. Flue Gas Temperatures in the Boiler

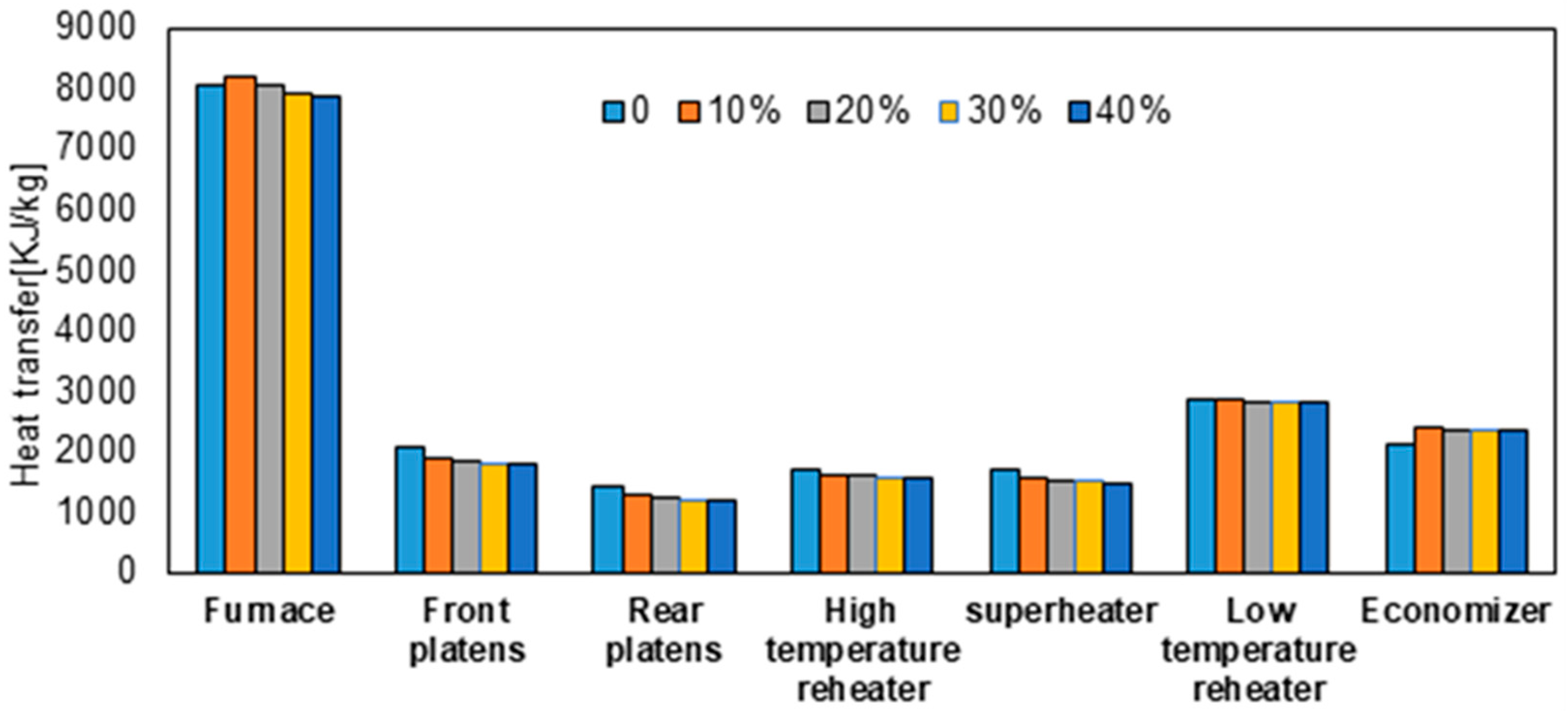

3.1.3. Heat Transfer Performance

3.1.4. Boiler Thermal Efficiency

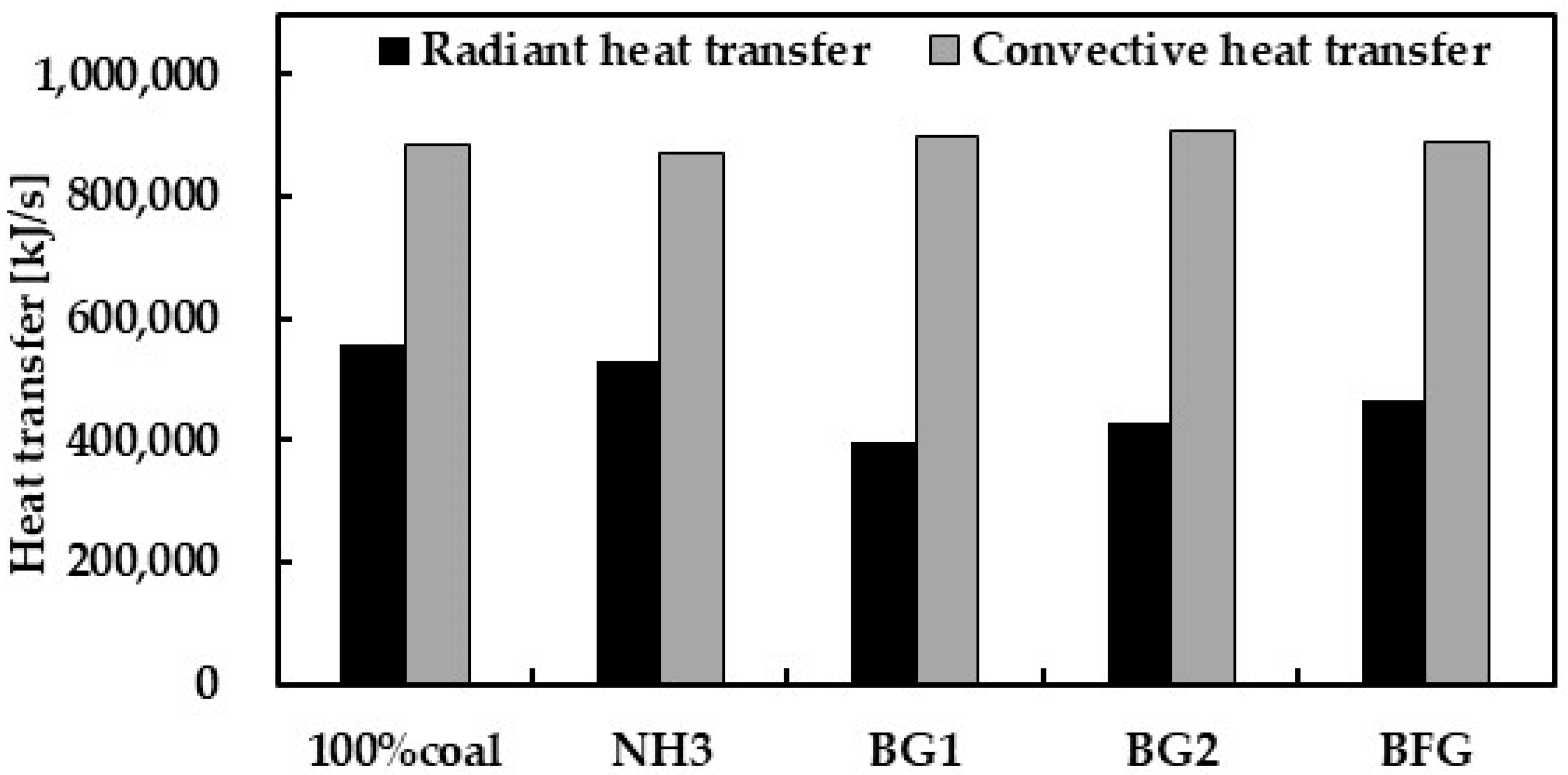

3.2. Comparison of Co-Firing Ammonia and Co-Firing Other Gaseous Fuels

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Convection Heating Surface | α1/W/m2·K | α2/W/m2·K | ε |

|---|---|---|---|

| Front platens | 197.60 | 48.45 | 0.718 |

| Rear platens | 206.31 | 57.5 | 0.640 |

| High-temperature reheater | 172.41 | 51.44 | 0.660 |

| High-temperature superheater | 127.11 | 71.01 | 0.636 |

| Low-temperature reheater (vertical) | 141.84 | 56.68 | 0.683 |

| Low-temperature reheater (transverse) | 97.71 | 65.99 | 0.687 |

| Economizer | 90.78 | 74.51 | 0.630 |

References

- Yanguas Parra, P.A.; Ganti, G.; Brecha, R.; Hare, B.; Schaeffer, M.; Fuentes, U. Global and Regional Coal Phase-Out Requirements of the Paris Agreement: Insights from the IPCC Special Report on 1.5 °C; Climate Analytics: Berlin, Germany, 2019. [Google Scholar]

- International Energy Agency. Phasing Out Unabated Coal—Current Status and Three Case Studies; Fernández, A.C., McNamara, K., Saive, G., Eds.; OECD Publishing: Paris, France, 2021.

- Global Energy Interconnection Development and Cooperation Organization. China’s Carbon Peak Research Report before 2030. Available online: https://news.bjx.com.cn/html/20210319/1142856.shtml (accessed on 6 March 2023).

- Xu, Y.; Yang, K.; Zhou, J.; Zhao, G. Coal-biomass co-firing power generation technology: Current status, challenges and policy implications. Sustainability 2020, 12, 3692. [Google Scholar] [CrossRef]

- Zhang, X.; Meloni, S. Technology Developments in the Co-Firing of Biomass. IEA Clean Coal Centre, 26 August 2020. Available online: https://www.sustainable-carbon.org/report/technology-developments-in-cofiring-biomass-ccc-305/ (accessed on 6 March 2023).

- Xu, Y.; Wang, H.; Liu, X.; Zhu, J.; Xu, J.; Xu, M. Mitigating CO2 emission in pulverized coal-fired power plant via co-firing ammonia: A simulation study of flue gas streams and exergy efficiency. Energy Convers. Manag. 2022, 256, 115328. [Google Scholar] [CrossRef]

- International Energy Agency. The Role of Low-Carbon Fuels in the Clean Energy Transitions of the Power Sector; OECD Publishing: Paris, France, 2021.

- Lee, H.; Lee, M.J. Recent advances in ammonia combustion technology in thermal power generation system for carbon emission reduction. Energies 2021, 14, 5604. [Google Scholar] [CrossRef]

- Kobayashi, H.; Hayakawa, A.; Somarathne, K.D.; Okafor, E.C. Science and technology of ammonia combustion. Proc. Combust. Inst. 2019, 37, 109–133. [Google Scholar] [CrossRef]

- Valera, M.A.; Amer, H.F.; Azad, A.K.; Dedoussi, I.C.; Joannon, M.; Fernandes, R.X.; Glarborg, P.; Hashemi, H.; He, X.; Mashruk, S.; et al. Review on ammonia as a potential fuel: From synthesis to economics. Energy Fuels 2021, 35, 6964–7029. [Google Scholar] [CrossRef]

- Genichiro, N.; Hiroki, I.; Takamasa, I.; Emi, O.; Yoshitomo, O. Development of co-firing method of pulverized coal and ammonia to reduce greenhouse gas emissions. IHI Eng. Rev. 2020, 53, 1–10. Available online: https://www.ihi.co.jp/ihi/technology/review_library/review_en/2020/_cms_conf01/__icsFiles/afieldfile/2021/01/14/Vol53No1_F.pdf (accessed on 8 March 2023).

- Tamura, M.; Gotou, T.; Ishii, H.; Riechelmann, D. Experimental investigation of ammonia combustion in a bench scale 1.2 MW-thermal pulverised coal firing furnace. Appl. Energy 2020, 277, 115580. [Google Scholar] [CrossRef]

- Wang, X.; Fan, W.; Chen, J.; Feng, G.; Zhang, X. Experimental study and kinetic analysis of the impact of ammonia co-firing ratio on products formation characteristics in ammonia/coal co-firing process. Fuel 2022, 329, 125496. [Google Scholar] [CrossRef]

- Chen, P.; Wang, H.; Jiang, B.; Wang, Y.; Gu, M.; Chen, G. An experimental and theoretical study of NO heterogeneous reduction in the reduction zone of ammonia co-firing in a coal-fired boiler: Influence of CO. Fuel Process. Technol. 2022, 231, 107184. [Google Scholar] [CrossRef]

- Taniguchi, M. Flame propagation velocity for co-combustion of pulverized coals and gas fuels. Energy Fuels 2021, 35, 6305–6314. [Google Scholar] [CrossRef]

- Xia, Y.; Hadi, K.; Hashimoto, G.; Hashimoto, N.; Fujita, O. Effect of ammonia/oxygen/nitrogen equivalence ratio on spherical turbulent flame propagation of pulverized coal/ammonia co-combustion. Proc. Combust. Inst. 2021, 38, 4043–4052. [Google Scholar] [CrossRef]

- Hadi, K.; Ichimura, R.; Hashimoto, G.; Xia, Y.; Hashimoto, N.; Fujita, O. Effect of fuel ratio of coal on the turbulent flame speed of ammonia/coal particle cloud co-combustion at atmospheric pressure. Proc. Combust. Inst. 2021, 38, 4131–4139. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, X.; Xu, Y.; Xu, J.; Wang, H.; Zhang, K.; Cheng, X.; Yu, D. Probing into volatile combustion flame and particulate formation behavior during the coal and ammonia co-firing process. Energy Fuels 2022, 36, 9347–9356. [Google Scholar] [CrossRef]

- Takatoshi, Y.; Takeshi, A.; Yuichiro, U.; Tadashi, S.; Teruyuki, O.; Akimasa, T. Development of Ammonia Co-firing Technology for Coal-fired Boilers toward Decarbonized Society. Mitsubishi Heavy Ind. Tech. Rev. 2022, 59. Available online: https://www.mhi.co.jp/technology/review/pdf/e594/e594060.pdf (accessed on 7 March 2023).

- Tan, J.X.; He, Y.; Zhu, R.; Zhu, Y.; Wang, Z. Experimental study on co-firing characteristics of ammonia with pulverized coal in a staged combustion drop tube furnace. Proc. Combust. Inst. 2022, in press. [Google Scholar] [CrossRef]

- Tanigawa, H. Test results of the ammonia mixed combustion at Mizushima power station unit No. 2 and related patent applications. In Proceedings of the 2018 AIChE Annual Meeting, Pittsburgh, PA, USA, 31 October 2018. [Google Scholar]

- Yoshizaki, T. Test of the Co-firing of Ammonia and Coal at Mizushima Power Station. In CO2 Free Ammonia as an Energy Carrier, 1st ed.; Ken-ichi, A., Hideaki, K., Eds.; Springer: Singapore, 2022; pp. 601–611. [Google Scholar]

- Bai, H.; Zhang, Z.; Li, Z.; Wu, X.; Guo, X.; Zhang, J.; Bi, D. Industrial Experiment on NOx Reduction by Urea Solution Injection in the Fuel-Rich Zone of a 330 MW Tangentially Pulverized Coal-Fired Boiler. ACS Omega 2022, 7, 11853–11861. [Google Scholar] [CrossRef]

- Hiroki, I.; Emi, O.; Takahiro, K.; Takamasa, I.; Toshiro, F. Development of co-firing technology of pulverized coal and ammonia for suppressing the NOx generation. Trans. JSME 2020, 86, 19–00363. [Google Scholar] [CrossRef] [Green Version]

- Niu, T.; Zhang, W.; Liu, X.; Hu, D.; Wang, T.; Xie, Y.; Wang, H. Industrial-scale experimental investigation of ammonia-coal cofiring in coal-fired boiler. Clean Coal Technol. 2022, 28, 193–200. [Google Scholar] [CrossRef]

- Zhang, J.; Ito, T.; Ishii, H.; Ishihara, S.; Fujimori, T. Numerical investigation on ammonia co-firing in a pulverized coal combustion facility: Effect of ammonia co-firing ratio. Fuel 2020, 267, 117166. [Google Scholar] [CrossRef]

- Ishihara, S.; Zhang, J.; Ito, T. Numerical calculation with detailed chemistry of effect of ammonia co-firing on NO emissions in a coal-fired boiler. Fuel 2020, 266, 116924. [Google Scholar] [CrossRef]

- Ishihara, S.; Zhang, J.; Ito, T. Numerical calculation with detailed chemistry on ammonia co-firing in a coal-fired boiler: Effect of ammonia co-firing ratio on NO emissions. Fuel 2020, 274, 117742. [Google Scholar] [CrossRef]

- Design Department of Beijing Boiler Plant. Standard Method for Calculating the Thermal Power of Boiler Units, 1st ed.; Machinery Industry Press: Beijing, China, 1976; pp. 29–37. [Google Scholar]

- Max, A. Ammonia: Principles and Industrial Practice, 1st ed.; WILEY-VCH: New York, NY, USA, 1999; pp. 9–12. [Google Scholar]

- Wang, Y.; Deng, L.; Chang, G.; Liu, H.; Lyu, K.; Nie, X.; Zhang, G. Influence of biomass gas parameters on coupled coal-fired biomass generation. Therm. Power Gener. 2021, 50, 35–40. (In Chinese) [Google Scholar] [CrossRef]

- Wang, C.; Wei, J.; Huang, J. Thermodynamic characteristics and economic analysis of a BFG /pulverized coal mixed combustion boiler. J. Chin. Soc. Power Eng. 2012, 32, 517–522. (In Chinese) [Google Scholar]

- Bolhar-Nordenkampf, M.; Isaksson, J. Operating experiences of large scale CFB-gasification plants for the substitution of fossil fuels. In Proceedings of the 24th European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016; pp. 375–381. [Google Scholar] [CrossRef]

| Proximate Analysis/wt% | Ultimate Analysis/wt% | Qnet/kJ/kg | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Moisture | Ash | Volatiles | Fixed Carbon | C | H | O | N | S | |

| 13.00 | 15.00 | 24.22 | 47.78 | 57.33 | 3.62 | 9.94 | 0.70 | 0.41 | 21,805 |

| Parameter | Value |

|---|---|

| Superheated steam rate/t/h | 1913 |

| Superheated steam pressure/MPa | 25.4 |

| Superheated steam temperature/°C | 571 |

| Reheated steam rate/t/h | 1586 |

| Reheated steam inlet pressure/MPa | 4.35 |

| Reheated steam inlet temperature/°C | 310 |

| Reheated steam outlet pressure/MPa | 4.16 |

| Reheated steam outlet temperature/°C | 569 |

| Feed water temperature/°C | 282 |

| Ambient temperature/°C | 20 |

| Flue gas exit temperature/°C | 126 |

| Item | CO/% | H2/% | CH4/% | C2H4/% | CO2/% | N2/% | H2O/% | Qnet/kJ/m3 |

|---|---|---|---|---|---|---|---|---|

| Biomass gas 1 | 12.40 | 14.10 | 3.90 | 1.80 | 16.30 | 37.90 | 13.60 | 5682 |

| Biomass gas 2 | 19.15 | 10.13 | 1.03 | 0 | 5.95 | 43.08 | 20.66 | 3880 |

| BFG | 24.00 | 2.30 | 0.90 | 0 | 15.60 | 57.20 | 0 | 3632 |

| Item | Adiabatic Flame Temperature/°C | Furnace Exit Temperature/°C | Boiler Thermal Efficiency/% | Total Flue Gas/m3/s |

|---|---|---|---|---|

| 100% coal | 1969 | 1380 | 93.7 | 434.5 |

| NH3 | 1946 | 1320 | 93.5 | 453.7 |

| BG1 | 1534 | 1069 | 89.9 | 760.2 |

| BG2 | 1568 | 1093 | 87.9 | 788.4 |

| BFG | 1696 | 1127 | 90.3 | 659.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Sheng, C. Evaluating the Effect of Ammonia Co-Firing on the Performance of a Pulverized Coal-Fired Utility Boiler. Energies 2023, 16, 2773. https://doi.org/10.3390/en16062773

Wang S, Sheng C. Evaluating the Effect of Ammonia Co-Firing on the Performance of a Pulverized Coal-Fired Utility Boiler. Energies. 2023; 16(6):2773. https://doi.org/10.3390/en16062773

Chicago/Turabian StyleWang, Shulei, and Changdong Sheng. 2023. "Evaluating the Effect of Ammonia Co-Firing on the Performance of a Pulverized Coal-Fired Utility Boiler" Energies 16, no. 6: 2773. https://doi.org/10.3390/en16062773

APA StyleWang, S., & Sheng, C. (2023). Evaluating the Effect of Ammonia Co-Firing on the Performance of a Pulverized Coal-Fired Utility Boiler. Energies, 16(6), 2773. https://doi.org/10.3390/en16062773