Enhancing the Energy Efficiency of Wastewater Treatment Plants through the Optimization of the Aeration Systems

Abstract

:1. Introduction

2. Materials and Methods

2.1. White Certificates in the Integrated Water Service

- RISP is the energy saved in EEO;

- KgO2 is the quantity of oxygen present in the volume of the air processed by the production system of compressed air in the ex-post situation, and is equal to the amount of air in Sm3 multiplied by 0.285 KgO2/Sm3;

- fe is the conversion factor (equal to 0.000187 toe/kWh) when withdrawing electricity from the grid;

- SAEbaseline is the aeration efficiency, which is referred to as the baseline solution. It is equal to the ratio between KgO2 and the energy consumed for the production of compressed air in KgO2/kWh;

- SAEex post is the aeration efficiency in operational conditions, referred to as the ex-post situation, measured in KgO2/kWh.

2.2. WWTP Configuration and Calculation of Energy Saving

- C is the average dissolved oxygen concentration within the process water volume, measured in mg/L;

- OTRf is the field oxygen transfer rate estimated for the system operating under process conditions at an average dissolved oxygen concentration (C) and temperature (T), measured in kg O2/h;

- SOTR is the oxygen transfer rate under standard conditions (20 °C, 1 atm, C = 0 mg/L), measured in kg O2/h;

- T is the field temperature;

- C*st is the dissolved oxygen surface saturation concentration at the operating temperature, measured in mg/L;

- C*s20 is the dissolved oxygen surface saturation concentration at a standard temperature (20 °C), measured in mg/L;

- τ is the temperature correction factor = C*st/C*s20;

- β is the relative DO saturation to clean water, expressed as C*wastewater/C*tap water;

- Pb is the barometric pressure at the test site (kPa);

- Ps is the standard barometric pressure (101.325 kPa);

- ω is the pressure correction factor, expressed as Pb/Ps;

- de is the mid-depth correction factor (0.40);

- Df is the depth of diffusers in the basins, measured in m;

- C*∞,20 is the saturated dissolved oxygen value at sea level and the standard temperature (20 °C) for diffused aeration, measured in mg/L. It is higher than Cst as it is affected by the oxygen transfer from bubbles under pressure in the water column. The value of C∞,20 can be estimated using the following equation:

- θ is the empirical temperature correction factor (1.024);

- α is the relative oxygen transfer rate in process water versus clean water (KLaf,20(wastewater)/KLaf,20(tap water));

- F is the fouling factor.

- Pw is the power requirement by blowers (kW);

- w is the weight of air flowrate (kg/s);

- R is the universal gas constant, R = 8.314 (J/mole K);

- T1 is the air absolute inlet temperature (K);

- p1 is the air absolute inlet pressure (atm);

- p2 is the air absolute outlet pressure (atm);

- n is (k − 1)/k, where k is the specific heat ratio, K = 1.395;

- 28.97 is the molecular weight of dry air;

- e is the efficiency of the blowers.

- ;

- ;

- ;

- ;

- .

3. Results and Discussion

3.1. Wastewater Treatment Plant Studies

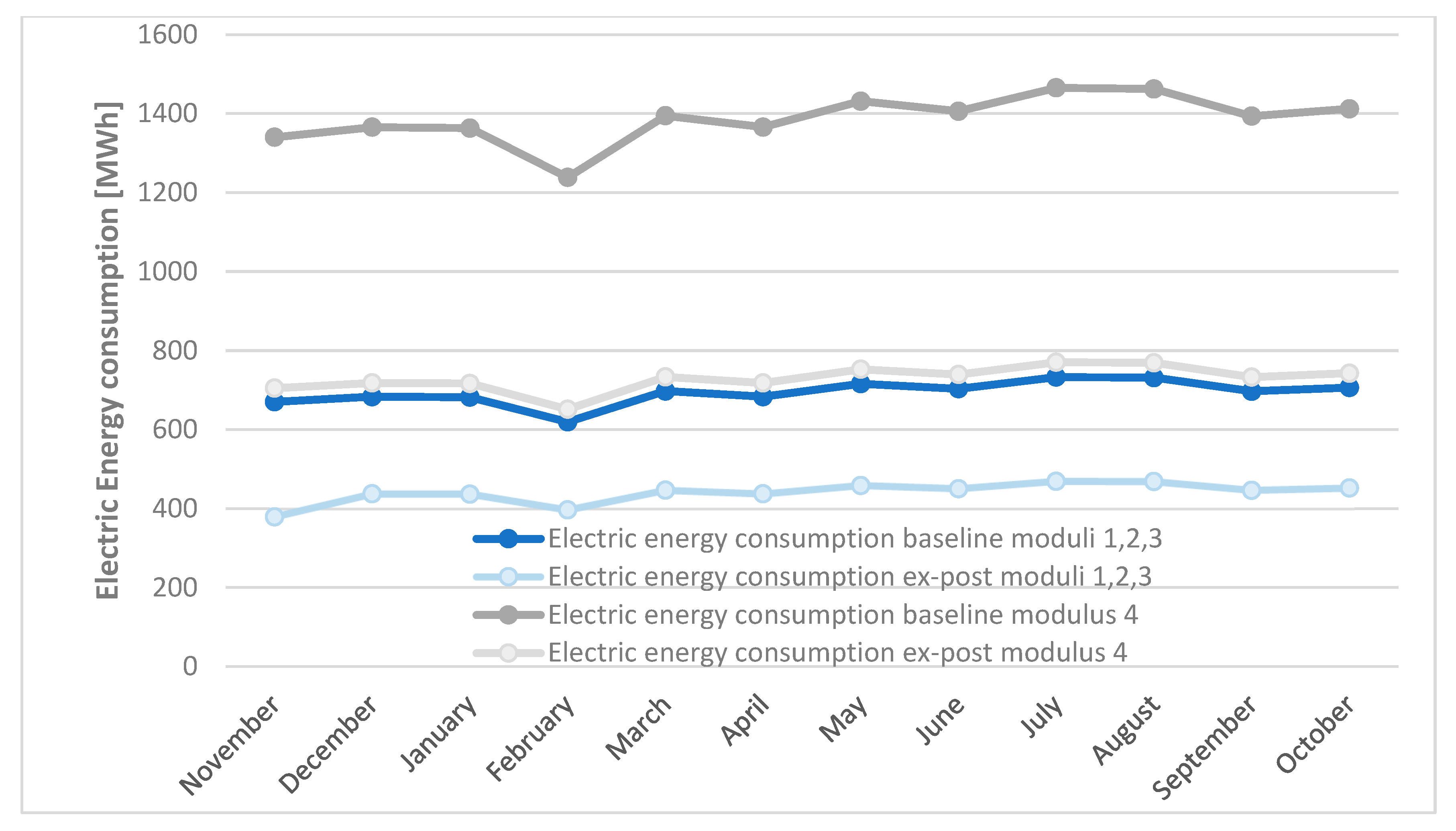

3.2. Power Requirement and Energy Consumption in Baseline and Ex-Post Configuration and Energy Savings Calculations

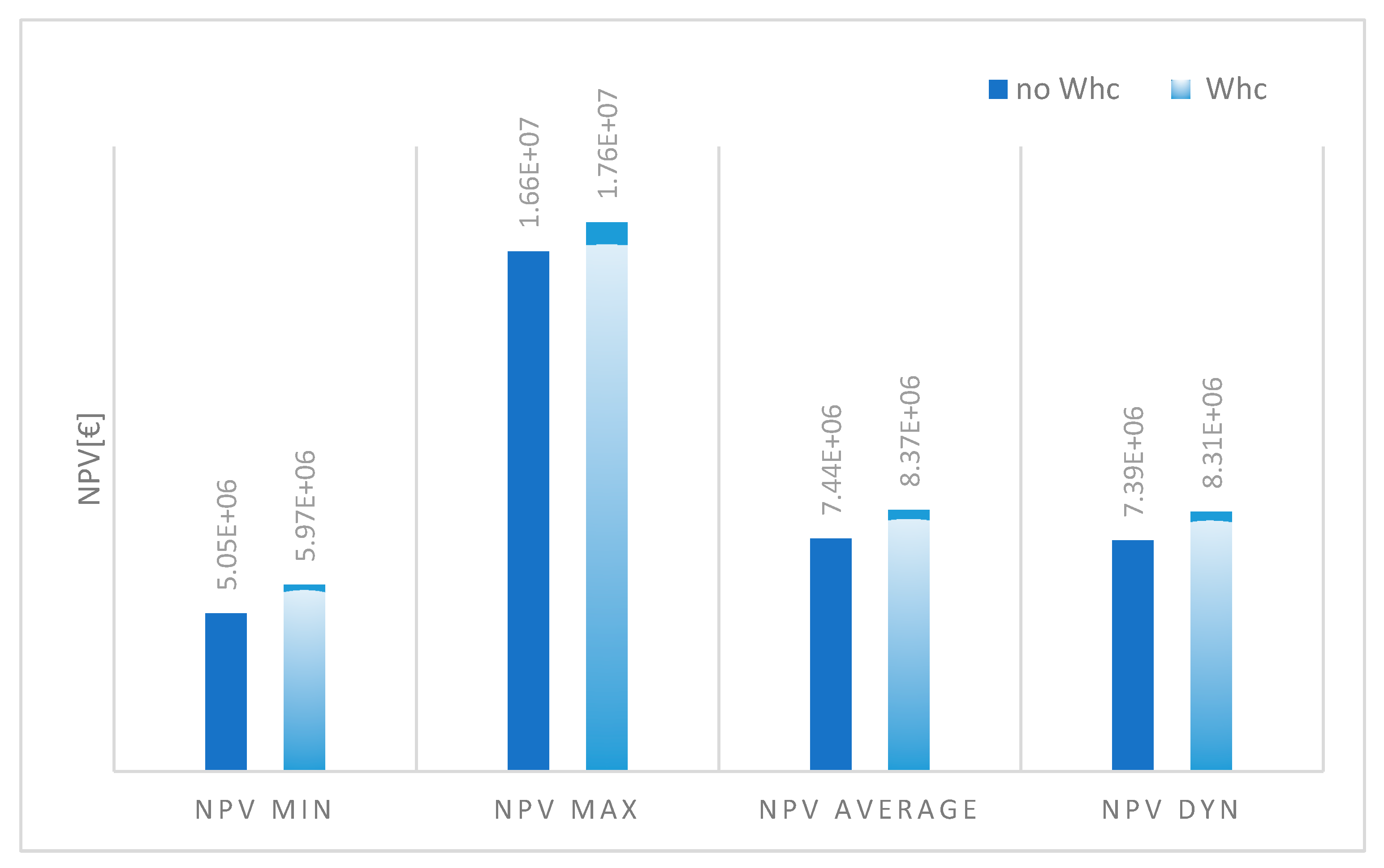

3.3. Economical Evaluation of the Investment from the Company Side

3.4. GHG Emissions Avoided with the Intervention

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- EUROSTAT. EU Energy Mix and Import Dependency [Internet]. 2022. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=EU_energy_mix_and_import_dependency (accessed on 29 September 2022).

- REPowerEU: Affordable, Secure and Sustainable Energy for Europe [Internet]. European Commission—European Commission. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal/repowereu-affordable-secure-and-sustainable-energy-europe_en (accessed on 29 September 2022).

- Factsheet on Energy Savings [Internet]. European Commission—European Commission. Available online: https://ec.europa.eu/commission/presscorner/detail/en/fs_22_3137 (accessed on 29 September 2022).

- European Commission. Best Available Techniques (BAT) Reference Document on Wastewater Treatment Facilities. 2016. Available online: chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://eippcb.jrc.ec.europa.eu/sites/default/files/2019-11/CWW_Bref_2016_published.pdf (accessed on 7 March 2023).

- Focus on Energy. Water and Wastewater Energy Best Practice Guidebook; Prepared for Wisconsin Department of Administration by the Focus on Energy Program; Focus on Energy: Madison, WI, USA, 2006. [Google Scholar]

- Ahmetovic, E.; Ibric, N.; Kravanja, Z. Optimal design for heat-integrated waterusing and wastewater treatment networks. Appl. Energy 2014, 135, 791–808. [Google Scholar] [CrossRef]

- ENERWATER. Standard Method and Online Tool for Assessing and Improving the Energy Efficiency of Wastewater Treatment Plants|ENERWATER Project|Fact Sheet|H2020 [Internet]. CORDIS|European Commission. Available online: https://cordis.europa.eu/project/id/649819 (accessed on 5 October 2022).

- Borzooei, S.; Amerlinck, Y.; Panepinto, D.; Abolfathi, S.; Nopens, I.; Scibilia, G.; Meucci, L.; Zanetti, M.C. Energy optimization of a wastewater treatment plant based on energy audit data: Small investment with high return. Environ. Sci. Pollut. Res. 2020, 27, 17972–17985. [Google Scholar] [CrossRef]

- Metcalf & Eddy Inc. Wastewater Engineering: Treatment and Resource Recovery, 5th ed.; McGraw-Hill Professional: New York, NY, USA, 2013. [Google Scholar]

- Rojas, J.; Zhelev, T. Energy efficiency optimisation of wastewater treatment: Study of ATAD. Comput. Chem. Eng. 2012, 38, 52–63. [Google Scholar] [CrossRef]

- Descoins, N.; Deleris, S.; Lestienne, R.; Trouvé, E.; Maréchal, F. Energy efficiency in waste water treatments plants: Optimization of activated sludge process coupled with anaerobic digestion. Energy 2012, 41, 153–164. [Google Scholar] [CrossRef]

- Metcalf and Eddy Inc. Wastewater Engineering: Treatment and Reuse, 4th ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Elías-Maxil, J.; van der Hoek, J.P.; Hofman, J.; Rietveld, L. Energy in the urban water cycle: Actions to reduce the total expenditure of fossil fuels with emphasis on heat reclamation from urban water. Renew. Sustain. Energy Rev. 2014, 30, 808–820. [Google Scholar] [CrossRef] [Green Version]

- Nakkasunchi, S.; Hewitt, N.J.; Zoppi, C.; Brandoni, C. A review of energy optimization modelling tools for the decarbonisation of wastewater treatment plants. J. Clean. Prod. 2021, 279, 123811. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, H.; Yin, Y.; Zeng, F.; Cui, Z. Smart energy savings for aeration control in wastewater treatment. Energy Rep. 2022, 8, 1711–1721. [Google Scholar] [CrossRef]

- Venkatesh, G.; Brattebø, H. Energy consumption, costs and environmental impacts for urban water cycle services: Case study of Oslo (Norway). Energy 2011, 36, 792–800. [Google Scholar] [CrossRef]

- Liu, H.; Ramnarayanan, R.; Logan, B.E. Production of electricity during waste-water treatment using a single chamber microbial fuel cell. Environ. Sci. Technol. 2004, 38, 2281–2285. [Google Scholar] [CrossRef]

- Descoins, N.; Stephane, D.; Remi, L.; Marechal, F. Energetic efficiency in Waste Water Treatments Plants: Optimization of activated sludge process coupled with anaerobic digestion. In Proceedings of the 23rd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Lausanne, Switzerland, 14–17 June 2010; pp. 1062–1069. [Google Scholar]

- Holenda, B.; Domokos, E.; Redey, A.; Fazakas, J. Aeration optimization of a wastewater treatment plant using genetic algorithm. Optim. Control. Appl. Methods 2007, 28, 191–208. [Google Scholar] [CrossRef]

- Fikar, M.; Chachuat, B.; Latifi, M.A. Optimal operation of alternating activated sludge processes. Control. Eng. Pr. 2005, 13, 853–861. [Google Scholar] [CrossRef] [Green Version]

- Lemos, D.; Dias, A.C.; Gabarrell, X.; Arroja, L. Environmental assessment of an urban water system. J. Clean. Prod. 2013, 54, 157–165. [Google Scholar] [CrossRef]

- Lundie, S.; Peters, G.M.; Beavis, P.C. Life Cycle Assessment for Sustainable Metropolitan Water Systems Planning. Environ. Sci. Technol. 2004, 38, 3465–3473. [Google Scholar] [CrossRef] [Green Version]

- Funamizu, N.; Iida, M.; Sakakura, Y.; Takakuwa, T. Reuse of heat energy in wastewater: Implementation examples in Japan. Water Sci. Technol. 2001, 43, 277–285. [Google Scholar] [CrossRef]

- Frijns, J.; Hofman, J.; Nederlof, M. The potential of (waste)water as energy carrier. Energy Convers. Manag. 2013, 65, 357–363. [Google Scholar] [CrossRef]

- Molinos-Senante, M.; Hanley, N.; Sala-Garrido, R. Measuring the CO2 shadow price for wastewater treatment: A directional distance function approach. Appl. Energy 2015, 144, 241–249. [Google Scholar] [CrossRef]

- Cano, R.; Pérez-Elvira, S.; Fdz-Polanco, F. Energy feasibility study of sludge pretreatments: A review. Appl. Energy 2015, 149, 176–185. [Google Scholar] [CrossRef]

- Soda, S.; Iwai, Y.; Sei, K.; Shimod, Y.; Ike, M. Model analysis of energy consumption and greenhouse gas emissions of sewage sludge treatment systems with different processes and scales. Water Sci. Technol. 2010, 61, 365–373. [Google Scholar] [CrossRef]

- Venkatesh, G.; Elmi, R.A. Economic–environmental analysis of handling biogas from sewage sludge digesters in WWTPs (wastewater treatment plants) for energy recovery: Case study of Bekkelaget WWTP in Oslo (Norway). Energy 2013, 58, 220–235. [Google Scholar] [CrossRef]

- Eastern Research Group, Inc. & Energy and Environmental Analysis Inc. Opportunities for and Benefits of Combined Heat and Power at Wastewater Treatment Facilities. Prepared for the United States Environmental Protection Agency. 2007. Available online: www.epa.gov/chp (accessed on 2 November 2015).

- Bidart, C.; Fröhling, M.; Schultmann, F. Electricity and substitute natural gas generation from the conversion of wastewater treatment plant sludge. Appl. Energy 2014, 113, 404–413. [Google Scholar] [CrossRef]

- Dixon, A.; Simon, M.; Burkitt, T. Assessing the environmental impact of two options for small-scale wastewater treatment: Comparing a reedbed and an aerated biological filter using a life cycle approach. Ecol. Eng. 2003, 20, 297–308. [Google Scholar] [CrossRef]

- Ko, J.Y.; Day, J.W.; Lane, R.R.; Day, J.N. A comparative evaluation of money-based and energy-based cost-benefit analyses of tertiary municipal wastewater treatment using forested wetlands vs. sand filtration in Louisiana. Ecol. Econ. 2004, 49, 331–347. [Google Scholar] [CrossRef]

- Panepinto, D.; Fiore, S.; Zappone, M.; Genon, G.; Meucci, L. Evaluation of the energy efficiency of a large wastewater treatment plant in Italy. Appl. Energy 2016, 161, 404–411. [Google Scholar] [CrossRef]

- Borzooei, S.; Campo, G.; Cerutti, A.; Meucci, L.; Panepinto, D.; Ravina, M.; Riggio, V.A.; Ruffino, B.; Scibilia, G.; Zanetti, M. Feasibility analysis for reduction of carbon footprint in a wastewater treatment plant. J. Clean. Prod. 2020, 271, 122526. [Google Scholar] [CrossRef]

- Ruffino, B.; Campo, G.; Genon, G.; Lorenzi, E.; Novarino, D.; Scibilia, G.; Zanetti, M. Improvement of anaerobic digestion of sewage sludge in a wastewater treatment plant by means of mechanical and thermal pre-treatments: Performance, energy and economical assessment. Bioresour. Technol. 2015, 175, 298–308. [Google Scholar] [CrossRef]

- GSE. Guida Operativa Certificati Bianchi; GSE: Rome, Italy, 1 January 2022. Available online: https://www.isprambiente.gov.it/files2022/pubblicazioni/rapporti/r363-2022.pdf (accessed on 1 January 2023).

- ISPRA. Indicatori di Efficienza e Decarbonizzazione del Sistema Energetico Nazionale e del Settore Elettrico; Report No.: 363; ISPRA: Rome, Italy, 2021. [Google Scholar]

- Sanaye, S.; Yazdani, M. Energy, exergy, economic and environmental analysis of a running integrated anaerobic digester-combined heat and power system in a municipal wastewater treatment plant. Energy Rep. 2022, 8, 9724–9741. [Google Scholar] [CrossRef]

- Arnd Wendland. Operation Cost of Wastewater Treatment Plant; Arnd Wendland: Ahrensburg, Germany, 2005. [Google Scholar]

| Modulus | Power Requirement Baseline [kW] | Power Requirement Ex-Post [kW] |

|---|---|---|

| 1, 2, 3 | 27,916.7 | 17,699.2 |

| 4 | 22,789.2 | 11,984.1 |

| Modulus | Electric Energy Consumption Baseline [MWh] | Electric Energy Consumption Ex-Post [MWh] |

|---|---|---|

| 1, 2, 3 | 8323 | 5277 |

| 4 | 16,639 | 8750 |

| Operation | Costs [€] |

|---|---|

| Cleaning of the tanks | 702,172 |

| Demolition of existing infrastructure and disposal of waste materials | 324,704 |

| Supply and installation of air diffusion network | 2,857,395 |

| Various completion works | 64,613 |

| Safety charges (not subject to rebate) related to services | 15,919.24 |

| Safety charges (not subject to rebate) related to the work | 23,878.86 |

| Total | 3,988,683 |

| Costs of Energy | [€/kWh] |

|---|---|

| cmax | 0.249 |

| caverage | 0.185 |

| cmin | 0.156 |

| cdyn | As in the period from 2008–2022 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Campo, G.; Miggiano, A.; Panepinto, D.; Zanetti, M. Enhancing the Energy Efficiency of Wastewater Treatment Plants through the Optimization of the Aeration Systems. Energies 2023, 16, 2819. https://doi.org/10.3390/en16062819

Campo G, Miggiano A, Panepinto D, Zanetti M. Enhancing the Energy Efficiency of Wastewater Treatment Plants through the Optimization of the Aeration Systems. Energies. 2023; 16(6):2819. https://doi.org/10.3390/en16062819

Chicago/Turabian StyleCampo, Giuseppe, Antonella Miggiano, Deborah Panepinto, and Mariachiara Zanetti. 2023. "Enhancing the Energy Efficiency of Wastewater Treatment Plants through the Optimization of the Aeration Systems" Energies 16, no. 6: 2819. https://doi.org/10.3390/en16062819