Perspectives on the Promotion of Solid Recovered Fuels in Taiwan

Abstract

1. Introduction

2. Data Mining

- -

- Baseline data on waste management and energy supply in Taiwan

- -

- Regulations for adopting SRFs in Taiwan

- -

- Challenges in the development of SRFs

3. Status of Waste Management and Energy Supply in Taiwan

3.1. Status of Waste Management

- -

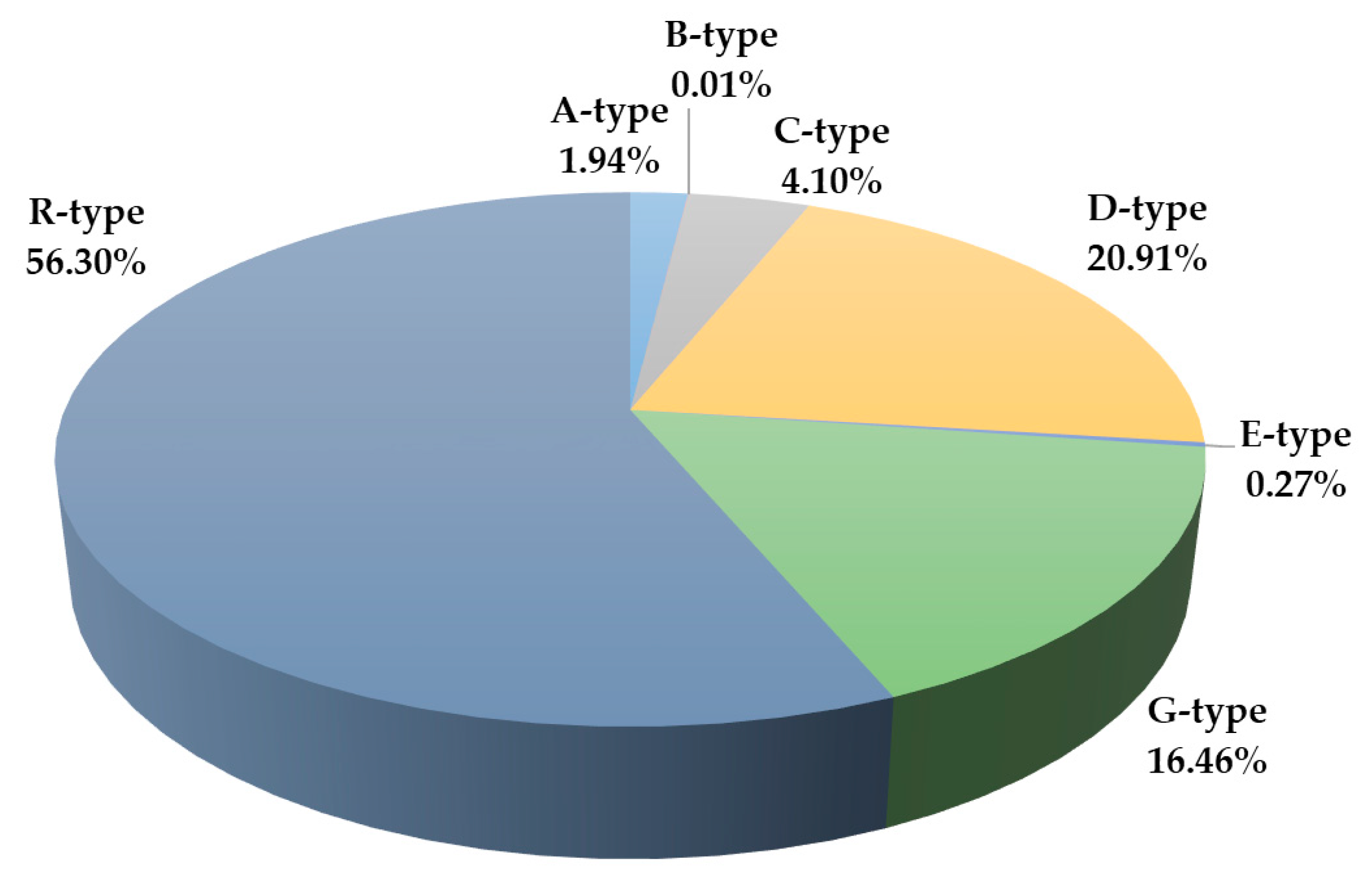

- A-type denotes manufactured hazardous industrial waste;

- -

- B-type denotes industrial waste containing toxic chemical substances;

- -

- C-type denotes biomedical/infectious waste and industrial waste identified by the standards;

- -

- D-type denotes general industrial waste without recyclable value;

- -

- E-type denotes scrap mixed metal;

- -

- G-type denotes the renewable resource that has lost its original usefulness and is economically and technologically feasible to be recycled or reused, as announced by the EPA;

- -

- R-type denotes industrial waste with recyclable value, as announced by the EPA.

3.2. Status of Energy Supply

3.2.1. Energy Supply

3.2.2. Waste-to-Energy

4. Regulations for Adopting Solid Recovered Fuels in Taiwan

5. Challenges in the Development of Solid Recovered Fuels in Taiwan

- -

- Environmental standards

- -

- According to the study on using different proportions of SRFs made by treated palm oil and others (i.e., coal ash, wood dust, and bentonite) [24], the results showed that the emissions of air toxics (e.g., heavy metals, dioxins, polycyclic aromatic hydrocarbons, and acidic gases) from industrial utilities (e.g., cement kiln, combustion chamber) in a CHP plant may be notable. Although the concentrations or levels of the emitted pollutants were lower than those of the discharge standards, it is necessary to adopt multiple air pollution control strategies for stationary sources. In this regard, some feedstocks (e.g., waste wood containing chromated copper arsenate) should be not used as auxiliary fuels the industrial utilities. In addition, the semi-dry (slurry lime) scrubber coupled with high-efficiency particulate control (e.g., bag filter) can be considered to be installed in the vent gas control system.

- -

- Economic benefits

- -

- The production of SRFs from non-hazardous waste (i.e., industrial general waste and MSW) mainly depends on large, reliable, available, homogeneous, and qualified amounts of high calorific fractions as input materials. In addition, these feedstocks for producing SRFs were also suitable for storage and transportation. In this regard, the input heat, based on the calorific value of SRFs and its fed amount, will be related to the economic efficiency in energy production and/or power generation. Table 3 listed the reported generation amounts of lignocellulosic waste categories used as feedstocks for producing SRFs in Taiwan [15], showing a significant shortage of domestic available materials compared to large amounts of coal consumed annually in the energy and industrial sectors (over 60 million metric tons) [1]. To increase the diversified sources of SRFs and lower the cost in Taiwan, several biomass resources, including crop residues (e.g., corn cob) and waste-activated sludge (e.g., food processing sludge) can be used as feedstocks for producing SRFs.

- -

- Engineering modifications

- -

- In order to evaluate the slagging and fouling tendency of solid fuels (e.g., coal) in industrial utilities, several indices have been developed to modify process engineering in recent years [25,26]. Table 4 summarized the suggested indices for slagging and fouling tendency when using SRFs in industrial boilers, including the alkali/acid ratio, the fouling index, the slagging index, the slag viscosity index, and chlorine content. Usually, these inorganic elements have been identified to cause operational problems during the coal/SRF co-firing in the combustion system [17,18]. To reduce the slagging and fouling tendency, some feedstocks containing high ash and sulfur contents (e.g., rubber, waste tire) for producing SRFs should be not used as auxiliary fuels for industrial utilities.

6. Conclusions and Recommendations

- -

- Expanding the available waste sources, including bamboo residues, spent mushroom compost, and biological sludge, which are in compliance with quality standards.

- -

- Revising the quality standards of SRFs by adding the elements relevant to air toxins and slagging and fouling tendency.

- -

- Increasing the production of SRFs from combustible MSW, which was used in high energy-consuming industries, such as steel manufacturing and cement making.

- -

- Co-firing SRFs in coal-fired power plants for reducing the use of fossil fuels and GHG emissions.

- -

- Surveying the concentrations (or levels) of the air pollutants emitted from the vent stack in the coal/SRF combustion systems.

- -

- Increasing the feed-in-tariff (FIT) rates of SRF-to-power systems due to the capital and operating costs increased.

- -

- Increasing the diversified sources of SRFs including crop residues (e.g., corn cob) and waste-activated sludge (e.g., food processing sludge).

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ministry of Economic Affairs (MOEA, Taiwan). Energy Statistics Handbook-2021; MOEA: Taipei, Taiwan, 2022. [Google Scholar]

- Environmental Protection Administration (EPA, Taiwan). Taiwan Greenhouse Gases Inventory; EPA: Taipei, Taiwan, 2021. [Google Scholar]

- Tsai, W.T. Promoting the Circular Economy via Waste-to-Power (WTP) in Taiwan. Resources 2019, 8, 95. [Google Scholar] [CrossRef]

- Lee, Y.R.; Tsai, W.T. Overview of biomass-to-energy supply and promotion policy in Taiwan. Energies 2022, 15, 6576. [Google Scholar] [CrossRef]

- Sarc, R.; Seidler, I.M.; Kandlbauer, L.; Lorber, K.E.; Pomberger, R. Design, quality and quality assurance of solid recovered fuels for the substitution of fossil feedstock in the cement industry—Update 2019. Waste Manag. Res. 2019, 37, 885–897. [Google Scholar] [CrossRef] [PubMed]

- Ferronato, N.; Mendoza, I.J.C.; Siñani, N.G.M.; Portillo, M.A.G.; Torretta, V. Perspectives in solid recovered fuel production in Bolivia: Analysis of characteristics and potential benefits. Waste Manag. 2022, 144, 324–335. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.S.; Lee, Y.J.; Kang, J.G.; Shin, S.K.; Jeon, T.W. Assessment of quality test methods for solid recovered fuel in South Korea. Waste Manag. 2020, 103, 240–250. [Google Scholar] [CrossRef] [PubMed]

- Viczek, S.A.; Aldrian, A.; Pomberger, R.; Sarc, R. Origins of major and minor ash constituents of solid recovered fuel for co-processing in the cement industry. Waste Manag. 2021, 126, 423–432. [Google Scholar] [CrossRef] [PubMed]

- Szydełko, A.; Ferens, W.; Rybak, W. Effects of calcium, sodium and potassium on ash fusion temperatures of solid recovered fuels (SRF). Waste Manag. 2022, 150, 161–173. [Google Scholar] [CrossRef] [PubMed]

- Gerassimidou, S.; Velis, C.A.; Komilis, D. Establishing a sub-sampling plan for waste-derived solid recovered fuels (SRF): Effects of shredding on representative sample preparation based on theory of sampling (ToS). Waste Manag. 2020, 113, 430–438. [Google Scholar] [CrossRef] [PubMed]

- Multiple Waste Treatment Plan (Environmental Protection Administration, Taiwan). Available online: https://www.ey.gov.tw/Page/448DE008087A1971/8f06d8fb-0864-41b3-911e-a8e31ed16b60 (accessed on 31 January 2023). (In Chinese)

- Rigamonti, L.; Borghi, G.; Martignon, G.; Grosso, M. Life cycle costing of energy recovery from solid recovered fuel produced in MBT plants in Italy. Waste Manag. 2019, 99, 154–162. [Google Scholar] [CrossRef] [PubMed]

- Environmental Protection Administration (EPA, Taiwan). Yearbook of Environmental Protection Statistics 2021; EPA: Taipei, Taiwan, 2022. [Google Scholar]

- Energy Statistics (Bureau of Energy, Ministry of Economic Affairs, Taiwan). Available online: https://www.moeaboe.gov.tw/ECW/english/content/SubMenu.aspx?menu_id=8706 (accessed on 22 January 2023).

- Industrial Waste Reporting and Management Information System (Environmental Protection Administration, Taiwan) (In Chinese). Available online: https://waste.epa.gov.tw/RWD/Statistics/?page=Month1 (accessed on 22 January 2023).

- Laws and Regulation Retrieving System (Ministry of Justice, Taiwan). Available online: https://law.moj.gov.tw/Eng/index.aspx (accessed on 13 January 2023).

- Szydełko, A.; Ferens, W.; Rybak, W. The effect of mineral additives on the process of chlorine bonding during combustion and co-combustion of Solid Recovered Fuels. Waste Manag. 2020, 102, 624–634. [Google Scholar] [CrossRef] [PubMed]

- Gerassimidou, S.; Velis, C.A.; Williams, P.T.; Castaldi, M.J.; Black, L.; Komilis, D. Chlorine in waste-derived solid recovered fuel (SRF), co-combusted in cement kilns: A systematic review of sources, reactions, fate and implications. Crit. Rev. Environ. Sci. Technol. 2021, 51, 140–186. [Google Scholar] [CrossRef]

- Tsai, W.T. Recycling waste electrical and electronic equipment (WEEE) and the management of its toxic substances in Taiwan—A case study. Toxics 2020, 8, 48. [Google Scholar] [CrossRef] [PubMed]

- Tsai, C.H.; Shen, Y.H.; Tsai, W.T. Sustainable material management of industrial hazardous waste in Taiwan: Case studies in circular economy. Sustainability 2021, 13, 9410. [Google Scholar] [CrossRef]

- Renewable Energy Development Act (Ministry of Economic Affairs, Taiwan). Available online: https://law.moj.gov.tw/ENG/LawClass/LawAll.aspx?pcode=J0130032 (accessed on 25 December 2022).

- Štofová, L.; Szaryszová, P.; Mihalčová, B. Testing the bioeconomic options of transitioning to solid recovered fuel: A Case Study of a thermal power plant in Slovakia. Energies 2021, 14, 1720. [Google Scholar] [CrossRef]

- Khan, M.M.H.; Havukainen, J.; Horttanainen, M. Impact of utilizing solid recovered fuel on the global warming potential of cement production and waste management system: A life cycle assessment approach. Waste Manag. Res. 2021, 39, 561–572. [Google Scholar] [CrossRef] [PubMed]

- Kuo, Y.M.; Huang, S.W.; Kuan, W.Y. Characteristics of emissions from reclamation of solid-recovered fuel (SRF) in a cogeneration plant. Aerosol. Air Qual. Res. 2021, 21, 210112. [Google Scholar] [CrossRef]

- Chen, C.; Bi, Y.; Huang, Y.; Huang, H. Review on slagging evaluation methods of biomass fuel combustion. J. Anal. Appl. Pyrolysis 2021, 135, 105082. [Google Scholar] [CrossRef]

- Lachman, J.; Balas, M.; Lisy, M.; Lisa, H.; Milcak, P.; Elbl, P. An overview of slagging and fouling indicators and their applicability to biomass fuels. Fuel. Process. Technol. 2021, 217, 106804. [Google Scholar] [CrossRef]

| Quality Item | Limit | Testing Method | Sample Basis |

|---|---|---|---|

| Net calorific value a | ≧10.0 MJ/kg (2392 kcal/kg) | CNS 10835 | As received b |

| Chlorine (Cl) | ≦3 wt% | EN 15408 | db c |

| Mercury (Hg) | ≦5 mg/kg | EN 15411 | As received b |

| Lead (Pb) | ≦150 mg/kg | EN 15411 | As received b |

| Cadmium (Cd) | ≦5 mg/kg | EN 15411 | As received b |

| Waste Type | Item Name a | Reporting Code |

|---|---|---|

| Plastic | Waste resin | D-0202 |

| Mixture containing waste plastic | D-0202 | |

| Waste plastic | R-0201 | |

| Waste plastic container (PET) | R-0202 | |

| Waste plastic container (PE) | R-0204 | |

| Waste plastic container (PP) | R-0205 | |

| Waste plastic container (PS foamed) | R-0206 | |

| Waste plastic container (PS unfoamed) | R-0207 | |

| Waste plastic container (Others) | R-0208 | |

| Waste bioplastic container (PLA) | R-0211 | |

| Rubber | Mixture containing waste rubber | D-0202 |

| Waste rubber | R-0301 | |

| Paper | Mixture containing paper | D-0609 |

| Waste paper | R-0601 | |

| Wood | Waste wooden pallet | D-0701 |

| Mixture containing wood | D-0799 | |

| Waste wood | R-0701 | |

| Fiber | Waste fiber | D-0801 |

| Waste cotton flock | D-0802 | |

| Waste cloth | D-0803 | |

| Mixture containing fiber, cotton, or cloth | D-0899 | |

| Waste synthetic fiber | R-0801 | |

| Texture leftover | R-0802 | |

| Sludge | Pulp sludge | R-0904 |

| Texture sludge | R-0906 | |

| Animal-/plant-derived waste | Sugarcane bagasse | R-0102 |

| Garbage | General waste from industrial activities | D-1801 b |

| Lignocellulosic Waste Categories (Waste Code) | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|---|

| Mixture containing paper (D-0699) | 214,996 | 202,614 | 248,303 | 209,097 | 204,647 | 232,907 |

| Waste paper (R-0601) | 2603 | 4277 | 3632 | 4120 | 3325 | 3476 |

| Waste wooden pallet (D-0701) | 3796 | 3444 | 2902 | 2312 | 2204 | 2005 |

| Mixture containing wood (D-0799) | 19,471 | 14,920 | 15,613 | 12,872 | 14,891 | 23,483 |

| Waste wood (R-0701) | 51,705 | 60,476 | 65,932 | 64,329 | 71,922 | 96,919 |

| Pulp sludge (R-0904) | 377,654 | 430,424 | 413,723 | 398,836 | 402,126 | 462,711 |

| Textile sludge (R-0906) | 42,509 | 47,358 | 45,264 | 53,837 | 53,734 | 61,243 |

| Sugarcane bagasse (R-0102) | 13,836 | 23,183 | 14,870 | 15,993 | 19,718 | 23,554 |

| Index | Expression by Molecule/Element Symbol a | Values | Tendency Degree |

|---|---|---|---|

| Alkali/acid ratio (RB/A) | RB/A = (Fe2O3 + CaO + MgO + K2O + Na2O)/(SiO2 + Al2O3 + TiO2) | ˂0.206 | Low |

| 0.206–0.400 | Medium | ||

| >0.400 | High | ||

| Slagging index (RS) | RB/A×S | ˂0.6 | Low |

| 0.6–2.0 | Medium | ||

| 2.0–2.6 | High | ||

| >2.6 | Severe | ||

| Fouling index (RF) | RB/A × (K2O + Na2O) | ˂0.6 | Low |

| 0.6–40 | Medium-high | ||

| >0.400 | Severe | ||

| Chlorine content | Cl | ˂0.2 | Low |

| 0.2–0.3 | Medium | ||

| 0.3–0.5 | High | ||

| >0.5 | Severe | ||

| Slag viscosity index (Sr) | 100 × SiO2/(SiO2 + Fe2O3 + CaO + MgO) | >72 | Low |

| 65–72 | Medium | ||

| ˂65 | High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, W.-T. Perspectives on the Promotion of Solid Recovered Fuels in Taiwan. Energies 2023, 16, 2944. https://doi.org/10.3390/en16072944

Tsai W-T. Perspectives on the Promotion of Solid Recovered Fuels in Taiwan. Energies. 2023; 16(7):2944. https://doi.org/10.3390/en16072944

Chicago/Turabian StyleTsai, Wen-Tien. 2023. "Perspectives on the Promotion of Solid Recovered Fuels in Taiwan" Energies 16, no. 7: 2944. https://doi.org/10.3390/en16072944

APA StyleTsai, W.-T. (2023). Perspectives on the Promotion of Solid Recovered Fuels in Taiwan. Energies, 16(7), 2944. https://doi.org/10.3390/en16072944