Biomass to H2: Evaluation of the Impact of PV and TES Power Supply on the Performance of an Integrated Bio-Thermo-Chemical Upgrading Process for Wet Residual Biomass

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Description

2.2. Feedstock

2.3. Power Demand

2.4. KPIs of the Plant

2.4.1. Hydrogen Yield

2.4.2. CO2 Emissions

- is the specific CO2 emission of the electricity in the grid;

- is the yearly electricity withdrawn from the central grid;

- is the specific CO2 emission of the electricity of the PV;

- is the yearly electricity production from the PV;

- is the carbon dioxide mass flow in the flue gas after reforming.

2.4.3. Plant Efficiency

- is the yearly hydrogen mass production;

- is the low heating value of hydrogen;

- is the difference between the final and initial energy content in TES;

- is the yearly oil organic fraction mass production;

- is the low heating value of the organic fraction of the oil;

- is the energy produced by PV or absorbed from the grid;

- is the yearly quinoa mass feed (only quinoa is accounted for since the sludge does not have a proper heating value);

- is the low heating value of quinoa.

2.4.4. Total Specific Energy Consumption (TEC) for H2 Production

- is the energy produced by PV or absorbed from the grid;

- is the yearly quinoa mass feed (only quinoa is accounted for since the sludge does not have a proper heating value);

- is the low heating value of biomass;

- is the yearly hydrogen mass production;

- is the yearly hydrogen normal volume production.

2.4.5. Electrical Specific Energy Consumption (EEC) for H2 Production

2.4.6. Specific CO2 Emissions

- is the specific CO2 emission in the electricity of the grid;

- is the yearly electricity withdrawn from the central grid;

- is the carbon dioxide mass flow in the flue gas;

- is the specific CO2 emission of the electricity of the PV;

- is the yearly electricity production from the PV;

- is the yearly hydrogen mass production;

- is the yearly hydrogen normal volume production.

2.4.7. Self-Consumption (SC)

- is the yearly photovoltaic electricity directly utilized by the system;

- is the yearly energy of TES utilized by the system;

- is the yearly energy consumption of the system.

3. Results and Discussion

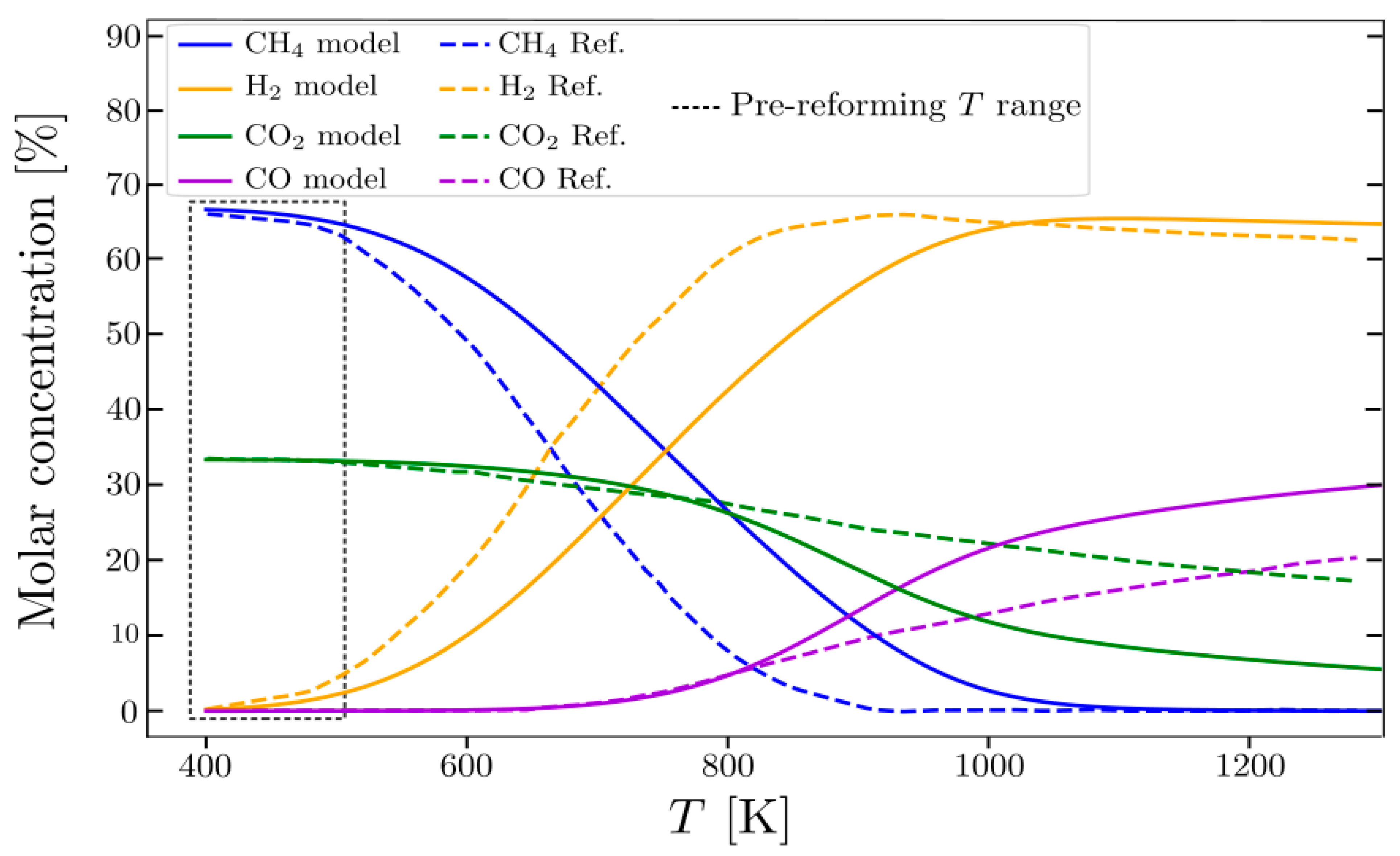

3.1. Validation of the Reforming Model

3.2. Evaluation of the KPIs

4. Conclusions

- TES is a key component to achieving a larger self-consumption path for the plant and reducing the carbon footprint of the hydrogen production, reaching a 42.8% self-consumption (SC) value;

- The proposed plant can achieve a specific electrical energy consumption of 17.16 , which is higher if compared to current electrolyzer technologies but can be obtained by valorizing residual low-energy biomasses.

- There is a good synergy in the plant process, reaching a hydrogen yield of 5.37%, demonstrated also by the balance between the hydrogen recovery potential from biogas and pyrolysis products (respectively 44.5% and 55.5%).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix A.1. Anaerobic Digestion

Appendix A.2. Pyrolysis

Appendix A.3. Electrical Steam Reforming

- Constancy of the number of atoms in each element;

- The number of moles in each species cannot be negative.

Appendix A.4. Water-Gas-Shift Membrane

Appendix A.5. Compressor

Appendix A.6. Photovoltaic

Appendix A.7. Thermal Energy Storage System

References

- Intergovernmental Panel on Climate Change. Climate Change 2022: Mitigation of Climate Change—Summary for Policymakers; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2022.

- Intergovernmental Panel on Climate Change. Climate Change 2022: Impacts, Adaptation and Vulnerability—Summary for Policymakers; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2022.

- Butera, G.; Jensen, S.H.; Gadsbøll, R.; Ahrenfeldt, J.; Clausen, L.R. Flexible biomass conversion to methanol integrating solid oxide cells and TwoStage gasifier. Fuel 2020, 271, 117654. [Google Scholar] [CrossRef]

- Prestipino, M.; Piccolo, A.; Polito, M.F.; Galvagno, A. Combined Bio-Hydrogen, Heat, and Power Production Based on Residual Biomass Gasification: Energy, Exergy, and Renewability Assessment of an Alternative Process Configuration. Energies 2022, 15, 5524. [Google Scholar] [CrossRef]

- Bach, Q.-V.; Nguyen, D.D.; Lee, C.-J. Effect of Torrefaction on Steam Gasification of Biomass in Dual Fluidized Bed Reactor—A Process Simulation Study. BioEnergy Res. 2019, 12, 1042–1051. [Google Scholar] [CrossRef]

- Tayibi, S.; Monlau, F.; Marias, F.; Thevenin, N.; Jimenez, R.; Oukarroum, A.; Alboulkas, A.; Zeroual, Y.; Barakat, A. Industrial symbiosis of anaerobic digestion and pyrolysis: Performances and agricultural interest of coupling biochar and liquid digestate. Sci. Total Environ. 2021, 793, 148461. [Google Scholar] [CrossRef] [PubMed]

- Kevin, A.; Glen, P. The trouble with negative emissions. Science 2016, 354, 182–183. [Google Scholar]

- Burns, W.; Nicholson, S. Bioenergy and carbon capture with storage (BECCS): The prospects and challenges of an emerging climate policy response. J. Environ. Stud. Sci. 2017, 7, 527–534. [Google Scholar] [CrossRef]

- Almena, A.; Thornley, P.; Chong, K.; Röder, M. Carbon dioxide removal potential from decentralised bioenergy with carbon capture and storage (BECCS) and the relevance of operational choices. Biomass Bioenergy 2022, 159, 106406. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal. 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 11 December 2019).

- Ringkjøb, H.-K.; Haugan, P.M.; Solbrekke, I.M. A review of modelling tools for energy and electricity systems with large shares of variable renewables. Renew. Sustain. Energy Rev. 2018, 96, 440–459. [Google Scholar] [CrossRef]

- Chen, X.; Mcelroy, M.B.; Wu, Q.; Shu, Y.; Xue, Y. Transition towards higher penetration of renewables: An overview of interlinked technical, environmental and socio-economic challenges. J. Mod. Power Syst. Clean Energy 2019, 7, 1–8. [Google Scholar] [CrossRef]

- Arraño-Vargas, F.; Shen, Z.; Jiang, S.; Fletcher, J.; Konstantinou, G. Challenges and Mitigation Measures in Power Systems with High Share of Renewables—The Australian Experience. Energies 2022, 15, 429. [Google Scholar] [CrossRef]

- Guerra, O.J.; Zhang, J.; Eichman, J.; Denholm, P.; Kurtz, J.; Hodge, B.-M. The value of seasonal energy storage technologies for the integration of wind and solar power. Energy Environ. Sci. 2020, 13, 1909–1922. [Google Scholar] [CrossRef]

- Gabrielli, P.; Poluzzi, A.; Kramer, G.J.; Spiers, C.; Mazzotti, M.; Gazzani, M. Seasonal energy storage for zero-emissions multi-energy systems via underground hydrogen storage. Renew. Sustain. Energy Rev. 2020, 121, 109629. [Google Scholar] [CrossRef]

- European Commission. A Hydrogen Strategy for a Climate-Neutral Europe; European Commission: Brussels, Belgium, 2020.

- Ministry of Economy, Trade and Industry (METI). Ministerial Council on Renewable Energy Hydrogen and Related Issues—Japan Government; Basic Hydrogen Strategy; Ministry of Economy, Trade and Industry (METI): Tokyo, Japan, 2017; pp. 1–37.

- Trieb, F.; Moser, M.; Kern, J. Liquid Solar Fuel—Liquid hydrocarbons from solar energy and biomass. Energy 2018, 153, 1–11. [Google Scholar] [CrossRef]

- Poluzzi, A.; Guandalini, G.; D’Amore, F.; Romano, M.C. The Potential of Power and Biomass-to-X Systems in the Decarbonization Challenge: A Critical Review. Curr. Sustain. Energy Rep. 2021, 8, 242–252. [Google Scholar] [CrossRef]

- Henriksen, U.; Ahrenfeldt, J.; Jensen, T.K.; Gøbel, B.; Bentzen, J.D.; Hindsgaul, C.; Sørensen, L.H. The design, construction and operation of a 75kW two-stage gasifier. Energy 2006, 31, 1542–1553. [Google Scholar] [CrossRef]

- Gadsbøll, R.; Clausen, L.; Thomsen, T.P.; Ahrenfeldt, J.; Henriksen, U.B. Flexible TwoStage biomass gasifier designs for polygeneration operation. Energy 2019, 166, 939–950. [Google Scholar] [CrossRef]

- Butera, G.; Jensen, S.H.; Ahrenfeldt, J.; Clausen, L.R. Techno-economic analysis of methanol production units coupling solid oxide cells and thermochemical biomass conversion via the TwoStage gasifier. Fuel Process. Technol. 2021, 215, 106718. [Google Scholar] [CrossRef]

- Bartolucci, L.; Bocci, E.; Cordiner, S.; De Maina, E.; Lombardi, F.; Marcantonio, V.; Mele, P.; Mulone, V.; Sorino, D. Biomass Polygeneration System for the Thermal Conversion of Softwood Waste into Hydrogen and Drop-In Biofuels. Energies 2023, 16, 1286. [Google Scholar] [CrossRef]

- Pecchi, M.; Baratieri, M. Coupling anaerobic digestion with gasification, pyrolysis or hydrothermal carbonization: A review. Renew. Sustain. Energy Rev. 2019, 105, 462–475. [Google Scholar] [CrossRef]

- Kan, X.; Yao, Z.; Zhang, J.; Tong, Y.W.; Yang, W.; Dai, Y.; Wang, C.-H. Energy performance of an integrated bio-and-thermal hybrid system for lignocellulosic biomass waste treatment. Bioresour. Technol. 2017, 228, 77–88. [Google Scholar] [CrossRef]

- Ramachandran, S.; Yao, Z.; You, S.; Massier, T.; Stimming, U.; Wang, C.-H. Life cycle assessment of a sewage sludge and woody biomass co-gasification system. Energy 2017, 137, 369–376. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; He, Y.; Zhang, C.; Liu, X.; Chen, C.; Liu, G. Anaerobic co-digestion of chicken manure and corn stover in batch and continuously stirred tank reactor (CSTR). Bioresour. Technol. 2014, 156, 342–347. [Google Scholar] [CrossRef] [PubMed]

- Luz, F.C.; Cordiner, S.; Manni, A.; Mulone, V.; Rocco, V. Pyrolysis in screw reactors: A 1-D numerical tool. Energy Procedia 2017, 126, 683–689. [Google Scholar] [CrossRef]

- Luz, F.C.; Cordiner, S.; Manni, A.; Mulone, V.; Rocco, V. Biomass fast pyrolysis in screw reactors: Prediction of spent coffee grounds bio-oil production through a monodimensional model. Energy Convers. Manag. 2018, 168, 98–106. [Google Scholar] [CrossRef]

- Bartolucci, L.; Cordiner, S.; Mulone, V.; Pasquale, S.; Sbarra, A. Design and management strategies for low emission building-scale Multi Energy Systems. Energy 2022, 239, 122160. [Google Scholar] [CrossRef]

- Yu, S.; Park, J.; Kim, M.; Ryu, C.; Park, J. Characterization of biochar and byproducts from slow pyrolysis of hinoki cypress. Bioresour. Technol. Rep. 2019, 6, 217–222. [Google Scholar] [CrossRef]

- Kechagiopoulos, P.N.; Voutetakis, S.S.; Lemonidou, A.A.; Vasalos, I.A. Hydrogen Production via Steam Reforming of the Aqueous Phase of Bio-Oil in a Fixed Bed Reactor. Energy Fuels 2006, 20, 2155–2163. [Google Scholar] [CrossRef]

- European Union. Directives Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast) (Text with EEA Relevance). Off. J. Eur. Union 2018, L328, 82–208. [Google Scholar]

- Kratzeisen, M.; Starcevic, N.; Martinov, M.; Maurer, C.; Müller, J. Applicability of biogas digestate as solid fuel. Fuel 2010, 89, 2544–2548. [Google Scholar] [CrossRef]

- Available online: https://www.eea.europa.eu/data-and-maps/daviz/co2-emission-intensity-12#tab-googlechartid_chart_11 (accessed on 26 October 2022).

- Peng, J.; Lu, L.; Yang, H. Review on life cycle assessment of energy payback and greenhouse gas emission of solar photovoltaic systems. Renew. Sustain. Energy Rev. 2013, 19, 255–274. [Google Scholar] [CrossRef]

- Hsu, C.-W. Constructing an evaluation model for hydrogen application pathways. Int. J. Hydrogen Energy 2013, 38, 15836–15842. [Google Scholar] [CrossRef]

- Bridgwater, A.V.; Peacocke, G.V.C. Fast Pyrolysis Processes for Biomass. Available online: www.elsevier.com/locate/rser (accessed on 22 March 2000).

- Vagia, E.C.; Lemonidou, A.A. Thermodynamic analysis of hydrogen production via autothermal steam reforming of selected components of aqueous bio-oil fraction. Int. J. Hydrogen Energy 2008, 33, 2489–2500. [Google Scholar] [CrossRef]

- Available online: https://ahdb.org.uk/knowledge-library/hydrogen-electrolysis (accessed on 26 January 2022).

- Koponen, J.; Kosonen, A.; Huoman, K.; Ahola, J.; Ahonen, T.; Ruuskanen, V. Specific energy consumption of PEM water electrolysers in atmospheric and pressurised conditions. In Proceedings of the 2016 18th European Conference on Power Electronics and Applications (EPE’16 ECCE Europe), Karlsruhe, Germany, 5–9 September 2016. [Google Scholar]

- Aziz, M.; Darmawan, A.; Juangsa, F.B. Hydrogen production from biomasses and wastes: A technological review. Int. J. Hydrogen Energy 2021, 46, 33756–33781. [Google Scholar] [CrossRef]

- Ting, Z.J.; Raheem, A.; Dastyar, W.; Yang, H.; Dong, W.; Yuan, H.; Li, X.; Wang, W.; Zhang, R.; Zhao, M. Alkaline pyrolysis of anaerobic digestion residue with selective hydrogen production. Int. J. Hydrogen Energy 2020, 45, 20933–20943. [Google Scholar] [CrossRef]

- Lopez, G.; Santamaria, L.; Lemonidou, A.; Zhang, S.; Wu, C.; Sipra, A.T.; Gao, N. Hydrogen generation from biomass by pyrolysis. Nat. Rev. Methods Prim. 2022, 2, 20. [Google Scholar] [CrossRef]

- Tippayawong, N.; Thanompongchart, P. Biogas quality upgrade by simultaneous removal of CO2 and H2S in a packed column reactor. Energy 2010, 35, 4531–4535. [Google Scholar] [CrossRef]

- Long, T.; Li, M.; Chen, Y.; Zhu, X. Study on Evaporation Characteristics of Bio-oil and its Compound Models. Bioresources 2014, 9, 4242–4252. [Google Scholar] [CrossRef]

- Wismann, S.T.; Engbæk, J.S.; Vendelbo, S.B.; Eriksen, W.L.; Frandsen, C.; Mortensen, P.M.; Chorkendorff, I. Electrified methane reforming: Elucidating transient phenomena. Chem. Eng. J. 2021, 425, 131509. [Google Scholar] [CrossRef]

- Oladokun, O.; Ahmad, A.; Abdullah, T.A.T.; Nyakuma, B.B.; Kamaroddin, M.F.A.; Nor, S.H.M. Biohydrogen production from Imperata cylindrica bio-oil using non-stoichiometric and thermodynamic model. Int. J. Hydrogen Energy 2017, 42, 9011–9023. [Google Scholar] [CrossRef]

- LeValley, T.L.; Richard, A.R.; Fan, M. The progress in water gas shift and steam reforming hydrogen production technologies—A review. Int. J. Hydrogen Energy 2014, 39, 16983–17000. [Google Scholar] [CrossRef]

- Chen, W.-H.; Chen, C.-Y. Water gas shift reaction for hydrogen production and carbon dioxide capture: A review. Appl. Energy 2020, 258, 114078. [Google Scholar] [CrossRef]

- Catalano, J.; Guazzone, F.; Mardilovich, I.; Ma, Y.H.; Kazantzis, N. Hydrogen production in a large scale water gas shift pd based membrane reactor. In Proceedings of the Separations Division—Core Programming Topic at the 2011 AIChE Annual Meeting, Minneapolis, MN, USA, 16–21 October 2011; Volume 2, pp. 1258–1259. [Google Scholar]

- Riedl, S.M. Development of a Hydrogen Refueling Station Design Tool. Int. J. Hydrogen Energy 2020, 45, 1–9. [Google Scholar] [CrossRef]

- Campbell, J. Solidification Structure. In Complete Casting Handbook, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

| Anaerobic Digester | Pyrolizer | PV System | |||

| Temperature [°C] | 35 ± 2 | length [m] | 0.25 | Panel power (W) | 285 |

| Specific Methane Production | 237 | diameter [m] | 0.02 | Numbers of panels | 63 |

| Hydraulic Retention Time [Days] | 41 | Screw rotational speed [rpm] | 45 | System power (kW) | 18 |

| Organic Load Rate | 2 | temperature [°C] | 500 | ||

| Pre-reformer | Reformer | TES | |||

| Length [m] | 0.7 | Length [m] | 0.7 | Capacity [kWh] | 700 |

| Diameter [mm] | 12.7 | Diameter [mm] | 12.7 | Initial capacity [kWh] | 300 |

| Temperature [°C] | 378.05 | Temperature [°C] | 866 | T max [°C] | 1200 |

| Steam/Carbon | 1 | Steam/Carbon | 2 | Heat loss in 24 h | <2% |

| Parameters | Quinoa Residues | Wastewater Sludge |

|---|---|---|

| DM (%wt) | 90.1 ± 0.1 | 18.7 ± 0.1 |

| VS (%wt,DM) | 88.9 ± 0.3 | 79.6 ± 2.2 |

| C (%wt) | 43.3 ± 0.2 | 41.2 ± 0.2 |

| H (%wt) | 6.0 ± 0.1 | 6.2 ± 0.2 |

| N (%wt) | 0.2 ± 0.0 | 7.0 ± 0.2 |

| S (%wt) | 0.1 ± 0.0 | 0.6 ± 0.0 |

| O (%wt) | 40.5 ± 0.3 | 41.2 ± 0.5 |

| Cellulose (%wt) | 24.6 ± 0.4 | - |

| Hemicellulose (%wt) | 14.1 ± 0.5 | - |

| Lignin (%wt) | 7.0 ± 0.3 | - |

| Ash (%wt) | 10.0 ± 0.2 | 3.8 ± 0.4 |

| Mass flow (kg/year) | 2972 | 19,550 |

| Low Heating Value (MJ/kg) | 14.05 | - |

| Component | Power [W] |

|---|---|

| Pre-reformer | 1700 |

| Reformer | 3000 |

| Steam generation | 1020 |

| Compressor | 364 |

| Pyrolizer | 263 |

| Drying | 3120 |

| AD | Depending on weather conditions (temperature) |

| Storage | Depending on weather conditions (PV production) |

| Performance Parameters | ||

|---|---|---|

| 340 | ||

| 5.37% | ||

| 18.91% | ||

| 315.17 | ||

| 28.12 | ||

| 192.35 | ||

| 17.16 | ||

| Performance Parameters | ||||

|---|---|---|---|---|

| Scenario 0 | Scenario 1 | Scenario 2 | ||

| 10,592 | 8536 | 5210 | ||

| 31.2 | 25.1 | 15.3 | ||

| 2.78 | 2.24 | 1.37 | ||

| [%] | 0 | 19% | 42.8% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baldelli, M.; Bartolucci, L.; Cordiner, S.; D’Andrea, G.; De Maina, E.; Mulone, V. Biomass to H2: Evaluation of the Impact of PV and TES Power Supply on the Performance of an Integrated Bio-Thermo-Chemical Upgrading Process for Wet Residual Biomass. Energies 2023, 16, 2966. https://doi.org/10.3390/en16072966

Baldelli M, Bartolucci L, Cordiner S, D’Andrea G, De Maina E, Mulone V. Biomass to H2: Evaluation of the Impact of PV and TES Power Supply on the Performance of an Integrated Bio-Thermo-Chemical Upgrading Process for Wet Residual Biomass. Energies. 2023; 16(7):2966. https://doi.org/10.3390/en16072966

Chicago/Turabian StyleBaldelli, Matteo, Lorenzo Bartolucci, Stefano Cordiner, Giorgio D’Andrea, Emanuele De Maina, and Vincenzo Mulone. 2023. "Biomass to H2: Evaluation of the Impact of PV and TES Power Supply on the Performance of an Integrated Bio-Thermo-Chemical Upgrading Process for Wet Residual Biomass" Energies 16, no. 7: 2966. https://doi.org/10.3390/en16072966

APA StyleBaldelli, M., Bartolucci, L., Cordiner, S., D’Andrea, G., De Maina, E., & Mulone, V. (2023). Biomass to H2: Evaluation of the Impact of PV and TES Power Supply on the Performance of an Integrated Bio-Thermo-Chemical Upgrading Process for Wet Residual Biomass. Energies, 16(7), 2966. https://doi.org/10.3390/en16072966