Investigations on Bi Doped Cu2Se Prepared by Solid State Reaction Technique for Thermoelectric Applications

Abstract

1. Introduction

2. Experiment Details

Material Synthesis

3. Results and Discussion

3.1. X-ray Diffraction (XRD) Analysis

3.1.1. Scherrer Method

3.1.2. Modified Scherrer Method

3.1.3. Size-Strain Plot (SSP)

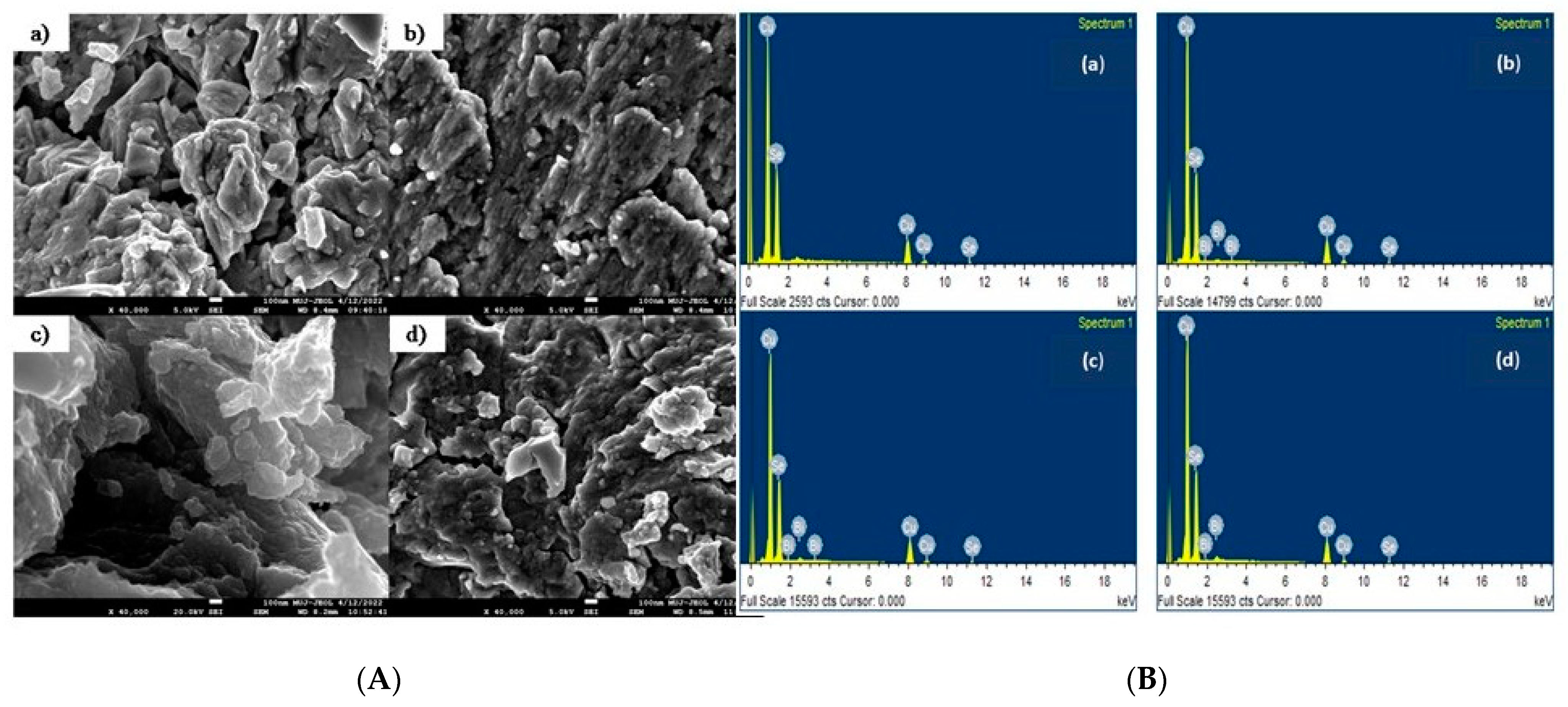

3.2. SEM and EDS Analysis

3.3. Electrical and Thermelectric Transport Properties

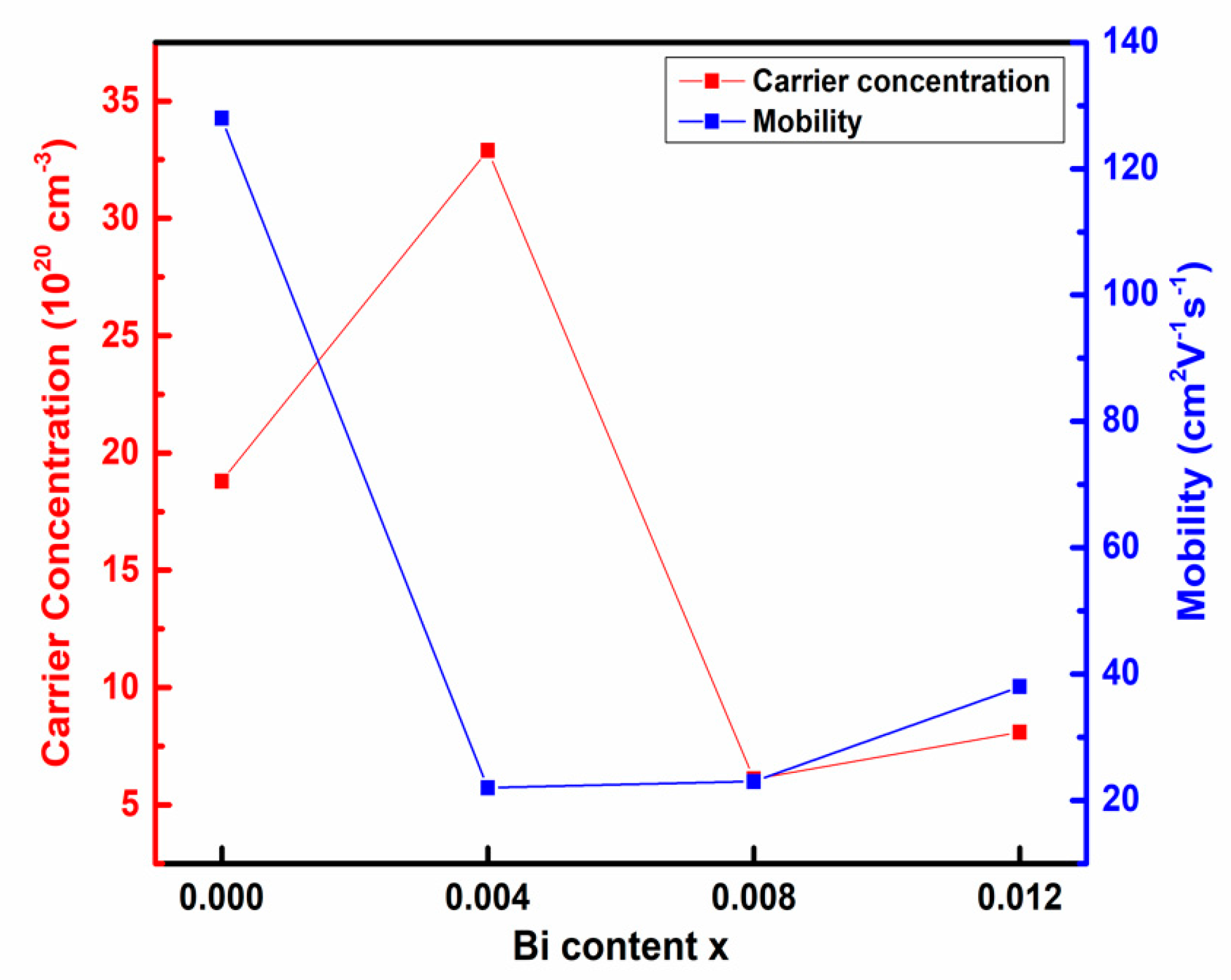

3.3.1. Hall Measurement

3.3.2. Resistivity Measurement

3.3.3. Seebeck Coefficient

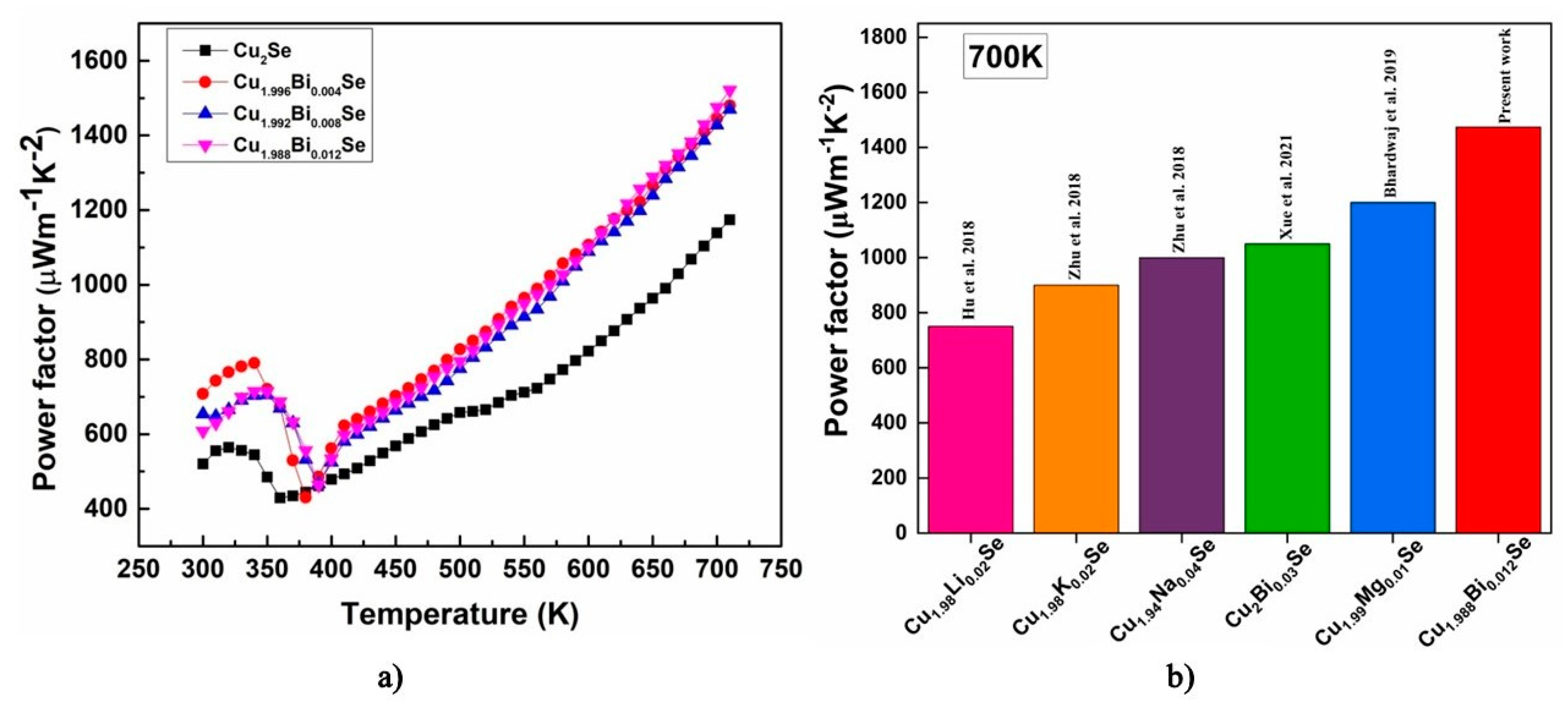

3.3.4. Power Factor

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mangavati, S.; Pal, A.; Rao, A.; Jiang, Z.-Z.; Kuo, Y.-K. Reduction in low-temperature thermal conductivity of Cu2Se via substitution of Se by Te atoms. J. Phys. Chem. Solids 2022, 160, 110301. [Google Scholar] [CrossRef]

- Xue, L.; Shen, W.; Zhang, Z.; Fang, C.; Zhang, Y.; Jia, X. Effects of Bi doping on thermoelectric properties of Cu2Se materials by high-pressure synthesis. Appl. Phys. A 2021, 127, 79. [Google Scholar] [CrossRef]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Horike, S.; Wei, Q.; Akaike, K.; Kirihara, K.; Mukaida, M.; Koshiba, Y.; Ishida, K. Bicyclic-ring base doping induces n-type conduction in carbon nanotubes with outstanding thermal stability in air. Nat. Commun. 2022, 13, 3517. [Google Scholar] [CrossRef] [PubMed]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 2008, 320, 630–634. [Google Scholar] [CrossRef]

- Xie, W.; Tang, X.; Yan, Y.; Zhang, Q.; Tritt, T.M. Unique nanostructures and enhanced thermoelectric performance of melt-spun BiSbTe alloys. Appl. Phys. Lett. 2009, 94, 102111. [Google Scholar] [CrossRef]

- Joshi, G.; Yan, X.; Wang, H.; Liu, W.; Chen, G.; Ren, Z. Enhancement in Thermoelectric Figure-Of-Merit of an N-Type Half-Heusler Compound by the Nanocomposite Approach. Adv. Energy Mater. 2011, 1, 643–647. [Google Scholar] [CrossRef]

- Yan, X.; Liu, W.; Chen, S.; Wang, H.; Zhang, Q.; Chen, G.; Ren, Z. Thermoelectric property study of nanostructured p-type half-heuslers (Hf, Zr, Ti) CoSb0.8Sn0.2. Adv. Energy Mater. 2013, 3, 1195–1200. [Google Scholar] [CrossRef]

- Fu, T.; Yue, X.; Wu, H.; Fu, C.; Zhu, T.; Liu, X.; Hu, L.; Ying, P.; He, J.; Zhao, X. Enhanced thermoelectric performance of PbTe bulk materials with figure of merit zT & 2 by multi-functional alloying. J. Mater. 2016, 2, 141–149. [Google Scholar] [CrossRef]

- Heremans, J.P.; Jovovic, V.; Toberer, E.S.; Saramat, A.; Kurosaki, K.; Charoenphakdee, A.; Yamanaka, S.; Snyder, G.J. Enhancement of Thermoelectric Efficiency in PbTe by Distortion of the Electronic Density of States. Science 2008, 321, 554–557. [Google Scholar] [CrossRef]

- Zhao, L.-D.; Tan, G.; Hao, S.; He, J.; Pei, Y.; Chi, H.; Wang, H.; Gong, S.; Xu, H.; Dravid, V.P.; et al. Ultrahigh power factor and thermoelectric performance in hole-doped single-crystal SnSe. Science 2016, 351, 141–144. [Google Scholar] [CrossRef] [PubMed]

- Duong, A.; Nguyen, V.; Duvjir, G.; Duong, V.; Kwon, S.; Song, J.; Lee, J.; Lee, J.; Park, S.; Min, T.; et al. Achieving ZT = 2.2 with Bi-doped ntype SnSe single crystals. Nat. Commun. 2016, 7, 13713. [Google Scholar] [CrossRef] [PubMed]

- Benyahia, M.; Ohorodniichuk, V.; Leroy, E.; Dauscher, A.; Lenoir, B.; Alleno, E. High thermoelectric figure of merit in mesostructured In0.25Co4Sb12 n-type skutterudite. J. Alloys. Compd. 2018, 735, 1096–1104. [Google Scholar] [CrossRef]

- Ducka, A.; Trawiński, B.; Bochentyn, B.; Dubiel, A.; Kusz, B. Structure and thermoelectric properties of nickel-doped copper selenide synthesised in a hydrogen atmosphere. Mater. Res. Bull. 2020, 133, 111042. [Google Scholar] [CrossRef]

- Ballikaya, S.; Chi, H.; Salvador, J.R.; Uher, C. Thermoelectric Properties of Ag-Doped Cu2Se and Cu2Te. J. Mater. Chem. A 2013, 1, 12478. [Google Scholar] [CrossRef]

- Bhardwaj, R.; Bhattacharya, A.; Tyagi, K.; Gahtori, B.; Chauhan, N.S.; Vishwakarma, A.; Johari, K.K.; Bathula, S.; Auluck, S.; Dhar, A. Enhancement in thermoelectric performance of single step synthesized Mg doped Cu2Se: An experimental and theoretical study. Intermetallics 2019, 112, 106541. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, Y.W.; Song, H.Z.; Li, X.J. Enhancement of the Thermoelectric Properties of Cu1.98Se by Na Doping. J. Electron. Mater. 2018, 47, 7514–7519. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, Y.; Song, H.; Li, X.-J. Enhancement of thermoelectric performance of Cu2Se by K doping. Appl. Phys. A 2018, 124, 871. [Google Scholar] [CrossRef]

- Liao, W.-W.; Yang, L.; Chen, J.; Zhou, D.-L.; Qu, X.-L.; Zheng, K.; Han, G.; Zhou, J.-B.; Hong, M.; Chen, Z.-G. Realizing Bi-doped α-Cu2Se as a promising near-room-temperature thermoelectric material. Chem. Eng. J. 2019, 371, 593–599. [Google Scholar] [CrossRef]

- Geng, Z.; Shi, D.; Shi, L.; Li, Y.; Snyder, G.J.; Lam, K.-H. Conventional sintered Cu2-Se thermoelectric material. J. Materiomics 2019, 5, 626–633. [Google Scholar] [CrossRef]

- Bindu, P.; Thomas, S. Estimation of lattice strain in ZnO nanoparticles: X-ray peak profile analysis. J. Theor. Appl. Phys. 2014, 8, 123–134. [Google Scholar] [CrossRef]

- Monshi, A.; Foroughi, M.R.; Monshi, M.R. Modified Scherrer Equation to Estimate More Accurately Nano-Crystallite Size Using XRD. World J. Nano Sci. Eng. 2012, 2, 154–160. [Google Scholar] [CrossRef]

- Rabiei, M.; Palevicius, A.; Monshi, A.; Nasiri, S.; Vilkauskas, A.; Janusas, G. Comparing Methods for Calculating Nano Crystal Size of Natural Hydroxyapatite Using X-Ray Diffraction. Nanomaterials 2020, 10, 1627. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Song, Y.; Zhang, X.; He, X.; Jiang, J. Enhanced thermoelectric performance of Cu2Se by tuning the aligned lamella microstructure. Mater. Lett. 2019, 250, 189–192. [Google Scholar] [CrossRef]

- Thomas, R.; Rao, A.; Bhardwaj, R.; Wang, L.-Y.; Kuo, Y.-K. Reduction in Thermal Conductivity and Electrical Resistivity in Cu2SnSe3/Cu2Se Composite Thermoelectric System. Mater. Res. Bull. 2019, 120, 110607. [Google Scholar] [CrossRef]

- Mangavati, S.; Gurukrishna, K.; Rao, A.; Petwal, V.C.; Verma, V.P.; Dwivedi, J. Enhancement of Thermoelectric Power Factor in Cu2Se Superionic Conductor via High Energy Electron Beam Irradiation. J. Mater. Sci. Mater. Electron. 2023, 34, 1–10. [Google Scholar] [CrossRef]

- Hu, Q.; Zhu, Z.; Zhang, Y.; Li, X.-J.; Song, H.; Zhang, Y. Remarkably high thermoelectric performance of Cu2−XLiXSe bulks with nanopores. J. Mater. Chem. A 2018, 6, 23417–23424. [Google Scholar] [CrossRef]

- Gurukrishna, K.; Rao, A.; Jiang, Z.-Z.; Kuo, Y.-K. Enhancement of thermoelectric performance by tuning selenium content in the Cu2SnSe3 compound. Intermetallics 2020, 122, 106803. [Google Scholar] [CrossRef]

- Li, M.; Cortie, D.L.; Liu, J.; Yu, D.; Islam, S.M.K.N.; Zhao, L.; Mitchell, D.R.; Mole, R.A.; Cortie, M.B.; Dou, S.; et al. Ultra-High Thermoelectric Performance in Graphene Incorporated Cu2Se: Role of Mismatching Phonon Modes. Nano Energy 2018, 53, 993. [Google Scholar] [CrossRef]

- Zhao, L.; Islam, S.M.K.N.; Wang, J.; Cortie, D.L.; Wang, X.; Cheng, Z.; Wang, J.; Ye, N.; Dou, S.; Shi, X.; et al. Significant Enhancement of Figure-of-Merit in Carbon-Reinforced Cu2Se Nanocrystalline Solids. Nano Energy 2017, 41, 164. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Z.; Lin, J.; Wang, Y.; Mao, J.; Xie, H.; Li, Z. Enhanced thermoelectric performance of hot-press Bi-doped n-type polycrystalline PbS. Mater. Sci. Semicond. Process. 2021, 121, 105393. [Google Scholar] [CrossRef]

- Kihoi, S.K.; Kahiu, J.N.; Kim, H.; Shenoy, U.S.; Bhat, D.K.; Yi, S.; Lee, H.S. Optimized Mn and Bi co-doping in SnTe based thermoelectric material: A case of band engineering and density of states tuning. J. Mater. Sci. Technol. 2021, 85, 76–86. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, J.; Zou, Y.; Hu, J.; Liu, G.; Shao, H.; Zhang, X.; Shi, Z.; Hussain, S.; Qiao, G. Tuning Ag content to achieve high thermoelectric properties of Bi-doped p-type Cu3SbSe4-based materials. J. Alloy. Compd. 2021, 872, 159659. [Google Scholar] [CrossRef]

- Jiang, J.; Yang, C.; Niu, Y.; Song, J.; Wang, C. Enhanced Stability and Thermoelectric Performance in Cu1.85Se-Based Compounds. ACS Appl. Mater. Interfaces 2021, 13, 37862–37872. [Google Scholar] [CrossRef] [PubMed]

| Compositions | x = 0.000 | x = 0.004 | x = 0.008 | x = 0.012 |

|---|---|---|---|---|

| a (Å) | 7.2095 ± 0.0003 | 7.1292 ± 0.0008 | 7.1477 ± 0.0009 | 7.1550 ± 0.0007 |

| b (Å) | 4.1058 ± 0.0001 | 4.1098 ± 0.0004 | 4.1223 ± 0.0004 | 4.1261 ± 0.0003 |

| c (Å) | 13.8195 ± 0.0015 | 13.7745 ± 0.0013 | 13.7836 ± 0.0020 | 13.7900 ± 0.0015 |

| α = γ (°) | 90.000 | 90.000 | 90.000 | 90.000 |

| β (°) | 101.490 | 101.290 | 101.325 | 101.341 |

| V () | 400.870 (0.050) | 395.775 (0.069) | 398.224 (0.083) | 399.157 (0.030) |

| Rp | 35.7 | 35.7 | 29.8 | 31.6 |

| Rwp | 28.0 | 30.9 | 27.3 | 28.5 |

| Rexp | 19.8 | 20.4 | 22.0 | 23.0 |

| 1.995 | 2.289 | 1.538 | 1.531 | |

| GoF-index | 1.4 | 1.5 | 1.2 | 1.2 |

| Bi Content, x | Crystallite Size, D (nm) | Dislocation Density, δ (1015 Lines/m2) | Strain, ε | |||||

|---|---|---|---|---|---|---|---|---|

| SSP | Modified Scherrer | Scherrer | SSP | Modified Scherrer | Scherrer | SSP | Scherrer | |

| 0.000 | 32 ± 3 | 43 ± 4 | 36 ± 4 | 1.00 | 0.54 | 0.77 | 0.007 | 0.001 |

| 0.004 | 63 ± 6 | 64 ± 6 | 51 ± 5 | 0.25 | 0.25 | 0.38 | 0.003 | 0.007 |

| 0.008 | 21 ± 2 | 21 ± 2 | 17 ± 2 | 2.22 | 2.29 | 3.38 | 0.014 | 0.002 |

| 0.012 | 17 ± 2 | 17 ± 2 | 17 ± 2 | 3.55 | 3.44 | 3.60 | 0.003 | 0.002 |

| Nominal Composition | Cu (At%) | Se (At%) | Bi (At%) |

|---|---|---|---|

| Cu2Se | 68.41 | 31.59 | 0.0 |

| Cu1.996Bi0.004Se | 68.92 | 30.94 | 0.14 |

| Cu1.992Bi0.008Se | 68.54 | 30.87 | 0.59 |

| Cu1.988Bi0.012Se | 68.35 | 31.01 | 0.65 |

| Bi Content x | Carrier Concentration (1020 cm−3) | Mobility (cm2V−1s−1) |

|---|---|---|

| 0.00 | 18 | 128 |

| 0.004 | 32 | 22 |

| 0.008 | 6 | 23 |

| 0.012 | 8 | 38 |

| Bi Content (x) | Resistivity (μΩ-m) | Seebeck Coefficient (μV/K) | Power Factor (ΩWm−1K−2) |

|---|---|---|---|

| 0.00 | 4.71 | 49.5 | 520 |

| 0.004 | 4.62 | 57.2 | 707 |

| 0.008 | 4.78 | 55.9 | 653 |

| 0.012 | 4.79 | 53.9 | 607 |

| Bi Content x | a | b |

|---|---|---|

| 0.000 | 0.00856 | 1.04451 |

| 0.004 | 0.00128 | 1.38871 |

| 0.008 | 0.00036 | 1.59499 |

| 0.012 | 0.00059 | 1.52026 |

| SI.No. | Compound | Year | Method | Power Factor~ (μWm−1K−2) | References | |

|---|---|---|---|---|---|---|

| At 300 K | At 700 K | |||||

| 1 | Cu1.988Bi0.012Se | Solid state reaction technique | 607 | 1474 | Present work | |

| 2 | Cu2Se | 2021 | High pressure synthesis | - | 1100 | [2] |

| 3 | Cu1.99Mg0.01Se | 2019 | Single step synthesis | - | 1200 | [16] |

| 4 | Cu2Se | 2022 | Solid state reaction technique | 550 | - | [1] |

| 5 | Cu1.99K0.01Se | 2018 | Hydrothermal method | - | 900 | [18] |

| 6 | Cu1.982Bi0.006Se | 2019 | Spark plasma sintering | 700 | - | [19] |

| 7 | Cu2SnSe2.96 | 2020 | Solid state reaction technique | 35 | - | [27] |

| 8 | Pb0.96Bi0.04S | 2021 | Hydrothermal method | - | 10 | [31] |

| 9 | Sn0.89Mn0.08Bi0.03Te | 2021 | Solid state reaction technique | - | 18 | [32] |

| 10 | Cu2.85Ag0.15Sb0.985Bi0.015Se4 | 2021 | Vacuum melting and hot pressing | - | 1200 | [33] |

| 11 | Li0.03Cu1.81Bi0.04Se | 2021 | Ball milling method | - | 10 | [34] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Purushottam Bhat, C.; Anusha; Ani, A.; Shanubhogue, U.D.; Poornesh, P.; Rao, A.; Chattopadhyay, S. Investigations on Bi Doped Cu2Se Prepared by Solid State Reaction Technique for Thermoelectric Applications. Energies 2023, 16, 3010. https://doi.org/10.3390/en16073010

Purushottam Bhat C, Anusha, Ani A, Shanubhogue UD, Poornesh P, Rao A, Chattopadhyay S. Investigations on Bi Doped Cu2Se Prepared by Solid State Reaction Technique for Thermoelectric Applications. Energies. 2023; 16(7):3010. https://doi.org/10.3390/en16073010

Chicago/Turabian StylePurushottam Bhat, Chaithanya, Anusha, Aninamol Ani, U. Deepika Shanubhogue, P. Poornesh, Ashok Rao, and Saikat Chattopadhyay. 2023. "Investigations on Bi Doped Cu2Se Prepared by Solid State Reaction Technique for Thermoelectric Applications" Energies 16, no. 7: 3010. https://doi.org/10.3390/en16073010

APA StylePurushottam Bhat, C., Anusha, Ani, A., Shanubhogue, U. D., Poornesh, P., Rao, A., & Chattopadhyay, S. (2023). Investigations on Bi Doped Cu2Se Prepared by Solid State Reaction Technique for Thermoelectric Applications. Energies, 16(7), 3010. https://doi.org/10.3390/en16073010