Optimal Design of Double Stage Internal Loop Air-Lift Bioreactor

Abstract

:1. Introduction

2. Materials and Methods

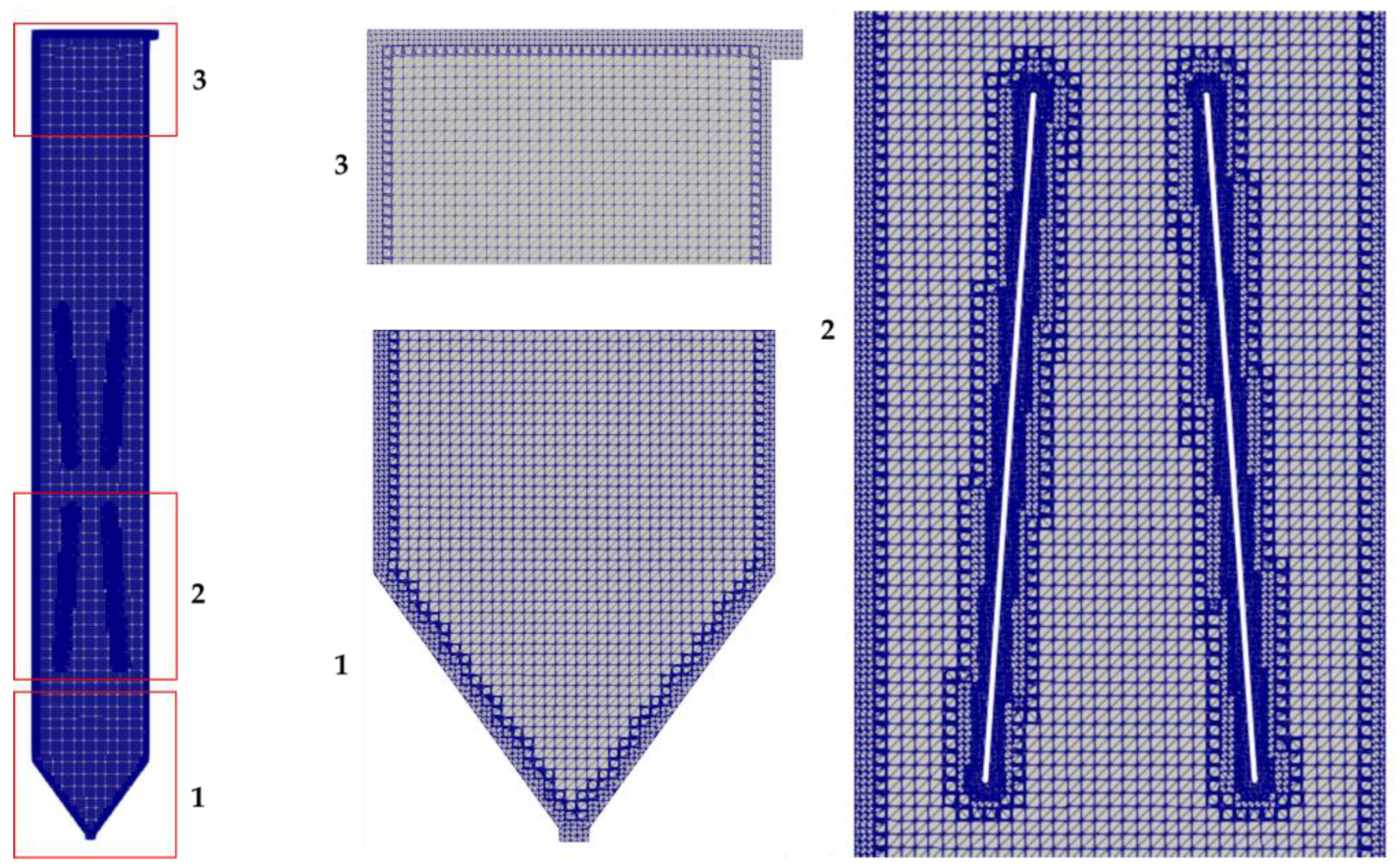

2.1. CFD Model

2.2. Mathematical Models

2.3. Geometries

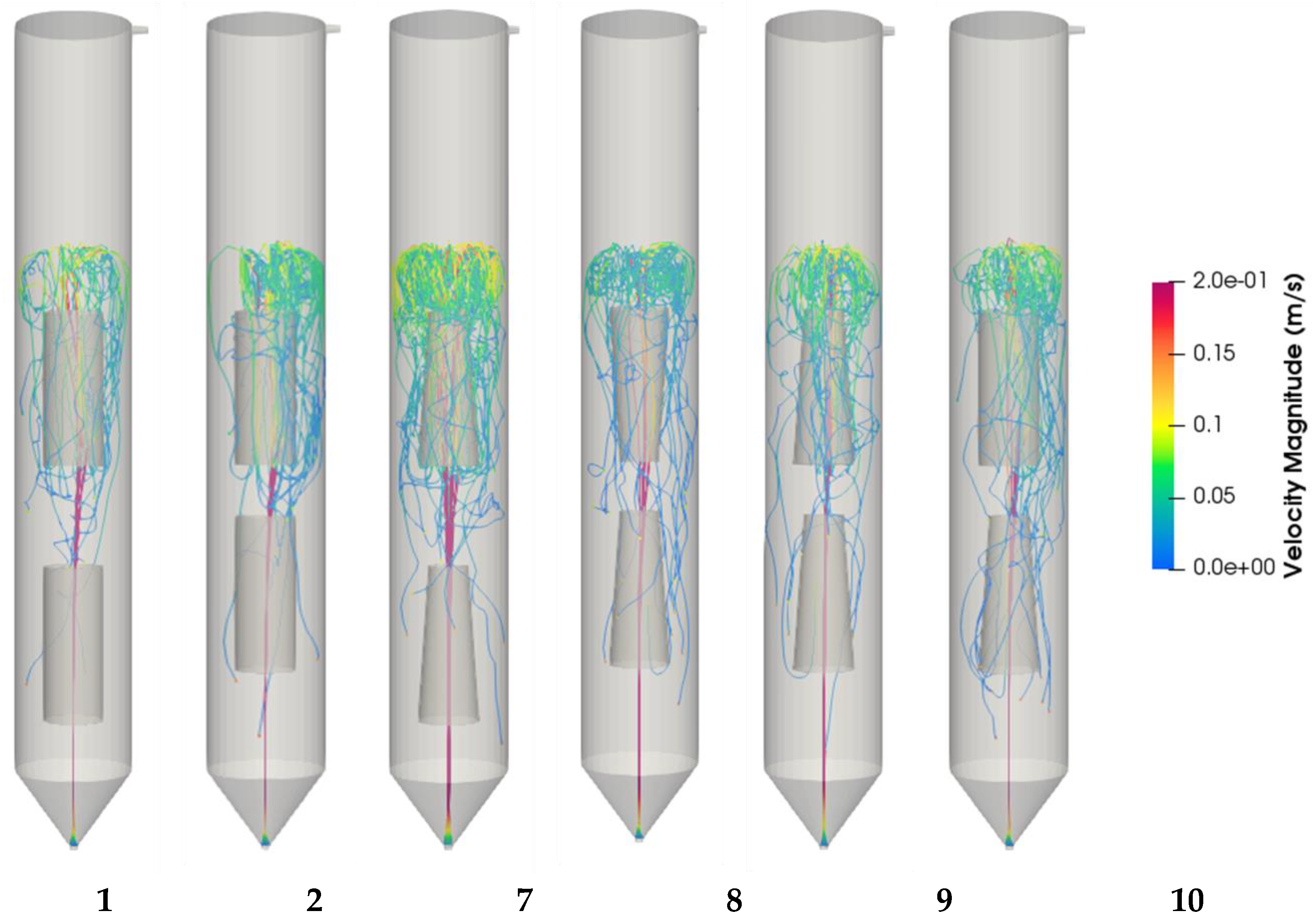

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lefrancois, M.L.; Mariller, C.G.; Mejane, J.V. Effectionnements Aux Procedes de Cultures Forgiques et de Fermentations Industrielles. Brev. D’invention Fr. 1955, 102. [Google Scholar]

- Blenke, H. Loop Reactors. Adv. Biochem. Eng. 1979, 13, 121–214. [Google Scholar] [CrossRef]

- Chisti, M.; Moo-Young, M. Airlift reactors: Characteristics, applications and design considerations. Chem. Eng. Commun. 1987, 60, 195–242. [Google Scholar] [CrossRef]

- Merchuk, J.C. Airlift Bioreactors: Review of Recent Advances. Can. J. Chem. Eng. 2003, 81, 324–337. [Google Scholar] [CrossRef]

- Zhang, T.; We, C.; Ren, Y.; Feng, C.; Wu, H. Advances in Airlift Reactors: Modified Design and Optimization of Operation Conditions. Rev. Chem. Eng. 2017, 33, 163–182. [Google Scholar] [CrossRef]

- Jasim, M.M.; Mohammed, T.J.; Sabri, L.S. Air-Lift Reactor’s Characterization via Computational Fluid Dynamic (CFD). Eng. Technol. J. 2022, 40, 484–497. [Google Scholar] [CrossRef]

- Siegel, M.H.; Robinson, C.W. Application of Airlift Gas-Liquid-Solid Reactors in Biotechnology. Chem. Eng. Sci. 1992, 47, 3215–3229. [Google Scholar] [CrossRef]

- Fadavi, A.; Chisti, Y. Gas Holdup and Mixing Characteristics of a Novel Forced Circulation Loop Reactor. Chem. Eng. J. 2007, 131, 105–111. [Google Scholar] [CrossRef]

- Merchuk, J.C. Why Use Air-Lift Bioreactors? Trends Biotechnol. 1990, 8, 66–71. [Google Scholar] [CrossRef]

- Smith, B.C.; Skidmore, D.R. Mass Transfer Phenomena in an Airlift Reactor: Effects of Solids Loading and Temperature. Biotechnol. Bioeng. 1990, 35, 483–491. [Google Scholar] [CrossRef]

- Lu, W.-J.; Hwang, S.-J.; Chang, C.-M. Liquid Mixing in Internal Loop Airlift Reactors. Ind. Eng. Chem. Res. 1994, 33, 2180–2186. [Google Scholar] [CrossRef]

- Bang, W.; Nikov2, I.; Delmas1, H.; Bascoul1, A. Gas-Liquid Mass Transfer in a New Three-Phase Stirred Airlift Reactor. J. Chem. Technol. Biotechnol. 1998, 72, 137–142. [Google Scholar] [CrossRef]

- Wei, C.; Xie, B.; Xiao, H.; Wang, D. Volumetric Mass Transfer Coefficient of Oxygen in an Internal Loop Airlift Reactor with a Convergence-Divergence Draft Tube. Eng. Technol. Ind. Chem.-Plant Equip.-Process Eng.-Biotechnol. 2000, 23, 597–603. [Google Scholar] [CrossRef]

- Siegel, M.H.; Merchuk, J.C. Mass Transfer in a Rectangular Air-Lift Reactor: Effects of Geometry and Gas Recirculation. Biotechnol. Bioeng. 1988, 32, 1128–1137. [Google Scholar] [CrossRef]

- Pironti, F.F.; Medina, V.R.; Calvo, R.; Sáez, A.E. Effect of Draft Tube Position on the Hydrodynamics of a Draft Tube Slurry Bubble Column. Chem. Eng. J. Biochem. Eng. J. 1995, 60, 155–160. [Google Scholar] [CrossRef]

- Verlaan, P.; Van Eijs, A.M.M.; Tramper, J.; Riet, K.V.; Luyben, K.C.A.M. Estimation of Axial Dispersion in Individual Sections of an Airlift-Loop Reactor. Chem. Eng. Sci. 1989, 44, 1139–1146. [Google Scholar] [CrossRef]

- Svendsen, H.F.; Jakobsen, H.A.; Torvik, R. Local Flow Structures in Internal Loop and Bubble Column Reactors. Chem. Eng. Sci. 1992, 47, 3297–3304. [Google Scholar] [CrossRef]

- Jakobsen, H.A.; Svendsen, H.F.; Hjarbo, K.W. On the Prediction of Local Flow Structures in Internal Loop and Bubble Column Reactors Using a Two-Fluid Model. Comput. Chem. Eng. 1993, 17, S531–S536. [Google Scholar] [CrossRef]

- Herrmann, J.; Bangga, G. Multi-Objective Optimization of a Thick Blade Root Airfoil to Improve the Energy Production of Large Wind Turbines. J. Renew. Sustain. Energy 2019, 11, 043304. [Google Scholar] [CrossRef]

- Becker, S.; Sokolichin, A.; Eigenberger, G. Gas—Liquid Flow in Bubble Columns and Loop Reactors: Part II. Comparison of Detailed Experiments and Flow Simulations. Chem. Eng. Sci. 1994, 49, 5747–5762. [Google Scholar] [CrossRef]

- Cockx, A.; Liné, A.; Roustan, M.; Do-Quang, Z.; Lazarova, V. Numerical Simulation and Physical Modeling of the Hydrodynamics in an Air-Lift Internal Loop Reactor. Chem. Eng. Sci. 1997, 52, 3787–3793. [Google Scholar] [CrossRef]

- Padial, N.T.; VanderHeyden, W.B.; Rauenzahn, R.M.; Yarbro, S.L. Three-Dimensional Simulation of a Three-Phase Draft-Tube Bubble Column. Chem. Eng. Sci. 2000, 55, 3261–3273. [Google Scholar] [CrossRef]

- Oey, R.S.; Mudde, R.F.; Portela, L.M.; Van Den Akker, H.E.A. Simulation of a Slurry Airlift Using a Two-Fluid Model. Chem. Eng. Sci. 2001, 56, 673–681. [Google Scholar] [CrossRef]

- Mudde, R.F.; Van Den Akker, H.E.A. 2D and 3D Simulations of an Internal Airlift Loop Reactor on the Basis of a Two-Fluid Model. Chem. Eng. Sci. 2001, 56, 6351–6358. [Google Scholar] [CrossRef]

- Petersen, E.E.; Margaritis, A. Hydrodynamic and Mass Transfer Characteristics of Three-Phase Gaslift Bioreactor Systems. Crit. Rev. Biotechnol. 2001, 21, 233–294. [Google Scholar] [CrossRef]

- Ding, F.; Yuan, N.; Liu, Z.; Ma, A.; Qiao, Y. Multi-Stage Loop Reactor. U.S. Patent US20030147791A1, 7 August 2003. [Google Scholar]

- Tunthikul, N.; Wongsuchoto, P.; Pavasant, P. Hydrodynamics and Mass Transfer Behavior in Multiple Draft Tube Airlift Contactors. Korean J. Chem. Eng. 2006, 23, 881–887. [Google Scholar] [CrossRef]

- Margaritis, A.; Sheppard, J.D. Mixing Time and Oxygen Transfer Characteristics of Double Draft Tube Airlift Fermentor. Biotechnol. Bioeng. 1981, 23, 2117–2135. [Google Scholar] [CrossRef]

- Behin, J. Modeling of Modified Airlift Loop Reactor with a Concentric Double-Draft Tube. Chem. Eng. Res. Des. 2010, 88, 919–927. [Google Scholar] [CrossRef]

- Oldani, F. Reaction Device with Air-Lift Type Internal Circulation. U.S. Patent US20170326507A1, 16 November 2016. [Google Scholar]

- Bakker, W.A.M.; van Can, H.J.L.; Tramper, J.; de Gooijer, C.D. Hydrodynamics and Mixing in a Multiple Air-Lift Loop Reactor. Biotechnol. Bioeng. 1993, 42, 994–1001. [Google Scholar] [CrossRef] [PubMed]

- Bun, S.; Chawaloesphonsiya, N.; Nakajima, F.; Tobino, T.; Painmanakul, P. Comparative Study of Local Gas-Liquid Hydrodynamics and Mass Transfer between Conventional and Modified Airlift Reactors. J. Environ. Chem. Eng. 2019, 7, 103206. [Google Scholar] [CrossRef]

- Karim, K.; Thoma, G.J.; Al-Dahhan, M.H. Gas-Lift Digester Configuration Effects on Mixing Effectiveness. Water Res. 2007, 41, 3051–3060. [Google Scholar] [CrossRef]

- Coughtrie, A.R.; Borman, D.J.; Sleigh, P.A. Effects of Turbulence Modelling on Prediction of Flow Characteristics in a Bench-Scale Anaerobic Gas-Lift Digester. Bioresour. Technol. 2013, 138, 297–306. [Google Scholar] [CrossRef] [Green Version]

- Aslanbay Guler, B.; Deniz, I.; Demirel, Z.; Imamoglu, E. Computational fluid dynamics Simulation in Scaling-up of Airlift Photobioreactor for Astaxanthin Production. J. Biosci. Bioeng. 2020, 129, 86–92. [Google Scholar] [CrossRef]

- Ruitenberg, R.; Schultz, C.E.; Buisman, C.J.N. Bio-Oxidation of Minerals in Air-Lift Loop Bioreactors. Int. J. Miner. Process. 2001, 62, 271–278. [Google Scholar] [CrossRef]

- Stasinopoulos, S.J.; Seviour, R.J. Exopolysaccharide Production by Acremonium Persicinum in Stirred-Tank and Air-Lift Fermentors. Appl. Microbiol. Biotechnol. 1992, 36, 465–468. [Google Scholar] [CrossRef]

- Günzel, B.; Yonsel, S.; Deckwer, W.D. Fermentative Production of 1,3-Propanediol from Glycerol by Clostridium Butyricum up to a Scale of 2m3. Appl. Microbiol. Biotechnol. 1991, 36, 289–294. [Google Scholar] [CrossRef]

- Kracke-Helm, H.A.; Rinas, U.; Hitzmann, B.; Schügerl, K. Cultivation of Recombinant E. Coli and Production of Fusion Protein in 60-l Bubble Column and Airlift Tower Loop Reactors. Enzym. Microb. Technol. 1991, 13, 554–564. [Google Scholar] [CrossRef]

- Bonnarme, P.; Jeffries, T.W. Selective Production of Extracellular Peroxidases from Phanerochaete Chrysosporium in an Airlift Bioreactor. J. Ferment. Bioeng. 1990, 70, 158–163. [Google Scholar] [CrossRef]

- Hopf, N.W.; Yonsel, S.; Deckwer, W.D. Ambruticin S Production in Air-Lift and Stirred-Tank Bioreactors. Appl. Microbiol. Biotechnol. 1990, 34, 350–353. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Mendiola, M.A.; Stafford, A.; Cresswell, R.; Arias-Castro, C. Bioreactors for Growth of Plant Roots. Enzym. Microb. Technol. 1991, 13, 697–702. [Google Scholar] [CrossRef]

- Couillard, D.; Mercier, G. Optimum Residence Time (in CSTR and Airlift Reactor) for Bacterial Leaching of Metals from Anaerobic Sewage Sludge. Water Res. 1991, 25, 211–218. [Google Scholar] [CrossRef]

- Siedenberg, D.; Gerlach, S.R.; Weigel, B.; Schugerl, K.; Giuseppin, M.L.F.; Hunik, J. Production of Xylanase by Aspergillus Awamori on Synthetic Medium in Stirred Tank and Airlift Tower Loop Reactors: The Influence of Stirrer Speed and Phosphate Concentration. J. Biotechnol. 1997, 56, 103–114. [Google Scholar] [CrossRef]

- El-Sayed, A.M.M.; Mahmoud, W.M.; Coughlin, R.W. Production of Dextransucrase by Leuconostoc Mesenteroides Immobilized in Calcium-Alginate Beads: I. Batch and Fed-Batch Fermentations. Biotechnol. Bioeng. 1990, 36, 338–345. [Google Scholar] [CrossRef] [PubMed]

- Keshavarz, T.; Eglin, R.; Walker, E.; Bucke, C.; Holt, G.; Bull, A.T.; Lilly, M.D. The Large-Scale Immobilization of Penicillium Chrysogenum: Batch and Continuous Operation in an Air-Lift Reactor. Biotechnol. Bioeng. 1990, 36, 763–770. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.P.; Al-Dahhan, M.H. Local Characteristics of Hydrodynamics in Draft Tube Airlift Bioreactor. Chem. Eng. Sci. 2008, 63, 3057–3068. [Google Scholar] [CrossRef]

- Luo, H.P.; Al-Dahhan, M.H. Verification and Validation of CFD Simulations for Local Flow Dynamics in a Draft Tube Airlift Bioreactor. Chem. Eng. Sci. 2011, 66, 907–923. [Google Scholar] [CrossRef]

- Zhang, T.; Wei, C.; Feng, C.; Zhu, J. A Novel Airlift Reactor Enhanced by Funnel Internals and Hydrodynamics Prediction by the CFD Method. Bioresour. Technol. 2012, 104, 600–607. [Google Scholar] [CrossRef] [PubMed]

- Pawar, S.B. CFD Analysis of Flow Regimes in Airlift Reactor Using Eulerian-Lagrangian Approach. Can. J. Chem. Eng. 2017, 95, 420–431. [Google Scholar] [CrossRef]

- Gemello, L.; Cappello, V.; Augier, F.; Marchisio, D.; Plais, C. CFD-Based Scale-up of Hydrodynamics and Mixing in Bubble Columns. Chem. Eng. Res. Des. 2018, 136, 846–858. [Google Scholar] [CrossRef]

- McClure, D.D.; Dolton, T.P.; Barton, G.W.; Fletcher, D.F.; Kavanagh, J.M. Hydrodynamics and Mixing in Airlift Contactors: Experimental Work and CFD Modelling. Chem. Eng. Res. Des. 2017, 127, 154–169. [Google Scholar] [CrossRef]

- Li, S.; Qi, T. Hydrodynamics and Flow Regimes of a Multi-Stage Internal Airlift Loop Reactor. Mater. Focus 2014, 3, 205–210. [Google Scholar] [CrossRef]

- Li, D.; Guo, K.; Li, J.; Huang, Y.; Zhou, J.; Liu, H.; Liu, C. Hydrodynamics and Bubble Behaviour in a Three-Phase Two-Stage Internal Loop Airlift Reactor. Chin. J. Chem. Eng. 2018, 26, 1359–1369. [Google Scholar] [CrossRef]

- Tao, J.; Huang, J.; Geng, S.; Gao, F.; He, T.; Huang, Q. Experimental Investigation of Hydrodynamics and Mass Transfer in a Slurry Multistage Internal Airlift Loop Reactor. Chem. Eng. J. 2020, 386, 122769. [Google Scholar] [CrossRef]

- Dabiri, S.; Kumar, P.; Rauch, W. Integrating Biokinetics with Computational fluid dynamics for Energy Performance Analysis in Anaerobic Digestion. Bioresour. Technol. 2023, 373, 128728. [Google Scholar] [CrossRef] [PubMed]

- Batstone, D.J.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.; Siegrist, H.; Vavilin, V.A. The IWA Anaerobic Digestion Model No 1 (ADM1). Water Sci. Technol. 2002, 45, 65–73. [Google Scholar] [CrossRef]

- Kumar, P.; Dabiri, S.; Rauch, W. 2D SPH Simulation of an Anaerobic Digester. Comput. Part. Mech. 2022, 9, 1073–1083. [Google Scholar] [CrossRef]

- Rezavand, M.; Winkler, D.; Sappl, J.; Seiler, L.; Meister, M.; Rauch, W. A Fully Lagrangian Computational Model for the Integration of Mixing and Biochemical Reactions in Anaerobic Digestion. Comput. Fluids 2019, 181, 224–235. [Google Scholar] [CrossRef]

- Shi, J.; Guo, K.; Wang, Z.; Zheng, L.; Liu, H.; Xiang, W.; Liu, C.; Li, X. Computational fluid dynamics Simulation of Hydrodynamics in a Two-Stage Internal Loop Airlift Reactor with Contraction-Expansion Guide Vane. ACS Omega 2021, 6, 6981–6995. [Google Scholar] [CrossRef]

- Ramonet, F.; Haddadi, B.; Jordan, C.; Harasek, M. Modelling and Design of Optimal Internal Loop Air-Lift Reactor Configurations Through Computational Fluid Dynamics. Chem. Eng. Trans. 2022, 94, 817–822. [Google Scholar] [CrossRef]

- Ničeno, B.; Dhotre, M.T.; Deen, N.G. One-Equation Sub-Grid Scale (SGS) Modelling for Euler–Euler Large Eddy Simulation (EELES) of Dispersed Bubbly Flow. Chem. Eng. Sci. 2008, 63, 3923–3931. [Google Scholar] [CrossRef]

- OpenCFD Ltd. Available online: https://www.openfoam.com/documentation/guides/latest/api/classFoam_1_1LESModels_1_1continuousGasKEqn.html (accessed on 27 January 2023).

- Schiller, L. A Drag Coefficient Correlation. Zeit. Ver. Deutsch 1933, 77, 318–320. [Google Scholar]

- van Baten, J.M.; Ellenberger, J.; Krishna, R. Hydrodynamics of Internal Air-Lift Reactors: Experiments versus CFD Simulations. Chem. Eng. Process. Process Intensif. 2003, 42, 733–742. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, H.; Liu, C.; Jia, M.; Xi, X. Numerical Analysis of Jet Breakup Based on a Modified Compressible Two-Fluid-LES Model. Fuel 2019, 254, 115608. [Google Scholar] [CrossRef]

- Zhu, S.J.; Ooi, A.; Manasseh, R. Large Eddy Simulation of Gas-Liquid Flow in a Partially Aerated Bubble Column. In Proceedings of the 21st Australasian Fluid Mechanics Conference, Adelaide, Australia, 10–13 December 2018. [Google Scholar]

- Roy, C.J.; Oberkampf, W.L. A Comprehensive Framework for Verification, Validation, and Uncertainty Quantification in Scientific Computing. Comput. Methods Appl. Mech. Eng. 2011, 200, 2131–2144. [Google Scholar] [CrossRef]

- Richards, S.A. COMPLETED RICHARDSON EXTRAPOLATION IN SPACE AND TIME. Commun. Numer. Meth. Eng. 1997, 13, 573–582. [Google Scholar] [CrossRef]

- Roy, C.J. Review of Code and Solution Verification Procedures for Computational Simulation. J. Comput. Phys. 2005, 205, 131–156. [Google Scholar] [CrossRef]

- Segui, M.; Abel, F.R.; Botez, R.M.; Ceruti, A. High-Fidelity Aerodynamic Modeling of an Aircraft Using OpenFoam—Application on the CRJ700. Aeronaut. J. 2022, 126, 585–606. [Google Scholar] [CrossRef]

- Greenshields, C. OpenFOAM User Guide; OpenFOAM Foundation Ltd.: Bologna, Italy, 2021; Volume 9. [Google Scholar]

- Courant, R.; Friedrichs, K.; Lewy, H. Über Die Partiellen Differenzengleichungen Der Mathematischen Physik. Math. Ann. 1928, 100, 32–74. [Google Scholar] [CrossRef]

- Jia, X.; Wen, J.; Feng, W.; Yuan, Q. Local Hydrodynamics Modeling of a Gas−Liquid−Solid Three-Phase Airlift Loop Reactor. Ind. Eng. Chem. Res. 2007, 46, 5210–5220. [Google Scholar] [CrossRef]

| Geometry | Type | DT Diameter (×10−2 m) | Liquid Height (m) | Distance from Inlet to DT (×10−2 m) | Distance from DT to Surface (×10−2 m) | |||

|---|---|---|---|---|---|---|---|---|

| d1 | d2 | d3 | d4 | |||||

| 1 | b | 95 | 95 | 95 | 95 | 0.85 | 20.88 | 11.80 |

| 2 | b | 95 | 95 | 95 | 95 | 1 | 28.88 | 11.80 |

| 3 | a | 95 | 95 | 95 | 95 | 1 | 7.54 | 26.20 |

| 4 | a | 95 | 95 | 95 | 95 | 0.85 | 7.74 | 34.40 |

| 5 | a | 95 | 95 | 95 | 95 | 0.85 | 7.74 | 19.40 |

| 6 | a | 95 | 95 | 95 | 95 | 0.85 | 7.54 | 11.20 |

| 7 | b | 95 | 60 | 95 | 60 | 0.85 | 20.88 | 11.80 |

| 8 | b | 95 | 60 | 60 | 95 | 0.85 | 28.88 | 11.80 |

| 9 | b | 95 | 60 | 95 | 60 | 0.85 | 28.88 | 11.80 |

| 10 | b | 95 | 60 | 95 | 95 | 0.85 | 28.88 | 11.80 |

| Mesh | Cell Count | Maximum Skewness | Air Velocity Magnitude (m/s) |

|---|---|---|---|

| 1 | 387,367 | 3.28 | 0.366688 |

| 2 | 603,148 | 2.88 | 0.366936 |

| 3 | 937,077 | 3.78 | 0.383900 |

| 4 | 1,534,081 | 4.13 | 0.365633 |

| Geometry | Cell Number (×103) | Max. Skewness | Max. Non-Orthogonality |

|---|---|---|---|

| 1 | 646 | 3.27 | 53.51 |

| 2 | 646 | 2.51 | 64.66 |

| 3 | 642 | 4.48 | 64.80 |

| 4 | 306 | 3.74 | 64.86 |

| 5 | 306 | 3.74 | 64.86 |

| 6 | 642 | 4.48 | 64.80 |

| 7 | 623 | 2.80 | 64.83 |

| 8 | 1012 | 2.84 | 54.85 |

| 9 | 683 | 3.15 | 46.39 |

| 10 | 1043 | 3.37 | 58.38 |

| Geometry | Computation Time (h) | Pressure (Pa) | Axial Velocity (m/s) | Turbulent Kinetic Energy (m2/s2) | Draft Tube Loop Circulation Time (s) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Top | Bottom | Top | Bottom | Top | Bottom | First | Second | ||

| 1 | 81 | 100,388 | 107,722 | 0.030711 | 0.004942 | 1.24 × 10−4 | 1.04 × 10−6 | 27.02 | 110.76 |

| 2 | 101 | 100,389 | 107,721 | 0.029952 | 0.002753 | 1.27 × 10−4 | 7.99 × 10−7 | 25.07 | 128.04 |

| 3 | 207 | 100,395 | 107,727 | 0.035534 | 0.002461 | 2.21 × 10−4 | 7.36 × 10−7 | 20.7 | 146.06 |

| 4 | 119 | 100,401 | 107,732 | 0.020659 | 0.003274 | 7.26 × 10−5 | 9.96 × 10−7 | 21.4 | 112.17 |

| 5 | 174 | 100402 | 106,268 | 0.017627 | 0.002926 | 1.20 × 10−4 | 1.04 × 10−6 | 23.81 | 104.77 |

| 6 | 438 | 100,396 | 106,266 | 0.038666 | 0.003935 | 1.57 x10−4 | 1.82 x10−6 | 18.59 | 91.75 |

| 7 | 112 | 100,388 | 107,723 | 0.023221 | 0.00652 | 5.95 × 10−5 | 9.20 × 10−7 | 24.45 | 73.48 |

| 8 | 318 | 100,387 | 107,721 | 0.034632 | 0.001516 | 3.04 × 10−4 | 8.27 × 10−7 | 36.97 | 156.27 |

| 9 | 219 | 100,374 | 107,707 | 0.057495 | 0.00233 | 5.90 × 10−4 | 1.05 × 10−6 | 21.63 | 98.41 |

| 10 | 284 | 100,388 | 107,721 | 0.033105 | 0.002221 | 6.11 × 10−5 | 8.66 × 10−7 | 23.58 | 110.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramonet, F.; Haddadi, B.; Harasek, M. Optimal Design of Double Stage Internal Loop Air-Lift Bioreactor. Energies 2023, 16, 3267. https://doi.org/10.3390/en16073267

Ramonet F, Haddadi B, Harasek M. Optimal Design of Double Stage Internal Loop Air-Lift Bioreactor. Energies. 2023; 16(7):3267. https://doi.org/10.3390/en16073267

Chicago/Turabian StyleRamonet, Fernando, Bahram Haddadi, and Michael Harasek. 2023. "Optimal Design of Double Stage Internal Loop Air-Lift Bioreactor" Energies 16, no. 7: 3267. https://doi.org/10.3390/en16073267

APA StyleRamonet, F., Haddadi, B., & Harasek, M. (2023). Optimal Design of Double Stage Internal Loop Air-Lift Bioreactor. Energies, 16(7), 3267. https://doi.org/10.3390/en16073267