Abstract

This paper presents a life cycle assessment (LCA) analysis of a new, high-concentration photovoltaic (HCPV) technology developed as part of the HIPERION project of hybrid photovoltaics for efficiency record using an integrated optical technology. In the LCA calculations, the production stage of a full module was adopted as a functional unit. SimaPro version 9.00.49, the recent Ecoinvent database (3.8), and the IPCC 2021 GWP 100a environmental model were applied to perform the calculations. The environmental impact of the HCPV panel was determined for constructional data and for recycling of the main elements of the module. The results of the calculations show that recycling of PMMA, rubber, and electronic elements reduced the total carbon footprint by 17%, from 240 to 201 kg CO2-eq. The biggest environmental load was generated by the PV cells: 99.9 kg CO2eq., which corresponds to 49.8% (41.7% without recycling) of the total environmental load due to the large number of solar cells used in the construction. The emission of CO2 over a 25-year lifespan was determined from 17.1 to 23.4 g CO2-eq/kWh (20.4 to 27.9 without recycling), depending on the location. The energy payback time (EPBT) for the analyzed module is 0.87 and 1.19 years, depending on the location and the related insolation factors (Madrid: 470 kWh/m2, Lyon: 344 kWh/m2). The results of the calculations proved that the application of recycling and recovery methods for solar cells can improve the sustainability of the photovoltaic industry.

1. Introduction

The current demand for energy requires an increase in the share of renewable energy and the development of high-efficiency technologies. In particular, solar power has a significant potential of being the biggest source of alternative energy [1]. In 2020, renewable sources accounted for almost 13% of world energy use, including 1.56% of the solar input [2]. Considering the technical potential and environmental benefits, the contribution of solar power to the global energy demand is still negligible. Despite serious technological developments in photovoltaic (PV) systems, the conversion efficiency is relatively low. The crystalline Si-based solar cell, which is dominating in the market, is able to achieve 26.7% conversion efficiency [3,4]. Moreover, power generation in PV systems heavily depends on environmental variables, such as weather, seasons, and times of day [5,6]. The position of the PV module (i.e., orientation and inclination) is an important parameter as well, and the optimal angle of solar incidence ensures the highest energy extractions [7]. Therefore, the installation site of the module cannot be random. Additionally, solar installation costs are high, which limits the widespread installation of photovoltaic systems, especially for domestic use [8]. As estimated, materials correspond to even 70% of the total cost of the technology [9]. Therefore, innovative proposals and technologies for solar systems are still needed so as to improve system efficiency.

Concentrated photovoltaic (CPV) has become a contemporary option for solar energy generation, eliminating some disadvantages of conventional systems. A novelty compared to conventional photovoltaic technologies is implementing an optical system, in the form of lenses or curved mirrors [10]. Such solutions intensify the focus of the sun rays on small cells and, ultimately, increase the efficiency of the panels. A major advantage of CPV is the potential to reduce the overall cost of the system with minimal impact on the environment. These economic and ecological benefits are achievable by applying low-cost optical devices and low semiconductor material employment [11,12]. In general, CPV systems are differentiated, according to the concentration factor, into a low-concentrated photovoltaic system (LCPV), medium- (MCPV), or high-concentrated photovoltaic system (HCPV) [13,14]. CPV can also operate in ultra-high-concentrated PV implementations (UHCPV) [15]. However, most of the globally installed capacity of CPV systems is based on HCPV technologies [16,17], simultaneously having the best perspective on cost reduction [14]. Efficiency is, thus, key to the return on investment to ultimately decrease the cost of energy in the future [18]. Along with the economy of new technologies, the environmental aspects should also be considered.

An environmental load of HCPV systems can be successfully evaluated based on the LCA methodology, as demonstrated by Ziemińska-Stolarska et al. [19]. Crucially, LCA is a normalized method to assess the environmental impact associated with all stages of a product’s life (i.e., from cradle to grave) [20]. An LCA study is particularly important for emerging technologies that have not yet been tested in real operating conditions. The preliminary results of the analysis, which allow for conclusions to be drawn at the design stage of the system, are also of great importance. Consequently, an LCA analysis has become an integral part of projects developing new technologies with a market implementation potential.

An important indicator of the environmental performance of PV is energy payback time (EPBT) [21] and greenhouse gas (GHG) emissions [22]. In general, EPBT depends on location and the related irradiation, efficiency, and cumulative energy demand (CED) of PV systems [23]. While mono-crystalline and multi-crystalline Si-PV systems have an energy payback time of about 1.1 and 0.9 years, respectively [24], some HCPV installations have an estimated EPBT value of 0.22–0.33 years, depending on location [25]. In turn, lifetime assumptions and system locations can affect the carbon footprint of PV technologies [26]. GHG emissions, usually expressed as g CO2-eq per unit of electricity produced, indicate a trend in decreasing the carbon footprint of the HCPV technology [27].

One of the first mounted CPV modules, produced under the Apollon project, produced 20 g CO2-eq/kWh with an EPBT of 1 year [28]. Fthenakis and Kim [29] performed an LCA analysis of the Amonix 7700 HCPV module in operation in Phoenix, USA. The estimated EPBT was only 0.9 years. The calculated carbon footprint was closely dependent on the assumed life cycle of the system, and was 26–27 g CO2-eq/kWh and 16 g CO2-eq/kWh for 30 and 50 years, respectively. A study of Corona et al. [30] reported an EPBT of 1.457 years and 53.3 g CO2-eq/kWh for a commercial 1.008 MWp HCPV plant located in Casablanca (Morocco), operating with an 820× concentration factor.

The huge variety of PV modules makes it difficult to unequivocally answer the question of which module components produce the greatest environmental load. Literature studies based on an LCA analysis show that the main contribution to the environmental load is focusing optics (often more than 50% of the contribution), a tracking system, and the frame (aluminum alloy or steel).

The variations between the environmental metrics of particular PV modules result, among others, from system specifications, e.g., module types and energy conversion efficiency and degradation. In general, the efficiency of the PV module in energy generation gradually decreases as the system’s lifetime increases. Natural degradation occurs due to corrosion, temperature variations, humidity, irradiation, etc. [31]. For this reason, the degradation rate can vary with climate conditions and geographical locations. Khan et al. [32] investigated the performance parameters of c-Si PV modules installed on a concrete base to evaluate photovoltaic degradation in damp–heat stress. The results demonstrated that PV module installation on concrete, in low humidity regions, decreases the loss in efficiency and degradation rate in relation to the reference module. The beneficial impact of the concrete slab on the performance degradation of PV modules was also noticed for temperature fluctuation stress [33]. Nordin et al. [34] found that neglecting the degradation factor prompts a significant underestimation of the LCA results. Their results showed that PV module degradation increases cumulative energy demand (CED) and greenhouse gas (GHG) emissions. Moreover, small variations in GHG emissions were observed for different geographical locations of CdTe PV systems, mainly due to a lower module degradation rate.

1.1. Recycling of PV Modules

An environmental load of solar panels cannot be assessed without the parallel consideration of the end-of-life scenario. Even though most modules have a long service life, the management of waste panels is an important environmental issue [35]. The literature data proved that photovoltaic modules have a great recycling value, both in the “closed-loop” (incorporating material from used modules in new modules) and “open closed-loop” (when the recycled material goes to another product system) recycling approaches [36]. According to Calì et al. [37], currently, existing technologies are capable of recycling 95–99% of PV panel materials. In particular, glass, aluminum, silicon, and wires made of copper are recyclable materials in PV modules. However, different recycling methods reach different efficiencies, and the cost/benefit ratio of the process cannot be neglected. The technologies of separation and the recovery of particular materials from PV panels can be divided into physical, chemical, and thermal treatments. Standard recycling approaches for the individual components of PV module recycling are shown in Table 1. Disassembly and separation of the aluminum part from the glass part is the first step in recycling Si-based PV panels. It was estimated that more than 90% of the removed glass can be reused in a closed-loop method of recycling [38]. As indicated by Strachala et al. [39], glass recycling can reduce energy consumption for PV module production by about 40%. High-value recycling methods are based on the recovery of silicon, semiconductors, and silver for reuse or return to the resource pool. Thermal and chemical treatments are used to recover silicon particles. If the Si is chemically coated, a hydrometallurgy process is used to extract the element [37]. In this way, it is possible to recover metals, such as indium and gallium [40]. In the case of concentrated PV modules, the recycling process includes optical devices, such as the Fresnel lens, constructed from polymethyl methacrylate (PMMA). This thermoplastic material can be recovered by means of pyrolysis and depolymerization. Moreover, the Fresnel lens can be reused in a new module if it is still in a usable condition [41]. The incorporation of recycling into the life cycle of photovoltaic modules further reinforces their “clean” image. Regardless of the energy consumption and emissions during recycling, the environmental impact of the process is insignificant in relation to the production stage of PV modules. Furthermore, the usage of secondary materials in the production of Si-solar cells can reduce the environmental load by almost 60%, as compared to applying virgin materials [42].

Table 1.

Recycling techniques for particular components of solar panels.

1.2. Policies for End-of-Life Disposal of PV Modules

As the lifetime of photovoltaic modules is approximately 20–25 years, the waste generated by this technology will increase significantly over the next few years. Waste generated from the photovoltaic sector is estimated at 1.7 million tons by 2030 and is expected to increase to more than 60 million tons by 2050 [44]. Hence, PV waste management should be supported by an adequate regulatory framework. Nowadays, management policies for photovoltaic modules are scarce, even in countries with fast-expanding PV markets, such as China, Japan, India, Australia, and USA. Currently, only Europe has a strong end-of-life disposal policy for photovoltaic modules [38]. In the European Union, end-of-life PV regulations are part of the Waste Electrical and Electronic Equipment Directive (WEEE Directive) [45]. Since 2014, the collection, transport, and recycling of end-of-life PV modules have been regulated in EU member states. The WEEE Directive stipulates that PV producers bear the primary responsibility for collection, handling, and treatment costs. In addition, manufacturers and importers of PV modules must register products with the relevant specifications and are responsible for managing the end-of-life of their products.

1.3. New HCPV Module

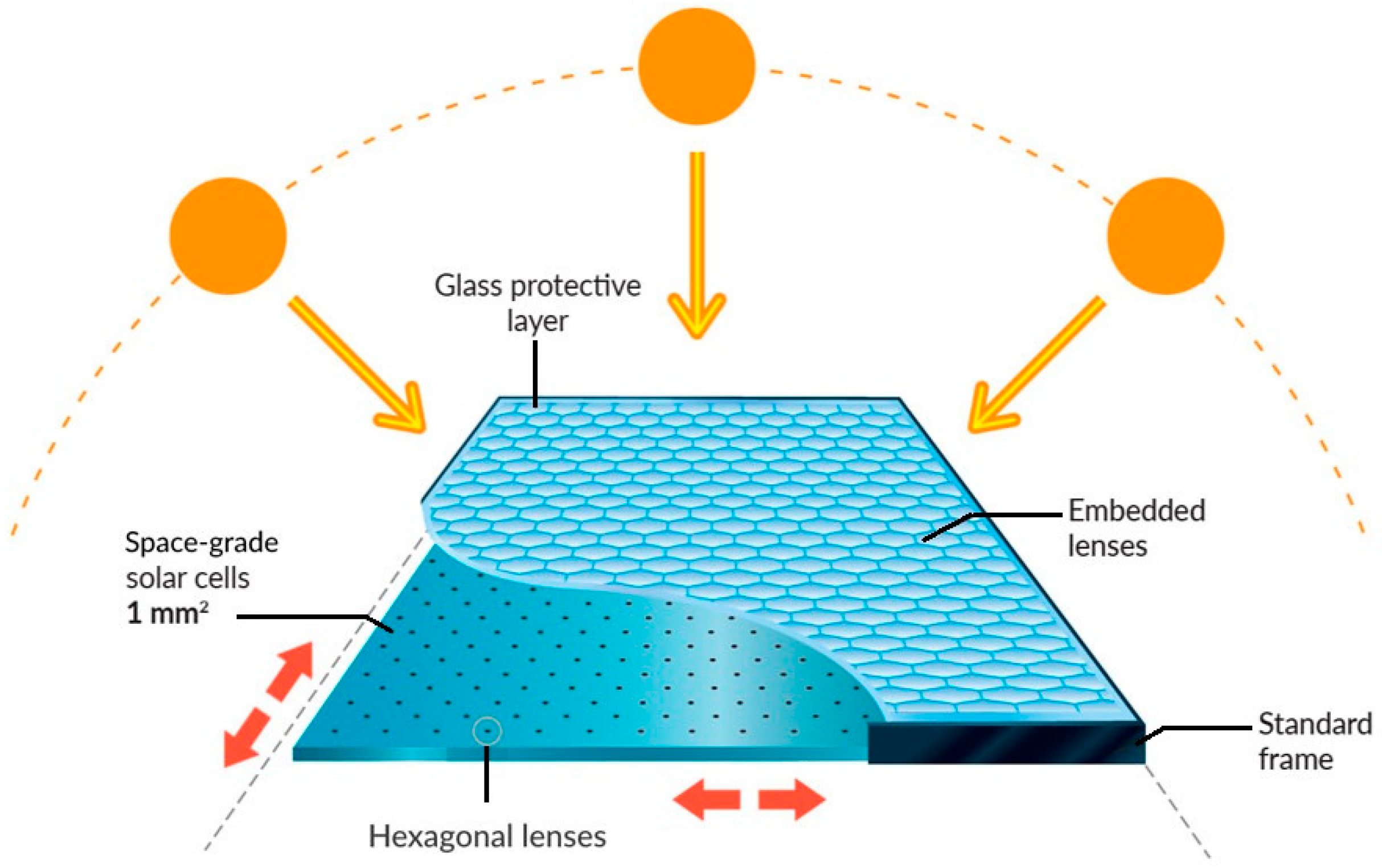

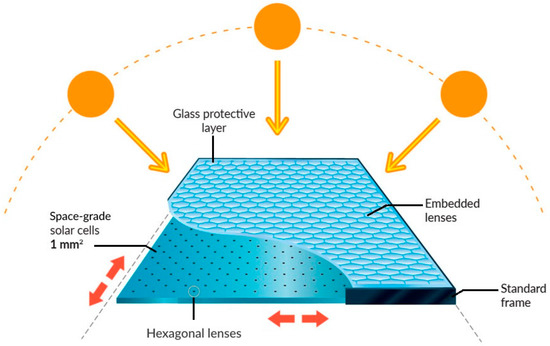

Recently, as part of the HIPERION project, novel, highly-efficient solar modules (>30% STC—standard test conditions for solar module evaluation) combining space-grade solar cells and optical micro-tracking have been developed, as shown in Figure 1.

Figure 1.

Optical micro-tracking technology of HIPERION panel (http://www.hiperion-project.eu/, accessed on 6 March 2023).

The combination of optical micro-tracking and space-grade photovoltaic cells enables module efficiencies of more than 30% under direct sunlight, compared to an average of 17–20% for standard silicon modules. Thanks to the optical concentration, only 0.5% of the total surface has to be covered with cells to reach optimal efficiency and cost-effectiveness. Since only a scattered array of cells is needed, space-grade cells become affordable.

This technology consists of an overlay assembled on top of a silicon backplane and enables the module’s performance to be significantly enhanced under direct sunlight. The overlay is a concentrating system that focuses sunlight on high-efficiency space-grade multi-junction solar cells (III-V cells), regardless of the orientation of the sun and without tilting the module. A micro-tracking system mounted on a conventional silicon backplane concentrates sunlight on the multi-junction solar cells [46]. The panels act as silicon modules under diffuse sunlight and provide record-breaking energy production per m2, with gains of up to 50% in Central Europe and up to 80% in Southern Europe.

The presented study applied life cycle assessment (LCA) to evaluate the environmental performance of the innovative HCPV system developed as part of the HIPERION project.

2. Materials and Methods

An LCA study can be performed using a variety of different calculation techniques and a wide range of approaches. Extensive literature screening revealed that the most suitable methodology for life cycle assessment of PV panels is SimaPro®. The software enables the measurement of the environmental impact of products and services at all stages of the life cycle and the identification of hotspots in each link of the supply chain. SimaPro version 9.00.49 and Ecoinvent 3.8 database were used to perform the LCA calculations. The Ecoinvent database contains life cycle inventory (LCI) data from various sectors, such as energy production, transport, building materials, production of chemicals, metal production, etc. The entire database consists of over 10,000 interlinked datasets, each of which describes the life cycle inventory at the process level. SimaPro provides six libraries, each containing all the processes found in the Ecoinvent database, but uses different system models (substitution point allocation, classification cut-off, and consequential) and includes either unit or system processes. Unit processes contain links to other unit processes from which SimaPro can calculate inventory flows. System processes use the already-calculated inventory flows and do not contain links to other processes [29,47].

This project uses the IPCC 2021 GWP 100a environmental model and the APOS-allocation methodology at the point of substitution to determine the environmental profile of the PV module [48,49,50].

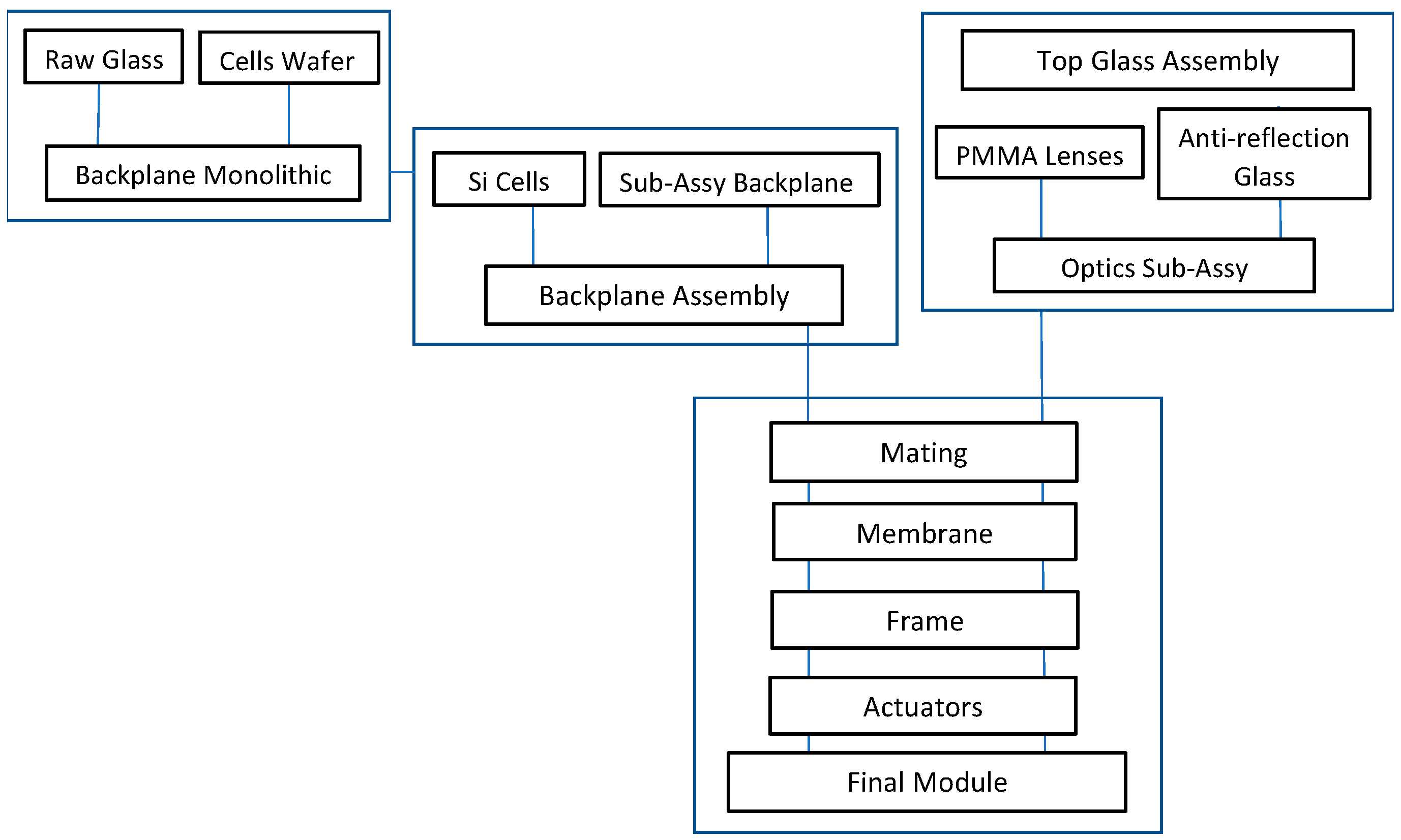

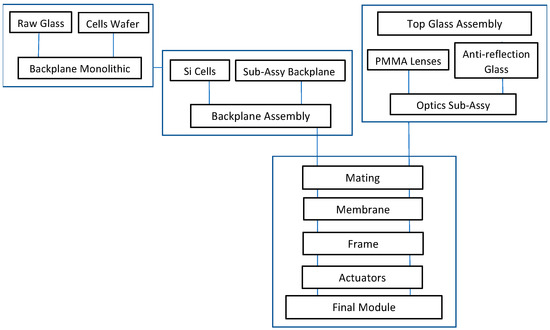

The LCA analysis was carried out according to ISO 14040 and ISO 14044, with the following steps: goal and scope definition, inventory analysis, impact assessment, and interpretation of results [51]. In this project, the full CPV module was adopted as the functional unit. The cradle-to-grave approach was selected. In order to ensure reliable results, an inventory analysis was collected from the producers (primary data), which should identify and quantify all material and energy flows and all waste discharges to the environment throughout the life cycle. Available databases and expert estimates, mass, and energy balances (secondary data) were also used to complete the inventory table. The boundary of the HIPERION HCPV panel production system is shown schematically in Figure 2.

Figure 2.

Flow diagram of the HCPV module production process.

The manufacturing process of the HIPERION HCPV panel begins with the production of a monolithic backplane using raw glass and cell wafers. In the next step, the backplane is mounted on the SI cells, and in parallel, the top glass is produced using PMMA lenses and anti-reflective glass. The final assembly of the module includes mating of the backplane and top glass, and assembling the membrane, frame, and actuators. Material and energy data were collected at each stage of the panel manufacturing process.

In addition, the impact of transporting raw materials was assessed. At the impact assessment stage, the potential effects of the system on the environment were identified and characterized.

In the interpretation phase, a review of all LCA stages to check the compliance with the assumptions and data quality in relation to the goal and scope of the study was performed.

3. Results

The development of new rooftop HCPV solar panels based on the planar optical micro-tracking technology should reduce environmental load due to the high efficiency of the module. To verify this assumption, an LCA analysis was performed according to ISO 14040-14044:2006.

In the first step of the LCA analysis, the inventory table for the HIPERION PV module was completed. The life cycle of a PV module (Figure 2) starts with the acquisition of materials, encompasses their production, component manufacturing, assembly/installation, and operation/maintenance, and then ends with the disposal. Not all of the elements used in the production of the HIPERION panel were available in the Ecoinvent database; appropriate substitutes were selected for inaccessible elements. Table 2 presents the materials used for the construction of the module and the materials finally used in the LCA calculations.

Table 2.

Inventory table for HCPV module.

Based on the data provided, LCA calculations of CO2 emissions and the impact of particular elements of the HIPERION module on the environmental burden at the production stage were carried out.

The environmental impact at the production stage of the HCPV panel was determined for the basic construction of the panel and for the recycling of the main components of the module.

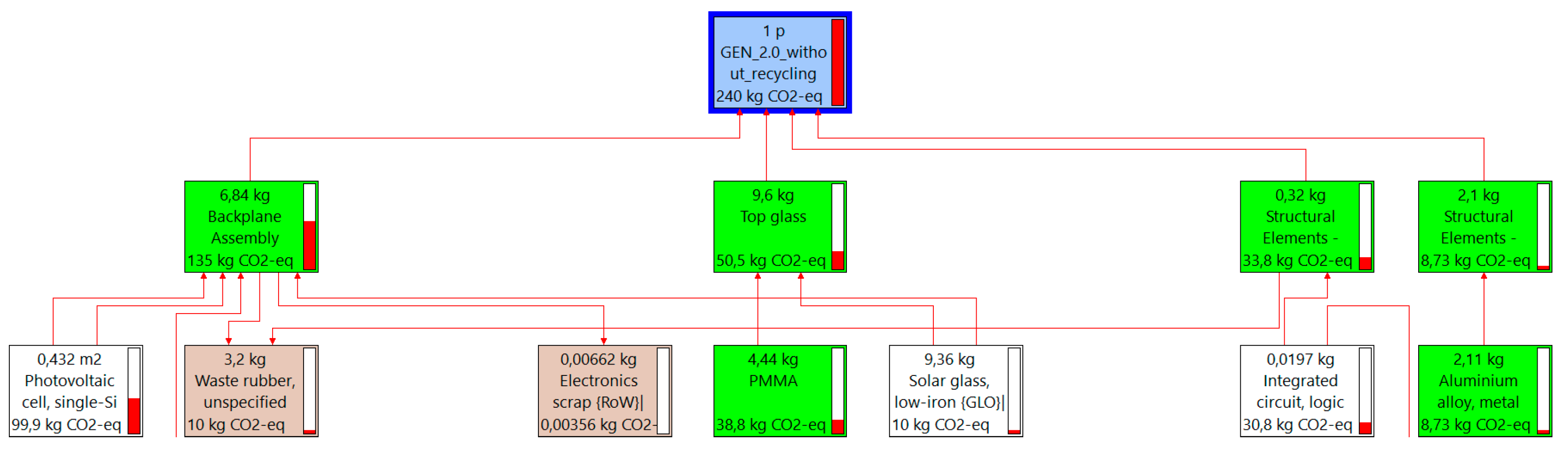

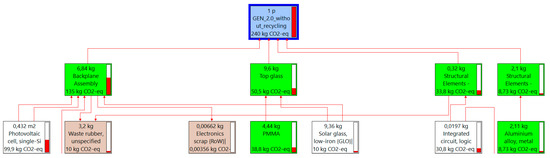

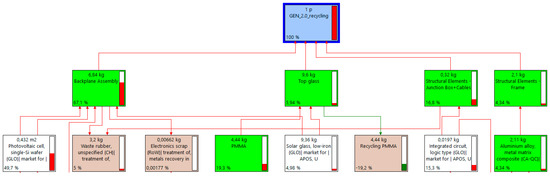

The results of the LCA calculations of CO2 emissions for the constructional data of the HCPV panel are shown in Figure 3.

Figure 3.

Reduced process showing the emission of CO2-eq. (in kg) of individual materials used in the production process of the module.

Figure 3 shows the elements of the process tree with a contribution to the environmental load higher than 3.5% in terms of the emission of kg CO2-eq. of the materials used in the production process of the module.

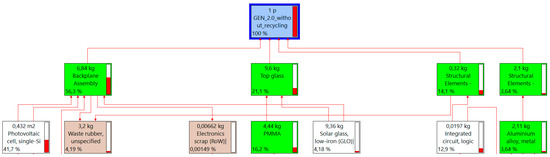

Figure 4 displays elements of the process tree with a contribution to the environmental load higher than 3.5% in terms of the emission of CO2-eq. (in %) of the materials used in the production process of the module.

Figure 4.

Reduced process showing the emission of CO2-eq. (in %) of individual materials used in the production process of the module.

The total CO2 emission per HIPERION module construction was 240 kg CO2-eq, giving CO2 emissions from 20.4 to 27.9 g CO2-eq/kWh over its lifetime (25 years). The PV cells generated the biggest load: 99.9 kg CO2-eq. (41.7% of the total environmental load) due to the large amount of material covering 0.68 m2 of the module surface. PMMA (16.2%), integrated circuits (12.9%), and aluminum frame (3.64%) also made a significant contribution.

In terms of the panel manufacturing process, the biggest load was produced by the backplane assembly (56.3%), top glass (21.1%), and structural elements (14.1%). In the next step, LCA calculations were carried out for the HIPERION module with the recycling of PMMA, rubber, and electronic elements. The calculation results are shown in Figure 5 and Figure 6.

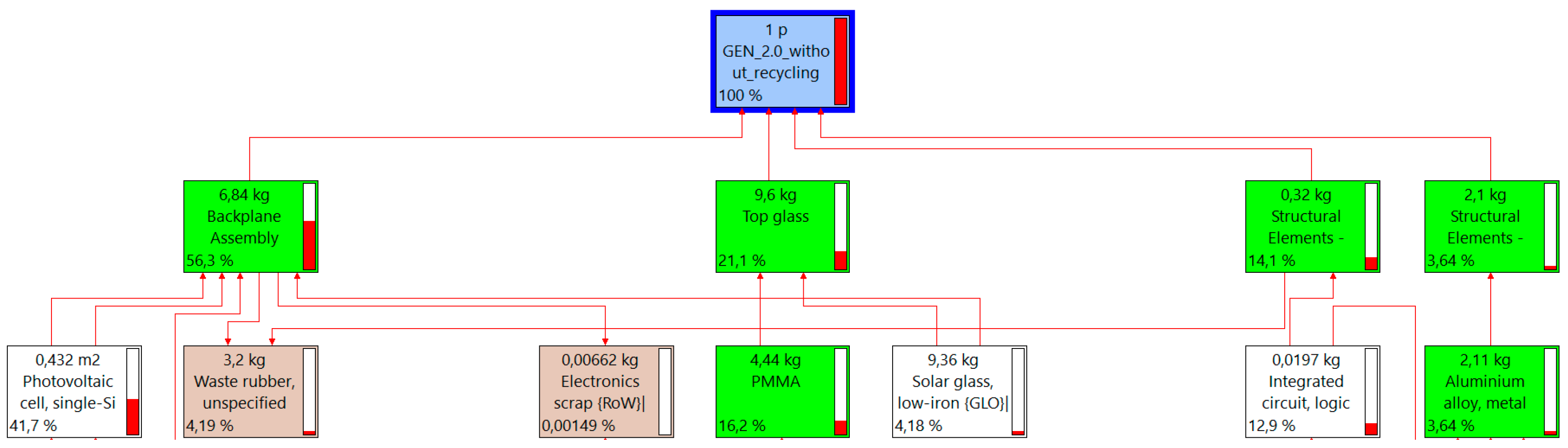

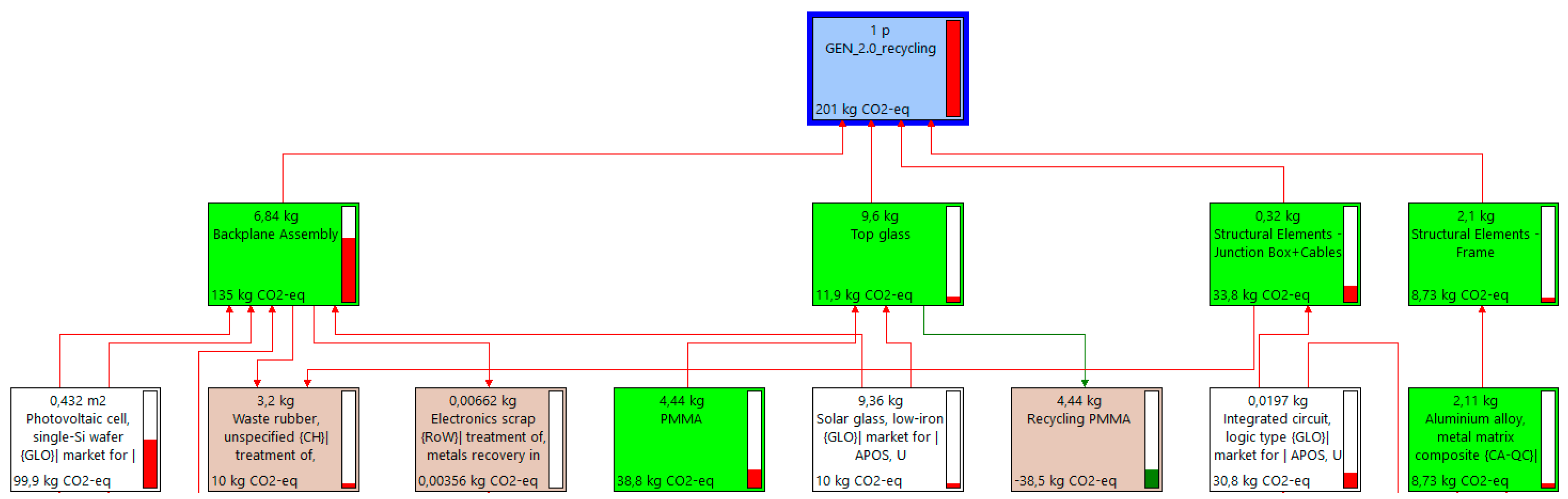

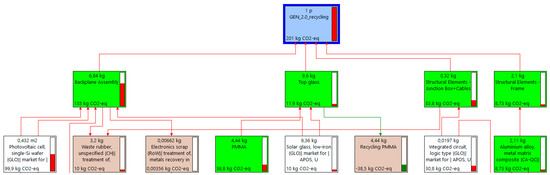

Figure 5.

Reduced process tree showing the contribution of individual materials used to manufacture the module with recycling of PMMA, rubber, and electronic elements (only elements with an impact higher than 3.5% are shown).

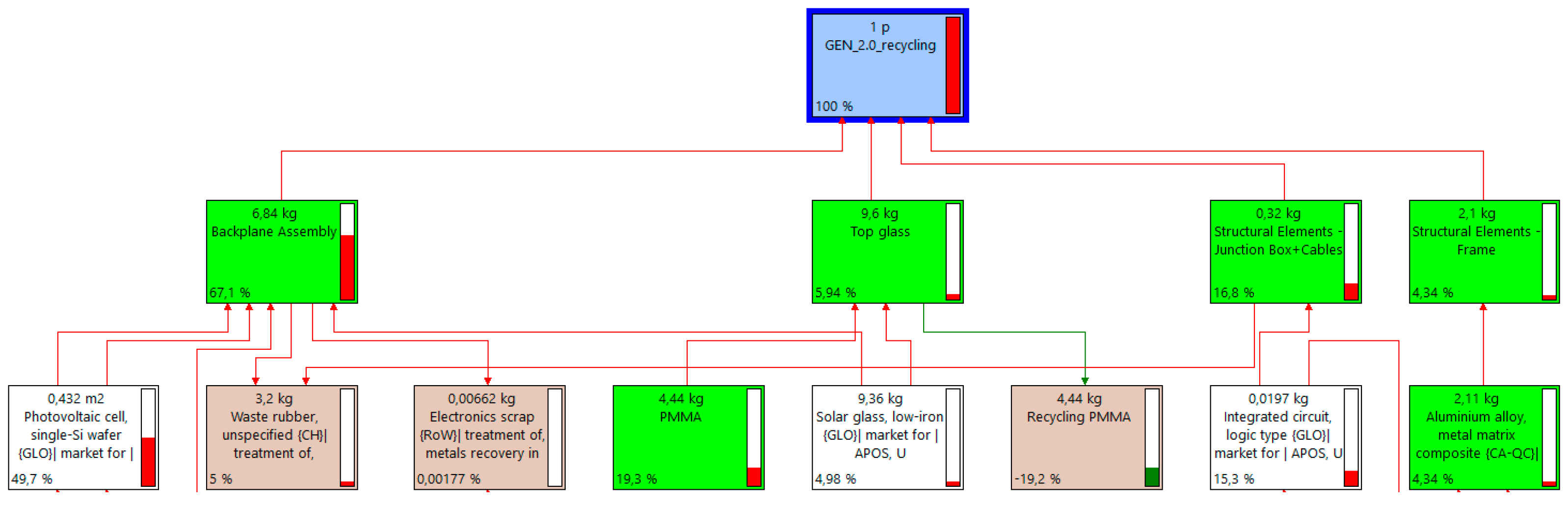

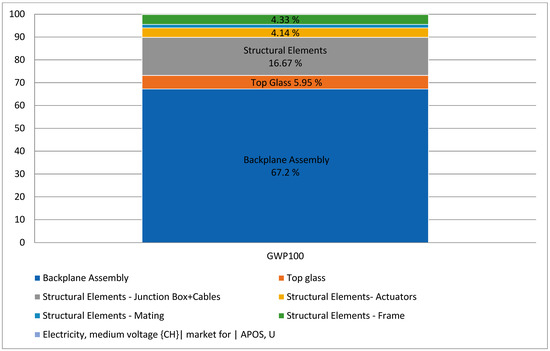

Figure 6.

Reduced process tree showing the percentage of contribution of individual materials used to manufacture the module with recycling of PMMA, rubber, and electronic elements (only elements with a contribution higher than 3.5% are shown).

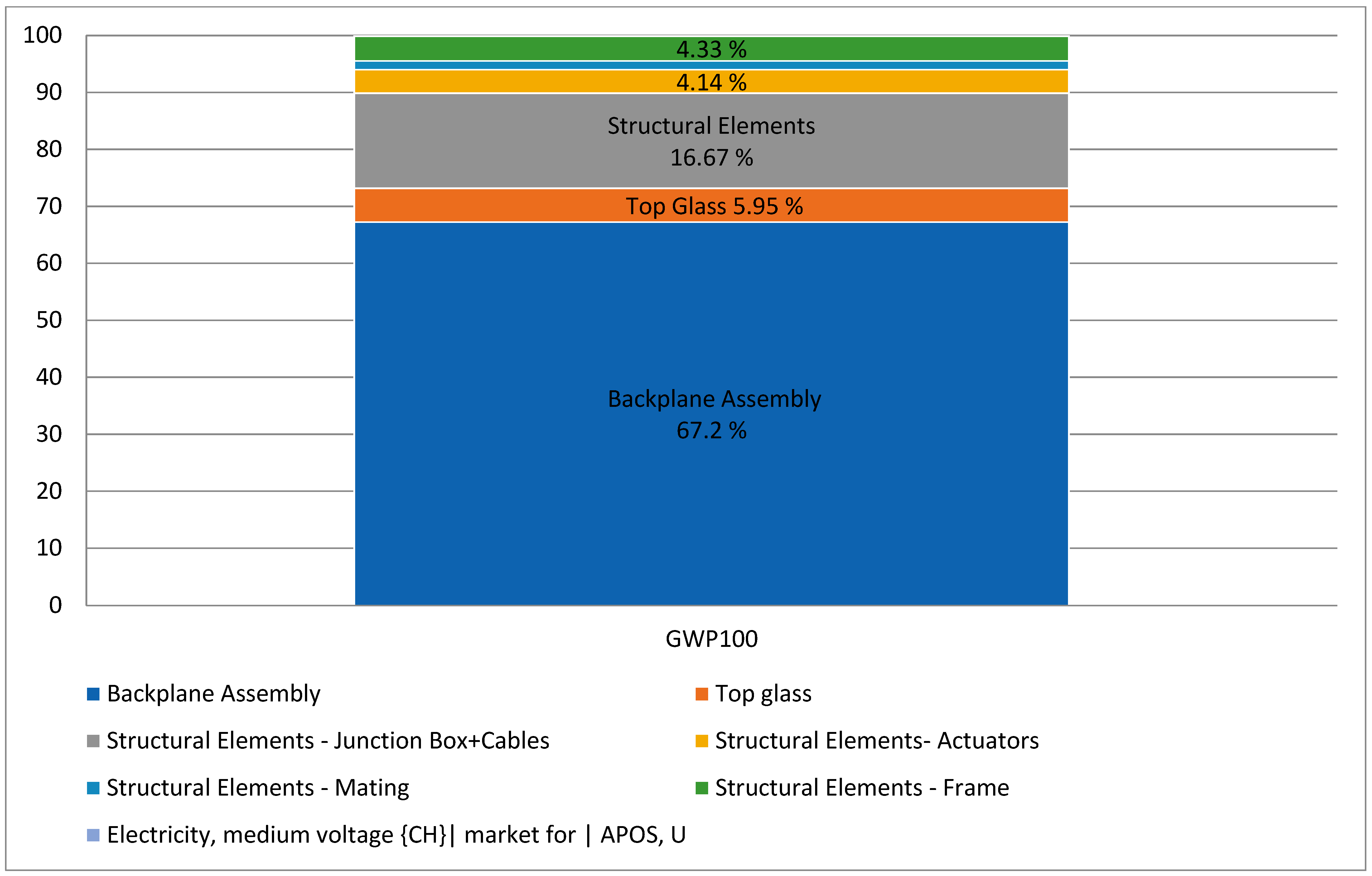

Recycling of PMMA, rubber, and electronic components reduced the total environmental load of the module by 20%, from 240 to 201 kg of CO2-eq. The PV cells generated the greatest environmental load: 99.9 kg of CO2-eq., which corresponds to 49.8% of the total environmental load. Reducing the environmental load also decreased the emissions of CO2 over 25 years of operation from 17.1 to 23.4 g CO2-eq/kWh per module for different locations. In terms of system production, the biggest load was produced by the backplane assembly (67.2%), top glass (5.95%), and structural elements (16.7%). The environmental load produced by PMMA was reduced from 38.9 to 0.22 kg CO2-eq due to the 100% recyclability of this material.

Figure 7 shows the percentage share of individual components of the module. The largest percentage applies to the backplane (67.2%) and, in particular, PV cells. The share of structural elements at the level of 16.67% is related to the use of integrated circuits and electronic components, both active and passive.

Figure 7.

Percentage share of the HIPERION module system components.

For the HIPERION module, the energy payback time (EPTB) was calculated, which is defined as the period required for a renewable energy system to generate the same amount of energy that was used to produce and manage the system itself [29].

The energy payback time of the HCPV module was calculated by using the Cumulative Energy Demand (CED) method. Equation (1) illustrates the integral elements of the EBPT computation methodology [27]:

CEDmat: CED (in MJ) to produce the materials comprising the PV system, CEDmanuf: CED (in MJ) to manufacture the PV system, CEDtrans: CED (in MJ) to transport the materials during the life cycle, CEDinfs: CED (in MJ) to install the system, CEDEOL: CED (in MJ) for end-of-life management, Eagen: mean annual electricity generation (in kWhelectric), CEDo&m: CED (in MJ) for operation and maintenance, and ηG: grid efficiency, primary energy to electricity conversion at the demand side (kWhelectric MJ).

EPBT is dependent on irradiation, but also on other factors, such as grid efficiency. Mean annual electricity generation (Eagen) is converted into its equivalent primary energy, based on the efficiency of electricity conversion at the demand side, using the grid mix where the system is installed. Therefore, in order to calculate the primary energy equivalent of the annual electricity generation (Eagen/ηG), knowledge of the energy conversion efficiency (ηG) of the country-specific energy mix used for electricity generation and material production is required. The average ηG for Western Europe is approx. 0.31 [52]. Better grid efficiency in Europe may decrease EPBT by typically 9.5% compared to PV modules produced in China [53]. Based on the obtained results, the EPBT for the analyzed module is 0.87 and 1.19 years, depending on the location and the related insolation factors (Madrid: 470 kWh/m2, Lyon: 344 kWh/m2).

4. Conclusions

The LCA calculations took into consideration the environmental impact of recycling HIPERION module components. The total carbon footprint of the module was estimated at 201 kg CO2-eq, while at 240 kg without recycling of the module components. PV cells produced a decisive contribution to the environmental load of the module: 99.9 kg CO2-eq (49.8%).

Recycling of PMMA reduced the environmental load from PMMA by 38.5 kg CO2-eq (−19.2%). In terms of the system, the biggest load was produced by the backplane assembly (67.2%), structural elements (16.7%), and top glass (5.95%).

The carbon footprint generated by the HIPERION module is in the range of 17–29 g CO2-eq/kWh, depending on the location. For PMMA and aluminum recycling, the emissions of CO2 over 25 years were estimated at between 17.1 and 23.4 g CO2-eq/kWh per module. The LCA analysis shows that the focusing optics have the most significant impact on total carbon dioxide emissions, making it difficult to significantly reduce the environmental impact of the modules as this part of the panel cannot be replaced.

The EPBT for the HIPERION module is 0.87 and 1.19 years, which is a typical value for HPCV panels.

The recycling and recovery of solar cells made of III-V semiconductors, which are currently being disposed of as hazardous waste, can improve the sustainability of the photovoltaic industry.

The novel architecture of the HIPERION modules can reduce the cost of solar energy due to the high efficiency of energy conversion and high energy yield compared to crystalline silicon panels.

Author Contributions

Conceptualization, A.Z.-S. and M.P.; methodology, A.Z.-S.; software, A.Z.-S. and I.Z.; validation, A.Z.-S. and I.Z.; formal analysis, A.Z.-S. and I.Z.; investigation, A.Z.-S.; resources, M.P.; data curation, M.P.; writing—A.Z.-S. and M.P.; writing—review and editing, A.Z.-S., M.P. and I.Z.; visualization, M.P.; supervision, I.Z.; project administration, I.Z.; funding acquisition, I.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement no. 857775.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to required consent of all project partners.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Güney, T. Solar energy, governance and CO2 emissions. Renew. Energy 2022, 184, 791–798. [Google Scholar] [CrossRef]

- Holechek, J.L.; Geli, H.M.E.; Sawalhah, M.N.; Valdez, R. A Global Assessment: Can Renewable Energy Replace Fossil Fuels by 2050? Sustainability 2022, 14, 4792. [Google Scholar] [CrossRef]

- Bhattacharya, S.; John, S. Beyond 30% Conversion Efficiency in Silicon Solar Cells: A Numerical Demonstration. Sci. Rep. 2019, 9, 12482. [Google Scholar] [CrossRef]

- Andreani, L.C.; Bozzola, A.; Kowalczewski, P.; Liscidini, M.; Redorici, L. Silicon Solar Cells: Toward the Efficiency Limits. Adv. Phys. 2019, 4, 125–148. [Google Scholar] [CrossRef]

- Brodziński, Z.; Brodzińska, K.; Szadziun, M. Photovoltaic Farms-Economic Efficiency of Investments in North-East Poland. Energies 2021, 14, 2087. [Google Scholar] [CrossRef]

- Moreno, G.; Santos, C.; Martín, P.; Rodríguez, F.J.; Peña, R.; Vuksanovic, B. Intra-Day Solar Power Forecasting Strategy for Managing Virtual Power Plants. Sensors 2021, 21, 5648. [Google Scholar] [CrossRef] [PubMed]

- Botero-Valencia, J.S.; Ospina-Rojas, E.; Mejia-Herrera, M.; Gonzalez-Montoya, D.; Durango-Flórez, M.; Ramos-Paja, C.A. Low-cost system for sunlight incidence angle measurement using optical fiber. Hardware X 2022, 11, e00302. [Google Scholar] [CrossRef]

- Alharbi, F.H.; Kais, S. Theoretical limits of photovoltaics efficiency and possible improvements by intuitive approaches learned from photosynthesis and quantum coherence. Renew. Sustain. Energy Rev. 2015, 43, 1073–1089. [Google Scholar] [CrossRef]

- Cengiz, M.S.; Mamis, M.S. Price-Efficiency Relationship for Photovoltaic Systems on a Global Basis. Int. J. Photoenergy 2015, 2015, 256101. [Google Scholar] [CrossRef]

- Renno, C. Energy and economic comparison of three optical systems adopted in a point-focus CPV system. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 99. [Google Scholar] [CrossRef]

- Rahmaniana, S.; Moein-Jahromia, M.; Rahmanian-Koushkaki, H.; Sopian, K. Performance investigation of inclined CPV system with composites of PCM, metal foam and nanoparticles. Sol. Energy 2021, 230, 883–901. [Google Scholar] [CrossRef]

- Shanks, K.; Senthilarasu, S.; Mallick, T.K. Optics for concentrating photovoltaics: Trends, limits and opportunities for materials and design. Renew. Sustain. Energy Rev. 2016, 60, 394–407. [Google Scholar] [CrossRef]

- Khamooshi, M.; Salati, H.; Egelioglu, F.; Faghiri, A.H.; Tarabishi, J.; Babadi, S. A Review of Solar Photovoltaic Concentrators. Int. J. Photoenergy 2014, 2014, 958521. [Google Scholar] [CrossRef]

- Pérez-Higueras, P.; Muñoz, E.; Almonacid, G.; Vidal, P.G. High Concentrator PhotoVoltaics efficiencies: Present status and forecast. Renew. Sustain. Energy Rev. 2011, 14, 1810–1815. [Google Scholar] [CrossRef]

- Alzahrani, M.; Ahmed, A.; Shanks, K.; Sundaram, S.; Mallick, T. Optical component analysis for ultrahigh concentrated photovoltaic system (UHCPV). Sol. Energy 2021, 227, 321–333. [Google Scholar] [CrossRef]

- Benhammane, M.; Notton, G.; Pichenot, G.; Voarino, P.; Ouvrard, D. Overview of electrical power models for concentrated photovoltaic systems and development of a new operational model with easily accessible inputs. Renew. Sustain. Energy Rev. 2021, 135, 110221. [Google Scholar] [CrossRef]

- Parupudi, R.V.; Singh, H.; Kolokotroni, M. Low Concentrating Photovoltaics (LCPV) for buildings and their performance analyses. Appl. Energy 2022, 279, 115839. [Google Scholar] [CrossRef]

- Kavlak, G.; McNerney, J.; Trancik, J.E. Evaluating the causes of cost reduction in photovoltaic modules. Energy Policy 2018, 123, 700–710. [Google Scholar] [CrossRef]

- Ziemińska-Stolarska, A.; Pietrzak, M.; Zbiciński, I. Application of LCA to Determine Environmental Impact of Concentrated Photovoltaic Solar Panels-State-of-the-Art. Energies 2021, 14, 3143. [Google Scholar] [CrossRef]

- Kovacs, E.; Hoaghia, M.A.; Senila, L.; Scurtu, D.A.; Varaticeanu, C.; Roman, C.; Dumitras, D.E. Life Cycle Assessment of Biofuels Production Processes in Viticulture in the Context of Circular Economy. Agronomy 2022, 12, 1320. [Google Scholar] [CrossRef]

- Bhandari, K.P.; Collier, J.M.; Ellingson, R.J.; Apul, D.S. Energy payback time (EPBT) and energy return on energy invested (EROI) of solar photovoltaic systems: A systematic review and meta-analysis. Renew. Sustain. Energy Rev. 2015, 47, 133–141. [Google Scholar] [CrossRef]

- Gerbinet, S.; Belboom, S.; Léonard, A. Life Cycle Analysis (LCA) of photovoltaic panels: A review. Renew. Sustain. Energy Rev. 2014, 38, 747–753. [Google Scholar] [CrossRef]

- Salibi, M.; Schönberger, F.; Makolli, Q.; Bousi, E.; Almajali, S.; Friedrich, L. Energy payback time of photovoltaic electricity generated by passivated emitter and rear cell (perc) solar modules: A novel methodology proposal. In Proceedings of the 38th European PV Solar Energy Conference and Exhibition, Lisbon, Portugal, 6–10 September 2021. [Google Scholar]

- Wetzel, T.; Borchers, S. Update of energy payback time and greenhouse gas emission data for crystalline silicon photovoltaic modules. Prog. Photovolt. Res. Appl. 2014, 23, 1429–1435. [Google Scholar] [CrossRef]

- Sandwell, P.; Duggan, G.; Nelson, J.; Ekins-Daukes, N. The environmental impact of lightweight HCPV modules: Efficient design and effective deployment. Prog. Photovolt. Res. Appl. 2016, 4, 1458–1472. [Google Scholar] [CrossRef]

- Hu, A.H.; Huang, L.H.; Lou, S.; Kuo, C.H.; Huang, C.Y.; Chian, K.J.; Chien, H.T.; Hong, H.F. Assessment of the Carbon Footprint, Social Benefit of Carbon Reduction, and Energy Payback Time of a High-Concentration Photovoltaic System. Sustainability 2017, 9, 27. [Google Scholar] [CrossRef]

- Frischknecht, R.; Stolz, P.; Heath, G.; Raugei, M.; Sinha, P.; de Wild-Scholten, M. Methodology Guidelines on Life Cycle Assessment of Photovoltaics 2020, IEA-PVPS Task 12, Report T12-18:2020, 4th ed.; IEA: Paris, France, 2020; Available online: https://iea-pvps.org/key-topics/methodology-guidelines-on-life-cycle-assessment-of-photovoltaic-2020/ (accessed on 15 January 2023).

- RSE. Results of the APOLLON Project and Concentrating Photovoltaic Perspective; Ricerca sul Sistema Energetico-RSE S.p.A.: Milan, Italy, 2014. [Google Scholar]

- Fthenakis, V.M.; Kim, H.C. Life cycle assessment of high-concentration photovoltaic systems. Prog. Photovolt. Res. Appl. 2013, 21, 379–388. [Google Scholar] [CrossRef]

- Corona, B.; Escuderol, L.; Quéméré, G.; Luque-Heredia, I.; San Miguel, G. Energy and environmental life cycle assessment of a high concentration photovoltaic power plant in Morocco. Int. J. Life Cycle Assess. 2017, 22, 364–373. [Google Scholar] [CrossRef]

- Ndiaye, A.; Charki, A.; Kobi, A.; Kébé, C.M.F.; Ndiaye, P.A.; Sambou, V. Degradations of Silicon Photovoltaic Modules: A Literature Review. Sol. Energy 2013, 96, 140–151. [Google Scholar] [CrossRef]

- Khan, F.; Alshahrani, T.; Fareed, I.; Kim, J.H. A Comprehensive Degradation Assessment of Silicon Photovoltaic Modules Installed on a Concrete Base under Hot and Low-Humidity Environments: Building Applications. Sustain. Energy Technol. Assess. 2022, 52, 102314. [Google Scholar] [CrossRef]

- Khan, F.; Rezgui, B.D.; Kim, J.H. Reliability Study of c-Si PV Module Mounted on a Concrete Slab by Thermal Cycling Using Electroluminescence Scanning: Application in Future Solar Roadways. Materials 2020, 13, 470. [Google Scholar] [CrossRef]

- Nordin, A.H.M.; Sulaiman, S.I.; Shaari, S. Life Cycle Impact of Photovoltaic Module Degradation on Energy and Environmental Metrics. Energy Rep. 2022, 8, 923–931. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Huda, N.; Alavi, Z.; Islam, M.T.; Behnia, M. End-of-life photovoltaic modules: A systematic quantitative literature review. Resour. Conserv. Recycl. 2019, 146, 1–16. [Google Scholar] [CrossRef]

- Farrell, C.C.; Osman, A.I.; Doherty, R.; Saad, M.; Zhang, X.; Murphy, A.; Harrison, J.; Vennard, A.S.M.; Kumaravel, V.; Al-Muhtaseb, A.H.; et al. Technical challenges and opportunities in realising a circular economy for waste photovoltaic modules. Renew. Sustain. Energy Rev. 2020, 128, 109911. [Google Scholar] [CrossRef]

- Calì, M.; Hajji, B.; Nitto, G.; Acri, A. The Design Value for Recycling End-of-Life Photovoltaic Panels. Appl. Sci. 2022, 12, 9092. [Google Scholar] [CrossRef]

- Lunardi, M.M.; Alvarez-Gaitan, J.P.; Bilbao, J.I.; Corkish, R. A Review of Recycling Processes for Photovoltaic Modules. In Solar Panels and Photovoltaic Materials; Zaidi, B., Ed.; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Strachala, D.; Hylský, J.; Vanek, J.; Fafilek, G.; Jandová, K. Methods for recycling photovoltaic modules and their impact on environment and raw material extraction. Acta Montan. Slovaca 2017, 22, 257–269. Available online: http://hdl.handle.net/11012/187727 (accessed on 6 March 2023).

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global status of recycling waste solar panels: A review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef]

- Wang, T.Y. Recycling of Solar Cell Materials at the End of Life. In Advances in Solar Photovoltaic Power Plants. Green Energy and Technology; Islam, M., Rahman, F., Xu, W., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 287–317. [Google Scholar] [CrossRef]

- Yu, H.F.; Hasanuzzaman, M.; Rahim, N.A.; Amin, N.; Nor Adzman, N. Global Challenges and Prospects of Photovoltaic Materials Disposal and Recycling: A Comprehensive Review. Sustainability 2022, 14, 8567. [Google Scholar] [CrossRef]

- Onusseit, H. The influence of adhesives on recycling. Resour. Conserv. Recycl. 2006, 46, 168–181. [Google Scholar] [CrossRef]

- Sharma, A.; Pandey, S.; Kolhe, M. Global Review of Policies & Guidelines for Recycling of Solar Pv Modules. Int. J. Smart Grid Clean Energy 2019, 8, 597–610. [Google Scholar] [CrossRef]

- European Union. Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on Waste Electrical and Electronic Equipment (WEEE). Off. J. Eur. Union 2012, 197, 38–71. [Google Scholar]

- Hiperion. Available online: https://hiperion-project.eu/ (accessed on 10 January 2023).

- Goedkoop, M.; Oele, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro. 2016. Available online: https://www.pre-sustainability.com/download/SimaPro8IntroductionToLCA.pdf (accessed on 6 March 2023).

- Intergovernmental Panel on Climate Change. IPCC Fifth Assessment Report. The Physical Science Basis. 2013. Available online: http://www.ipcc.ch/report/ar5/wg1/ (accessed on 6 March 2023).

- International Reference Life Cycle Data System (ILCD). Handbook—General Guide for Life Cycle Assessment—Detailed Guidance; Publications Office of the European Union: Luxembourg, 2010. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC58190 (accessed on 6 March 2023).

- Sima Pro. 2018. Available online: https://simapro.com/ (accessed on 22 March 2019).

- EN ISO 14040; Environmental Management-Life Cycle Assessment-Principles and Framework. ISO: London, UK, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 22 March 2019).

- Franklin Associates. Summary Report: LCA Streamlining Demonstration Study; Franklin Associates, Ltd. for Research Triangle Institute: Research Triangle Park, NC, USA, 1996. [Google Scholar]

- Fraunhofer Institute for Solar Energy Systems. Photovoltaics Report; ISE: Freiburg, Germany, 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).