Assessment of the Prospects of Polish Non-Food Energy Agriculture in the Context of a Renewable Energy Source

Abstract

:1. Introduction

- I.

- Waste materials;

- II.

- Materials that are by-products;

- III.

- Plant products deliberately cultivated for the purposes of energy.

- −

- Waste wood;

- −

- Straw;

- −

- Cereals (maize, sorghum, oats, rye);

- −

- Energy crops (Jerusalem artichoke, Sakhalin knotweed, Pennsylvanian mallow, miscanthus, prairie spartina, reed canary seed, rotary millet, elongated couch grass).

- −

- Biological origin;

- −

- Physicochemical properties of the materials (ash, humidity, flammable substances, volatile matter);

- −

- Resource balance (yield, fertilizing variants);

- −

- Energy characteristics of raw materials (energy content, energy production, energy value, heat of combustion, calorific value, fuel consumption);

- −

- Territorial dependence affecting the production of biomass.

2. Materials and Methods

- -

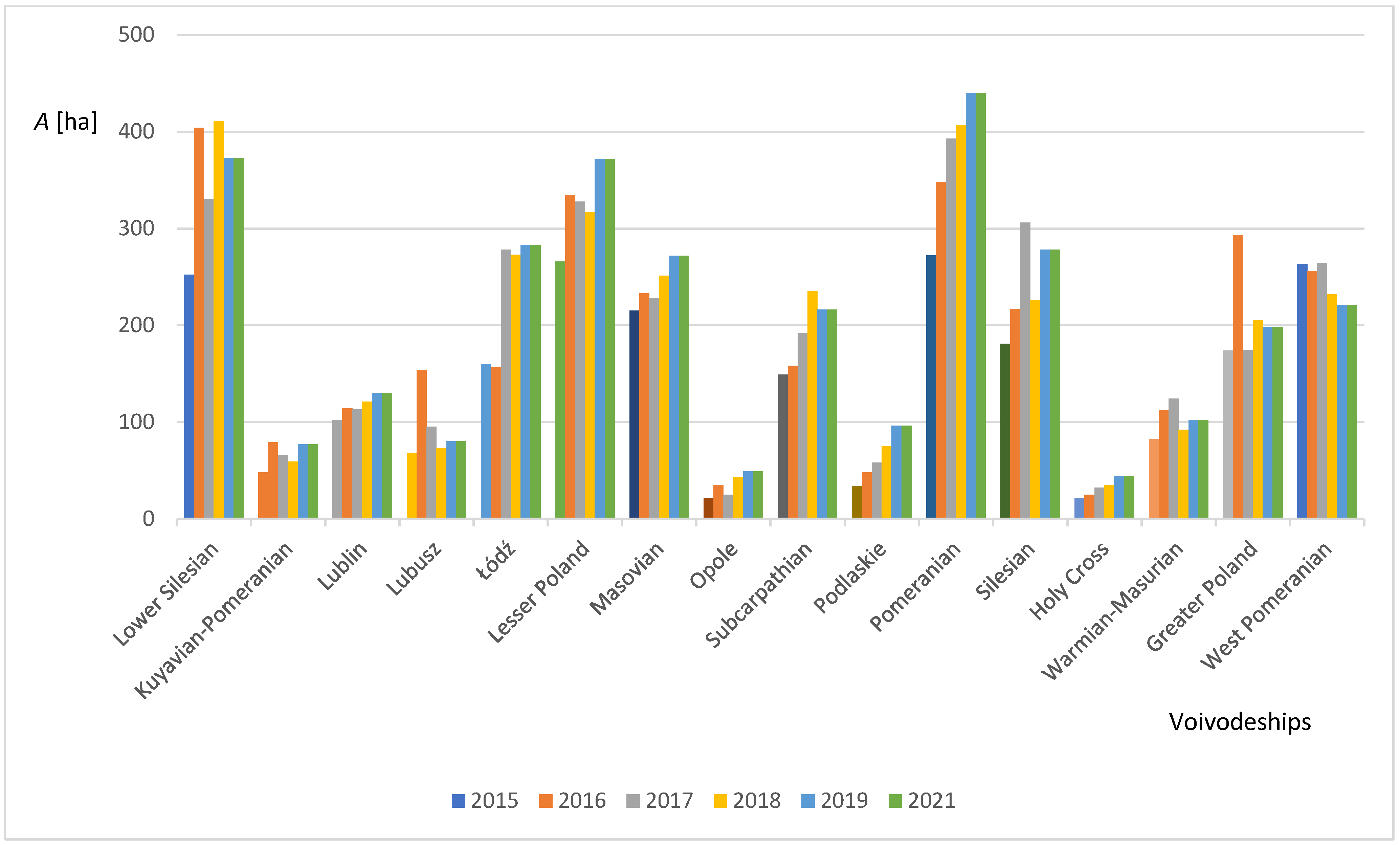

- The area of agricultural land that is potentially useful for the cultivation of energy crops is interpreted;

- -

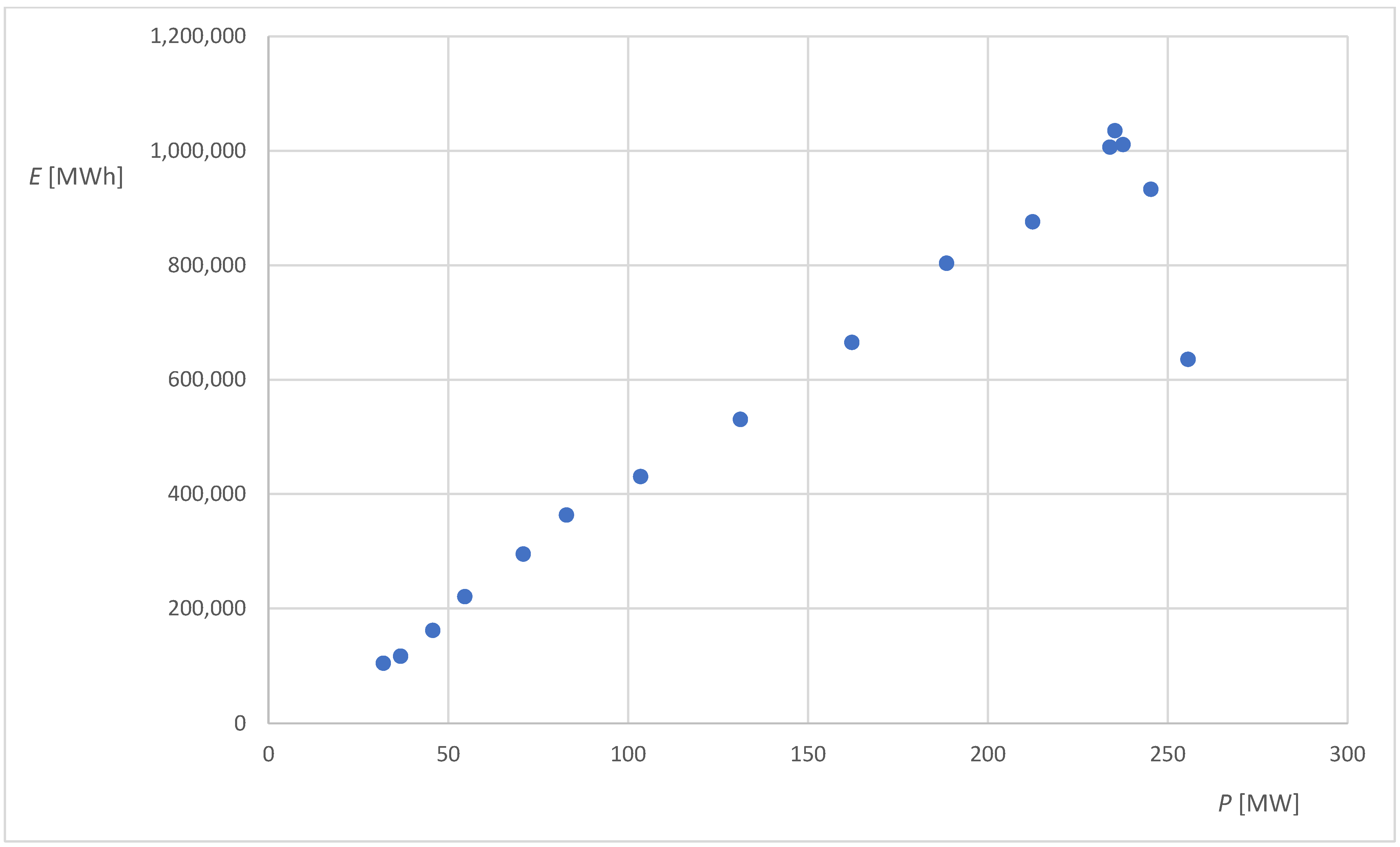

- The relationship between the installed biogas capacity and the amount of electricity produced from biogas is demonstrated;

- -

- The relationship between the installed power coming from biomass and the amount of electricity produced from it is demonstrated;

- -

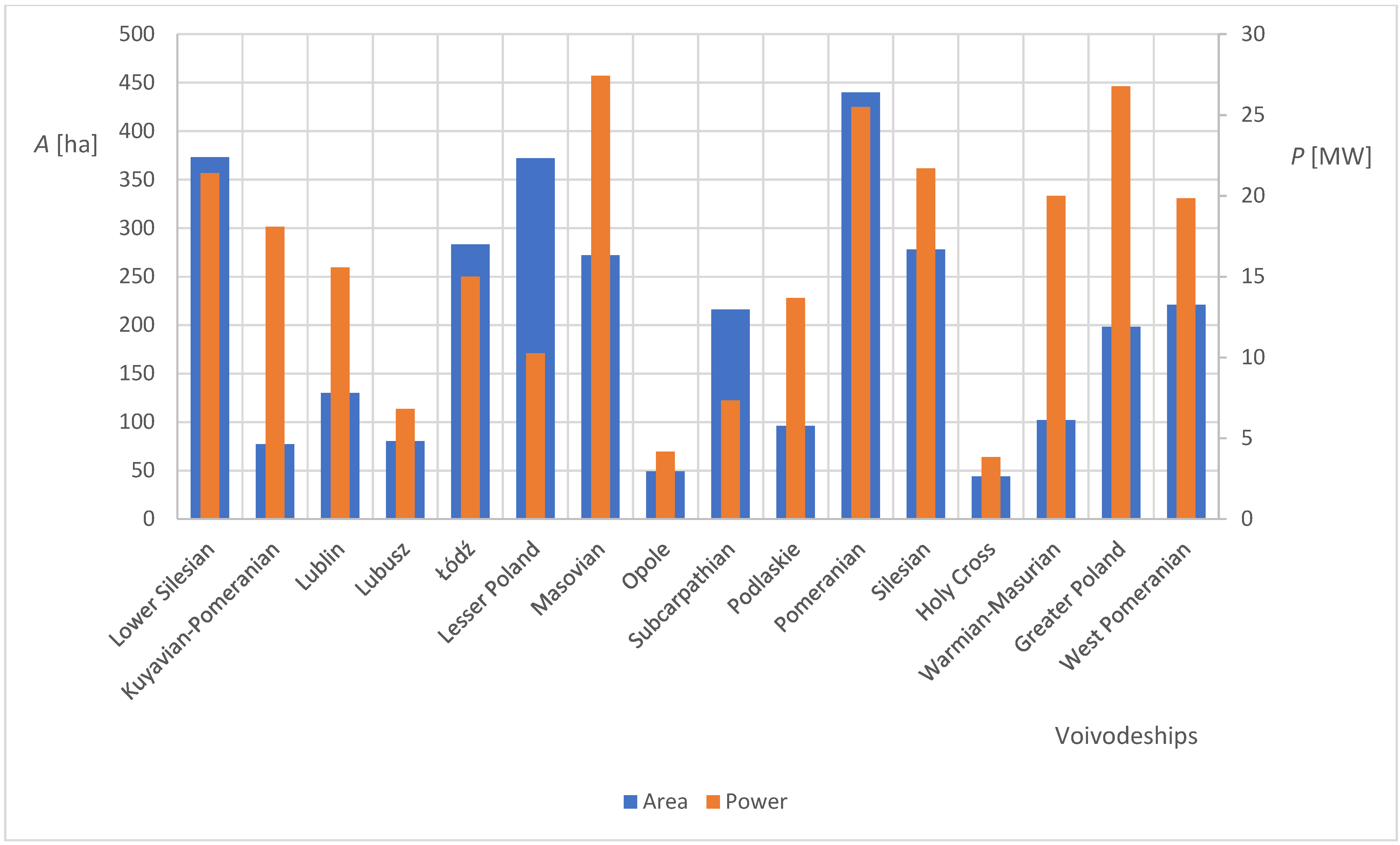

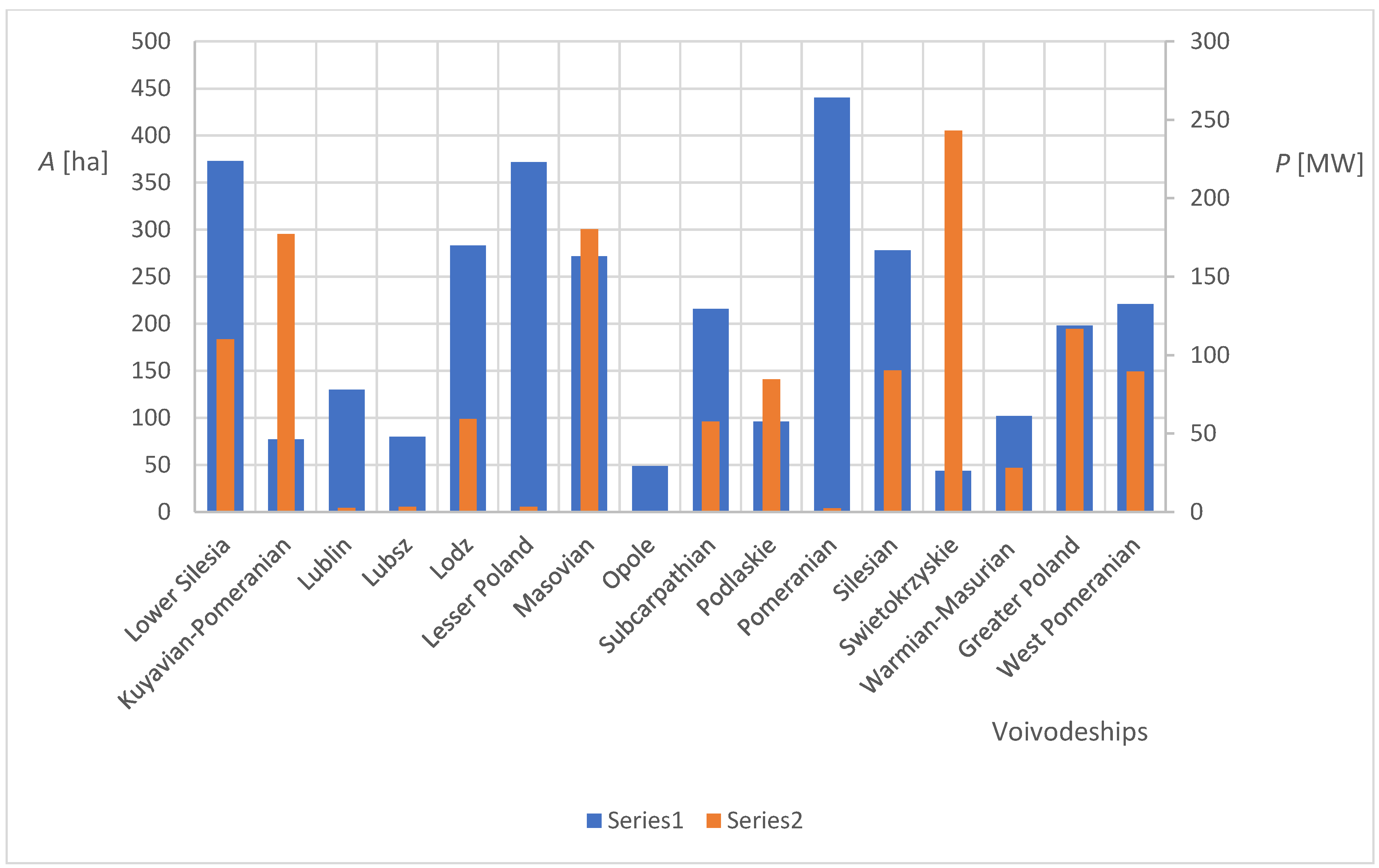

- The relationship between the area of agricultural land that is potentially useful for the cultivation of energy crops and the regional approach to the installation of energy from biogas and to the capacity installed from biomass is demonstrated.

Biomass Potential in Poland

- (A).

- Natural fertilizers, including manure and non-mineralized guano, classified as category 2 materials according to the EU regulation on animal by-products [15].

- (B).

- Waste of plant origin from agricultural production (e.g., cereals that do not meet quality standards), classified according to the waste catalog [16] as subgroup 02 01 waste from agriculture, horticulture, hydroponics, forestry, hunting and fishing.

- (C).

- Slaughterhouse waste, classified as category 2 and 3 materials according to the EU regulation on animal by-products.

- (D).

- Food processing waste, classified according to the waste catalog into the following subgroups:

- -

- 02 02 waste from the preparation and processing of food products of animal origin;

- -

- 02 03 waste from the preparation and processing of food products and stimulants, waste of plant origin, including waste from fruit, vegetables, cereal products, edible oils, cocoa, coffee and tea, waste from the preparation and processing of tobacco and yeast, waste from the production of yeast extracts, and waste from the preparation and fermentation of molasses (except 02 07);

- -

- 02 04 waste from the sugar industry;

- -

- 02 05 waste from the dairy industry;

- -

- 02 06 waste from the baking and confectionery industry;

- -

- 02 07 waste from the production of alcoholic and non-alcoholic beverages (except for coffee, tea and cocoa).

- (E).

- Crops dedicated to the organic recycling process through biogasification.

3. Results and Discussion

3.1. Waste Wood

- MWhe—megawatt hours of electricity;

- MWhc—megawatt hours of thermal energy.

3.2. Straw

- -

- A significant surplus of straw exceeding the needs arising from agricultural production, until at least 2030;

- -

- A favorable area structure of farms, i.e., a significant number of large-area farms over 50 ha.

- -

- Currently, these conditions are met by three regions of Poland [36]:

- -

- South-east, eastern part of Lublin and Podkarpacie Voivodeships;

- -

- South-west, Lower Silesia Voivodeship;

- -

- North-west, Pomeranian and West Pomeranian Voivodeships.

- -

- Heat load of 70 kW;

- -

- Hourly load of 2968 h∙year−1;

- -

- Energy demand of 207,786 kWh∙year−1.

3.3. Cereals and Energy Plants

- -

- High yield potential (based on information from Polish farmers, up to 9 Mg of grain per ha can be obtained in Poland);

- -

- Wide range of uses (consumption, feed, industrial grain);

- -

- Belongs to the group of gluten-free cereals (important for the production of gluten-free food);

- -

- Low water requirements and high resistance to drought [61];

- -

- Lower costs of seeds and tending treatments than in maize cultivation;

- -

- High energy value and content of minerals (nutritional value similar to that of maize);

- -

- High content of antioxidants, in relation to other cereals;

- -

- Very good water management, helping sorghum to survive drought.

- -

- Long growing season, necessitating harvesting in late autumn;

- -

- The possibility of strong infestation of the grain by fungi, especially in unfavorable weather conditions and under improper handling after harvesting (in wet grain, fungi develop very quickly);

- -

- The possibility of birds destroying the ripening grain and the decrease in the amount and quality of the grain yield;

- -

- High (too high in the case of a monodiet) content of some amino acids: valine, methionine, cysteine, isoleucine, phenylalanine, tyrosine and especially leucine (excess leucine may cause pellagra-Lombard erythema) [62].

- -

- Oats have low soil requirements, which means they can be grown almost anywhere;

- -

- There is a long tradition of growing this grain in Poland;

- -

- Machines for growing and harvesting cereal grains are widely available;

- -

- Energy grain is easy to store and transport [77].

- -

- A (13 farms)—oat grain used for heating purposes came from own production and was additionally purchased at the end of the 2007/2008 heating season; the oat cultivation area per farm was 1.68 ha on average.

- -

- B (8 farms)—oats from own production were used for heating, and, additionally, barley grain was added at the end of the heating season; the oat cultivation area per farm was 3.13 ha on average.

- -

- C (5 farms)—oat grain from own production was used for heating, and, additionally, sour cherry stones were purchased; the oat cultivation area was, on average, 2.18 ha per farm.

- -

- Annual plants;

- -

- Fast-rotation woody plants;

- -

- Perennial, fast-growing, annual-yielding grasses;

- -

- Fast-growing, annual-yielding perennials.

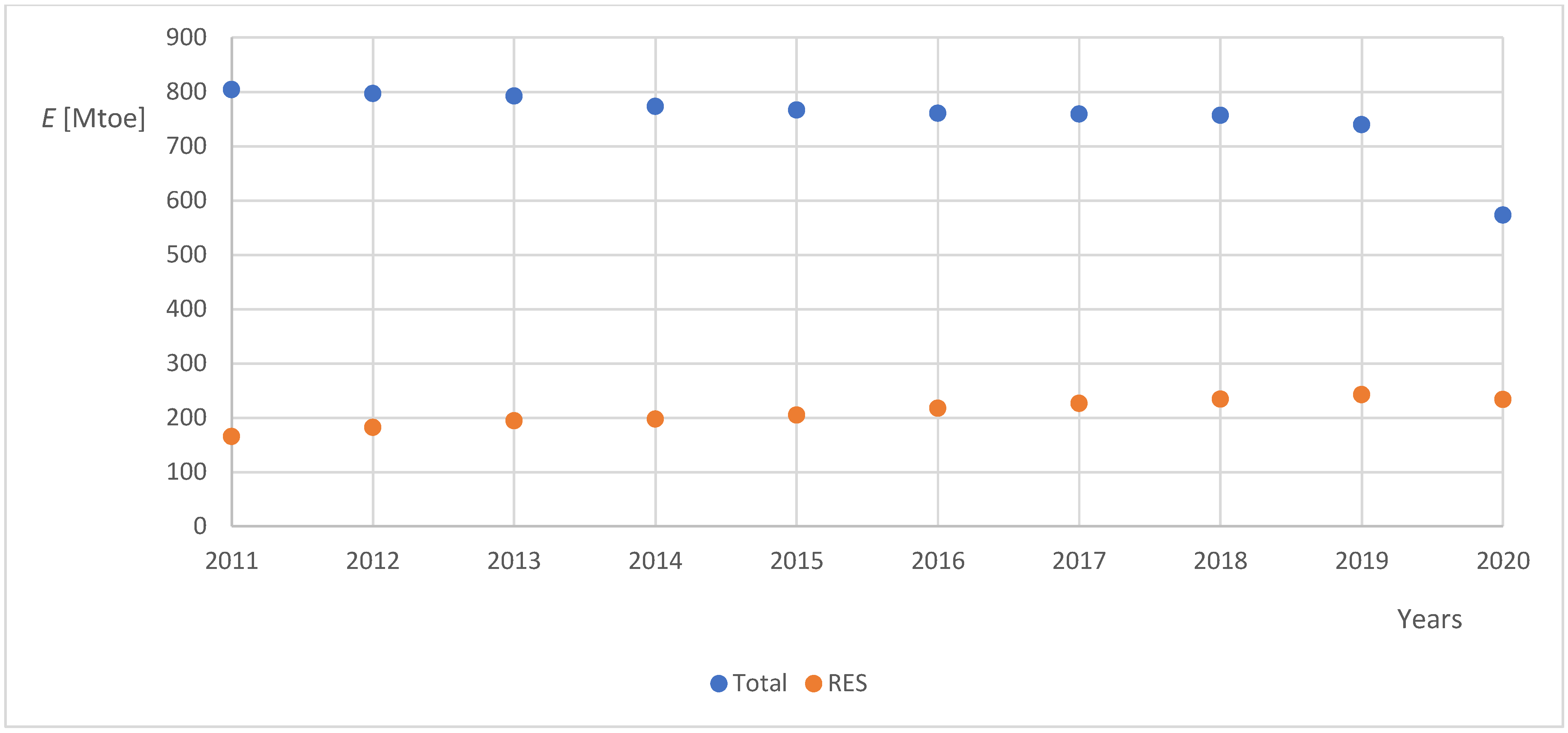

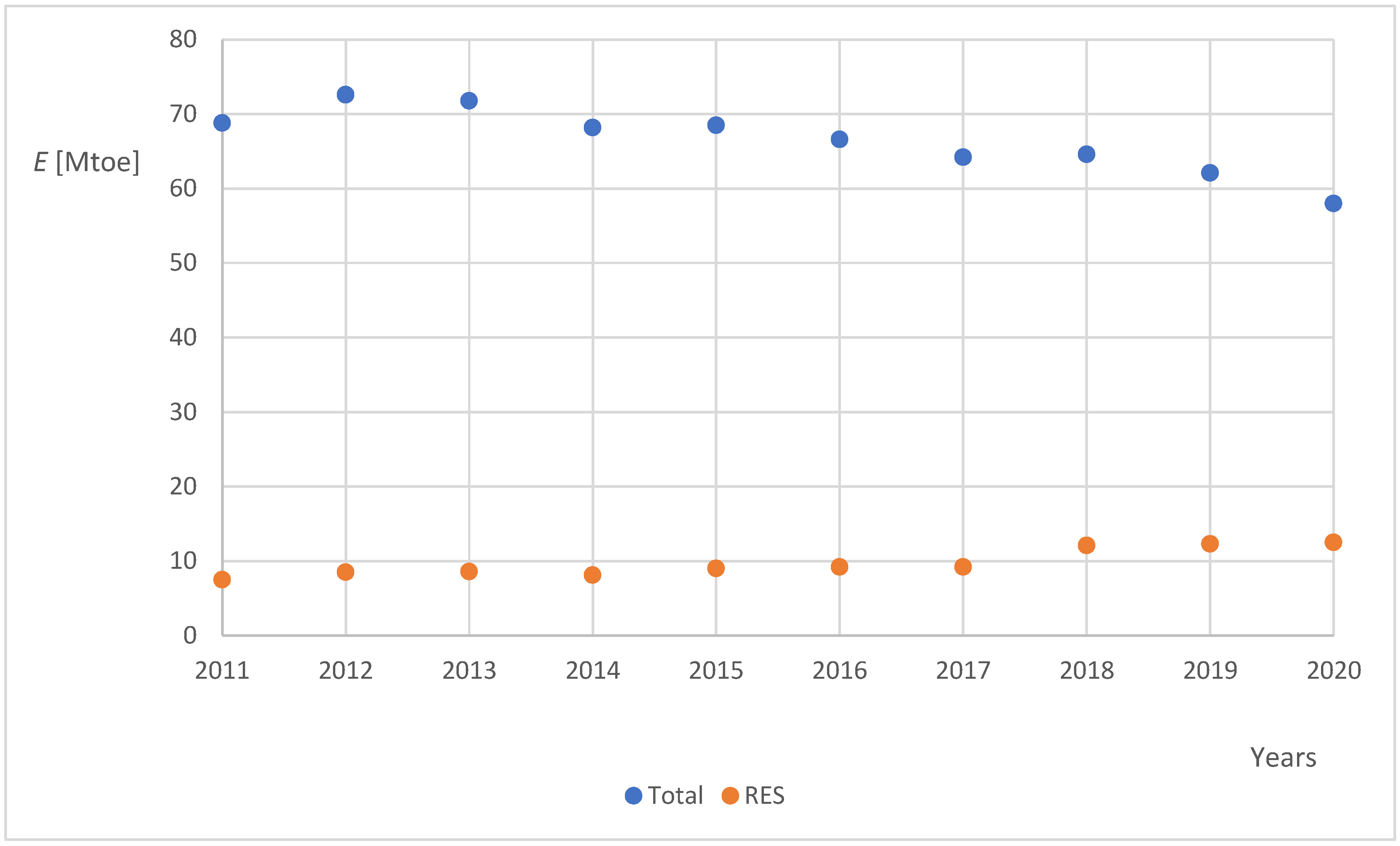

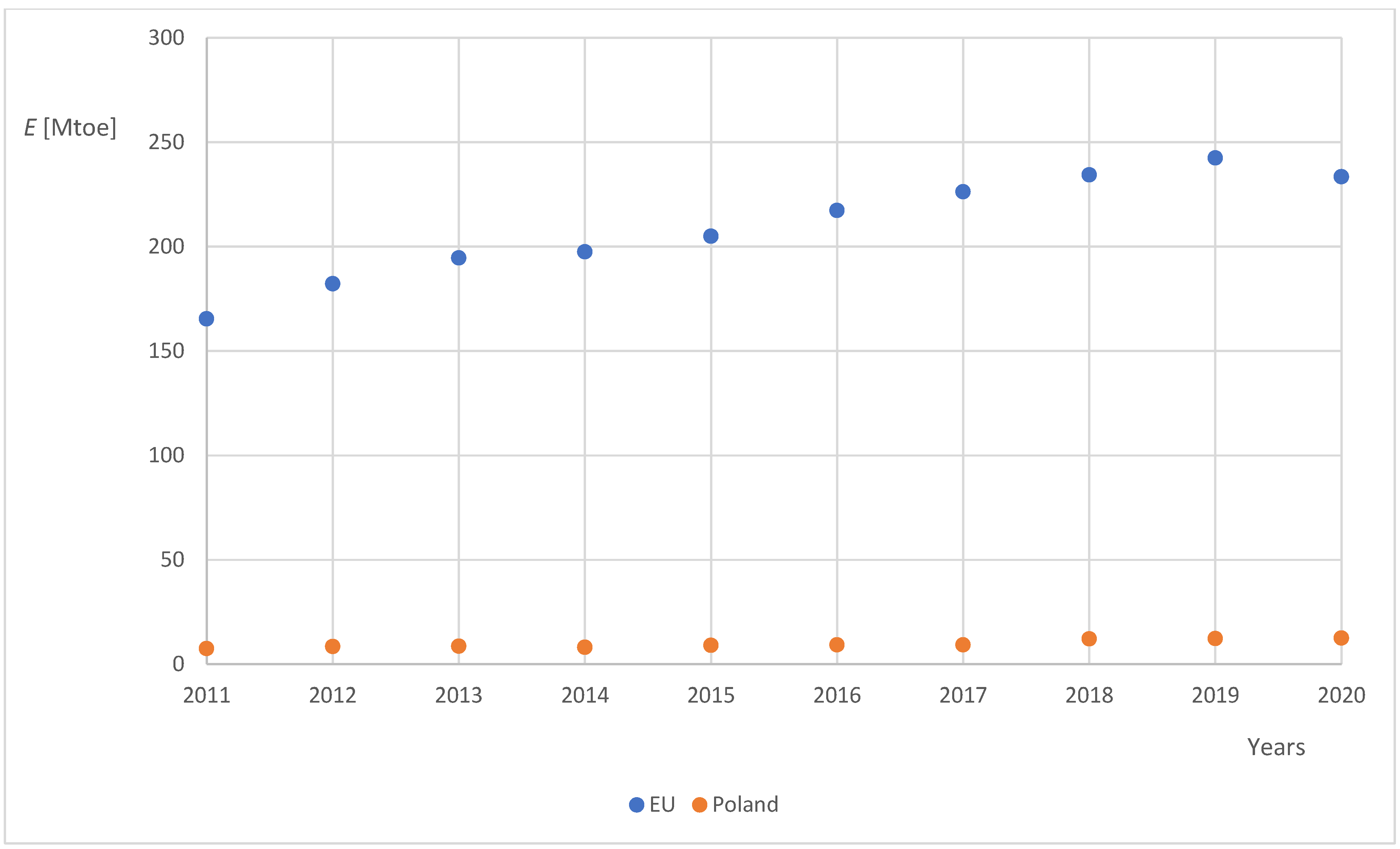

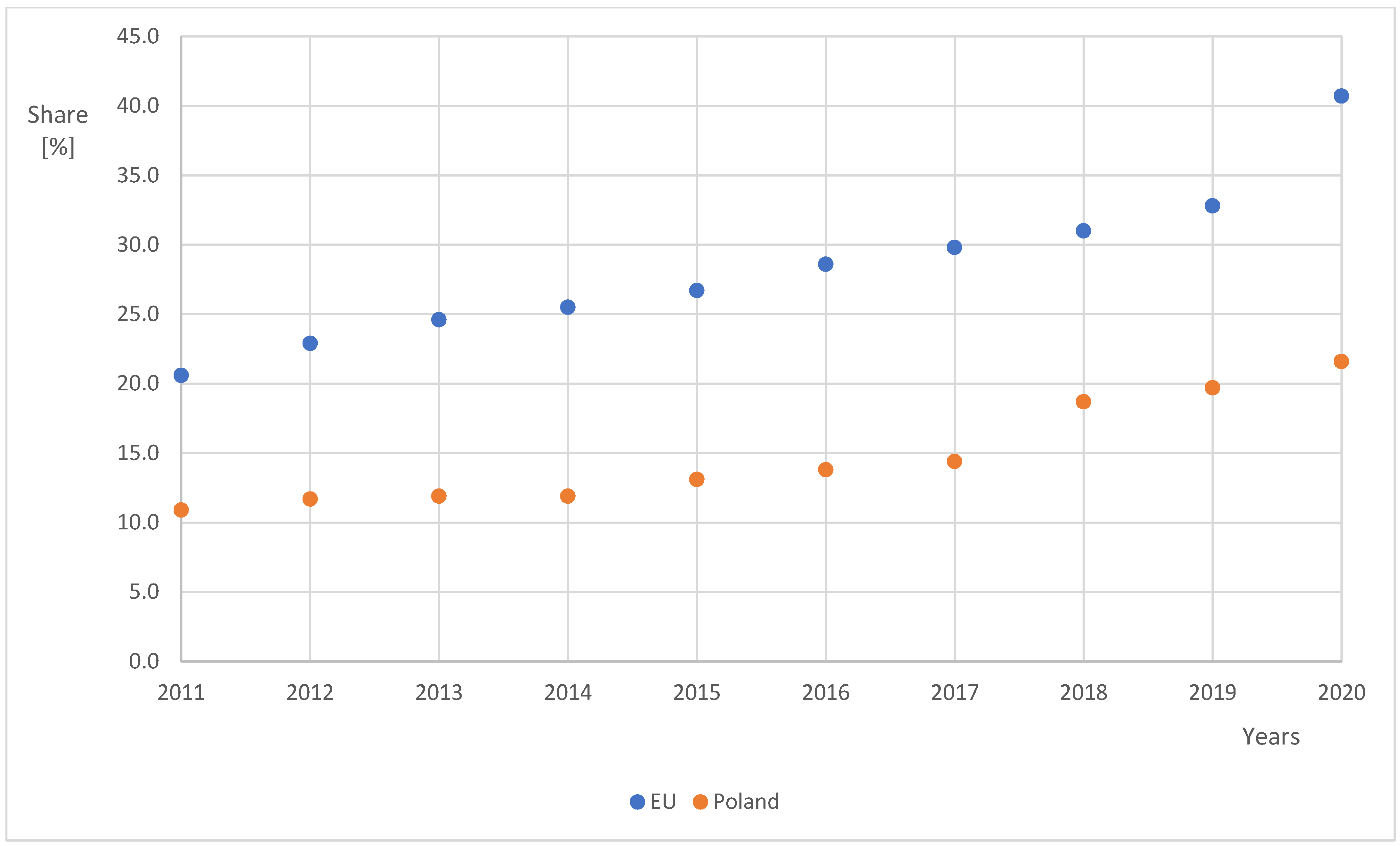

3.4. Obtaining Primary Energy, including Energy from Renewable Sources, in the European Union and Poland

3.5. The Area of Agricultural Land Potentially Useful for the Cultivation of Energy Crops in Poland

- (a)

- Arable land—part of land and agricultural land subjected to continuous and seasonal cropping.

- (b)

- Cultivation—cereals, 71%; industrial plants, 11%; fodder plants, 10%; potatoes, 3%; legumes, 2%.

- (c)

- Meadows and pastures—agricultural land occupied for the cultivation of grasses or other herbaceous crops (herbs, legumes), both natural and resulting from agricultural activity.

- (d)

- Orchards—an agricultural area or plantation where trees or shrubs providing edible fruit are grown.

- (e)

- Agricultural wasteland, marginal land—these are areas which, as a result of bad agricultural, industrial and forestry activities, do not have or have lost their value in use; wasteland also includes: swamps, dunes, floating sands, ravines, rocks, devastated areas.

- -

- The first is related to the diversity of species and varieties of cultivated plants and species and breeds of farm animals;

- -

- The second is related to the biodiversity of plants and wild animals accompanying agricultural production.

4. Conclusions

- (1)

- Within the first group of materials, there is large variation in terms of energy usefulness and the degree of difficulty of processing for combustion purposes. Leaves, needles and grass from lawns, while having a relatively high energy value, are often very polluted. Their humidity is also variable, but usually very high. Group I is free from potential concerns related to the limits on their use for energy purposes. However, foresters are trying to increase their share in the biomass inflow to forest soils. The energy value of wood chips after drying is about 17 MJ∙kg−1 [11]. The cost of obtaining leaves depends on the degree of mechanization of their collection and increases with the involvement of more technical means. The caloric content of the leaves varies depending on the species and the degree of contamination, ranging from 10 to 17 MJ∙kg−1 [149].

- (2)

- The second group of raw materials is mainly cereal and rapeseed straw. These materials are used both for low-density combustion (cubes from traditional presses), mainly by individual farms, and in the form of cylindrical bales and large-size square bales. The studies conducted and the experiences of producers [11] indicate the deliberate use of simplified, low-cost technologies with limited fertilization and limited use of plant protection products. Thanks to this method of cultivation in light soils, it can be considered beneficial, because the yield of rapeseed straw from 1 ha should be in the range of 2–5 Mg∙ha−1—it seems realistic to assume a value of 2.5 Mg∙ha−1. With the assumed capacity and two-shift operation, the capacity of the pelletizing or briquetting line should be about 500 kg∙h−1. The parameters of pellets and briquettes made of grass straw and sawdust show high stability in properties. Typically, the calorific value oscillates in the range of 15–20 MJ∙kg−1, and the humidity is in the range of 6–10%. In Polish climatic conditions, it is possible to use these materials for energy purposes, while the remaining maize straw remains after growing maize for grain, the use of which for fodder purposes is ineffective. The large mass of maize straw (10 Mg DM∙ha−1) and its relatively high energy value (approx. 15 MJ∙kg−1 [143]) make it an attractive energy resource.

- (3)

- The third group of raw materials includes the aforementioned crops, in particular cereals intended for burning in the form of whole plants or parts of the crop, for example, grain alone, chaff, husks and straw with an admixture of harvested weeds. This method is particularly suitable for low-quality grain produced in low-input crops. The cultivation of cereals for energy purposes can be an alternative to fallow land, as well as the cultivation of specialized energy crops. Their cultivation in Poland generally has no tradition, and producers do not have specialized equipment for their harvesting and cultivation, or experience in their cultivation. Often, these plants are also not fully tolerant of the Polish climate. Growing plants for energy purposes can be safe. Burning whole crops is technically problematic because, like straw, they are low-density materials. The exception is grain, the density of which changes relatively little during briquetting or pelleting. Grain can be burned both in small furnaces adapted from eco-pea coal furnaces, and in a condensed form.

- (4)

- The use of renewable energy sources significantly reduces the harmful impact of the power industry on the natural environment, mainly by reducing the emission of harmful substances, especially greenhouse gases [144]. Between 2011 and 2019, there was a very mild decrease in the amount of energy produced in the EU.

- (5)

- The highest indicators of the amount of energy obtained from biogas plants per area unit in Poland were found in Warmian-Masurian, Greater Poland, West Pomeranian and Masovian Voivodeships.

- (6)

- On the scale of Poland, the problem is the ineffective use of potentially available land for cultivation for the purposes of obtaining biomass.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tomicka, I. Plant Production 2; State Agricultural and Forest Publishing House: Warsaw, Poland, 1995. [Google Scholar]

- Widrex. Available online: http://www.widrex.pl/biomasa.html (accessed on 28 January 2021).

- Directive 2001/77/WE the European Parliament and the Council on 27 September 2001 of the Promotion of Electricity Produced from Renewable Energy Sources in the Internal Market (Dz.U. L 283 z 27.10.2001. 33). Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/PDF/?uri=CELEX:32001L0077&from=LV (accessed on 1 March 2023).

- Green Energy. Available online: https://zielona-energia.cire.pl/ (accessed on 28 January 2021).

- Bartnikowska, S.; Frankowski, J. Advantages and Disadvantages of Perennials Grown for Energy Purposes. Energy Security. Raw Materials and Energy Markets. In Energy–Security in Research Challenges; Law–Economy–Society–Biotechnologies–Environmental Protection–Health Safety; Kwiatkiewicz, P., Szczerbowski, R., Eds.; Wyższej Szkoły Bezpieczeństwa: Poznan, Poland, 2017; Volume 2, pp. 325–332. [Google Scholar]

- Artyszak, D. Energy Plants–Characteristics of Basic Species and Their Use in the Polish Energy Industry. In Proceedings of the Modern Energy in Central and Eastern Europe, Warsaw, Poland, 14 October 2015. [Google Scholar]

- Stańczyk, K.; Ludwik, M. Cultivation of energy crops–possibilities of developing wastelands and arable lands where agricultural production is unprofitable. Sci. Work. GIG 2003, 3, 71–81. [Google Scholar]

- Frankowski, J. Possibilities of Growing and Using Perennial Grasses for Energy Purposes. Energy Security. Raw Materials and Energy Markets. In Energy–Security in Research Challenges; Law–Economy–Society–Biotechnologies–Environmental Protection–Health, Safety; Kwiatkiewicz, P., Szczerbowski, R., Eds.; Wyższej Szkoły Bezpieczeństwa: Poznan, Poland, 2017; Volume 2, pp. 333–342. [Google Scholar]

- Kuś, J.; Matyka, M. Growing Plants for Energy Purposes; IUNG—PIB: Puławy, Poland, 2010; p. 64. ISBN 978-83-7562-072-6. [Google Scholar]

- Wałowski, G. Analysis and Classification of Agricultural Biomass as a Raw Material for Biorefineries. In Lignocellulosic Material and Aquatic Plants, Biogas Production in a Biomass Refinery including Aspects of Biogas Plant, Operation; Wawrzyniak, A., Ed.; ITP-PIB Publishing House: Poznan, Poland, 2020; pp. 49–79. ISBN 978-83-65426-46-8. [Google Scholar]

- Kaszkowiak, J.; Kaszkowiak, E. Possibilities of Obtaining Material of Plant Origin for the Production of Pellets and Briquettes. In IX ECO-€URO-ENERGY; Mroźiński, A., Ed.; Renewable Energy Sources Engineering: Bydgoszcz, Poland, 2016; pp. 167–174. ISBN 978-83-64423-33-8. [Google Scholar]

- Grassi, G.; Trebbi, G.; Pike, D.C. (Eds.) Electricity from Biomass; CPL Press: Berkshire, UK, 1992; p. 72. [Google Scholar]

- Kowalik, P. The Use of Biomass as an Energy Raw Material. Foundation for the Efficient Use of Energy. Energy Use of Biomass. Training on Working Examples of Renewable Energy Applications in Poland and Denmark. Within the TEMPUS Program of the European Union Entitled: Sustainable Energy Development. Polish Foundation for Energy Efficiency—Center in Cracov, 16–28 June 2002. Available online: Energetyczne-wykorzystanie-biomasy-tempus_sprawozd_dania_2002.pdf (accessed on 1 March 2023).

- Act of 20 February 2015 on Renewable Energy Sources (Journal of Laws of 2022, item 1378). Available online: https://www.fao.org/faolex/results/details/en/c/LEX-FAOC151966/ (accessed on 1 March 2023).

- Regulation (EC) No. 1069/2009 of the European Parliament and of the Council of 21 October 2009 Laying down Health Rules for Animal by-Products Not Intended for Human Consumption and Repealing Regulation 1774/2002 are Classified as Category 3 Material of Waste of Animal Origin (EU OJ L 300 of 14 November 2009). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02009R1069-20191214&from=LV (accessed on 1 March 2023).

- Regulation of the Minister of Climate of January 3, 2020 on the Catalog of Waste (Journal of Laws 2020, Item 10). Available online: https://leap.unep.org/countries/pl/national-legislation/regulation-catalogue-wastes-0 (accessed on 1 March 2023).

- Gołaszewski, J. The use of substrates of agricultural origin in biogas plants in Poland. Adv. Agric. Sci. 2011, 2, 69–94. [Google Scholar]

- Jędrejek, A.; Jarosz, Z. Regional possibilities of agricultural biogas production. Assoc. Agric. Agribus. Economists. Sci. Ann. XVIII 2016, 18, 61–66. [Google Scholar]

- Kwaśny, J.; Banach, M.; Kowalski, Z. Overview of biogas production technologies of various origins. Chem. Tech. J. Publ. House Crac. Univ. Technol. 2012, 109, 83–102. [Google Scholar]

- Wiącek, D.; Tys, J. Biogas–Production and Possibilities of Its Use; Acta Agrophysica; The Bohdan Dobrzański Institute of Agrophysics PAN: Lublin, Poland, 2015. [Google Scholar]

- Banaszkiewicz, T.; Wysmyk, J. Ecological aspect of the use of agricultural substrates. Eur. Reg. 2015, XXIII, 21–34. [Google Scholar]

- Ginalski, Z. Substrates for Agricultural Biogas Plants. Agricultural Advisory Center in Brwinów, Radom Branch. Available online: www.cdr.gov.pl (accessed on 17 February 2023).

- Kowalczyk-Juśko, A. Efficiency of biogas production from agricultural waste and agri-food processing. Sci. J. 2009, 11, 149–154. [Google Scholar]

- Wiśniewski, G.; Oniszk-Popławska, A.; Sulima, P. Directions of Agricultural Biogas Technology Development in the EU and Poland; EC BREC Institute of Renewable Energy: Warsaw, Poland, 2008. [Google Scholar]

- Commission Regulation (EU) No. 142/2011 of 25 February 2011 on the Implementation of Regulation (EC) No. 1069/2009 of the European Parliament and of the Council Laying down Sanitary Rules for Animal by-Products. Not Intended for Human Consumption. and on the Implementation of Council Directive 97/78/EC as Regards Certain Samples and Items Exempt from Veterinary Checks at the Borders (OJ L 54 of 26 February 2011. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2011:054:0001:0254:EN:PDF (accessed on 1 March 2023).

- Nikiciuk, M. Ecological and Pro-Growth Potential of the Agricultural Biogas Plant Sector. In Podlaskie Voivodeship w Contemporary Economic Problems in the Research of Young Scientists, T. 3. Macro- and Mesoeconomic Analyses; Gruszewska, E., Roszkowska, M., Eds.; Polish Economic Society, University of Bialystok: Bialystok, Poland, 2019; pp. 98–117. [Google Scholar]

- Gołaszewski, J. (Ed.) Model Agro-Energy Complexes: Technologies for Obtaining and Conditioning Agricultural and Water Biomass for Biogas Plants and Gasifiers; Publishing House UWM: Olsztyn, Poland, 2014. [Google Scholar]

- Jasiulewicz, M.; Janiszewska, D.A. Potential development opportunities for biogas plants on the example of the West Pomeranian Voivodeship. Agric. Eng. 2013, 2, 91–102. [Google Scholar]

- Dąbkowska, K. Alkaline pretreatment of lignocellulosic corn waste. Chem. Eng. Appar. 2017, 56, 66–67. [Google Scholar]

- Guzenda, R.; Świgoń, J. Technical and ecological aspects of energy use of wood and wood waste. Fuel Energy Manag. 1997, 1, 10–12. [Google Scholar]

- Kowalik, P. Technical Possibilities of Using Willows for Energy Purposes; Białobok, S., Ed.; Willows PWN: Warsaw-Poznan, Poland, 1990; pp. 365–375. [Google Scholar]

- Szczukowski, S.; Tworkowski, J.; Kwiatkowski, J. Possibilities of using the Salix sp. Biomass obtained from arable land as an ecological fuel and raw material for the production of cellulose and chipboards. Adv. Agric. Sci. 1998, 2, 53–63. [Google Scholar]

- Gawrońska, G. Assessment of Energy Resources of Waste Wood Biomass in the Provinces of Nowy Sącz. Tarnow and Krośnieńskie. Seminar in the Series "Renewable Energy. A Step towards Ecology". on Ecological. Energy and Economic effects of Using Renewable Energy; Publishing House CPPGSMiE PAN: Cracow, Poland, 1997; pp. 91–98. [Google Scholar]

- Kowalik, P. Potential opportunities for energy use of biomass in Poland. Fuel Energy Manag. 1994, 42, 9–12. [Google Scholar]

- Gutkowski, J. Renewable Energy–Current State against the Backdrop of Optimistic Forecasts of its Possible Use in Poland. In Renewable Energy Sources at the Threshold of the 21st Century; IBMER: Warsaw, Poland, 2001; pp. 58–66. [Google Scholar]

- Gradziuk, P. Opportunities and Barriers to the Development of Advanced Biofuels in Poland. Institute of Rural and Agricultural Development of the Polish Academy of Sciences; Wyd. Polish Ecological Club: Warsaw, Poland, 2017. [Google Scholar]

- BULiGL. Available online: https://www.buligl.pl/ (accessed on 23 May 2020).

- LP. Available online: https://www.lasy.gov.pl/pl/ (accessed on 23 May 2020).

- Act of February 20 2018 on Renewable Energy Sources. As Amended. Dz, U. z 2018 r. poz. 478. Available online: https://www.fao.org/faolex/results/details/en/c/LEX-FAOC182634/ (accessed on 21 February 2016).

- Vassilev, S.; Baxter, D.; Andersen, L.; Vassileva, C.; Morgan, T. An overview of the organic and inorganic phase composition of biomass. Fuel 2012, 94, 1–33. [Google Scholar] [CrossRef]

- Zajączkowski, S. Forecasts of Wood Harvesting in Poland in the Perspective of 20 Years and the Possibility of Using Them to Estimate Wood Resources for Energy Purposes. In Forest Biomass for Energy Purposes; Gołos, P., Kaliszewka, A., Eds.; Forest Research Institute: Sękocin Stary, Poland, 2013; pp. 21–31. [Google Scholar]

- Rybak, W. Combustion and Co-Combustion of Solid Biofuels; Publishing House of the Wrocław University of Technology: Wrocław, Poland, 2006; p. 411. [Google Scholar]

- Rural Development Programme for 2007–2013; Ministry of Agriculture and Rural Development: Warsaw, Poland, 2007.

- CIRE 2022. Available online: https://www.cire.pl/pliki/2/ciepl_biom.pdf (accessed on 25 August 2022).

- Frankowski, J. Assessment of energy suitability of selected types of cereals. Energy security. raw materials and energy markets. In Energy–Security in Research Challenges; Law–Economy–Society–Biotechnologies–Environmental Protection–Health, Safety; Kwiatkiewicz, P., Szczerbowski, R., Eds.; Wyższej Szkoły Bezpieczeństwa: Poznan, Poland, 2017; Volume 2, pp. 343–352. [Google Scholar]

- Corn. Available online: https://www.yara.pl/odzywianie-roslin/kukurydza/ (accessed on 28 January 2021).

- Działkowiec. Available online: http://dzialkowiec.pixelart.com.pl/kukurydza.html (accessed on 28 January 2021).

- Kołodziej, B.; Matyka, M. Renewable Energy Sources—Agricultural Energy Resources; PWRiL: Poznań, Poland, 2012; Volume 2, p. 594. ISBN 978-83-09-01139. [Google Scholar]

- Czeczko, R. Growing selected energy crops. Bezpieczeństwo I ekologia. Autobusy 170-172. In Proceedings of the XVIII Konferencja Studenckich i Doktoranckich Kół Naukowych, Siedlce, Poland, 9 September 2019. [Google Scholar]

- Burczyk, H. Usefulness of one-year-old plants grown for the production of biomass for the purposes of commercial power industry. Probl. Agric. Eng. 2012, 1, 59–68. [Google Scholar]

- Podkówka, W.; Podkówka, Z. Substrates for Agricultural Biogas Plants; Agro Serwis: Warsaw, Poland, 2010. [Google Scholar]

- Podkówka, W. Biofuels today and tomorrow. Corn 2007, 2, 4–35. [Google Scholar]

- Lipski, S. Sow. Choosing a Variety for Cultivation. Available online: http://www.kukurydza.org.pl/siew.php (accessed on 7 December 2016).

- Michalski, T. Problems of Agrotechnics and the Use of Maize and Sorghum; Poznan of University Life Sciences: Poznan, Poland, 2008. [Google Scholar]

- Michalski, T. Corn as a raw material for various industries. Tomorrow’s Village 2002, 6, 53–55. [Google Scholar]

- Michalski, T. Maize Is an Excellent Raw Material for the Production of Bioethanol and Biogas; Polagra Agropremiery: Poznan, Poland; Agro Service: Poznan, Poland, 2007; pp. 5–8. [Google Scholar]

- Frankowski, J.; Burczyk, H. Biomass of Annual Energy Plants as an Element of Diversification of Energy Sources in Poland. In Monographs Environmental Engineering–Young Eye; Ecoenergy, I., Skoczko, J., Piekutin, M., Drobiszewskiej, I., Mokryckiego, R., Eds.; Publishing House of the Bialystok University of Technology: Białystok, Poland, 2016; pp. 83–109. [Google Scholar]

- Lewandowski, M.; Ryms, M. Biofuels. Pro-Ecological Renewable Energy Sources; Scientific and Technical Publishing House: Warsaw, Poland, 2013; ISBN 978-83-63623-73-9. [Google Scholar]

- Sorghum. Available online: https://zielonyogrodek.pl/katalog-roslin/inne/9789-sorgo (accessed on 28 January 2021).

- Majtkowski, W. Sorghum and sorrel. Agroenergetics 2007, 2, 9–10. [Google Scholar]

- Waligóra, R. When does sorghum play the first fiddle? Agrotechnics. Farmer’s Guide 2013, 5, 47. [Google Scholar]

- Agrofakt. Available online: https://www.agrofakt.pl/sorgo-uprawiane-ziarno-5-zboze-swiecie/ (accessed on 28 January 2021).

- Księżak, J.; Bojarszczuk, J.; Staniak, M. The productivity of maize and sorghum depending on the level of nitrogen fertilization. Pol. J. Agron. 2012, 8, 20–28. [Google Scholar] [CrossRef]

- Frankowski, J. Grain sorghum–an annual plant for the production of bioethanol. biogas. solid biofuels. Biomass Mag. 2016, 8, 24–27. [Google Scholar]

- Burczyk, H. Usability of the winter aftercrop as well as the maize and sorghum in the aftercrop to biomass production for a biogas plant. Probl. Agric. Eng. 2013, 2, 87–97. [Google Scholar]

- Sałagan, P.; Dobek, T.K.; Kołosowski, P. The yield potential of biogas from sugar sorghum (Sorghum bicolor). Agric. Eng. 2013, 4, 291. [Google Scholar]

- Chmielewska, J.; Dziuba, E.; Foszczyńska, B.; Kawa-Rygielska, J.; Pietrzak, W.; Sowiński, J. Selection of the method of preparing sugar sorghum biomass for ethanol production. Acta Sci. Pol. Biotechnol. 2015, 14, 5–12. [Google Scholar]

- Anioł, M.; Sowiński, J.; Aniołowska, M. The content of soluble sugars and lignocellulosic compounds in sorghum varieties. Chem. Ind. 2015, 10, 1832–1834. [Google Scholar]

- Batog, J.; Wawro, A.; Pieprzyk-Kokocha, D. Efficiency of physico-chemical treatment of sorghum and miscanthus biomass in the production of second generation bioethanol. Chem. Ind. 2016, 9, 1679–1682. [Google Scholar]

- Burczyk, H.; Batog, J.; Frankowski, J.; Wawro, A. Yielding of selected sorghum varieties cultivated as primary and secondary crops for bioethanol production. Zagadnienia Doradz. Rol. 2017, 4, 7–79. [Google Scholar]

- Rynek. Available online: https://www.rynek-rolny.pl/artykul/owies-zwyczajny-opis-charakterystyka-i-zastosowanie.html?page=2 (accessed on 28 January 2021).

- Oats. Available online: https://www.doz.pl/czytelnia/a1515-Owies_8211_nie_tylko_dla_koni (accessed on 28 January 2021).

- Cultivation of Oats. Available online: https://www.rynek-rolny.pl/artykul/uprawa-owsa-wyjasniamy-najwazniejsze-aspekty.html (accessed on 28 January 2021).

- Yearbook of International Statistics; Central Statistical Office: Warsaw, Poland, 2012.

- Kwaśniewski, D. Production and use of oats as a renewable energy source. Probl. Agric. Eng. 2010, 3, 95–101. [Google Scholar]

- Janowicz, L. Warmth from the grain. Agroenergetics 2006, 1, 39–41. [Google Scholar]

- Dzik, T.; Mięso, R. Production and Combustion of Fuels from Plant Biomass in Small and Micro Scale; Monograph. Publish. School of Environmental Protection and Engineering, W. Goetl: Cracow, Poland, 2005; p. 253. [Google Scholar]

- Dzienis, G. Winter rye–a species underestimated in Poland. Agron. Sci. 2018, 73, 19–28. [Google Scholar] [CrossRef]

- Piechota, T.; Sawinska, Z.; Kowalski, M.; Majchrzak, L.; Świtek, S.; Dopierała, A. Yield and health of selected varieties of winter rye grown for biogas. Fragm. Agron. 2017, 34, 67–74. [Google Scholar]

- Bielski, S.; Jankowski, K.; Budzyński, W. The energy efficiency of oil seed crops production and their biomass conversion into liquid fuels. Chem. Ind. 2014, 93, 2270–2273. [Google Scholar]

- Izdebski, W.; Skudlarski, J.; Zając, S. The use of agricultural raw materials for the production of transport biofuels in Poland. Year Sci. SERiA 2014, 16, 93–97. [Google Scholar]

- Jankowski, K.; Dubis, B.; Budzyński, W.; Bórawski, P.; Bułkowska, K. Energy efficiency of crops grown for biogas production in a large-scale farm in Poland. Energy 2016, 109, 277–286. [Google Scholar] [CrossRef]

- Kacprzak, A.; Michalska, K.; Romanowska-Duda, Z.; Grzesiak, M. Energy plants as a raw material for biogas production. KOSMOS Probl. Biol. Sci. 2012, 61, 281–293. [Google Scholar]

- Stankiewicz, D. Possibilities of using agricultural raw materials for energy production in Poland. BAS Stud. 2010, 1, 237–265. [Google Scholar]

- Faber, A.; Kuś, J.; Matyka, M. Cultivation of Plants for the Needs of Energy; W&B Wiesław Krzewiński: Warsaw, Poland, 2009; p. 30. [Google Scholar]

- Góral, S. Value in use of Jerusalem artichoke (Halianthus tuberosus L.). Probl. Noteb. Adv. Agric. Sci. 1999, 468, 89–94. [Google Scholar]

- Rokosz, E. Growing Energy Crops; Uprawa Roślin Energetycznych: Barzkowice, Poland, 2010. [Google Scholar]

- Mystkowska, I.; Zarzecka, K.; Gugała, M.; Baranowska, A. Probiotic and pharmacological properties of Jerusalem artichoke (Helianthus tuberosus L.). Probl Hig Epidemiol. 2015, 96, 64–66. [Google Scholar]

- Ochmańska, M.; Jaroszewski, J. Types of Biomass and Possibilities of Its Use; Agricultural Advisory Center: Zarzeczewo, Poland, 2009; p. 26. [Google Scholar]

- Kowalczyk-Juśko, A.; Cholewińska, E. Possibilities of Energetic Use of the Jerusalem Artichoke Biomass (Helianthus tuberosus L.). Autobusy 232–234. Available online: https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-7895abff-8f0a-4944-b3c5-7f3e7d05c14e/c/Kowalczyk-Jusko_Mozliwosci.pdf, (accessed on 1 March 2023).

- Kowalczyk-Juśko, A.; Jóźwiakowski, K.; Gizińska, M.; Zarajczyk, J. Jerusalem artichoke (Helianthus tuberosus L.) as renewable energy raw material. TEKA. Comm. Mot. Energetics Agric. 2012, 12, 117–121. [Google Scholar]

- Grzybek, A.; Gradziuk, P.; Kowalczyk, K. Straw–Energy Fuel; The village of Tomorrow: Warsaw, Poland, 2001. [Google Scholar]

- Sawicka, B. Energy value of Jerusalem artichoke (Helianthus tuberosus L.) as a source of biomass. Sci. Noteb. UP Wroc. Rol. 2010, XCVII, 578. [Google Scholar]

- Majtkowski, W. Solid Fuel Energy Plants. In Biomass for Energy and Heating–Opportunities and Problems; The Village of Tomorrow: Warsaw, Poland, 2007. [Google Scholar]

- Kościk, B. Energy Raw Materials of Agricultural Origin; PWSZ: Jarosław, Poland, 2007. [Google Scholar]

- Piskier, T. Labor outlays and costs of topinambour cultivation. Agric. Eng. 2006, 11, 359–365. [Google Scholar]

- Bartnikowska, S.; Janczak, D.; Frankowski, J. Determination of the Energy potential of the Biomass of Jerusalem Artichoke and Sakhalin Knotweed Coming from Wastelands. Environ. Eng.–Young Eye Monogr. 2016, 26, 155–175. [Google Scholar]

- Domaradzki, K.; Jezierska-Domaradzka, A.; Badowski, M.; Matkowski, A. Occurrence. productivity and the possibility of Japanese knotweed and giant knotweed control. Prog. Plant Prot. 2019, 59, 5–12. [Google Scholar] [CrossRef]

- Zając, A.; Zając, M. Distribution Atlas of Vascular Plants in Poland; Laboratory of Computer Chorology of the Institute of Botany of the Jagiellonian University: Craców, Poland, 2001; p. 715. [Google Scholar]

- Gregorczyk, A.; Wereszczaka, J.; Stankowski, S. Utilization of knotweed biomass (polygonum cuspidatum siebold & zucc.) for energy purposes. Folia Pomer. Univ. Technol. Stetin. Agric. Aliment. Pisc. Zootech. 2012, 293, 35–40. [Google Scholar]

- Grzesik, M.; Janas, R.; Romanowska-Duda, Z. Stimulation of growth and metabolic processes of Pennsylvania’s mallow (Sida hermaphrodita L. Rusby) by means of seed hydroconditioning. Probl. Agric. Eng. 2011, 4, 81–89. [Google Scholar]

- Szymańska, M. Renewable Energy Sources. Available online: https://zasobyip2.ore.edu.pl/pl/publications/download/7905 (accessed on 28 January 2021).

- Borkowska, H.; Styk, B. Virginia Mallow (Sida Harmaphrodita Rusby); Publishing House of the Agricultural University: Lublin, Poland, 2006; p. 69. [Google Scholar]

- Ginalski, Z. Cultivation of Selected Energy Crops. Available online: http://www.cdr.gov.pl/pol/projekty/AZE/uprawa_roslin_energ.pdf (accessed on 28 January 2021).

- Tworkowski, J.; Szczukowski, S.; Stolarski, M.J.; Kwiatkowski, J.; Graban, Ł. Productivity and properties of Virginia mallow biomass as a fuel depending on the seed material and plant density. Fragm. Agron. 2014, 31, 115–125. [Google Scholar]

- Howaniec, N.; Smoliński, A. Steam gasification of energy crops of high cultivation potential in Poland to hydrogen-rich gas. Int. J. Hydrogen Energ. 2011, 36, 2038–2043. [Google Scholar] [CrossRef]

- Tworkowski, J.; Stolarski, M.; Wróblewska, H.; Szczukowski, S. Chemical composition and energy value of biomass of shrub willow. Virginia mallow and Miscanthus. Zesz. Probl. Post. Nauk Rol. 2010, 547, 401–408. [Google Scholar]

- Stolarski, M. Agrotechnical and economic aspects of the production of shrub willow (Salix spp.) biomass as an energy raw material. Rozpr. Monogr. UWM Olsztyn 2009, 148, 145. [Google Scholar]

- Poskart, A.; Szwaja, S.; Musiał, D. Torrefaction of Virginia Mallow as Substitute Fuel for Domestic Boilers. Energy Mark. 2016. Available online: https://www.cire.pl/pliki/2/2017/15___poskart___karbonizat_slazowca___rec16.pdf (accessed on 1 March 2023).

- Kupryś-Caruk, M. Effect of enzyme preparation on the kinetics of biogas production from Miscanthus giganteus (Miscanthus x gigantem J.M. Greef & M. Deuter). Chem. Eng. Appar. 2017, 2, 41–42. [Google Scholar]

- Stolarski, M. Miscanthus. Szczukowski, S., Ed.; Perennial Energy Crops: Warsaw, Poland, 2012. [Google Scholar]

- Wiśniewski, G.; Podlaski, S. Agrotechnics of Plants Grown for Energy Purposes; Gradziuk, P., Ed.; Renewable energy: Plonsk, Poland, 2008. [Google Scholar]

- Chmiel, J.; Kasprowicz, M. Flora and Vegetation of Central Wielkopolska. In A Guide to Field Exercises; Bogucki Publishing House Scientific S.C: Poznan, Poland, 2004; p. 138. [Google Scholar]

- Buzar, M.; Galek, R.; Góra, J.; Grzyś, E.; Hurej, M.; Kotecki, A.; Kozak, M.; Piszcz, U.; Pląskowska, E.; Pusz, W.; et al. Growing Miscanthus. Energy and Non-Energy Possibilities of Using Straw; Kotecki, A., Ed.; Wrocław University of Environmental and Life Sciences: Wrocław, Poland, 2010; ISSN 1898-1151. ISBN 978-83-60574-96-6. [Google Scholar]

- Kozaczka, J. Combustion Processes; AGH: Cracow, Poland, 1993. [Google Scholar]

- Ebeling, J.M.; Jenkins, B.M. Physical and Chemical Properties of Biomass Fuels. Trans. ASAE 1985, 28, 898–902. [Google Scholar] [CrossRef]

- Demirbas, A. Calculation of higher heating values of biomass fuels. Fuel 1997, 76, 431–434. [Google Scholar] [CrossRef]

- Gaur, S.; Reed, T.B. An atlas of thermal data for biomass and over fuels. NREL/TP–433-7965. National Renewable Energy Laboratory, Colorado, USA. 1995. Available online: https://www.nrel.gov/docs/legosti/old/7965.pdf, (accessed on 1 March 2023).

- Francik, S.; Knapik, P. Chinese miscanthus (Miscanthus sinensis) as a potential energy plant. Autobusy Technol. Oper. Transp. Syst. 2012, 13, 192–197. [Google Scholar]

- Stewart, J.R.; Toma, Y.; Fernandez, F.G.; Nishiwaki, A.; Yamada, T.; Bollero, G. The ecology and agronomy of Miscanthus sinensis. A species important to bioenergy crop development. In its native range in Japan: A review. Glob. Change Biol. Bioenergy 2009, 1, 126–153. [Google Scholar] [CrossRef]

- Fritz, M.; Formowitz, B. Berichte aus dem TFZ. Miscanthus: Anbau un Nutzung. Inf. Für Die Prax. 2009, 10. [Google Scholar]

- Visser, P.; Pignatelli, V. Utilisation of Miscanthus. In Miscanthus; Routledge: London, UK; p. 2001.

- Krzyżaniak, M. Prairie Spartina; Szczukowski, S., Ed.; Perennial Energy Crops: Warsaw, Poland, 2012. [Google Scholar]

- Kowalczyk-Juśko, A. Biometric and energetic parameters of the prairie spartina (Spartina pectinata Link.) in the first three years of vegetation. Probl. Agric. Eng. 2013, 2, 69–77. [Google Scholar]

- Nesheim, L.; Jørgensen, U. Development of Energy Crops in the Nordic Countries; Grzybek, A., Ed.; Modeling of Energy Use of Biomass: Warsaw, Poland, 2011. [Google Scholar]

- Kuś, J. Productivity of Energy Plants in Various Habitats; Gradziuk, P., Ed.; Renewable Energy: Plonsk, Poland, 2008. [Google Scholar]

- Grzelak, M. Rush yield. chemical composition and energy value of reed brain. Fragm. Agron. 2009, 26, 38–45. [Google Scholar]

- Harkot, W.; Warda, M.; Sawicki, J.; Lipińska, T.; Wyłupek, T.; Czarnecki, Z.; Kulik, M. Possibilities of using the meadow sward for energy purposes. Łąk. Pol. 2007, 10, 59–67. [Google Scholar]

- Rogalski, M.; Sawicki, B.; Bajonko, M.; Wieczorek, A. Use of native grass species as renewable energy sources. Monogr. Optimex Szczec. 2005, 15–25. [Google Scholar]

- Dadrach, A.; Gąbka, D.; Szlachta, J.; Wolski, K. The energy value of several species of grasses grown on light soil. Łąk. Pol. 2007, 10, 29–35. [Google Scholar]

- Grzybek, A. Use of pellets as fuel. Pure Energy 2005, 6, 32–33. Available online: http://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-article-BPOH-0016-0008?q=bwmeta1.element.baztech-volume-1643-126X-czysta_energia-2005-nr_6;7&qt=CHILDREN-STATELESS (accessed on 1 March 2023).

- Łabiak, M.; Fiszer, A.; Świgoń, J. Straw briquetting–evaluation of selected physicochemical parameters. Selected ecological issues in modern agriculture. PIMR Poznań. 2005, 2, 51–55. [Google Scholar]

- Olejnik, A. Hay briquetting using the rolling method. Theory and construction. Typescript No PIMR 4231. PIMR Poznań. 1974, 67–84. [Google Scholar]

- USDE. Biomass Program. Energy Efficiency & Renewable Energy. Available online: http://www.eere.energy.gov (accessed on 28 January 2021).

- Bals, B.; Rogers, C.; Jin, M.; Balan, V.; Dale, B. Evaluation of ammonia fiber expansion (AFEX) pretreatment for enzymatic hydrolysis of switchgrass harvested in different seasons and locations. Biotechnol. Biofuels 2010, 3, 1. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Podlaski, S.; Chołuj, D.; Wiśniewski, G. Production of biomass from energy crops. Adv. Agric. Sci. 2010, 2, 163–174. [Google Scholar]

- Martyniak, D. Millet rod. Farmer 2019, 9, 74–75. [Google Scholar]

- Martyniak, D.; Martyniak, J. Grasses for seeds. Agro Serwis 2005, 7, 67–75. [Google Scholar]

- Żurek, G.; Martyniak, D. Selected Aspects of Environmental and Economic Effects of Growing Couch Grass Extended for Energy Purposes. Available online: http://www.bartazek.pl/linki/prezentacja_zurek.pdf (accessed on 17 November 2016).

- Martyniak, D.; Martyniak, J. New energetic grass. Farmer 2009, 18, 28–29. [Google Scholar]

- Martyniak, D.; Martyniak, J. Instruction. Basic Principles of the Technology of Growing Couch Grass of an Elongated Variety “Bamar” for Biomass. The Study Was Carried Out during the Implementation of the Multiannual Program IHAR-PIB 2008–2013. Available online: www.ihar.edu.pl/download.php?id=904 (accessed on 11 November 2016).

- Martyniak, D.; Martyniak, J. The elongated clump couch grass is a source of cheap bioenergy (phytoenergy). Pure Energy 2011, 8, 119–120. [Google Scholar]

- GUS. Energia ze Źródeł Odnawialnych w 2016–2021. Available online: https://stat.gov.pl/wyszukiwarka/?query=tag:energia+ze+%C5%BAr%C3%B3de%C5%82+odnawialnych (accessed on 1 March 2023).

- Available online: https://portalstatystyczny.pl/energia-ze-zrodel-odnawialnych-w-polsce-najnowsze-dane/ (accessed on 1 March 2023).

- Available online: https://www.fdpa.org.pl/sposoby-rolniczego-uzytkowania-a-stan-bioroznorodnosci (accessed on 1 March 2023).

- GUS. Rocznik Statystyczny Rolnictwa 2016–2021. Available online: https://stat.gov.pl/obszary-tematyczne/roczniki-statystyczne/roczniki-statystyczne/rocznik-statystyczny-rolnictwa-2021,6,15.html (accessed on 1 March 2023).

- Wałowski, G. Development of biogas and biorafinery systems in Polish rural communities. J. Water Land Dev. 2021, 49, 156–168. [Google Scholar] [CrossRef]

- Wałowski, G. Assessment of polydisperse substrate flow in a fermentor for computational fluid dynamics modeling. J. Water Land Dev. 2022, 56, 1–7. [Google Scholar] [CrossRef]

- Szul, T. Profitability assessment of straw pellets production. Agric. Tech. For. Gard. 2013, 2, 17–19. [Google Scholar]

| Group I | Group II | Group III | |

|---|---|---|---|

| Waste | By-products | Plant products deliberately grown for energy purposes | |

| Plants used in human and animal nutrition but with a changed use | Plants grown specifically for energy purposes | ||

|

|

|

|

| They are often treated as troublesome waste, and their disposal is troublesome and costly. | Straw briquetting and pelleting are attractive forms of straw compaction that can be used as solid fuel that can be incinerated or co-incinerated. | Cereals intended for combustion as whole plants or part of the crop (grain—especially low-quality chaff, husks and straw with an admixture of collected weeds). Burning grasses requires similar requirements to burning straw; the advantage is the high yield, and there is no risk in the event of changes in the law limiting the use of plants that can be a source of food for energy purposes. | There are plant varieties bred specifically for energy purposes; the most advantageous use of cereal and rapeseed straw is as a material for the production of pellets and briquettes. |

| Substrate Name | Dry Matter Content per Ton of Substrate | Organic Matter Content | Biogas Production | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [%] | [% Dry Weight] | [m3/Mg Dry Organic Matter] | |||||||||||||

| acc. | [21] | [19] | [17] | [20] | [22] | [21] | [19] | [17] | [20] | [22] | [21] | [19] | [17] | [20] | [22] |

| Natural fertilizers | |||||||||||||||

| Cattle slurry | 9.5 | 8.0 | 10.0 | 8.0–11.0 | 8–11 | 77.4 | 86.0 | 93.0 | 77.4 | 75–82 | 222.5 | 280.0 | 225.0 | 200.0–500.0 | 200.0–500.0 |

| Pig slurry | 6.6 | 6.0 | 6.0 | ok.7.0 | ok 7.0 | 76.1 | 80.0 | 96.0 | 76.1 | 75–86 | 301.0 | 400.0 | 300.0 | 300.0–700.0 | 300.0–700.0 |

| Poultry droppings wet with litter | 15.1 | - | 15.0 | ok. 32.0 | ok.32 | 75.6 | - | 77.0 | 63–80 | 63–80 | 320.0 | - | 560.0 | 250.0–450.0 | 250.0–450.0 |

| Dried poultry droppings | 30.0 | - | - | - | - | 72.7 | - | - | - | - | 230.0 | - | - | - | - |

| Turkey droppings | 15.1 | - | - | - | - | 75.6 | - | - | - | - | 320.0 | - | - | - | - |

| Liquid manure | 8.5 | - | - | - | - | 85.5 | - | - | 154.0 | - | - | ||||

| Dairy cow slurry | 2.1 | - | - | - | 60.0 | - | - | - | - | 222.5 | - | - | - | - | |

| Manure | - | 25.0 | - | - | - | - | 80.0 | - | - | - | - | 450.00 | - | - | - |

| Animal feces (manure) cattle | - | - | 8.0 | ok.25.0 | ok. 25.0 | - | - | 80.0 | 68.0–76.0 | 68.0–76.0 | - | - | 410.0 | 210.0–300.0 | 210.0–300.0 |

| Animal feces (manure) pigs | - | - | 8.0 | 20.0–25.0 | 20.0–25.0 | - | - | 70.0 | 75.0–80.0 | 75.0–80.0 | - | - | 420.0 | 270.0–450.0 | 270.0–450.0 |

| Slaughterhouse waste | |||||||||||||||

| Flotation sludge from slaughterhouses | 14.6 | - | - | 5–24 | - | 90.6 | - | - | 80.0–95.0 | - | 680.0 | - | - | 900.0–1200.0 | - |

| Bovine stomach contents | 15.0 | - | - | 11.0–19.0 | - | 84.0 | - | - | 80.0–90.0 | - | 264.0 | - | - | 200.0–400.0 | - |

| Stomach contents | - | - | - | - | 12.0–15.0 | - | - | - | - | 75.0–86.0 | - | - | - | - | 250.0–450.0 |

| Separated adipose tissue | 34.3 | - | - | - | - | 49.1 | - | - | - | - | 700.0 | - | - | - | - |

| Food processing | |||||||||||||||

| Fruit waste and scraps | 45.0 | - | - | - | - | 61.5 | - | - | - | - | 400.0 | - | - | - | - |

| Fruit pomace | - | - | - | - | 25.0–45.0 | - | - | - | - | 90.0–95.0 | - | - | - | 590.0–660.0 | |

| Waste and leftovers of vegetables | 13.6 | - | - | - | - | 80.2 | - | - | - | - | 370.0 | - | - | - | - |

| Molasses | 81.7 | - | 73.0 | - | - | 92.5 | - | 78.0 | - | - | 301.6 | - | 510.0 | - | |

| Brewer’s grains | 20.5 | - | - | - | 20.0–25.0 | 81.2 | - | - | - | 70.0–80.0 | 545.1 | - | - | - | 580.0–750.0 |

| Distillery potato broth | 13.6 | - | - | - | 6.0–7.0 | 89.5 | - | - | - | 85.0–95.0 | 387.7 | - | - | - | 400.0–700.0 |

| Grain decoction | - | - | - | - | 6.0–8.0 | - | - | - | - | 83.0–88.0 | - | - | - | - | 430.0–700.0 |

| Waste from oil production | 78.8 | - | - | - | - | 97.0 | - | - | - | - | 600.0 | - | - | - | - |

| Whey (serwatka) | 5.4 | - | - | - | - | 86.0 | - | - | - | - | 383.3 | - | - | - | - |

| Cheese production waste | 79.3 | - | - | - | - | 94.0 | - | - | - | - | 610.2 | - | - | - | - |

| Bakery waste | 87.7 | - | - | - | - | 97.1 | - | - | - | - | 403.4 | - | - | - | - |

| Agricultural production and dedicated crops | |||||||||||||||

| Corn silage | - | 32.0 | 35.0 | 20.0–35.0 | 20.0–35.0 | 95.0 | 97.0 | 85.0–95.0 | 85.0–95.0 | 600.0 | 730.0 | 450.0–700.0 | 450.0–700.0 | ||

| Whole grain silage | - | 40.0 | - | - | - | - | 95.0 | - | - | - | - | 520.0 | - | - | - |

| Rye silage | - | - | 33.0 | - | - | - | - | 93.0 | - | - | - | - | 730.0 | - | - |

| Potato pulp | - | - | 14.0 | - | - | - | - | 93.0 | - | - | - | - | - | - | - |

| Grass silage | - | - | 35.0 | 25.0–50.0 | 25.0–50.0 | - | - | 91.0 | 70.0–95.0 | 70.0–95.0 | - | 720.0 | 540.0 | 550.0–620.0 | 550.0–620.0 |

| Shredded corn cobs | - | 65.0 | - | - | - | - | 98.0 | - | - | - | - | 680.0 | - | - | - |

| A grain of grain | - | 86.0 | - | - | - | 98.0 | - | - | - | - | 700.0 | - | - | - | |

| Rye | - | - | - | 30.0–35.0 | 30.0–35.0 | - | - | - | 92.0–98.0 | 92.0–98.0 | - | - | - | 550.0–680.0 | 550.0–680.0 |

| Fodder beet | - | - | - | 12.0 | - | - | - | - | 75.0–85.0 | - | - | - | - | 620.0–850.0 | - |

| Sugar beet root | - | - | 22.0 | 23.0 | - | - | - | 90.0 | 90.0–95.0 | - | - | - | 840.0 | 170.0–180.0 | - |

| Beet leaves | - | - | - | 16.0 | - | - | - | - | 75.0–80.0 | - | - | - | - | 550.0–600.0 | - |

| Mown grass | - | - | - | - | ok 12.0 | - | - | - | - | 83.0–92.0 | - | - | - | - | 550.0–680.0 |

| Assortment | National Forests | Private Forests | Together |

|---|---|---|---|

| mln m3 | |||

| Thickness of fuel | 3.05 | 0.78 | 3.83 |

| Small-sized wood: | 2.44 | 0.30 | 2.74 |

| including general heating material | 1.63 | 0.24 | 1.87 |

| Framework residues | 2.04 | 0.30 | 2.34 |

| Together | 7.53 | 1.38 | 8.91 |

| Together without industrial groupage | 6.72 | 1.32 | 8.04 |

| Wood Waste Assortment | Total Moisture Content—Virgin Material without Drying and Storage | Bulk Density |

|---|---|---|

| % | kg∙m−3 | |

| Wood chips | 40–60 | 250–400 |

| Chips from wood waste | 10–50 | 150–300 |

| Bark | 50–60 | 250–350 |

| Scobs | 45–60 | 250–350 |

| Shavings | 5–15 | 80–120 |

| Sawdust from grinding waste | 5–15 | 100–150 |

| Unpainted demolition wood | 15–30 | 150–250 |

| Device Power | Fuel Consumption | Expense | ||

|---|---|---|---|---|

| Straw | Coal | Straw | Coal | |

| kW | kg∙h−1 | PLN∙kg−1 | ||

| 70 | 19.4 | 14.6 | 0.06 | 0.162 |

| 100 | 27.6 | 20.8 | ||

| 200 | 55.4 | 41.6 | ||

| 300 | 83.0 | 62.4 | ||

| 400 | 110.7 | 83.2 | ||

| 500 | 138.3 | 104.0 | ||

| 600 | 166.1 | 124.8 | ||

| 700 | 193.7 | 145.6 | ||

| 800 | 221.4 | 166.4 | ||

| 900 | 249.1 | 187.2 | ||

| 1000 | 276.7 | 208.0 | ||

| 2000 | 528.9 | 416.0 | ||

| 5000 | 1322.2 | 1040.0 | ||

| Type of Fuel | Straw | Coal | Wood Chips | Pellets | Natural Gas | Heating Oil | |

|---|---|---|---|---|---|---|---|

| Unit | PLN∙kg−1 | PLN∙m−3 | PLN∙l−1 | ||||

| Value | 0.15 | 0.75 | 0.40 | 0.675 | 3.56 | 3.84 | |

| Characteristic | Unit | ||||||

| Unit costs of fuels | PLN∙m−3 | 7.50 | 525.00 | 60.00 | 607.50 | 3.56 | 3840.00 |

| Annual fuel costs | PLN∙year−1 | 8506.52 | 15,577.72 | 34,922.02 | 37,302.01 | 67,369.60 | 78,882.67 |

| Fuel costs | PLN∙MWh−1 | 32.80 | 61.50 | 117.60 | 143.60 | 291.80 | 322.70 |

| PLN∙GJ−1 | 9.10 | 17.10 | 32.70 | 39.90 | 81.10 | 89.60 | |

| Fuel demand | m3∙year−1 | 11,434.00 | 26,673.00 | 404.00 | 84.00 | 24,302.00 | 24.00 |

| kg∙year−1 | 56,710.00 | 20,770.00 | 8305.00 | 55,262.00 | 18,924.00 | 20,542.00 | |

| Boiler efficiency | % | 80.00 | 82.00 | 70.00 | 80.00 | 90.00 | 85.00 |

| Final energy requirement | kWh∙year−1 | 207,786.00 | 207,786.00 | 207,786.00 | 207,786.00 | 207,786.00 | 207,786.00 |

| Fuel moisture | % wag. | 20.00 | 23.00 | 30.00 | 8.00 | 0.00 | 0.00 |

| Calorific value | MJ∙kg−1 | 16.50 | 30.00 | 12.30 | 17.00 | 44.00 | 42.70 |

| kWh∙kg−1 | 4.58 | 12.20 | 3.40 | 4.70 | 12.20 | 11.90 | |

| MJ∙m−3 | 825.00 | 34.30 | 2644.00 | 11,079.00 | 34.30 | 36,078.00 | |

| kWh∙m−3 | 229.00 | 9.50 | 735.00 | 3077.00 | 9.50 | 10,022.00 | |

| Grain (5–10) Mg∙ha−1 | Biomass (8–20) Mg d.m.∙ha−1 | Straw (3–6) Mg d.m.∙ha−1 | Cores (1–2) Mg d.m.∙ha−1 | ||

|---|---|---|---|---|---|

| Fermentation industry | Burning, energy and domestic installations | Whole plants or pickled | By-product after harvesting grain or CCM | By-product after harvesting whole flasks | |

| Biogas plants | Biogas plants | Combustion—energetics | Combustion—energetics | ||

| Production volume from 1 Mg of raw material | |||||

| 370–410 L of ethanol, 400 L of stock | Around 19 GJ | 600–700 m3 of biogas including 350–450 m3 of methane | 250–300 m3 of biogas including around 150 m3 of methane | Around 15 GJ | Around 15 GJ |

| Variety of Sorghum | Primary Yield | |||

|---|---|---|---|---|

| Cellulose | Hemicellulose | Holocellulose | Lignin | |

| % | % | % | % | |

| Sucrosorgo 506 | 32.8 | 32.9 | 65.7 | 19.4 |

| Santos | 34.7 | 32.8 | 67.5 | 20.2 |

| Rona 1 | 34.6 | 29.4 | 64.0 | 19.2 |

| Secondary Yield | ||||

| Sucrosorgo 506 | 27.0 | 38.5 | 65.5 | 17.9 |

| Santos | 32.1 | 31.2 | 63.3 | 20.8 |

| Rona 1 | 25.8 | 35.6 | 61.4 | 18.3 |

| Group of Farms | Surface of the Dwelling House to Be Heated | Hard Coal | Coal Dust | Fuel Timber | Oat Grains |

|---|---|---|---|---|---|

| m2 | Mg∙year−1 | m3⋅year−1 | Mg⋅year−1 | ||

| A | 168.1 | 3.6 | 2.5 | 4.1 | 5.5 |

| B | 191.3 | 5.2 | 3.3 | 3.9 | 5.3 |

| C | 174.0 | 4.4 | 4.0 | 2.8 | 5.7 |

| In total | 176.3 | 4.2 | 3.0 | 3.8 | 5.5 |

| Parameter | Symbol | Unit | State | ||

|---|---|---|---|---|---|

| Analytical | Dry | Dry and Ashless | |||

| Analytical moisture | Wa | % | 9.6 | - | - |

| Ash | A | % | 4.9 | 5.4 | - |

| Combustible substance | - | % | 85.5 | 94.6 | |

| Volatile parts | V | % | 67.2 | 74.4 | 78.6 |

| Heat of combustion | Qs | kcal·kg−1 | 3736 | 4134 | 4371 |

| MJ·kg−1 | 15.64 | 17.31 | 18.30 | ||

| Calorific value | Qi | kcal·kg−1 | 3419 | 3846 | 4066 |

| MJ·kg−1 | 14.32 | 16.10 | 17.02 | ||

| Part of Plant | Fresh Mass | |

|---|---|---|

| Mg∙ha−1 | ||

| Giant Knotweed | Japanese Knotweed | |

| Aboveground parts | 101.5 | 79.5 |

| Underground parts | 129.3 | 107.5 |

| Number of Harvests | Fertilization Variant | Mean | |||

|---|---|---|---|---|---|

| kg N2·ha−1 | |||||

| 25 | 50 | 75 | 100 | ||

| Calorific Value | |||||

| MJ·kg−1 | |||||

| One | 16.84 | 16.99 | 16.96 | 16.93 | 16.93 |

| Two | 16.24 | 15.63 | 15.91 | 16.41 | 16.05 |

| Mean | 16.54 | 16.31 | 16.43 | 16.67 | 16.49 |

| Specification | Unit | Type of Propagules and Seeding/Planting Density | |||||

|---|---|---|---|---|---|---|---|

| Seeds | Rooted Cuttings | Seedlings | |||||

| kg∙ha−1 | thous.∙psc ha−1 | ||||||

| 1.5 | 4.5 | 20 | 60 | 20 | 60 | ||

| Ash content | % | 2.65 | 2.65 | 2.47 | 2.30 | 2.53 | 2.35 |

| Higher heating value | MJ∙kg−1 d.m. | 19.0 | 19.1 | 19.0 | 19.1 | 19.0 | 19.0 |

| Lower heating value | MJ∙kg−1 | 14.0 | 13.9 | 14.0 | 14.0 | 14.0 | 14.1 |

| Calorific value of the yield | GJ∙kg−1 | 173 | 191 | 175 | 214 | 190 | 225 |

| No. | Sources Used for Calculations | Combustion Heat | Heating Value for Moisture | |

|---|---|---|---|---|

| % | % | |||

| 10 | 30 | |||

| s. m. kJ·kg−1 | kJ·kg−1 | kJ·kg−1 | ||

| 1 | Kozaczka [115] | 18,317 | 15,051 | 11,163 |

| 2 | Ebeling and Jenkins [116] | 18,998 | 15,664 | 11,640 |

| 3 | Demirbas [117] | 17,890 | 14,666 | 10,864 |

| 4 | Gaur and Reed [118] | 20,259 | 16,799 | 12,523 |

| 6 | Mean | 18,759 | 15,448 | 11,472 |

| Parameter | Symbol | Unit | Condition | |||||

|---|---|---|---|---|---|---|---|---|

| Analytical | Dry | Dry and Ash-Free | ||||||

| I Year | III Year | I Year | III Year | I Year | III Year | |||

| Analytical moisture content | Wa | % | 13.4 | 13.5 | ||||

| Ash | A | % | 5.1 | 3.6 | 5.9 | 4.1 | ||

| Combustible matter | % | 81.5 | 83.0 | 94.1 | 95.9 | |||

| Volatile matter | V | % | 65.1 | 69.1 | 75.2 | 79.8 | 80.0 | 83.3 |

| Gross calorific value | Qs | kcal·kg−1 | 3811 | 3932 | 4402 | 4544 | 4679 | 4740 |

| MJ·kg−1 | 15.96 | 16.46 | 18.43 | 19.02 | 19.59 | 19.85 | ||

| Net calorific value | Qi | kcal·kg−1 | 3486 | 3609 | 4118 | 4261 | 4377 | 4446 |

| MJ·kg−1 | 14.59 | 15.11 | 17.24 | 17.84 | 18.32 | 18.61 | ||

| Author of Investigations | Energy Value of Yield | Incinerating Warmth | Ash | Moisture |

|---|---|---|---|---|

| MJ·kg−1 d.m. | MJ·kg−1 d.m. | g·kg−1 d.m. | % | |

| Grzelak [112] | 18.2 | 19.4 | 69 | 7.7 |

| Dadrach et al. [115] | 17.0 | 17.0 | 68 | 6.8 |

| Harkot et al. [113] | 18.0 | 19.1 | 55 | – |

| Rogalski et al. [114] | 15.5 | 17.6 | 128 | – |

| Plant | Yield d.m. | Energy Content | Net Energy Production |

|---|---|---|---|

| Mg∙ha−1 | GJ∙Mg−1 | GJ∙ha−1 | |

| Rod millet | 9.0 | 19.0 | 163.8 |

| Rape | 3.0 | 25.0 | 89.2 |

| Corn for grain | 5.7 | 18.8 | 64.0 |

| Itemization | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|---|---|---|---|

| Mtoe | ||||||||||

| Total primary energy recovery in the EU | 804.0 | 796.8 | 792.0 | 772.9 | 766.6 | 760.4 | 758.8 | 756.6 | 739.4 | 573.1 |

| including from renewable sources | 165.4 | 182.2 | 194.6 | 197.5 | 205.0 | 217.4 | 226.3 | 234.4 | 242.5 | 233.5 |

| Total primary energy recovery in Poland | 68.8 | 72.6 | 71.8 | 68.2 | 68.5 | 66.6 | 64.2 | 64.6 | 62.1 | 58.0 |

| including from renewable sources | 7.5 | 8.5 | 8.6 | 8.1 | 9.0 | 9.2 | 9.2 | 12.1 | 12.3 | 12.5 |

| Itemization | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 |

| % | ||||||||||

| Share of energy from renewable sources in total primary energy in the EU | 20.6 | 22.9 | 24.6 | 25.5 | 26.7 | 28.6 | 29.8 | 31.0 | 32.8 | 40.7 |

| Share of energy from renewable sources in total primary energy in Poland | 10.9 | 11.7 | 11.9 | 11.9 | 13.1 | 13.8 | 14.4 | 18.7 | 19.7 | 21.6 |

| Voivodeships | 2015 | 2016 | 2017 | 2018 | 2019 | 2021 |

|---|---|---|---|---|---|---|

| A [ha] | ||||||

| Lower Silesian | 252 | 404 | 330 | 411 | 373 | 373 |

| Kuyavian-Pomeranian | 48 | 79 | 66 | 59 | 77 | 77 |

| Lublin | 102 | 114 | 113 | 121 | 130 | 130 |

| Lubusz | 68 | 154 | 95 | 73 | 80 | 80 |

| Łódź | 160 | 157 | 278 | 273 | 283 | 283 |

| Lesser Poland | 266 | 334 | 328 | 317 | 372 | 372 |

| Masovian | 215 | 233 | 228 | 251 | 272 | 272 |

| Opole | 21 | 35 | 25 | 43 | 49 | 49 |

| Subcarpathian | 149 | 158 | 192 | 235 | 216 | 216 |

| Podlaskie | 34 | 48 | 58 | 75 | 96 | 96 |

| Pomeranian | 272 | 348 | 393 | 407 | 440 | 440 |

| Silesian | 181 | 217 | 306 | 226 | 278 | 278 |

| Holy Cross | 21 | 25 | 32 | 35 | 44 | 44 |

| Warmian-Masurian | 82 | 112 | 124 | 92 | 102 | 102 |

| Greater Poland | 174 | 293 | 174 | 205 | 198 | 198 |

| West Pomeranian | 263 | 256 | 264 | 232 | 221 | 221 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dybek, B.; Anders, D.; Hołaj-Krzak, J.T.; Hałasa, Ł.; Maj, G.; Kapłan, M.; Klimek, K.; Filipczak, G.; Wałowski, G. Assessment of the Prospects of Polish Non-Food Energy Agriculture in the Context of a Renewable Energy Source. Energies 2023, 16, 3315. https://doi.org/10.3390/en16083315

Dybek B, Anders D, Hołaj-Krzak JT, Hałasa Ł, Maj G, Kapłan M, Klimek K, Filipczak G, Wałowski G. Assessment of the Prospects of Polish Non-Food Energy Agriculture in the Context of a Renewable Energy Source. Energies. 2023; 16(8):3315. https://doi.org/10.3390/en16083315

Chicago/Turabian StyleDybek, Barbara, Dorota Anders, Jakub T. Hołaj-Krzak, Łukasz Hałasa, Grzegorz Maj, Magdalena Kapłan, Kamila Klimek, Gabriel Filipczak, and Grzegorz Wałowski. 2023. "Assessment of the Prospects of Polish Non-Food Energy Agriculture in the Context of a Renewable Energy Source" Energies 16, no. 8: 3315. https://doi.org/10.3390/en16083315