Charge Equalization System for an Electric Vehicle with a Solar Panel

Abstract

1. Introduction

2. Materials and Methods

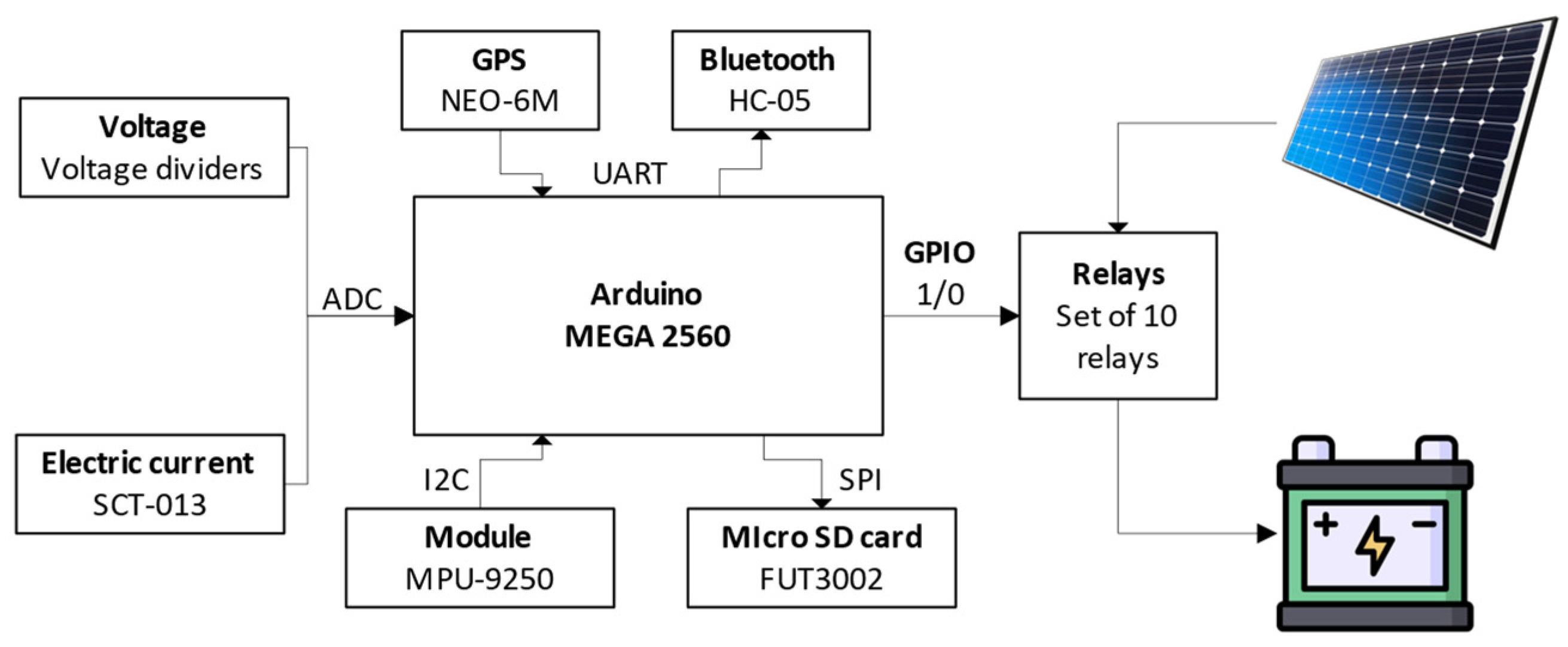

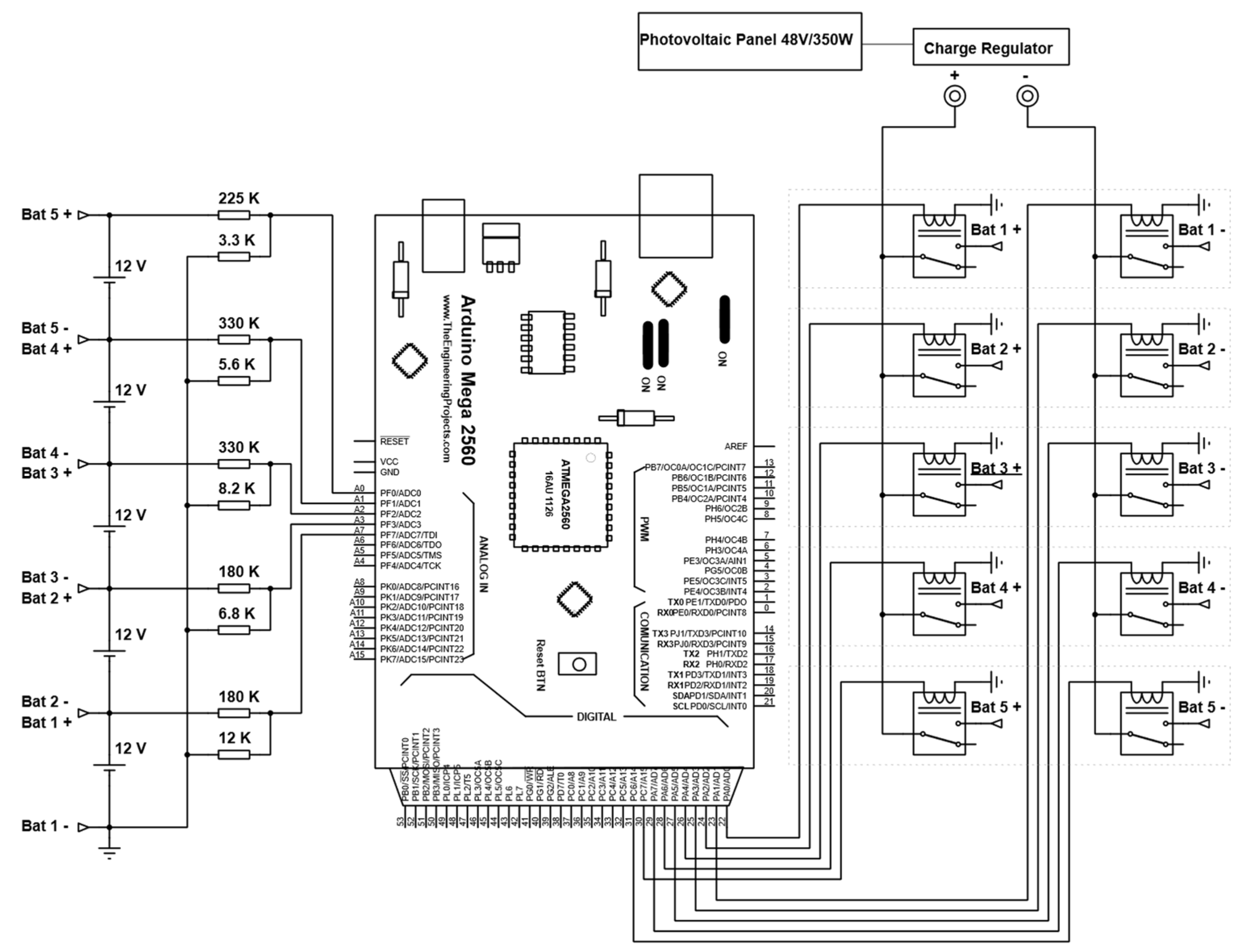

2.1. Hardware Architecture

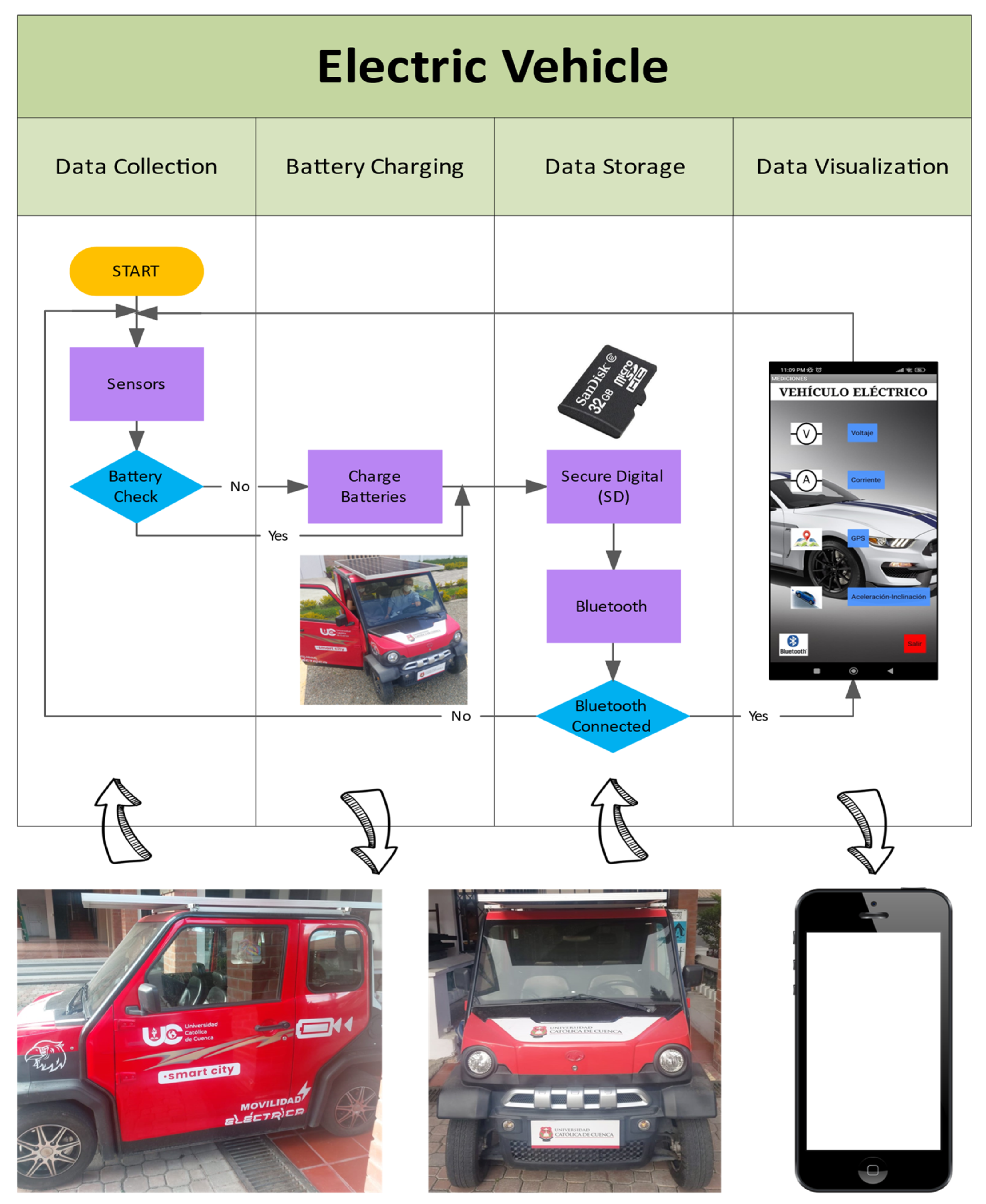

2.2. Software Design

- Data collection: In this phase, as its name indicates, information on some physical variables is obtained using sensors. The sensors detect the battery voltage, current consumption, acceleration, and location.

- Battery charging: At this stage, power is used from the 350 W PV, which is responsible for sending energy to each battery via a relay system through a programmed sequence. The charge cycle conditions are set based on the discharge level of each battery.

- Data storage: At this stage, the information obtained from the sensors are saved in two ways:

- SD module for Arduino: The data are programmatically stored in a .txt file on a microSD card;

- Cellphone: Another way to save the data is on a cellphone via an app. The data are only saved if the cellphone is connected to the vehicle through Bluetooth. The information is also stored in a .txt file in the SD of the cell phone.

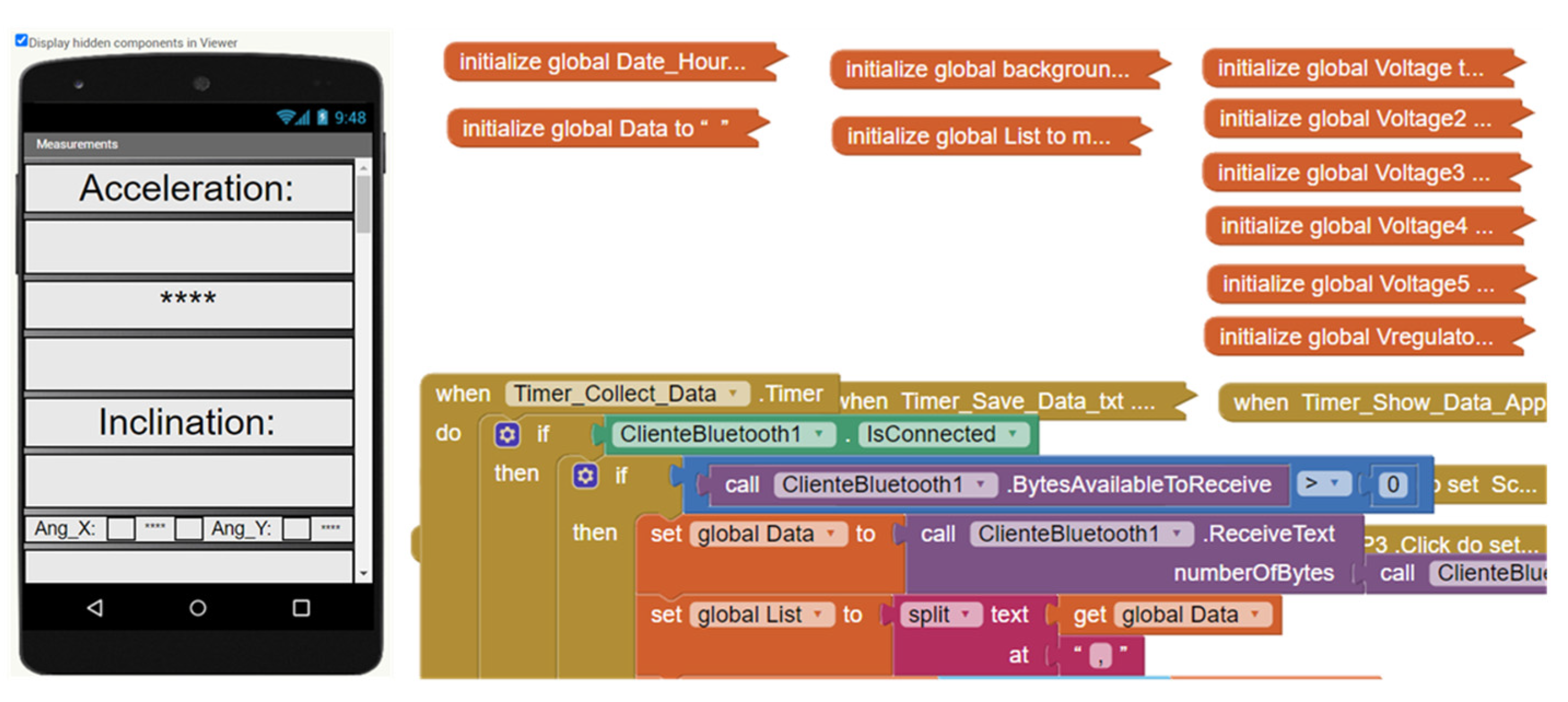

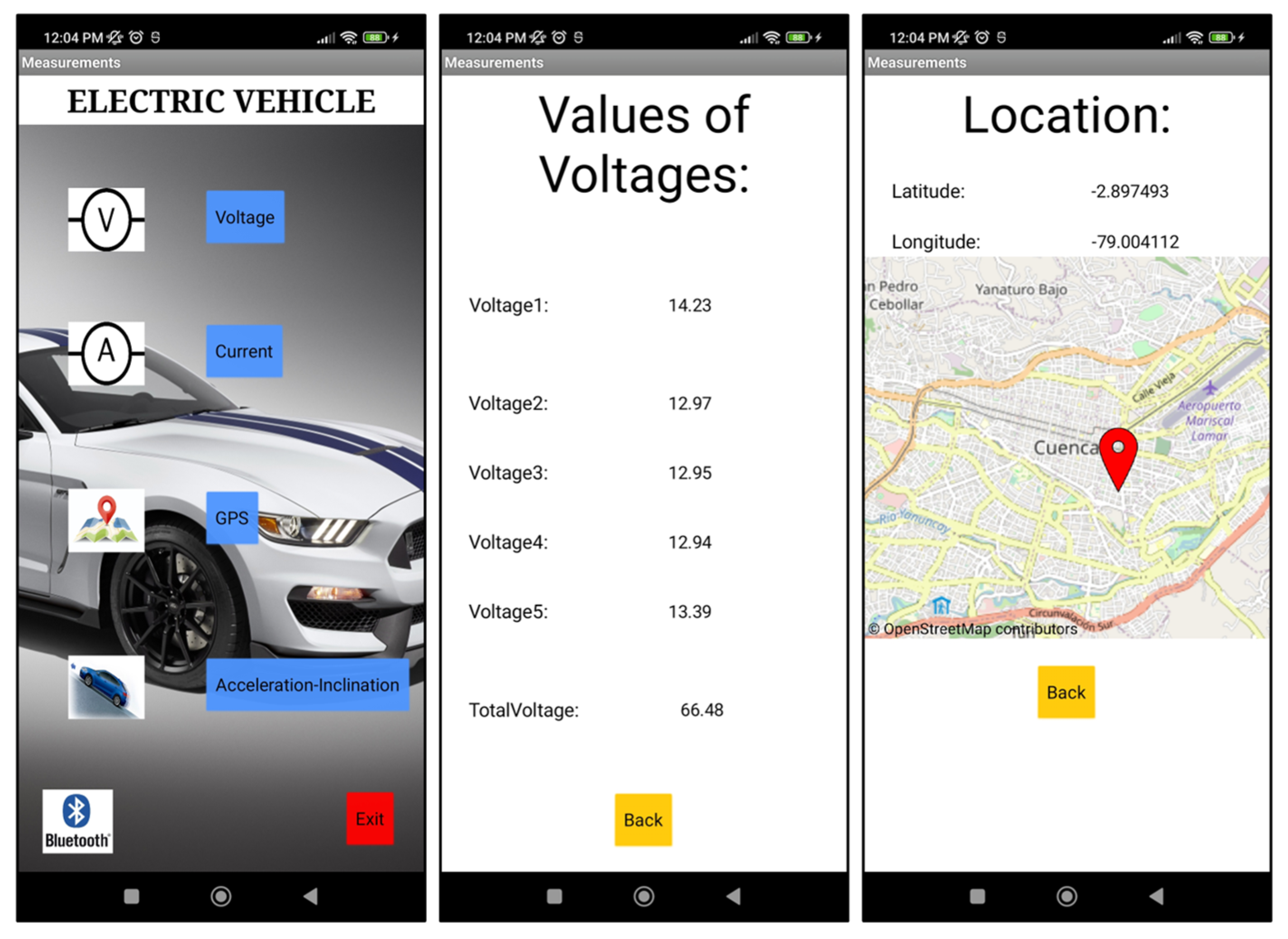

- Data visualization: This stage is an add-on, as it is not essential for the functioning of the project. The data obtained by the sensors are visualized in an application created using App Inventor, which is connected via Bluetooth to the module in the EV for its operation. It allows the user to navigate through different screens to observe the data on the parameters.

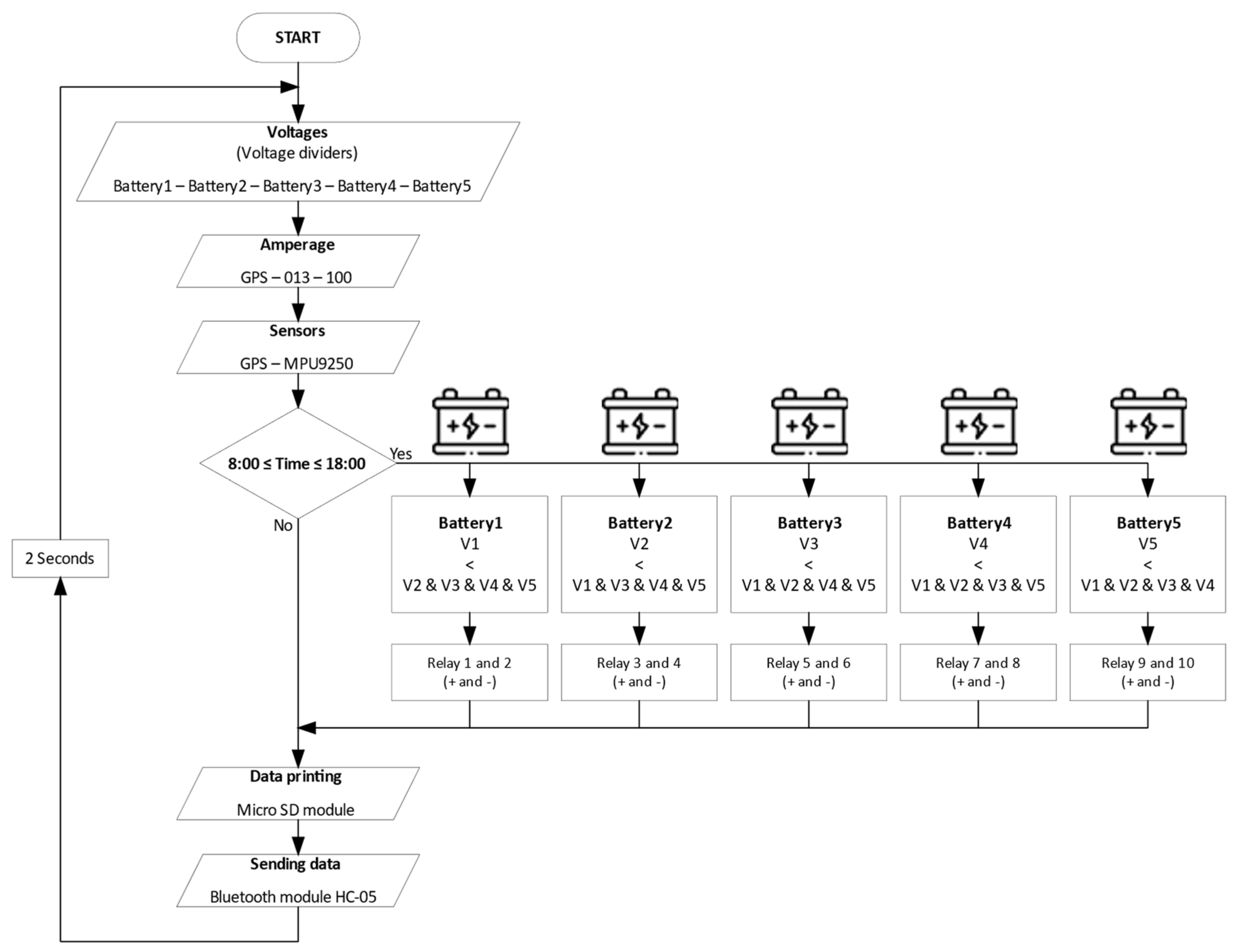

2.3. Software Developed for the EV

2.4. Cellphone Application

2.5. Load Equalization System

3. Results

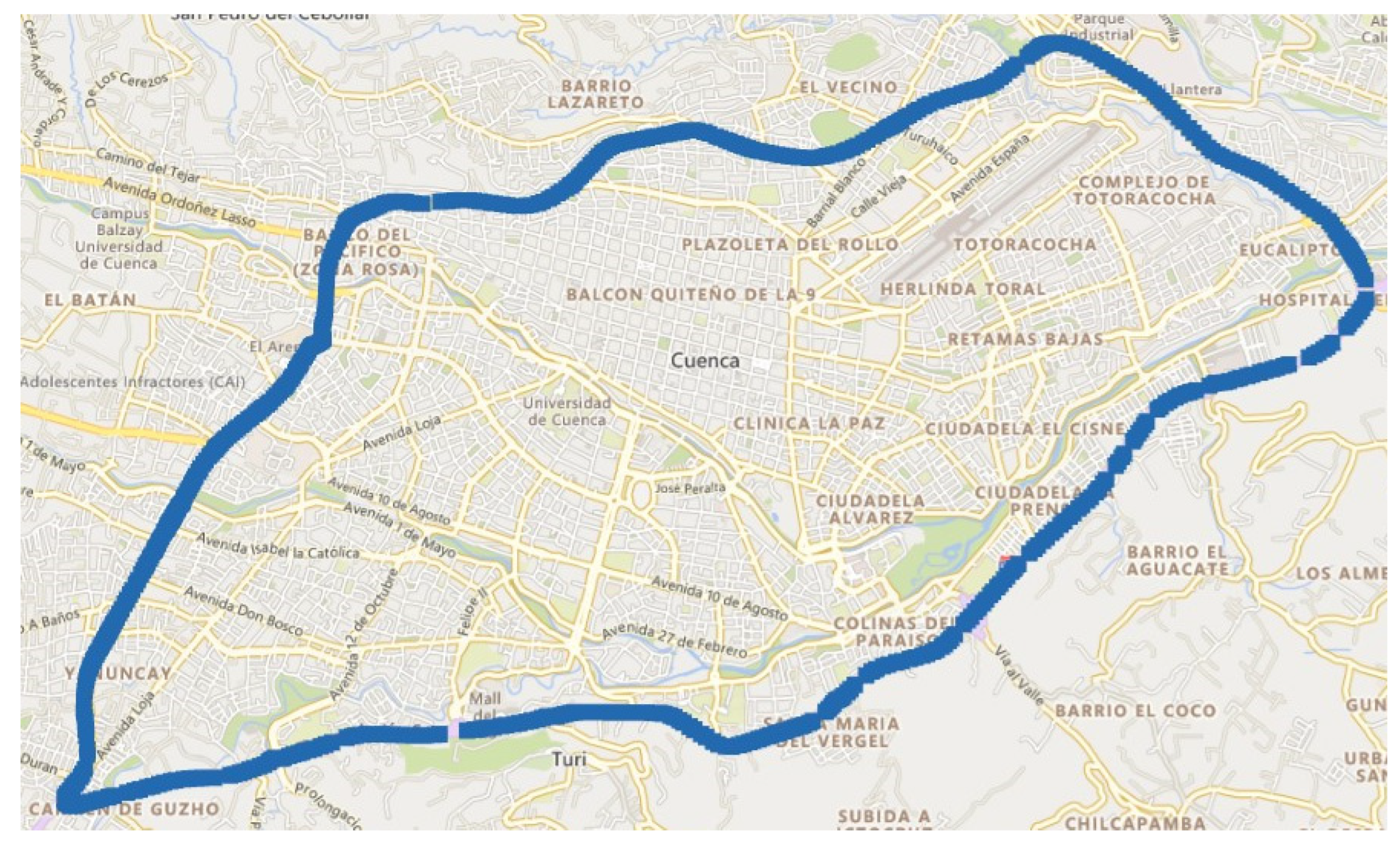

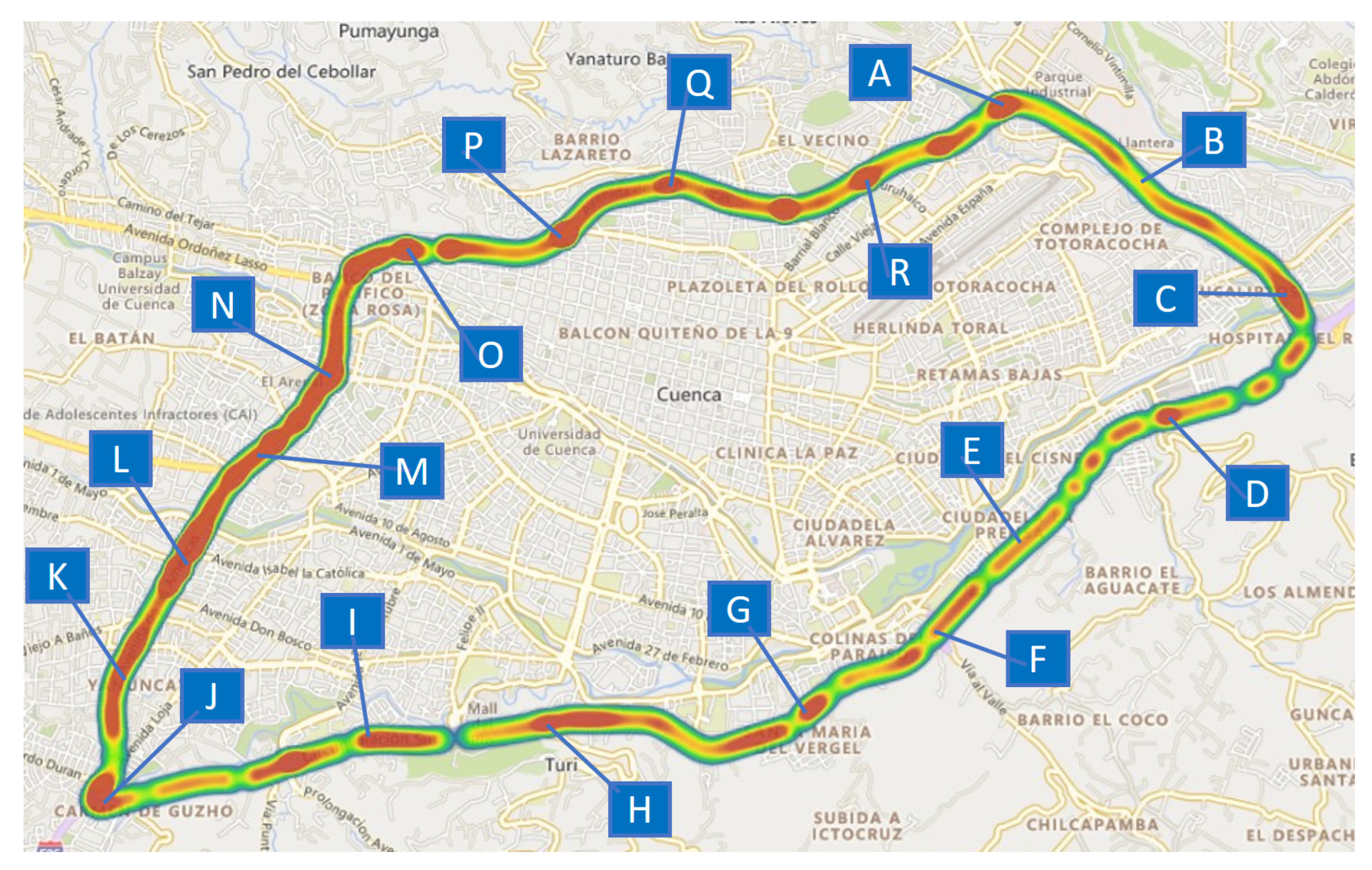

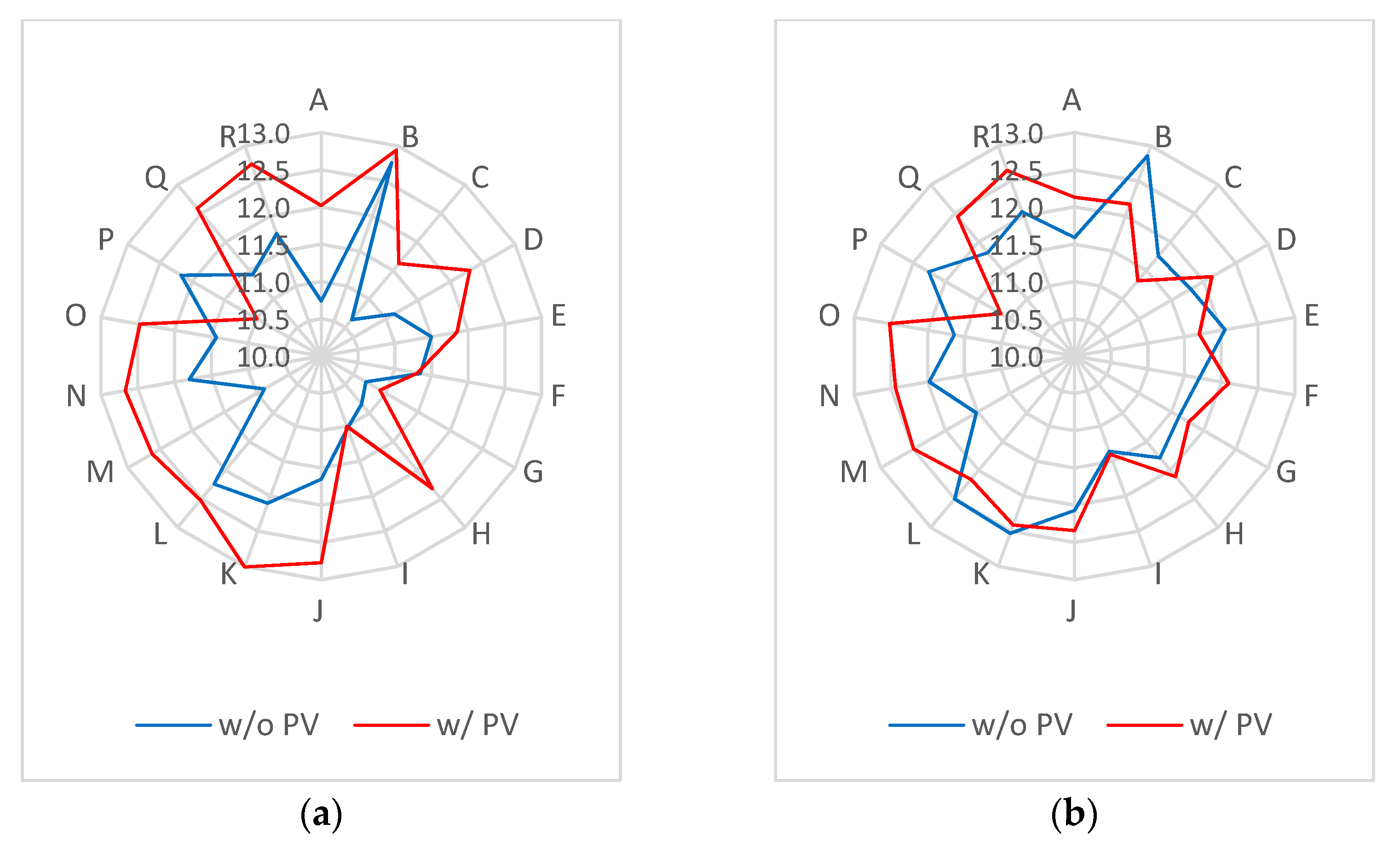

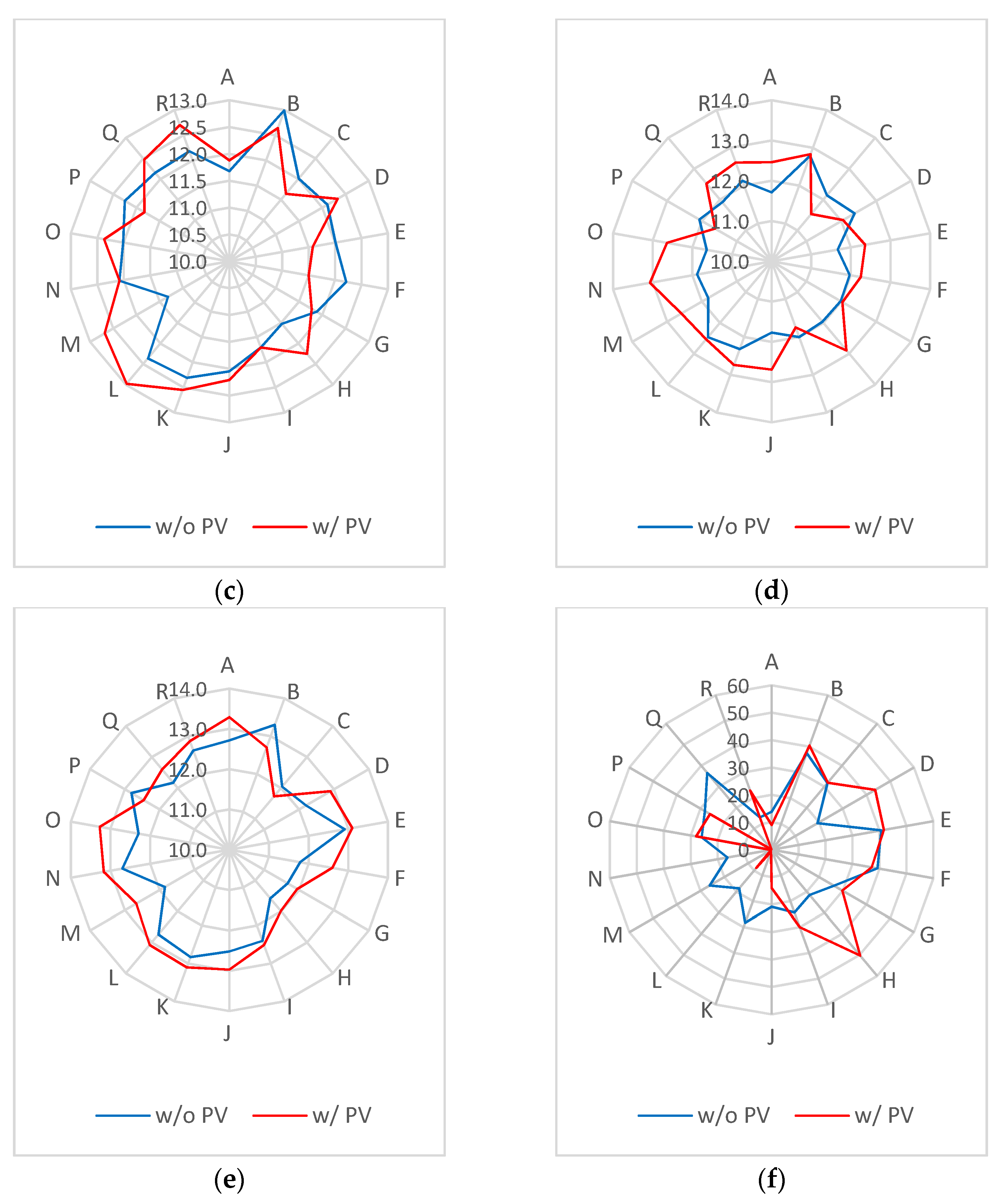

- Section A–C. This path began at the De los Choferes gas station roundabout, as this is a road section with a fast vehicular flow. It can be seen from Figure 9a that the EV traveled at a high speed, causing the high energy consumption of the batteries. A high current is observed, and the battery voltage starts to decrease. Figure 9b shows similar behavior, except with a decrease in speed due to a single traffic light on the route. Similarly, at point C (the Y-intersection of the Hospital del Rio sector), there is a decrease in speed and intensity due to an increase in traffic flow in this area until the Cuenca–Azogues–Biblián expressway is reached.

- Section D–G. This section begins at the IESS roundabout (where there is little traffic as it is a high-speed road). There is fast vehicular flow at points E and F, so there is an increase in speed and intensity that are almost constant throughout the trajectory until the Mollobamba roundabout is reached, where there is an evident decrease in the speed of the EV.

- Section H–J. From the Camino a Turi roundabout, a decrease in average speed can be observed due to the increase in vehicular traffic in this area. After point I, there is a road with a negative inclination, and at the same time, it undergoes a broad division into Diego de Tapia Street, so there are no traffic problems. It can therefore be seen from Figure 9 that the speed and intensity of the EV are higher. At point J, there is an increase in vehicular flow at the traffic interchange, so the speed and intensity values decrease.

- Section K–R. After leaving the interchange and between De las Américas Avenue and the De los Choferes Gas Station Roundabout, the trajectory becomes slow because this avenue has several traffic lights and is within a populated area of the city where the tramway runs. This generates an increase in traffic, and it can be clearly seen from Figure 8 that there are increases and decreases in speed and intensity over this road section.

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Banco Mundial. Desarrollo Urbano: Panorama General. Available online: https://www.bancomundial.org/es/topic/urbandevelopment/overview#:~:text=Enelmundo%2Cmásdel,crecimientoyproporcionarserviciosbásicos (accessed on 28 November 2021).

- Lazaroiu, G.C.; Roscia, M. Definition Methodology for the Smart Cities Model. Energy 2012, 47, 326–332. [Google Scholar] [CrossRef]

- Silva-Castaño, F. Conducción, En Condiciones Reales de Galicia, de Un Vehículo Eléctrico Con Autonomía Extendida (REX). Dínamo Técnica 2016, 19, 1–4. [Google Scholar]

- Saavedra-Moreira, R.-I. Diagnóstico de Transporte Inteligente Para La Ciudad de Guayaquil. Ph.D. Thesis, Universidad Internacional del Ecuador, Quito, Ecuador, 2021. [Google Scholar]

- Kasprzyk, L. Modelling and Analysis of Dynamic States of the Lead-Acid Batteries in Electric Vehicles. Eksploat. Niezawodn. 2017, 19, 229–236. [Google Scholar] [CrossRef]

- Mendoza-Varela, I.A.; Alvarez-Diazcomas, A.; Martinez-Prado, M.A.; Rodriguez-Resendiz, J. Modeling and Control of a Phase-Shifted Full-Bridge Converter for a LiFePO4 Battery Charger. Electronics 2021, 10, 2568. [Google Scholar] [CrossRef]

- López-Redondo, N. Comparando Las Emisiones de Los Vehículos de Combustión y Los Eléctricos: ¿cuál Es Realmente Menos Contaminante? Available online: https://movilidadelectrica.com/emisiones-gasolina-electrico-cual-emite-menos/ (accessed on 28 November 2021).

- Ota, Y.; Araki, K.; Nagaoka, A.; Nishioka, K. Facilitating Vehicle-Integrated Photovoltaics by Considering the Radius of Curvature of the Roof Surface for Solar Cell Coverage. Clean. Eng. Technol. 2022, 7, 100446. [Google Scholar] [CrossRef]

- Sinuraya, A.; Sinaga, D.H.; Simamora, Y.; Wahyudi, R. Solar Photovoltaic Application for Electric Vehicle Battery Charging. J. Phys. Conf. Ser. 2022, 2193, 12075. [Google Scholar] [CrossRef]

- Yu, F.; Zhu, Z.; Liu, X.; Zhang, Z. Electric-Drive-Reconstructed Onboard Charger for Solar-Powered Electric Vehicles Incorporating Six-Phase Machine. IEEE Trans. Power Electron. 2022, 37, 6544–6555. [Google Scholar] [CrossRef]

- Srivastava, S.; Karthikeyan, S.; Arumugam, P.; Kumar, A.; Thanigaivel, G. Design, Development and Experimental Investigation on the Effect of HVAC Power Consumption in Electric Vehicle Integrated with Thin Film Solar PV Panels; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2021. [Google Scholar] [CrossRef]

- Mil’shtein, S.; Zinaddinov, M.; Asthana, D.N.; Scheminger, J. Design and Testing of Solar/Electric Cart. J. Phys. Conf. Ser. 2021, 1921, 12021. [Google Scholar] [CrossRef]

- Masuda, T.; Araki, K.; Okumura, K.; Urabe, S.; Kudo, Y.; Kimura, K.; Nakado, T.; Sato, A.; Yamaguchi, M. Next Environment-Friendly Cars: Application of Solar Power as Automobile Energy Source. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; pp. 580–584. [Google Scholar]

- Sekhar, G.C.; Krishna, D.G.; Abhimanue, H.; Meeran, F.K.; Janardhanan, S. Shape Improvisation of the Solar Panels on the Roof of an Electric Vehicle. J. Inst. Eng. (India) Ser. C 2021, 102, 1041–1050. [Google Scholar] [CrossRef]

- Alvarez-Diazcomas, A.; López, H.; Carrillo-Serrano, R.V.; Rodríguez-Reséndiz, J.; Vázquez, N.; Herrera-Ruiz, G. A Novel Integrated Topology to Interface Electric Vehicles and Renewable Energies with the Grid. Energies 2019, 12, 4091. [Google Scholar] [CrossRef]

- Alvarez-Diazcomas, A.; Rodríguez-Reséndiz, J.; Carrillo-Serrano, R.V. An Improved Battery Equalizer with Reduced Number of Components Applied to Electric Vehicles. Batteries 2023, 9, 65. [Google Scholar] [CrossRef]

- Alvarez-Diazcomas, A.; Estévez-Bén, A.A.; Rodríguez-Reséndiz, J.; Martínez-Prado, M.A.; Carrillo-Serrano, R.V.; Thenozhi, S. A Review of Battery Equalizer Circuits for Electric Vehicle Applications. Energies 2020, 13, 5688. [Google Scholar] [CrossRef]

- Quraan, M.; Yeo, T.; Tricoli, P. Design and Control of Modular Multilevel Converters for Battery Electric Vehicles. IEEE Trans. Power Electron. 2016, 31, 507–517. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Masuda, T.; Nakado, T.; Zushi, Y.; Araki, K.; Takamoto, T.; Okumura, K.; Satou, A.; Yamada, K.; Ota, Y. Importance of Developing Photovoltaics-Powered Vehicles. Energy Power Eng. 2021, 13, 147–162. [Google Scholar] [CrossRef]

- Villanueva-Gutiérrez, L. Implementación de Un Sistema Fotovoltaico En Un Vehículo Eléctrico Para La Carga de Batería. Grade Thesis, Pontificia Universidad Católica de Chile, Santiago de Chile, Chile, 2009. [Google Scholar]

- Consejo Nacional de Electricidad (CONELEC) Plan de Electrificación 2013–2022. Available online: https://www.ariae.org/servicio-documental/plan-de-electrificacion-2013-2022#:~:text=ElPlanMaestrodeElectrificación,%2Cregularidad%2Ccontinuidadycalidad (accessed on 7 April 2022).

- Delgado-Orellana, G.; Orellana-Samaniego, M. Estimación de La Radiación Solar Global Diaria En El Cantón Cuenca Mediante La Aplicación Del Modelo Bristow & Campbell. Bachelor’s Thesis, Universidad Politécnica Salesiana, Cuenca, Ecuador, 2015. [Google Scholar]

- Kaiying Power Supply & Electrical Equip Co., Ltd. Batería de Ciclo Profundo 6-Evf-150 Batería Para Coche de Golf de La Batería de Plomo Ácido/Batería VRLA Batería Eléctrica. Available online: https://es.made-in-china.com/co_longwaybattery/product_Deep-Cycle-Battery-6-Evf-150-Battery-for-Golf-Car-Lead-Acid-Battery-VRLA-Battery-Electric-Battery_hrnonehyu.html (accessed on 29 October 2022).

- Xupai Power Co., Ltd. 6-EVF-150 Electric Golf Car Battery Pack 12 V 150 AH. Available online: https://www.alibaba.com/product-detail/6-EVF-150-Electric-Golf-Car_60462967801.html (accessed on 12 January 2023).

- Dam, S.K.; John, V. Low-Frequency Selection Switch Based Cell-to-Cell Battery Voltage Equalizer with Reduced Switch Count. IEEE Trans. Ind. Appl. 2021, 57, 3842–3851. [Google Scholar] [CrossRef]

- NASA. POWER NASA Prediction of Worldwide Energy Resources. Available online: https://power.larc.nasa.gov/data-access-viewer/ (accessed on 18 March 2023).

- Reinoso, L.; Ortega, J. Incremento de La Autonomía de Un Vehículo Eléctrico Dayang CHOK-S Mediante Paneles Solares. Rev. Digit. Novasinergia 2020, 3, 40–46. [Google Scholar]

- Mohamed, N.; Aymen, F.; Altamimi, A.; Khan, Z.A.; Lassaad, S. Power Management and Control of a Hybrid Electric Vehicle Based on Photovoltaic, Fuel Cells, and Battery Energy Sources. Sustainability 2022, 14, 2551. [Google Scholar] [CrossRef]

- Amin, A.; Budiman, A.C.; Kaleg, S.; Sudirja, S.; Hapid, A. Active Battery Balancing System for Electric Vehicles Based on Cell Charger. Int. J. Power Electron. Drive Syst. 2021, 12, 1729. [Google Scholar]

| Electrical Component | Description |

|---|---|

| Arduino Mega 2560 | This microcontroller is one of the most versatile of the Arduino family, due to its high number of digital and analogue pins. |

| SCT-013 | One of the advantages of this sensor is that it can measure AC current without interrupting (cutting) the cable. |

| GPS-neo-6m | This is a receiver module for any application requiring geolocation. It has a powerful antenna and is compatible with most microprocessors. |

| Bluetooth HC-05 | This module is compatible with any wireless device on the market. |

| MPU-9250 | This module offers three functionalities: gyroscope, magnetometer, and accelerometer, the last of which is necessary to calculate the degrees of inclination of the EV. |

| SD Card FUT302 | This device is required for data storage. |

| Day | Hour | Average Temperature (°C) | Maximum Temperature (°C) | Minimum Temperature (°C) | Irradiance (kW-h/m2) |

|---|---|---|---|---|---|

| 8 December 2021 | 15:47 | 15.1 | 22.1 | 9.7 | 3.64 |

| 16:36 | 3.48 | ||||

| 15 December 2021 | 13:37 | 15.8 | 21.1 | 13 | 3.34 |

| 14:31 | 3.31 |

| Date | Hour | Location | Situation | Construction Height | Track Width (m) | Description | |||

|---|---|---|---|---|---|---|---|---|---|

| Point | Zone | Inclination | Traffic or Traffic Lights | Circulation | |||||

| 8 December 2021 | 15:47:25 | A | De las Américas Avenue | X | H1 | 11 | Intersection of De las Américas Avenue and Rio Machángara Street De Los Choferes gas station roundabout | ||

| 15:47:25 | B | De las Américas Avenue | X | H1 | 26 | Las Américas Ave., in front of the Metales y Metales store | |||

| 15:51:58 | C | De las Américas Avenue | X | H2 | 30 | Intersection of Americas Avenue and Gonzalez Suarez Avenue; Y-intersection of the Hospital del Rio sector | |||

| 15:54:11 | D | Cuenca–Azogues–Biblián expressway | X | H2 | 47 | Intersection of the Cuenca–Azogues–Biblián expressway and the road to Rayoloma, IESS roundabout | |||

| 15:56:17 | E | Cuenca–Azogues–Biblián expressway | X | H1 | 30 | Panamerican Highway, perpendicular to Restrepo brothers | |||

| 15:57:48 | F | Cuenca–Azogues–Biblián expressway | X | H1 | 24 | Traffic distributor Camino del Valle | |||

| 15:59:43 | G | Cuenca–Azogues–Biblián expressway | X | H1 | 42 | Mollobamba roundabout | |||

| 16:03:24 | H | Cuenca–Azogues–Biblián expressway | X | H1 | 42 | Camino a Turi roundabout | |||

| 16:05:33 | I | Cuenca–Azogues–Biblián expressway | X | H2 | 26 | Panamerican Highway and Diego de Tapia | |||

| 16:09:07 | J | Cuenca–Azogues–Biblián expressway | X | H1 | 8 | Panamerican Highway and De las Americas Avenue, at the overpass | |||

| 16:11:27 | K | De las Américas Avenue | X | H2 | 27 | In front of the Coral Hipermercados supermarket | |||

| 16:14:22 | L | De las Américas Avenue | X | H1 | 27 | Intersection of Luis Moscoso and De las Américas Ave | |||

| 16:18:16 | M | De las Américas Avenue | X | H2 | 27 | In front of Dragon Park | |||

| 16:21:11 | N | De las Américas Avenue | X | H2 | 25 | De las Américas Avenue and Remigio Crespo Avenue, in front of El Arenal Market | |||

| 16:25:30 | O | De las Américas Avenue | X | H2 | 27 | De las Americas Ave. and Miguel Cabello Balboa | |||

| 16:27:29 | P | De las Américas Avenue | X | H1 | 32 | Intersection of Héroes de Verdeloma Avenue and De las Américas Avenue, De las Américas Park sector | |||

| 16:30:38 | Q | De las Américas Avenue | X | H1 | 29 | Intersection of Luis Cordero and De las Americas Ave. | |||

| 16:33:23 | R | De las Américas Avenue | X | H2 | 39 | Miraflores roundabout, park sector | |||

| H1 < 10 m | H2 ≥ 10 m o < 30 | H3 ≥ 30 m | |||||||

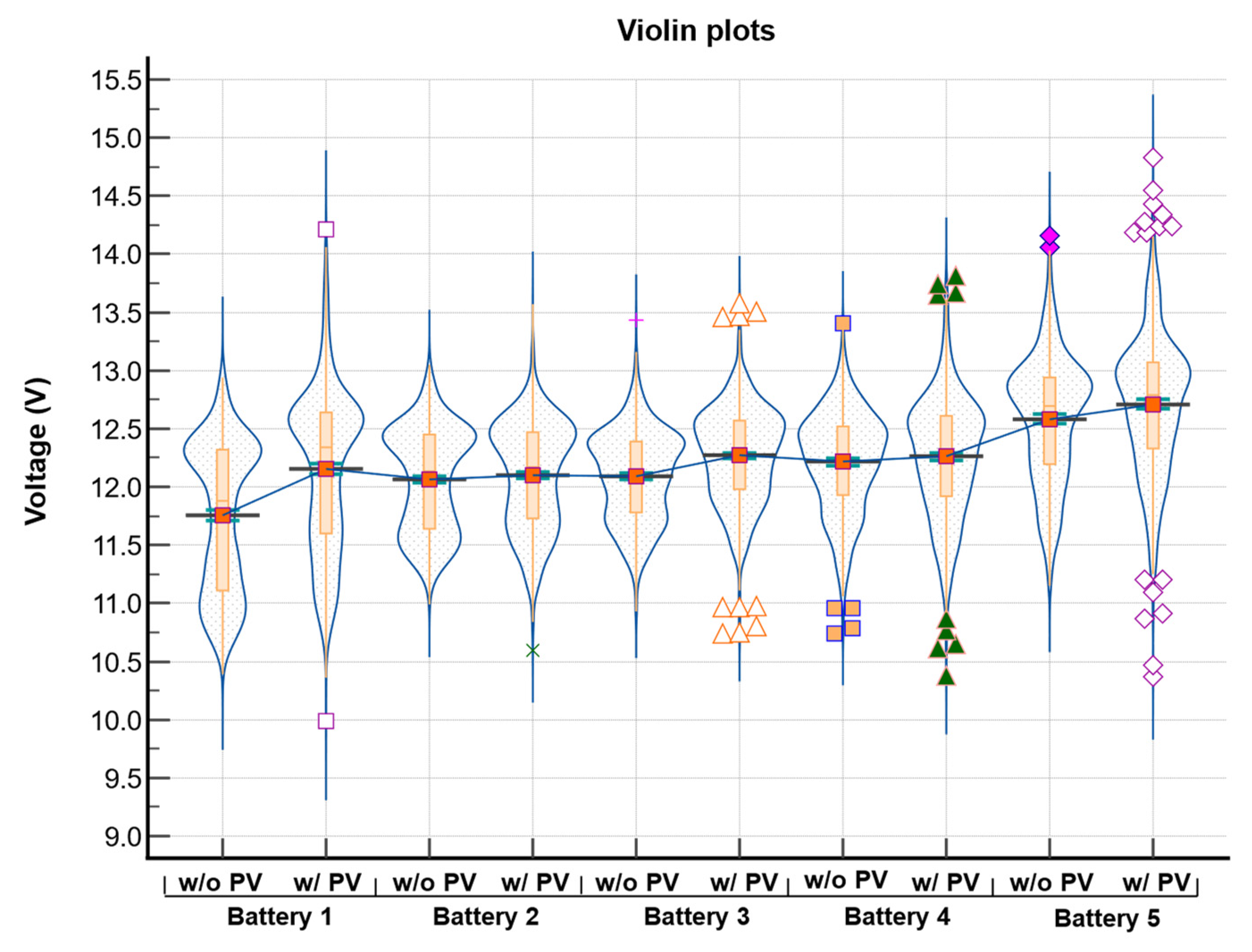

| Data Comparison | ||||||

|---|---|---|---|---|---|---|

| Battery Number | Data Type | Lowest Value | Highest Value | Median | 25th Percentile | 75th Percentile |

| 1 | Data w/o PV | 10.39 | 12.94 | 11.88 | 11.11 | 12.32 |

| Data w/ PV | 9.99 | 14.21 | 12.34 | 11.60 | 12.64 | |

| 2 | Data w/o PV | 10.99 | 13.05 | 12.13 | 11.64 | 12.45 |

| Data w/ PV | 10.6 | 13.57 | 12.17 | 11.73 | 12.47 | |

| 3 | Data w/o PV | 10.93 | 13.43 | 12.13 | 11.78 | 12.39 |

| Data w/ PV | 10.74 | 13.58 | 12.32 | 11.98 | 12.57 | |

| 4 | Data w/o PV | 10.74 | 13.41 | 12.28 | 11.93 | 12.52 |

| Data w/ PV | 10.38 | 13.81 | 12.32 | 11.92 | 12.61 | |

| 5 | Data w/o PV | 11.15 | 14.16 | 12.69 | 12.19 | 12.94 |

| Data w/ PV | 10.37 | 14.83 | 12.79 | 12.33 | 13.07 | |

| Similar Schemes | Improvements in Our Approach |

|---|---|

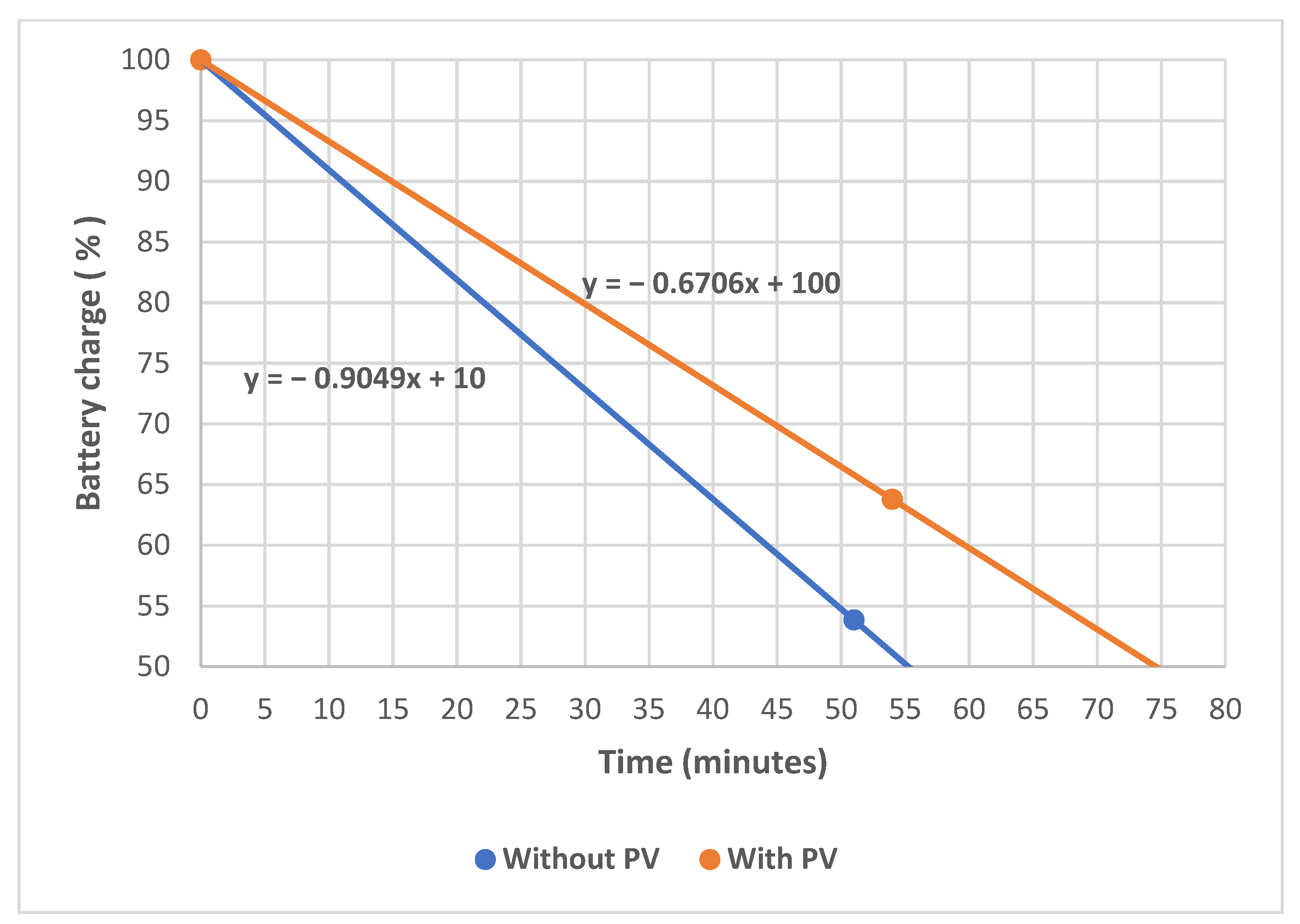

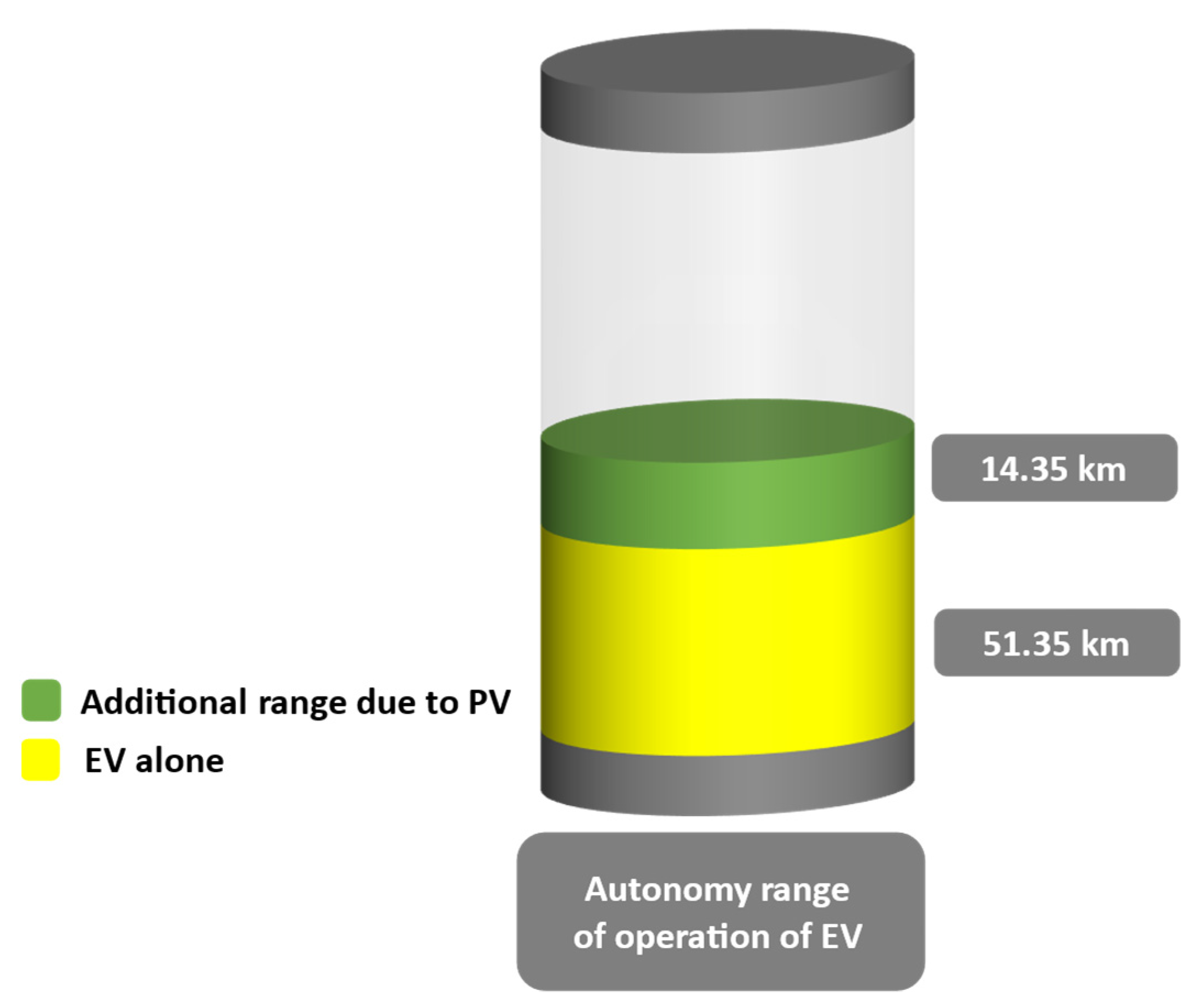

| The authors presented a battery charging system using four 100 W monocrystalline PVs to supply power to an EV with a 1 kW motor; this provided an additional range of 1.2 h when the system was fully charged [9]. | We realized a charge equalizer system with a 350 W panel, which improved the vehicle’s range by 27.9%. |

| Using an EV running at 48 V, the authors installed thin-film PVs on the roof with the aim of meeting the power demand of the air-conditioning system [11]. | Our system was designed to meet the global energy demand of the entire vehicle. |

| The authors designed and ran tests on a lightweight four-wheel drive EV. The car could carry four passengers and an additional attached load of about 500 kg. It had a battery pack with LiFePO4 cells with an output of 6000 W. A 600 W PV was installed on the roof, which provided constant recharging for the lithium-ion batteries [12]. | Although our vehicle did not have the same characteristics, an increase in operational range was realized with a 350 W panel, and a charge equalizer was designed and developed. |

| In similar research carried out on the same EV (Dayang Chock S2), it was observed that the use of PV also improved the autonomous range of the EV between 16% and 33% depending on the variation in solar radiation [27]. However, in this study, deep discharges were carried out, which is not recommended, as they reduce the autonomous range of the car and damage the useful life of the batteries. | Our results were achieved without carrying out deep discharge tests on the batteries, as these can damage their useful life. In addition, analysis and monitoring of the batteries were carried out. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Angamarca-Avendaño, D.-A.; Saquicela-Moncayo, J.-F.; Capa-Carrillo, B.-H.; Cobos-Torres, J.-C. Charge Equalization System for an Electric Vehicle with a Solar Panel. Energies 2023, 16, 3360. https://doi.org/10.3390/en16083360

Angamarca-Avendaño D-A, Saquicela-Moncayo J-F, Capa-Carrillo B-H, Cobos-Torres J-C. Charge Equalization System for an Electric Vehicle with a Solar Panel. Energies. 2023; 16(8):3360. https://doi.org/10.3390/en16083360

Chicago/Turabian StyleAngamarca-Avendaño, Darwin-Alexander, Jonnathan-Francisco Saquicela-Moncayo, Byron-Humberto Capa-Carrillo, and Juan-Carlos Cobos-Torres. 2023. "Charge Equalization System for an Electric Vehicle with a Solar Panel" Energies 16, no. 8: 3360. https://doi.org/10.3390/en16083360

APA StyleAngamarca-Avendaño, D.-A., Saquicela-Moncayo, J.-F., Capa-Carrillo, B.-H., & Cobos-Torres, J.-C. (2023). Charge Equalization System for an Electric Vehicle with a Solar Panel. Energies, 16(8), 3360. https://doi.org/10.3390/en16083360