Abstract

The structure of large biomass circulating fluidized bed (BCFB) boilers is complex, and control schemes for coal-fired boilers cannot be simply applied to biomass boilers. Multivariable coupling and operational disturbances are also common issues. In this study, a state space model of a 130 t/h BCFB boiler was established under different operating conditions. Using the 100% operating point as an example, a model predictive controller was designed and tested under output disturbance and input disturbance conditions. The results show that the predictive control system designed in this study has a fast response speed and good stability.

1. Introduction

Currently, the use of green renewable energy for power generation has become a crucial concern worldwide due to the issue of environmental protection and the grand vision of achieving carbon peak and carbon neutrality [1]. Biomass resources, such as crop straw and forestry waste, have carbon neutrality during their life cycles [2]. It is anticipated that when advanced Carbon Capture, Utilization, and Storage (CCUS) technologies are combined [3,4,5], it will be possible to achieve negative carbon emissions at an economically feasible scale. Therefore, the development of biomass fuels for the production of the power industry has become an indispensable part of the technological path to achieve carbon neutrality. Developed European countries, including France, the United Kingdom, and Germany, have established distinct targets and strategies for reducing emissions from coal-fired power plants [6]. Their plans involve the gradual phase-out of coal-fired power generation, with the aim of complete elimination by 2022, 2025, and 2050, respectively. Instead, they plan to transition to biomass power plants. Recently, the International Renewable Energy Agency (IRENA) released data showing that the globally installed capacity of biomass has exceeded 120 GWe [7].

However, due to the variety of biomass species, the physicochemical properties vary widely. Biomass means that most alkali are released during combustion of biomass fuels, whereas in the case of coal at least the potassium tend to be bound in the ashes in the temperature range of circulating fluidized bed (CFB) combustion [8]. In addition, biomass fuel typically has a high moisture (20~50%) content with a large range of variation. As a result, directly burning biomass in coal-fired boilers often leads to issues such as poor combustion, high levels of pollutant emissions, and severe ash slagging, as noted in previous studies [9,10,11]. Currently, CFB boilers are extensively utilized to combust low-quality, substandard fuels. CFB boilers offer numerous benefits, including broad fuel adaptability, high combustion efficiency, easy temperature regulation of the furnace, and excellent load regulation performance [12]. In the current field of biomass power generation, circulating fluidized bed boilers are also one of the most widely used mainstream furnace types.

BCFB boilers are more complex in structure than ordinary boilers. Changes in biomass type and combustion rate can cause disturbances in CFB boiler combustion. The composition of the biomass, including calorific value and water content, can have an impact on the furnace combustion and ultimately affect the heat load, steam output, and fluidized bed temperature. Especially in the variable load operation of the unit, the conventional PI, PD, and other control methods will cause large fluctuations in the furnace pressure and steam pressure, which will affect the safe, stable, and economical operation of the unit. This is because the BCFB has characteristics of strong nonlinearity, large inertia, and is multivariable and time-varying. Moreover, the coupling between multiple input multiple output variables is stronger than that of traditional pulverized coal furnaces. The combustion process in the furnace of a BCFB boiler is complex, involving many scientific fields such as combustion, fluid mechanics, thermodynamics, and heat transfer [13,14,15]. It is an important basis for the design of high precision and high reliability combustion process automatic control systems to deeply understand and master the overall dynamic characteristics of high parameter and large capacity BCFB boiler combustion systems. There have been a lot of fruitful studies on the heat transfer, mass transfer, and combustion processes in the boiler by computational fluid dynamics. Therefore, the dynamic mathematical model of the furnace combustion system is obtained through data recognition or mechanism modeling. Through reasonable simplification, the control-oriented simple mathematical model is obtained. Based on this, designing the controller has become a common approach for designing complex industrial thermal control systems.

Compared with pulverized coal boilers of the same scale, the structure of BCFB boilers is mostly more complicated because it includes additional components such as cyclone separators and feeding devices. The combustion system has a notable time delay, which can create difficulties in precisely controlling critical parameters, such as bed temperature and pressure in a CFB boiler. Valsalam et al. [16] developed a state predictive controller using a Kalman filter to achieve accurate control of the main steam temperature and improve boiler efficiency. This controller was designed based on a comprehensive eighth order mathematical model. Zhu et al. [17] used multi-model predictive control for CFB bed temperature regulation, which solved the bed temperature control problem of CFBs in a wide operating range and obtained satisfactory control performance. Tomochika et al. [18] developed an energy recovery system for fluidized bed incinerators that utilizes a multivariable model predictive control (MPC). This system can maintain stable control of the generation rate, temperature, and pressure of superheated steam by adjusting the steam flow valve and primary air flow entering the energy recovery zone. Zlatkovikj et al. [19] developed a dynamic model of a biomass bubbling fluidized bed cogeneration power plant based on Dymola‘s mass and energy balance. The state space model of the object is obtained by system identification (SID), and the feedforward and predictive controller is designed. The superiority of feedforward model predictive control in parameter control has been demonstrated when compared to proportional integral, feedforward proportional integral, and model predictive control.

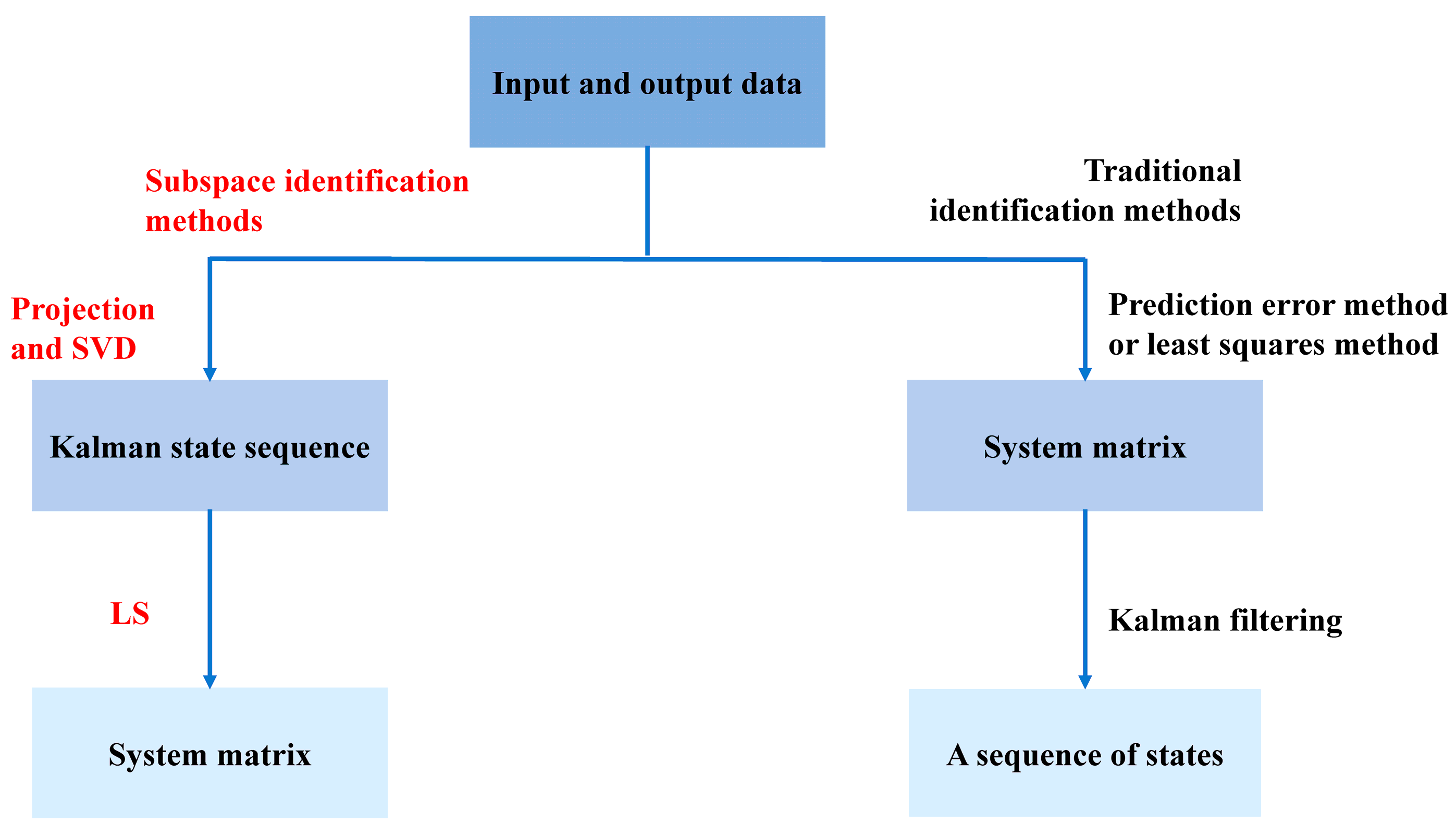

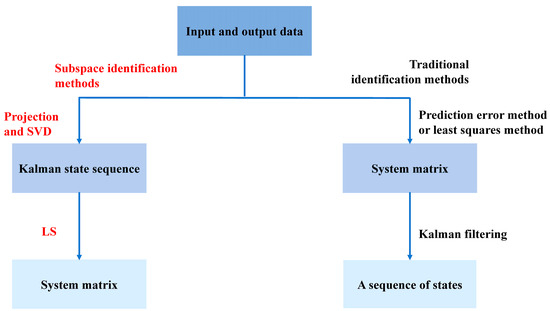

The precise model of the heat-work processing object is the key to designing and guaranteeing a controller, and it seems more important. With the ongoing advancements in control techniques, such as predictive control, there has been continuous development in the field of process control. Identification modeling has also transformed from simply pursuing accuracy, and towards higher targets suitable for controller design. Subspace identification [20,21,22,23], as a new state space model identification method, was proposed in the late 20th century. Since the state space model is suitable for the application of advanced control theory and the expression of advanced multivariable controller design, subspace identification has quickly attracted wide attention in the field of system identification and control. The difference between subspace identification and traditional identification is shown in Figure 1. SID extracts models from data Hankel matrices [24] using computational tools like QR decomposition and singular value decomposition (SVD) [25,26], and thus offers several advantages over traditional optimization-based methods [27,28]. These advantages include high computational efficiency, avoidance of local minimum and convergence problems, no requirement for initial conditions, and ease of selection for the system order.

Figure 1.

The difference between subspace identification methods and traditional identification methods.

Currently, the 130 t/h BCFB boiler is widely used in biomass power generation, but there is a lack of research on its dynamic characteristics, and the application of advanced control methods remains limited. Limited research has been conducted on the dynamic characteristics and control of thermal biomass plants, as noted in a review paper by Atsonios et al. [29]. However, Kortela and Jämsä-Jounela were able to develop an MPC system for a biomass CHP plant’s grate boiler, which was reported to achieve a shorter settling time compared to the traditional PI control [30]. Therefore, based on Modelica language and MWorks platform, a 130 t/h BCFB whole system mechanism model is established. The state space model of different load conditions of BCFB boiler combustion systems is obtained based on subspace identification method. On this basis, the MPC theory is used to design the predictive controller, and the effectiveness of the designed predictive controller is verified when the bed temperature and bed pressure requirements change. The research in this paper has important guiding significance for improving the actual industrial operation level of BCFB boilers. On this basis, the MPC theoretical design predictor controller is adopted, and the effectiveness of the predictive controller is designed when the bed temperature and bed pressure requirements are changed. The relevant research in this work has certain guiding significance for improving the industrial operation level of BCFB boilers.

2. Controlled Object and Raw Material

2.1. Boiler Physical Object

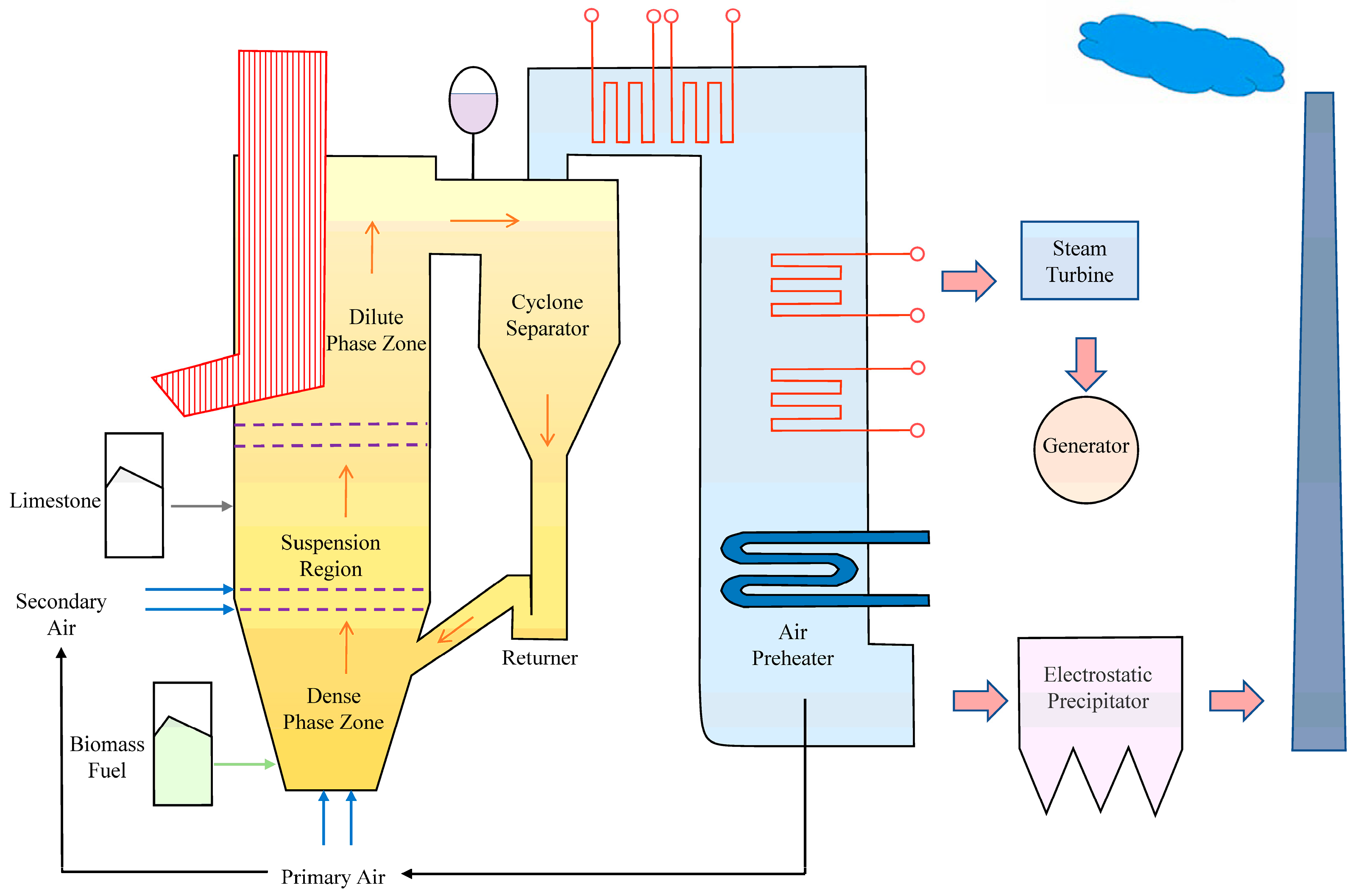

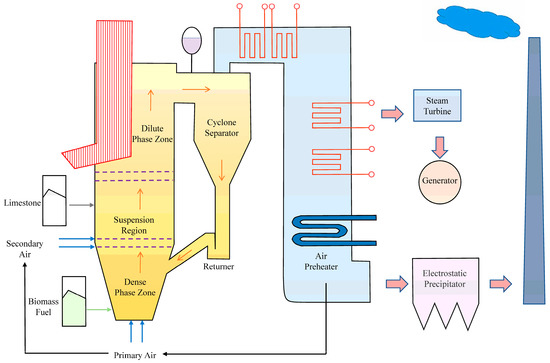

The research boiler is a 130 t/h biomass direct combustion circulating fluidized bed boiler produced by a boiler company in Jinan. The main design and operating parameters are shown in Table 1. The main layout is shown in Figure 2. The combustion system of a BCFB boiler comprises a combustion chamber, which includes dense phase, dilute phase, and suspension zones, as well as a circulation circuit, which includes a high-temperature gas-solid separator and a return material system. The primary air and secondary air required for the combustion of a CFB boiler are fed from the bottom and side wall of the furnace, respectively. The combustion of fuel is mainly completed in the furnace, and the water wall is arranged around the furnace to absorb part of the heat generated by combustion. The solid materials brought out of the furnace by the air flow are collected in the gas-solid separation device and sent back to the furnace through the return device. The boiler has a rated evaporation capacity of 130 t/h and a maximum continuous rating of 143 t/h, with a rated steam pressure of 9.2 MPa and a rated steam temperature of 540 °C. Its thermal efficiency is 90.3%. It is also equipped with a 30 MW high-temperature and high-pressure extraction-condensing turbine generator set.

Table 1.

BCFB Boiler design and operation parameters.

Figure 2.

Schematic diagram of 130 t/h BCFB boiler structure.

2.2. Boiler Physical Object

The main fuel used in the power plant comes from the debris generated by the production of furniture and the surrounding crop straw. The blended fuel includes 40% bark, 30% sawdust, 20% wood, 5% wheat straw, and 5% corn straw. It is worth noting that compared to coal, solid biomass fuels provided to power plants exhibit significant characteristics, such as high oxygen content and high volatile matter, as well as low carbon content and low ash content [31].

2.3. BCFB Boiler Combustion System Model Based on Mworks

Our research group established a dynamic model of a 130 t/h BCFB boiler combustion system through MWorks [32]. The model proposed in this study is composed of different modules, namely the input module (for feeding biomass fuel, primary air, and secondary air), combustion chamber module (including the dense phase zone, suspended phase zone, and dilute phase zone), cyclone separator module, and loop seal module. A series of characteristic tests of relevant parameters (the biomass feed rate, limestone amount, excess air co-efficient, and different ratios of primary air and secondary air) on the operation of biomass circulating fluidized bed were carried out, and the influence of different input operating conditions on the biomass circulating fluidized bed boiler was obtained. The ratio of primary air to secondary air had a considerable impact on the composition of the flue gas [33]. Additionally, during the normal operation of the boiler, the bed pressure should be controlled between 5000 and 7000 Pa. Excessive bed pressure may bring a good load to the boiler, but it will aggravate the change of the furnace bed temperature and the wear of the inertia return chamber, which is not conducive to safe operation. Therefore, bed pressure is also a very important variable in boiler control.

The simulated results of the model were compared with actual measured values and the relative errors for bed temperature, flue gas oxygen content, and bed pressure were found to be 6.99%, 3.80%, and 2.92%, respectively. It shows that the established 130 t/h BCFB boiler combustion system model has high reliability and can be used as a platform for dynamic characteristic analysis of the system and controller performance test.

3. Results and Discussion

3.1. Subspace Identification Principle and Combustion System Subspace Model

3.1.1. Subspace Identification Algorithm

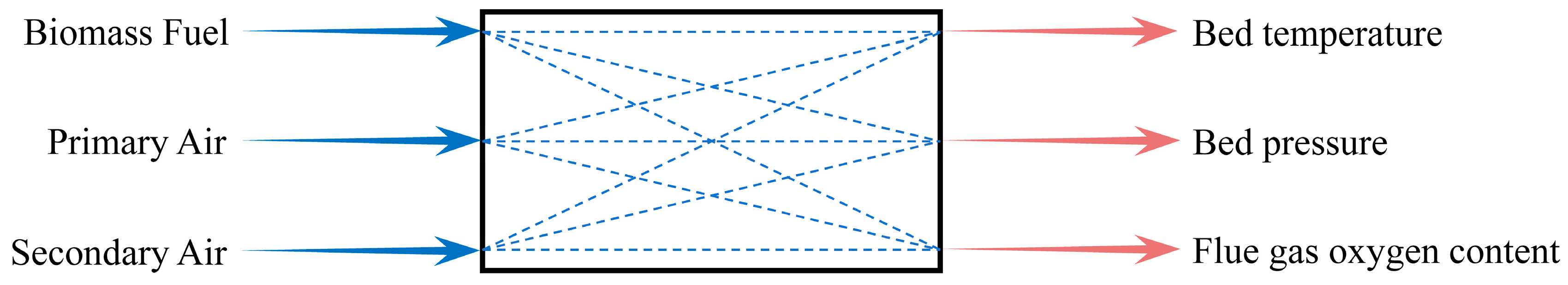

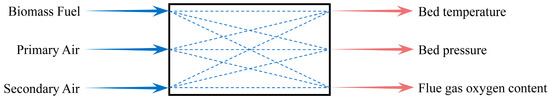

The BCFB boiler combustion system can be simplified to a three-input three-output physical model (as shown in Figure 3). It is common to use bed temperature, bed pressure, and oxygen content of flue gas as control parameters for furnace combustion processes. These parameters can be manipulated to maintain optimal combustion efficiency and minimize emissions. Proper control of bed temperature can prevent excessive temperature fluctuations and ensure stable combustion. Control of bed pressure is important to prevent bed defluidization and ensure adequate air supply for combustion. Oxygen content of flue gas is an indicator of the combustion efficiency and can be used to optimize the fuel-to-air ratio for optimal combustion. According to the control task, the three physical quantities mainly adjusted, include fuel valve opening, primary air and secondary air valve opening.

Figure 3.

Structure diagram of combustion SID model.

3.1.2. Subspace Identification Test of Combustion System

The input signal used for SID plays a crucial role in determining the accuracy of the identified model parameters. A well-designed input signal can provide enough information for the identification algorithm to accurately estimate the model parameters, while a poorly designed input signal may lead to inaccurate or unreliable results. The selection of the identification input signal is a crucial factor in achieving accurate identification results when using SID methods to establish mathematical models for systems [34]. While white noise may result in better identification results, it is often not practical or feasible to use in engineering applications as it is a theoretical concept and difficult to implement in practice. M sequence and inverse M sequence have the advantages of approximate periodic white noise, simple structure, and easy implementation. They are often used as input excitation signals for modal analysis and SID in control engineering, vibration engineering, and other research fields [35]. Using it as the identification input signal is a practical and effective approach that can achieve high identification accuracy and is easily implemented in engineering.

The discrete time identification state space model of BCFB boiler combustion system is expressed by Equation (1):

where: x is state vector, Ts is sampling time, u is input vector, e is disturbance vector, y is output vector, and A, B, C, D and K are state space matrices.

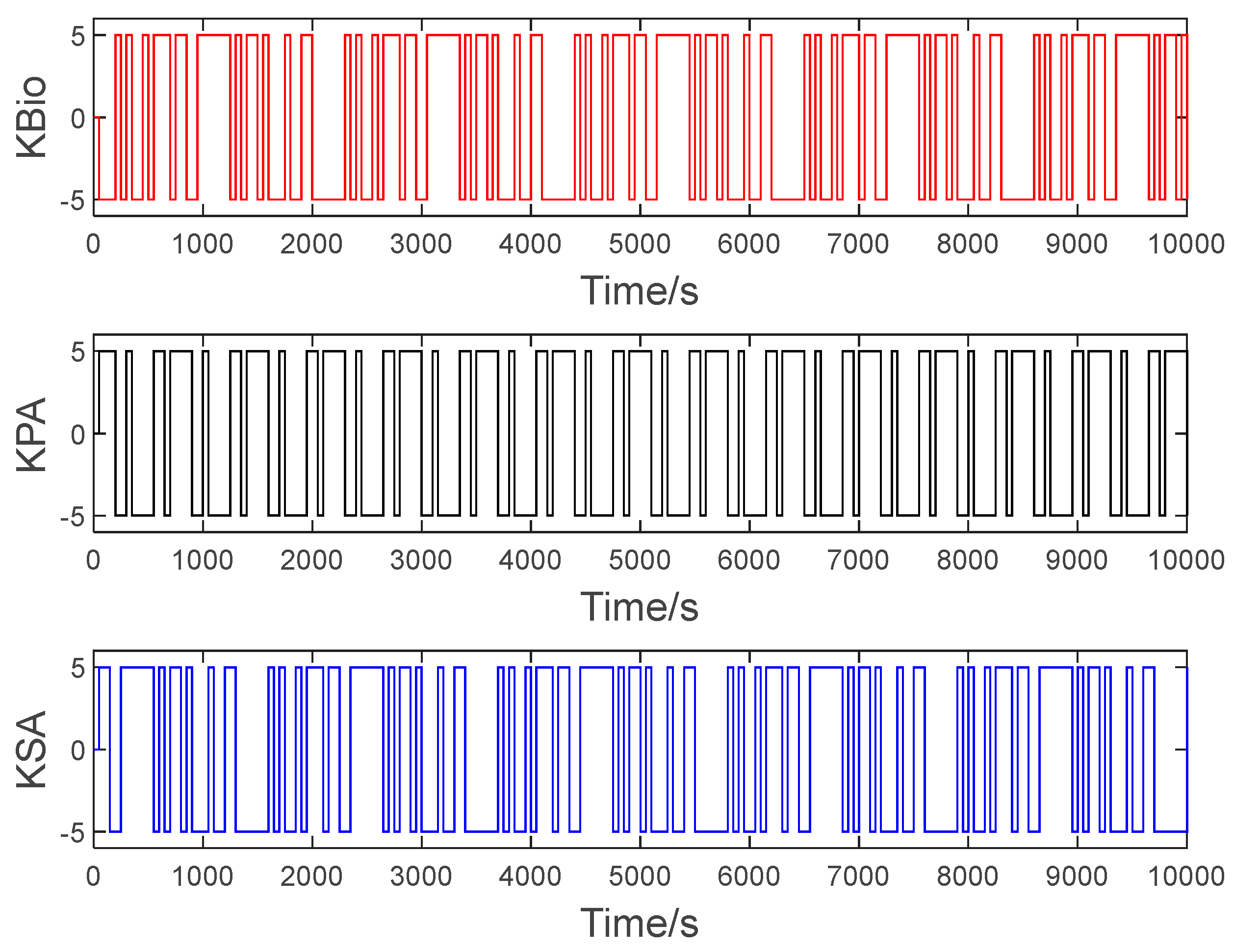

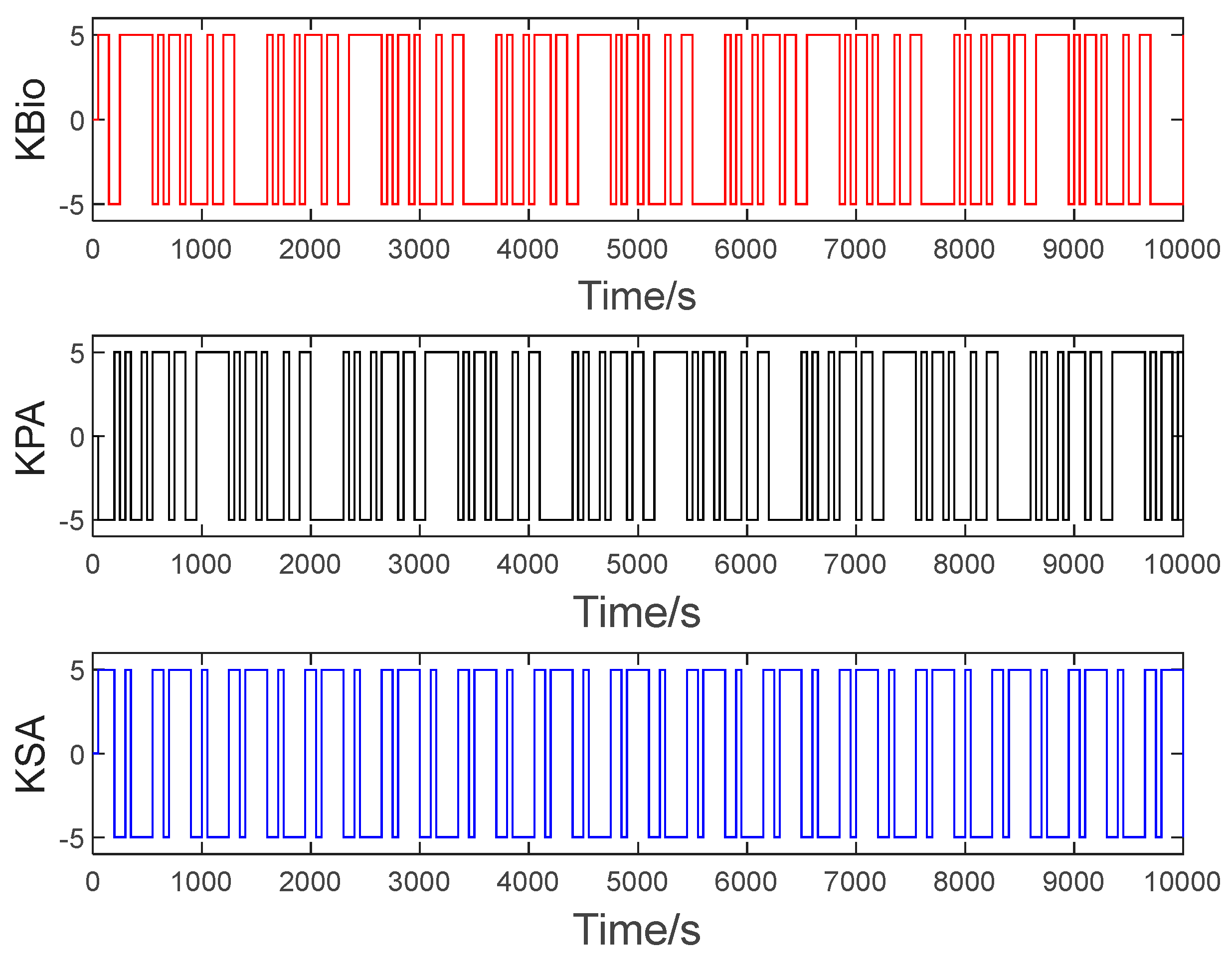

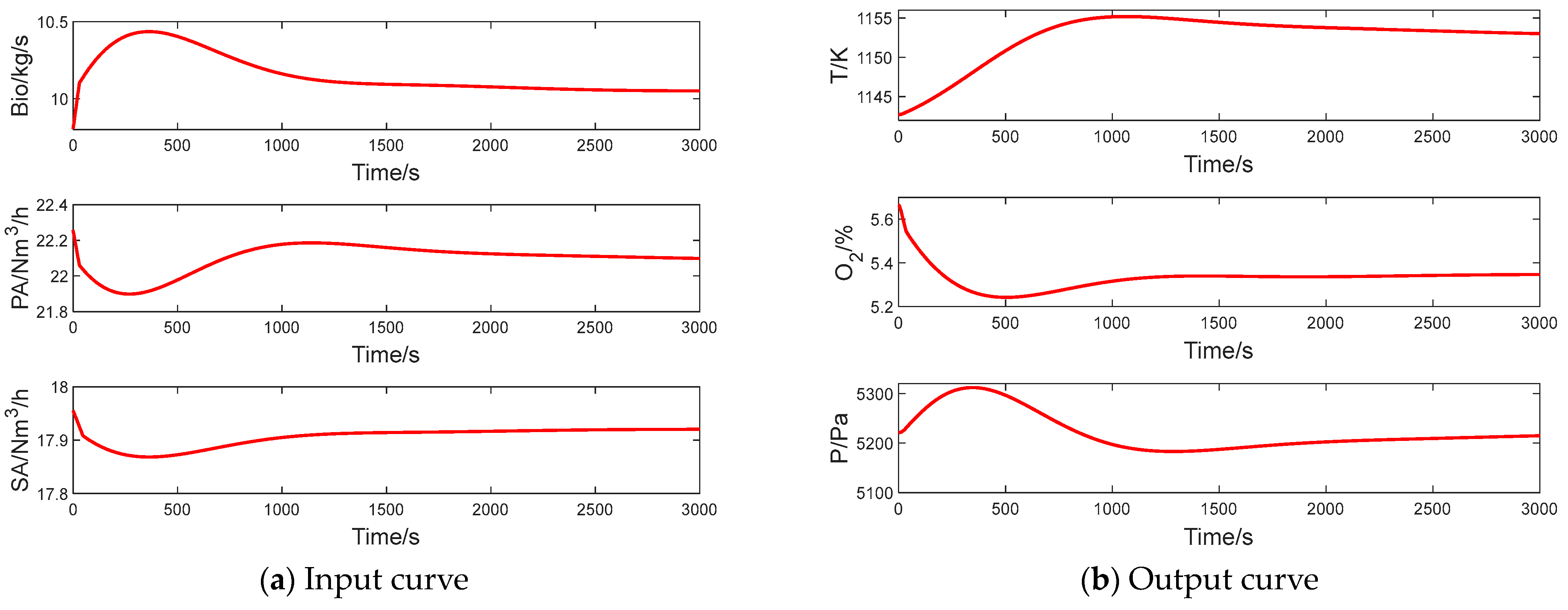

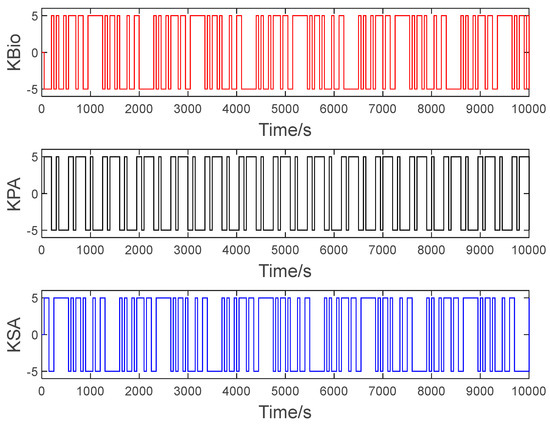

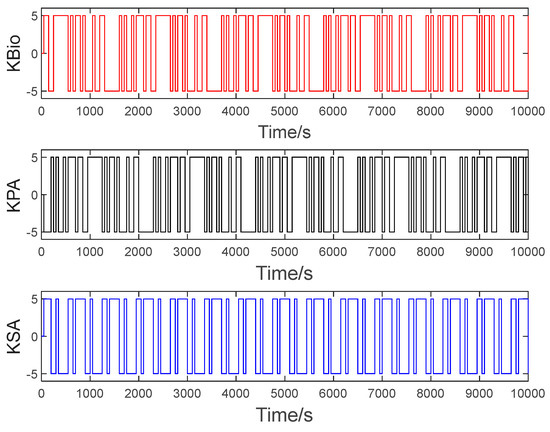

The subspace identification method is utilized to obtain the linear state space model, which is subsequently employed as an internal model in the design of MPC. In order to ensure high-quality model identification, it is crucial for the identified model to accurately capture the process dynamics and fit well with the output data. The N4SID subspace identification method [36] was used to identify the combustion system of a 130 t/h BCFB boiler at operating points near 100%, 90%, 80%, and 70%, resulting in a local state space model for each operating point. The model inputs in this case are the fuel valve opening (KBio), primary air valve opening (KPA), and secondary air valve opening (KSA), while the model outputs are the bed temperature in the furnace (T), oxygen content in the flue gas at the furnace outlet (O2), and the bed pressure difference in the furnace (P). In order to obtain sufficient identification input and output data, a set of inverse M sequences are designed for the BCFB boiler at the above operating points as identification excitation signals (Figure 4).

Figure 4.

Inverse M sequence excitation signal.

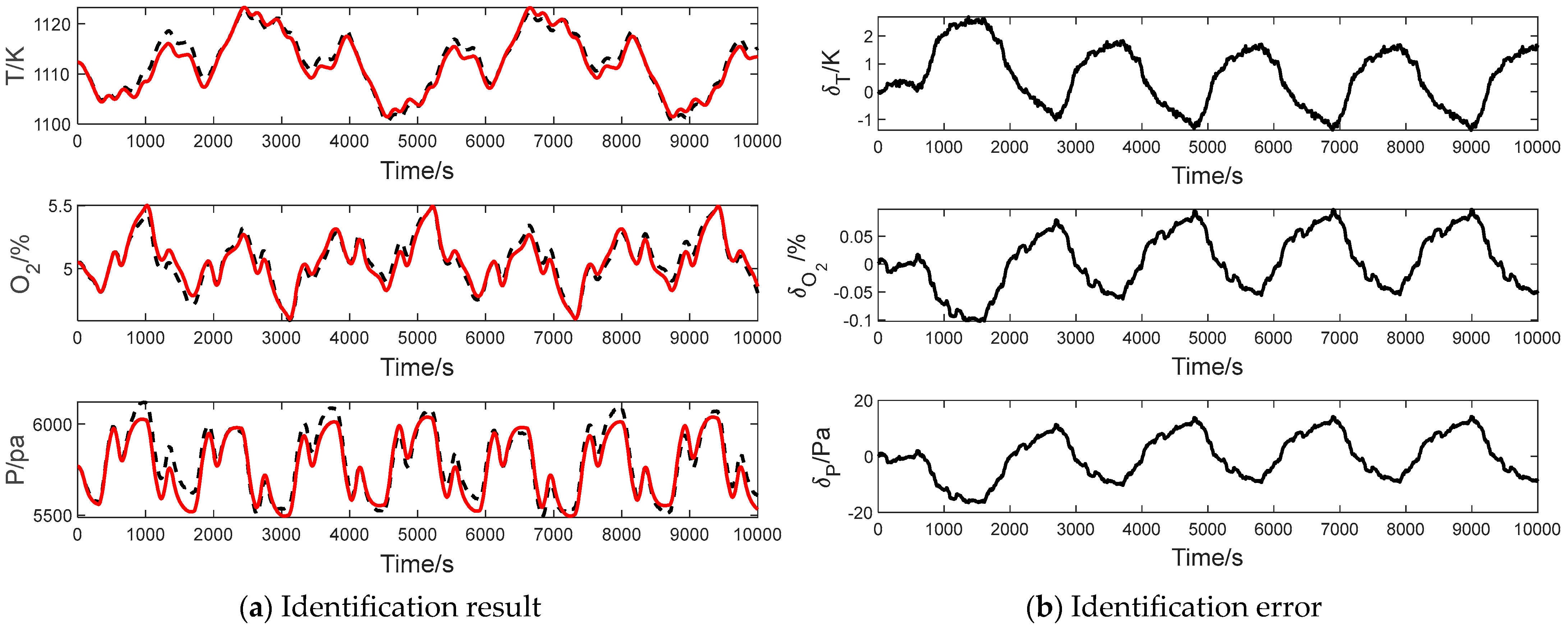

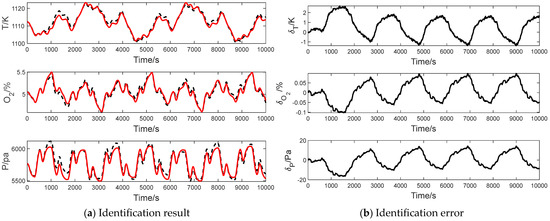

Because the BCFB boiler is a complex system with large delay and large time delay, the inverse M sequence time interval is 100 s for the full excitation model. Under 100% load condition, u0 = (100, 100, 100), y0 = (1112.3236, 5.0477, 5767.3460). In total, 1000 sets of input and output data were collected, and the sampling time was Ts = 10 s. Using the subspace identification method, the identification error curve of the model and the object is shown in Figure 5.

Figure 5.

Identification results and identification error (In (a), the black dotted curve represents the actual output of the system, while the red full curve represents the output of the identified model).

The subspace identification method (N4SID) was used to identify the combustion system of the 130 t/h BCFB boiler at different operating points. The identified model accurately predicted the bed temperature and bed pressure difference outputs as shown in Figure 5a. However, the identified model deviated from the actual output of the system, as shown by the error plot in Figure 5b. Nevertheless, the identified model can effectively control the difference between the output of the identified model and the actual object output. The error of bed temperature was controlled at ±4 K, the oxygen content of flue gas at the furnace outlet was controlled at ±0.2 Vol%, and the bed pressure difference was controlled at ±40 Pa.

Under 100% operating conditions, the order of the state space model of the system is four. The identified system model is as follows:

In the formula

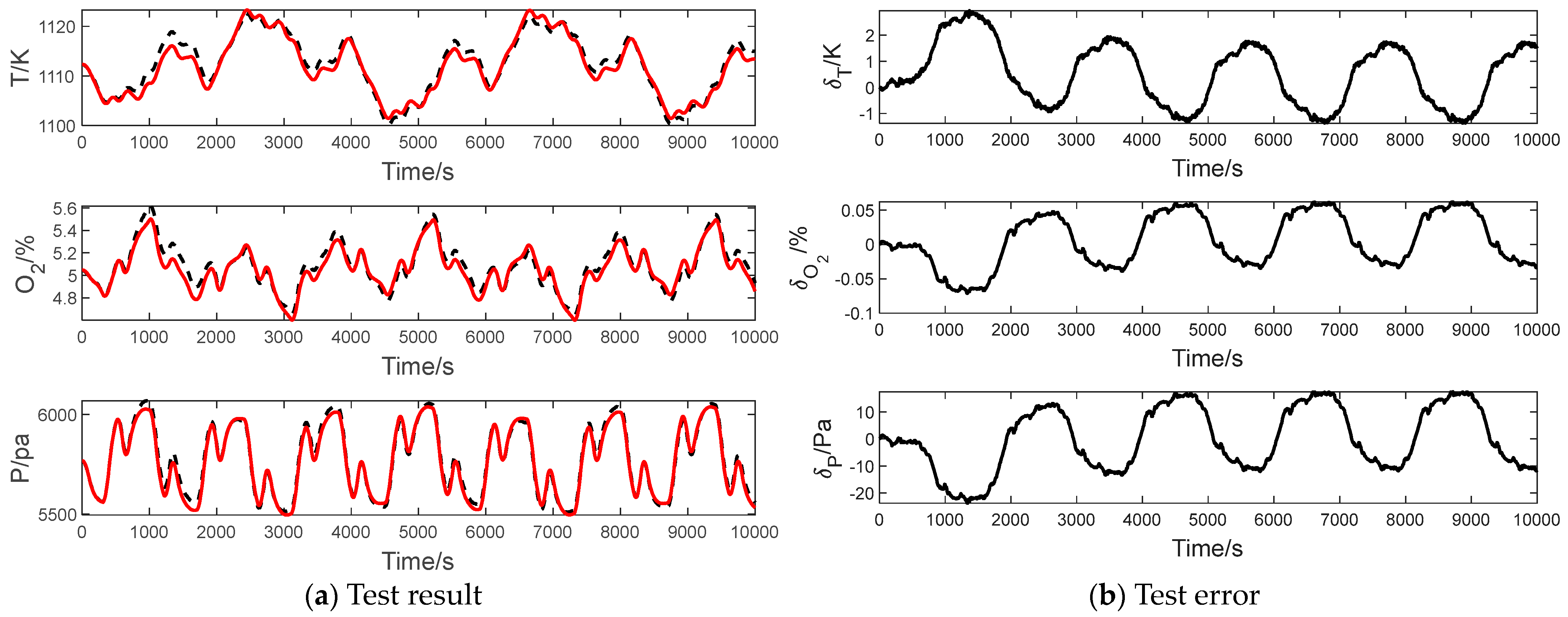

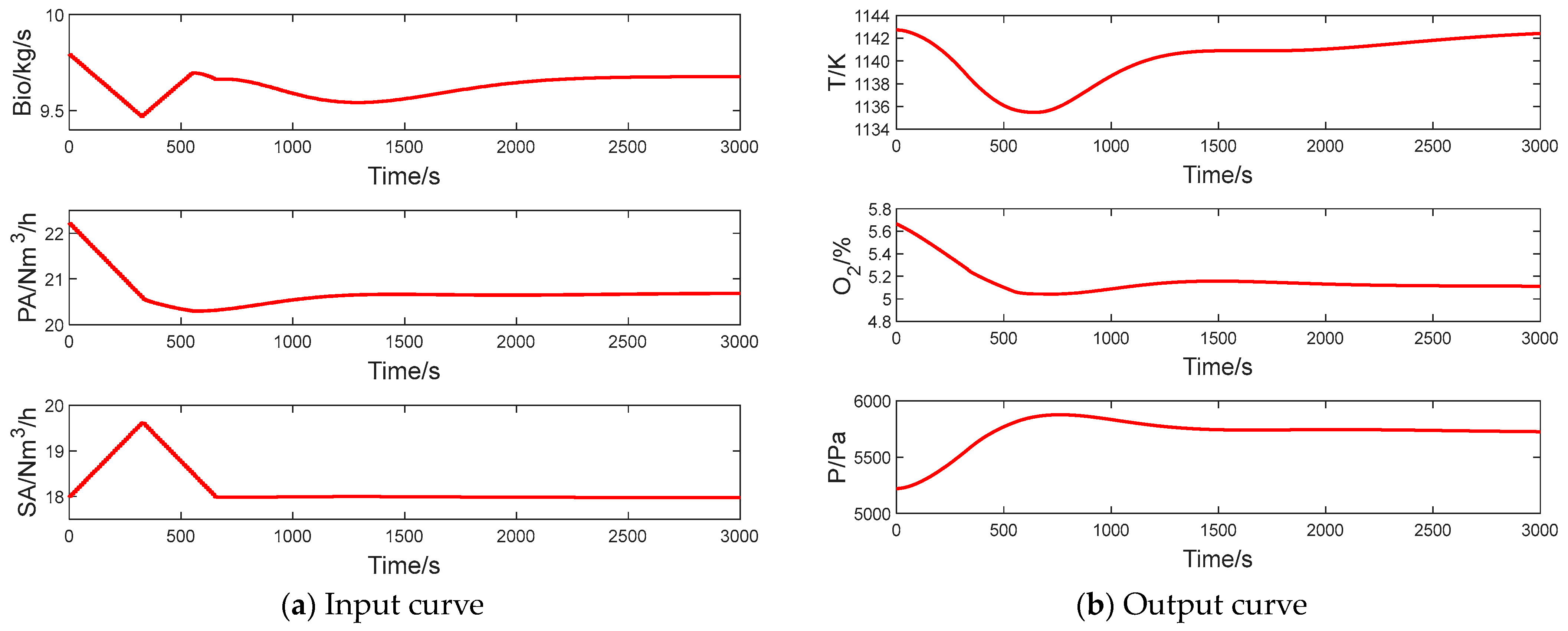

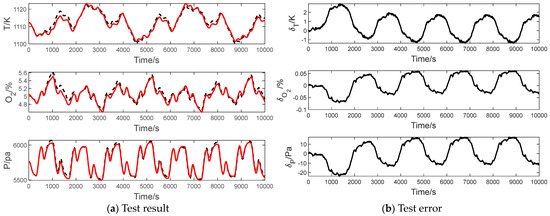

The purpose of using another set of inverse M sequences as the input signal, as shown in Figure 6, is to further evaluate the accuracy of the identified model by comparing the output results of the object and the state space model. Results are presented in Figure 7, which shows the test results (a) and the error between the model output and the actual output of the object (b). The results of the test depicted in Figure 7a show that the bed temperature, bed pressure difference, and flue gas oxygen content at the furnace outlet can be well identified using this set of data. However, in Figure 7, the test error for bed pressure difference is larger than that in Figure 4, where it was mostly controlled within ±40 Pa. Combined with the boiler furnace whose pressure difference can reach more than 5000 Pa, this deviation range can be accepted. This indicates that the identified model can still maintain good identification accuracy and provide a basis for subsequent controller design.

Figure 6.

Inverse M sequence test signal.

Figure 7.

Identification results and identification error under test conditions (In (a), the black dotted curve represents the actual output of the system, while the red full curve represents the output of the identified model).

Repeat the above method under the load conditions of 90%, 80% and 70%, and the biomass fuel flow, primary and secondary air, and related model parameters of the BCFB established according to the load adjustment are determined. The inverse M sequence is used to stimulate the model, and the input and output data are collected to further identify the state space model of the BCFB boiler furnace object under 90%, 80% and 70% load operation.

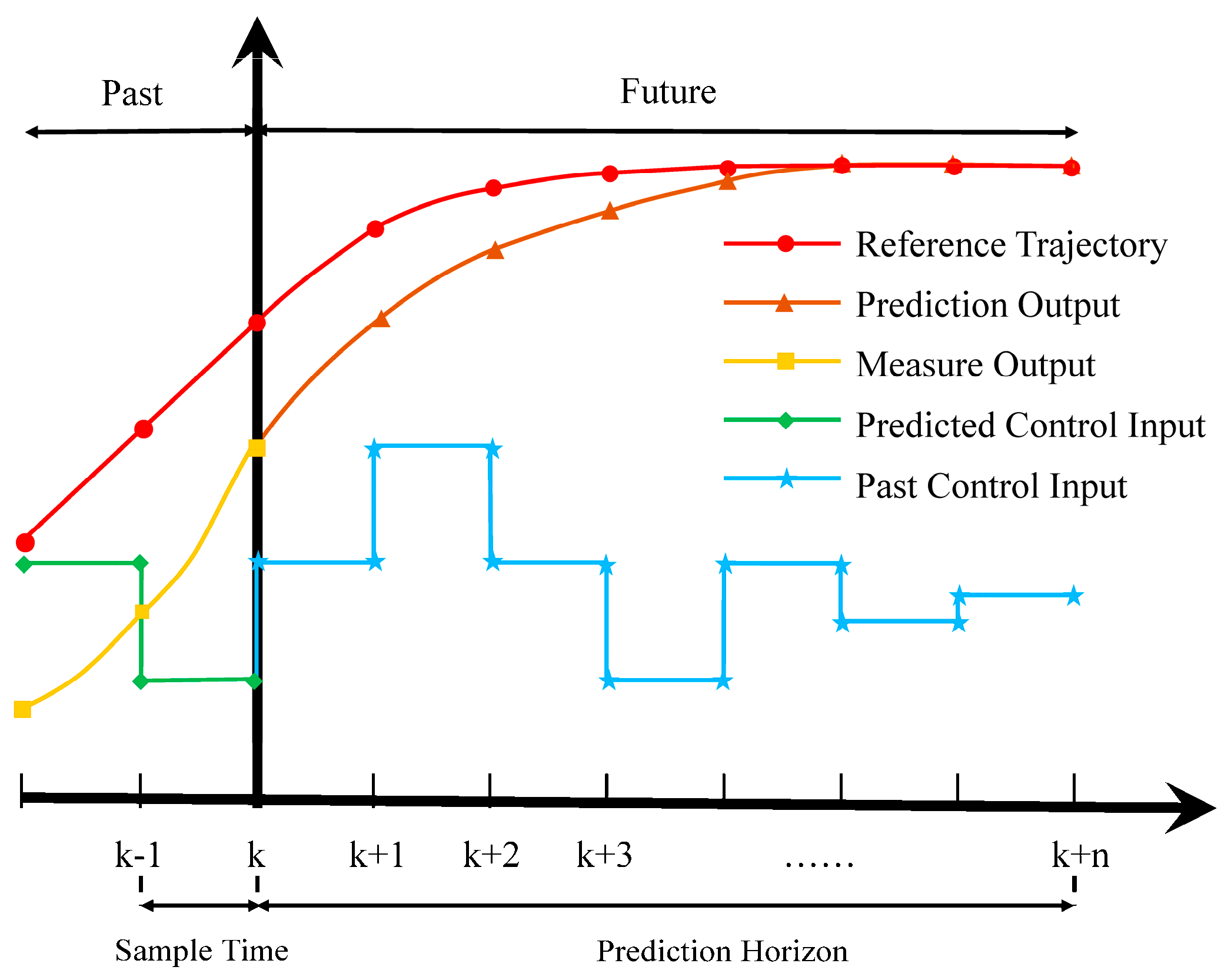

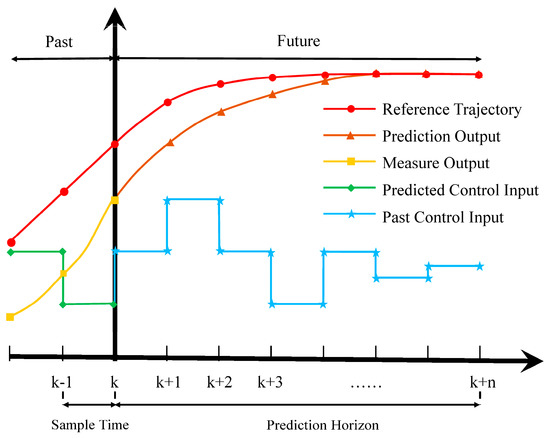

3.2. MPC of BCFB Boiler Combustion System

Since the multi-model system obtained by subspace identification has a state-space form, it is suitable for the design of various advanced controllers. The MPC method is chosen in this paper to achieve control performance and impose constraints on input variables, in order to ensure stable operation of the BCFB combustion system. Moreover, the effectiveness of the MPC controller is verified by different parameter perturbations. There are many forms of MPC control algorithm, and the technical details are also very different. However, no matter which form is used, all kinds of MPC technologies have some common points. The common features include prediction model, rolling optimization and feedback correction. The main process is shown in Figure 8 [37]. The MPC designed by the MPC Designer toolbox in MATLAB is based on the nonlinear model identified from the system identification process. It has a three-input three-output structure and three controllable variables. In order to verify the optimization performance of the MPC algorithm, the 100% working condition is taken as an example for simulation, and the obtained state space model is used to design the MPC controller. Under the premise of considering the actual situation of the model and balancing the calculation and performance of the controller, the following parameters are set for the MPC: sampling time Ts = 1 s, prediction time domain Ny = 10, control time domain Nu = 1. Due to the physical characteristics of the valve, the input amplitude and rate constraints are given as follows:

where refers to the fuel valve opening, refers to the primary air valve opening, refers to the secondary air valve opening. refers to the change rate of fuel valve, refers to the change rate of primary air valve, and refers to the change rate of secondary air valve.

Figure 8.

MPC process.

3.2.1. Control System Simulation under Given Value Disturbance

The set values of bed temperature and pressure are not fixed and should be determined based on the established boiler load conditions to maintain normal operation. However, when changing the type or moisture content of biomass fuel, frequent adjustments are required to meet unit load and operating parameters, which may result in combustion instability and large fluctuations in bed temperature and pressure, posing a safety risk to the unit. Therefore, appropriate values for bed temperature and pressure are crucial for achieving efficient combustion and combustion quality. The values of bed temperature and pressure vary depending on the boiler load, ash particle size, fuel quality, and particle size of the crushed fuel. In a circulating fluidized bed combustion process, there exists a complex interaction and coupling relationship between input and output variables. For example, fuel supply and air flow rate can affect output variables such as bed temperature, bed pressure difference, and flue gas oxygen content, while bed temperature and pressure difference can, in turn, affect the fuel supply and air flow rate, forming an interactive and dynamic system. Therefore, it is necessary to comprehensively consider the impact of various input variables on output variables to ensure stable operation and efficient combustion of a circulating fluidized bed. In response to changes in key factors, such as bed temperature and pressure set values, the controller needs to make corresponding parameter adjustments accurately and in a timely manner.

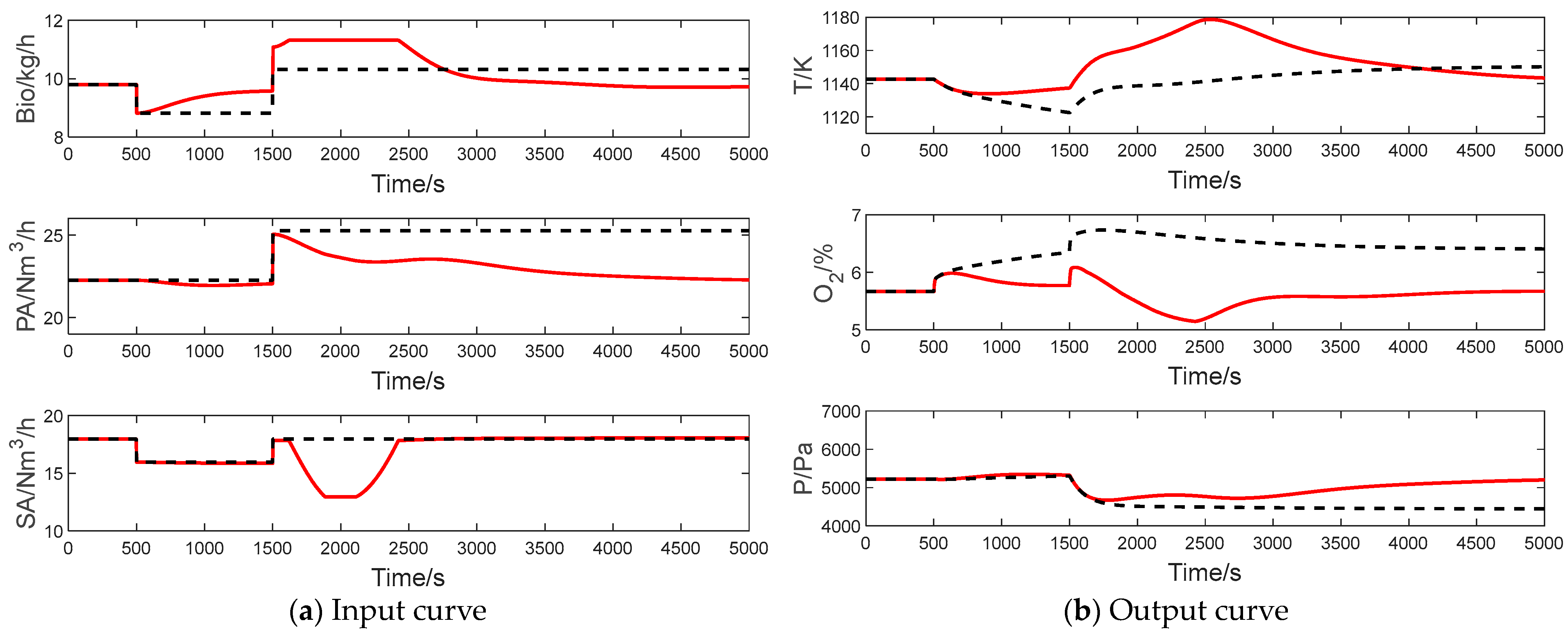

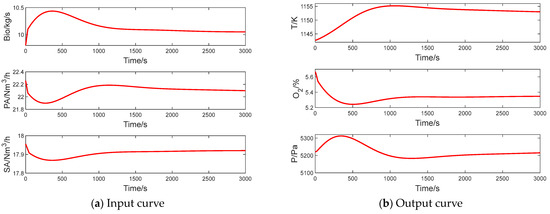

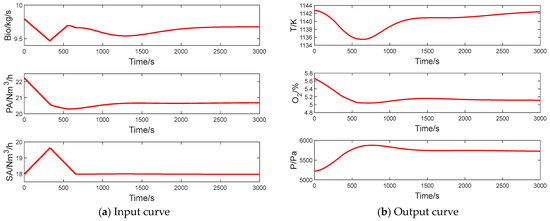

Figure 9 is the simulation curve when the bed temperature is increased by 10 K. Under the action of the control system, the amount of fuel, primary air, and secondary air act rapidly, and the bed temperature can respond quickly. The bed temperature curve rises to a given value in about 700 s and then slightly overshoots, slowly decreases in about 1000 s, and stabilizes in about 2500 s. The variation range of bed pressure is about 300 Pa. Due to the thermal inertia of the bed, the response time will be longer than that of pulverized coal boilers [38]. It can be seen from the input curve under the action of the controller that it is mainly achieved by increasing the amount of fuel. Firstly, the bed temperature is rapidly increased to the target by increasing the biomass fuel and reducing the primary and secondary air. Once the bed temperature reaches the desired level, the controller produces the opposite response, but the primary and secondary air are reduced compared to their initial values for the input fuel. Due to the change of input, the bed pressure and oxygen content of flue gas changed slightly. The oxygen content of flue gas decreased by 0.3 Vol%, and the bed pressure decreased by 13 Pa. It can be seen from the input and output curves that it is mainly achieved by less primary wind. Firstly, the bed pressure can be increased rapidly by reducing the amount of fuel and primary air, and increasing secondary air. When it is stable, the biomass fuel and primary air are reduced compared to the initial amounts, and the secondary air is basically unchanged. Figure 10 shows the input and output response curves of the system when the given value of bed pressure increases by 500 Pa. The results indicate that the disturbance system can quickly respond to changes in the set value of bed pressure, with a response time of approximately 1500 s. However, the change in bed temperature is significantly different, with a difference of around 8 K.

Figure 9.

The given value of bed temperature increases 10 K input and output response. (In the figure, Bio is the biomass fuel, PA is the primary air, and SA is the secondary air; T is the bed temperature in the furnace, is furnace outlet flue gas oxygen content, P is the bed pressure difference in the furnace).

Figure 10.

Bed pressure given value rise 500 Pa input and output response (In the figure, Bio is the biomass fuel, PA is the primary air, and SA is the secondary air; T is the bed temperature in the furnace, is furnace outlet flue gas oxygen content, P is the bed pressure difference in the furnace).

3.2.2. The Influence of Key Disturbances on Controller Characteristics

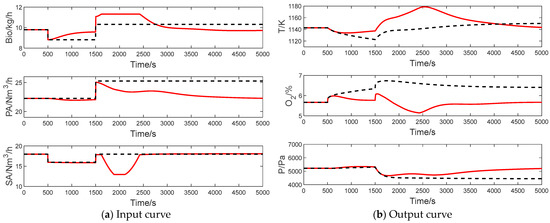

Different disturbances such as changes in fuel quality, fluctuations in the air supply, or changes in the load demand can all have an impact on the operation of the boiler. The control quantity in the control system may fluctuate due to some factors, resulting in interference. The emergence of interference will interfere with the role of the controller, reduce the performance of the controller, and have a greater impact on the stability of the control system. Affected by many factors such as equipment and environment, the input will change constantly, so it is of great significance to study the controller to deal with multiple interference scenarios to simulate and deal with practical problems. As shown in Figure 11, it is assumed that the biomass fuel is reduced by 10% and then increased by 17%. The primary wind decreases by 9% and then increases by 15%. The secondary air increased by 9% and then decreased by 9%. In the face of complex input fluctuations, the goal of the controller is to keep all outputs stable. According to the output curve, the controller should take measures to reduce the heat in the system and increase the bed pressure. All outputs are basically stable at about 4000 s.

Figure 11.

Perturbation response to controller input and output. Bio is the biomass fuel, PA is the primary air, and SA is the secondary air; t is the bed temperature in the furnace, is furnace outlet flue gas oxygen content, P is the bed pressure difference in the furnace; the red full line represents the curve under the action of the controller, and the black dotted line represents the role of no controller).

4. Conclusions

During the operation of biomass circulating fluidized bed boilers, various disturbances can affect the system performance. Due to the characteristics of multiple variables, strong coupling, and long response time, the combustion system itself is challenging to control using conventional coal-fired boiler controllers. This study aims to investigate the impact of biomass fuel, primary and secondary air flow rates on bed temperature, bed pressure, and flue gas oxygen content in a BCFB boiler combustion system. To simplify the system according to actual operational requirements, the subspace identification algorithm is applied to develop a three-input three-output model, and the state space model is obtained for different operating conditions. The model output is verified and shows good agreement with the actual data. A predictive controller is designed for 100% operating conditions, and its performance is evaluated under step and disturbance conditions. The results demonstrate that MPC is suitable for this system and has excellent steady-state performance.

Author Contributions

Research methodology, H.W. and S.L.; writing—original draft preparation, H.W. and J.H.; writing—review and editing, Y.L. and G.Z.; visualization, H.W., S.L. and J.H. All authors have read and agreed to the published version of the manuscript.

Funding

The research was sponsored by National Natural Science Foundation of China (No. 51606113), National Key Research and Development Program of China (No. 2019YFD1100602), SDUT and Zhangdian City Integration Development Project (No. 2021JSCG0013).

Data Availability Statement

Not applicable.

Acknowledgments

Authors’ gratitude is extended to the prospective editor and reviewers that have spared time to guide toward a successful publication.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| BCFB | Biomass circulating fluidized bed |

| CCUS | Carbon Capture, Utilization, and Storage |

| IRENA | International Renewable Energy Agency |

| CFB | Circulating fluidized bed |

| PI | Proportion Integral |

| PD | Proportion Differential |

| MPC | Model predictive control |

| SID | System identification |

| SVD | Singular value decomposition |

| LS | Least square |

| BMCR | Boiler maximum continuous rate |

| KBio | Biomass fuel valve opening |

| KPA | Primary air valve opening |

| KSA | Secondary air valve opening |

| T | Bed temperature in the furnace |

| O2 | Oxygen content in the flue gas |

| P | Bed pressure difference in the furnace |

| Bed pressure difference error | |

| Oxygen content in the flue gas error | |

| Bed temperature error | |

| Ts | Sampling time |

| Ny | Prediction time domain |

| Nu | Control time domain |

| Fuel valve opening, | |

| Primary air valve opening, | |

| Secondary air valve opening. | |

| Change rate of fuel valve, | |

| Change rate of primary air valve, and | |

| Change rate of secondary air valve. | |

| Bio | Biomass fuel flow |

| PA | Primary air flow |

| SA | Secondary air flow |

References

- He, J.; Liu, S.; Yao, D.; Kong, R.; Liu, Y. Influence of fuel type and water content variation on pollutant emission characteristics of a biomass circulating fluidized bed boiler. Energies 2021, 14, 5962. [Google Scholar] [CrossRef]

- Niu, Y.; Tan, H. Ash-related issues during biomass combustion: Alkali-induced slagging, silicate melt-induced slagging (ash fusion), agglomeration, corrosion, ash utilization, and related countermeasures. Prog. Energy Combust. Sci. 2016, 52, 1–61. [Google Scholar] [CrossRef]

- Bi, D.; Huang, F.; Jiang, M.; He, Z.; Lin, X. Effect of pyrolysis conditions on environmentally persistent free radicals (EPFRs) in biochar from co-pyrolysis of urea and cellulose. Sci. Total Environ. 2022, 805, 150339. [Google Scholar] [CrossRef] [PubMed]

- Vassilev, S.V.; Vassileva, C.G.; Vassilev, V.S. Advantages and disadvantages of composition and properties of biomass in comparison with coal: An overview. Fuel 2015, 158, 330–350. [Google Scholar] [CrossRef]

- Zhao, A.; Liu, S.; Yao, J.; Huang, F.; He, Z.; Liu, J. Characteristics of bio-oil and biochar from cotton stalk pyrolysis: Effects of torrefaction temperature and duration in an ammonia environment. Bioresour. Technol. 2022, 343, 126145. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, Z.; Xu, G.; Ren, J.; Wang, H.; Li, J. Sustainability assessment of straw direct combustion power generation in China: From the environmental and economic perspectives of straw substitute to coal. J. Clean. Prod. 2020, 273, 122890. [Google Scholar] [CrossRef]

- Guo, H.; Cui, J.; Li, J. Biomass power generation in China: Status, policies and recommendations. Energy Rep. 2022, 8, 687–696. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, Z.; Liu, Q.; Li, J.; He, J.; He, N.; Liao, Z. Design of Biomass-fired Circulating Fluidized Bed Boiler. Gas Heat 2014, 34, 6–8. [Google Scholar]

- Deng, M.; Nie, Y.; Yuan, Y.; Ma, R.; Shan, M.; Yang, X. The impact of oxygen content in the primary air supply on fuel burning rate and pollutant emissions in a forced-draft biomass stove. Fuel 2022, 321, 124129. [Google Scholar] [CrossRef]

- Wang, S.; Feng, H.; Zou, B.; Yang, Z.; Ding, Y. Correlation between biomass burning and air pollution in China: Spatial heterogeneity and corresponding factors. Glob. Planet. Change 2022, 213, 103823. [Google Scholar] [CrossRef]

- Wu, J.; Kong, S.; Yan, Y.; Yao, L.; Yan, Q.; Liu, D.; Shen, G.; Zhang, X.; Qi, S. Neglected biomass burning emissions of air pollutants in China-views from the corncob burning test, emission estimation, and simulations. Atmos. Environ. 2022, 278, 119082. [Google Scholar] [CrossRef]

- Kong, R.; Bi, D.; Yao, D.; Zhang, Y.; He, J.; Liu, J. CFD-DEM study of a V-shaped Down-tube pyrolysis Reactor: Flow and heat transfer between heat carrier and biomass. Appl. Therm. Eng. 2022, 207, 118179. [Google Scholar] [CrossRef]

- Di Renzo, A.; Napolitano, E.S.; Di Maio, F.P. Coarse-grain dem modelling in fluidized bed simulation: A review. Processes 2021, 9, 279. [Google Scholar] [CrossRef]

- Huttunen, M.; Peltola, J.; Kallio, S.; Karvonen, L.; Niemi, T.; Ylä-Outinen, V. Analysis of the processes in fluidized bed boiler furnaces during load changes. Energy Procedia 2017, 120, 580–587. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, S.; Shen, Y. CFD-DEM modelling of the migration of fines in suspension flow through a solid packed bed. Chem. Eng. Sci. 2021, 231, 116261. [Google Scholar] [CrossRef]

- Valsalam, S.R.; Anish, S.; Singh, B.R. Boiler modelling and optimal control of steam temperature in power plants. IFAC Proc. Vol. 2009, 42, 125–130. [Google Scholar] [CrossRef]

- Zhu, H.; Shen, J.; Lee, K.Y.; Sun, L. Multi-model based predictive sliding mode control for bed temperature regulation in circulating fluidized bed boiler. Control Eng. Pract. 2020, 101, 104484. [Google Scholar] [CrossRef]

- Tomochika, N.; Maeda, T.; Nakayama, M.; Kitamura, A.; Shiraishi, Y. Combustion Control for Energy Recovery Furnace Using Model Predictive Control. IFAC Proc. Vol. 2001, 34, 409–414. [Google Scholar] [CrossRef]

- Zlatkovikj, M.; Li, H.; Zaccaria, V.; Aslanidou, I. Development of feed-forward model predictive control for applications in biomass bubbling fluidized bed boilers. J. Process Control 2022, 115, 167–180. [Google Scholar] [CrossRef]

- Zhen, J.; Liu, X.-J. Constrained Power Plant Coordinated Predictive Control Using Neurofuzzy Model1. ACTA Autom. Sin. 2006, 32, 785–790. [Google Scholar]

- Liu, X.; Guan, P.; Chan, C. Nonlinear multivariable power plant coordinate control by constrained predictive scheme. IEEE Trans. Control Syst. Technol. 2009, 18, 1116–1125. [Google Scholar] [CrossRef]

- Patel, N.; Corbett, B.; Mhaskar, P. Model predictive control using subspace model identification. Comput. Chem. Eng. 2021, 149, 107276. [Google Scholar] [CrossRef]

- Priori, C.; De Angelis, M.; Betti, R. On the selection of user-defined parameters in data-driven stochastic subspace identification. Mech. Syst. Signal Process. 2018, 100, 501–523. [Google Scholar] [CrossRef]

- Alenany, A.; Shang, H. Recursive subspace identification with prior information using the constrained least squares approach. Comput. Chem. Eng. 2013, 54, 174–180. [Google Scholar] [CrossRef]

- Jhinaoui, A. Subspace-Based Identification and Vibration Monitoring Algorithms for Rotating Systems. Ph.D. Thesis, University of Rennes 1, Rennes, France, 2014. [Google Scholar]

- Cadoret, A.; Denimal, E.; Leroy, J.-M.; Pfister, J.-L.; Mevel, L. Linear time invariant approximation for subspace identification of linear periodic systems applied to wind turbines. IFAC-PapersOnLine 2022, 55, 49–54. [Google Scholar] [CrossRef]

- Carrasco, D.S.; Goodwin, G.C. Feedforward model predictive control. Annu. Rev. Control 2011, 35, 199–206. [Google Scholar] [CrossRef]

- Qin, S.J. An overview of subspace identification. Comput. Chem. Eng. 2006, 30, 1502–1513. [Google Scholar] [CrossRef]

- Atsonios, K.; Nesiadis, A.; Detsios, N.; Koutita, K.; Nikolopoulos, N.; Grammelis, P. Review on dynamic process modeling of gasification based biorefineries and bio-based heat & power plants. Fuel Process. Technol. 2020, 197, 106188. [Google Scholar]

- Kortela, J.; Jämsä-Jounela, S.-L. Modeling and model predictive control of the BioPower combined heat and power (CHP) plant. Int. J. Electr. Power Energy Syst. 2015, 65, 453–462. [Google Scholar] [CrossRef]

- Lu, Z.; Chen, X.; Yao, S.; Qin, H.; Zhang, L.; Yao, X.; Yu, Z.; Lu, J. Feasibility study of gross calorific value, carbon content, volatile matter content and ash content of solid biomass fuel using laser-induced breakdown spectroscopy. Fuel 2019, 258, 116150. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, S.; Li, Y.; Li, Y.; He, J. Influence of Operating Parameters on Chlorine Release and Pollutant Emission Characteristics of a 130 t/h BCFB Combustion System. ACS Omega 2021, 6, 12530–12540. [Google Scholar] [CrossRef] [PubMed]

- Brück, D.; Elmqvist, H.; Mattsson, S.E.; Olsson, H. In Dymola for multi-engineering modeling and simulation. Proc. Model. Citeseer 2002, 2002, 55-1–55-8. [Google Scholar]

- Huang, B.; Kadali, R. Dynamic Modeling, Predictive Control and Performance Monitoring: A Data-Driven Subspace Approach; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Oh, T.H.; Kim, J.W.; Son, S.H.; Jeong, D.H.; Lee, J.M. Multi-strategy control to extend the feasibility region for robust model predictive control. J. Process Control 2022, 116, 25–33. [Google Scholar] [CrossRef]

- Jamaludin, I.; Wahab, N.; Khalid, N.; Sahlan, S.; Ibrahim, Z.; Rahmat, M.F. N4SID and MOESP subspace identification methods. In Proceedings of the 2013 IEEE 9th International Colloquium on Signal Processing and Its Applications, Kuala Lumpur, Malaysia, 8–10 March 2013; pp. 140–145. [Google Scholar]

- Chen, C.; Pan, L.; Shen, J.; Lee, K.Y.; Zhang, F.; Sun, L.; Wu, X.; Zhang, J.; Xue, W. Control of Nonlinear Constrained Ultra-Supercritical Boiler–Turbine Units Using Offset-Free Output-Feedback Stable MPC. IFAC-PapersOnLine 2018, 51, 155–160. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, M.; Liu, S.; Wu, X. Dynamic modeling and coupling characteristics analysis of biomass power plant integrated with carbon capture process. Energy Convers. Manag. 2022, 273, 116431. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).