Numerical Simulation of Flow and Heat Transfer Characteristics in Non-Closed Ring-Shaped Micro-Pin-Fin Arrays

Abstract

1. Introduction

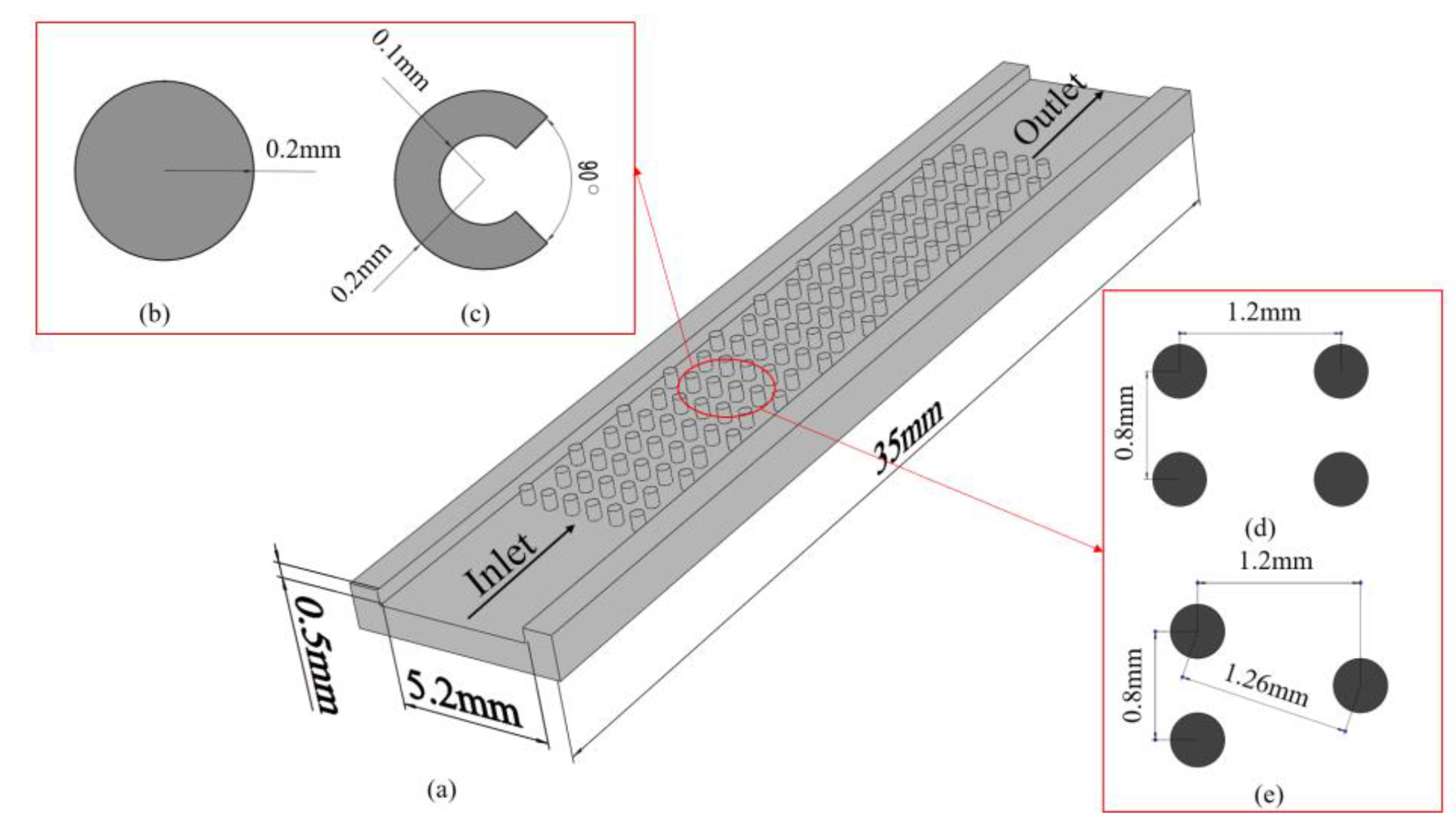

2. Establishment of the Model

2.1. Physical Model

2.2. Numerical Simulation

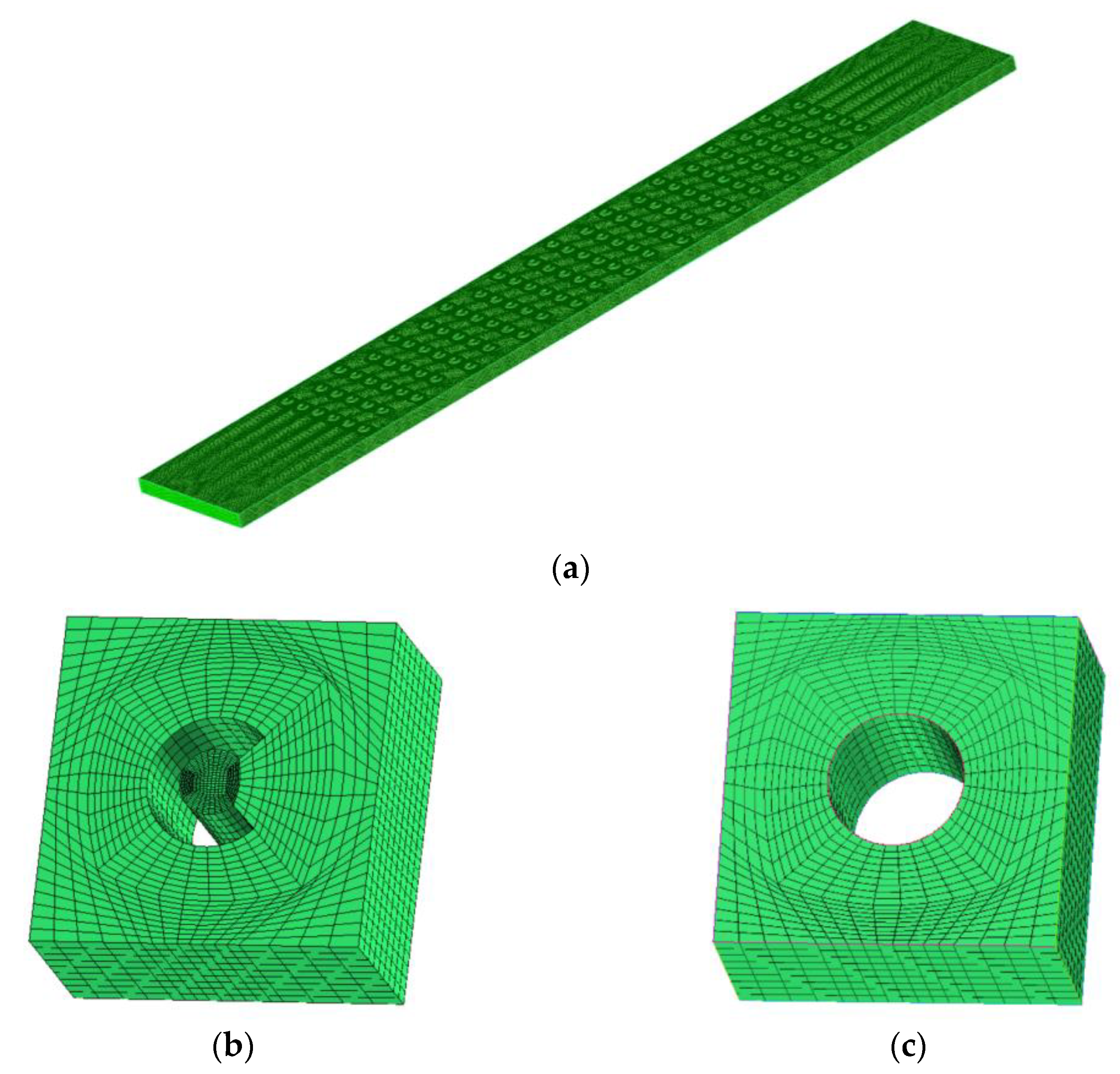

2.3. Verification of Mesh Independence

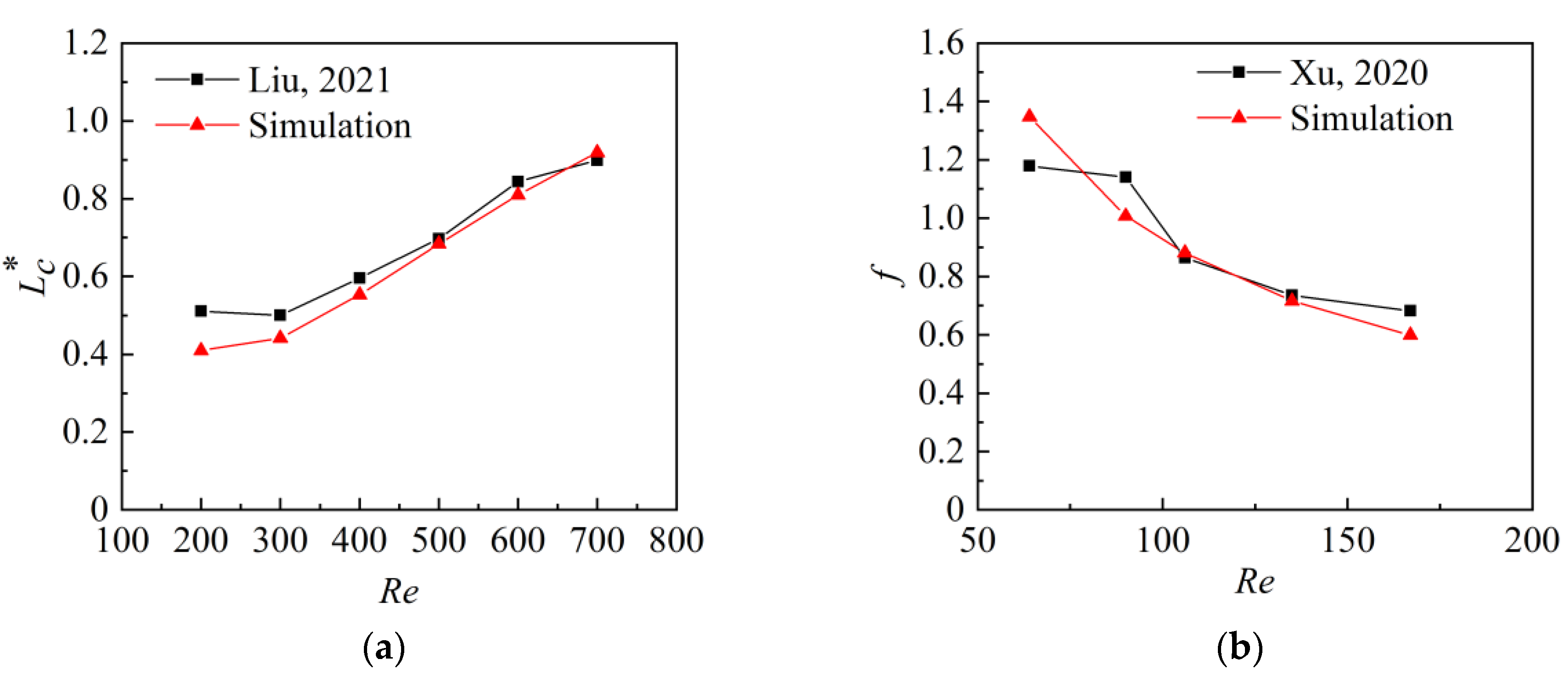

2.4. Model Validation

3. Results and Discussion

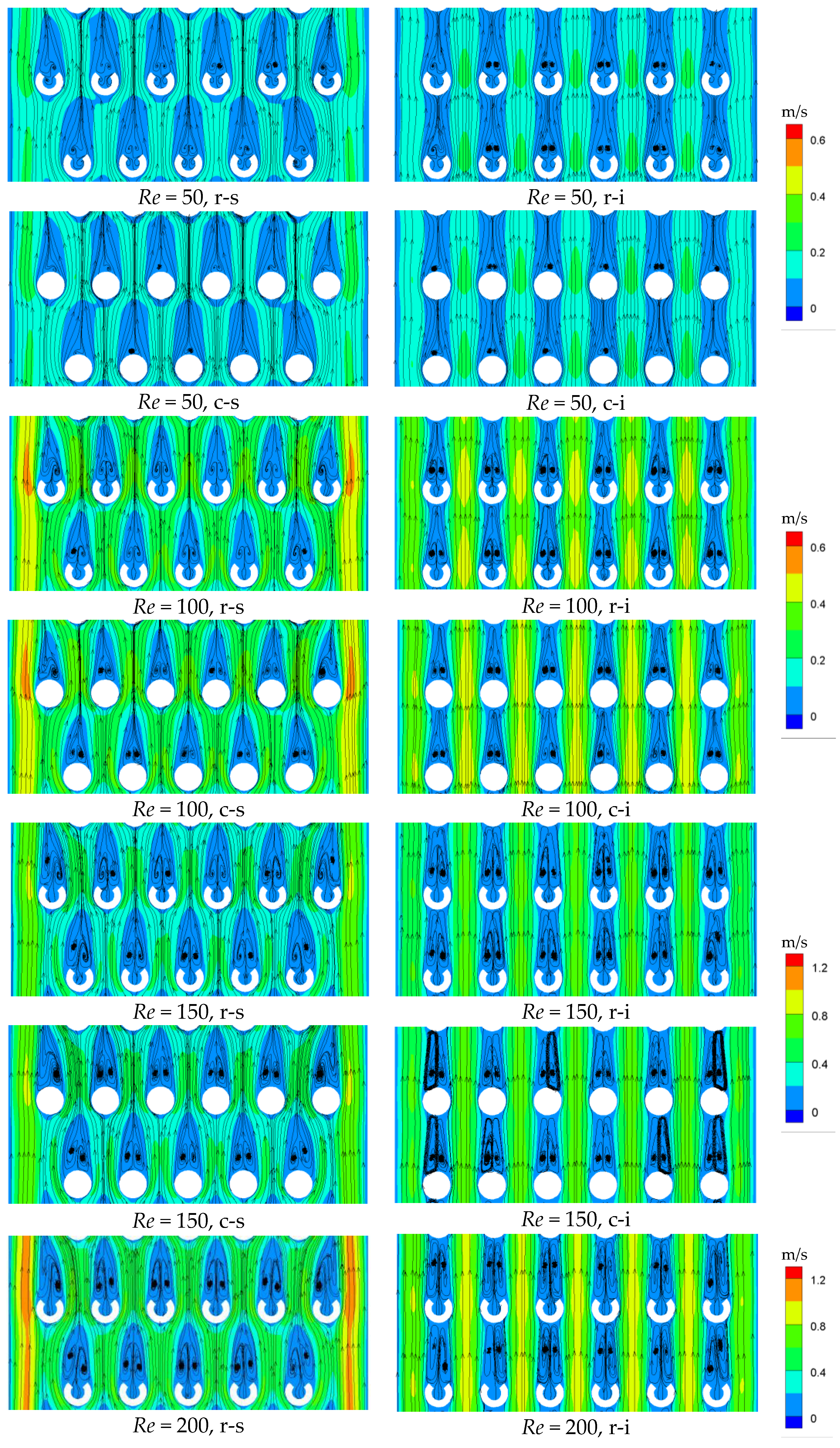

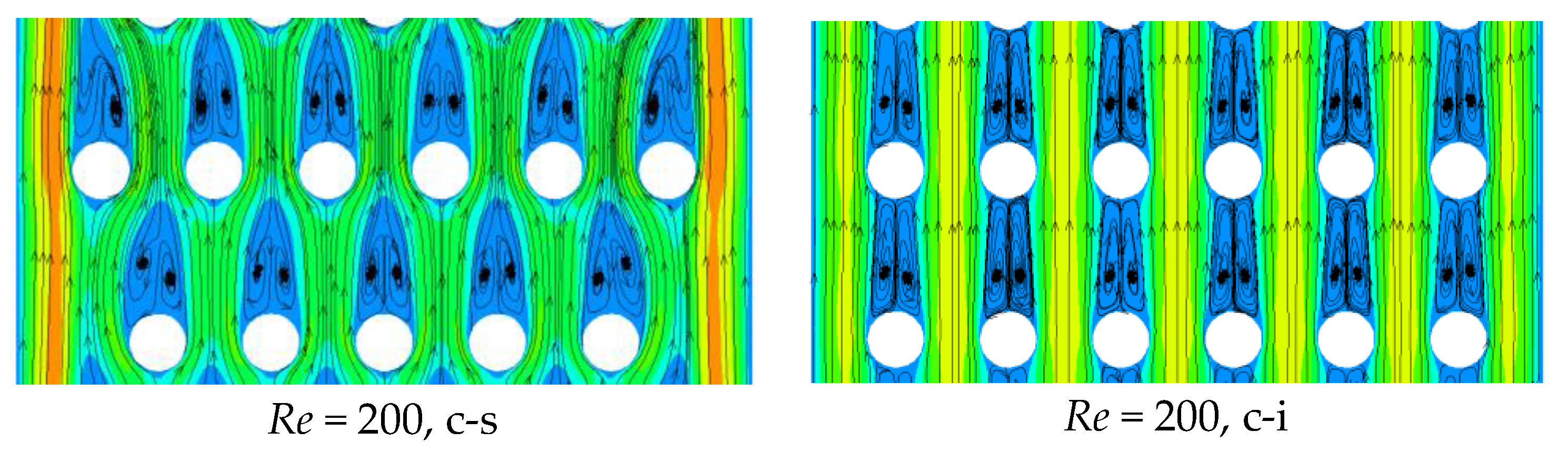

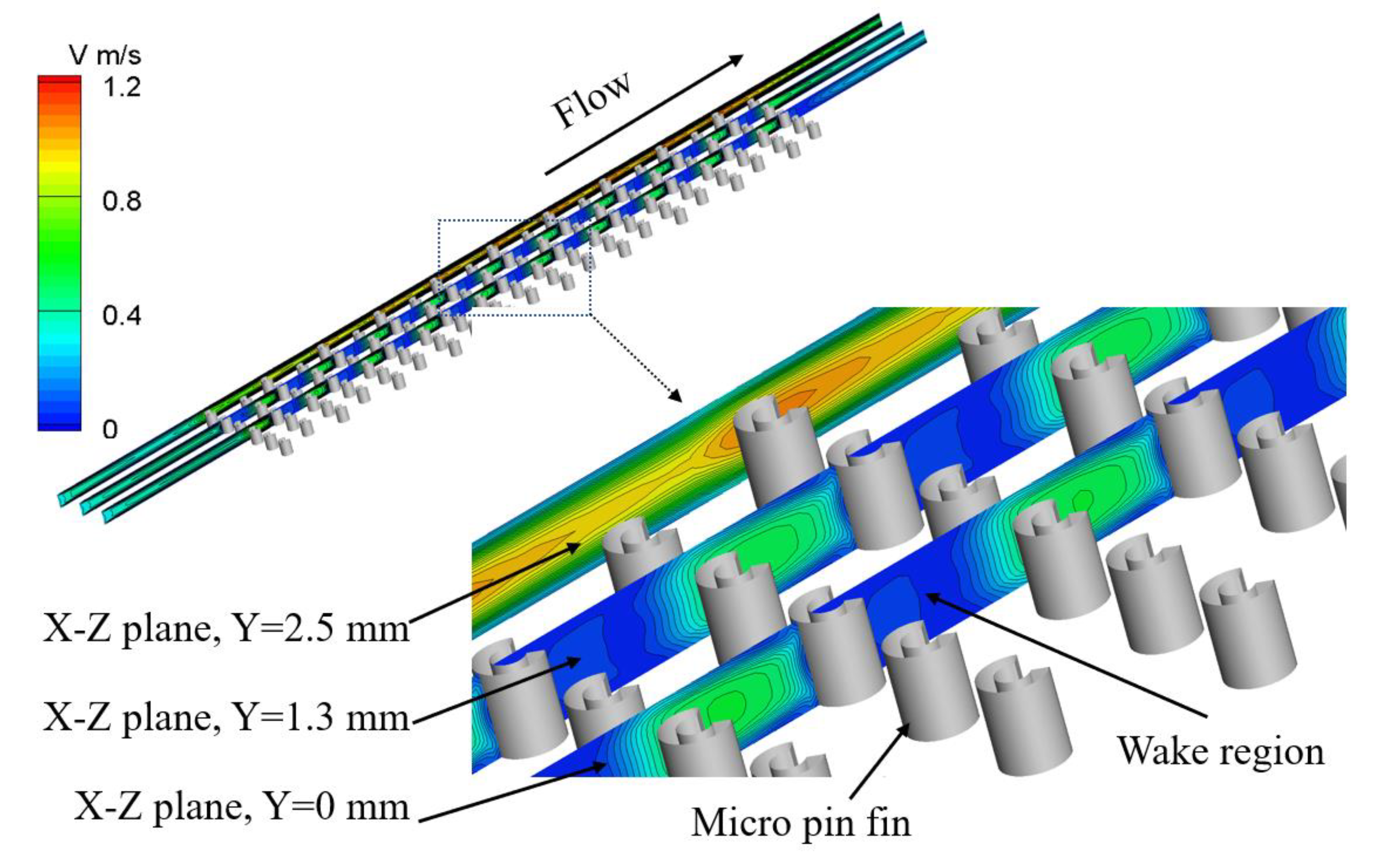

3.1. Velocity Field and Distribution of Streamline

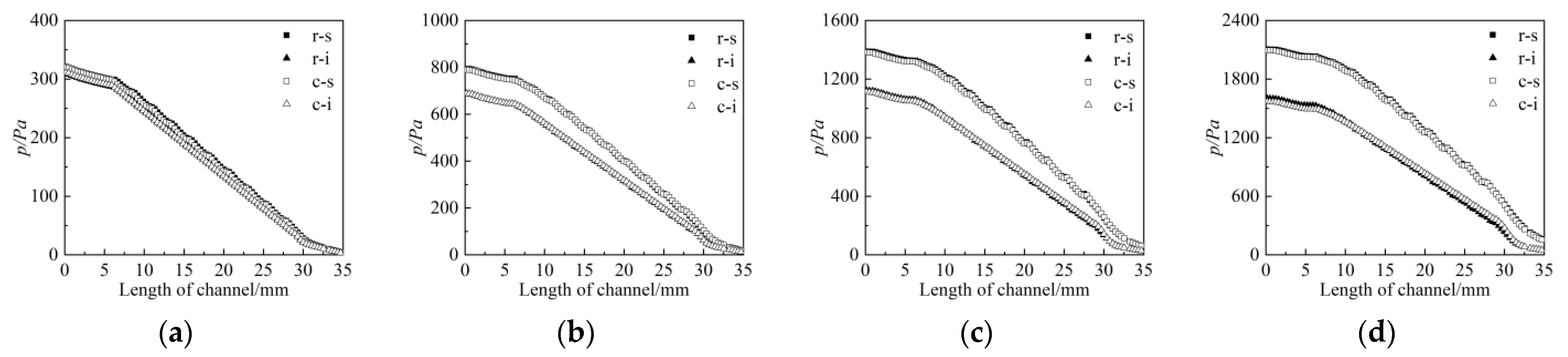

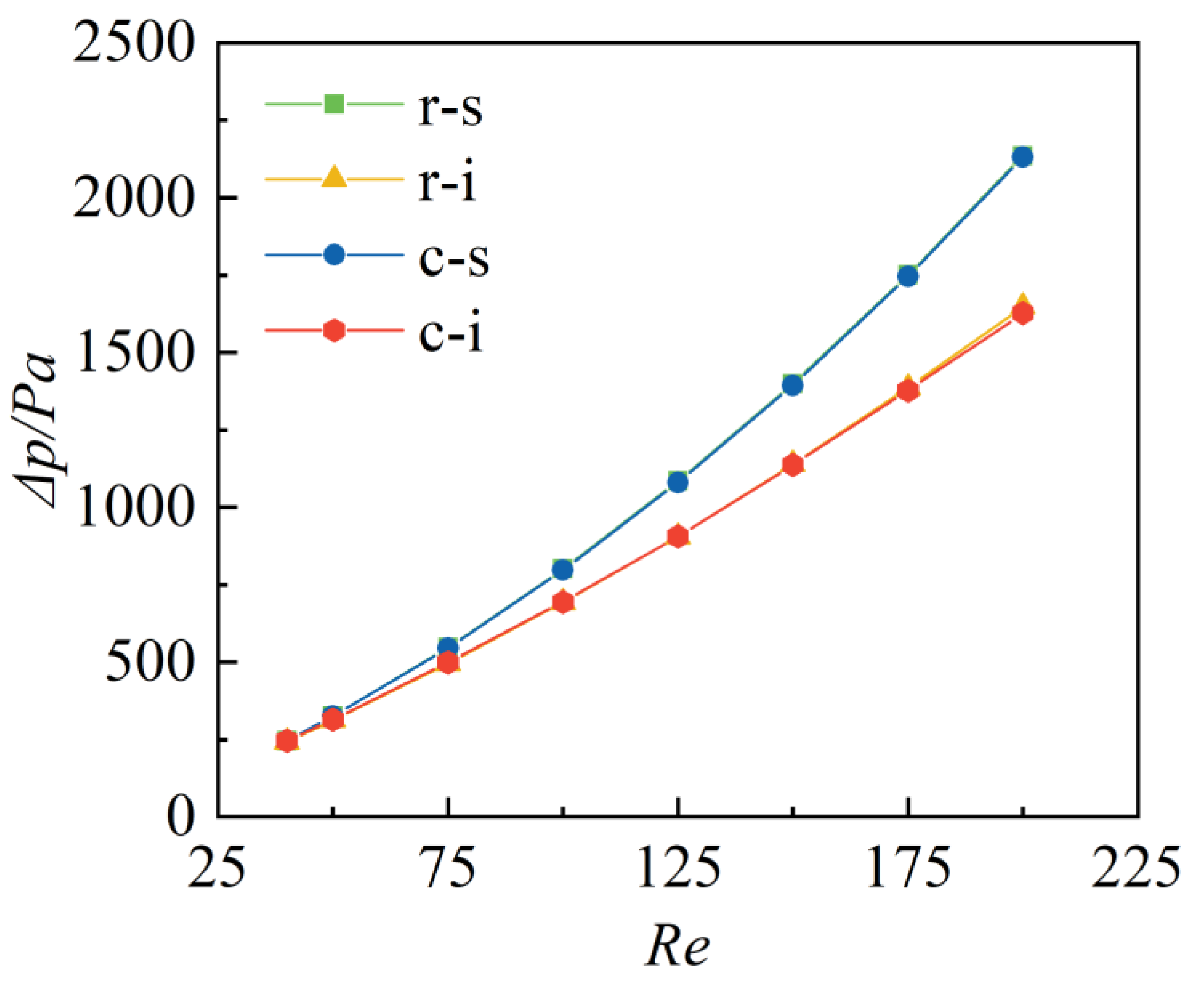

3.2. Pressure Drop Curve

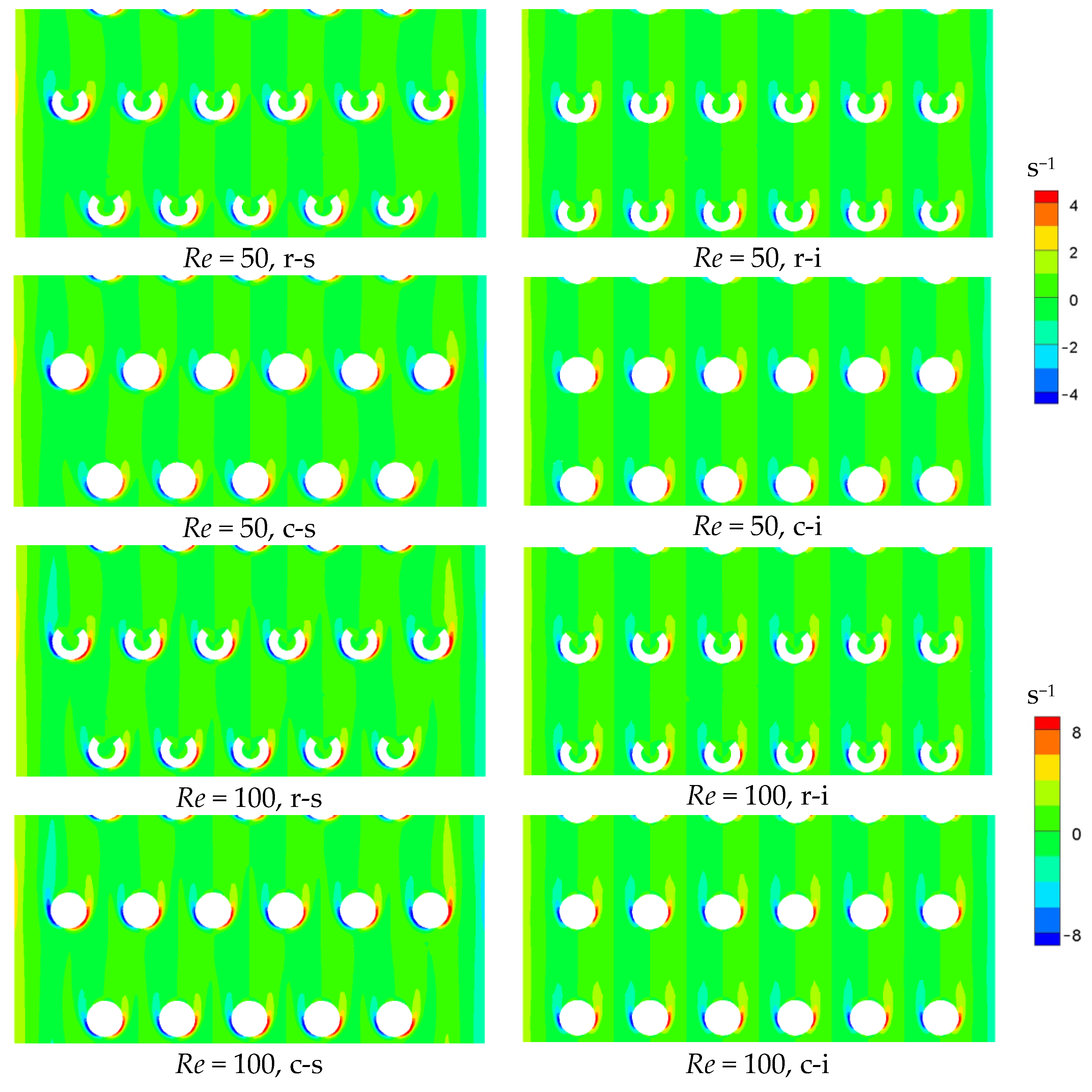

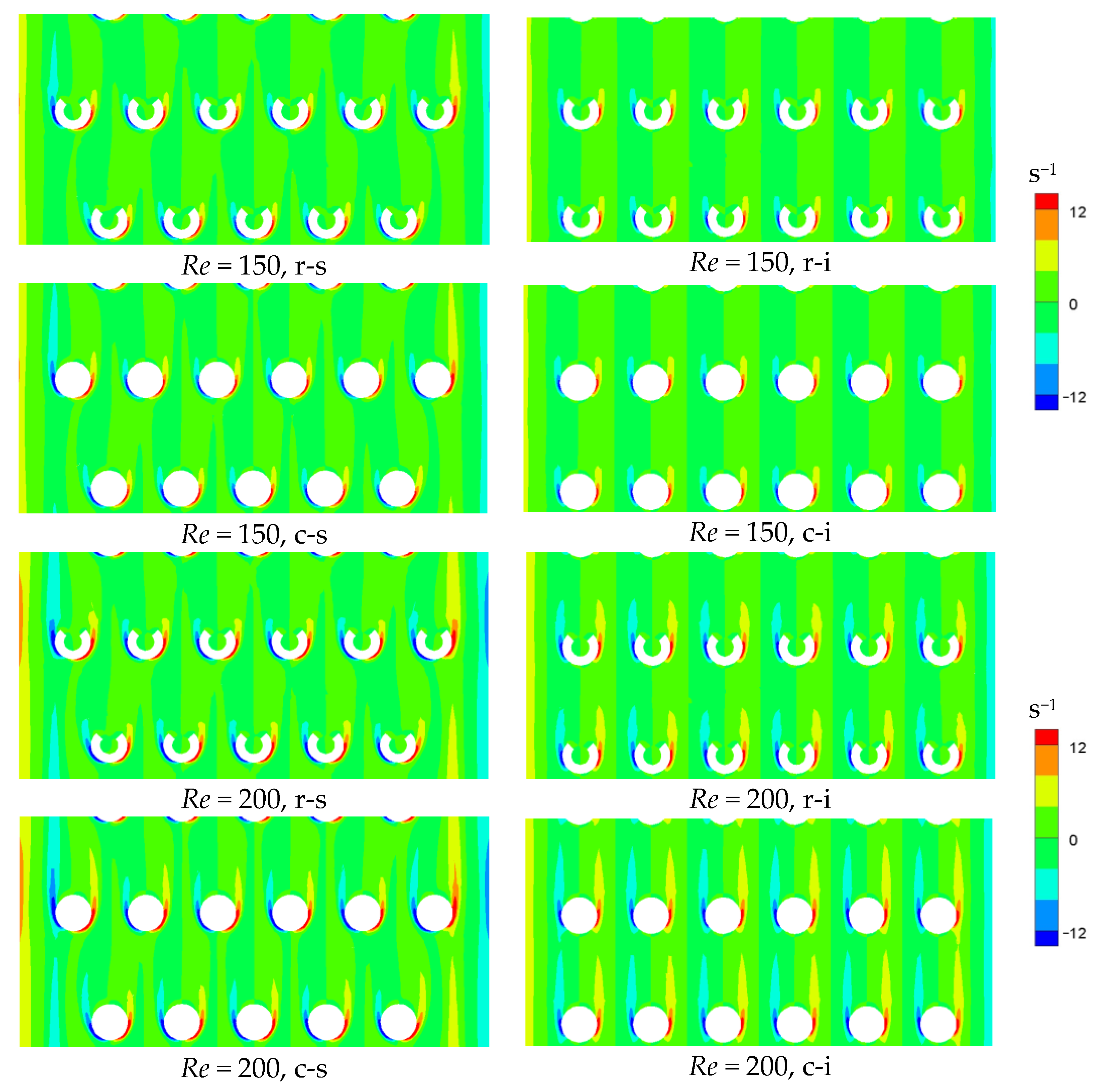

3.3. Vorticity Analysis

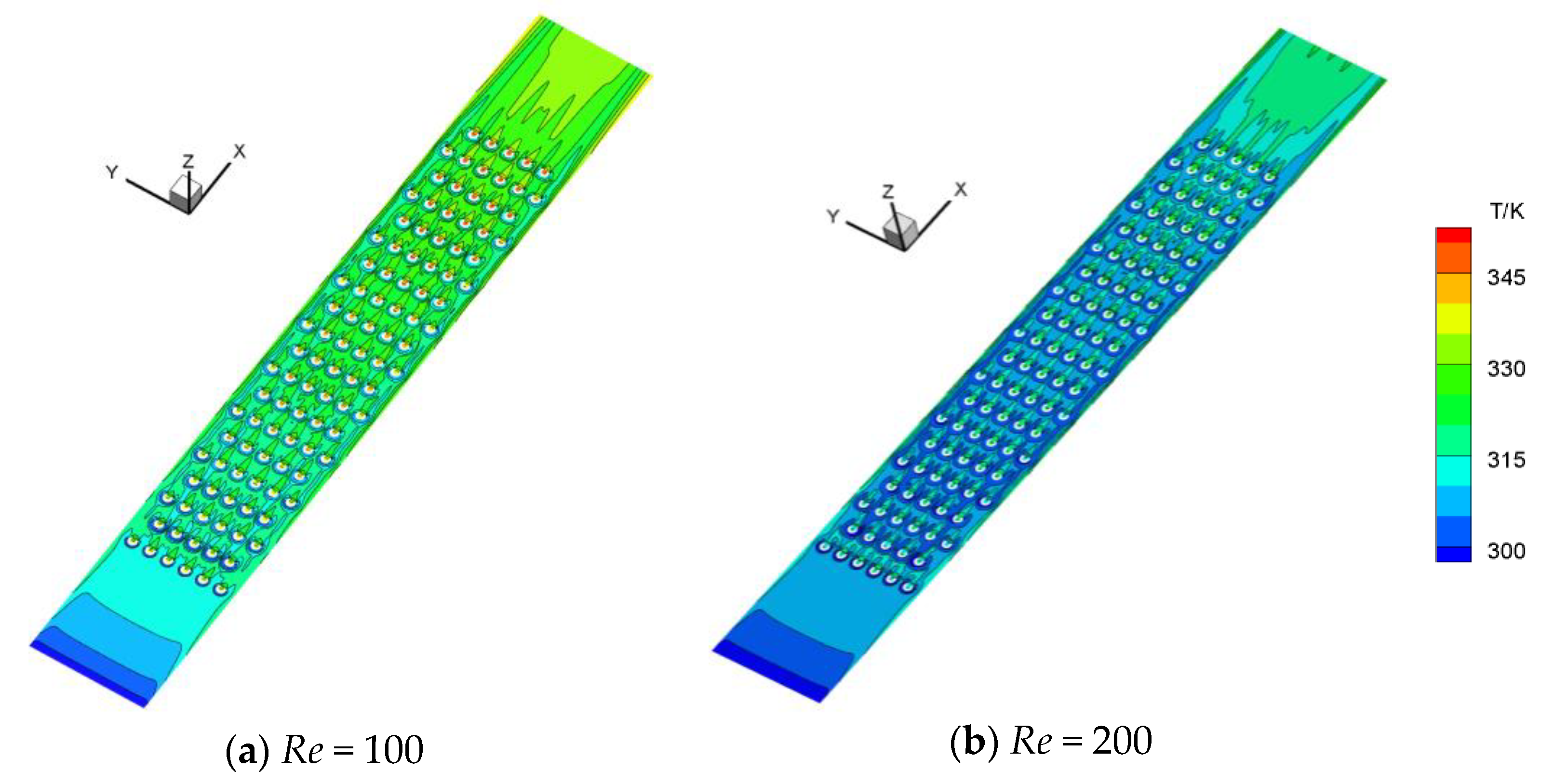

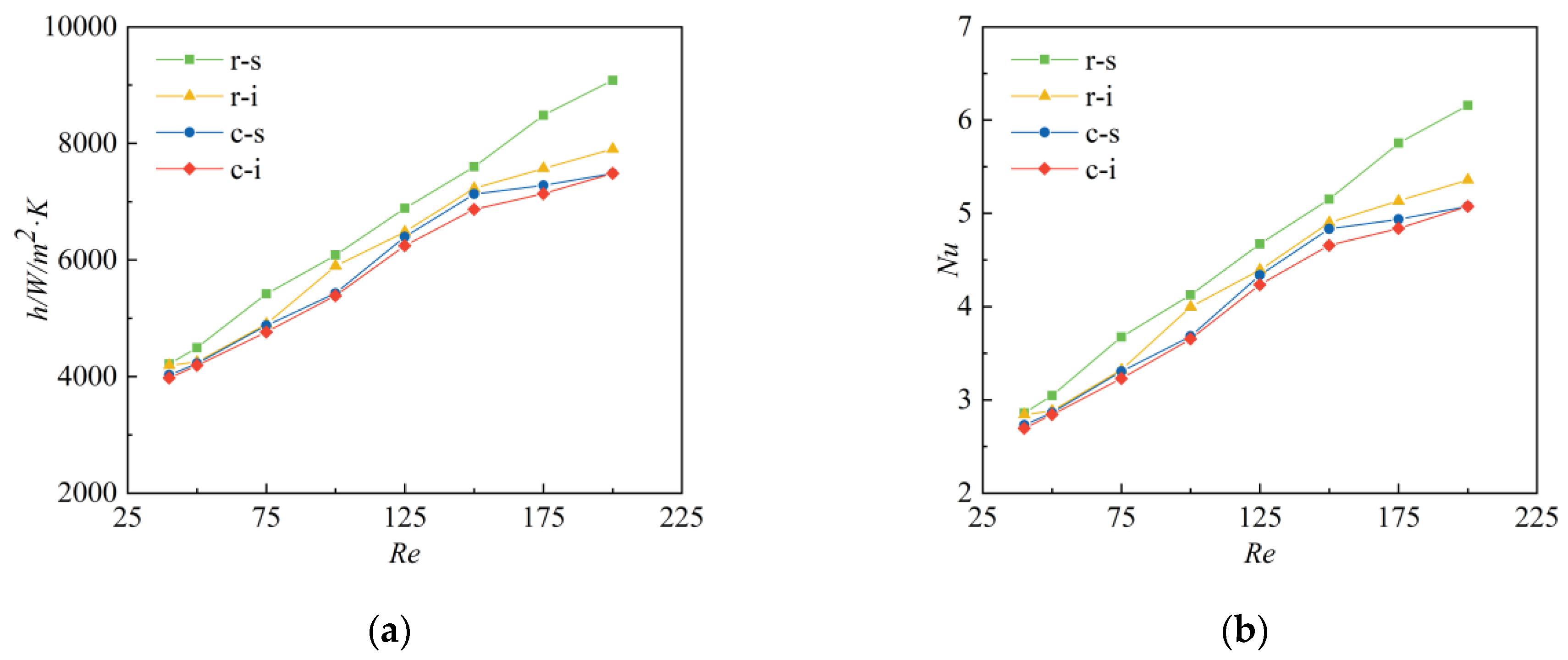

3.4. Heat Transfer Characteristics

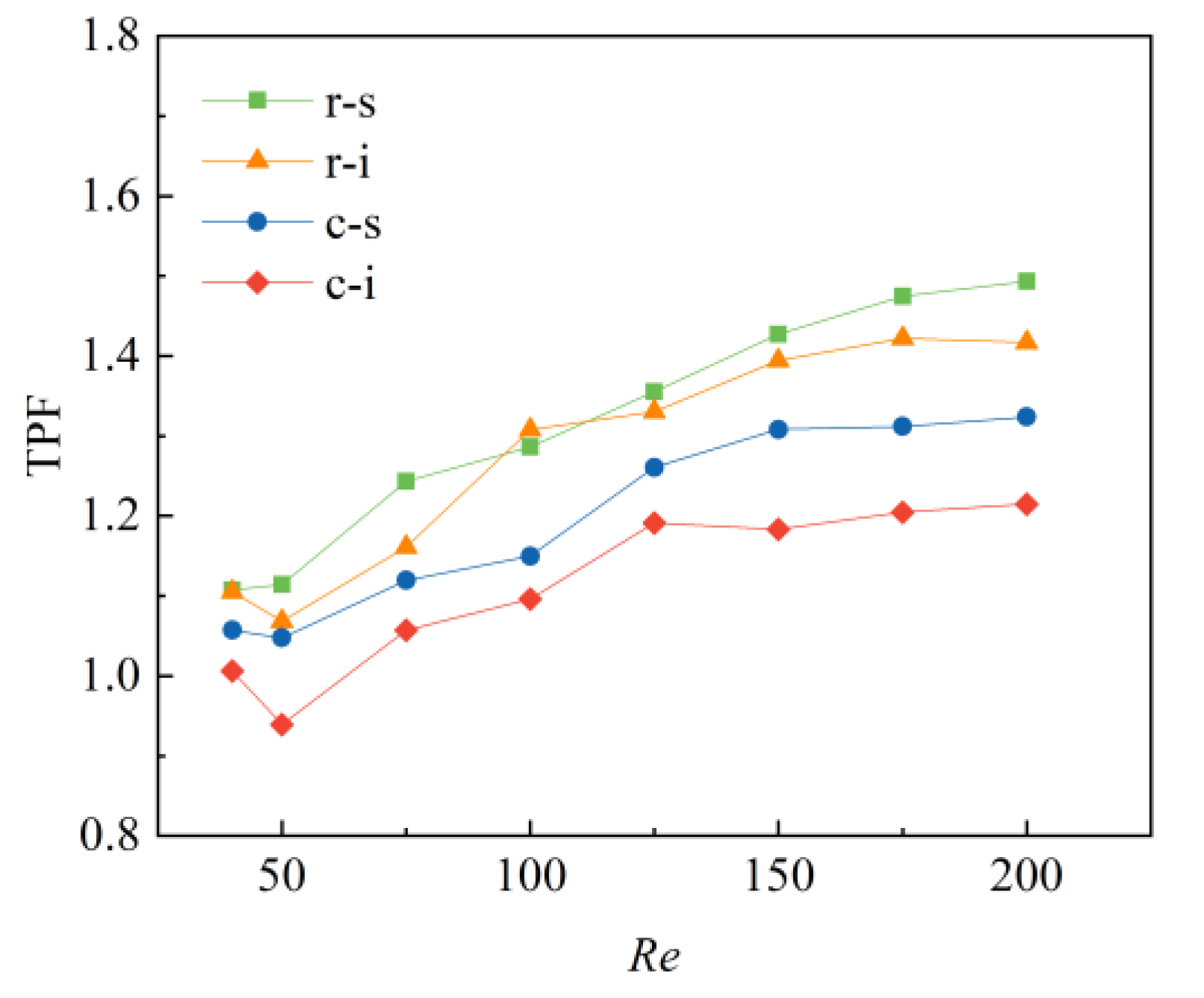

3.5. Thermal-Hydraulic Performance Evaluation

3.6. Effect of the Pin-Fin Height

4. Conclusions

- (1)

- Vortex pairs appear at a lower Reynolds number downstream of the ring-shaped micro-pin-fin than in the traditional circular micro-pin-fin array under the same layout. With the increase of Reynolds number, the wake region expands and the vortex center shifts downstream. Better symmetry in the wake is observed in the in-line array for both cross-section shapes.

- (2)

- Difference in overall pressure drop in these four microchannels is subtle at low Reynolds numbers, but becomes noticeable as Re increases. The layout of the pin-fins, rather than the cross-section shape, plays a major role in influencing the pressure drop.

- (3)

- High vorticity regions appear on two sides of the pin-fins, with similar intensity and opposite direction. With the increase of Re, the vorticity intensifies and diffuses further downstream but narrows in width.

- (4)

- The staggered 3/4 ring-shaped micro-pin-fin array exhibits the best thermal performance among four types of micro-structure studied. Compared with the circular micro-pin-fin array, a maximum increase of 21.34% in heat transfer coefficient is observed in the ring-shaped micro-pin-fin array.

- (5)

- The best overall thermal-hydraulic performance is achieved with the staggered 3/4 ring-shaped micro-pin-fin array with a fin height of 0.5 mm, with a 49.4% increase in thermal-hydraulic performance factor compared with the plain microchannel.

- (6)

- On the basis of acquired findings of this investigation, future studies shall include experimental investigations on non-closed ring-shaped micro-pin-fin arrays with different heights, spacings and opening angles, exploration of flow boiling characteristics in the novel structure, integration of a multi-layer micro-pin-fin heat exchanger, etc.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Roman symbols | |

| Amin | minimum cross-sectional area of flow passage in the microchannel, m2 |

| A | cross-sectional area of the channel inlet, m2 |

| c-i | in-line circular micro-pin-fin array |

| c-s | staggered circular micro-pin-fin array |

| D | diameter of the micro-pin-fin, m |

| f | friction factor |

| h | heat transfer coefficient, W/(m2·K) |

| Lc | distance from the rear stagnation point to the center of vortex, m |

| Lc* | dimensionless vortex center location |

| Nu | Nusselt number |

| p | pressure, Pa |

| qv | volumetric flow rate, m3/s |

| qw | heat flux, kW/m2 |

| Re | Reynolds number |

| r-i | in-line ring-shaped micro-pin-fin array |

| r-s | staggered ring-shaped micro-pin-fin array |

| T | temperature, K |

| TPF | thermal-hydraulic performance factor |

| uin | channel inlet velocity, m/s |

| Umin | average velocity at the minimum section of the channel, m/s |

| velocity, m/s | |

| Greek symbols | |

| λ | thermal conductivity, W/(m·K) |

| μ | dynamic viscosity, N·s/m2 |

| ρ | density, kg/m3 |

References

- Reda, S. 3D integration advances computing. Nature 2017, 547, 38–39. [Google Scholar] [CrossRef]

- Lu, Y.; Guo, Z.; Gong, Y.; Zhang, T.; Huang, Y.; Niu, F. Optimal study of swordfish fin microchannel heat exchanger for the next generation nuclear power conversion system of lead-based reactor. Ann. Nucl. Energy 2022, 165, 108679. [Google Scholar] [CrossRef]

- Yu, H.; Li, T.L.; Zeng, X.X.; He, T.B.; Mao, N. A critical review on geometric improvements for heat transfer augmentation of microchannels. Energies 2022, 15, 9474. [Google Scholar] [CrossRef]

- Kim, D.E.; Yu, D.I.; Jerng, D.W.; Kim, M.H.; Ahn, H.S. Review of boiling heat transfer enhancement on micro/nanostructured surfaces. Exp. Therm. Fluid Sci. 2015, 66, 173–196. [Google Scholar] [CrossRef]

- Xin, Z.Q.; Kong, X.Y.; Chen, J. Enhancement of heat transfer in a microchannel via passive and active control of a jet issued from the circular cylinder. Energies 2022, 15, 8287. [Google Scholar] [CrossRef]

- Siddiqa, S.; Molla, M.M.; Naqvi, S.B. Carreau ferrofluid flow with inclined magnetic field in an enclosure having heated cylinder. Phys. Scr. 2021, 96, 105007. [Google Scholar] [CrossRef]

- Roy, N.C.; Hossain, M.A.; Gorla, R.S.R.; Siddiqa, S. Natural convection around a locally heated circular cylinder placed in a rectangular enclosure. J. Non-Equilib. Thermodyn. 2021, 46, 45–59. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Lyu, S.S.; Luo, J.L.; Luo, Z.Y.; Fu, Y.X.; Heng, Y.; Zhang, J.H.; Mo, D.C. Copper vertical micro dendrite fin arrays and their superior boiling heat transfer capability. Appl. Surf. Sci. 2017, 422, 388–393. [Google Scholar] [CrossRef]

- Mohammadi, A.; Koşar, A. Review on heat and fluid flow in micro pin fin heat sinks under single-phase and two-phase flow conditions. Nanoscale Microscale Thermophys. Eng. 2018, 22, 153–197. [Google Scholar] [CrossRef]

- Ji, C.; Liu, Z.G.; Lv, M.M. Micro-particle image velocimetry study on hydrodynamic characteristics of in-line and staggered micro pin fin arrays. Chem. Eng. Process.-Process Intensif. 2022, 179, 109058. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Zhou, J.; Zhou, W.J.; Qi, B.J.; Wei, J.J. CHF correlation of boiling in FC-72 with micro-pin-fins for electronics cooling. Appl. Therm. Eng. 2018, 138, 494–500. [Google Scholar] [CrossRef]

- Jung, K.M.; Ajith, K.R.; Udaya, K.G.; Lee, H.J. Experimental study on two-phase pressure drop and flow boiling heat transfer in a micro pin fin channel heat sink under constant heat flux. Exp. Heat Transf. 2021, 34, 162–185. [Google Scholar] [CrossRef]

- Mohammadi, A.; Kosar, A. Hydrodynamic and thermal performance of microchannels with different staggered arrangements of cylindrical micro pin fins. J. Heat Transf. 2017, 139, 062402. [Google Scholar] [CrossRef]

- Mohammadi, A.; Kosar, A. Hydrodynamic and thermal performance of microchannels with different in-line arrangements of cylindrical micro pin fins. J. Heat Transf. 2016, 138, 122403. [Google Scholar] [CrossRef]

- Guan, N.; Liu, Z.G.; Zhang, C.W. Numerical investigation on heat transfer of liquid flow at low Reynolds number in micro-cylinder-groups. Heat Mass Transf. 2012, 48, 1141–1153. [Google Scholar] [CrossRef]

- Guan, N.; Luan, T.; Jiang, G.L.; Liu, Z.G.; Zhang, C.W. Influence of heating load on heat transfer characteristics in micro-pin-fin arrays. Heat Mass Transf. 2016, 52, 393–405. [Google Scholar] [CrossRef]

- Hithaish, D.; Saravanan, V.; Umesh, C.K.; Seetharamu, K.N. Thermal management of electronics: Numerical investigation of triangular finned heat sink. Therm. Sci. Eng. Prog. 2022, 30, 108679. [Google Scholar] [CrossRef]

- Hou, T.B.; Xu, D.M. Pressure drop and heat transfer performance of microchannel heat exchangers with elliptical concave cavities. Appl. Therm. Eng. 2023, 218, 119351. [Google Scholar] [CrossRef]

- Bhandari, P.; Prajapati, Y.K. Influences of tip clearance on flow and heat transfer characterstics of open type micro pin fin heat sink. Int. J. Therm. Sci. 2022, 179, 107714. [Google Scholar] [CrossRef]

- Lv, M.M.; Liu, Z.G.; Chi, W.T.; Ma, C.; Duan, L. Investigation on flow through staggered micro pin fin arrays with variable longitudinal spacings using Micro-PIV. Nanoscale Microscale Thermophys. Eng. 2022, 26, 198–217. [Google Scholar] [CrossRef]

- Jia, Y.T.; Huang, J.W.; Wang, J.T.; Li, H.W. Heat transfer and fluid flow characteristics of microchannel with oval-shaped micro pin fins. Entropy 2021, 23, 1482. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Chen, L. Thermal and hydraulic performance of micro pin fin heat sinks with different pin fin shapes. IOP Conf. Ser. Mater. Sci. Eng. 2019, 542, 012053. [Google Scholar] [CrossRef]

- Xu, F.Y.; Pan, Z.H.; Wu, H.Y. Experimental investigation on the flow transition in different pin-fin arranged microchannels. Microfluid. Nanofluidics 2018, 22, 11. [Google Scholar] [CrossRef]

- Liu, Z.G.; Guan, N.; Zhang, C.W.; Jiang, G.L. The flow resistance and heat transfer characteristics of micro pin fins with different cross-sectional shapes. Nanoscale Microscale Thermophys. Eng. 2015, 19, 221–243. [Google Scholar] [CrossRef]

- Xia, G.D.; Chen, Z.; Cheng, L.X.; Ma, D.D.; Zhai, Y.L. Micro-PIV visualization and numerical simulation of flow and heat transfer in three micro pin-fin heat sinks. Int. J. Therm. Sci. 2017, 119, 9–23. [Google Scholar] [CrossRef]

- Dupuis, P.; Cormier, Y.; Fenech, M.; Jodoin, B. Heat transfer and flow structure characterization for pin fins produced by cold spray additive manufacturing. Int. J. Heat Mass Transf. 2016, 98, 650–661. [Google Scholar] [CrossRef]

- Hua, J.Y.; Li, G.; Zhao, X.B.; Li, Q.H. Experimental study on thermal performance of micro pin fin heat sinks with various shapes. Heat Mass Transf. 2017, 53, 1093–1104. [Google Scholar] [CrossRef]

- Omri, M.; Smaoui, H.; Frechette, L.; Kolsi, L. A new microchannel heat exchanger configuration using CNT-nanofluid and allowing uniform temperature on the active wall. Case Stud. Therm. Eng. 2022, 32, 101866. [Google Scholar] [CrossRef]

- Yan, Y.F.; Xue, Z.G.; Xu, F.L.; Li, L.X.; Shen, K.M.; Li, J.B.; Yang, Z.Q.; He, Z.Q. Numerical investigation on thermal-hydraulic characteristics of the micro heat sink with gradient distribution pin fin arrays and narrow slots. Appl. Therm. Eng. 2022, 202, 117836. [Google Scholar] [CrossRef]

- Woodcock, C.; Yu, X.; Plawsky, J.; Peles, Y. Piranha Pin Fin (PPF)—Advanced flow boiling microstructures with low surface tension dielectric fluids. Int. J. Heat Mass Transf. 2015, 90, 591–604. [Google Scholar] [CrossRef]

- Yu, X.; Woodcock, C.; Plawsky, J.; Peles, Y. An investigation of convective heat transfer in microchannel with Piranha Pin Fin. Int. J. Heat Mass Transf. 2016, 103, 1125–1132. [Google Scholar] [CrossRef]

- Chien, L.H.; Liao, W.R.; Ghalambaz, M.; Yan, W.M. Experimental study on convective boiling of micro-pin-finned channels with parallel arrangement fins for FC-72 dielectric fluid. Int. J. Heat Mass Transf. 2019, 138, 390–400. [Google Scholar] [CrossRef]

- Liao, W.R.; Chien, L.H.; Ghalambaz, M.; Yan, W.M. Experimental study of boiling heat transfer in a microchannel with nucleated-shape columnar micro-pin-fins. Int. Commun. Heat Mass Transf. 2019, 108, 104277. [Google Scholar] [CrossRef]

- Liu, Z.G.; Dong, K.M.; Lyu, M.M.; Ji, C.; Jiang, Y.K. Study on characteristics of flow field in micro pin fin array based on Micro-PIV. CIESC J. 2021, 72, 5094–5101. [Google Scholar]

- Xu, D. Simulation and Experimental Study on Flow and Heat Transfer Properties of Micro Pin Fins with Different Shapes; Nanjing Normal University: Nanjing, China, 2020. [Google Scholar]

| Micro-Structure | Number of Mesh Elements |

|---|---|

| r-s | 2.02 × 106 |

| r-i | 2.00 × 106 |

| c-s | 2.03 × 106 |

| c-i | 1.85 × 106 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.; Ji, C.; Liu, Z.; Wang, N. Numerical Simulation of Flow and Heat Transfer Characteristics in Non-Closed Ring-Shaped Micro-Pin-Fin Arrays. Energies 2023, 16, 3481. https://doi.org/10.3390/en16083481

Chen M, Ji C, Liu Z, Wang N. Numerical Simulation of Flow and Heat Transfer Characteristics in Non-Closed Ring-Shaped Micro-Pin-Fin Arrays. Energies. 2023; 16(8):3481. https://doi.org/10.3390/en16083481

Chicago/Turabian StyleChen, Ming, Can Ji, Zhigang Liu, and Naihua Wang. 2023. "Numerical Simulation of Flow and Heat Transfer Characteristics in Non-Closed Ring-Shaped Micro-Pin-Fin Arrays" Energies 16, no. 8: 3481. https://doi.org/10.3390/en16083481

APA StyleChen, M., Ji, C., Liu, Z., & Wang, N. (2023). Numerical Simulation of Flow and Heat Transfer Characteristics in Non-Closed Ring-Shaped Micro-Pin-Fin Arrays. Energies, 16(8), 3481. https://doi.org/10.3390/en16083481