Analysis of the Level of Efficiency of Control Methods in the Context of Energy Intensity

Abstract

1. Introduction

- method based on indicator analysis;

- application in the area of quality control of a manufacturing enterprise;

- multifaceted analysis (capturing the effectiveness of the method of nonconformity detection, cost, and time of unit detection and energy intensity of detection methods);

- identification of relationships occurring between quantities key to quality control management (effectiveness of nonconformity detection method, cost and time per unit detection, and energy intensity of detection methods);

- verification of the model in one of the foundry companies;

- development of proprietary software CmEfficiencyNew version 1.1.5 based on the assumptions of the model;

- quick turnaround time of the analysis;

- generation of a summary analysis report;

- the possibility of adapting CmEfficiencyNew software to online operation (correlation of software with automated quality control).

2. A Model for Analysing Control Methods

2.1. Step 1. X-ray Examination

- introduction of Χ and γ radiation;

- obtaining an image in the form of a “shadow”, in the direction of propagation of radiation;

- registration on radiographic films and computer registration in real-time radiographic systems;

- preparation of a report on the examination of the casting.

2.2. Step 2. Ultrasonic Testing

- introduction of ultrasonic waves (elastic waves) into the object, i.e., mechanical vibrations with frequencies higher than 20 kHz; it is necessary to scan the surface of the object, moving the head along the surface of the object;

- detection of signals (pulses), sent by waves passing through objects;

- development of a casting test report.

2.3. Step 3. Eddy Current Testing

- placing objects made of electrically conductive materials in the area of influence of a time-varying magnetic field, produced by inductive transducers;

- processing the signals of the transducers, the amplitude and phase of which contain information about the presence of discontinuities in the objects and changes in the composition of the materials and structure of the objects.

2.4. Step 4. Dimensional Control

2.5. Step 5. Visual Inspection

- Direct visual testing makes it possible to examine the casting surfaces directly accessible. Inspection is carried out with the naked eye or with the help of magnifying glasses (with magnifications up to 20×) or microscopes.

- Indirect visual examinations are optical examinations that allow examination of surfaces that are not directly accessible for visual inspection. These examinations are carried out using a set of mirrors, endoscopes, periscopes, or videoscopes.

2.6. Step 6. Determination of the Identification Data of the Analysis

2.7. Step 7. Input of Detection Results from Steps 1–5

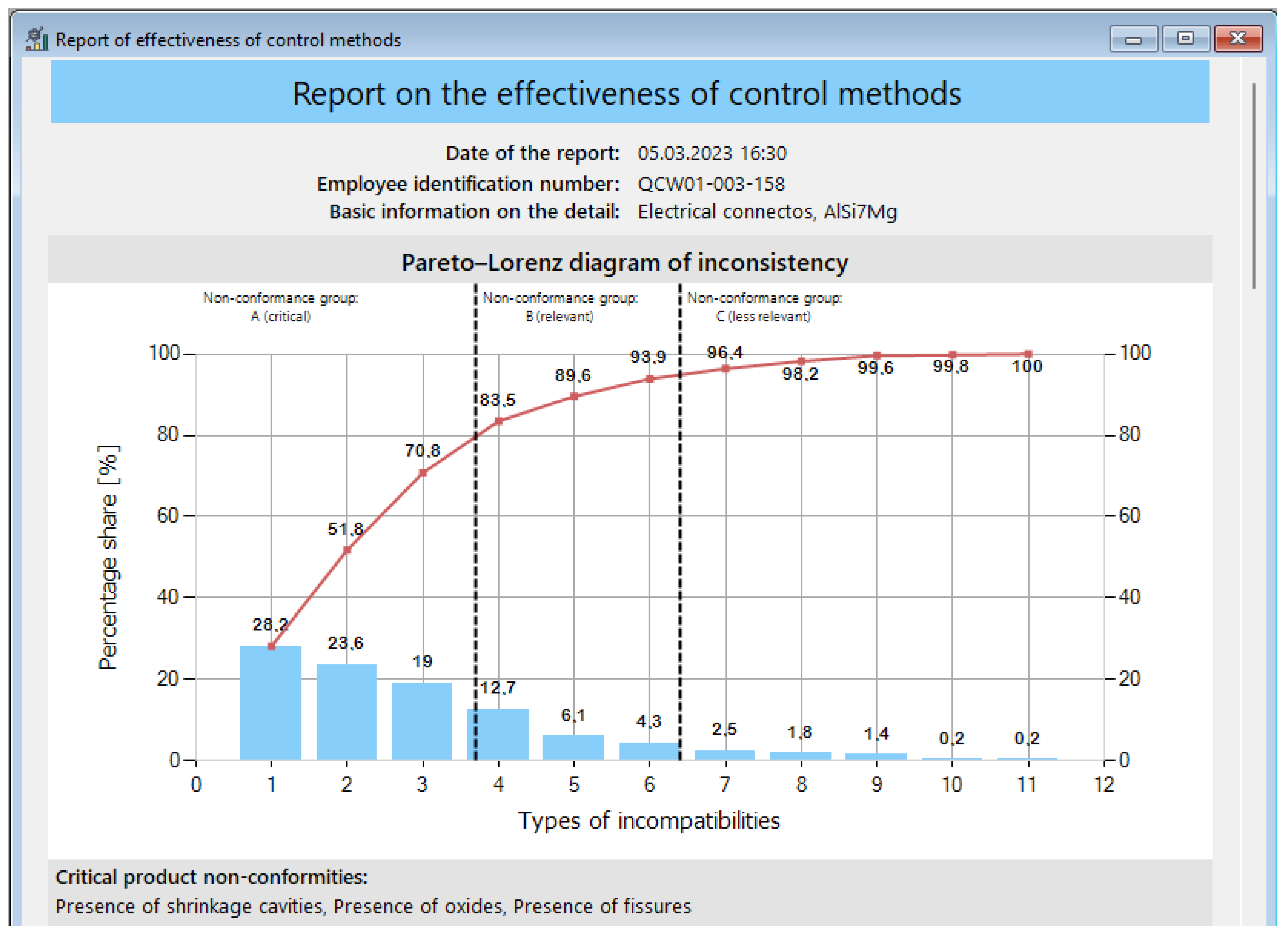

2.8. Step 8. Identification of Critical Product Defects

- group A—critical nonconformities;

- group B—nonconformities that are significant;

- group C—nonconformities of lesser importance.

2.9. Step 9. Identification of the Relationship: Share of Control—Detected Nonconformities

- in the first step between the frequency of nonconformity identification and the frequency of detection methods, understood in subsequent steps as the effectiveness of the control method;

- in the second step between the effectiveness of the control method and the unit cost of detection;

- in step three between the effectiveness of the control method and the unit detection time;

- in step four between the effectiveness of the control method and the intensity of detection.

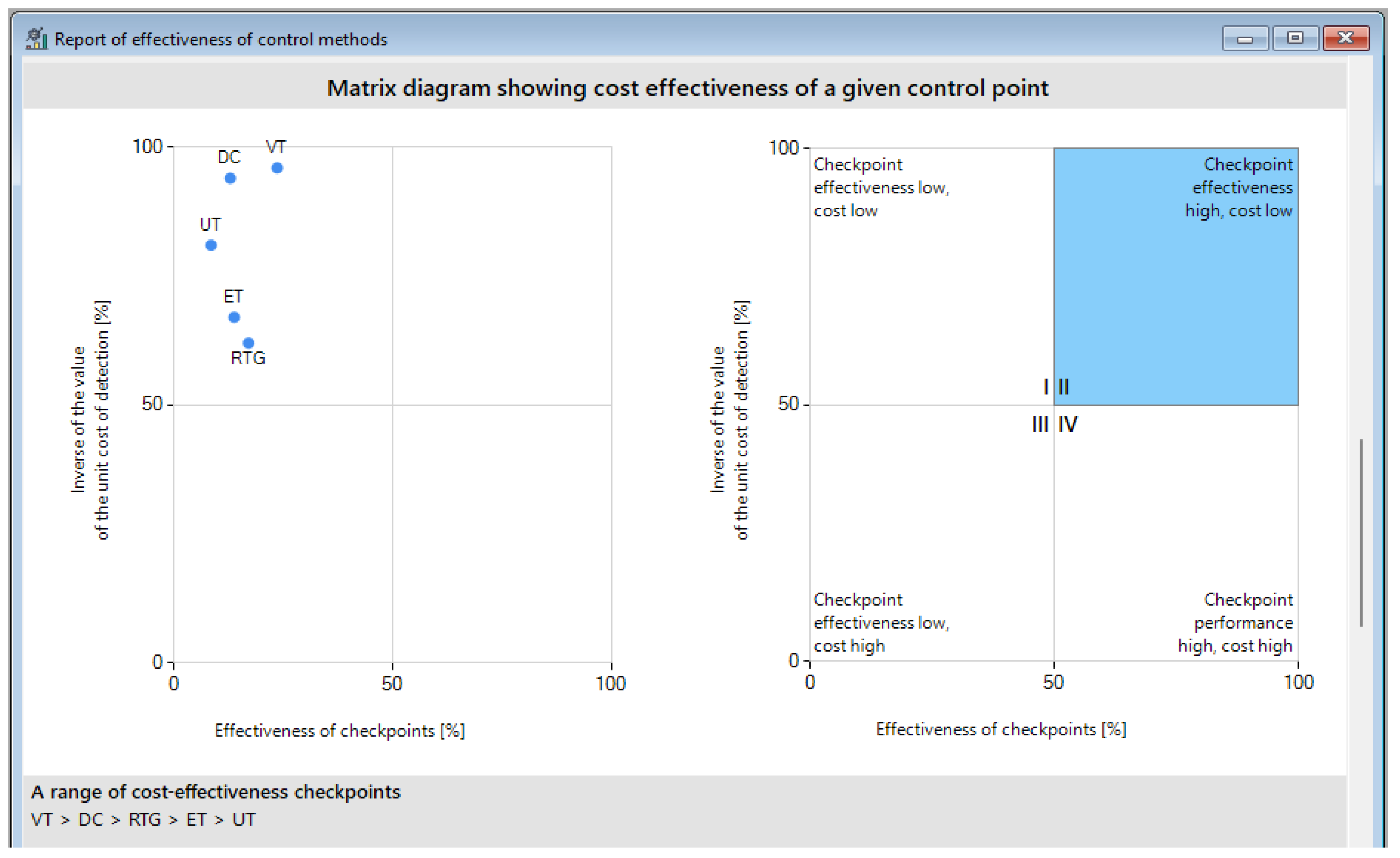

2.10. Step 10. Ranking of Detection Methods

3. Model Verification and Results

- secondary, which included: literature on the subject, documentation on the production process, and quality control;

- primary, which included interviews with company representatives.

4. Results and Discussion

5. Conclusions

- the software allows one to configure detection methods integrally, which contributes to reducing the level of diagnostic uncertainty;

- the software allows one to identify critical inconsistencies of the analysed casting that affect significantly the formation of quality problems;

- the software allows one to make quality analysis and appropriate corrective actions (going beyond passive control);

- the software allows one to organise and collect data on the specifics of detection methods and identified nonconformities;

- the software makes it possible to determine the level of effectiveness, time efficiency, cost, and energy intensity of detection units;

- the software makes it possible to create a ranking of the total efficiency of checkpoints;

- the software allows comparison of selected detection periods;

- the use of software will facilitate the improvement of the quality control process in terms of maintaining optimum relationships between product quality and energy intensity of detection methods.

- rationalisation of electricity consumption levels;

- optimisation of the distribution of checkpoints within the entire production process (reducing the cost and time of the quality control process);

- elimination of waste (product inconsistencies, overproduction, and waiting);

- reduction of production costs;

- conscious response in situations of loss of quality stability of products: acceleration of the decision-making process to carry out improvement activities.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wozniak, M.; Kud, K.; Badora, A.; Wozniak, L. Electricity production and consumption perspectives in the opinion of the youth of south-eastern Poland. Energies 2022, 15, 4776. [Google Scholar] [CrossRef]

- Hu, Z.; He, Z. Production function with electricity consumption and its applications. Energy Econ. 2013, 39, 313–321. [Google Scholar] [CrossRef]

- Koch, M.; Harnisch, J. CO2 emissions related to the electricity consumption in the European primary aluminium production—A comparison of electricity supply approaches. Int. J. Life Cycle Assess. 2002, 7, 283–289. [Google Scholar] [CrossRef]

- Gazda, A.; Pacana, A.; Dušan, M. Study on Improving the Quality of Stretch Film by Taguchi Method. Przem. Chem. 2013, 92, 980–982. [Google Scholar]

- Jha, A.P.; Mahajan, A.; Singh, S.K.; Kumar, P. Renewable energy proliferation for sustainable development: Role of cross-border electricity trade. Renew. Energy 2022, 201, 1189–1199. [Google Scholar] [CrossRef]

- Halkos, G.E.; Tsirivis, A.S. Electricity production and sustainable development: The role of renewable energy sources and specific socioeconomic factors. Energies 2023, 16, 721. [Google Scholar] [CrossRef]

- Dolega, W. Energy efficiency of national economy-selected aspects. Przegląd Elektrotechniczny 2022, 98, 118–122. [Google Scholar] [CrossRef]

- Rahman, M.M.; Sultana, N.; Velayutham, E. Renewable energy, energy intensity and carbon reduction: Experience of large emerging economies. Renew. Energy 2022, 184, 252–265. [Google Scholar] [CrossRef]

- Voigt, S.Z.; Cian, E.; Schymura, M.; Verdolini, E. Energy intensity developments in 40 major economies: Structural change or technology improvement? Energy Econ. 2014, 41, 47–62. [Google Scholar] [CrossRef]

- Antoszewski, M. Macroeconomic, sectoral, and fiscal implications of decreasing energy intensity in the Polish economy. Gospod. Nar. Pol. J. Econ. 2020, 303, 53–81. [Google Scholar] [CrossRef]

- Qi, S.Z.; Li, K. The convergence analysis on the economic growth and energy intensity gap between regional sectors. Chin. J. Popul. Resour. Environ. 2011, 9, 33–46. [Google Scholar]

- Chaika, L.V. Objectives and methods of analyzing energy efficiency in the economy. Econ. Soc. Chang. Facts Trends Forecast. 2018, 11, 117–126. [Google Scholar] [CrossRef]

- Mutumba, G.S.; Odongo, T.; Okurut, N.F.; Begire, V. A survey of literature on energy consumption and economic growth. Energy Rep. 2021, 7, 9150–9239. [Google Scholar] [CrossRef]

- Amasyali, K.; El-Gohary, N.M. A review of data-driven building energy consumption prediction studies. Renew. Sustain. Energy Rev. 2018, 81, 1192–1205. [Google Scholar] [CrossRef]

- Gvozdenac-Urosevic, B. Energy efficiency and the gross domestic product. Therm. Sci. 2010, 14, 799–808. [Google Scholar] [CrossRef]

- Vladucu, L.V. Analysis of the correlation between the Gross Domestic Product and the final consumption of electricity. Proc. Int. Conf. Bus. Excell. 2020, 14, 59–73. [Google Scholar] [CrossRef]

- Liu, Y.H.; Huang, X.J.; Chen, W.L. The Dynamic Effect of High-Tech Industries’ R&D Investment on Energy Consumption. Sustanability 2019, 11, 4090. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. A Pro-Environmental Method of Sample Size Determination to Predict the Quality Level of Products Considering Current Customers’ Expectations. Sustainability 2021, 13, 5542. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. Model Supporting Development Decisions by Considering Qualitative–Environmental Aspects. Sustainability 2021, 13, 9067. [Google Scholar] [CrossRef]

- Li, W.; Shen, Y.B.; Zhang, H.X. Evaluation of the influencing factors of energy consumption in China’s energy-intensive industries. J. Energy Eng. 2017, 143, 04017017. [Google Scholar] [CrossRef]

- Olaru, L.M.; Gellert, A.; Fiore, U.; Palmieri, F. Electricity production and consumption modeling through fuzzy logic. Int. J. Intell. Syst. 2022, 37, 8348–8364. [Google Scholar] [CrossRef]

- Matos, C.; Sola, A.V.H.; Matias, G.D.; Lermen, F.H.; Ribeiro, J.L.D.; Siqueira, H.V. Model for integrating the electricity cost consumption and power demand into aggregate production planning. Appl. Sci. 2022, 12, 7577. [Google Scholar] [CrossRef]

- Lakovic, M.; Pavlovic, I.; Banjac, M.; Jovic, M.; Mancic, M. Numerical computation and prediction of electricity consumption in tobacco industry. Facta Univ. Ser. Mech. Eng. 2018, 15, 457–465. [Google Scholar] [CrossRef]

- Jasiński, T. Modeling electricity consumption using nighttime light images and artificial neural networks. Energy 2019, 179, 831–842. [Google Scholar] [CrossRef]

- Grigoras, G.; Neagu, B.C.; Iwanow, O. An Efficient Approach for Flattening the Electricity Consumption Profile at Small and Medium Enterprises. In Proceedings of the 2019 8th International Conference on Modern Power Systems (MPS), Cluj Napoca, Romania, 21–23 May 2019. [Google Scholar]

- Corsi, A.; Barboza, B.M.L.; Pagani, R.N.; Chiroli, D.M.D.; Kowalski, J.L. Technology transfer oriented to sustainable development: Barriers and opportunities. J. Inf. Knowl. Manag. 2021, 20, 2150015. [Google Scholar] [CrossRef]

- Pandey, N.; de Coninck, H.; Sagar, A.D. Beyond technology transfer: Innovation cooperation to advance sustainable development in developing countries. Wiley Interdiscip. Rev. Energy Environ. 2022, 11, e422. [Google Scholar] [CrossRef]

- Craiut, L.; Bangau, C.; Negru, P.A.; Bungau, T.; Radu, A.F. Technology transfer in the context of sustainable development-a bibliometric analysis of publications in the field. Sustanability 2022, 14, 11973. [Google Scholar] [CrossRef]

- Chung, H. Adoption and development of the fourth industrial revolution technology: Features and determinants. Sustanability 2021, 13, 871. [Google Scholar] [CrossRef]

- Wolniak, R.; Saniuk, S.; Grabowska, S.; Gajdzik, B. Identification of energy efficiency trends in the context of the development of industry 4.0 using the Polish steel sector as an example. Energies 2020, 13, 2867. [Google Scholar] [CrossRef]

- Bendjama, H.; Bouhouche, S.; Aouabdi, S.; Bast, J. Monitoring of casting quality using principal component analysis and self-organizing map. Int. J. Adv. Manuf. Technol. 2022, 120, 3599–3607. [Google Scholar] [CrossRef]

- Pacana, A.; Czerwińska, K. Model of diagnosing and searching for incompatibilities in aluminium castings. Materials 2021, 14, 6497. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.Y.; Ummethala, R.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G.; Wang, Z. Additive manufacturing of aluminum-based metal matrix composites-a review. Adv. Eng. Mater. 2021, 23, 7. [Google Scholar] [CrossRef]

- Beals, R.; Niu, X.P.; Brown, Z. Development of Advanced Aluminum Alloy for Structural Castings. In Light Metals 2022; Minerals Metals & Materials Series; Springer International Publishing: Cham, Switzerland, 2022; pp. 73–82. [Google Scholar] [CrossRef]

- Zyska, A.; Boron, K. Comparison of the porosity of aluminum alloys castings produced by squeeze casting. Manuf. Technol. 2021, 21, 725–734. [Google Scholar] [CrossRef]

- Li, Y.; Liu, J.X.; Zhang, Q.; Huang, W.Q. Casting defects and microstructure distribution characteristics of aluminum alloy cylinder head with complex structure. Mater. Today Commun. 2021, 27, 102416. [Google Scholar] [CrossRef]

- Chelladurai, C.; Mohan, N.S.; Hariharashayee, D.; Manikandan, S.; Sivaperumal, P. Analyzing the casting defects in small scale casting industry. Mater. Today Proc. 2021, 37, 386–394. [Google Scholar] [CrossRef]

- Pacana, A.; Czerwińska, K. Comparative tests of the quality of the piston combustion chamber for a diesel engine. Tech. Vjestn. Tech. Gaz. 2020, 27, 1021–2024. [Google Scholar] [CrossRef]

- Ulewicz, R.; Mazur, M.; Novy, F. The impact of lean tools on the level of occupational safety in metals foundries. In Proceedings of the 28th International Conference on Metallurgy and Materials (METAL 2019), Brno, Czech Republic, 22–24 May 2019; pp. 2013–2019. [Google Scholar]

- Six, S.; Fischer, L.; Gusarova, T.; Schulze, S.; van den Bogert, R.J.; Kamperman, A.A. Advanced cast product quality testing. Metall. Ital. 2022, 1, 79–85. [Google Scholar]

- Kong, D.C.; Sun, D.Z.; Yang, B.C.; Qiao, H.B.; Wei, C.Y.; Lang, Y.L.; Song, H.W.; Gao, J. Characterization and modeling of damage behavior of a casting aluminum wheel considering inhomogeneity of microstructure and microdefects. Eng. Fail. Anal. 2023, 145, 107018. [Google Scholar] [CrossRef]

- Huang, M.Y.; Zhou, Q.; Wang, J.Y.; Li, S. Die casting die design and process optimization of aluminum alloy gearbox shell. Materials 2021, 14, 3999. [Google Scholar] [CrossRef]

- Pacana, A.; Czerwińska, K. Analysis of the causes of control panel inconsistencies in the gravitational casting process by means of quality management instruments. Prod. Eng. Arch. 2019, 25, 12–16. [Google Scholar] [CrossRef]

- Parlak, I.E.; Emel, E. Deep learning-based detection of aluminum casting defects and their types. Eng. Appl. Ertificial Intell. 2023, 188, 105636. [Google Scholar] [CrossRef]

- Szalva, P.; Orbulov, I.N. Effects of artificial and natural defects on fatigue strength of a cast aluminum alloy. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 3214–3218. [Google Scholar] [CrossRef]

- Gupta, M.; Khan, M.A.; Butola, R.; Singari, R.M. Advances in Applications of Non-Destructive Testing (NDT): A review. Adv. Mater. Process. Technol. 2022, 8, 2286–2307. [Google Scholar] [CrossRef]

- Towsyfyan, H.; Biguri, A.; Boardman, R.; Blumensath, T. Successes and challenges in non-destructive testing of aircraft composite structures. Chin. J. Aeronaut. 2020, 33, 771–791. [Google Scholar] [CrossRef]

- Arsic, M.; Arsic, D.; Flajs, A.; Grabovic, A.; Todić, A. Application of non-destructive testing for condition analysis, repair of dam-ages and integrity assessment of vital steel structures. Russ. J. Nondestruct. Test. 2021, 57, 918–931. [Google Scholar] [CrossRef]

- Pacana, A.; Radon-Cholewa, A.; Pacana, J.; Woźny, A. The study of stickiness of packaging film by Shainin method. Przem. Chem. 2015, 94, 1334–1336. [Google Scholar]

- Górska, M.; Daron, M. Importance of machine modernization in energy efficiency management of manufacturing companies. Energies 2021, 14, 8383. [Google Scholar] [CrossRef]

- Bosu, I.; Mahmoud, H.; Hussan, H. Energy audit and management of an industrial site based on energy efficiency, economic, and environmental analysis. Appl. Energy 2023, 333, 120619. [Google Scholar] [CrossRef]

- Siemeonovski, K.; Kaftandzieva, T. Energy efficiency management across eu countries: A dea approach. Energies 2021, 14, 2619. [Google Scholar] [CrossRef]

- Ziabina, Y.; Navickas, V. Innovations in energy efficiency management: Role of public governance. Mark. Manag. Innov. 2022, 4, 218–227. [Google Scholar] [CrossRef]

- Jalo, N.; Johansson, I.; Andrei, M.; Nehler, T.; Thollander, P. Barriers to and drivers of energy management in Swedish SMEs. Energies 2021, 14, 6925. [Google Scholar] [CrossRef]

- Andrei, M.; Thollander, P. Knowledge demands for energy management in manufacturing industry-A systematic literature review. Renew. Sustain. Energy Rev. 2022, 159, 112168. [Google Scholar] [CrossRef]

- Hasan, A.S.M.M.; Raza, M.; Katic, M.; Trianni, A. Towards a framework linking industrial energy efficiency measures with production resources. In Proceedings of the 11th International Conference on Power and Energy Systems (Icpes 2021), Shanghai, China, 18–20 December 2021; pp. 856–860. [Google Scholar] [CrossRef]

- Smith, K.M.; Wilson, S.; Hassall, M.E. Could focusing on barriers to industrial energy efficiency create a new barrier to energy efficiency? J. Clean. Prod. 2021, 310, 127387. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Liu, J.; Zhang, Y.X.; Yuan, H.P.; Zhang, R.X.; Srinivasan, R.S. Practical issues in implementing machine-learning models for building energy efficiency: Moving beyond obstacles. Renew. Sustain. Energy Rev. 2021, 143, 110929. [Google Scholar] [CrossRef]

- Saunders, H.D.; Roy, J.; Azevedo, I.M.L.; Chakravarty, D.; Dasgupta, S.; Du Can, S.D.; Druckman, A.; Fourquet, R.; Grubb, M.; Lin, B.; et al. Energy Efficiency: What Has Research Delivered in the Last 40 Years? Annu. Rev. Environ. Resour. 2021, 46, 135–165. [Google Scholar] [CrossRef]

- Hsieh, J.C. Study of energy strategy by evaluating energy-environmental efficiency. Energy Rep. 2021, 8, 1379–1409. [Google Scholar] [CrossRef]

- Ulewicz, R.; Czerwińska, K.; Pacana, A. A rank model of casting non-conformity detection methods in the context of Industry 4.0. Materials 2023, 2022, 723. [Google Scholar] [CrossRef] [PubMed]

- Korzyński, M.; Pacana, A. Centreless burnishing and influence of its parameters on machining effects. J. Mater. Process. Technol. 2010, 210, 1217–1223. [Google Scholar] [CrossRef]

- Civera, M.; Surace, C. Non-Destructive Techniques for the Condition and Structural Health Monitoring of Wind Turbines: A Literature Review of the Last 20 Years. Sensors 2022, 22, 1627. [Google Scholar] [CrossRef] [PubMed]

- Charalampous, P.; Kostavelis, I.; Tzovaras, D. Non-destructive quality control methods in additive manufacturing: A survey. Rapid Prototyp. J. 2020, 26, 777–790. [Google Scholar] [CrossRef]

- Velev, B.G.; Ivanov, I.S.; Kamenov, V.V. Automated System for Complex Non-Destructive Testing of the Structure and Mechanical Properties of Mechanical Engineering Materials. Russ. J. Nondestruct. Test. 2021, 57, 203–211. [Google Scholar] [CrossRef]

- Wang, B.; Zhong, S.C.; Lee, T.L.; Fancey, K.S.; Mi, J.W. Non-destructive testing and evaluation of composite materials/structures: A state-of-the-art review. Adv. Mech. Eng. 2020, 12, 4. [Google Scholar] [CrossRef]

- Gandhi, N.; Rose, R.; Croxford, A.J.; Ward, C. Understanding system complexity in the non-destructive testing of advanced composite products. J. Manuf. Mater. Process. 2022, 6, 71. [Google Scholar] [CrossRef]

- Pacana, A.; Czerwinska, K.; Bednarova, L. Comprehensive improvement of the surface quality of the diesel engine piston. Metalurgija 2019, 58, 329–332. [Google Scholar]

- Mineo, C.; Vasilev, M.; Cowan, B.; MacLeod, C.N.; Pierce, S.G.; Wong, C.; Yang, E.; Fuentes, R.; Cross, E.J. Enabling robotic adaptive behaviour capabilities for new Industry 4.0 automated quality inspection paradigms. Insight 2020, 62, 338–344. [Google Scholar] [CrossRef]

- Li, T.; Xie, J.; Yin, Q. Application and Development of Radiographic Inspection Technique in PWRs. Front. Manuf. Sci. Meas. Technol. V 2015, 68–72. [Google Scholar]

- Shark, L.K.; Matuszewski, B.J.; Smith, J.P.; Varley, M.R. Automatic feature-based fusion of ultrasonic, radiographic and shearographic images for aerospace NDT. Insight 2001, 43, 607–615. [Google Scholar]

- Farrell, S.P. Detection of Aberrations in Bulk Density in Additive Manufactured 300 M Steel using X-ray Radiographic Testing and Ultrasonic Testing. J. Nondestruct. Eval. 2021, 40, 4. [Google Scholar] [CrossRef]

- Kumar, A.; Arnold, W. High resolution in non-destructive testing: A review. J. Appl. Phys. 2022, 132, 10. [Google Scholar] [CrossRef]

- Davis, G.; Nagarajah, R.; Palanisamy, S.; Rashid, R. Laser ultrasonic inspection of additive manufactured components. Int. J. Adv. Manuf. Technol. 2019, 102, 2571–2579. [Google Scholar] [CrossRef]

- Zhang, J.; Cho, Y.; Kim, J.; Malikov, A.K.U.; Kim, Y.H.; Yi, J.H.; Li, W.B. Non-Destructive Evaluation of Coating Thickness Using Water Immersion Ultrasonic Testing. Coatings 2022, 11, 1421. [Google Scholar] [CrossRef]

- Gudra, T.; Cieplik, P.; Opielinski, K.J. Ultrasonic Spectroscopy in Non-Destructive Testing (NDT) of Materials. Int. Congr. Ultrason. 2011, 1433, 408–411. [Google Scholar] [CrossRef]

- Pacana, A.; Czerwińska, K. Improving the quality level in the automotive industry. Prod. Eng. Arch. 2020, 26, 162–164. [Google Scholar] [CrossRef]

- Honarvar, F.; Varvani-Farahani, A. A review of ultrasonic testing applications in additive manufacturing: Defect evaluation, material characterization, and process control. Ultrasonics 2020, 108, 106227. [Google Scholar] [CrossRef] [PubMed]

- Rifai, D.; Abdalla, A.N.; Ali, K.; Razali, R. Giant magnetoresistance sensors: A review on structures and non-destructive eddy current testing applications. Sensors 2016, 16, 298. [Google Scholar] [CrossRef] [PubMed]

- Li, H.C.; Yu, Y.T.; Li, L.F.; Liu, B.W. A weighted estimation algorithm for enhancing pulsed eddy current infrared image in ecpt non-destructive testing. Appl. Sci. 2019, 9, 4199. [Google Scholar] [CrossRef]

- Kryukov, I.; Bohm, S. Prospects and limitations of eddy current shearography for non-destructive testing of adhesively bonded structural joints. J. Adhes. 2019, 95, 874–886. [Google Scholar] [CrossRef]

- Gao, P.; Wang, C.; Li, Y.; Kong, Z. Electromagnetic and eddy current NDT in weld inspection: A review. Insight 2015, 57, 337–345. [Google Scholar] [CrossRef]

- Lu, M.Y.; Meng, X.B.; Huang, R.C.; Chen, L.M.; Peyton, A.; Yin, W.L. Lift-off invariant inductance of steels in multi-frequency eddy-current testing. NDT E Int. 2021, 121, 102458. [Google Scholar] [CrossRef]

- Papas, N.; Tsongas, K.; Tzetzis, D. Investigation of traction sheave failure: Experimental and finite element analysis. J. Fail. Anal. Prev. 2022, 22, 595–608. [Google Scholar] [CrossRef]

- Luo, Q.W.; Fang, X.X.; Su, J.J.; Zhou, J.; Zhou, B.X.; Yang, C.H.; Liu, L.; Gui, W.H.; Tian, L. Automated visual defect classification for flat steel surface: A survey. IEEE Trans. Instrum. Meas. 2020, 69, 9329–9349. [Google Scholar] [CrossRef]

- Schimpg, D.W.; Paters, F. 3D analysis of casting surface characterization based on the variogram roughness method. Int. J. Met. 2021, 16, 1079–1090. [Google Scholar] [CrossRef]

- Lou, Q.W.; Fang, X.X.; Liu, L.; Yang, C.H.; Sun, Y.C. Automated visual defect detection for flat steel surface: A survey. IEEE Trans. Instrum. Meas. 2020, 63, 626–644. [Google Scholar] [CrossRef]

- Skotnicka-Zasadzien, B.; Wolniak, R.; Zasadzien, M. Use of quality engineering tools and methods for the analysis of production processes-case study. In Proceedings of the Second International Conference on Economic and Business Management (FEBM 2017), Wuhan, China, 20–22 October 2017; Volume 33, pp. 240–245. [Google Scholar]

- Klimecka-Tatar, D.; Ingaldi, M. How to indicate the areas for improvement in service process-the knowledge management and value stream mapping as the crucial elements of the business approach. Rev. Gest. Tecnol.-J. Manag. Technol. 2020, 20, 52–74. [Google Scholar] [CrossRef]

- Sun, S.Z.; Anwar, S. Electricity consumption, industrial production, and entrepreneurship in Singapore. Energy Policy 2015, 77, 70–78. [Google Scholar] [CrossRef]

- Kott, M.; Kott, J. Indicators of energy intensity in industry. In Proceedings of the 2014 11th International Conference on the European Energy Market (EEM), Krakow, Poland, 28–30 May 2014. [Google Scholar]

- Caratas, M.A.; Spatariu, E.C. Energy efficiency barriers contemporary approaches for energetic auditors. J. Environ. Prot. Ecol. 2014, 15, 382–386. [Google Scholar]

- Łucja, U.; Grisolia, G. Exergy inefficiency: An indicator for sustainable development analysis. Energy Rep. 2020, 5, 62–69. [Google Scholar] [CrossRef]

- Venu, N.; Revanesh, M.; Supriya, M.; Talawar, M.B.; Asha, A.; Isaac, L.D.; Ferede, A.W. Energy auditing and broken path identification for routing in large-scale mobile networks using machine learning. Wirel. Commun. Mob. Comput. 2022, 2022, 9418172. [Google Scholar] [CrossRef]

- Patterson, M.; Singh, P.; Cho, H. The current state of the industrial energy assessment and its impacts on the manufacturing industry. Energy Rep. 2022, 8, 7297–7311. [Google Scholar] [CrossRef]

| Author of the Study | Method | Application | Brief Description of the Method | Model Verification |

|---|---|---|---|---|

| Olaru, LM.; Gellert, A.; Fiore, U.; Palmieri, F. [21] | A method based on based on fuzzy logic | Modelling of electricity production and consumption | An intelligent energy management system that can make decisions and adjust consumption according to the current context and future electricity levels. | Evaluations of the method were carried out on a data set collected in a real household |

| Matos, C.; Sola, AVH.; Matias, GD.; Lermen, FH.; Ribeiro, JLD.; Siqueira, HV. [22] | A method based on the Holt–Winters predictive model | Energy Demand Planning in the production processes of enterprises | The model integrates costs with electricity consumption and power demand in aggregate production planning, taking into account market uncertainty. | The model was empirically applied to the food industry, considering a family of potato chips. |

| Lakovic, M.; Pavlovic, I.; Banjac, M.; Jovic, M.; Mancic, M. [23] | Method based on time series model (autoregressive model—AR) | Electricity consumption forecasts | The model uses a Monte Carlo simulation method to predict and analyse changes in energy consumption. One of the main parts of the AR model is a seasonal pattern that takes into account the climatic conditions for a given geographic area. This part of the model was determined by the Fourier transform and was used to avoid model complexity. A probabilistic range of input values is used to determine the future probabilistic level of energy consumption. | The model was verified using data from a tobacco plant as an example. |

| Jasiński, T. [24] | Method based on night light images and artificial neural networks | A model used to predict electricity production and consumption in the manufacturing sectors. | The SSN input variables were based on night-time light images from VIIRS DNB. The use of SSN enabled modelling of nonlinear relationships related to the complex structure of electricity demand. Satellite data were collected for 2013–2016 and included images of better quality (including higher resolution). The images were used to create multilayer perceptron models. The results obtained using the SSN method were compared with those obtained using linear regressions. | The survey covered the area of Poland |

| Grigoras, G.; Neagu, BC.; Iwanow. O. [25] | Method based on production scheduling in small and medium-sized enterprises | Model used to flatten consumption profile, save energy, and improve energy efficiency and economic performance | An effective approach to flattening the electricity consumption profile based on production scheduling in small and medium-sized enterprises. | Approach tested on an industrial customer (small car repair company) |

| Name | Model | Designation |

|---|---|---|

| Effectiveness of detection methods | (1) | S—checkpoint efficiency [%]; |

| CN—frequency of detection of nonconformities [%]; | ||

| F—frequency of occurrence of the control method [%]. | ||

| Cost-effectiveness of detection methods | (2) | EK—checkpoint cost-effectiveness [%]; |

| S—checkpoint efficiency [%]; | ||

| K—unit detection cost [%]. | ||

| Time efficiency of detection methods | (3) | EC—checkpoint time efficiency [%]; |

| S—checkpoint efficiency [%]; | ||

| Cz—unit detection time [%]. | ||

| Energy efficiency of detection methods | (4) | EE—energy efficiency of the checkpoint [%]; |

| S—checkpoint efficiency [%]; | ||

| En—energy intensity of the unit detection [%]. | ||

| Total efficiency of checkpoints | (5) | E—total efficiency [%]; |

| S—checkpoint efficiency [%]; | ||

| K—cost of unit detection [%]; | ||

| Cz—completion time of unit detection [%]; | ||

| En—energy intensity of the unit detection [%]. |

| Index | Ranking of Detection Methods |

|---|---|

| Effectiveness of detection methods | VT > RTG > ET > DC > UT (33) |

| Cost-effectiveness of detection methods | VT > DC > RTG > ET > UT (34) |

| Time efficiency of detection methods | VT > RTG > ET > UT > DC (35) |

| Energy efficiency of detection methods | VT > DC > RTG > ET > UT (36) |

| Total efficiency of checkpoints | VT > RTG > DC > ET > UT (37) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pacana, A.; Czerwińska, K.; Ostasz, G. Analysis of the Level of Efficiency of Control Methods in the Context of Energy Intensity. Energies 2023, 16, 3507. https://doi.org/10.3390/en16083507

Pacana A, Czerwińska K, Ostasz G. Analysis of the Level of Efficiency of Control Methods in the Context of Energy Intensity. Energies. 2023; 16(8):3507. https://doi.org/10.3390/en16083507

Chicago/Turabian StylePacana, Andrzej, Karolina Czerwińska, and Grzegorz Ostasz. 2023. "Analysis of the Level of Efficiency of Control Methods in the Context of Energy Intensity" Energies 16, no. 8: 3507. https://doi.org/10.3390/en16083507

APA StylePacana, A., Czerwińska, K., & Ostasz, G. (2023). Analysis of the Level of Efficiency of Control Methods in the Context of Energy Intensity. Energies, 16(8), 3507. https://doi.org/10.3390/en16083507