Experimental Study on Coal Seam Gas Desorption Characteristics Caused by Moisture under Stepwise Depressurization

Abstract

1. Introduction

2. Materials and Methods

2.1. Coal Sample Collection and Preparation

2.2. Basic Parameters of Coal Samples

2.3. Experimental Equipment

- (1)

- Vacuum degassing unit

- (2)

- High-pressure water injection unit

- (3)

- High-pressure gas injection unit

- (4)

- Isothermal adsorption test unit

- (5)

- Back pressure unit

- (6)

- Automatic metering unit

- (7)

- Data acquisition unit

2.4. Experimental Procedure

- (1)

- Coal sample preparation and air tightness checking: Weigh an appropriate amount of the coal sample and place it in the drying box at 105 °C for 6 h to remove the moisture. After cooling, use an electronic balance to weigh out 60 g of the dry coal sample and put it into the coal sample tank, then check the tightness of the coal sample tank and pipeline.

- (2)

- Vacuum degassing: Place the coal sample tank into the constant temperature water bath device, adjust the temperature to 60 °C, run the vacuum pump, pump the coal sample tank and pipeline to the vacuum state, and maintain the vacuum state for more than 12 h.

- (3)

- Adsorption balance under constant temperature: adjust the temperature of the water bath device to 30 °C and regulate the valve so that the gas adsorption equilibrium pressure is stable at the set pressure.

- (4)

- Water injection and replacement: inject a set volume of water into the coal sample tank through the water injection unit, close the valve of injection device, and open the valve of the back-pressure one. Then, adjust the back pressure to the first adsorption equilibrium, open the automatic gas metering device, collect the replaced gas into the air collection bag, and record the replaced amount of gas.

- (5)

- Desorption under stepwise depressurization: Set the first level of desorption pressure, collect the free gas under this level with the gas-collecting bag, close the valve connecting the coal sample tank to the bag when the pressure of the coal sample tank reaches the first level of desorption, start the back-pressure device and the automatic gas metering device, keep the back-pressure constant for desorption, and record the desorption. Repeat the above operation to complete the planned stepwise depressurization desorption.

- (6)

- Determination of water added: After the desorption experiment, remove all the coal samples and weigh them. The difference between the measured quality of the coal sample and that of the dried one is the actual water injection.

- (7)

- Data processing: Convert the desorption data obtained in the experiment into the volume under standard conditions (101,325 Pa, 0 °C). The conversion formula is as follows:where is the gas desorption amount in a standard state, mL/g; is the measured gas desorption amount at room temperature, mL/g; T is the laboratory temperature during the experiment, °C; and P0 is the atmospheric pressure, Pa.

- (8)

- Cycle experiments: Set a different moisture level, repeat the steps above, and carry out the stepwise depressurization desorption experiment under distinct moisture and diverse adsorption equilibrium pressure conditions, respectively. Record the desorption of gas under each experimental condition.

3. Results and Discussion

3.1. Replacement of Coal Sample Gas by External Water

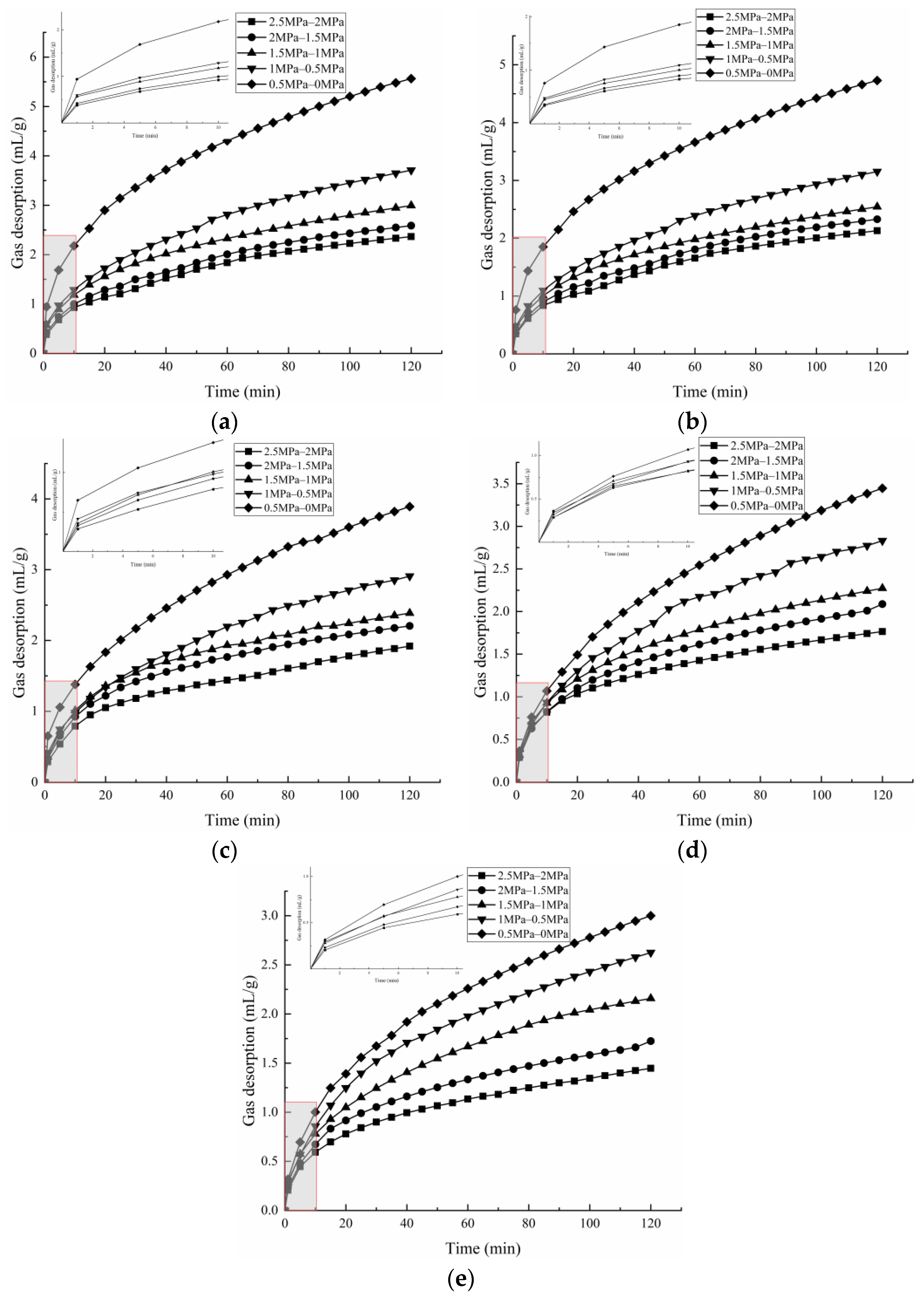

3.2. Gas Desorption Amount of Coal Samples with Different Moisture under Stepwise Depressurization Condition

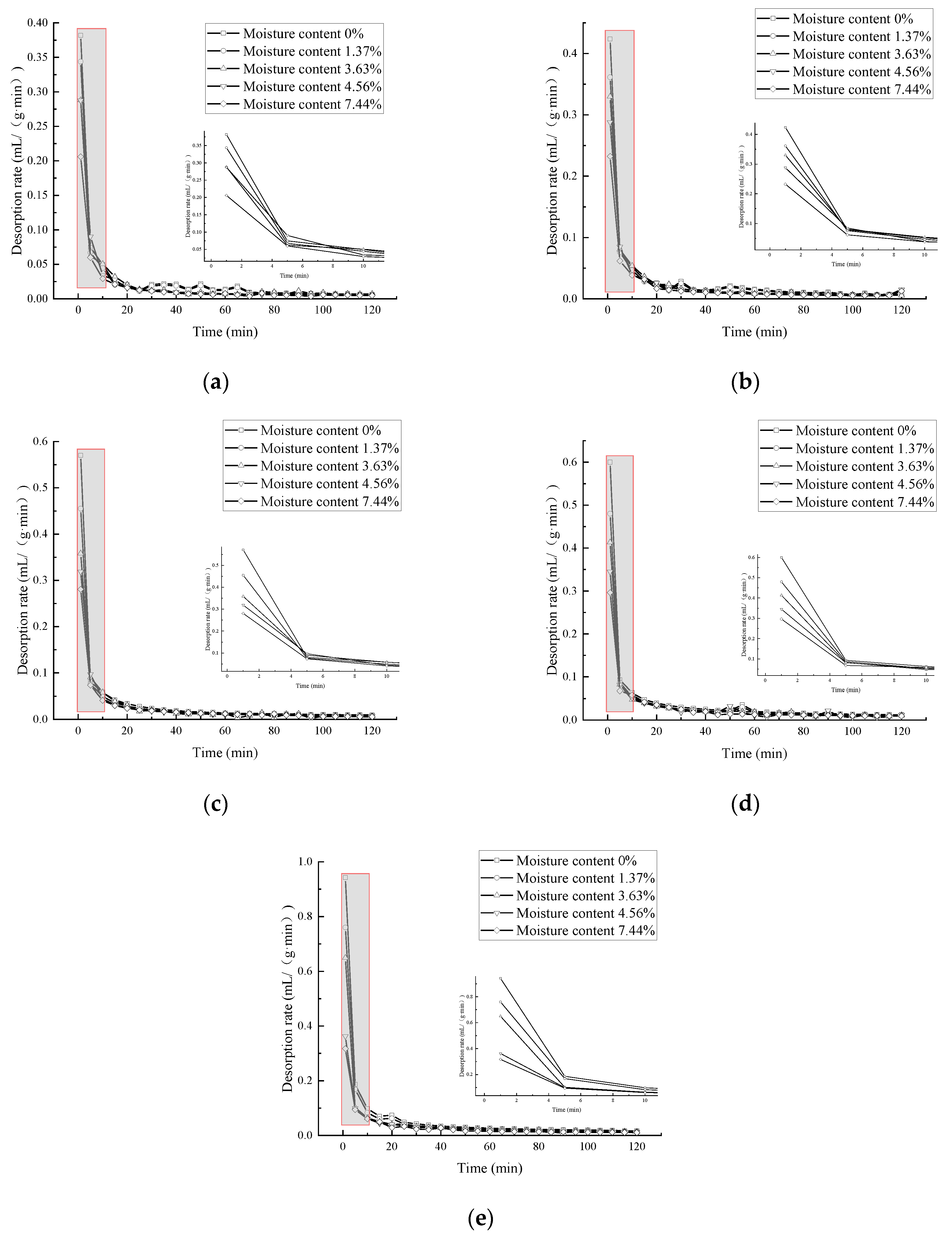

3.3. Gas Desorption Rate of Coal Samples with Different Moisture Levels under Stepwise Depressurization

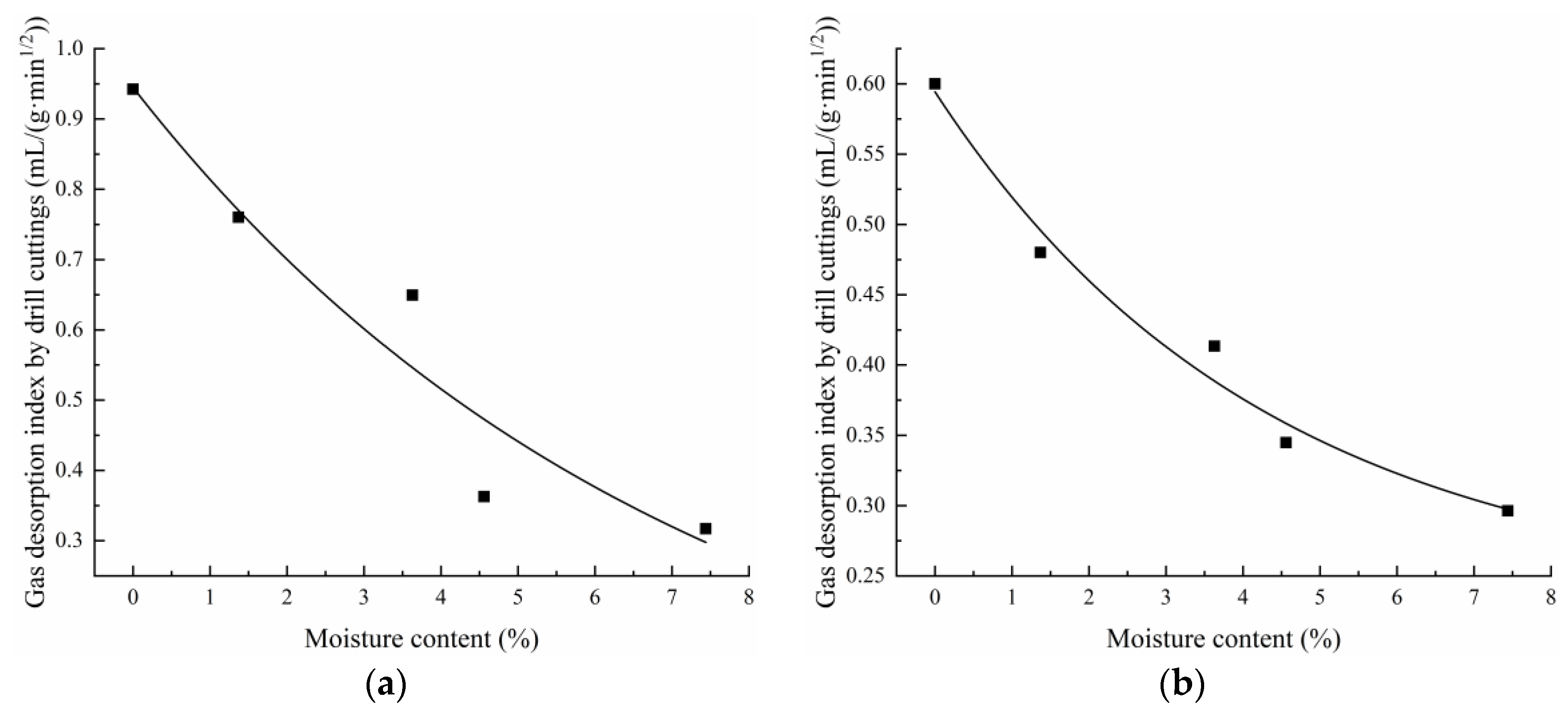

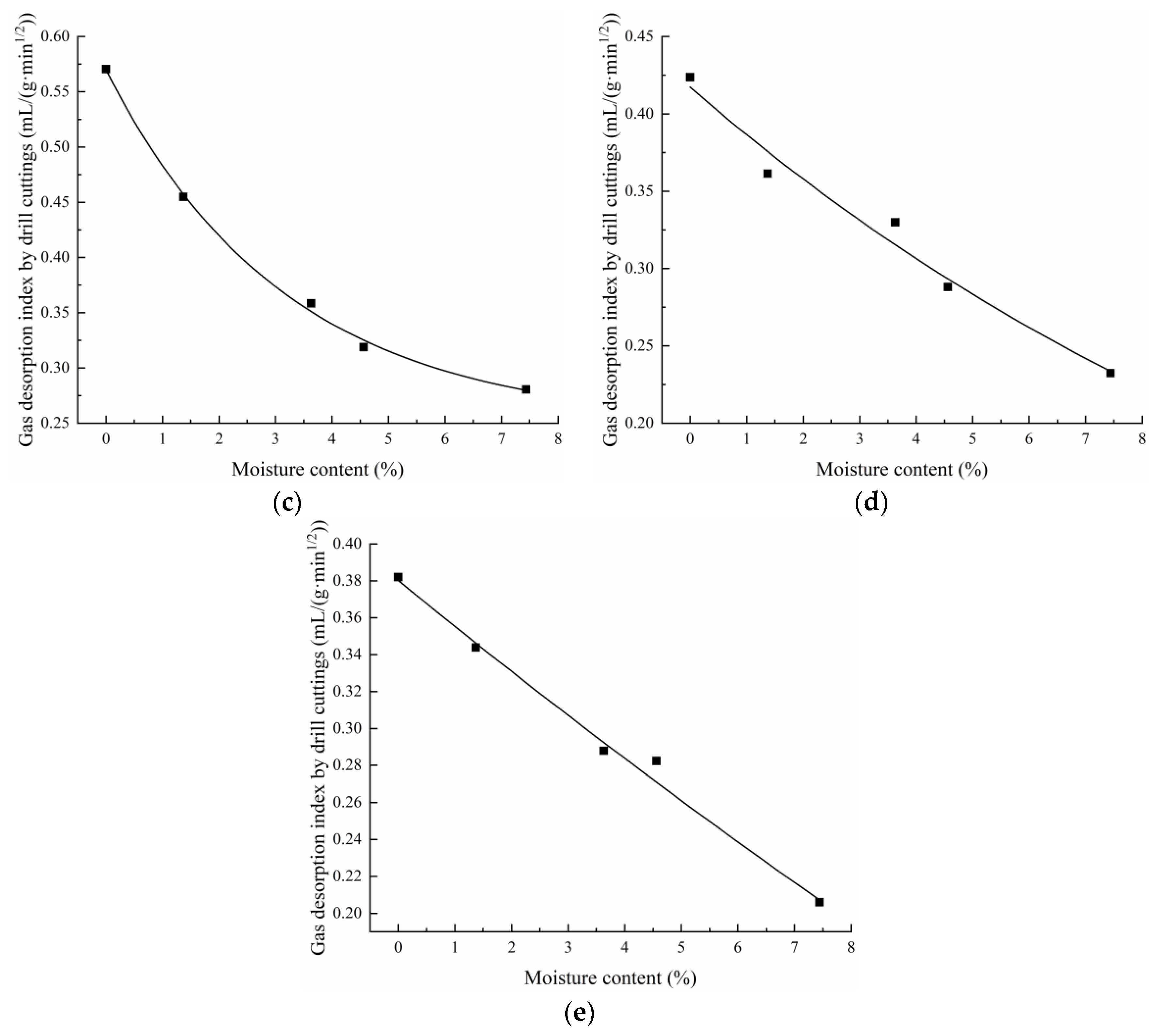

3.4. The Gas Desorption Index of Drill (K1) with Different Moisture Levels under Stepwise Depressurization Conditions

4. Conclusions

- (1)

- Added water can replace some of the adsorbed gas in coal samples. When the humidity rises from 0% to 7.44%, the replacement level reaches 8.04 mL/g. However, the increment shows a downtrend at different pressure drop stages, decreasing from 3.53 mL/g to 1.77 mL/g.

- (2)

- Added water can reduce the amount of gas desorption, and the desorption decreases from 17.219 mL/g to 10.954 mL/g under experimental conditions. When the adsorption equilibrium pressure changes from 0.5 MPa to 2.0 MPa, a reduction in amplitude occurs from 46.1% to 36.2%, and the range of desorption decreases gradually.

- (3)

- In the first 10 min, the desorption rate is faster and shows an obvious decreasing trend; after 30 min of desorption, the rate at different pressure drop stages is consistent and gradually approaches 0 mL/(g min). In the first 30 min, the rate decelerates, while after 30 min, the desorption rate remains basically the same under different humidity levels.

- (4)

- Water injection can reduce the risk of outburst. During each pressure drop stage, the indicator K1 shows a decreasing trend. When the water content increases from 0% to 7.44%, the decrease in K1 changes from 66.3% to 46.1%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jing, G.; Liu, M. Statistics and analysis of coal mine gas accidents in China from 2015 to 2019. J. Saf. Environ. 2022, 22, 1680–1686. [Google Scholar]

- Yuan, L. Research progress of mining response and disaster prevention and control in deep coal mines. J. China Coal Soc. 2021, 46, 716–725. [Google Scholar]

- Zhang, H.; Cheng, Y.; Deng, C.; Shu, L.; Pan, Z.; Yuan, L.; Wang, L.; Liu, Q. A Novel In-Seam Borehole Discontinuous Hydraulic Flushing Technology in the Driving Face of Soft Coal Seams: Enhanced Gas Extraction Mechanism and Field Application. Rock Mech. Rock Eng. 2022, 55, 885–907. [Google Scholar] [CrossRef]

- Yang, W.; Lu, C.; Si, G.; Lin, B.; Jiao, X. Coal and Gas Outburst Control Using Uniform Hydraulic Fracturing by Destress Blasting and Water-Driven Gas Release. J. Nat. Gas Sci. Eng. 2020, 79, 103360. [Google Scholar] [CrossRef]

- Lyu, S.; Wang, S.; Li, J.; Chen, X.; Chen, L.; Dong, Q.; Zhang, X.; Huang, P. Massive Hydraulic Fracturing to Control Gas Outbursts in Soft Coal Seams. Rock Mech. Rock Eng. 2022, 55, 1759–1776. [Google Scholar] [CrossRef]

- Niu, X.; Zhao, Y.; Li, K.; Zhang, Y. Ultra-High-Pressure Hydraulic Slitting Pressure Relief and Penetration Enhancement Technology and Equipment for Soft Coal Seams. Geofluids 2022, 2022, 1895836. [Google Scholar] [CrossRef]

- Hao, C.; Cheng, Y.; Liu, H.; Wang, L.; Liu, Q. A Novel Technology for High-Efficiency Borehole-Enlarging to Enhance Gas Drainage in Coal Seam by Mechanical Cutting Assisted by Waterjet. Energy Sources Part A-Recovery Util. Environ. Eff. 2022, 44, 1336–1353. [Google Scholar] [CrossRef]

- Lu, S.; Wang, C.; Wang, W.; Li, M.; Zhang, D. Analysis on the Shape and Impact Pressure of the High-Pressure Water Jet during the Hydraulic Flushing Cavity Technique. Geofluids 2021, 2021, 7496540. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Fu, X.; Zhao, Y.; Gao, Y.; Yang, W. Modeling Coupled Gas Flow and Geomechanics Process in Stimulated Coal Seam by Hydraulic Flushing. Int. J. Rock Mech. Min. Sci. 2021, 142, 104769. [Google Scholar] [CrossRef]

- Shi, Y.; Lin, B.; Liu, T.; Zhao, Y.; Hao, Z. Synergistic ECBM Extraction Technology and Engineering Application Based on Hydraulic Flushing Combing Gas Injection Displacement in Low Permeability Coal Seams. Fuel 2022, 318, 123688. [Google Scholar] [CrossRef]

- Hu, Q.; Liu, L.; Li, Q.; Wu, Y.; Wang, X.; Jiang, Z.; Yan, F.; Xu, Y.; Wu, X. Experimental Investigation on Crack Competitive Extension during Hydraulic Fracturing in Coal Measures Strata. Fuel 2020, 265, 117003. [Google Scholar] [CrossRef]

- Guanhua, N.; Kai, D.; Shang, L.; Qian, S. Gas Desorption Characteristics Effected by the Pulsating Hydraulic Fracturing in Coal. Fuel 2019, 236, 190–200. [Google Scholar] [CrossRef]

- Mou, P.; Pan, J.; Wang, K.; Wei, J.; Yang, Y.; Wang, X. Influences of Hydraulic Fracturing on Microfractures of High-Rank Coal under Different in-Situ Stress Conditions. Fuel 2021, 287, 119566. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Q.; Li, Q. Investigation of the Stress Evolution under the Effect of Hydraulic Fracturing in the Application of Coalbed Methane Recovery. Fuel 2021, 300, 120930. [Google Scholar] [CrossRef]

- Shang, Z.; Wang, Z.; Cheng, Z.; Wang, H.; Chen, L.; Li, L.; Fu, J.; Liu, H. Permeability Enhancement Technology for Soft and Low-Permeability Coal Seams Combined with Hydraulic Perforation and Hydraulic Fracturing. Geofluids 2022, 2022, 7958712. [Google Scholar] [CrossRef]

- Lu, W.; Huang, B.; Zhao, X. A Review of Recent Research and Development of the Effect of Hydraulic Fracturing on Gas Adsorption and Desorption in Coal Seams. Adsorpt. Sci. Technol. 2019, 37, 509–529. [Google Scholar] [CrossRef]

- Guo, C.; Gou, J.; Ma, D.; Bao, Y.; Shi, Q.; Meng, J.; Gao, J.; Lu, L. Adsorption and Desorption Behavior under Coal-Water-Gas Coupling Conditions of High- and Low-Rank Coal Samples. Front. Earth Sci. 2022. [Google Scholar] [CrossRef]

- Wang, C.; Li, X.; Xu, C.; Chen, Y.; Tang, Z.; Zhang, C.; Du, Y.; Gao, X.; Jiang, C. Dynamic Characterization during Gas Initial Desorption of Coal Particles and Its Influence on the Initiation of Coal and Gas Outbursts. Processes 2021, 9, 1101. [Google Scholar] [CrossRef]

- Cheng, M.; Fu, X.; Kang, J.; Chen, Z.; Tian, Z. Effect of Water on Methane Diffusion in Coal under Temperature and Pressure: A LF-NMR Experimental Study on Successive Depressurization Desorption. Fuel 2022, 324, 124578. [Google Scholar] [CrossRef]

- Wang, L.; Wang, B.; Zhu, J.; Liao, X.; Ni, S.; Shen, S. Experimental Study on Alleviating Water-Blocking Effect and Promoting Coal Gas Desorption by Gas Wettability Alteration. J. Nat. Gas Sci. Eng. 2022, 108, 104805. [Google Scholar] [CrossRef]

- Chen, M.; Chen, X.; Zhang, X.; Tian, F.; Sun, W.; Yang, Y.; Zhang, T. Experimental Study of the Pore Structure and Gas Desorption Characteristics of a Low-Rank Coal: Impact of Moisture. ACS Omega 2022, 7, 37293–37303. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Du, F.; Wang, F.; Zhang, P.; Jiang, Y.; Cui, B. Influence of Water Injection on the Desorption Characteristics of Coalbed Methane. Energy Sci. Eng. 2020, 8, 4222–4228. [Google Scholar] [CrossRef]

- Zhang, K.; Cheng, Y.; Wang, L.; Dong, J.; Hao, C.; Jiang, J. Pore Morphology Characterization and Its Effect on Methane Desorption in Water-Containing Coal: An Exploratory Study on the Mechanism of Gas Migration in Water-Injected Coal Seam. J. Nat. Gas Sci. Eng. 2020, 75, 103152. [Google Scholar] [CrossRef]

- Pu, Y.; Wang, Y.; Shi, J.; Wu, K. Reconsideration of the Adsorption/Desorption Characteristics with the Influences of Water in Unconventional Gas Systems. Geofluids 2020, 2020, 8882307. [Google Scholar] [CrossRef]

- Mou, J.; Liu, H.; Zou, Y.; Li, Q. A New Method to Determine the Sensitivity of Coal and Gas Outburst Prediction Index. Arab. J. Geosci. 2020, 13, 465. [Google Scholar] [CrossRef]

- Sun, Z.; Li, L.; Wang, F.; Zhou, G. Desorption Characterization of Soft and Hard Coal and Its Influence on Outburst Prediction Index. Energy Sources Part A-Recovery Util. Environ. Eff. 2020, 42, 2807–2821. [Google Scholar] [CrossRef]

- Wang, F.; Liang, Y.; Sun, Z.; Li, L.; Li, X. Determination of the Sensitivity Index and Its Critical Value for Outburst Risk Prediction: A Case Study in Fuxiang Mine, China. Adsorpt. Sci. Technol. 2020, 38, 502–527. [Google Scholar] [CrossRef]

| Test Project | Moisture Mad (%) | Ash Ad (%) | Volatile Vdaf (%) | a (m3/t) | b (MPa−1) | True Density (g/cm3) | Apparent Density (g/cm3) | Porosity (%) |

|---|---|---|---|---|---|---|---|---|

| Test Results | 1.50 | 9.47 | 4.03 | 40.97 | 1.03 | 1.58 | 1.47 | 6.99 |

| Moisture/% | 0.00 | 1.37 | 3.63 | 4.50 | 7.44 |

| Replacement volume/(mL/g) | 0.00 | 3.53 | 4.43 | 6.27 | 8.04 |

| Adsorption equilibrium pressure after water injection/MPa | 2.50 | 2.90 | 3.01 | 3.21 | 3.41 |

| Gas Desorption Stage | Moisture 0% | Moisture 1.37% | Moisture 3.63% | Moisture 4.56% | Moisture 7.44% |

|---|---|---|---|---|---|

| 2.5 MPa–2 MPa | 2.365 | 2.129 | 1.920 | 1.764 | 1.448 |

| 2 MPa–1.5 MPa | 2.588 | 2.329 | 2.205 | 2.087 | 1.725 |

| 1.5 MPa–1 MPa | 2.994 | 2.545 | 2.386 | 2.272 | 2.158 |

| 1 MPa–0.5 MPa | 3.709 | 3.153 | 2.909 | 2.831 | 2.624 |

| 0.5 MPa–0 Pa | 5.563 | 4.728 | 3.891 | 3.446 | 2.999 |

| Aggregate | 17.219 | 14.884 | 13.311 | 12.400 | 10.954 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Chen, X.; Wang, L.; Shi, H.; Yu, T. Experimental Study on Coal Seam Gas Desorption Characteristics Caused by Moisture under Stepwise Depressurization. Energies 2023, 16, 3566. https://doi.org/10.3390/en16083566

Li X, Chen X, Wang L, Shi H, Yu T. Experimental Study on Coal Seam Gas Desorption Characteristics Caused by Moisture under Stepwise Depressurization. Energies. 2023; 16(8):3566. https://doi.org/10.3390/en16083566

Chicago/Turabian StyleLi, Xinjian, Xiangjun Chen, Lin Wang, Haoyang Shi, and Tongyong Yu. 2023. "Experimental Study on Coal Seam Gas Desorption Characteristics Caused by Moisture under Stepwise Depressurization" Energies 16, no. 8: 3566. https://doi.org/10.3390/en16083566

APA StyleLi, X., Chen, X., Wang, L., Shi, H., & Yu, T. (2023). Experimental Study on Coal Seam Gas Desorption Characteristics Caused by Moisture under Stepwise Depressurization. Energies, 16(8), 3566. https://doi.org/10.3390/en16083566