Testing Method for Electric Bus Auxiliary Heater Emissions

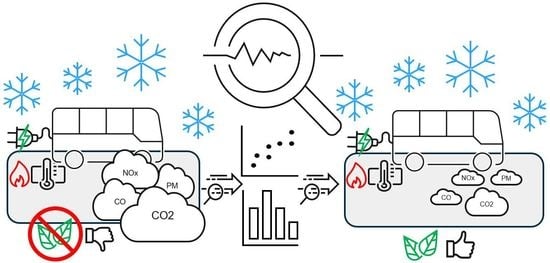

Abstract

:1. Introduction

Cabin Heating System of Electric Buses

2. Materials and Methods

2.1. Field Tests (Pre-Screening)

2.2. Laboratory Tests

- Opening and closing all cabin doors in a sequence representing an average door-opening sequence of an operating bus service—test time: 30 min.

- Doors were opened for 15 s every 75 s (baseline formed from HSL bus line 23, operating within the central area of Helsinki).

- Measurements were repeated with doors closed to represent the minimum thermal loss of the vehicle (best-case scenario)—test time: 30 min.

2.3. Utilisation Monitoring

- If the exhaust temperature is higher than in the previous timestep and exceeds 100 °C, active combustion is deduced.

- If the exhaust temperature is lower than in the previous timestep, but still exceeds 300 °C, active combustion is deduced.

- In all other cases, combustion is deduced to be not active.

3. Results

3.1. Pre-Screening in Field Conditions

3.2. Laboratory Tests

3.2.1. Ambient Conditions and Interior Temperatures

3.2.2. Auxiliary Heater Emissions

3.2.3. Utilisation Monitoring

3.3. Comparison against Real World Data

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. Global EV Data Explorer; IEA: Paris, France, 2022; Available online: https://www.iea.org/data-and-statistics/data-tools/global-ev-data-explorer (accessed on 27 February 2023).

- European Commission. Directive (EU) 2019/1161 of the European Parliament and of the Council of 20 June 2019, Amending Directive 2009/33/EC on the Promotion of Clean and Energy-Efficient Road Transport Vehicles. Off. J. Eur. Union 2019, 1–15. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019L1161&from=EN (accessed on 27 February 2023).

- UITP Europe. Frequently Asked Questions: Revised Clean Vehicles Directive. 2020, pp. 3–5, No. 1370. Available online: https://cleanbusplatform.eu/storage/files/faq-clean-vehicles-directive-revised-january-2020.pdf (accessed on 27 February 2023).

- Sutton, K.; Jokinen, K.; Silver, F. Fuel-Fired Heaters: Emissions, Fuel Utilization, and Regulations in Battery Electric Transit Buses. 2021. Available online: https://calstart.org/wp-content/uploads/2022/01/FFH-White-Paper_Final.pdf (accessed on 27 February 2023).

- Mobile Source Control Division. 2019-20 Grant Solicitation: Hybrid and Zero-Emission Truck and Bus Voucher Incentive Project (HVIP). 2019. Available online: https://ww2.arb.ca.gov/sites/default/files/classic/msprog/mailouts/msc1921/msc1921grantsolicitation.pdf (accessed on 27 February 2023).

- Vehviläinen, M.; Lavikka, R.; Rantala, S.; Paakkinen, M.; Laurila, J.; Vainio, T. Setting Up and Operating Electric City Buses in Harsh Winter Conditionse. Appl. Sci. 2022, 12, 2762. [Google Scholar] [CrossRef]

- Su, Z.; Li, H.; Liu, E.; Zhang, Z.; Yu, Z.; Han, C.; Bai, J.; Niu, H.; Zhai, J. Experimental study on performance of heat pump air conditioning system for pure electric bus with economizer. Therm. Sci. 2021, 25, 2075–2081. [Google Scholar] [CrossRef]

- Design Zero-Emission Transport Systems with VTT Smart eFleet Service. Customer References/Case: Jyväskylä, Finland. VTT. 2023. Available online: https://www.vttresearch.com/en/ourservices/design-zero-emission-transport-systems-vtt-smart-efleet-service (accessed on 27 February 2023).

- Müller, E.; Onder, C.; Guzzella, L.; Kneifel, M. Optimal control of a fuel-fired auxiliary heater for an improved passenger vehicle warm-up. Control Eng. Pract. 2009, 17, 664–675. [Google Scholar] [CrossRef]

- Blaschke, W.; Humburg, M.; Jensen, H.; Pfister, W. Reducing Emissions from Fuel Operated Vehicle Heaters. ATZ Worldw. 2018, 120, 54–59. [Google Scholar] [CrossRef]

- Karjalainen, P.; Nikka, M.; Olin, M.; Martikainen, S.; Rostedt, A.; Arffman, A.; Mikkonen, S. Fuel-Operated Auxiliary Heaters Are a Major Additional Source of Vehicular Particulate Emissions in Cold Regions. Atmosphere 2021, 12, 1105. [Google Scholar] [CrossRef]

- Force Technology. Measurement of Emissions from Diesel Fired Heaters for Buses. 2018. Available online: https://cleanbusplatform.eu/storage/files/measurement-of-emissions-from-diesel-fired-heaters-for-buses-report-force-738844-1.pdf (accessed on 27 February 2023).

- Vojtisek-Lom, M.; Dittrich, L.; Fenkl, M. Measurement of emissions from independent bus heaters. In Proceedings of the 19th Conference on Combustion Generated Nanoparticles, Zurich, Switzerland, 28 June–1 July 2015. [Google Scholar]

- Danish Technological Institute. Measurement of Emissions from Diesel Fired Heaters, January–March 2021. 2021. Available online: https://cleanbusplatform.eu/storage/files/measurement-of-emissions-from-diesel-heaters-ti-2021-1143767-1.pdf (accessed on 27 February 2023).

- ISO 8178-4; Reciprocating Internal Combustion Engines—Exhaust Emission Measurement—Part 4: Steady-State and Transient Test Cycles for Different Engine Applications. International Organization for Standardization: Geneva, Switzerland, 2020; p. 240.

- EPA (USA). Nitrogen Oxides (NOx), Why and How They Are Controlled; Epa-456/F-99-006R, No. November; Diane Publishing: Darby, PA, USA, 1999; p. 48.

| DUT | DUT | DUT | DUT | DUT | DUT | DUT | DUT | DUT | Average | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| #1 | #2 | #3 | #4 | #5 | #6 | #7 | #8 | #9 | All | ||

| Gross Power (avg) | kW | 43.1 | 34.7 | 39.4 | 38.6 | 40.5 | 42.6 | 38.0 | 39.5 | 40.4 | 39.6 |

| Net Power (avg) | kW | 35.3 | 28.5 | 32.3 | 31.6 | 33.2 | 34.9 | 31.1 | 32.4 | 33.1 | 32.5 |

| Amb | Condition | Utilisation Rate | Gross Power | Net Power | Fuel Consumption | CO2 | CO | NOx | Soot | Avg. Battery Power |

|---|---|---|---|---|---|---|---|---|---|---|

| °C | % | kW | kW | kg/h | kg/h | g/h | g/h | g/h | kW | |

| 10 | Doors operated | 0% | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 6.8 |

| Doors closed | 0% | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 6.1 | |

| Average | 0% | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 6.4 | |

| 0 | Doors operated | 33.7% | 14.4 | 11.8 | 1.2 | 3.7 | 2.3 | 2.6 | 0.019 | 5.1 |

| Doors closed | 13.5% | 5.7 | 4.7 | 0.5 | 1.5 | 1.9 | 0.9 | 0.004 | 4.4 | |

| Average | 23.6% | 10.0 | 8.2 | 0.8 | 2.6 | 2.1 | 1.7 | 0.012 | 4.8 | |

| −10 | Doors operated | 52.2% | 22.2 | 18.2 | 1.8 | 5.7 | 5.0 | 3.9 | 0.040 | 4.7 |

| Doors closed | 10.2% | 4.3 | 3.6 | 0.4 | 1.1 | 1.2 | 0.8 | 0.005 | 7.4 | |

| Average | 31.2% | 13.3 | 10.9 | 1.1 | 3.4 | 3.1 | 2.3 | 0.022 | 6.1 | |

| −20 | Doors operated | 61.5% | 26.2 | 21.5 | 2.2 | 6.7 | 7.9 | 4.8 | 0.132 | 7.4 |

| Doors closed | 47.0% | 20.0 | 16.4 | 1.6 | 5.1 | 7.1 | 3.6 | 0.128 | 6.9 | |

| Average | 54.3% | 23.1 | 18.9 | 1.9 | 5.9 | 7.5 | 4.2 | 0.130 | 7.2 |

| Period | Duration | Utilisation Rate | Average Temperature | Minimum Temperature | Maximum Temperature |

|---|---|---|---|---|---|

| hh:mm | % | °C | °C | °C | |

| 1 | 0:35 | 54.6% | −7.5 | −8.5 | −6.5 |

| 2 | 0:49 | 49.0% | −4.0 | −4.1 | −3.9 |

| 3 | 1:05 | 47.1% | −6.2 | −6.4 | −5.9 |

| 4 | 1:20 | 42.7% | −3.9 | −4.2 | −3.6 |

| 5 | 2:10 | 41.8% | −2.8 | −3.4 | −2.5 |

| 6 | 1:17 | 39.3% | −3.2 | −3.3 | −3.0 |

| 7 | 2:02 | 38.8% | −5.2 | −5.6 | −4.4 |

| 8 | 1:10 | 36.4% | −5.1 | −5.4 | −4.8 |

| 9 | 2:45 | 36.4% | −1.8 | −2.0 | −1.7 |

| 10 | 1:40 | 35.6% | −4.5 | −4.8 | −4.3 |

| 11 | 2:00 | 34.4% | −6.1 | −6.5 | −5.3 |

| 12 | 2:27 | 33.8% | −3.7 | −4.5 | −3.1 |

| 13 | 0:35 | 31.5% | −4.4 | −4.8 | −3.9 |

| 14 | 2:08 | 29.8% | −5.7 | −6.3 | −5.2 |

| 15 | 7:20 | 29.8% | −3.0 | −3.5 | −2.6 |

| 16 | 2:45 | 28.6% | −4.0 | −4.5 | −3.4 |

| 17 | 1:38 | 27.9% | −1.9 | −2.0 | −1.8 |

| 18 | 2:02 | 27.2% | −4.3 | −4.6 | −3.7 |

| 19 | 0:25 | 25.1% | −2.9 | −3.0 | −2.9 |

| 20 | 3:50 | 24.8% | −4.4 | −4.9 | −3.9 |

| 21 | 1:52 | 22.1% | −4.1 | −4.2 | −3.9 |

| 22 | 0:54 | 20.7% | −4.8 | −5.0 | −4.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pettinen, R.; Anttila, J.; Muona, T.; Pihlatie, M.; Åman, R. Testing Method for Electric Bus Auxiliary Heater Emissions. Energies 2023, 16, 3578. https://doi.org/10.3390/en16083578

Pettinen R, Anttila J, Muona T, Pihlatie M, Åman R. Testing Method for Electric Bus Auxiliary Heater Emissions. Energies. 2023; 16(8):3578. https://doi.org/10.3390/en16083578

Chicago/Turabian StylePettinen, Rasmus, Joel Anttila, Tommi Muona, Mikko Pihlatie, and Rafael Åman. 2023. "Testing Method for Electric Bus Auxiliary Heater Emissions" Energies 16, no. 8: 3578. https://doi.org/10.3390/en16083578

APA StylePettinen, R., Anttila, J., Muona, T., Pihlatie, M., & Åman, R. (2023). Testing Method for Electric Bus Auxiliary Heater Emissions. Energies, 16(8), 3578. https://doi.org/10.3390/en16083578