High Heat Flux Testing of Graded W-Steel Joining Concepts for the First Wall

Abstract

:1. Introduction

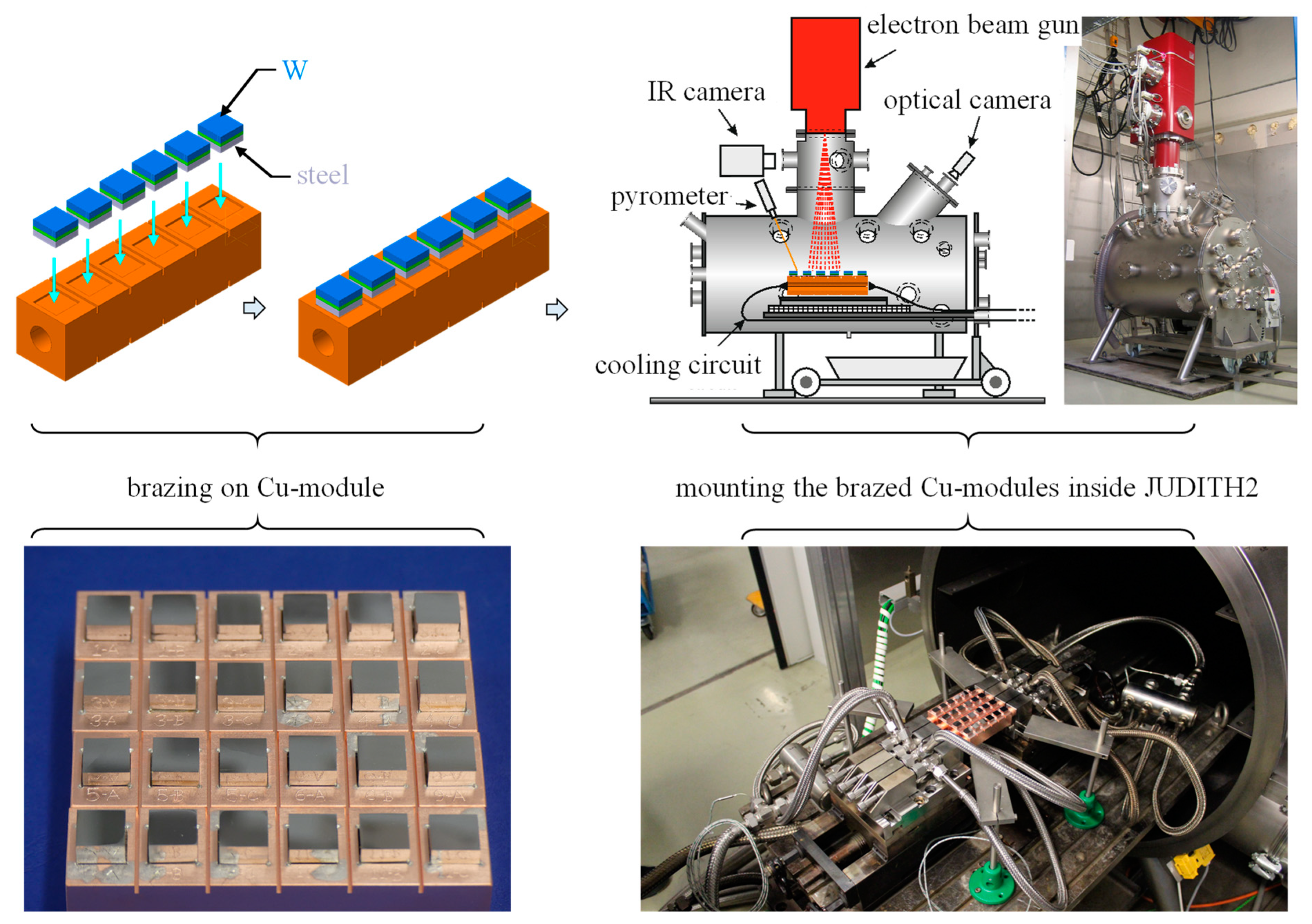

2. Components and Testing Methodology

2.1. Overview of the Manufactured W and Steel Joints

2.2. HHF Testing Procedure

2.3. Thermal Loading Protocol

2.4. Post Mortem Analysis

3. Results

3.1. Temperature Evolution of Joints

3.2. Post-Mortem Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barrett, T.R.; Ellwood, G.; Pérez, G.; Kovari, M.; Fursdon, M.; Domptail, F.; Kirk, S.; McIntosh, S.C.; Roberts, S.; Zheng, S.; et al. Progress in the engineering design and assessment of the European DEMO first wall and divertor plasma facing components. Fusion Eng. Des. 2016, 109–111, 917–924. [Google Scholar] [CrossRef]

- Catanzaro, I.; Arena, P.; Basile, S.; Bongiovì, G.; Chiovaro, P.; Del Nevo, A.; Di Maio, P.A.; Forte, R.; Maione, I.A.; Vallone, E. Structural assessment of the EU-DEMO WCLL Central Outboard Blanket segment under normal and off-normal operating conditions. Fusion Eng. Des. 2021, 167, 112350. [Google Scholar] [CrossRef]

- Arena, P.; Del Nevo, A.; Moro, F.; Noce, S.; Mozzillo, R.; Imbriani, V.; Giannetti, F.; Edemetti, F.; Froio, A.; Savoldi, L.; et al. The DEMO Water-Cooled Lead–Lithium Breeding Blanket: Design Status at the End of the Pre-Conceptual Design Phase. Appl. Sci. 2021, 11, 11592. [Google Scholar] [CrossRef]

- Heuer, S.; Weber, T.; Pintsuk, G.; Coenen, J.W.; Matejicek, J.; Linsmeier, C. Aiming at understanding thermo-mechanical loads in the first wall of DEMO: Stress-strain evolution in a Eurofer-tungsten test component featuring a functionally graded interlayer. Fusion Eng. Des. 2018, 135, 141–153. [Google Scholar] [CrossRef]

- Qu, D.; Basuki, W.W.; Aktaa, J. Numerical assessment of functionally graded tungsten/EUROFER coating system for first wall applications. Fusion Eng. Des. 2015, 98–99, 1389–1393. [Google Scholar] [CrossRef]

- Kavka, T.; Matejicek, J.; Ctibor, P.; Hrabovsky, M. Spraying of metallic powders by hybrid gas/water torch and the effects of inert gas shrouding. J. Therm. Spray Technol. 2012, 21, 695–705. [Google Scholar] [CrossRef]

- Ganesh, V.; Dorow-Gerspach, D.; Heuer, S.; Matejicek, J.; Vilemova, M.; Bram, M.; Coenen, J.W.; Wirtz, M.; Pintsuk, G.; Theisen, W.; et al. Manufacturing of W-steel joint using plasma sprayed graded W/steel-interlayer with current assisted diffusion bonding. Fusion Eng. Des. 2021, 172, 112896. [Google Scholar] [CrossRef]

- Matejicek, J.; Boldyryeva, H. Processing and temperature-dependent properties of plasma-sprayed tungsten–stainless steel composites. Phys. Scr. 2009, T138, 14041. [Google Scholar] [CrossRef]

- Ganesh, V.; Dorow-Gerspach, D.; Bram, M.; Coenen, J.W.; Wirtz, M.; Pintsuk, G.; Theisen, W.; Linsmeier, C. Processing and properties of sintered W/steel composites for the first wall of future fusion reactor. JNE 2023, 4, 177–192. [Google Scholar] [CrossRef]

- Hirose, T.; Shiba, K.; Ando, M.; Enoeda, M.; Akiba, M. Joining technologies of reduced activation ferritic/martensitic steel for blanket fabrication. Fusion Eng. Des. 2006, 81, 645–651. [Google Scholar] [CrossRef]

- De Prado, J.; Sanchez, M.; Wirtz, M.; Pintsuk, G.; Du, J.; Linke, J.; Urena, A. Impact of thermal fatigue on W–W brazed joints for divertor components. J. Mater. Process. Technol. 2018, 252, 211–216. [Google Scholar] [CrossRef]

- De Prado, J.; Sanchez, M.; Wirtz, M.; Pintsuk, G.; Du, J.; Linke, J.; Urena, A. High heat flux performance of W-Eurofer brazed joints. J. Nucl. Mater. 2018, 499, 225–232. [Google Scholar] [CrossRef]

- Casalegno, V.; Perero, S.; Girman, V.; Sedlák, R.; Scarpellini, A.; Dorow-Gerspach, D.; Heuer, S.; Ferraris, M. W/Fe co-sputtered layers for tungsten to steel joints. Nucl. Mater. Energy 2023, 35, 101421. [Google Scholar] [CrossRef]

- Schmidt, A.; Bürger, A.; Dominiczak, K.; Keusemann, S.; Loewenhoff, T.; Linke, J.; Roedig, M.; Thomser, C. High heat flux testing of components for future fusion devices by means of the facility JUDITH 2. In Proceedings of the International Conference on High-Power Electron Beam Technology, International Conference on High-Power Electron Beam Technology, Reno, NV, USA, 24–26 October 2010; Curran: Red Hook, NY, USA, 2011. ISBN 9781617823992. [Google Scholar]

- Maviglia, F.; Bachmann, C.; Federici, G.; Franke, T.; Siccinio, M.; Albanese, R.; Ambrosino, R.; Arter, W.; Bonifetto, R.; Calabrò, G.; et al. Integrated design strategy for EU-DEMO first wall protection from plasma transients Fusion Engineering and Design 177 (2022) 113067. Fusion Eng. Des. 2022, 178, 113125. [Google Scholar] [CrossRef]

- Touloukian, Y.S.; Powell, R.W.; Ho, C.Y.; Klemens, P.G. Thermophysical Properties of Matter—The TPRC Data Series: Volume 1. Thermal Conductivity-Metallic Elements and Alloys; Springer: Boston, MA, USA, 1970; ISBN 978-1-4615-9602-8. [Google Scholar]

- Richou, M.; Gallay, F.; Böswirth, B.; Chu, I.; Dose, G.; Greuner, H.; Kermouche, G.; Lenci, M.; Loewenhoff, T.; Maestracci, R.; et al. Performance assessment of thick W/Cu graded interlayer for DEMO divertor target. Fusion Eng. Des. 2020, 157, 111610. [Google Scholar] [CrossRef]

- Müller, A.V.; Böswirth, B.; Cerri, V.; Greuner, H.; Neu, R.; Siefken, U.; Visca, E.; You, J.-H. Application of tungsten–copper composite heat sink materials to plasma-facing component mock-ups. Phys. Scr. 2020, T171, 14015. [Google Scholar] [CrossRef]

- Heuer, S.; Coenen, J.W.; Pintsuk, G.; Matejicek, J.; Vilemova, M.; Linsmeier, C. Overview of challenges and developments in joining tungsten and steel for future fusion reactors. Phys. Scr. 2020, T171, 14028. [Google Scholar] [CrossRef]

represents the lifetime of each sample and

represents the lifetime of each sample and  represents the scatter).

represents the scatter).

represents the lifetime of each sample and

represents the lifetime of each sample and  represents the scatter).

represents the scatter).

| Configuration | SEM Image | Nomenclature | Manufacturing Route | Joining Parameter | Interlayer Thickness (mm) |

|---|---|---|---|---|---|

| Graded joint featuring plasma sprayed FGM |  | FGM-APS | Modified atmospheric plasma spraying and joining by current assisted diffusion bonding | 1000 °C 30 min 50 MPa | V: 0.21 |

| 75W: 0.40 | |||||

| 50W: 0.39 | |||||

| 25W: 0.42 | |||||

| Graded joint featuring sintered FGM |  | FGM-SPS | Spark plasma sintering | 1000 °C 5 min 125 MPa | 75W: 0.59 |

| 50W: 0.50 | |||||

| 25W: 0.48 | |||||

| Joint featuring V interlayer |  | V(1.5) | Current assisted diffusion bonding | 1000 °C 30 min 20 MPa | V: 1.50 |

| Reference joint directly bonded |  | Direct | Current assisted diffusion bonding | 1000 °C 15 min 20 MPa | - |

| Heat Flux (MW/m2) | No. of Cycles | Cumulative No. of Cycles 1 |

|---|---|---|

| 1.0 | 200 | 200 |

| 1.5 | 200 | 400 |

| 2.0 | 200 | 600 |

| 2.5 | 200 | 800 |

| 3.0 | 200 | 1000 |

| 3.5 | 200 | 1200 |

| 4.0 | 200 | 1400 |

| 4.5 | 200 | 1600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ganesh, V.; Dorow-Gerspach, D.; Bram, M.; Linsmeier, C.; Matejicek, J.; Vilemova, M. High Heat Flux Testing of Graded W-Steel Joining Concepts for the First Wall. Energies 2023, 16, 3664. https://doi.org/10.3390/en16093664

Ganesh V, Dorow-Gerspach D, Bram M, Linsmeier C, Matejicek J, Vilemova M. High Heat Flux Testing of Graded W-Steel Joining Concepts for the First Wall. Energies. 2023; 16(9):3664. https://doi.org/10.3390/en16093664

Chicago/Turabian StyleGanesh, Vishnu, Daniel Dorow-Gerspach, Martin Bram, Christian Linsmeier, Jiri Matejicek, and Monika Vilemova. 2023. "High Heat Flux Testing of Graded W-Steel Joining Concepts for the First Wall" Energies 16, no. 9: 3664. https://doi.org/10.3390/en16093664

APA StyleGanesh, V., Dorow-Gerspach, D., Bram, M., Linsmeier, C., Matejicek, J., & Vilemova, M. (2023). High Heat Flux Testing of Graded W-Steel Joining Concepts for the First Wall. Energies, 16(9), 3664. https://doi.org/10.3390/en16093664