Smoke Formation during Combustion of Biofuel Blends in the Internal Combustion Compression Ignition Engine

Abstract

:1. Introduction

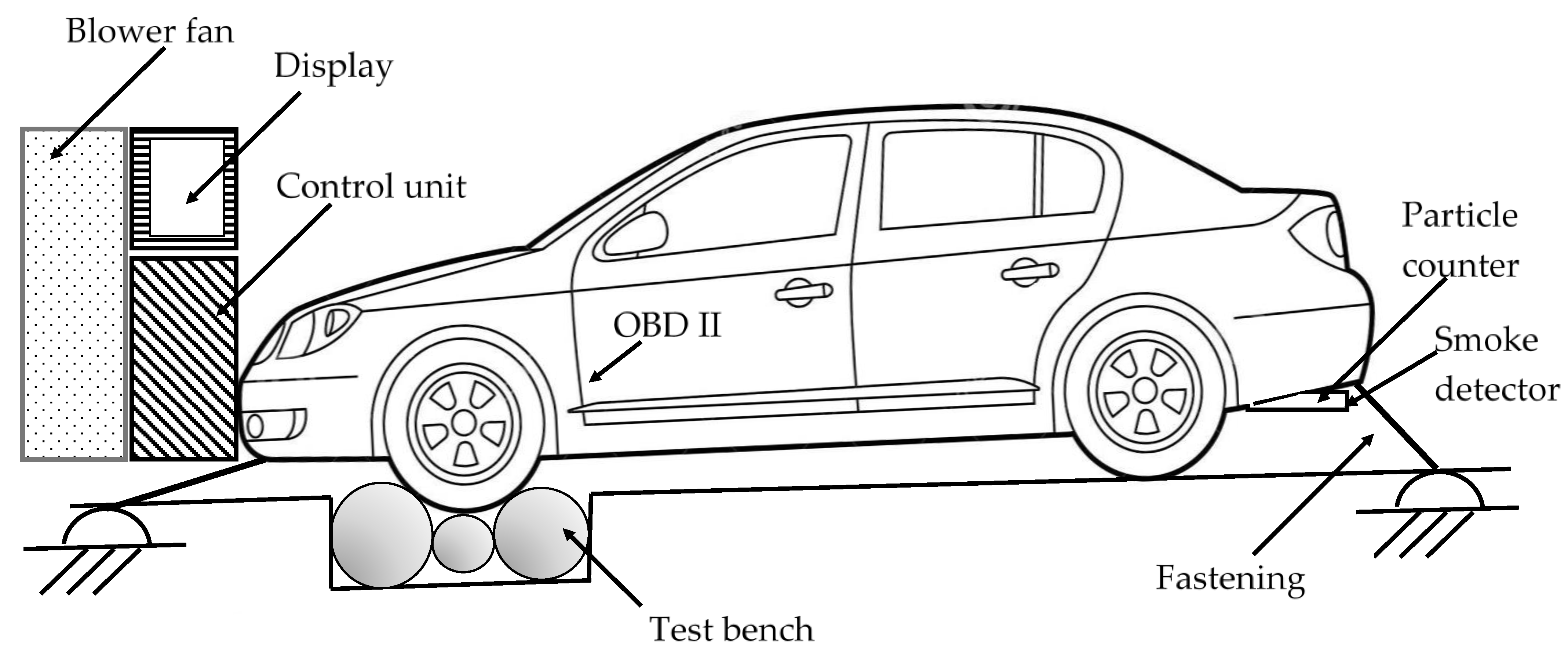

2. Materials and Methods

3. Results

4. Discussion

- Increasing biobutanol concentration does not affect the strength of the correlation between smokiness and PN indicators;

- After the use of biofuels, when resupplying diesel to the engine, the correlation dependence between smokiness and PN decreased by 45% when evaluating the values of the Pearson correlation coefficient and changed from a very strong dependence to a weak dependence of the smokiness and PN indicators, according to the Pearson correlation coefficient.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.; Ke, Y.; Zuo, J.; Xiong, W.; Wu, P. Evaluation of sustainable transport research in 2000–2019. J. Clean. Prod. 2020, 256, 120404. [Google Scholar] [CrossRef]

- Govender, P.; Sivakumar, V. Application of k-means and hierarchical clustering techniques for analysis of air pollution: A review (1980–2019). Atmos. Pollut. Res. 2020, 11, 40–56. [Google Scholar] [CrossRef]

- Puricelli, S.; Cardellini, G.; Casadei, S.; Faedo, D.; Van den Oever, A.E.M.; Grosso, M. A review on biofuels for light-duty vehicles in Europe. Renew. Sustain. Energy Rev. 2020, 137, 110398. [Google Scholar] [CrossRef]

- SNAP Nomenclature. Available online: https://en.eustat.eus/documentos/elem_13173/definicion.html (accessed on 2 April 2023).

- Kiba-Janiak, M. EU cities’ potentials for formulation and implementation of sustainable urban freight transport strategic plans. Transp. Res. Procedia 2019, 39, 150–159. [Google Scholar] [CrossRef]

- André, M.; Joumard, R.; Vidon, R.; Tassel, P.; Perret, P. Real-world European driving cycles, for measuring pollutant emissions from high- and low-powered cars. Atmos. Environ. 2006, 40, 5944–5953. [Google Scholar] [CrossRef]

- Tilt, B. China’s air pollution crisis: Science and policy perspectives. Environ. Sci. Policy 2019, 92, 275–280. [Google Scholar] [CrossRef]

- Sarkan, B.; Skrucany, T.; Semanova, S.; Madlenak, R.; Kuranc, A.; Sejkorova, M.; Caban, J. Vehicle coast-down method as a tool for calculating total resistance for the purposes of type-approval fuel consumption. Sci. J. Sil. Univ. Technol. Ser. Transp. 2018, 98, 161–172. [Google Scholar]

- Hasan, M.; Abedin, M.Z.; Amin, M.B.; Nekmahmud, M.; Oláh, J. Sustainable biofuel economy: A mapping through bibliometric research. J. Environ. Manag. 2023, 336, 117644. [Google Scholar] [CrossRef]

- Bracco, S. Effectiveness of EU biofuels sustainability criteria in the context of land acquisitions in Africa. Renew. Sustain. Energy Rev. 2015, 50, 130–143. [Google Scholar] [CrossRef]

- Robaina, M.; Neves, A. Complete decomposition analysis of CO2 emissions intensity in the transport sector in Europe. Res. Transp. Econ. 2021, 90, 101074. [Google Scholar] [CrossRef]

- Kumar, V.; Saluja, R.K. The effect of operating parameters on performance and emissions of DI diesel engine fuelled with Jatropha biodiesel. Fuel 2020, 278, 118256. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Inda, C.S.; Sharma, S.; Sharma, P.K.; Jhalani, A. A comprehensive review of physicochemical properties, production process, performance and emissions characteristics of 2nd generation biodiesel feedstock: Jatropha curcas. Fuel 2021, 285, 119110. [Google Scholar] [CrossRef]

- Cheikh, K.; Sary, A.; Khaled, L.; Abdelkrim, L.; Mohand, T. Experimental Assessment of Performance and Emissions Maps for Biodiesel Fueled Compression Ignition Engine. Appl. Energy 2016, 161, 320–329. [Google Scholar] [CrossRef]

- Atabani, A.E.; Silitonga, A.S.; Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Badruddin, I.A.; Fayaz, H. Non-edible vegetable oils: A critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production. Renew. Sustain. Energy Rev. 2013, 18, 211–245. [Google Scholar] [CrossRef]

- Milojevic, S.; Savić, S.; Marić, D.; Stopka, O.; Krstić, B.; Stoja, B. Correlation between Emission and Combustion Characteristics with the Compression Ratio and Fuel Injection Timing in Tribologically Optimized Diesel Engine. Teh. Vjesn. 2022, 29, 1210–1219. [Google Scholar]

- Uneven Tyre Tread Wear—Causes and Effects. Available online: https://intercars.pl/blog/kola/nietypowe-zuzycie-bieznika-przyczyny-i-skutki/ (accessed on 2 April 2023).

- Adamczyk, J.; Dzikuć, M. The analysis of suppositions included in the Polish Energetic Policy using the LCA technique—Poland case study. Renew. Sustain. Energy Rev. 2014, 39, 42–50. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M. Analysis of the diversity in emissions of selected gaseous and particulate pollutants in the European Union countries. J. Environ. Manag. 2019, 231, 582–595. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Wasiak, A.; Świć, A.; Dybaś, W. Capacity Market Implementation in Poland: Analysis of a Survey on Consequences for the Electricity Market and for Energy Management. Energies 2019, 12, 839. [Google Scholar] [CrossRef]

- Łagowski, P. The Effect of Biofuel on the Emission of Exhaust Gas from an Engine with the Common Rail System. Arch. Automot. Eng. Arch. Motoryz. 2020, 90, 33–44. [Google Scholar] [CrossRef]

- Šarkan, B.; Stopka, O. Quantification of road vehicle performance parameters under laboratory conditions. Adv. Sci. Technol. Res. J. 2018, 12, 16–23. [Google Scholar] [CrossRef]

- European Climate Law. Available online: https://ec.europa.eu/clima/eu-action/european-green-deal/european-climate-law_en (accessed on 2 April 2023).

- Stattman, S.L.; Gupta, A.; Partzsch, L.; Oosterveer, P. Toward Sustainable Biofuels in the European Union? Lessons from a Decade of Hybrid Biofuel Governance. Sustainability 2018, 10, 4111. [Google Scholar] [CrossRef]

- Fact Sheets on the European Union. Energy Policy: General Principles. Available online: https://www.europarl.europa.eu/factsheets/en/sheet/68/energy-policy-general-principles (accessed on 2 April 2023).

- Gao, J.; Chen, H.; Li, Y.; Chen, J.; Zhang, Y.; Dave, K.; Huang, Y. Fuel consumption and exhaust emissions of diesel vehicles in worldwide harmonized light vehicles test cycles and their sensitivities to eco-driving factors. Energy Convers. Manag. 2019, 196, 605–613. [Google Scholar] [CrossRef]

- Slavin, V.; Shuba, Y.; Caban, J.; Matijosius, J.; Rimkus, A.; Korpach, A.; Gutarevych, S. The Performance of a Car with Various Engine Power Systems—Part I. LOGI—Sci. J. Transp. Logist. 2022, 13, 130–140. [Google Scholar] [CrossRef]

- Slavin, V.; Shuba, Y.; Caban, J.; Matijosius, J.; Rimkus, A.; Korpach, A.; Gutarevych, S. The Performance of a Car with Various Engine Power Systems—Part II. LOGI—Sci. J. Transp. Logist. 2022, 13, 141–151. [Google Scholar] [CrossRef]

- Skrúcaný, T.; Stopková, M.; Stopka, O.; Kalašová, A.; Ovčiarik, P. User’s determination of a proper method for quantifying fuel consumption of a passenger car with compression ignition engine in specific operation conditions. Open Eng. 2021, 11, 151–160. [Google Scholar] [CrossRef]

- Simsek, S.; Uslu, S. Determination of a diesel engine operating parameters powered with canola, safflower and waste vegetable oil based biodiesel combination using response surface methodology (RSM). Fuel 2020, 270, 117496. [Google Scholar] [CrossRef]

- Ponte, S.; Daugbjerg, C. Biofuel sustainability and the formation of transnational hybrid governance. Environ. Politics 2015, 24, 96–114. [Google Scholar]

- Wasiak, A. Modeling Energetic Efficiency of Biofuels Production. Green Energy and Technology, 1st ed.; Springer Nature Switzerland: Cham, Switzerland, 2018; pp. 29–47. ISBN 978-3-319-98430-8. [Google Scholar] [CrossRef]

- Saxena, M.R.; Maurya, R.K.; Mishra, P. Assessment of performance, combustion and emissions characteristics of methanol-diesel dual-fuel compression ignition engine: A review. J. Traffic Transp. Eng. 2021, 8, 638–680. [Google Scholar] [CrossRef]

- Upendra, R.; Nageswara, R.; Ağbulut, U.; Suat, S.; Asif, A.; Tikendra, N. Modifying diesel fuel with nanoparticles of zinc oxide to investigate its influences on engine behaviors. Fuel 2023, 345, 128196. [Google Scholar] [CrossRef]

- Subrata, B.; Abhishek, P.; Rajsekhar, P.; Subrata, K.G. Performance, combustion and emission characteristics of a diesel engine fueled with diesel-kerosene-ethanol: A multi-objective optimization study. Energy 2020, 211, 118305. [Google Scholar] [CrossRef]

- Tsai, T.Y.; Lo, Y.C.; Dong, C.D.; Nagarajan, D.; Chang, J.S.; Lee, D.J. Biobutanol production from lignocellulosic biomass using immobilized Clostridium acetobutylicum. Appl. Energy 2020, 277, 115531. [Google Scholar] [CrossRef]

- Bharathiraja, B.; Jayamuthunagai, J.; Sudharsanaa, T.; Bharghavi, A.; Praveenkumar, R.; Chakravarthy, M.; Yuvaraj, D. Biobutanol—An impending biofuel for future: A review on upstream and downstream processing tecniques. Renew. Sustain. Energy Rev. 2017, 68, 788–807. [Google Scholar] [CrossRef]

- Goga, G.; Chauhan, B.S.; Mahla, S.K.; Cho, H.M. Performance and emission characteristics of diesel engine fueled with rice bran biodiesel and n-butanol. Energy Rep. 2019, 5, 78–83. [Google Scholar] [CrossRef]

- Singer, A.; Schröder, O.; Pabst, C.; Munack, A.; Bünger, J.; Ruck, W.; Krahl, J. Aging studies of biodiesel and HVO and their testing as neat fuel and blends for exhaust emissions in heavy-duty engines and passenger cars. Fuel 2015, 153, 595–603. [Google Scholar] [CrossRef]

- Bortel, I.; Vávra, J.; Takáts, M. Effect of HVO fuel mixtures on emissions and performance of a passenger car size diesel engine. Renew. Energy 2019, 140, 680–691. [Google Scholar] [CrossRef]

- Tucki, K.; Mruk, R.; Orynycz, O.; Gola, A. The Effects of Pressure and Temperature on the Process of Auto-Ignition and Combustion of Rape Oil and Its Mixtures. Sustainability 2019, 11, 3451. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Wasiak, A.; Świć, A.; Mieszkalski, L.; Mruk, R.; Gola, A.; Słoma, J.; Botwińska, K.; Gawron, J. A Computer Tool Using OpenModelica for Modelling CO2 Emissions in Driving Tests. Energies 2022, 15, 995. [Google Scholar] [CrossRef]

- Tucki, K. A Computer Tool for Modelling CO2 Emissions in Driving Cycles for Spark Ignition Engines Powered by Biofuels. Energies 2021, 14, 1400. [Google Scholar] [CrossRef]

- Tucki, K. A Computer Tool for Modelling CO2 Emissions in Driving Tests for Vehicles with Diesel Engines. Energies 2021, 14, 266. [Google Scholar] [CrossRef]

- Shepel, O.; Matijošius, J.; Rimkus, A.; Orynycz, O.; Tucki, K.; Świć, A. Combustion, Ecological, and Energetic Indicators for Mixtures of Hydrotreated Vegetable Oil (HVO) with Duck Fat Applied as Fuel in a Compression Ignition Engine. Energies 2022, 15, 7892. [Google Scholar] [CrossRef]

- Abed, K.A.; El Morsi, A.K.; Sayed, M.M.; El Shaib, A.A.; Gad, M.S. Effect of waste cooking-oil biodiesel on performance and exhaust emissions of a diesel engine. Egypt. J. Pet. 2018, 27, 985–989. [Google Scholar] [CrossRef]

- Kanthasamy, P.; Selvan, V.A.M.; Shanmugam, P. Investigation on the performance, emissions and combustion characteristics of CRDI engine fuelled with tallow methyl ester biodiesel blends with exhaust gas recirculation. J. Therm. Anal. Calorim. 2020, 141, 2325–2333. [Google Scholar] [CrossRef]

- Emiroglu, A.O.; Keskin, A.; Sen, M. Experimental investigation of the effects of turkey rendering fat biodiesel on combustion, performance and exhaust emissions of a diesel engine. Fuel 2018, 216, 266–273. [Google Scholar] [CrossRef]

- Specifications for Skoda Octavia 1.9 TDI Generation 1Z. Available online: https://www.car.info/en-se/skoda/octavia/1z-19-tdi-dct6-24107173/specs (accessed on 2 April 2023).

- Emission, Function and Performance Dynamometers. Available online: https://www.maha.ru/upload/iblock/a8e/a8e11397fb2b2f09876572eb316514b5.pdf (accessed on 2 April 2023).

- United Nations Global Technical Regulation No. 15—UNECE. Available online: https://unece.org/sites/default/files/2021-01/ECE-TRANS-180a15am6e.pdf (accessed on 22 April 2023).

- Regulation No 83 of the Economic Commission for Europe of the United Nations (UN/ECE)—Uniform Provisions Concerning the Approval of Vehicles with Regard to the Emission of Pollutants According to Engine Fuel Requirements. Available online: https://op.europa.eu/en/publication-detail/-/publication/2f8f0ce5-66fb-4a38-ae68-558ae1b04a5f/language-en (accessed on 22 April 2023).

- Commission Regulation (EC) No 692/2008 of 18 July 2008 Implementing and Amending Regulation (EC) No 715/2007 of the European Parliament and of the Council on Type-Approval of Motor Vehicles with Respect to Emissions from Light Passenger and Commercial Vehicles (Euro 5 and Euro 6) and on Access to Vehicle Repair and Maintenance Information (Text with EEA relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32008R0692 (accessed on 22 April 2023).

- OBDI/OBDII Diagnostic Interfaces. Available online: https://smartmoto.pl/pol_m_Diagnostyka_Interfejsy-diagnostyczne_Interfejsy-OBDI-OBDII-1561535.html (accessed on 2 April 2023).

- ECU Explained. Available online: https://www.ecutesting.com/categories/ecu-explained/ (accessed on 2 April 2023).

- ROSS-TECH VCDS. Available online: https://www.ross-tech.com/vcds/tour/logging.php (accessed on 2 April 2023).

- Wang, T.; Lin, B. Fuel consumption in road transport: A comparative study of China and OECD countries. J. Clean. Prod. 2019, 206, 156–170. [Google Scholar] [CrossRef]

- Ballesteros, M.; Manzanares, P. Chapter Three—Liquid Biofuels. In The Role of Bioenergy in the Bioeconomy, 1st ed.; Lago, C., Caldés, N., Lechón, Y., Eds.; Academic Press: Waltham, MA, USA, 2019; pp. 113–144. [Google Scholar]

- Kordylewski, W. Combustion and Fuels, 5th ed.; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Polska, 2008; pp. 10–470. ISBN 978-83-7493-378-0. [Google Scholar]

- Baczewski, K.; Kałdoński, T. Fuels for Compression-Ignition Engines, 2nd ed.; Wydawnictwa Komunikacji i Łączności: Warszawa, Polska, 2017; pp. 50–210. [Google Scholar]

- STATISTICA Electronic Manual. Available online: https://www.scribd.com/document/321061529/STATISTICA-Electronic-Manual# (accessed on 22 April 2023).

- Two-Sample Kolmogorov-Smirnov Test. Available online: https://real-statistics.com/non-parametric-tests/goodness-of-fit-tests/two-sample-kolmogorov-smirnov-test/ (accessed on 22 April 2023).

| Parameter | Value |

|---|---|

| Engine type—number of cylinders | Inline 4 |

| Engine code | ALH |

| Fuel type | Diesel |

| Engine alignment | Transverse |

| Engine displacement | 1896 cm3 |

| Bore × stroke | 79.5 × 95.5 mm |

| Number of valves | 8 valves |

| Aspiration | Turbo |

| Maximum power | 66 kW (4000 rpm) |

| Maximum torque | 210 Nm (1900 rpm) |

| Drive wheels | FWD |

| Piston diameter, mm | 79.5 mm |

| Piston stroke, mm | 95.5 mm |

| Compression ratio | 19.5 |

| Displacement | 1896 cm3 |

| Number of cylinders | 4/OHC |

| Fuel injection | Direct (single) |

| Nozzle type | Hole-type |

| Nozzle opening pressure | 190 bar |

| Nozzle and holder assembly | Two-spring |

| Cooling system type | Liquid cooling |

| Transmission gearbox—number of Speeds | 5-speed manual |

| Parameter | Value |

|---|---|

| Load equipment | Electromagnetic brake |

| Rate adjustment limits | 260 |

| Maximum measuring load | 6 kN (attractive force) |

| Maximum break power, kW | 260 |

| Measurement error | ±2 |

| Parameter | Value |

|---|---|

| Concentration range | 0–500,000 pcs/cm3 |

| Aerodynamic PM diameter range | 0.02–1 μm |

| Temperature range | −40–70 °C |

| Intake air flow | approximately 100 cm3/min |

| Device memory | 470 points |

| Type of alcohol used | 100% isopropanol |

| Parameter | Diesel | Hydrotreated Vegetable Oil | Biobutanol | Castor Oil |

|---|---|---|---|---|

| Density at 15 °C, kg/m3 | 835.2 | 779.1 | 810.0 | 964.4 |

| Element composition: (% mass): Carbon | 86.50 | 84.80 | 65.00 | 73.80 |

| Hydrogen | 13.40 | 15.30 | 13.55 | 11.50 |

| Oxygen | 0.0 | 0.0 | 21.50 | 14.85 |

| Stoichiometric AFR | 14.79 | 15.18 | 11.30 | 11.91 |

| Cetane number | 51 | 70 | 18 | 28 |

| Lower heating value, MJ/kg | 43.09 | 44.9 | 33.3 | 43.1 |

| Lower heating value, MJ/l | 36.90 | 34.10 | 26.71 | 39.81 |

| Purity,% | N/A | N/A | 99.5 | 100 |

| Manufacturer, country | Orlean Lietuva, Lithuania | Neste, Finland | Carl Roth GmbH, Germany | Biochemlit, Lithuania |

| Properties | HVOB5 | HVOB10 | HVOB20 |

|---|---|---|---|

| Density at 15° C, kg/m3 | 780.5 | 782.4 | 786.4 |

| Element composition: (% mass): carbon | 83.45 | 82.55 | 80.58 |

| Hydrogen | 15.32 | 15.25 | 15.03 |

| Oxygen | 1.11 | 2.21 | 4.41 |

| Stoichiometric AFR | 14.99 | 14.77 | 14.38 |

| Cetane number | 67.3 | 64.7 | 59.3 |

| Lower heating value, MJ/kg | 43.55 | 42.98 | 41.88 |

| Lower heating value, MJ/L | 33.98 | 33.64 | 32.93 |

| Fuel Blends | D100 before Tests | D100 after Tests | HVO100 | HVO5 | HVO10 | HVO20 |

|---|---|---|---|---|---|---|

| Parameter | Standard Deviation | |||||

| Smoke, m−1 | 0.04509 | 0.09849 | 0.03215 | 0.02082 | 0.05 | 0.01528 |

| PN, particle/cm3 | 13,658.54433 | 4582.57569 | 9018.49951 | 5507.57055 | 10,940.44484 | 15,378.5565 |

| Shapiro–Wilk Normality Test | ||||||

| Smoke, m−1 | 0.9959 | 0.93041 | 0.87097 | 0.92308 | 1 | 0.96429 |

| PN, particle/cm3 | 0.97711 | 0.96429 | 0.9959 | 0.99725 | 0.95783 | 0.90727 |

| Kolmogorov–Smirnov Normality Test | ||||||

| Smoke, m−1 | 0.19613 | 0.28633 | 0.32752 | 0.29228 | 0.17468 | 0.25304 |

| PN, particle/cm3 | 0.21863 | 0.25304 | 0.19613 | 0.1908 | 0.20515 | 0.20261 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valeika, G.; Matijošius, J.; Orynycz, O.; Rimkus, A.; Świć, A.; Tucki, K. Smoke Formation during Combustion of Biofuel Blends in the Internal Combustion Compression Ignition Engine. Energies 2023, 16, 3682. https://doi.org/10.3390/en16093682

Valeika G, Matijošius J, Orynycz O, Rimkus A, Świć A, Tucki K. Smoke Formation during Combustion of Biofuel Blends in the Internal Combustion Compression Ignition Engine. Energies. 2023; 16(9):3682. https://doi.org/10.3390/en16093682

Chicago/Turabian StyleValeika, Gintaras, Jonas Matijošius, Olga Orynycz, Alfredas Rimkus, Antoni Świć, and Karol Tucki. 2023. "Smoke Formation during Combustion of Biofuel Blends in the Internal Combustion Compression Ignition Engine" Energies 16, no. 9: 3682. https://doi.org/10.3390/en16093682

APA StyleValeika, G., Matijošius, J., Orynycz, O., Rimkus, A., Świć, A., & Tucki, K. (2023). Smoke Formation during Combustion of Biofuel Blends in the Internal Combustion Compression Ignition Engine. Energies, 16(9), 3682. https://doi.org/10.3390/en16093682