1. Introduction

Web drying in the paper machine is one of the most energy-consuming processes in the paper industry [

1,

2,

3]. Energy consumption in paper drying is therefore an important factor influencing the profitability of the production [

4]. Currently, rising energy costs and the energy transformation mean that new solutions are being sought to reduce energy consumption in the paper production process [

5]. In Europe, tissue papers are mainly produced in machines with a Yankee cylinder and a dryer hood (

Figure 1).

The system is supplied with energy from gas and low-pressure steam. The energy is used mainly to evaporate the water from the paper. Improving the energy efficiency of the machine should not be limited only to the modernization of the drying section. The advantages that can be obtained by increasing the mechanical dewatering of the paper in the press section or the heat recovery from the exhaust air discharged into the atmosphere should also be considered. In Poland, heat energy consumption per ton of produced tissue paper is generally within the range of 5.2–7.4 GJ/ADt. These are older machines found in many paper mills [

6,

7].

Many industrial plants in Poland have not yet adapted their energy systems to the new requirements related to the adoption of best available techniques (BAT) in order to reduce their impact on the environment. Given the rising costs of electricity and gas, paper mills will be forced to introduce new, energy-efficient solutions in paper production in order to be competitive in the market. Recently, many articles have been written describing ways to improve the energy efficiency of pulp and paper mills [

1,

2,

7,

8].

A study of steam systems [

9] by Deacon has produced several guidelines that can help reduce heat energy consumption in heavy, food and pharmaceutical plants. The guidelines apply to the monitoring and maintenance of pipelines of the steam system. Bhutani et al. [

10] in the publication presented a method that allows for the reduction of heat energy consumption in a paper machine. The method was based on the results of research on mass and volumetric flows in the heat system of a paper machine and a comparison of energy consumption in similar solutions. A similar method allowing the reduction of steam consumption in the steam system of a paper machine was presented by Lindberg et al. [

11]. A significant improvement in the energy efficiency of the dryer can be achieved by paper drying directly with superheated steam (flotation drying) instead of drying cylinders [

12,

13]. Koufos et al. [

14] and Schaareman et al. [

15] developed guidelines based on the pinch method to reduce fresh water intake and reduce steam consumption in the pulp and paper industry. Beer et al. [

16] described the method of selecting appropriate technological solutions in the production of paper to improve the energy efficiency of paper mills based on an exergy analysis of thermal processes. Gabbrielli et al. [

17] presented a project carried out at the Lucca paper mill in Italy concerning the reduction of energy consumption in a tissue machine. High energy losses were caused by the leakage of high-pressure steam from the separator downstream of the Yankee cylinder. In order to reduce steam consumption, a new steam system was designed to save natural gas and fresh water, and to reduce CO

2 emissions. Simulation and energy system optimization models can realize the accurate monitoring of key variables and reduce the energy consumption of the drying process. Many publications have been devoted to the modeling of processes occurring in the drying section of a paper machine [

18,

19,

20,

21,

22,

23]. Mobarakeh et al. [

24] developed a model to analyze energy consumption (heat and electricity) and CO

2 emission in the main processes involved in paper production. Janošovský et al. [

25] analyzed the possibilities of energy savings in a paper machine using a mathematical model based on mass and energy balances. Modeling of the paper drying process was also used by Ghodbanan et al. [

2]. Process modeling allows the optimization of the total consumption of steam and air in the drying section of the paper machine. The possibilities of using micro-nozzle modules for heat recovery from exhaust air discharged to the atmosphere was described by Szewczyk et al. [

26] and Kryłłowicz [

27]. The micro-nozzle modules were also used for zonal control of the transverse profile of the moisture content of the moving web and for increasing the efficiency of the drying part of the tissue machine. Management of energy generated in pulp and paper mills with the use of mathematical programming tools was presented by Sarimveis et al. [

28]. The overall aim of this research was to use mathematical programming tools in the energy management of power plants in pulp and paper mills. According to Sarimveis et al. [

28], the developed method can be a very useful tool to reduce production costs by minimizing fuel and electricity costs. Khan et al. [

29] presented several methods based on artificial intelligence and machine learning to improve the accuracy of predicting energy consumption. The model presented by Zhang et al. [

30] was based only on machine learning.

The aim of the studies was to investigate the influence of the main process parameters of the tissue paper production machine on its energy consumption and production capacity. An important aspect of this studies was the identification of the relationship between production capacity and energy consumption in the machine. In most publications, researchers focus only on single systems, installations or processes in terms of energy, environment, operation, etc.

The emerging changes in production technology, in particular in the drying section over several years, has allowed for a deeper analysis of this issue. The control of processes related to paper production in the absence of supporting automation systems is extremely difficult. The knowledge and experience of the machine operators is important in this case. Many years of studies have allowed exploration of this issue and influence the activities leading to the optimization of the machine. An important part of the studies was the determination of changes in specific heat consumption in the paper drying process, which allowed for the analysis of the energy consumption of the process.

Achieving the goals was related to determining the actual parameters and technological indicators of the drying system in various operating conditions of the machine during subsequent measurements. The obtained parameters and indicators were compared with those obtained during the previous studies.

This article presents the results of research on the paper production process carried out in 2013–2022 on one of the paper machines operating in Poland.

2. Research Object

The studied paper machine is a Fourdrinier machine of the Polish machine manufacturer PMPoland with a Yankee cylinder and dryer hood, producing tissue papers with a basis weight of 20–45 g/m

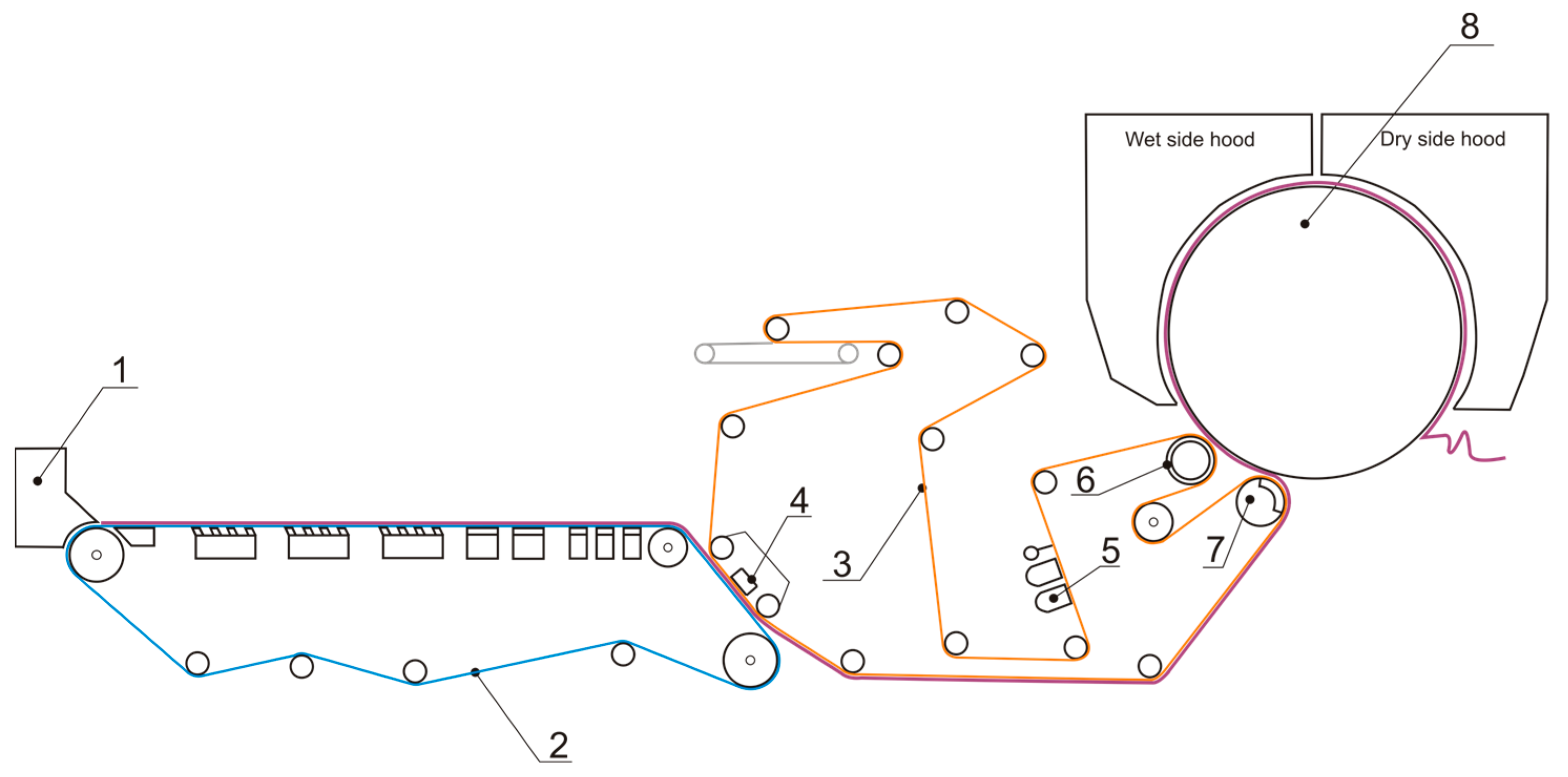

2. The scheme of the machine is shown in

Figure 2.

The paper web is formed in the wire section. After the wire section, the dryness of the web is 17–20%. Dewatering the web with two roller presses results in obtaining a moisture content in the range of 45–50%. Pressing is very economical—the degree of web dewatering in the presses significantly affects the steam consumption in the drying section. Increasing the dryness of the web after the press section by 1% may lower the steam consumption in the drying section [

31] by 4–5%.

The machine is equipped with a hydraulic headbox with a slice for adjusting the basis weight profile of the web in the transverse direction. During the tests, the consistency and temperature of the pulp in the headbox were 0.7–0.8% and 40–45 °C, respectively. The wire table has four hydrofoil boxes, one two-chamber vacuum water box (I ch.-8 kPa, II ch.-10 kPa) and a three-chamber suction box (12 ÷ 15 kPa). The press system comprises a suction press roll and a blind drilled press roll, and the drying section is a 3.5 m diameter steel steam-heated Yankee cylinder and a gas-powered dryer hood. The studies used TissueFlex D2 press felt with a basis weight of 1153 g/m2 and KraftStar forming fabric. The linear load of the suction press in 2013–2022 was 80–90 kN/m, and the blind press 90–100 kN/m. The temperature of the Yankee cylinder, depending on the production conditions, was approx. 80–90 °C.

Figure 3 shows a scheme of the ventilation and recuperation system of the studied paper machine with a dryer hood and a Yankee cylinder.

The air from the burners is supplied through ducts 1 and 2 to the nozzles of the hood. Exhaust air from under the hood, discharged through ducts 3 and 3′, goes to the recuperation system (duct 4) or is returned to be reheated (ducts 1′ and 2′). The air for the burners is taken from the hall in ducts 10 and 11 and heated in the heaters. In the summer season, the exhaust air after heat dissipation in the 1st recuperation stage is released to the atmosphere (duct 8). However, in the winter season, the exhaust air is directed to the second stage of recuperation and then to the atmosphere (duct 9). The studies on the production process were carried out mainly on the production of hygienic papers from mixed recycled pulp with a basis weight of approx. 40 g/m2. The web width on the roll was constant at 2.52 m, and the crepe ratio was approx. 5.5%.

3. Methodology

The study focused on determining the influence of the main process parameters of the paper machine on its production capacity and the consumption of heat energy used to dry the paper. For the same dryer section operated under different machine process parameters, the energy consumption may be varied significantly. Parameters such as steam pressure and temperature, web temperature and moisture content in the drying section, and air humidity are of key importance for the heat and mass transfer process during paper drying. Their potential changes can lead to, for example, process instability and problems with production and quality paper.

In the ducts marked in

Figure 3, dry and wet thermometer temperature measurements were carried out. On this basis, the thermodynamic parameters of the flowing medium (fresh air and exhaust air) were determined, such as humidity, relative humidity and density. In ducts 9, 10 and 11, the velocity of the flowing medium was measured directly with an anemometric vane probe, while, in the remaining ducts, dynamic pressure measurements were made, which were used to determine the velocity of the medium.

Mass and volume flows were determined based on measurements made in the ventilation and recuperation system. This allowed for the preparation of mass and energy balances of the flowing media and the calculation of basic process indicators.

Each measurement in the ventilation and recuperation system was performed 5 times. The standard deviation of the data set was calculated with the following relationship:

where:

—one measurement data from the set;

—average value from the measurements; and

—number of measurements in the set.

The uncertainty u of the calculated value was estimated from the law of propagation of uncertainty, as a geometric sum of partial differences according to the equation [

32,

33,

34]:

where:

—function;

—the complex uncertainty of the y function;

, , —the derivative of y with respect to the first, second,… variable;

, , —uncertainty of the first, second,… variable.

3.1. Measuring Devices

The measuring system installed in the machine was used to measure the properties of the produced papers and the parameters of the technological process. In the case of the impossibility of taking measurements or the need to verify the indications of devices installed in the machine, portable measuring devices or laboratory methods were used (

Table 1). The surface temperature of the drying cylinders and the paper web were measured using SWEMA contact probes. The use of a thermal imaging camera in this case did not provide the required accuracy due to the measurement conditions. The emission parameters of a paper web change during its consolidation and require individual identification at particular stages of production. Problems related to the use of thermal imaging methods of temperature measurement to monitor the operation of a paper machine were discussed by Pełczyński [

35].

For the measurements of the moisture content of the paper along the press-drying section, paper samples were taken at equal distances from the edge of the web. The collected samples were placed in previously weighed hermetic measuring containers. The samples with the containers were weighed on a laboratory balance. Then the samples were dried in a laboratory drier until constant mass was obtained and re-weighed. Based on the above data, the dryness of the paper samples was calculated.

3.2. Selected Parameters Characterizing the Efficiency of the Drying System

In this study, selected indicators relating to the production process were analyzed:

- -

production capacity, (

) (see Equation (3));

- -

specific evaporation

of water from the paper

on the Yankee cylinder, (

) (see Equation (4));

- -

heat energy consumption per 1 ton of production, (

) (see Equation (5));

- -

speed of the paper web on the winder (operating speed of the machine), (

);

- -

dryness of paper web after pressing, ().

Theoretical production capacity of the machine (on the reel) [

36,

37]:

where:

—paper basis weight on the reel [g/m2];

—width of the paper on the reel [m];

—converter of parameter units used in the Equation (1) to kg/h.

Specific evaporation of water from the paper on the Yankee cylinder (the amount of evaporated water related to 1 kg of dried paper) [

37]:

where:

—total evaporation of water from the paper [kg evaporated H2O/h].

Total heat energy consumption of the machine [

37]:

where:

—total theoretical heat energy consumption for drying paper produced per 1 h;

[kJ/h];

—theoretical specific heat consumption for drying one kilogram of paper to final dryness on the reel [kJ/kg];

—heat efficiency of the hood dryer [%].

4. Results and Discussion

In the years 2013–2022, cyclic measurements of the operation of the studied machine producing hygienic papers were carried out. The studies included comprehensive technological measurements of the wet and dry end. The influence of machine speed, web moisture content before and after pressing, parameters of steam supplied to the cylinder, and parameters of hot air in the hood on the efficiency and consumption of heat energy in the machine were analyzed. The results of these measurements and related calculations were the basis for assessing the energy efficiency, production capacity and tracking changes in machine operation over the years. The results of the studies allowed for the analysis of the production process of hygienic papers and the successive introduction of improvements in the machine. The basic operating conditions of the studied paper machine in the years 2013–2022 are shown in

Table 2.

The studies of the machine were carried out at different times of the year. In order to maintain comparable machine operating conditions, the article presents and analyzes only the test results obtained in the spring periods. In addition, the results obtained in the production of papers with a high basis weight of 40 g/m2 were analyzed.

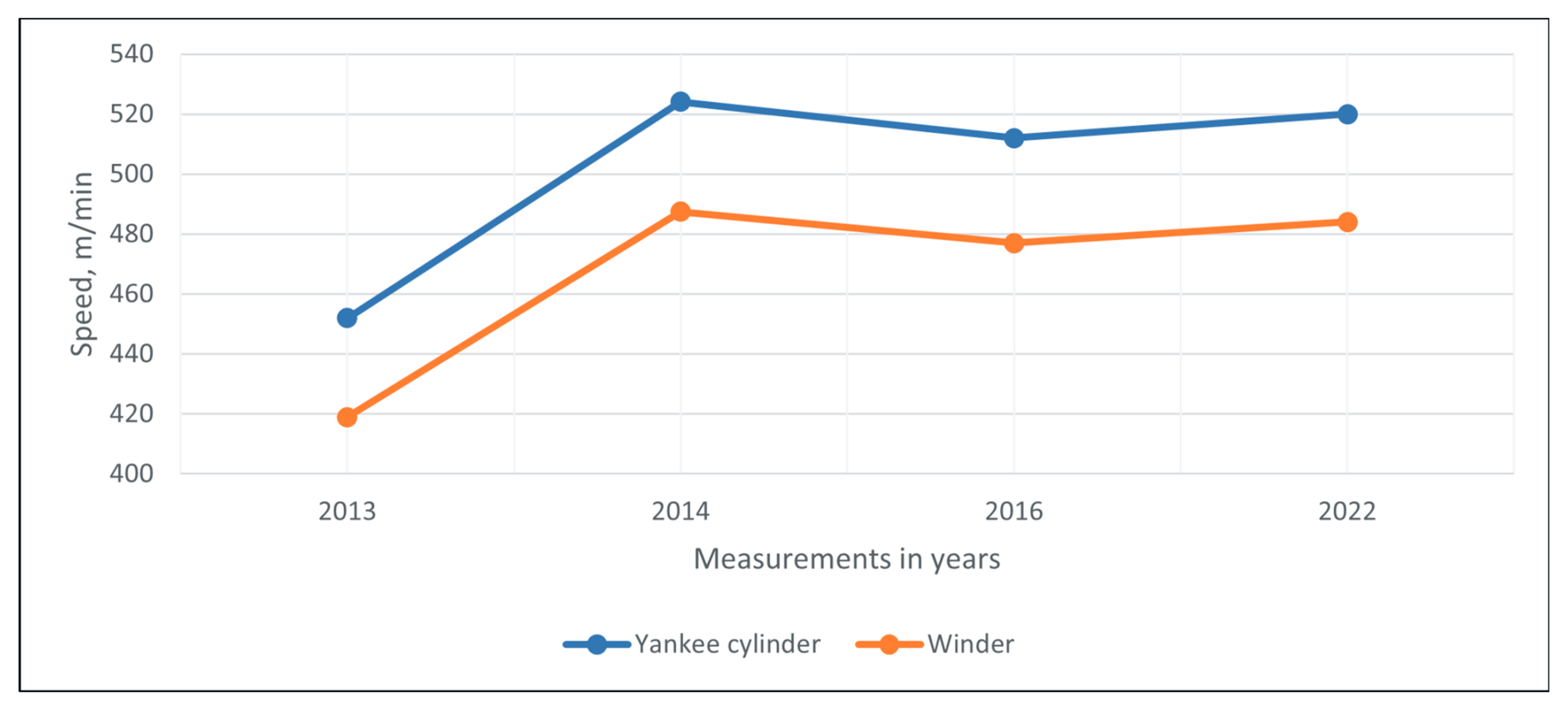

4.1. Speed and Production Capacity of Paper Machine

Figure 4 shows the course of changes in the operating speeds of the cylinder and the winder in the years 2013–2022. The course of changes in the production capacity of the paper machine is shown in

Figure 5. The production capacity is related to the basis weight of the produced paper, width and speed of the machine. In the analyzed period, only the speed of the machine was a variable parameter influencing its performance. Therefore, in

Figure 4 and

Figure 5, the similarity of changes in the speed and production capacity of the machine as a function of time (2013–2022) can be seen.

In the period from 2013 to 2014, a large increase in machine speed and the resulting increase in production capacity of the machine can be observed. In 2013, the web moisture content across the reel exceeded 8% in several areas. To equalize the moisture content profile on the reel, the paper was overdried, which resulted in a low cylinder speed of 452 m/min (

Figure 4) and a low production capacity of the machine of 2671 kg/h (

Figure 5).

One of the reasons for the uneven moisture content profile in the transverse direction of the web was an incorrectly performing forming wire cleaning system. In addition, during the production of paper, the linear load of the suction press was changed, causing changes in the deflection of the press roll and thus uneven pressure across the web. To increase the speed of the machine, the forming wire cleaning system had to be improved.

Figure 6 shows a scheme of the operation of a high-pressure shower in the machine in 2013.

One high-pressure shower was installed in the wire section of the paper machine. The shower was composed of 14 nozzles with a diameter of 1 mm with a spacing of 20 cm. In the shower only eight nozzles were in good condition. The distribution of these nozzles in the shower is shown in

Figure 6. This cleaning system was incorrect and resulted in dirty streaks on the wire, affecting the uneven dewatering process of the paper web. The oscillation amplitude was correct and equal to the nozzle spacing of 20 cm. The water pressure in the shower was 1.7 MPa and was within the allowable limit. Replacing the nozzles in the shower improved the transverse web moisture profile. The variations in moisture content across the web did not exceed 4% of its average value. The studies in the following years showed again large variations in moisture content of the web above 4% from its average value. Therefore, in 2016 it was decided to install a multi-chamber blow box on the machine. The box was installed in front of the high-efficiency Yankee hood. This allowed additional heat flux to be delivered to areas of the web where higher moisture content was observed. Thereby, the supply of heat energy to the area of the web with the appropriate moisture content was limited. Air pressure in the range of 10–30 kPa was used in the blow box. The temperature of the air outflow of the box was 255–360 °C.

In 2013, the high dryness of the web after the press section (

Figure 7) (54.1%) was significantly affected by the low speed of the machine of 419 m/min. The linear load of the suction press was then 80 kN/m, while the blind drilled press was 90 kN/m.

Rebuilding the wire section in 2014 intensified the process of paper web dewatering. As mentioned earlier, paper dewatering in the drying section is the most energy consuming and therefore the most expensive. To reduce the share of moisture evaporated on the cylinder, changes were made to the press section of the machine [

38]. The linear load of the suction press was increased to 90 kN/m and the blind drilled press only to approx. 100 kN/m so as not to cause paper crushing. Additionally, the water collection capacity in the vacuum system of the suction roll was improved. In this way, the production capacity of the paper machine was increased to 2984 kg/h (

Figure 5) and the speed of the machine from 419 m/min to 488 m/min. Similarly, the speed of the Yankee cylinder also increased to 524 m/min. Unfortunately, these changes reduced the dryness of the web after pressing to 53%. When analyzing the operating speed of the machine in 2014–2016 (

Figure 4), a slight decrease in 2016 (by 11 m/min) can be noticed. It relates to the necessity to evaporate more water (

Figure 8), which results from the lower dryness of the web after the presses (51.8%) (

Figure 7). One of the reasons for the too-low dryness of the web after pressing was the higher basis weight of the paper. The results of measurements carried out in 2016 showed an increased paper basis weight (average value) of approx. 4% from the nominal value. In the analyzed period, a lower air flow velocity from nozzles in the wet and dry end hood was also noted, compared with 2014. In the wet end hood, the air velocity slightly decreased from 84.9 m/s to 81 m/s, and, in the dry end, from 85.6 m/s to 83.7 m/s. In the years 2014–2016, the temperature of the air flowing from the nozzles of the hood in both wet and dry ends was constant and amounted to 420 and 430 °C, respectively. The above factors forced the speed of the machine to be limited to 477 m/min. It is also important to blow hot air uniformly from the hood onto the web along its width [

39].

In 2016, the decrease in the speed of the machine resulted in a decrease in its production capacity, recorded in the same period, to 2893 kg/h (

Figure 5). In the years 2016–2022, there was a slight increase in the machine speed of 7 m/min (from 477 m/min to 484 m/min). This is a similar level of machine speed compared with 2014 (

Figure 4). A similar change can be noticed in the production capacity of the paper machine (

Figure 5).

After studies carried out in 2016, which showed an increased paper basis weight (average value) of approx. 4% from the nominal value, the paper basis weight was reduced to the nominal value of 40 g/m2. As a result, in 2022 the dryness of the web after pressing was higher by 0.7% (52.5%).

All the changes made to the wet and drying sections of the machine allowed the cylinder to finally increase its operating speed from 452 m/min (2013) to 520 m/min (2022). In 2022, the production capacity of the paper machine increased from 2671 kg/h to 2939 kg/h compared with the results for 2013 (

Figure 5). The increase in production capacity did not result in a decrease in the quality of the produced paper.

4.2. Heat Energy Consumption per Ton of Produced Paper

Yankee cylinder studies in 2013 showed that one of the problems with its low energy efficiency was internal condensate water in the cylinder [

40]. In order to improve the operation of the drying section, in 2014 the share of the Yankee cylinder in the drying process was increased. The steam pressure supplying the cylinder was increased from 3.4 bar to 4.2 bar, and the steam temperature was increased from 130 °C to 140 °C [

4]. Since 2014, the steam pressure is kept constant at 4.2 bar and its temperature is 140 °C.

In 2013, the specific evaporation of water from the paper () in the drying section (the amount of evaporated water related to 1 kg of dried paper) was 0.747 kg/kg. In 2014, there was a slight increase to 0.755 kg/kg.

In 2014, in order to increase the intensity of paper drying, the nozzles and heating system of the high-efficiency Yankee hood were modernized. After modernization, the air velocity in the wet end hood was increased from 77.1 m/s to 84.9 m/s, and in the dry end from 78.8 m/s to 85.6 m/s. There was also an increase in air temperature compared with 2013 in the wet end hood by 50 °C to 420 °C and in the dry end hood by 60 °C to 430 °C.

In 2016, the drying system of the machine was improved. The steam–condensate system was modernized by replacing the scoops and the steam–condensate head. A flow and circulation power system for the cylinder with a thermocompressor was also introduced.

In the period from 2013 to 2022, the distance of the nozzles from the surface of the paper web in the hood and the surface area of the nozzle openings in the wet end (0.172 m

2) and in the dry end of the Yankee hood (0.195 m

2) did not change. In 2016, a significant increase in specific evaporation of water from the paper on the drying cylinder can be observed (

Figure 8). The higher specific evaporation is due to the lower web dryness after pressing (51.8%) (

Figure 7) compared with 2014 (53.0%). In 2022, specific evaporation of water from the paper was 0.83 kg/kg and was lower than the values from 2016 by 0.01 kg/kg. A lower average Yankee cylinder temperature of 4 °C compared with previous studies was also noted. It is assumed that this was caused by the increased mass of water over time in contact with the outer surface of the cylinder, causing its temperature to drop.

In 2022, the temperature of the air flowing from the nozzles in the dry end of the Yankee hood was 436 °C. It was higher than the temperature air measured in 2016 by 6 °C. The air velocity that flows out of the nozzles in the high-efficiency hood in both the wet and dry ends was like the 2016 values and was 81.5 m/s and 83.0 m/s, respectively.

Figure 8 shows a slight decrease in specific evaporation of water from the paper in the drying section during this period. The above-described changes introduced in the paper machine resulted in an increase in the drying rate (amount of water evaporated per hour per unit area of drying surface) from 80.3 kg/m

2h (2013) to 90.4 kg/m

2h (2022), i.e., by 11.2%. Such a value of the drying rate is achieved in only a few machines in the country.

Analyzing the years 2013–2014, it can be seen that the speed of the machine had a significant impact on the drying rate. The increase in the speed of the machine caused an increase in its production capacity and thus an increase in the total evaporation in the dryer, with a small difference in the specific evaporation value.

Thus, specific evaporation did not significantly affect the drying rate in 2014 (

Table 2).

The high value of the drying rate resulted mainly from the high value of the parameters of the drying air flowing from the nozzles of the high-efficiency Yankee hood. The studies carried out in 2013 showed an unsuitable mass balance in the hood system. The measurements were made at full maximum load of the motors driving the drying air circulation fans, stable temperature of this air and the velocity of its outflow from the nozzles. Over-pressure was created in the hood and hot air outflowed into the machine hall. In this case, there were losses of air and heat energy, and deterioration of the climatic conditions in the hall. To avoid fresh/cold air being pull in and hot air to come out of the Yankee cylinder–hood system, the gas/steam and air mass streams entering the hood should be equal to the exhaust air mass streams discharged through the chimney to the atmosphere. In 2014, after making improvements to the Yankee hood, a balanced mass system of streams was obtained, i.e., air flowing into the hood and exhaust air discharged into the atmosphere. Improvements included the increase in the temperature of the drying air in the dry end hood by almost 60 °C (up to 430 °C) and the velocity of air flow from the nozzles by 6.8 m/s. This change undoubtedly contributed to an increase in the heat efficiency of the drying system and its energy efficiency. In 2013–2014, despite an increase in the specific evaporation of water from the paper in the drying section by 0.008 kg/kg (

Figure 8), the increase in the heat efficiency of the dryer contributed to a decrease in the heat energy consumption per 1 ton of paper production to the value of 4.22 GJ/t (

Figure 9). The mass balance in the hood system was controlled in the following years of the machine’s operation by cyclical streams measurements and maintained in the equilibrium state.

Figure 9 shows the course of changes in the heat energy consumption per 1 ton of paper production in the analyzed period.

In 2013, the equalizing of an unevenly distributed moisture content in a moving web of paper by drying it resulted in high heat energy consumption per ton of paper production (5.2 GJ/t) (

Figure 9). The measurement and calculation data show that the current heat energy consumption per 1 ton of produced paper is 4.35 GJ/t, which is lower than in 2013 (5.20 GJ/t) by 16.3% (

Figure 9). The current value of the above-mentioned index puts the machine at the forefront of European countries, for which the average heat consumption is 4.3 GJ/t ÷ 4.7 GJ/t.

5. Conclusions

The speed of the machine depends largely on the level of the machine’s ability to remove water after each section. The dryness of the web after pressing is strictly dependent on the speed of the machine and the linear load of the presses. As paper machine speeds increase, the nip residence time decreases, which results in low dryness of the web after pressing. The obtained study results do not show this. The reason for this could be the variable moisture content of the web after the wire section. The presses in a paper machine are usually operated with the highest linear load possible to reduce energy consumption in the drying section.

The limitation in the use of higher linear loads in a press is its design and paper quality considerations. Thus, an increase in the speed of the machine is associated with a greater consumption of heat energy in the drying section of the machine (increase in steam pressure and temperature in the cylinder, temperature and velocities of air outflow from the nozzles of the hood). However, by comparing the consumption of heat energy with tons of paper produced, a lower energy consumption per ton of paper is finally obtained.

Important observations:

- -

changes in the velocities of air outflow from the nozzles of the hood in the range of 5% did not significantly affect the drying rate;

- -

a 5% decrease in cylinder temperature (possible problems with condensate removal) resulted in a decrease in the drying rate of less than 10%.

The technological changes and rebuild of the discussed paper machine described in the article contributed to the improvement of its speed and production capacity. Significant changes introduced in the paper machine include:

- -

modernization of the forming and press part of the machine, enabling obtaining paper dryness after pressing at the level of 53–54%, and thus a decrease in specific evaporation below 0.8 kg/kg;

- -

modernization of the nozzles and heating system of the high-efficiency hood, giving higher velocities of air outflow from the nozzles of over 80 m/s and at air temperatures of over 400 °C;

- -

increasing the drying rate to over 90 kg/m2h;

- -

improvement of Yankee cylinder drainage by modernizing the steam and condensate system.

The proposed improvements allowed most of all the obtainment of significant economic benefits in the paper mill. The modernizations implemented in the machine in the years 2013–2022 resulted in an increase in its performance in this period by 10% and a decrease in heat energy consumption per 1 ton of produced paper by 16.3%.

In order to obtain continuous improvement of indicators, it is necessary to research the paper machine systematically. In the absence of appropriate control and measurement equipment in the machine, measurements can be made with specialized portable equipment.

In-line process studies are extremely difficult to perform; however, they provide valuable knowledge that allows you to increase productivity and reduce energy consumption in the machine. The obtained research results can be used, e.g., to create better mathematical models in process controls in papermaking.