The Role of Biogas Production in Circular Economy Approach from the Perspective of Locality

Abstract

1. Introduction

1.1. Background of Circular Economy

- Maintaining and increasing capital by controlling depletable resources and balancing the flow of renewable resources;

- Optimising profits through resources in circulation, both biological and technical;

- Increasing efficiency through discovery and design without negative impact on the external environment.

1.2. Renewable Energy and Its Relation to Circular Economy

1.3. Recent Progress in Biogas Supply Chains in Circular Economy

1.4. Aim of the Research

2. Materials and Methods

3. Results

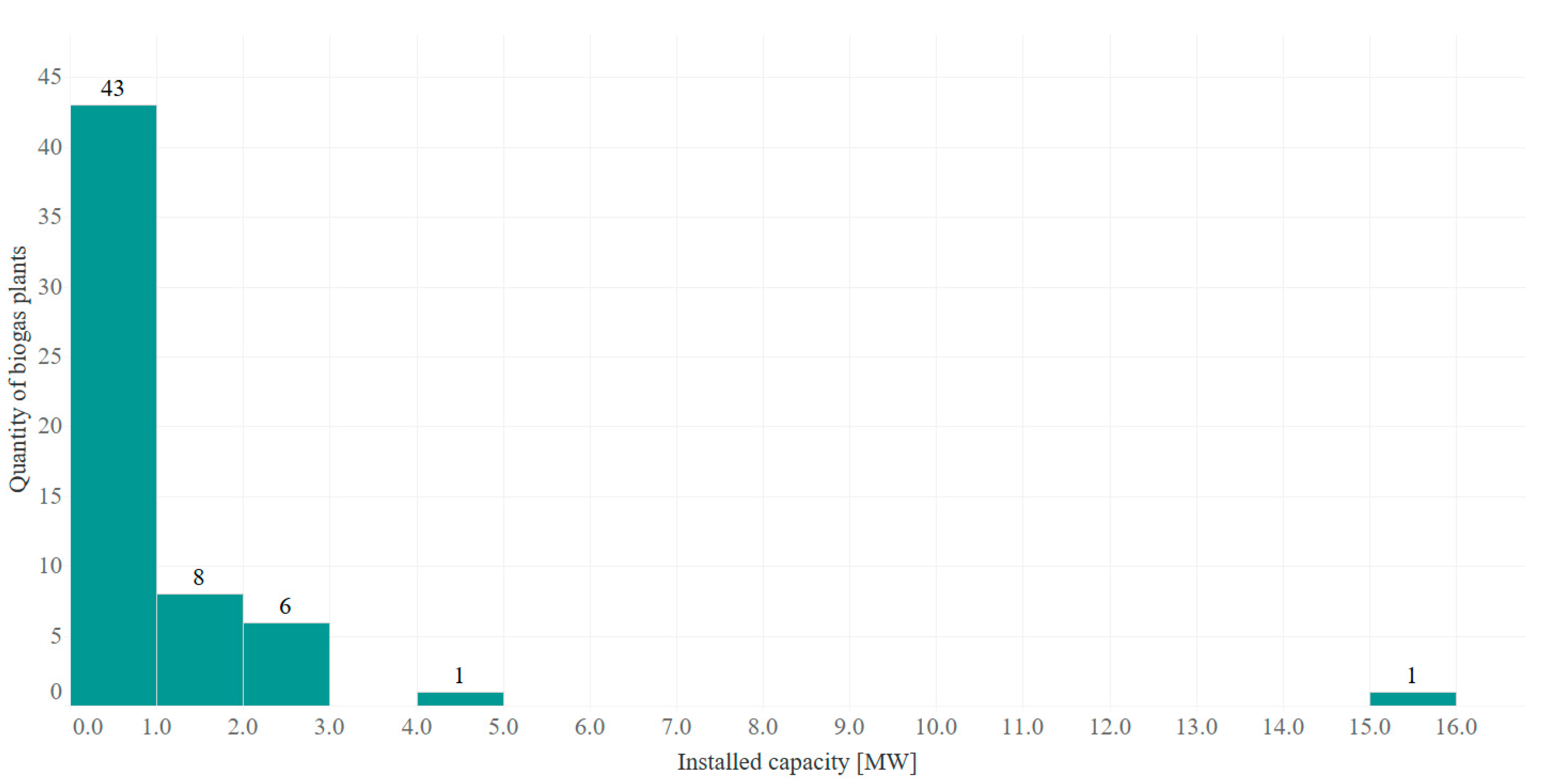

3.1. Analysis of Installed Capacity

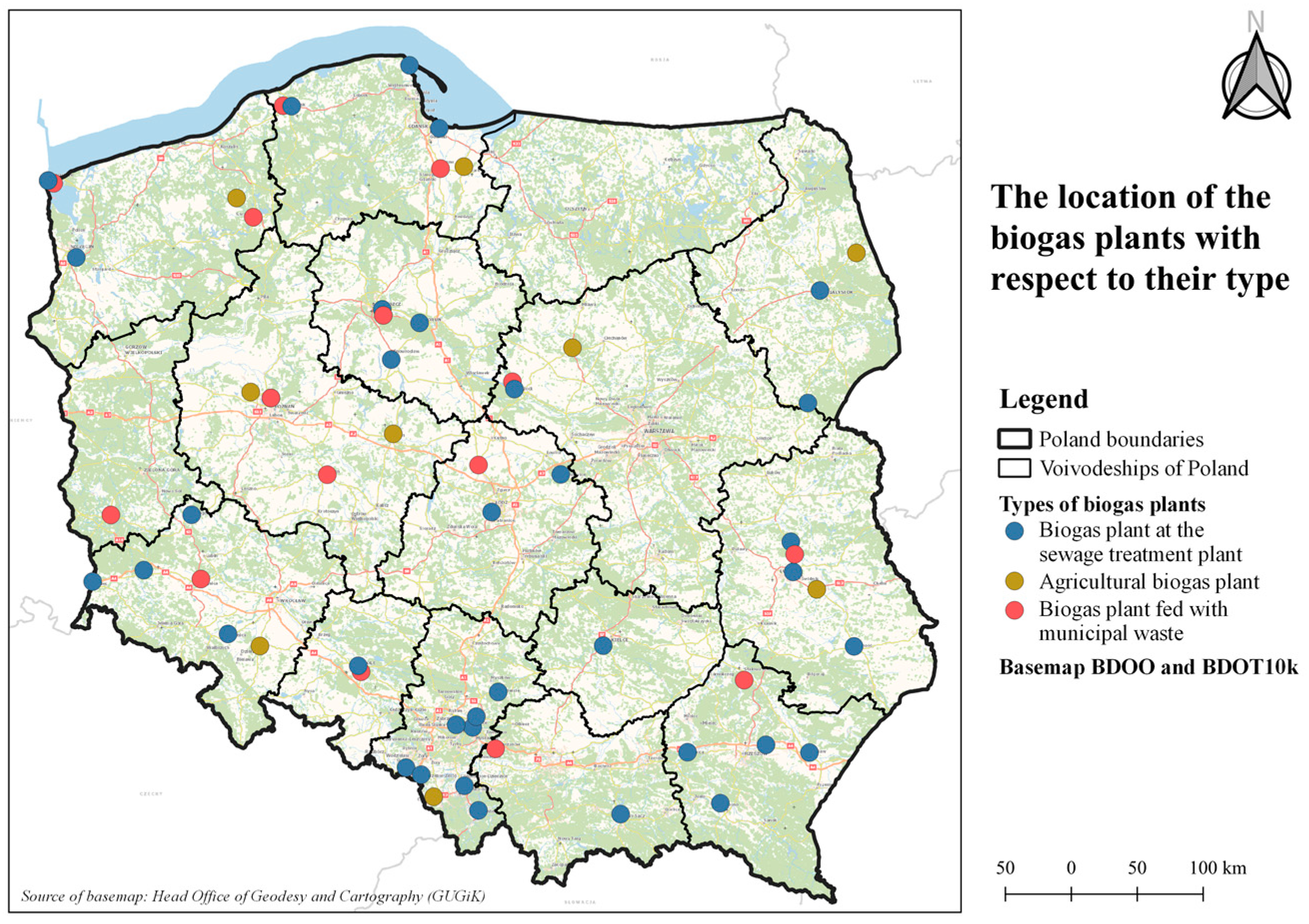

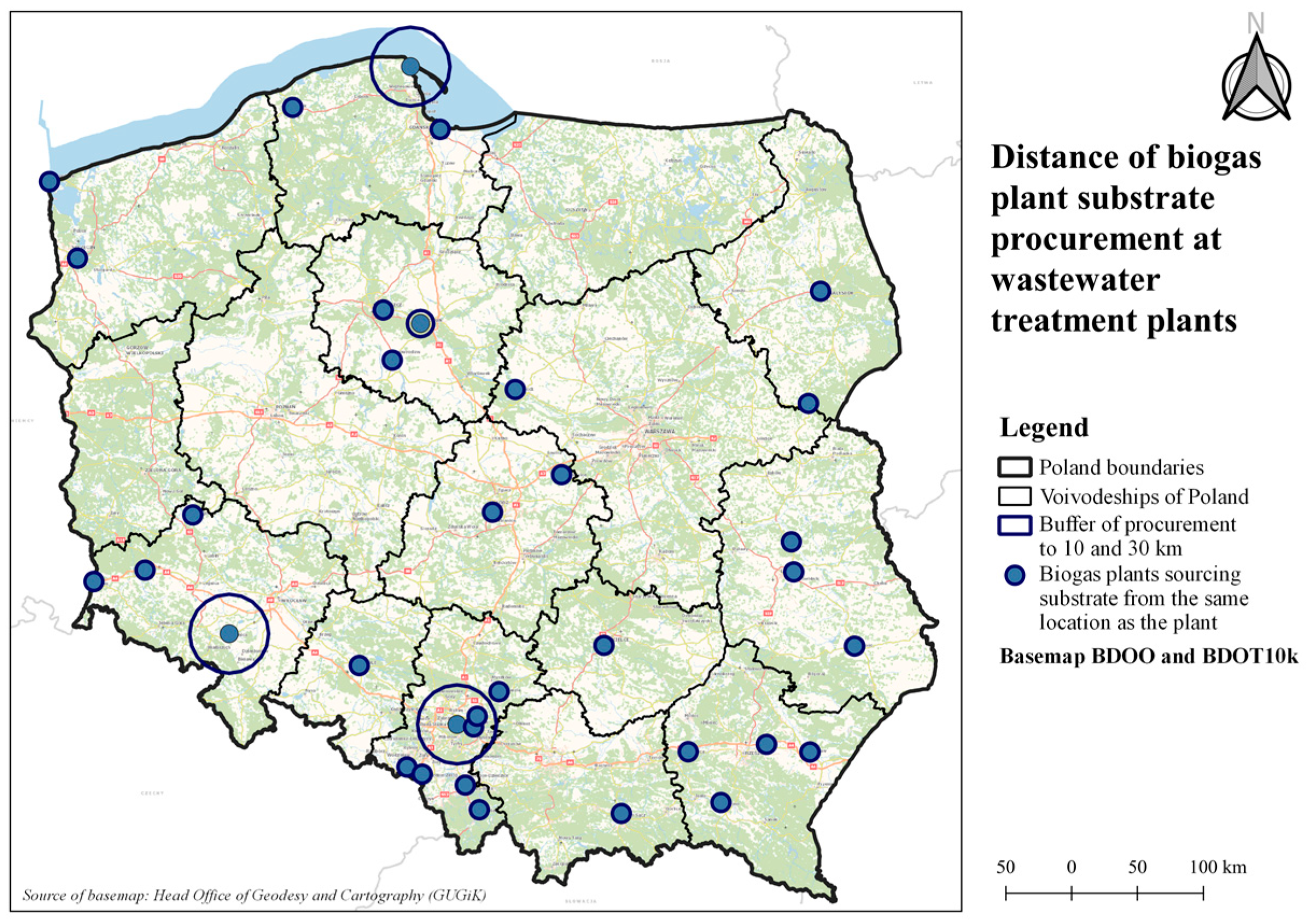

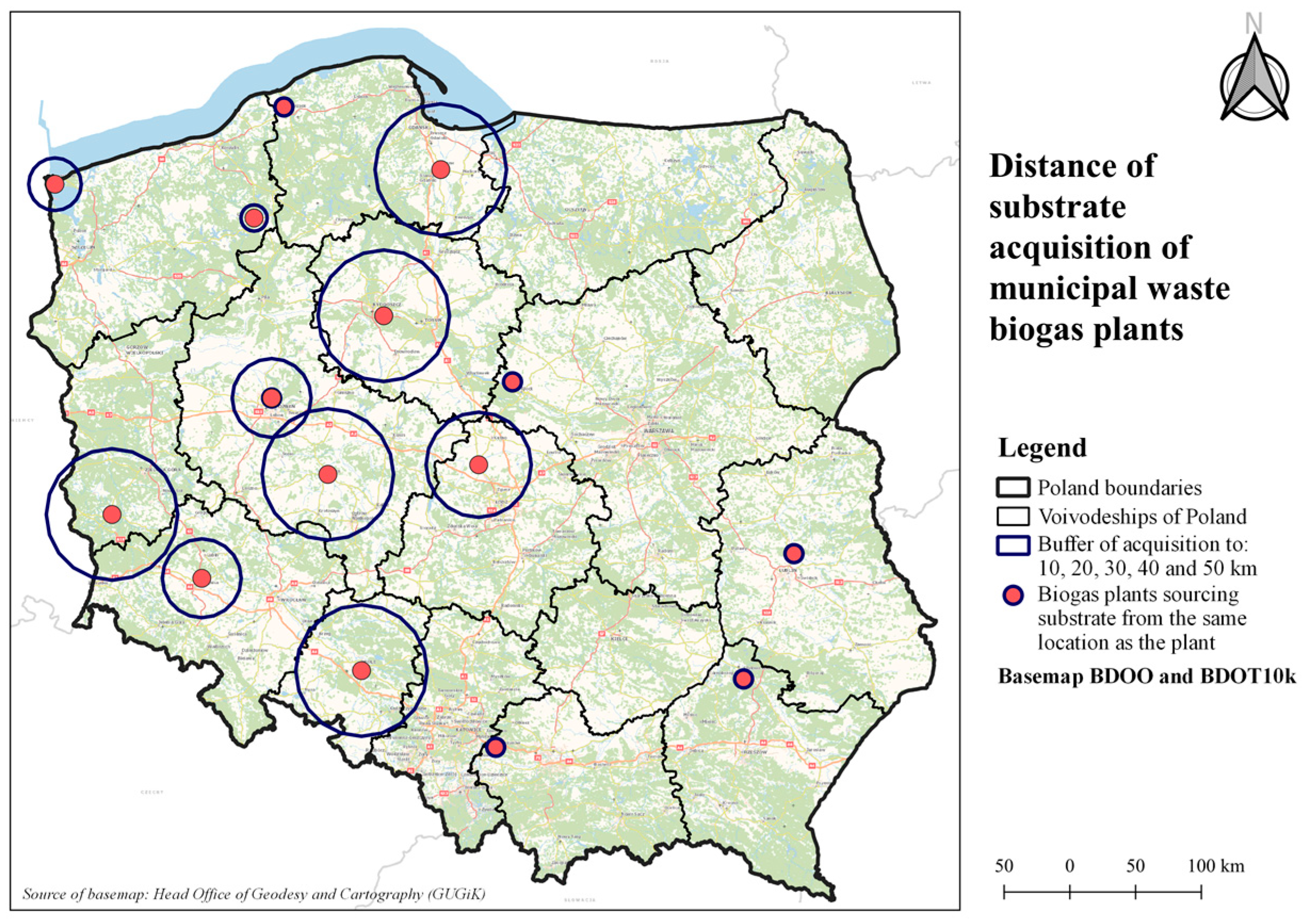

3.2. Analysis of the Localisation of Biogas Plant Operation

3.3. Management of Fermentation Waste

- What is the percentage of fermentation waste in relation to substrate you feed into the biogas plan (e.g., on average in one month the fermentation waste constitutes X% of the total substrate weight)?

- 2.

- How do you manage fermentation waste? If you transfer fermentation waste, do you have information on what happens to it afterwards?

- recultivation of industrial sites;

- composting and biological transformation processes;

- fertiliser in agriculture;

- reclamation of the tailings pile.

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Commission. European Green Deal; COM(2019) 640 Final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Langergraber, G.; Castellar, J.A.C.; Pucher, B.; Baganz, G.F.M.; Milosevic, D.; Andreucci, M.-B.; Kearney, K.; Pineda-Martos, R.; Atanasova, N. A Framework for Addressing Circularity Challenges in Cities with Nature-Based Solutions. Water 2021, 13, 2355. [Google Scholar] [CrossRef]

- Service of the Republic of Poland. Ministry of Development and Technology. Available online: https://www.gov.pl/web/rozwoj-technologia/gospodarka-o-obiegu-zamknietym (accessed on 2 March 2022).

- Ellen MacArthur Foundation. Towards the Circular Economy: Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Isle of Wight, UK, 2015. [Google Scholar]

- Oberle, B.; Bringezu, S.; Hatfield-Dodds, S.; Hellweg, S.; Schandl, H.; Clement, J.; Cabernard, L.; Che, N.; Chen, D.; Droz-Georget, H.; et al. Global Resources Outlook 2019: Natural Resources for the Future We Want; A Report of the International Resource Panel; United Nations Environment Programme: Nairobi, Kenya, 2019. [Google Scholar]

- WWF. Living Planet Report 2020—Bending the Curve of Biodiversity Loss; Almond, R.E.A., Grooten, M., Petersen, T., Eds.; WWF: Gland, Switzerland, 2020. [Google Scholar]

- Nzelibe, I.U.; Ojediran, D.D.; Moses, M. Geospatial Assessment and Mapping of Suitable Sites for a Utility-scale Solar PV Farm. Geomat. Environ. Eng. 2022, 16, 79–101. [Google Scholar] [CrossRef]

- Davybida, L.; Wyczałek, I.; Plichta, A. Using GIS and SDSS Tools in the Design of a Photovoltaic System for a Built-up Roof. Geomat. Environ. Eng. 2022, 16, 31–58. [Google Scholar] [CrossRef]

- Mitka, B.; Klapa, P.; Gniadek, J. Use of Terrestrial Laser Scanning for Measurements of Wind Power Stations. Geomat. Environ. Eng. 2019, 13, 39–49. [Google Scholar] [CrossRef]

- Greinert, A.; Mrówczyńska, M.; Grech, R.; Szefner, W. The Use of Plant Biomass Pellets for Energy Production by Combustion in Dedicated Furnaces. Energies 2020, 13, 463. [Google Scholar] [CrossRef][Green Version]

- Woch, F.; Hernik, J.; Sankowski, E.; Pióro, P.; Pazdan, M.; Noszczyk, T. Evaluating the Potential Use of Forest Biomass for Renewable Energy: A Case Study with Elements of a Systems Approach. Pol. J. Environ. Stud. 2020, 29, 885–891. [Google Scholar] [CrossRef]

- Greinert, A.; Mrówczyńska, M.; Szefner, W. The Use of Waste Biomass from the Wood Industry and Municipal Sources for Energy Production. Sustainability 2019, 11, 3083. [Google Scholar] [CrossRef][Green Version]

- Cvetkovic, S.; Kaludjerović Radoičić, T.; Kijevcanin, M. Perspective of using biogas in Serbia in European context. Energy Sources Part B Econ. Plan. Policy 2017, 12, 372–376. [Google Scholar] [CrossRef]

- Hernik, J.; Noszczyk, T.; Rutkowska, A. Towards a better understanding of the variables that influence renewable energy sources in eastern Poland. J. Clean. Prod. 2019, 241, 118075. [Google Scholar] [CrossRef]

- Furmankiewicz, M.; Richard, J.H.; Kazak, J.K. Can rural stakeholders drive the low-carbon transition? Analysis of climate-related activities planned in local development strategies in Poland. Renew. Sustain. Energy Rev. 2021, 150, 111419. [Google Scholar] [CrossRef]

- Furmankiewicz, M.; Hewitt, R.J.; Janc, K.; Kazak, J. Europeanisation of energy policy and area-based partnerships: Regional diversity of interest in renewable energy sources in local development strategies in Poland. IOP Conf. Ser. Earth Environ. Sci. 2020, 609, 012033. [Google Scholar] [CrossRef]

- Chodkowska-Miszczuk, J.; Kulla, M.; Novotný, L. The Role of Energy Policy in Agricultural Biogas Energy Production in Visegrad Countries. Bull. Geogr. Socio-Econ. Ser. 2017, 35, 19–24. [Google Scholar] [CrossRef][Green Version]

- Bazan-Krzywoszańska, A.; Skiba, M.; Mrówczyńska, M.; Sztubecka, M.; Bazuń, D.; Kwiatkowski, M. Green energy in municipal planning documents. E3S Web Conf. 2018, 45, 00006. [Google Scholar] [CrossRef]

- Kowalczyk-Juśko, A. Rozwój Innowacyjnych Technologii Odnawialnych Źródeł Energii na Obszarach Wiejskich; Centrum Doradztwa Rolniczego w Brwinowie: Radom, Poland, 2020; ISBN 978-83-66776-01-2.

- Makara, A.; Kowalski, Z.; Fela, K. Zagospodarowanie substancji pofermentacyjnej w aspekcie bezpieczeństwa ekologicznego. Prace Nauk. Akad. Im. Jana Długosza Częstochowie. Tech. Inform. Saf. Eng. 2017, 5, 177–190. [Google Scholar] [CrossRef]

- Europejska Agencja Środowiskowa. Nie na Moim Podwórku—Transport Odpadów do Innych Krajów a Środowisko. Available online: https://www.eea.europa.eu/pl/articles/nie-na-moim-podworku-2014-transport-odpadow-do-innych-krajow-a-srodowisko (accessed on 8 June 2022).

- Olofsson, M.; Sahlin, J.; Ekvall, T.; Sundberg, J. Driving forces for import of waste for energy recovery in Sweden. Waste Manag. Res. 2005, 23, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Mundler, G.; Criner, G. Food Systems: Food Miles. In Encyclopedia of Food and Health; Elsevier: Amsterdam, The Netherlands, 2016; pp. 77–82. [Google Scholar] [CrossRef]

- Ke, J.; Khanna, N.; Zhou, N. Indirect estimation of willingness to pay for energy technology adoption. Appl. Energy 2022, 312, 118701. [Google Scholar] [CrossRef]

- Pirelli, T.; Chiumenti, A.; Morese, M.M.; Bonati, G.; Fabiani, S.; Pulighe, G. Environmental sustainability of the biogas pathway in Italy through the methodology of the Global Bioenergy Partnership. J. Clean. Prod. 2021, 318, 128483. [Google Scholar] [CrossRef]

- Sawale, S.; Patil, D.; Joshi, C.; Rachappanavar, B.; Mishra, D.; Kulkarni, A. Biogas Commercialization: Commercial Players, Key Business Drivers, Potential Market, and Fostering Investment. In Biogas Production; Balagurusamy, N., Chandel, A.K., Eds.; Springer: Cham, Switzerland, 2021; pp. 343–387. ISBN 978-3-030-58827-4. [Google Scholar]

- Picardo, A.; Soltero, V.M.; Peralta, M.E.; Chacartegui, R. District heating based on biogas from wastewater treatment plant. Energy 2019, 180, 649–664. [Google Scholar] [CrossRef]

- Naroznova, I.; Møller, J.; Scheutz, C. Characterisation of the biochemical methane potential (BMP) of individual material fractions in Danish source-separated organic household waste. Waste Manag. 2016, 50, 39–48. [Google Scholar] [CrossRef][Green Version]

- Morales-Polo, C.; Cledera-Castro, M.d.M.; Revuelta-Aramburu, M.; Hueso-Kortekaas, K. Enhancing Energy Recovery in Form of Biogas, from Vegetable and Fruit Wholesale Markets By-Products and Wastes, with Pretreatments. Plants 2021, 10, 1298. [Google Scholar] [CrossRef]

- Valentino, F.; Lorini, L.; Pavan, P.; Majone, M. Development of a Biorefinery Platform for Urban Waste Valorisation into Biogas and Added-value Products. Chem. Eng. Trans. 2021, 86, 13–18. [Google Scholar] [CrossRef]

- Chen, S.; Tao, Z.; Yao, F.; Wu, B.; He, L.; Hou, K.; Pi, Z.; Fu, J.; Yin, H.; Huang, Q.; et al. Enhanced anaerobic co-digestion of waste activated sludge and food waste by sulfidated microscale zerovalent iron: Insights in direct interspecies electron transfer mechanism. Bioresour. Technol. 2020, 316, 123901. [Google Scholar] [CrossRef]

- Bentivoglio, D.; Chiaraluce, G.; Finco, A. Economic assessment for vegetable waste valorization through the biogas-biomethane chain in Italy with a circular economy approach. Front. Sustain. Food Syst. 2022, 6, 1035357. [Google Scholar] [CrossRef]

- Klimek, K.; Kapłan, M.; Syrotyuk, S.; Bakach, N.; Kapustin, N.; Konieczny, R.; Dobrzyński, J.; Borek, K.; Anders, D.; Dybek, B.; et al. Investment Model of Agricultural Biogas Plants for Individual Farms in Poland. Energies 2021, 14, 7375. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M. An economic analysis of biogas-biomethane chain from animal residues in Italy. J. Clean. Prod. 2019, 230, 888–897. [Google Scholar] [CrossRef]

- Yazan, D.M.; Cafagna, D.; Fraccascia, L.; Mes, M.; Pontrandolfo, P.; Zijm, H. Economic sustainability of biogas production from animal manure: A regional circular economy model. Manag. Res. Rev. 2018, 41, 605–624. [Google Scholar] [CrossRef][Green Version]

- de Jesus, R.H.G.; Barros, M.V.; Salvador, R.; de Souza, J.T.; Piekarski, C.M.; de Francisco, A.C. Forming clusters based on strategic partnerships and circular economy for biogas production: A GIS analysis for optimal location. Biomass Bioenergy 2021, 150, 106097. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Axsen, J.; Sorrell, S. Promoting novelty, rigor, and style in energy social science: Towards codes of practice for appropriate methods and research design. Energy Res. Soc. Sci. 2018, 45, 12–42. [Google Scholar] [CrossRef]

- Ma, X.W.; Wang, M.; Lan, J.K.; Li, C.D.; Zou, L.L. Influencing factors and paths of direct carbon emissions from the energy consumption of rural residents in central China determined using a questionnaire survey. Adv. Clim. Chang. Res. 2022, 13, 759–767. [Google Scholar] [CrossRef]

- Bedi, A.S.; Sparrow, R.; Tasciotti, L. Indonesia’s Domestic Biogas Programme—Household panel survey data. Data Brief 2018, 17, 1388–1390. [Google Scholar] [CrossRef]

- Katuwal, H. Biogas adoption in Nepal: Empirical evidence from a nationwide survey. Heliyon 2022, 8, e10106. [Google Scholar] [CrossRef]

- Burg, V.; Troitzsch, K.G.; Akyol, D.; Baier, U.; Hellweg, S.; Thees, O. Farmer’s willingness to adopt private and collective biogas facilities: An agent-based modeling approach. Resour. Conserv. Recycl. 2021, 167, 105400. [Google Scholar] [CrossRef]

- Feiz, R.; Johansson, M.; Lindkvist, E.; Moested, J.; Påledal, S.N.; Ometto, F. The biogas yield, climate impact, energy balance, nutrient recovery, and resource cost of biogas production from household food waste—A comparison of multiple cases from Sweden. J. Clean. Prod. 2022, 378, 134536. [Google Scholar] [CrossRef]

- Alao, M.A.; Popoola, O.M.; Ayodele, T.R. Sustainable prime movers selection for biogas-based combined heat and power for a community microgrid: A hybrid fuzzy multi criteria decision-making approach with consolidated ranking strategies. Energy Convers. Manag. X 2022, 16, 100281. [Google Scholar] [CrossRef]

- Urząd Regulacji Energetyki. Instalacje Odnawialnych Źródeł Energii—Stan na 31 Grudnia 2021 r. Available online: https://www.ure.gov.pl/pl/oze/potencjal-krajowy-oze/8108,Instalacje-odnawialnych-zrodel-energii-stan-na-31-grudnia-2021-r.html (accessed on 30 October 2021).

- Lubańska, A. The Role of Biogas Plants in Circular Economy. Master’s Thesis, Wrocław University of Environmental and Life Sciences, Wrocław, Poland, 2022. [Google Scholar]

- Świąder, M.; Szewrański, S.; Kazak, J.K. Foodshed as an Example of Preliminary Research for Conducting Environmental Carrying Capacity Analysis. Sustainability 2018, 10, 882. [Google Scholar] [CrossRef][Green Version]

- Augère-Granier, M.L. Short Food Supply Chains and Local Food Systems in the EU; European Parliament: Strasbourg, France, 2016. [Google Scholar]

- Łucka, I.A.; Kołodziej, A.U.; Szymańska, M.; Pilarski, K. Rolnicze wykorzystanie masy pofermentacyjnej z biogazowni rolniczej. In Wykorzystanie Biomasy w Energetyce, Aspekty Ekonomiczne i Ekologiczne; Jasiulewicz, M., Ed.; Polskie Towarzystwo Ekonomiczne: Koszalin, Poland, 2011; pp. 277–304. [Google Scholar]

- Węglarzy, K. Agro Biogazownia; Podkówka, W., Ed.; Zakład Doświadczalny Instytutu Zootechniki PIB: Grodziec Śląski, Poland, 2010. [Google Scholar]

- Węglarzy, K.; Skrzyżala, I.; Pellar, A. Agricultural biogas plant in Kostkowice, First experiences. J. Res. Appl. Agric. Eng. 2011, 56, 189–192. [Google Scholar]

- Igliński, B.; Buczkowski, R.; Cichosz, M. Biogazownie rolnicze w Polsce—Stan aktualny, potencjał, analiza SWOT. Rynek Energii 2015, 3, 93–101. [Google Scholar]

- Curkowski, A.; Oniszk-Popławska, A.; Mroczkowski, P.; Zowsik, M.; Wiśniewski, G. Przewodnik dla Inwestorów Zainteresowanych Budową Biogazowni Rolniczych; Instytut Energetyki Odnawialnej: Warszawa, Poland, 2011. [Google Scholar]

- Grešlová, P.; Štych, P.; Salata, T.; Hernik, J.; Knížková, I.; Bičík, I.; Jeleček, L.; Prus, B.; Noszczyk, T. Agroecosystem energy metabolism in Czechia and Poland in the two decades after the fall of communism: From a centrally planned system to market oriented mode of production. Land Use Policy 2019, 82, 807–820. [Google Scholar] [CrossRef]

- Woch, F.; Hernik, J.; Linke, H.J.; Sankowski, E.; Bęczkowska, M.; Noszczyk, T. Renewable Energy and Rural Autonomy: A Case Study with Generalizations. Pol. J. Environ. Stud. 2017, 26, 2823–2832. [Google Scholar] [CrossRef]

- Kazak, J.K.; Kamińska, J.A.; Madej, R.; Bochenkiewicz, M. Where Renewable Energy Sources Funds are Invested? Spatial Analysis of Energy Production Potential and Public Support. Energies 2020, 13, 5551. [Google Scholar] [CrossRef]

- Chodkowska-Miszczuk, J. Institutional Support for Biogas Enterprises—The Local Perspective. Quaest. Geogr. 2019, 38, 137–147. [Google Scholar] [CrossRef][Green Version]

- Chodkowska-Miszczuk, J.; Martinat, S.; Kulla, M.; Novotný, L. Renewables projects in peripheries: Determinants, challenges and perspectives of biogas plants—Insights from Central European countries. Reg. Stud. Reg. Sci. 2020, 7, 362–381. [Google Scholar] [CrossRef]

- Chodkowska-Miszczuk, J.; Szymańska, D. Agricultural biogas plants-Achance for diversification of agriculture in Poland. Renew. Sustain. Energy Rev. 2013, 20, 514–518. [Google Scholar] [CrossRef]

- Chodkowska-Miszczuk, J. A new narrative for sustainability: Exploring biogas plants as ‘first movers’ in raising energy awareness. Aust. J. Environ. Educ. 2022, 38, 152–167. [Google Scholar] [CrossRef]

- Mazzanti, M.; Modica, M.; Rampa, A. The biogas dilemma: An analysis on the social approval of large new plants. Waste Manag. 2021, 133, 10–18. [Google Scholar] [CrossRef]

- D’Adamo, I.; Ribichini, M.; Tsagarakis, K.P. Biomethane as an energy resource for achieving sustainable production: Economic assessments and policy implications. Sustain. Prod. Consum. 2023, 35, 13–27. [Google Scholar] [CrossRef]

| Measure | Group 1 [MW] | Group 2 [MW] |

|---|---|---|

| Minimum value | 0.050 | 0.050 |

| Maximum value | 15.536 | 4.266 |

| Arithmetic mean | 1.138 | 0.890 |

| Median | 0.562 | 0.561 |

| Standard deviation | 2.089 | 0.844 |

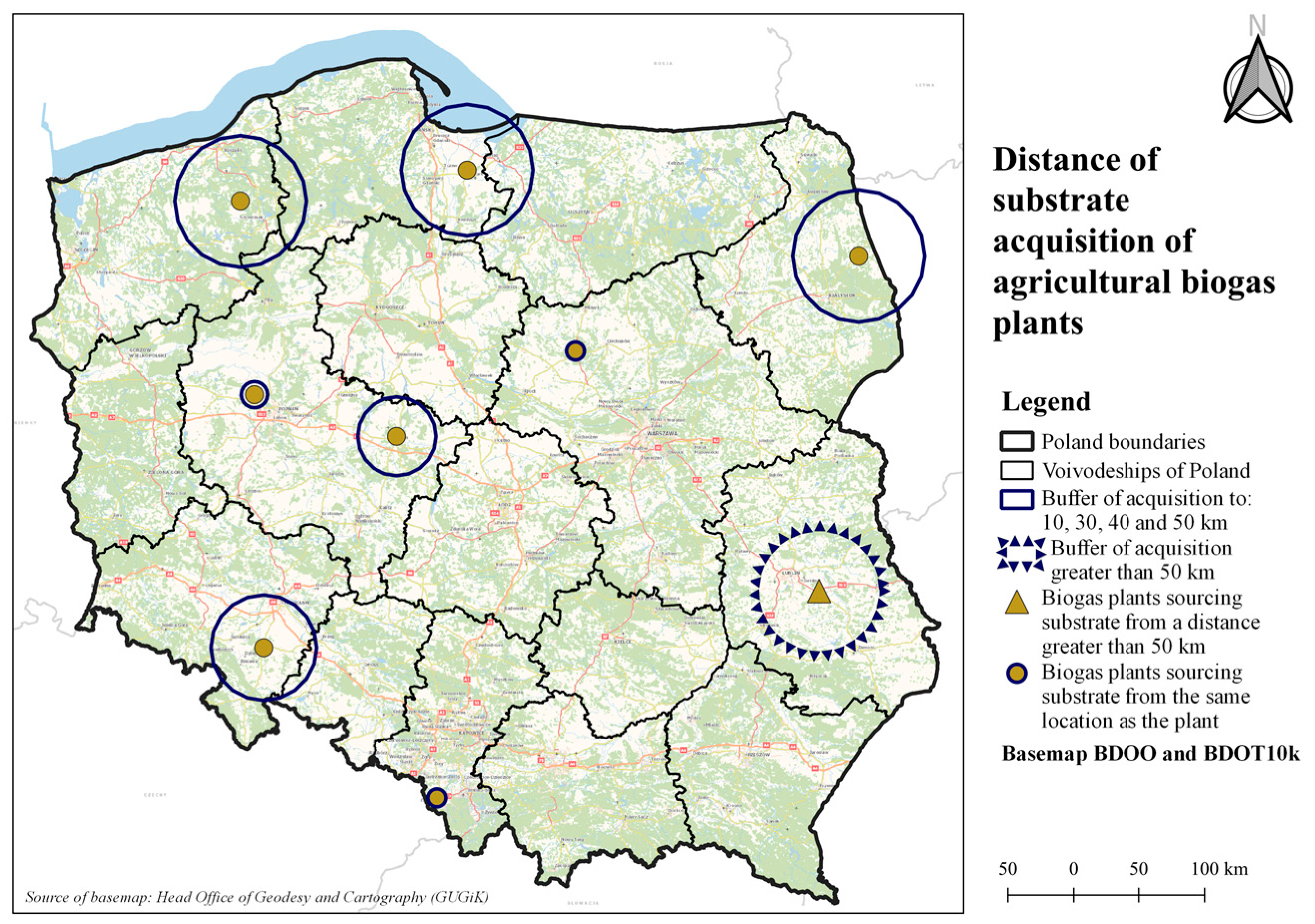

| Distance | Type of Biogas Plant | ||

|---|---|---|---|

| Biogas Plant at the Sewage Treatment Plant | Biogas Plant Fed with Municipal Waste | Agricultural Biogas Plant | |

| Up to 10 km | 1 | 1 | 1 |

| Up to 20 km | - | 1 | - |

| Up to 30 km | 3 | 2 | 1 |

| Up to 40 km | - | 1 | 1 |

| Up to 50 km | - | 5 | 3 |

| Over 50 km | - | - | 1 |

| The material is sourced from the same site as the biogas plant | 32 | 6 | 2 |

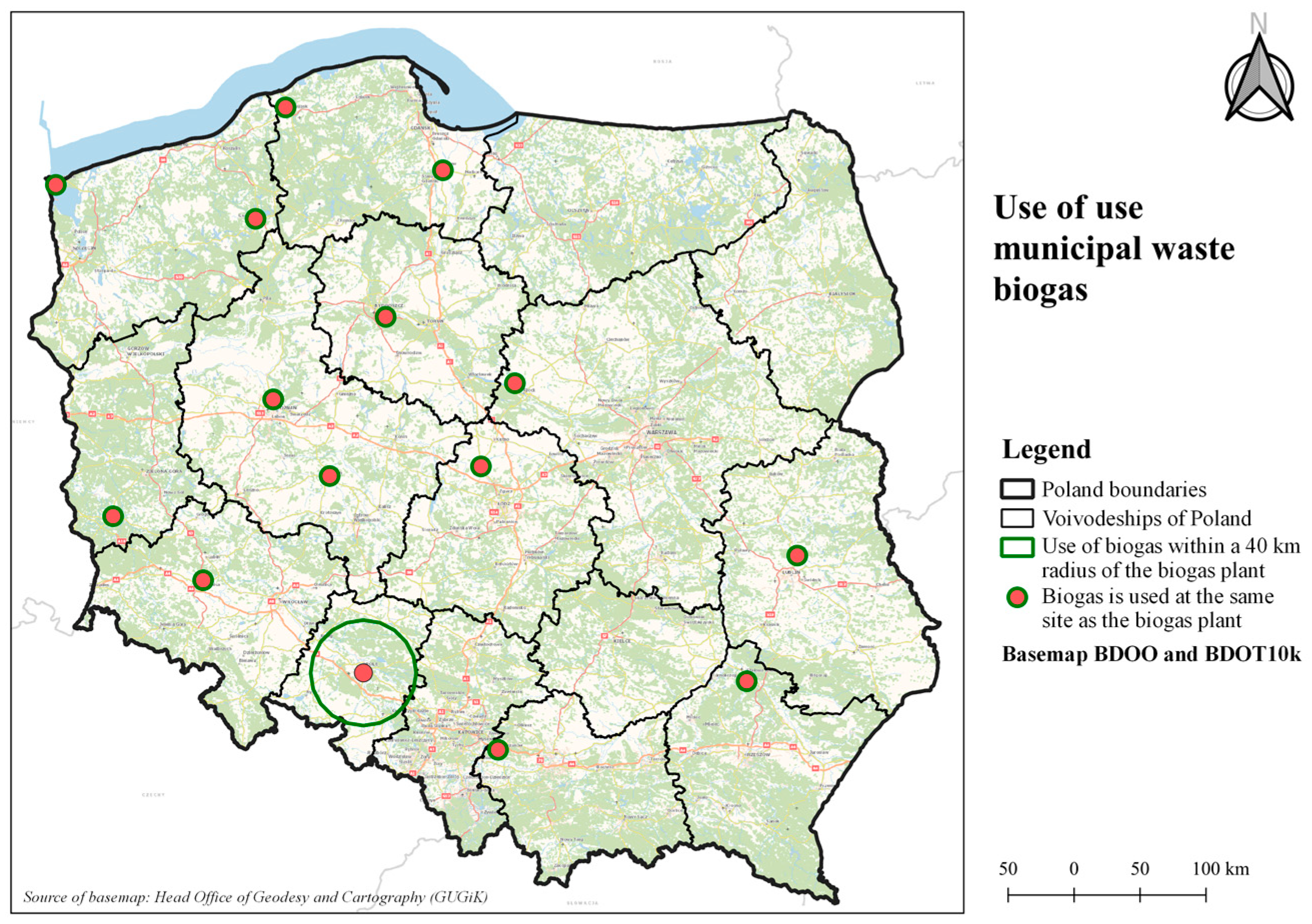

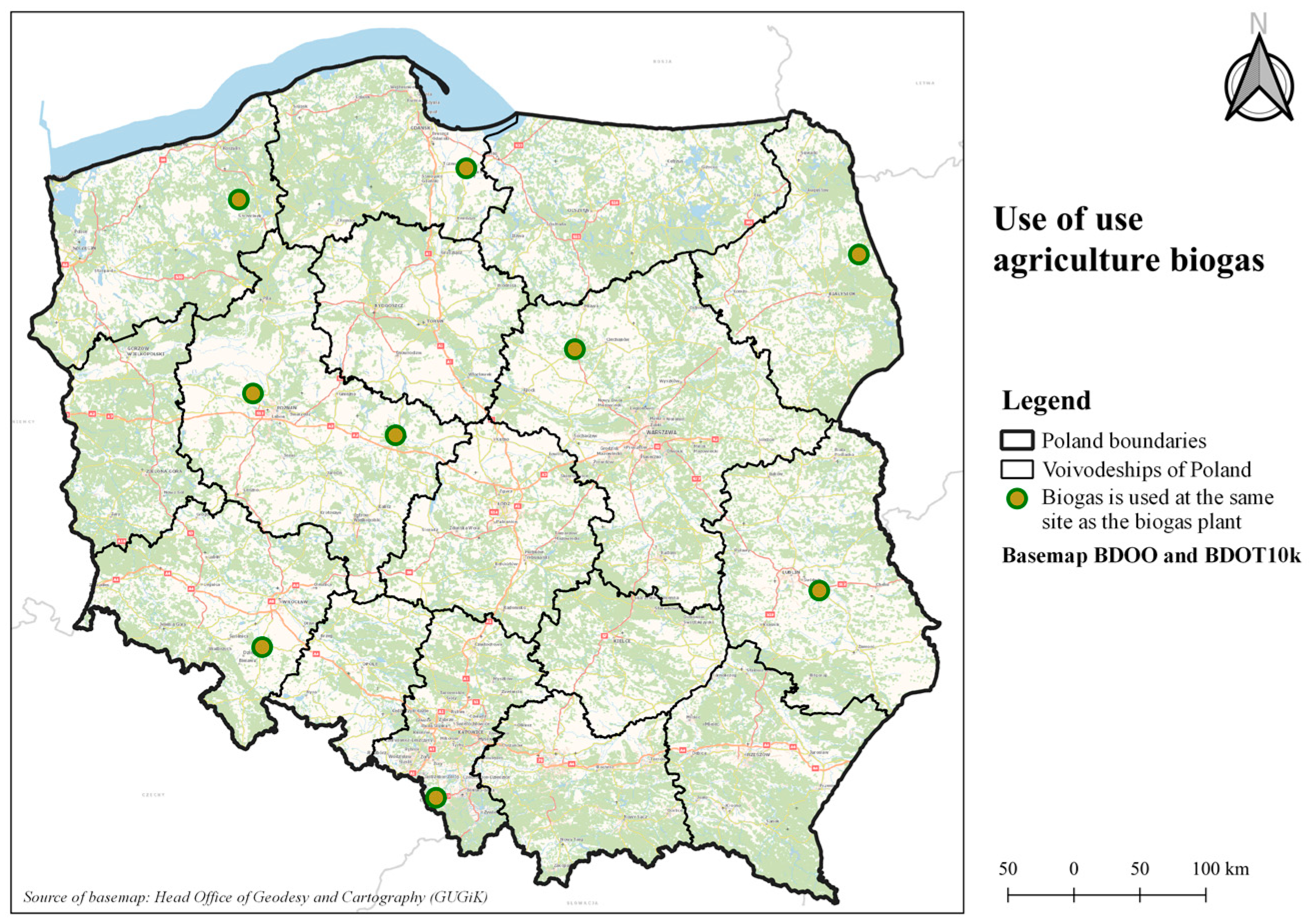

| Distance the Use of Biogas | Who Uses Manufactured Biogas | |

|---|---|---|

| Our Company/Farm | Our Enterprise/Farm, the Surplus Is Sold or Given to the Network | |

| Biogas is used at the same site as the biogas plant | 58 | 2 |

| Up to 40 km | 1 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lubańska, A.; Kazak, J.K. The Role of Biogas Production in Circular Economy Approach from the Perspective of Locality. Energies 2023, 16, 3801. https://doi.org/10.3390/en16093801

Lubańska A, Kazak JK. The Role of Biogas Production in Circular Economy Approach from the Perspective of Locality. Energies. 2023; 16(9):3801. https://doi.org/10.3390/en16093801

Chicago/Turabian StyleLubańska, Aleksandra, and Jan K. Kazak. 2023. "The Role of Biogas Production in Circular Economy Approach from the Perspective of Locality" Energies 16, no. 9: 3801. https://doi.org/10.3390/en16093801

APA StyleLubańska, A., & Kazak, J. K. (2023). The Role of Biogas Production in Circular Economy Approach from the Perspective of Locality. Energies, 16(9), 3801. https://doi.org/10.3390/en16093801