Reducing Soot Nanoparticles and NOX Emissions in CRDI Diesel Engine by Incorporating TiO2 Nano-Additives into Biodiesel Blends and Using High Rate of EGR

Abstract

:1. Introduction

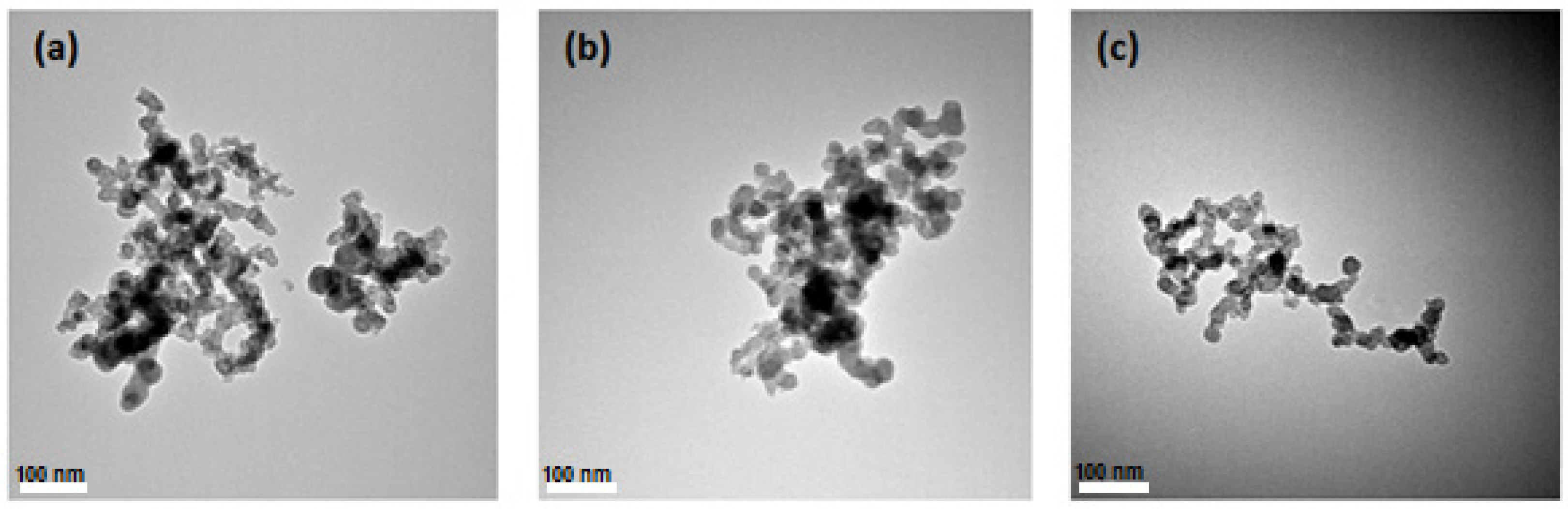

2. Materials and Methods

2.1. Preparation of Fuel Blend with TiO2 Nanoparticles

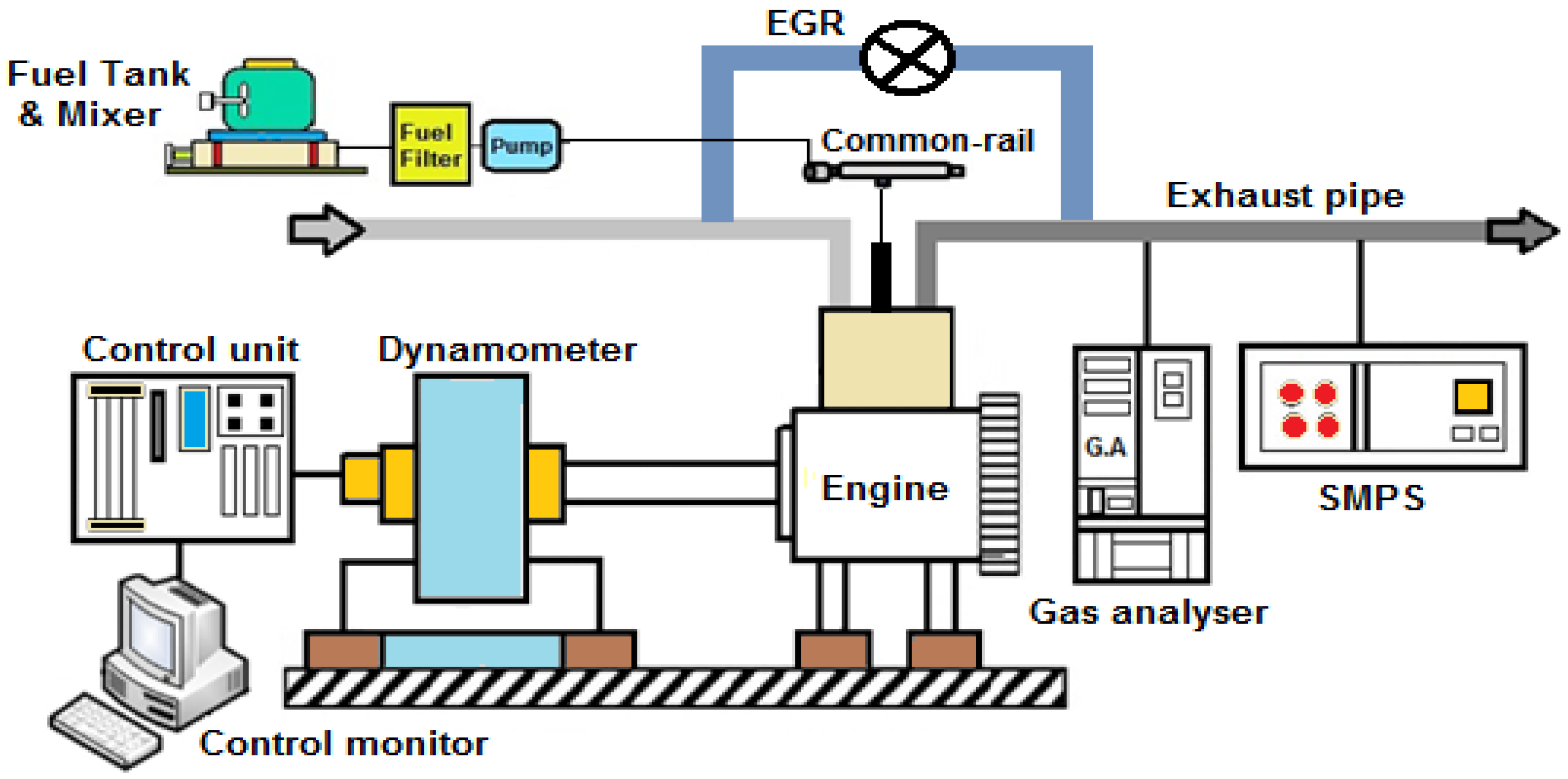

2.2. Engine and Equipment

3. Results and Discussion

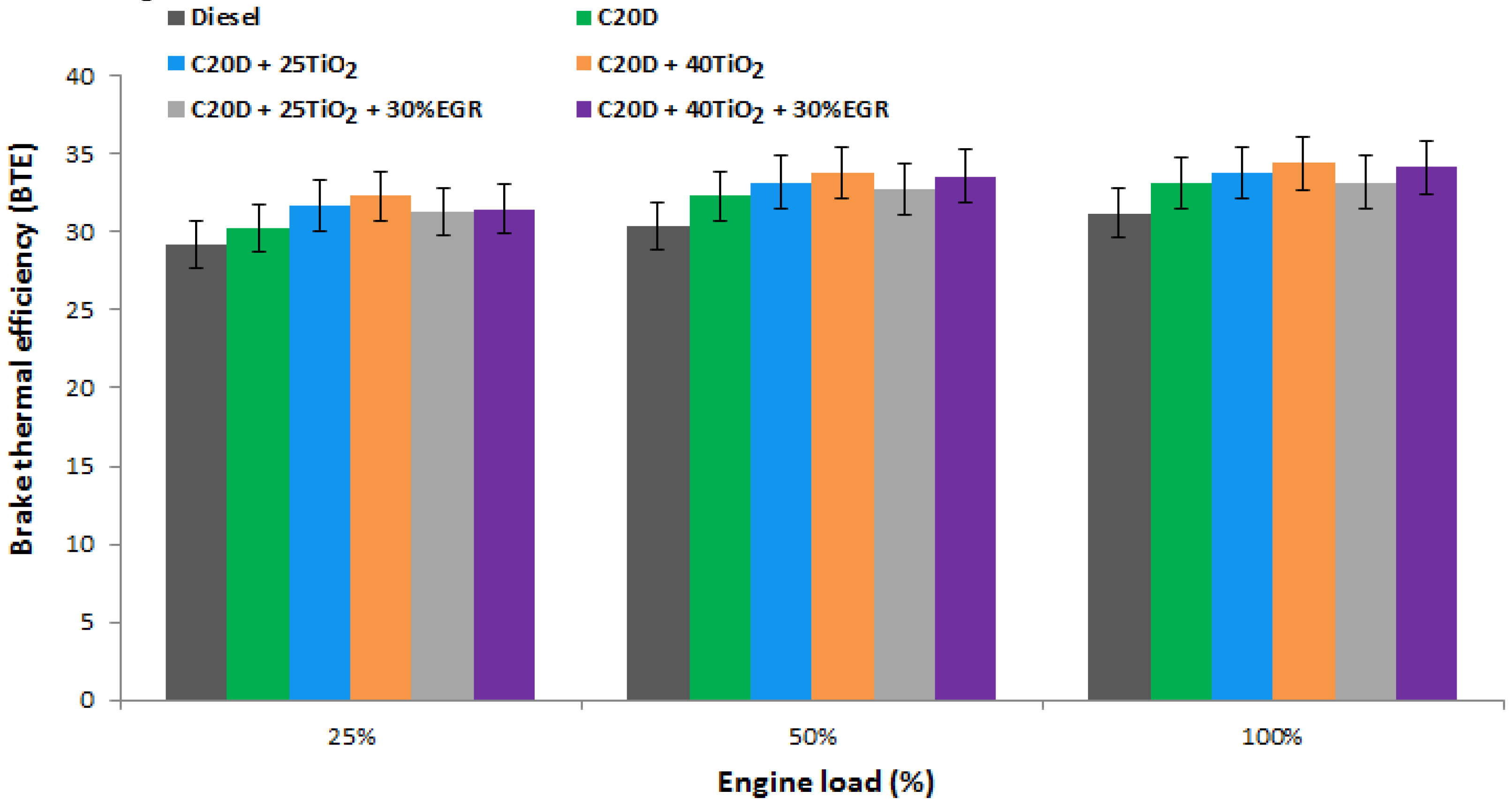

3.1. Brake-Specific Fuel Consumption (BSFC) and Brake Thermal Efficiency (BTE)

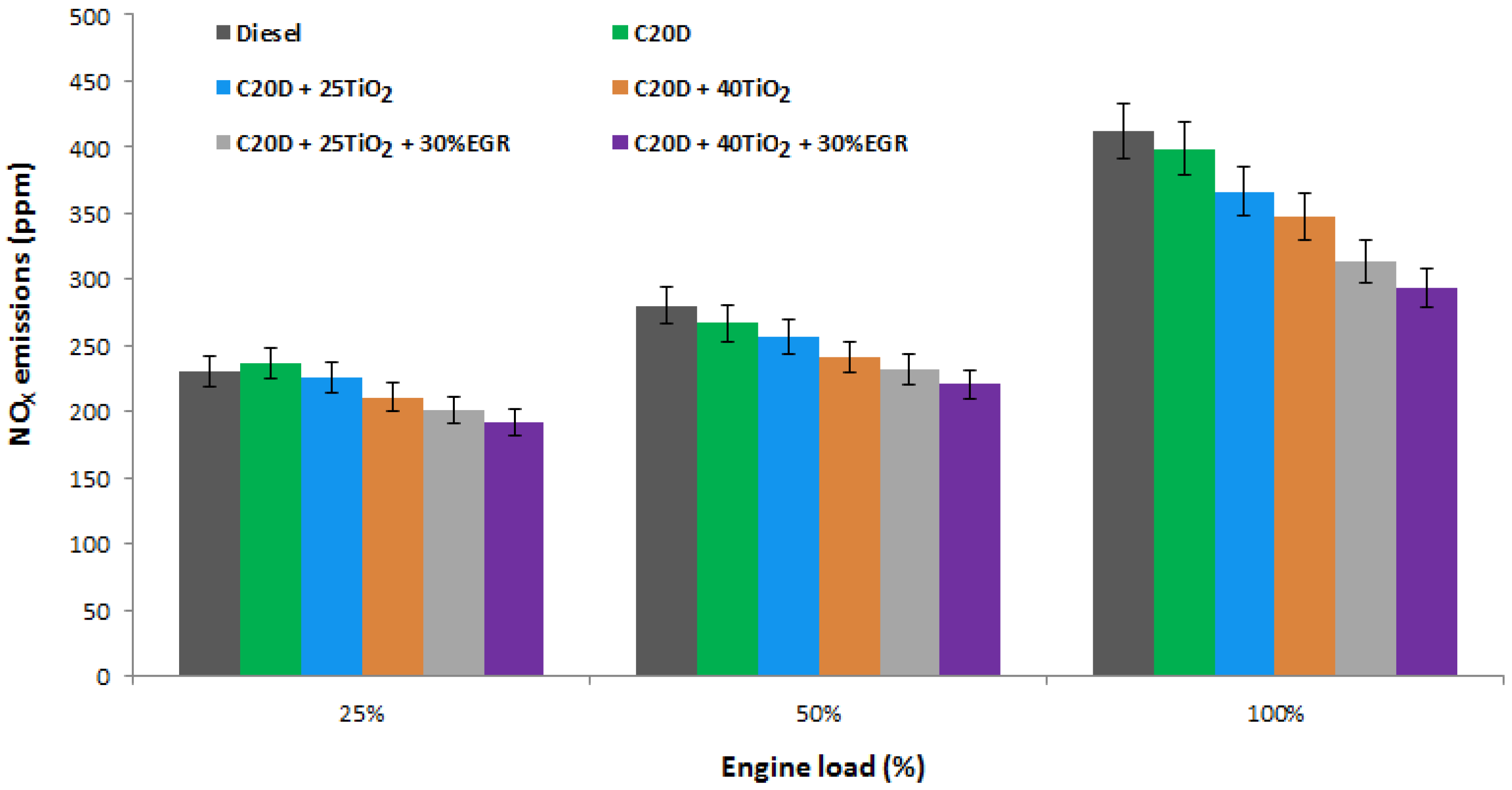

3.2. NOX Emissions

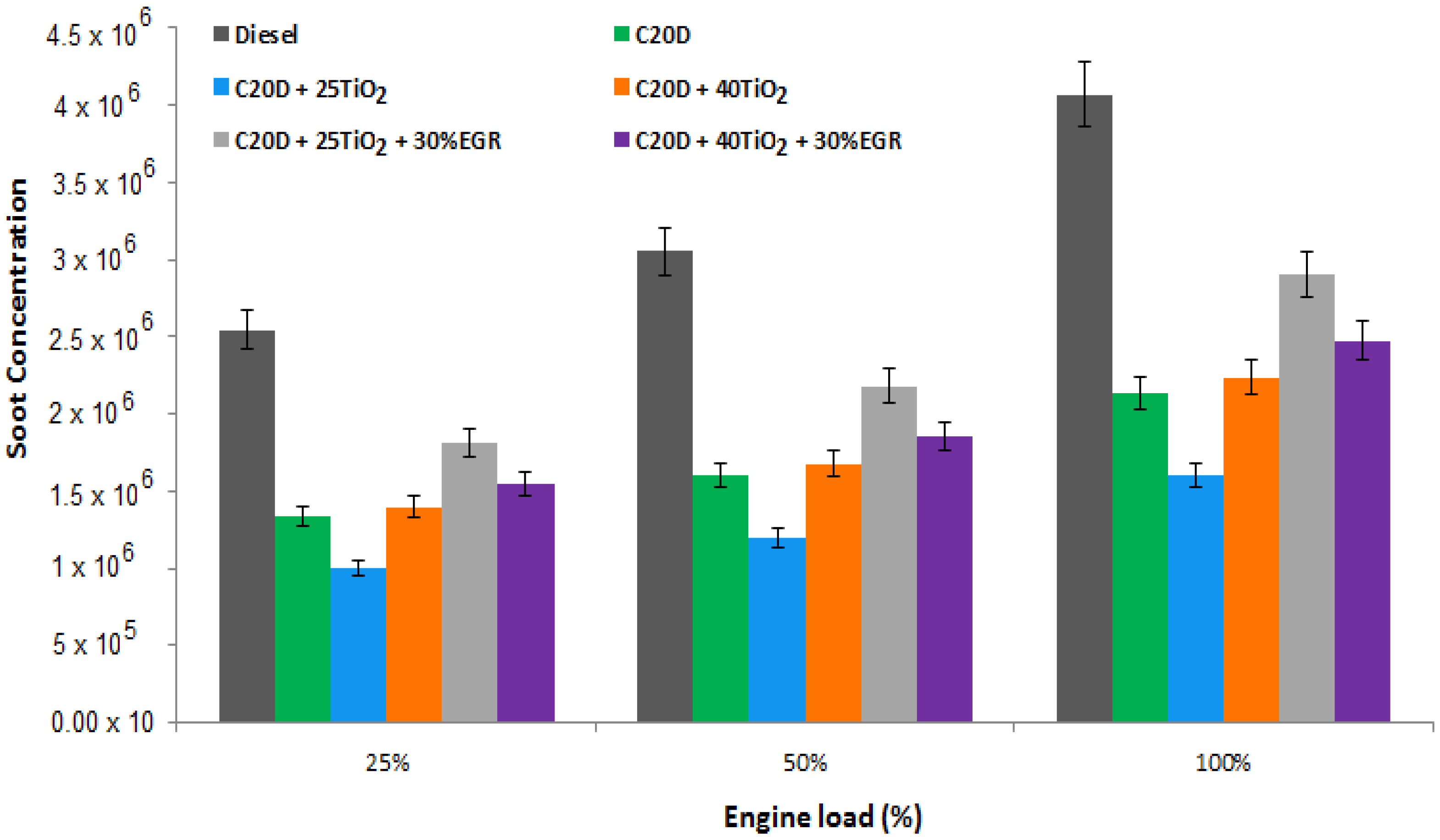

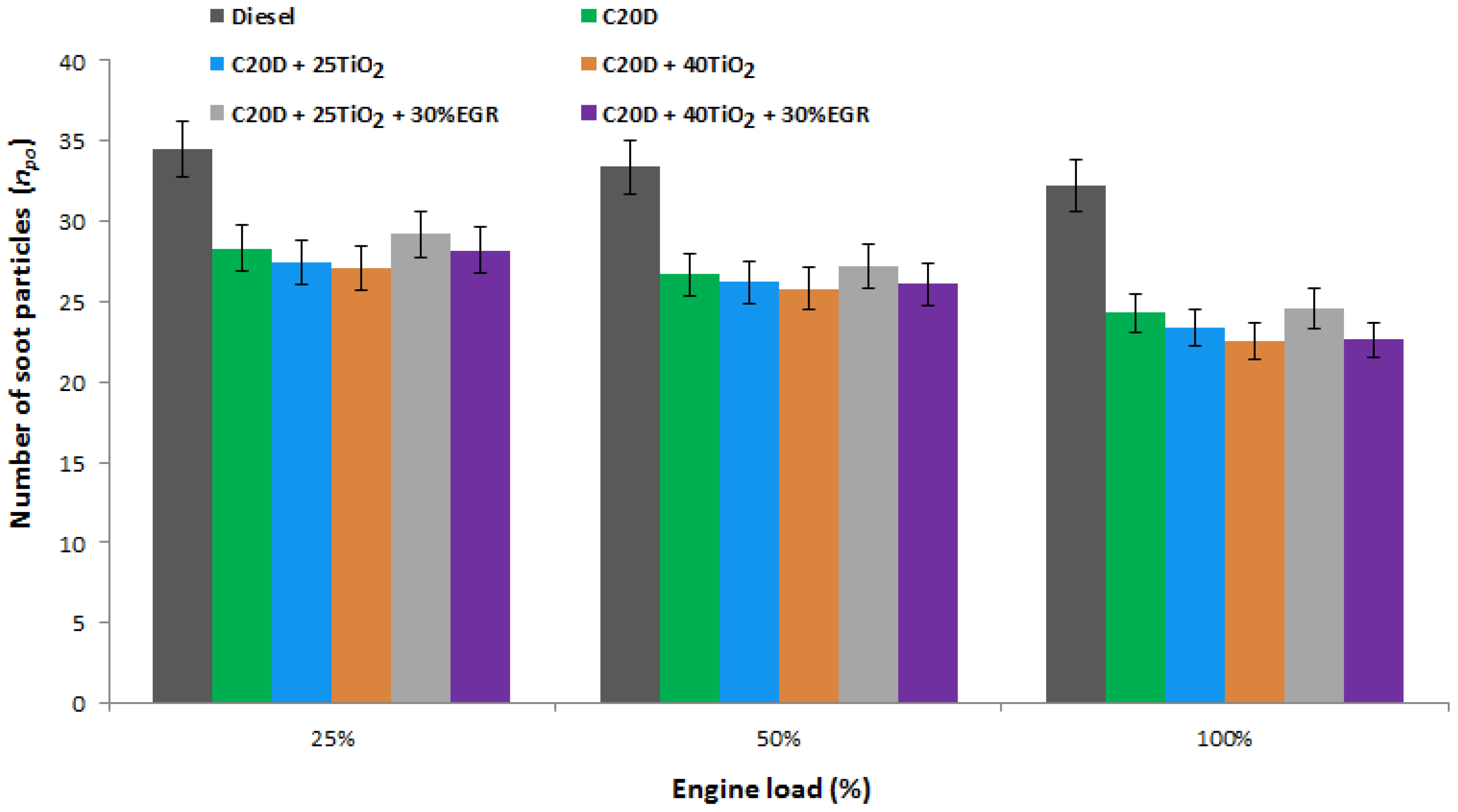

3.3. Soot Nanoparticle Emissions

4. Conclusions

- It was found that the BSFC decreased with the addition of 25 ppm and 40 ppm of TiO2 to the nano blend compared to the fuel without nano-additives. The reduction in BSFC was clearly due to the addition of 40 ppm of TiO2 nanoparticles as opposed to the addition of 25 ppm of TiO2 to the nano blend.

- It was concluded that the BTE improved by 6.4% with the addition of TiO2 into the castor oil blend compared to the neat biodiesel blend and diesel fuel.

- The engine performance was decreased with the application of a high rate of EGR and low concentration of nanoparticles into the nano blend, while the engine performance slightly improved with the increase in the nanoparticle concentration of TiO2 in the C20D fuel and applying a high EGR rate.

- The NOX emissions were reduced by 13.42% when the nano blend was combusted in comparison with the C20D fuel. Moreover, there was a significant decrease in NOX emissions with the application of a high EGR rate and a nano blend.

- The soot emission concentration and number of soot particles were evidently decreased with the addition of 25 ppm and 40 ppm of TiO2 to the C20D fuel in comparison with absence of TiO2 in the C20D and diesel fuels, while these parameters increased with the occurrence of a high rate of EGR.

- It was observed that the integration of a high concentration of TiO2 nanoparticles and a high rate of EGR produces beneficial effects on engine performance as well as a slight reduction in NOX emissions and soot emissions (concentration and number).

- We suggest that future research should attempt to determine the effects of fuel injection strategies, the EGR rate, and the use of a nano blend (TiO2 with biodiesel blend) on NOX emissions and PM characteristics, as this will be an engaging topic.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| BSFC | brake-specific fuel consumption |

| BTE | brake thermal efficiency |

| CO100 | castor oil |

| C20D | 20% castor oil methyl ester and 80% diesel fuel |

| CO | carbon monoxide |

| CRDI | common-rail direct injection |

| CO2 | carbon dioxide |

| DI | direct injection |

| EGR | exhaust gas recirculation |

| EGT | exhaust gas temperature |

| SEM | scanning electron microscope |

| SMPS | scanning mobility particle-sizer |

| TEM | transmission electron microscopy |

| TiO2 | titanium dioxide |

| HC | hydrocarbon |

| THC | total hydrocarbon |

| NOX | nitrogen oxides |

| PM | particulate matter |

References

- Fayad, M.A.; Chaichan, M.T.; Dhahad, H.A.; Al-Amiery, A.A.; Wan Isahak, W.N.R. Reducing the Effect of High Sulfur Content in Diesel Fuel on NO x Emissions and PM Characteristics Using a PPCI Mode Engine and Gasoline–Diesel Blends. ACS Omega 2022, 7, 37328–37339. [Google Scholar] [CrossRef] [PubMed]

- Vithanage, M.; Bandara, P.C.; Novo, L.A.B.; Kumar, A.; Ambade, B.; Naveendrakumar, G.; Ranagalage, M.; Magana-Arachchi, D.N. Deposition of trace metals associated with atmospheric particulate matter: Environmental fate and health risk assessment. Chemosphere 2022, 303, 135051. [Google Scholar] [CrossRef] [PubMed]

- Wyer, K.E.; Kelleghan, D.B.; Blanes-Vidal, V.; Schauberger, G.; Curran, T.P. Ammonia emissions from agriculture and their contribution to fine particulate matter: A review of implications for human health. J. Environ. Manag. 2022, 323, 116285. [Google Scholar] [CrossRef] [PubMed]

- Chaichan, M.; Gaaz, T.S.; Al-Amiery, A.; Kadhum, A.A. Biodiesel Blends Startability and Emissions During Cold, Warm and Hot Conditions. J. Nanofluids 2020, 9, 75–89. [Google Scholar] [CrossRef]

- Lamba, B.Y.; Chen, W. Experimental Investigation of Biodiesel Blends with High-Speed Diesels—A Comprehensive Study. Energies 2022, 15, 7878. [Google Scholar] [CrossRef]

- Singh, A.K.; Pali, H.S.; Khan, M.M. Performance and Emission Analysis of Waste Animal Fat Methyl Esters Blends on Naturally Aspirated Single Cylinder Engine. J. Eng. Res. 2021, 10, 15833. [Google Scholar] [CrossRef]

- Ge, J.C.; Choi, N.J. Soot particle size distribution, regulated and unregulated emissions of a diesel engine fueled with palm oil biodiesel blends. Energies 2020, 13, 5736. [Google Scholar] [CrossRef]

- Balat, M.; Balat, H. A critical review of bio-diesel as a vehicular fuel. Energy Convers. Manag. 2008, 49, 2727–2741. [Google Scholar] [CrossRef]

- Fayad, M.A.; AL-Ogaidi, B.R.; Abood, M.K.; AL-Salihi, H.A. Influence of post-injection strategies and CeO2 nanoparticles additives in the C30D blends and diesel on engine performance, NOX emissions, and PM characteristics in diesel engine. Part. Sci. Technol. 2021, 40, 2017088. [Google Scholar] [CrossRef]

- Kumar, A.; Pali, H.S.; Kumar, M. Effect of injection timing of waste plastic oil and its blends on CRDI diesel engine. Int. J. Engine Res. 2022, 14680874221119131. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Vignesh, D.S. Calophyllum inophyllum methyl ester biodiesel blend as an alternate fuel for diesel engine applications. Alex. Eng. J. 2018, 57, 1239–1247. [Google Scholar] [CrossRef]

- Hwang, J.; Qi, D.; Jung, Y.; Bae, C. Effect of injection parameters on the combustion and emission characteristics in a common-rail direct injection diesel engine fueled with waste cooking oil biodiesel. Renew. Energy 2014, 63, 9–17. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Masjuki, H.H.; Kalam, M.A.; Abedin, M.J.; Sanjid, A.; Rahman, M.d.M. Assessing idling effects on a compression ignition engine fueled with Jatropha and Palm biodiesel blends. Renew. Energy 2014, 68, 644–650. [Google Scholar] [CrossRef]

- Kadarohman, A.; Hernani, K.F.; Astuti, R.M. A potential study on clove oil, eugenol and eugenyl acetate as diesel fuel bio-additives and their performance on one cylinder engine. Transport 2010, 25, 66–76. [Google Scholar] [CrossRef]

- Bazooyar, B.; Hosseini, S.Y.; Begloo, S.M.G.; Shariati, A.; Hashemabadi, S.H.; Shaahmadi, F. Mixed modified Fe2O3-WO3 as new fuel borne catalyst (FBC) for biodiesel fuel. Energy 2018, 149, 438–453. [Google Scholar] [CrossRef]

- Abdullah, N.A.; Rani, M.S.A.; Mohammad, M.; Sainorudin, M.H.; Asim, N.; Yaakob, Z.; Razali, H.; Emdadi, Z. Nanocellulose from agricultural waste as an emerging nanotechnology material for nanotechnology applications–an overview. Polimery 2021, 66, 157–168. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Ashok, B.; Tamilarasu, A.; Johny, A.; Mohan, A. Influence on the effect of zinc oxide and titanium dioxide nanoparticles as an additive with Calophyllum inophyllum methyl ester in a CI engine. Energy Convers. Manag. 2017, 146, 8–19. [Google Scholar] [CrossRef]

- Prabu, A.; Anand, R.B. Emission control strategy by adding alumina and cerium oxide nano particle in biodiesel. J. Energy Inst. 2016, 89, 366–372. [Google Scholar] [CrossRef]

- Sajith, V.; Sobhan, C.B.; Peterson, G.P. Experimental investigations on the effects of cerium oxide nanoparticle fuel additives on biodiesel. Adv. Mech. Eng. 2010, 2, 581407. [Google Scholar] [CrossRef]

- Lakhera, A.; Kumar, N.; Sharma, A.; Saxena, A.; Padap, A.K.; Yadav, A.K.; Dwivedi, V.K. Optimization of diesel engine performance and emission characteristics with cerium oxide nanoparticles mixed waste cooking oil biodiesel blends. Int. J. Engine Res. 2022, 14680874221133223. [Google Scholar] [CrossRef]

- Bhaskar, P.B.; Srihari, S. Effect of exhaust gas recirculation on emissions of a diesel engine fuelled with castor seed biodiesel. Appl. Mech. Mater. 2015, 813–814, 819–823. [Google Scholar] [CrossRef]

- Chaichan, M.T. Performance and emission characteristics of CIE using hydrogen, biodiesel, and massive EGR. Int. J. Hydrog. Energy 2018, 43, 5415–5435. [Google Scholar] [CrossRef]

- Can, Ö.; Öztürk, E.; Solmaz, H.; Aksoy, F.; Çinar, C.; Yücesu, H.S. Combined effects of soybean biodiesel fuel addition and EGR application on the combustion and exhaust emissions in a diesel engine. Appl. Therm. Eng. 2016, 95, 115–124. [Google Scholar] [CrossRef]

- Kumar, B.R.; Saravanan, S.; Rana, D.; Anish, V.; Nagendran, A. Effect of a sustainable biofuel–n-octanol–on the combustion, performance and emissions of a DI diesel engine under naturally aspirated and exhaust gas recirculation (EGR) modes. Energy Convers. Manag. 2016, 118, 275–286. [Google Scholar] [CrossRef]

- Qi, D.; Ma, L.; Chen, R.; Jin, X.; Xie, M. Effects of EGR rate on the combustion and emission characteristics of diesel-palm oil-ethanol ternary blends used in a CRDI diesel engine with double injection strategy. Appl. Therm. Eng. 2021, 199, 117530. [Google Scholar] [CrossRef]

- Yasin, M.H.M.; Mamat, R.; Yusop, A.F.; Idris, D.M.N.D.; Yusaf, T.; Rasul, M.; Najafi, G. Study of a diesel engine performance with exhaust gas recirculation (EGR) system fuelled with palm biodiesel. Energy Procedia 2017, 110, 26–31. [Google Scholar] [CrossRef]

- Magno, A.; Mancaruso, E.; Vaglieco, B.M. Analysis of combustion phenomena and pollutant formation in a small compression ignition engine fuelled with blended and pure rapeseed methyl ester. Energy 2016, 106, 618–630. [Google Scholar] [CrossRef]

- Sathiyamoorthi, R.; Sankaranarayanan, G.; Pitchandi, K. Combined effect of nanoemulsion and EGR on combustion and emission characteristics of neat lemongrass oil (LGO)-DEE-diesel blend fuelled diesel engine. Appl. Therm. Eng. 2017, 112, 1421–1432. [Google Scholar] [CrossRef]

- Praveena, V.; Martin, M.L.J.; Geo, V.E. Effect of EGR on emissions of a modified DI compression ignition engine energized with nanoemulsive blends of grapeseed biodiesel. Fuel 2020, 267, 117317. [Google Scholar] [CrossRef]

- Hasannuddin, A.K.; Yahya, W.J.; Sarah, S.; Ithnin, A.M.; Syahrullail, S.; Sidik, N.A.C.; Kassim, K.A.A.; Ahmad, Y.; Hirofumi, N.; Ahmad, M.A. Nano-additives incorporated water in diesel emulsion fuel: Fuel properties, performance and emission characteristics assessment. Energy Convers. Manag. 2018, 169, 291–314. [Google Scholar] [CrossRef]

- Yuvarajan, D.; Babu, M.D.; BeemKumar, N.; Kishore, P.A. Experimental investigation on the influence of titanium dioxide nanofluid on emission pattern of biodiesel in a diesel engine. Atmos. Pollut. Res. 2018, 9, 47–52. [Google Scholar] [CrossRef]

- Venu, H.; Subramani, L.; Raju, V.D. Emission reduction in a DI diesel engine using exhaust gas recirculation (EGR) of palm biodiesel blended with TiO2 nano additives. Renew. Energy 2019, 140, 245–263. [Google Scholar] [CrossRef]

- Das, S.K.; Choi, S.U.; Yu, W.; Pradeep, T. Nanofluids: Science and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Li, C.H. Experimental study of nanoadditives for biofuel combustion improvement. In Proceedings of the ASME 2011 International Mechanical Engineering Congress and Exposition, Denver, CO, USA, 11–17 November 2011. [Google Scholar]

- Hajbabaei, M.; Johnson, K.C.; Okamoto, R.; Durbin, T.D. Evaluation of the Impacts of Biofuels on Emissions for a California Certified Diesel Fuel from Heavy-Duty Engines. SAE Int. J. Fuels Lubr. 2013, 6, 393–406. [Google Scholar] [CrossRef]

- Fayad, M.A. Investigation of the impact of injection timing and pressure on emissions characteristics and smoke/soot emissions in diesel engine fuelling with soybean fuel. J. Eng. Res. 2021, 9, 296–307. [Google Scholar] [CrossRef]

- D’Silva, R.; Vinoothan, K.; Binu, K.G.; Thirumaleshwara, B.; Raju, K. Effect of titanium dioxide and calcium carbonate nanoadditives on the performance and emission characteristics of CI engine. J. Mech. Eng. Autom. 2016, 6, 28–31. [Google Scholar]

- Saraee, H.S.; Taghavifar, H.; Jafarmadar, S. Experimental and numerical consideration of the effect of CeO2 nanoparticles on diesel engine performance and exhaust emission with the aid of artificial neural network. Appl. Therm. Eng. 2017, 113, 663–672. [Google Scholar] [CrossRef]

- Agarwal, D.; Singh, S.K.; Agarwal, A.K. Effect of Exhaust Gas Recirculation (EGR) on performance, emissions, deposits and durability of a constant speed compression ignition engine. Appl. Energy 2011, 88, 2900–2907. [Google Scholar] [CrossRef]

- Al Ezzi, A.; Fayad, M.A.; Al Jubori, A.M.; Jaber, A.A.; Alsadawi, L.A.; Dhahad, H.A.; Chaichan, M.T.; Yusaf, T. Influence of fuel injection pressure and RME on combustion, NOx emissions and soot nanoparticles characteristics in common-rail HSDI diesel engine. Int. J. 2022, 15, 100173. [Google Scholar]

- Chaichan, M.T.; Fayad, M.A.; Al Ezzi, A.; Dhahad, H.A.; Megaritis, T.; Yusaf, T.; Al-Amiery, A.; Wan Isahak, W.N.R. Ultralow Sulfur Diesel and Rapeseed Methyl Ester Fuel Impact on Performance, Emitted Regulated, Unregulated, and Nanoparticle Pollutants. ACS Omega 2022, 7, 26056–26075. [Google Scholar] [CrossRef]

- Ge, S.; Brindhadevi, K.; Xia, C.; Khalifa, A.S.; Elfasakhany, A.; Unpaprom, Y.; Whangchai, K. Performance, combustion and emission characteristics of the CI engine fueled with Botryococcus braunii microalgae with addition of TiO2 nanoparticle. Fuel 2022, 317, 121898. [Google Scholar] [CrossRef]

- Fayad, M.A.; Ibrahim, S.I.; Omran, S.H.; Martos, F.J.; Badawy, T.; Al Jubori, A.M.; Dhahad, H.A.; Chaichan, M.T. Experimental effect of CuO2 nanoparticles into the RME and EGR rates on NOX and morphological characteristics of soot nanoparticles. Fuel 2023, 331, 125549. [Google Scholar] [CrossRef]

- Patel, H.K.; Kumar, S. Experimental analysis on performance of diesel engine using mixture of diesel and bio-diesel as a working fuel with aluminum oxide nanoparticle additive. Therm. Sci. Eng. Prog. 2017, 4, 252–258. [Google Scholar] [CrossRef]

- Bidir, M.G.; Narayanan, K.M.; Adaramola, M.S.; Hagos, F.Y.; Singh, R.C. Comparative study on the effect of nanoparticles in ternary fuel blends on combustion, performance, and emissions characteristics of diesel engine. Int. J. Engine Res. 2022, 14680874221132963. [Google Scholar] [CrossRef]

- Venu, H.; Madhavan, V. Effect of Al2O3 nanoparticles in biodiesel-diesel-ethanol blends at various injection strategies: Performance, combustion and emission characteristics. Fuel 2016, 186, 176–189. [Google Scholar] [CrossRef]

- Fayad, M.A.; Tsolakis, A.; Martos, F.J.; Bogarra, M.; Lefort, I.; Dearn, K.D. Investigation the effect of fuel injection strategies on combustion and morphology characteristics of PM in modern diesel engine operated with oxygenate fuel blending. Therm. Sci. Eng. Prog. 2022, 35, 101476. [Google Scholar] [CrossRef]

- Zhang, Z.; Balasubramanian, R. Effects of oxygenated fuel blends on carbonaceous particulate composition and particle size distributions from a stationary diesel engine. Fuel 2015, 141, 1–8. [Google Scholar] [CrossRef]

- Jung, Y.; Hwang, J.; Bae, C. Assessment of particulate matter in exhaust gas for biodiesel and diesel under conventional and low temperature combustion in a compression ignition engine. Fuel 2016, 165, 413–424. [Google Scholar] [CrossRef]

- Rastogi, P.M.; Sharma, A.; Kumar, N. Effect of CuO nanoparticles concentration on the performance and emission characteristics of the diesel engine running on jojoba (Simmondsia Chinensis) biodiesel. Fuel 2021, 286, 119358. [Google Scholar] [CrossRef]

- Kalaimurugan, K.; Karthikeyan, S.; Periyasamy, M.; Mahendran, G.; Dharmaprabhakaran, T. Experimental studies on the influence of copper oxide nanoparticle on biodiesel-diesel fuel blend in CI engine. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 1–16. [Google Scholar] [CrossRef]

- Liu, J.; Wu, P.; Sun, P.; Ji, Q.; Zhang, Q.; Wang, P. Effects of iron-based fuel borne catalyst addition on combustion, in-cylinder soot distribution and exhaust emission characteristics in a common-rail diesel engine. Fuel 2021, 290, 120096. [Google Scholar] [CrossRef]

- Crookes, R.J.; Sivalingam, G.; Nazha, M.A.A.; Rajakaruna, H. Prediction and measurement of soot particulate formation in a confined diesel fuel spray-flame at 2.1 MPa. Int. J. Therm. Sci. 2003, 42, 639–646. [Google Scholar] [CrossRef]

| Properties | Diesel | CO | C20D |

|---|---|---|---|

| Derived cetane number | 51.8 | 48.4 | 50.3 |

| Kinematic viscosity at 40 °C (cSt) | 2.67 | 3.224 | 3.465 |

| Density at 15 °C (kg/m3) | 842.3 | 881.6 | 858.4 |

| Latent heat of vaporization (kJ/kg) | 241 | 221 | 232 |

| Thermal conductivity (W/m K) | 0.123 | 0.123 | 0.133 |

| Calorific value (MJ/kg) | 44.70 | 39.46 | 45.74 |

| Flash point (°C) | 57 | 71 | 66 |

| Total aromatics (wt%) | 25.2 | 0 | 14.63 |

| Lubricity at 60 °C (μm) | 311 | 206.5 | 311.5 |

| Detail | Properties |

|---|---|

| Name (TiO2) | Nanoparticles of Titanium dioxide |

| Appearance | White |

| Purity of TiO2 | 96% |

| Particle size | 30–50 nm |

| Surface area | >42 m2/g |

| Melting point | >233 °C |

| Formula | C19H42NBr |

| Engine Parameters | Specifications |

|---|---|

| Type | Common-rail DI Diesel |

| Number of cylinders and strokes | 4 × 4 |

| Cylinder bore × stroke (mm) | 104 × 118 |

| Connecting rod length (mm) | 160 |

| Compression ratio | 17.9:1 |

| Displacement (cc) | 3.6 L |

| Maximum engine speed range (rpm) | 3000 |

| Dynamometer | Electrical AC |

| Fuel pressure range (bar) | 500–1000 |

| Parameter | Errors (±) |

|---|---|

| Engine speed | 0.1% |

| Engine load | 0.2% |

| Temperature | 0.1% |

| Time | 0.1% |

| Thermocouples | 1.1% |

| Measurement of fuel | 2.0% |

| BTE | 1.7% |

| BSFC | 1.5% |

| Emissions of NOX | 0.2% |

| Emissions of PM | 0.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fayad, M.A.; Sobhi, M.; Chaichan, M.T.; Badawy, T.; Abdul-Lateef, W.E.; Dhahad, H.A.; Yusaf, T.; Isahak, W.N.R.W.; Takriff, M.S.; Al-Amiery, A.A. Reducing Soot Nanoparticles and NOX Emissions in CRDI Diesel Engine by Incorporating TiO2 Nano-Additives into Biodiesel Blends and Using High Rate of EGR. Energies 2023, 16, 3921. https://doi.org/10.3390/en16093921

Fayad MA, Sobhi M, Chaichan MT, Badawy T, Abdul-Lateef WE, Dhahad HA, Yusaf T, Isahak WNRW, Takriff MS, Al-Amiery AA. Reducing Soot Nanoparticles and NOX Emissions in CRDI Diesel Engine by Incorporating TiO2 Nano-Additives into Biodiesel Blends and Using High Rate of EGR. Energies. 2023; 16(9):3921. https://doi.org/10.3390/en16093921

Chicago/Turabian StyleFayad, Mohammed A., Mohammed Sobhi, Miqdam T. Chaichan, Tawfik Badawy, Wisam Essmat Abdul-Lateef, Hayder A. Dhahad, Talal Yusaf, Wan Nor Roslam Wan Isahak, Mohd S. Takriff, and Ahmed A. Al-Amiery. 2023. "Reducing Soot Nanoparticles and NOX Emissions in CRDI Diesel Engine by Incorporating TiO2 Nano-Additives into Biodiesel Blends and Using High Rate of EGR" Energies 16, no. 9: 3921. https://doi.org/10.3390/en16093921