Construction and Electrothermal Performance Evaluation of a Solar-Powered Emergency Shelter

Abstract

:1. Introduction

2. Design and Construction of SPES

2.1. Overall Design Conceptualization

2.2. Construction of Main Structure

2.3. Installation of the Enclosure

- -

- Irradiance: 1000 W/m2;

- -

- Cell temperature: 25 °C;

- -

- Spectral distribution: AM 1.5.

3. Methodology

3.1. Theoretical Energy Model of Photovoltaic Enclosure

3.2. Experimental Apparatus and Methods

3.3. CFD Model

- -

- All materials exhibit isotropic physical parameters that remain constant regardless of temperature variations;

- -

- The gas contained within the solar emergency relief tent exhibits the characteristic of being an incompressible fluid, and the Boussinesq assumptions are satisfied;

- -

- Air infiltration is not contemplated for the well-sealed thin-film photovoltaic system and building envelope;

- -

- The entirety of the solar radiation absorbed by thin-film photovoltaic cells that are not used to produce electricity is converted to heat.

3.4. Data Analysis

3.4.1. Variance Based Analysis

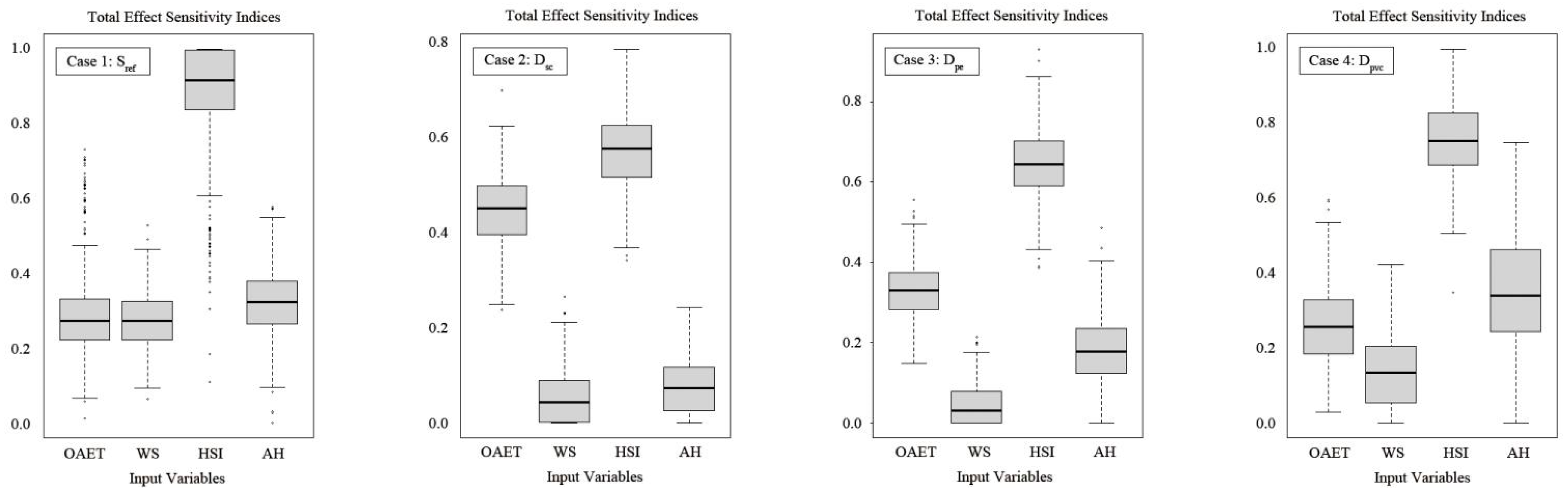

3.4.2. Sensitivity Analysis

4. Experimental Study

4.1. Inner Roof Interior Side Temperature

4.2. Electricity Power Generation

4.3. Environmental Influences on the Operating Temperature of Photovoltaics

5. The Optimization of Parameter

5.1. Normal Vertical Distance between Enclosure and Inner Roof

5.2. Influence of Mechanical Ventilation

5.3. Top Mechanical Ventilation Coupled Evaporative Cooler

6. Conclusions

- (1)

- A series of concepts and methods of SPES from design to construction are elaborated in detail, beginning with the overall design conceptualization, followed by the construction of the main structure, and then with the installation of the enclosure for the 1:2 solid model. A single-roof model and three double-roof models with inner roof materials of sailcloth, polyethylene, and polyvinyl chloride, respectively, were also developed in order to investigate electrothermal performance.

- (2)

- In winter conditions in China’s cold zone, experimental results show that the maximum differences between the inner roof interior side temperature (IRIST) and the outdoor ambient environment temperature (OAET) for Sref, Dsc, Dpe, and Dpvc are 33.3 °C, 32.9 °C, 28.1 °C, and 25.9 °C, respectively.

- (3)

- The construction form of the enclosure has a statistically significant impact on the interior surface temperature based on the analysis of variance (ANOVA). Variation in photovoltaic operating temperature for single-layer designs is mainly attributable to varying environmental conditions, with horizontal solar irradiance predominating. The influence of the outdoor ambient environment temperature (OAET), wind speed (WS), horizontal solar irradiance (HSI), and ambient humidity (AH) on the photovoltaic operating temperature is marginally different for the double-layer structure with a canvas interior layer designated as Case 2.

- (4)

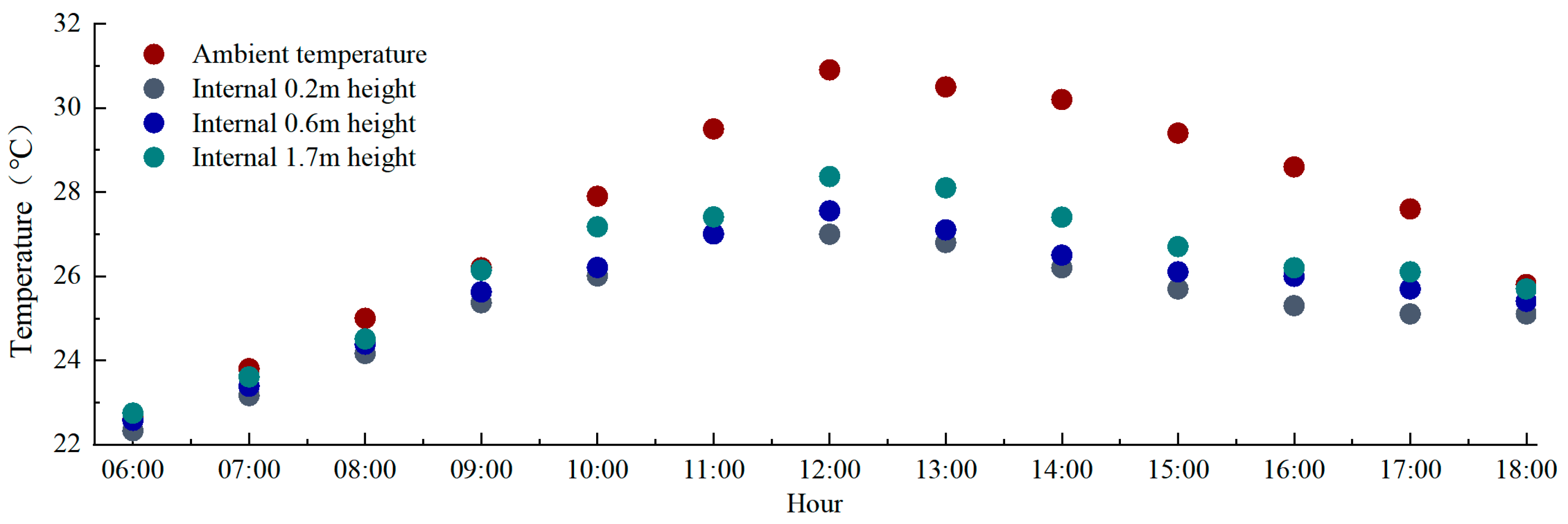

- The design parameters of SPES were optimized for typical summer operation situations in Poso City, Indonesia, characterized by equatorial humid climatic conditions, by a CFD model that was confirmed with experimental data. Based on the available data, it is recommended that the air interlayer be 0.2 meters thick. When the exhaust air volume was gradually increased from 0.3 m3/s, the indoor temperature remained stable with the exception of the measurement site at a height of 0.2 m, where the temperature continued to decrease. Mechanical ventilation rates have a limited effect on room temperature distribution, and coupled evaporative conditioners can further reduce room temperatures effectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| SPES | solar-powered emergency shelter |

| IRIST | inner roof interior side temperature |

| OAET | outdoor ambient environment temperature |

| MBE | Mean Bias Error |

| RMSE | Root Mean Squared Error |

| ANOVA | analysis of variance |

| WS | wind speed |

| HIS | horizontal solar irradiance |

| AH | ambient humidity |

| Sref | single-roof case |

| Dsc | double-roof case with sailcloth as inner roof |

| Dpe | double-roof case with polyethylene as inner roof |

| Dpvc | double-roof case with polyvinyl chloride as inner roof |

References

- Johnson, C. What’s the big deal about temporary housing? Planning considerations for temporary accommodation after disasters: Example of the 1999 Turkish earthquakes. In Proceedings of the 2002 TIEMS Disaster Management Conference, Waterloo, ON, Canada, 14 May 2002. [Google Scholar]

- Quarantelli, E.L. Patterns of sheltering and housing in US disasters. Disaster Prev. Manag. 1995, 4, 43–53. [Google Scholar] [CrossRef]

- Regan, P. Interim Housing Provision Following Earthquake Disaster; Springer: Berlin/Heidelberg, Germany, 2015; pp. 1237–1254. [Google Scholar]

- Fuji, G. Japan’s Disaster Response System; China Architecture Publishing & Media Co., Ltd.: Beijing, China, 2003. [Google Scholar]

- Asfour, O.S. Learning from the past: Temporary housing criteria in conflict areas with reference to thermal comfort. Int. J. Disaster Risk Reduct. 2019, 38, 101206. [Google Scholar] [CrossRef]

- Editorial Board of the Journal. For the Memorial of “May 12”-Crossing: Dialogues for Emergency Architecture. Chin. Art Dig. 2009, 4, 66–67. [Google Scholar]

- Thapa, R.; Rijal, H.B.; Shukuya, M.; Imagawa, H. Study on the wintry thermal improvement of makeshift shelters built after Nepal earthquake 2015. Energy Build. 2019, 199, 62–71. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Long, E.; Deng, S. An experimental study on the indoor thermal environment in prefabricated houses in the subtropics. Energy Build. 2016, 127, 529–539. [Google Scholar] [CrossRef]

- Kim, J.G.; Lee, J.; Ahn, B.L.; Shin, H.; Yoo, S.; Jang, C.Y.; Song, D.; Kim, J. Indoor Thermal Environment of Temporary Mobile Energy Shelter Houses (MeSHs) in South Korea. Energies 2015, 8, 11139–11152. [Google Scholar] [CrossRef]

- Zhang, L.; Meng, X.; Liu, F.; Xu, L.; Long, E. Effect of retro-reflective materials on temperature environment in tents. Case Stud. Therm. Eng. 2017, 9, 122–127. [Google Scholar] [CrossRef]

- Salvalai, G.; Imperadori, M.; Scaccabarozzi, D.; Pusceddu, C. Thermal performance measurement and application of a multilayer insulator for emergency architecture. Appl. Therm. Eng. 2015, 82, 110–119. [Google Scholar] [CrossRef]

- Marin, P.; Saffari, M.; de Gracia, A.; Zhu, X.; Farid, M.M.; Cabeza, L.F.; Ushak, S. Energy savings due to the use of PCM for relocatable lightweight buildings passive heating and cooling in different weather conditions. Energy Build. 2016, 129, 274–283. [Google Scholar] [CrossRef]

- Wang, C.; Huang, X.; Deng, S.; Long, E.; Niu, J. An experimental study on applying PCMs to disaster-relief prefabricated temporary houses for improving internal thermal environment in summer. Energy Build. 2018, 179, 301–310. [Google Scholar] [CrossRef]

- Samani, P.; Leal, V.; Mendes, A.; Correia, N. Comparison of passive cooling techniques in improving thermal comfort of occupants of a pre-fabricated building. Energy Build. 2016, 120, 30–44. [Google Scholar] [CrossRef]

- Maghami, M.R.; Maghoul, A.; Dehkohneh, S.S.; Gomes, C.; Hizam, H.; Othman, M.L.B. Hybrid renewable energy as power supply for shelter during natural disasters. In Proceedings of the 2016 IEEE International Conference on Automatic Control and Intelligent Systems, I2CACIS 2016, Selangor, Malaysia, 22–22 October 2016; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Hendarti, R.; Katarina, W.; Wangidjaja, W. The study of the application of crystalline silicone solar cell type for a temporary flood camp. IOP Conf. Ser. Earth Environ. Sci. 2017, 109, 012040. [Google Scholar] [CrossRef]

- Cornaro, C.; Sapori, D.; Bucci, F.; Pierro, M.; Giammanco, C. Thermal performance analysis of an emergency shelter using dynamic building simulation. Energy Build. 2015, 88, 122–134. [Google Scholar] [CrossRef]

- Brandhorst, R. Solar-powered, modular, emergency/disaster response housing. In Proceedings of the Photovoltaic Specialists Conference, Philadelphia, PA, USA, 7–12 June 2009; IEEE: Piscataway, NJ, USA, 2009. [Google Scholar]

- Higier, A.; Arbide, A.; Awaad, A.; Eiroa, J.; Miller, J.; Munroe, N.; Ravinet, A.; Redding, B. Design, development and deployment of a hybrid renewable energy powered mobile medical clinic with automated modular control system. Renew. Energy 2013, 50, 847–857. [Google Scholar] [CrossRef]

- Dhere, N.G.; Schleith, S. Reliability of hybrid photovoltaic DC micro-grid systems for emergency shelters and other applications. In Proceedings of the Spie Solar Energy + Technology, San Diego, CA, USA, 17–21 August 2014; p. 91790F. [Google Scholar]

- Barroso, J.S.; Barth, N.; Correia, J.P.M.; Ahzi, S.; Khaleel, M.A. A computational analysis of coupled thermal and electrical behavior of PV panels. Sol. Energy Mater. Sol. Cells 2016, 148, 73–86. [Google Scholar] [CrossRef]

- Aly, S.P.; Ahzi, S.; Barth, N.; Abdallah, A. Using energy balance method to study the thermal behavior of PV panels under time-varying field conditions. Energy Convers. Manag. 2018, 175, 246–262. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Perrella, S.; Bruno, R.; Arcuri, N. An accurate thermal model for the PV electric generation prediction: Long-term validation in different climatic conditions. Renew. Energy 2021, 163, 1092–1112. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Tian, W.; Yang, S.; Zuo, J.; Li, Z.; Liu, Y. Relationship between built form and energy performance of office buildings in a severe cold Chinese region. Build. Simul. 2016, 10, 11–24. [Google Scholar] [CrossRef]

| Material | Internal View | Smoothness | Thicknesses (mm) | Density (kg/m3) | Thermal Conductivity (W/(m·K)) |

|---|---|---|---|---|---|

| Sailcloth |  | Worse | 0.3 | 2140 | 0.23 |

| Polyethylene |  | General | 0.3 | 1390 | 0.14 |

| Polyvinyl chloride |  | General | 0.3 | 960 | 0.42 |

| Parameters | Unit | Parameters | Unit |

|---|---|---|---|

| Solar Cell Type | CIGS | Open Circuit Voltage (Voc) | 10.89 +/− 1 V |

| Maximum Power Output (Pmax) | 21.87 +/− 2 W | Short Circuit Current (Isc) | 1.40 +/− 0.2 A |

| Voltage at Maximum Power Point (Vmpp) | 8.83 +/− 1 V | Operating Temperature | −10 °C~45 °C |

| Current at Maximum Power Point (Impp) | 2.48 +/− 0.2 A | Efficiency | 15% |

| Single Roof | Double Roof | |

|---|---|---|

| MBE | 1% | 1.4% |

| RMSE | 18.7% | 17.2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, T.; Liu, B.; Liu, R.; Zhu, L.; Huo, Y.; Ji, M. Construction and Electrothermal Performance Evaluation of a Solar-Powered Emergency Shelter. Energies 2024, 17, 118. https://doi.org/10.3390/en17010118

Lv T, Liu B, Liu R, Zhu L, Huo Y, Ji M. Construction and Electrothermal Performance Evaluation of a Solar-Powered Emergency Shelter. Energies. 2024; 17(1):118. https://doi.org/10.3390/en17010118

Chicago/Turabian StyleLv, Tiangang, Bing Liu, Rujie Liu, Li Zhu, Yujiao Huo, and Mingda Ji. 2024. "Construction and Electrothermal Performance Evaluation of a Solar-Powered Emergency Shelter" Energies 17, no. 1: 118. https://doi.org/10.3390/en17010118