Study on the Effect of Coupled Internal and External EGR on Homogeneous Charge Compression Ignition under High Pressure Rise Rate

Abstract

:1. Introduction

2. Experimental Setup and Methods

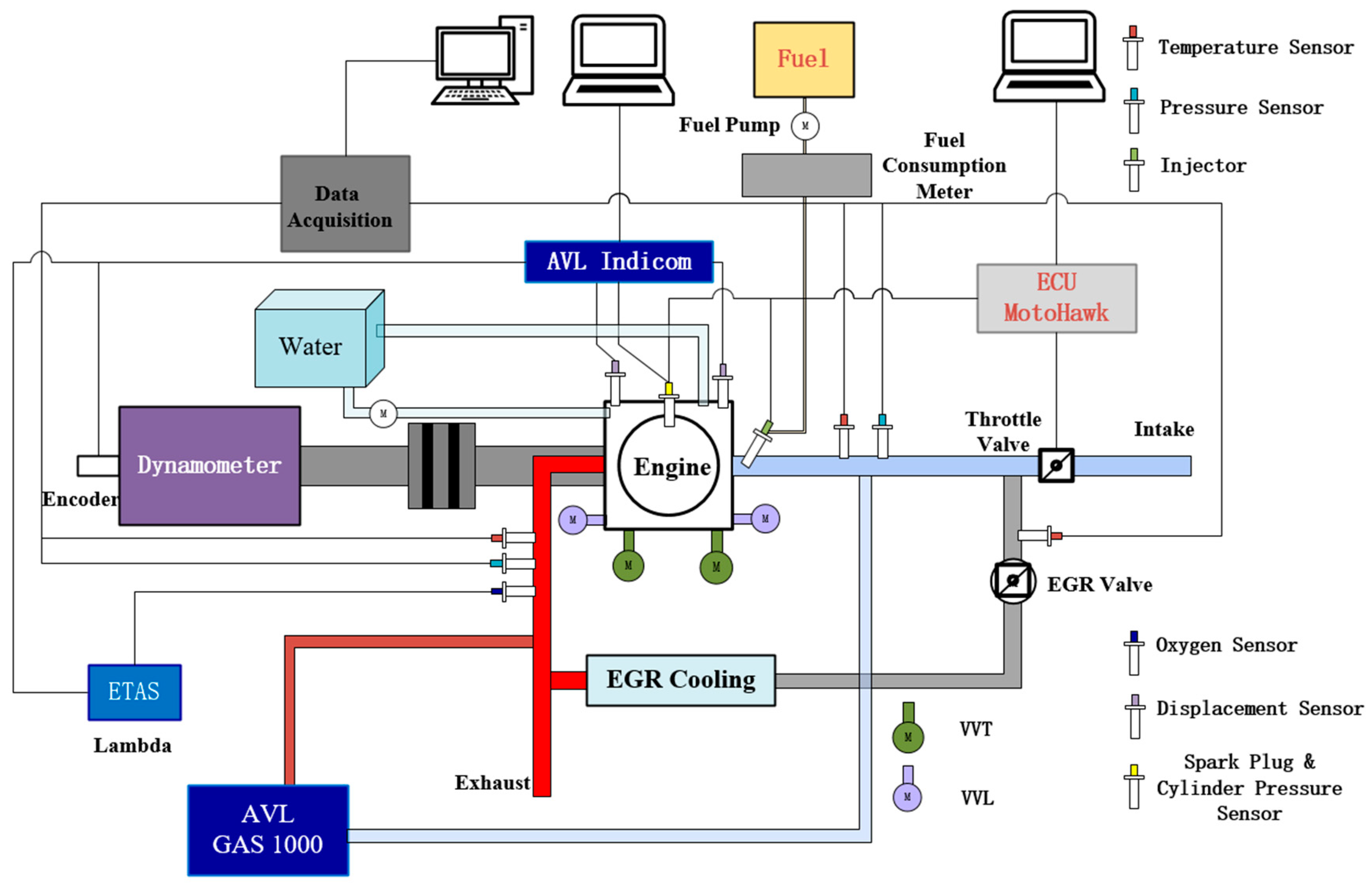

2.1. Experimental Setup

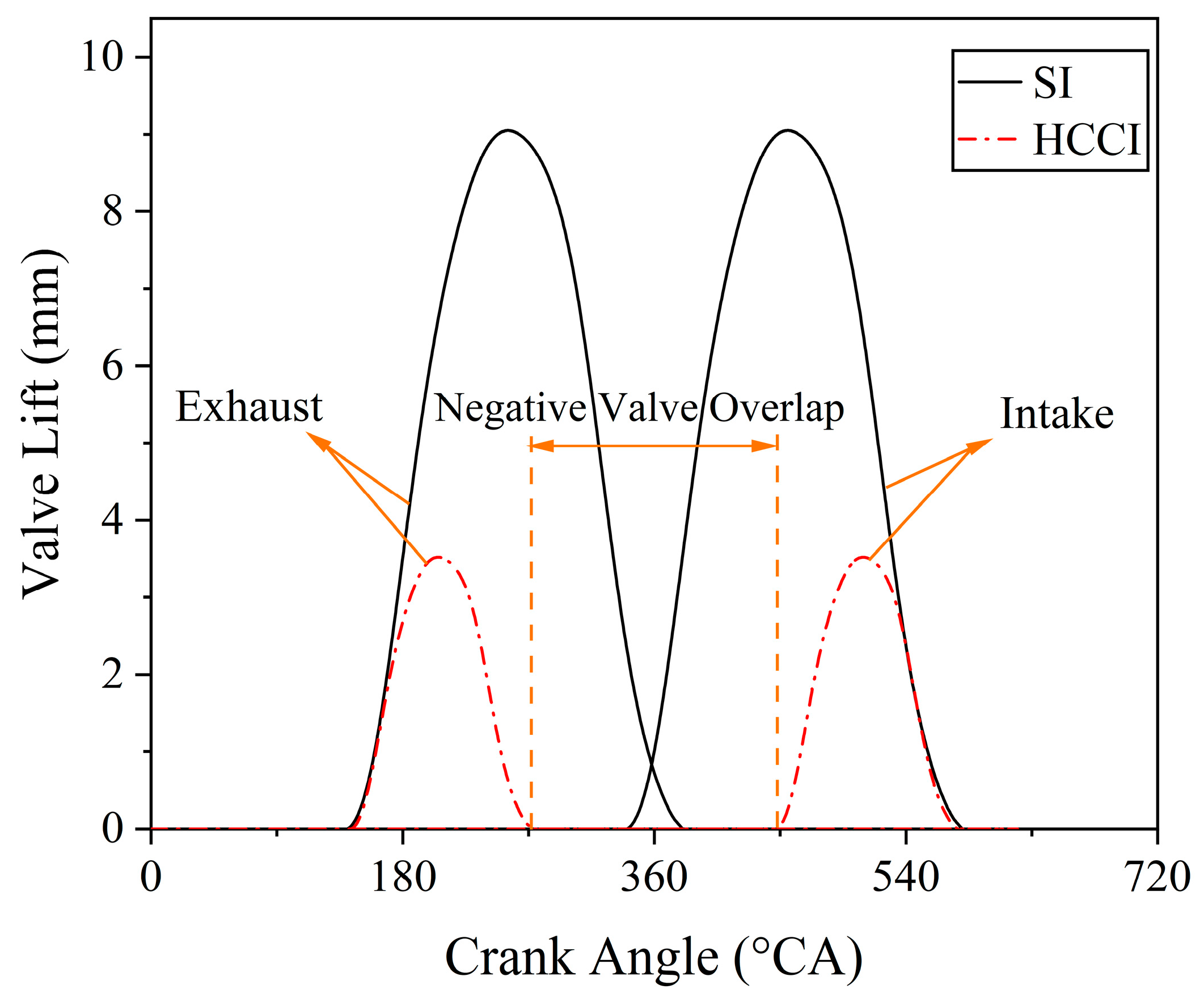

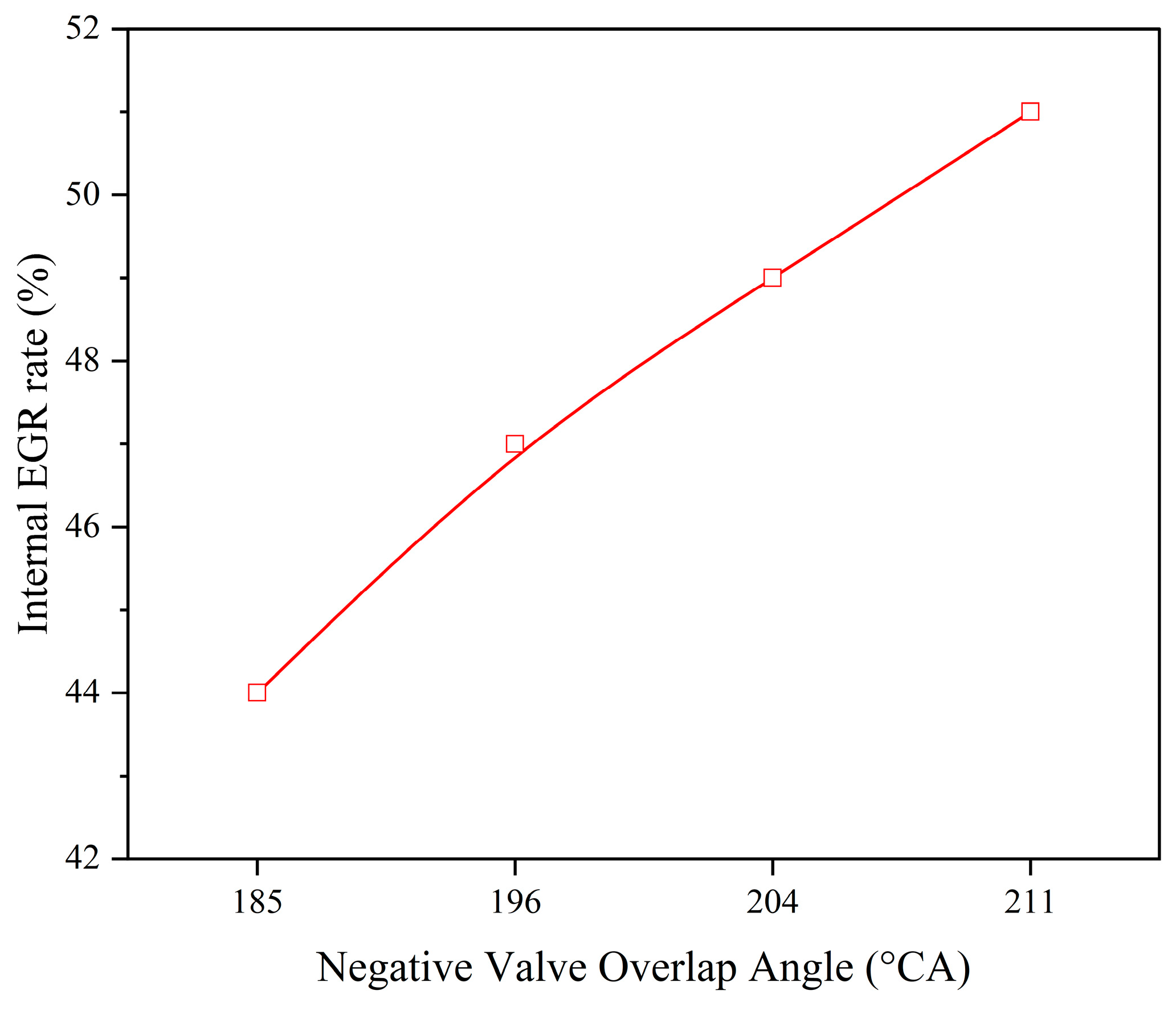

2.2. Internal EGR Rate Estimation

2.3. External EGR Rate Estimation

2.4. Calculation of Heat Release Rate

3. Results and Discussion

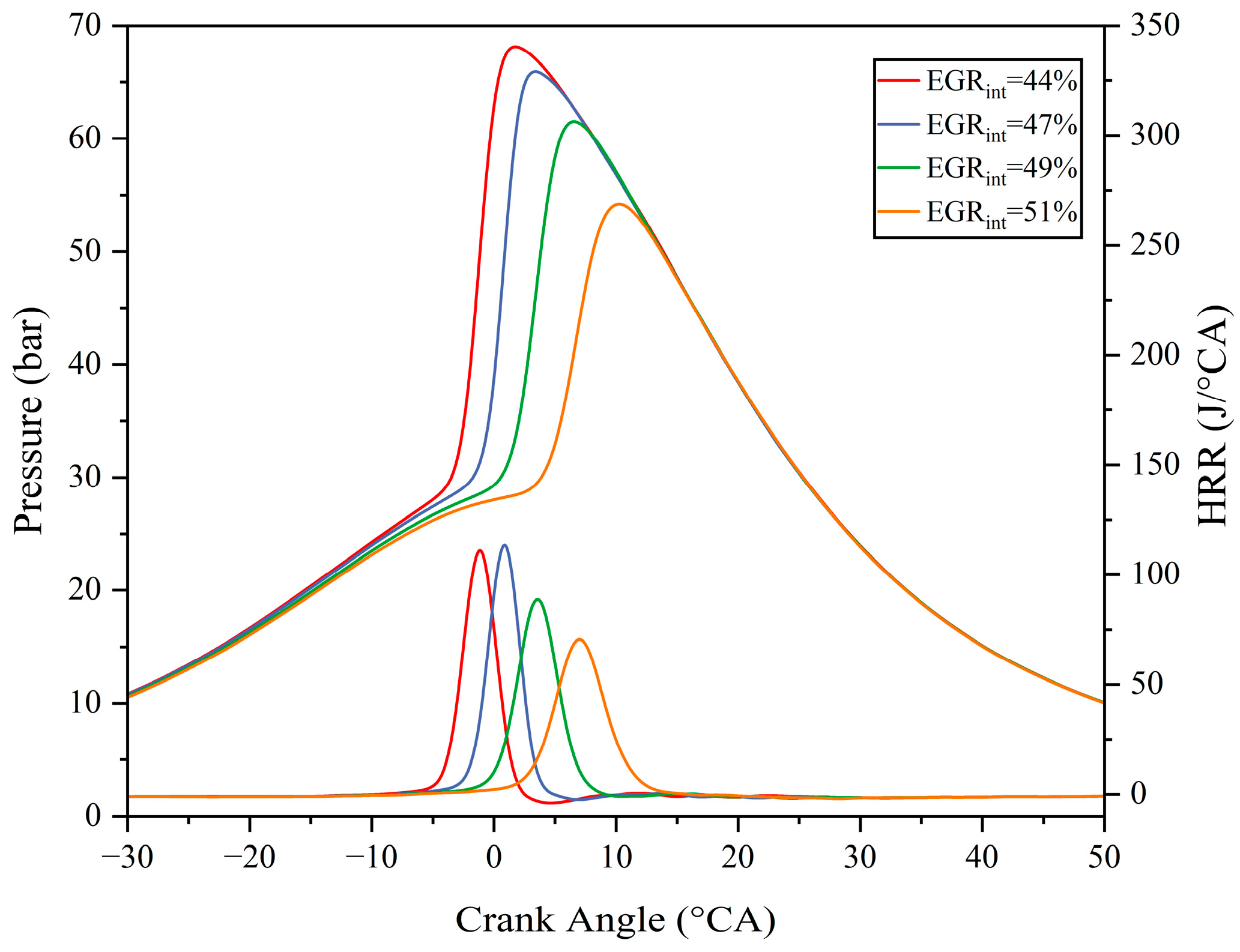

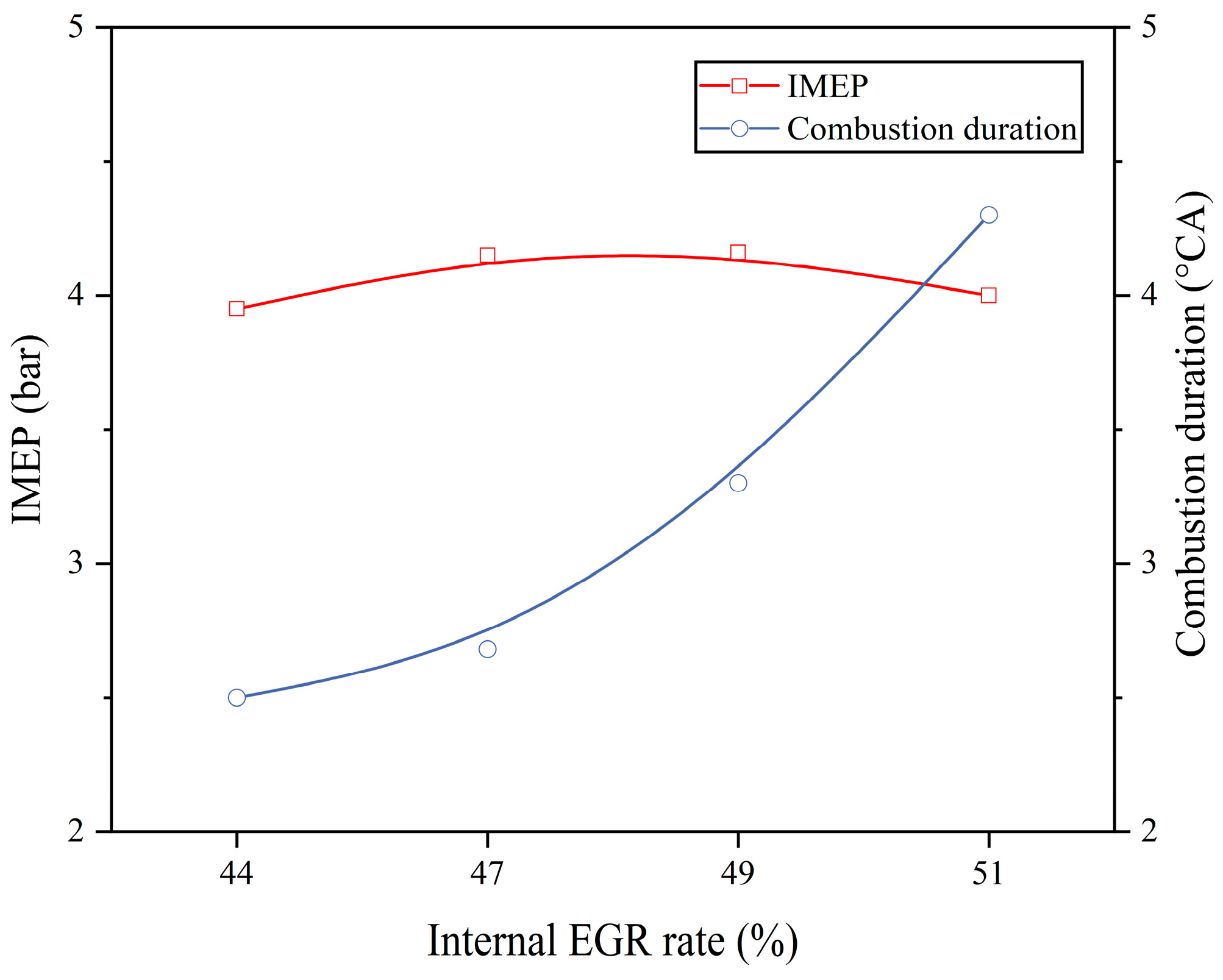

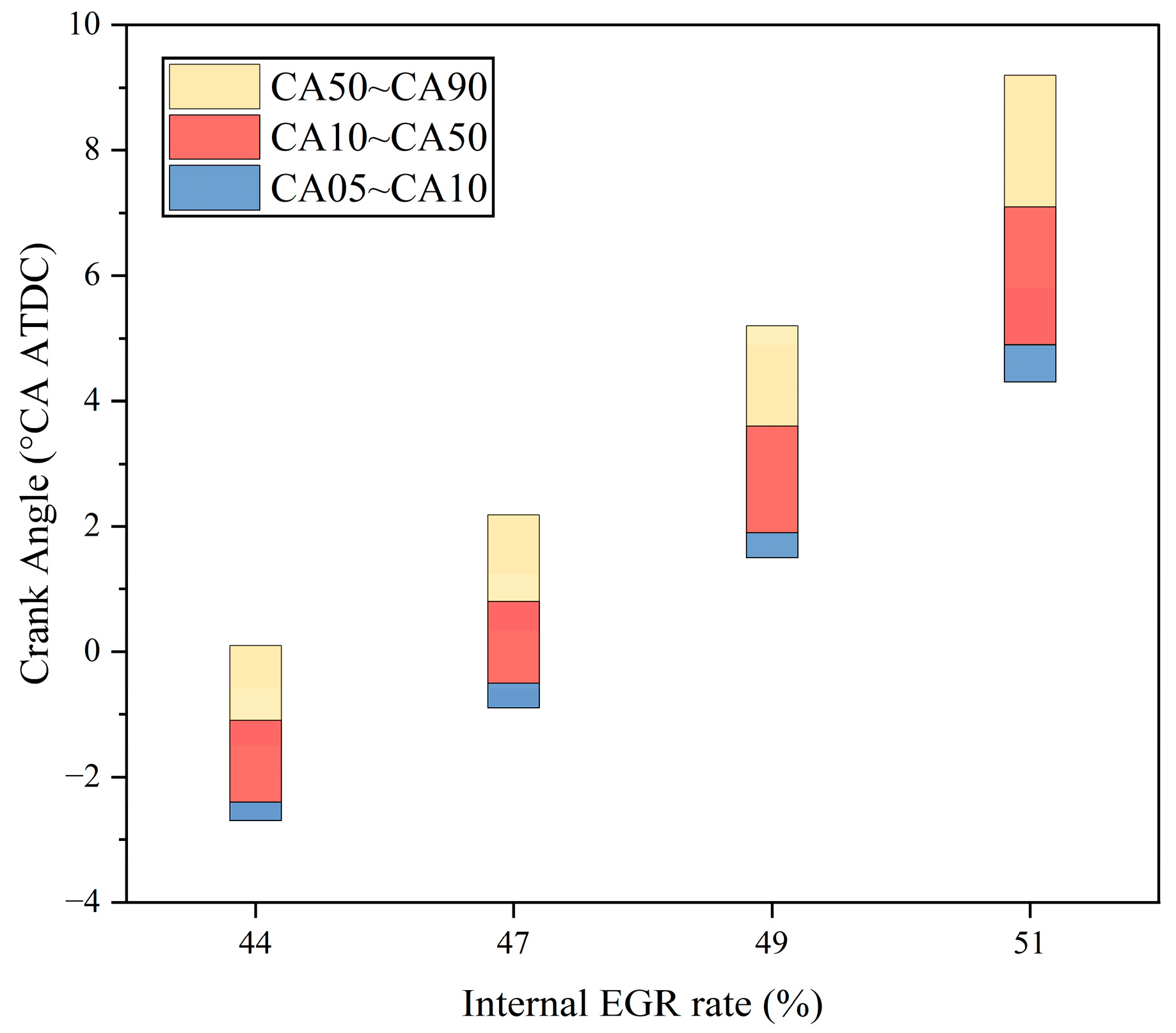

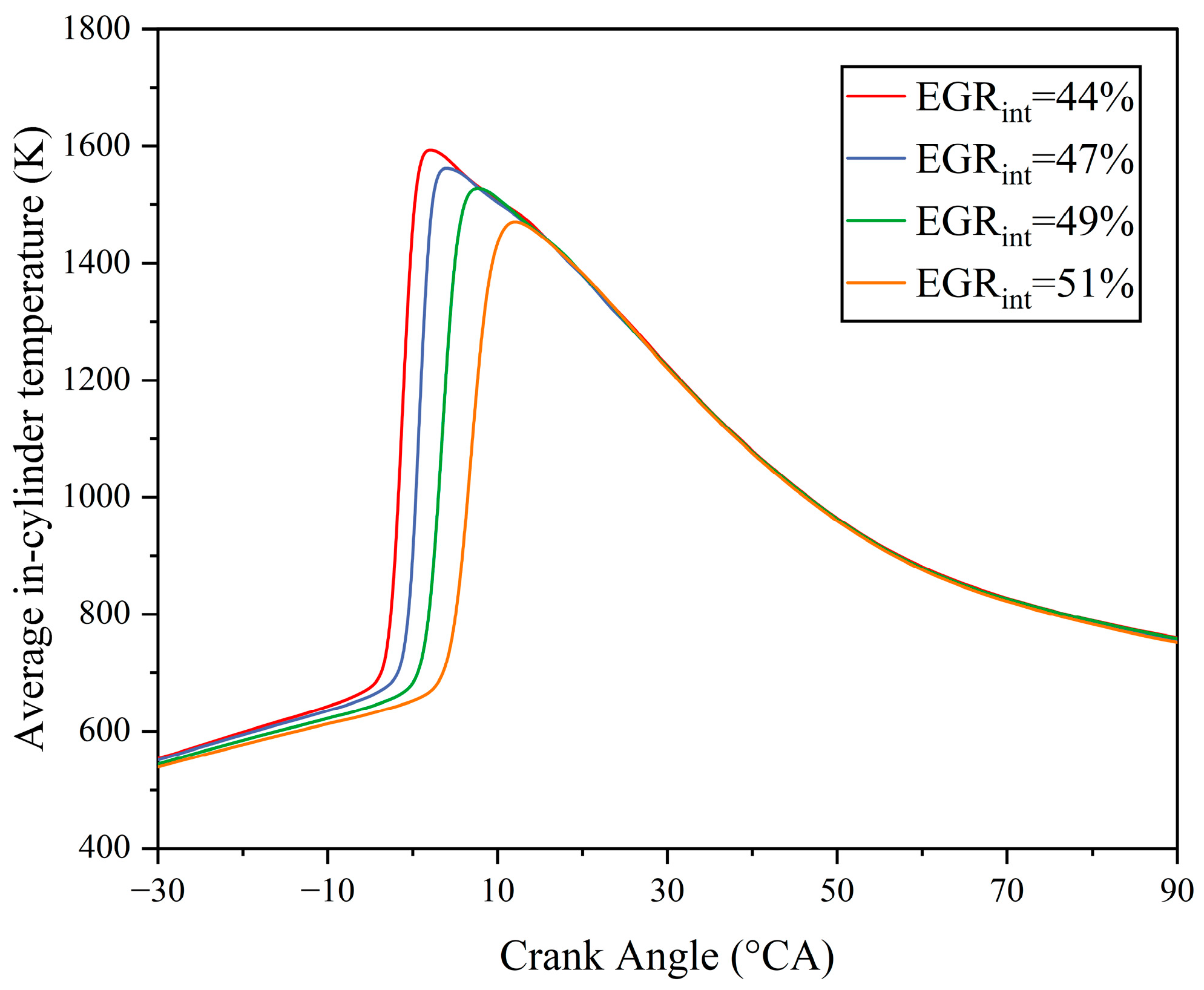

3.1. Effect of Internal EGR on HCCI Combustion and Emissions

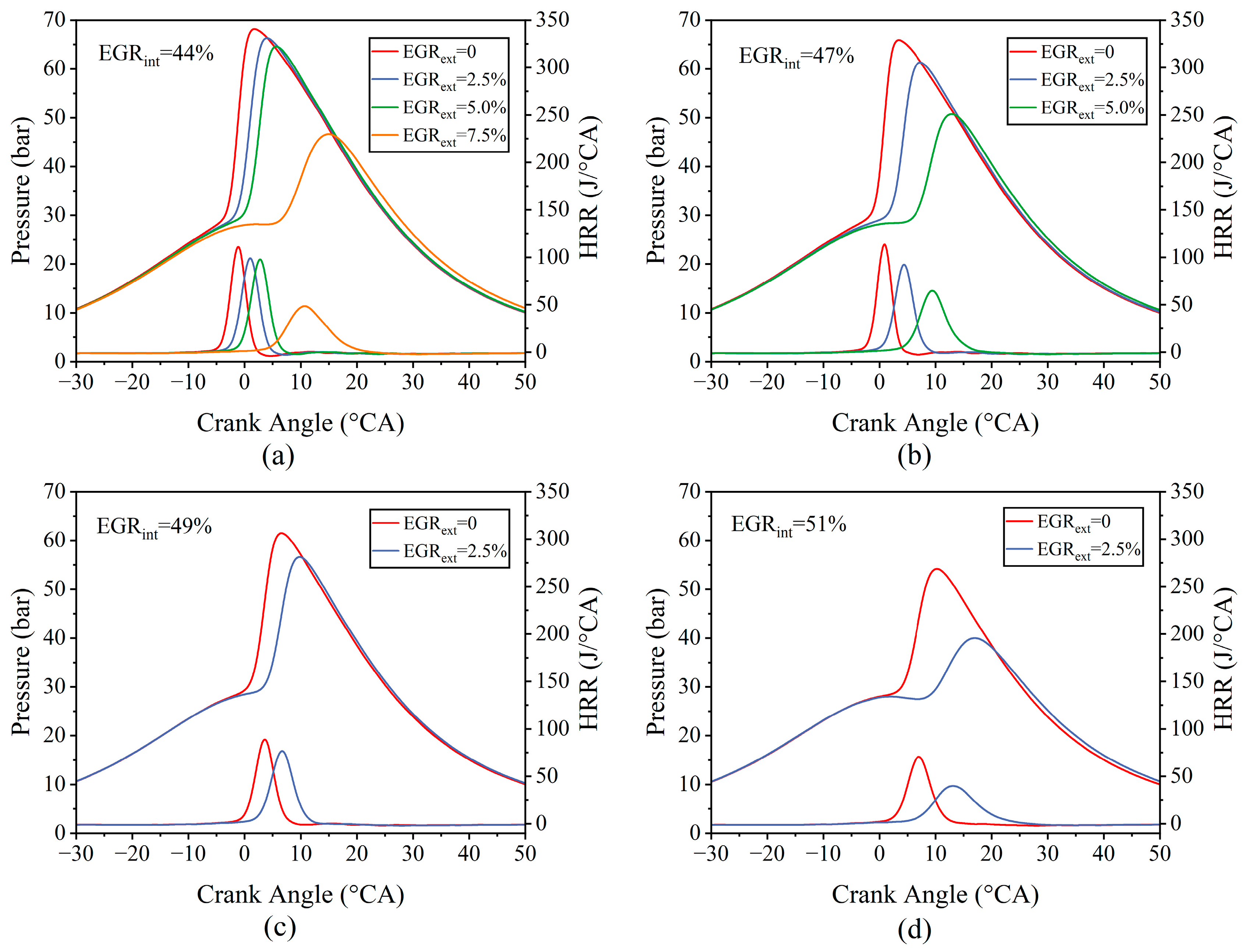

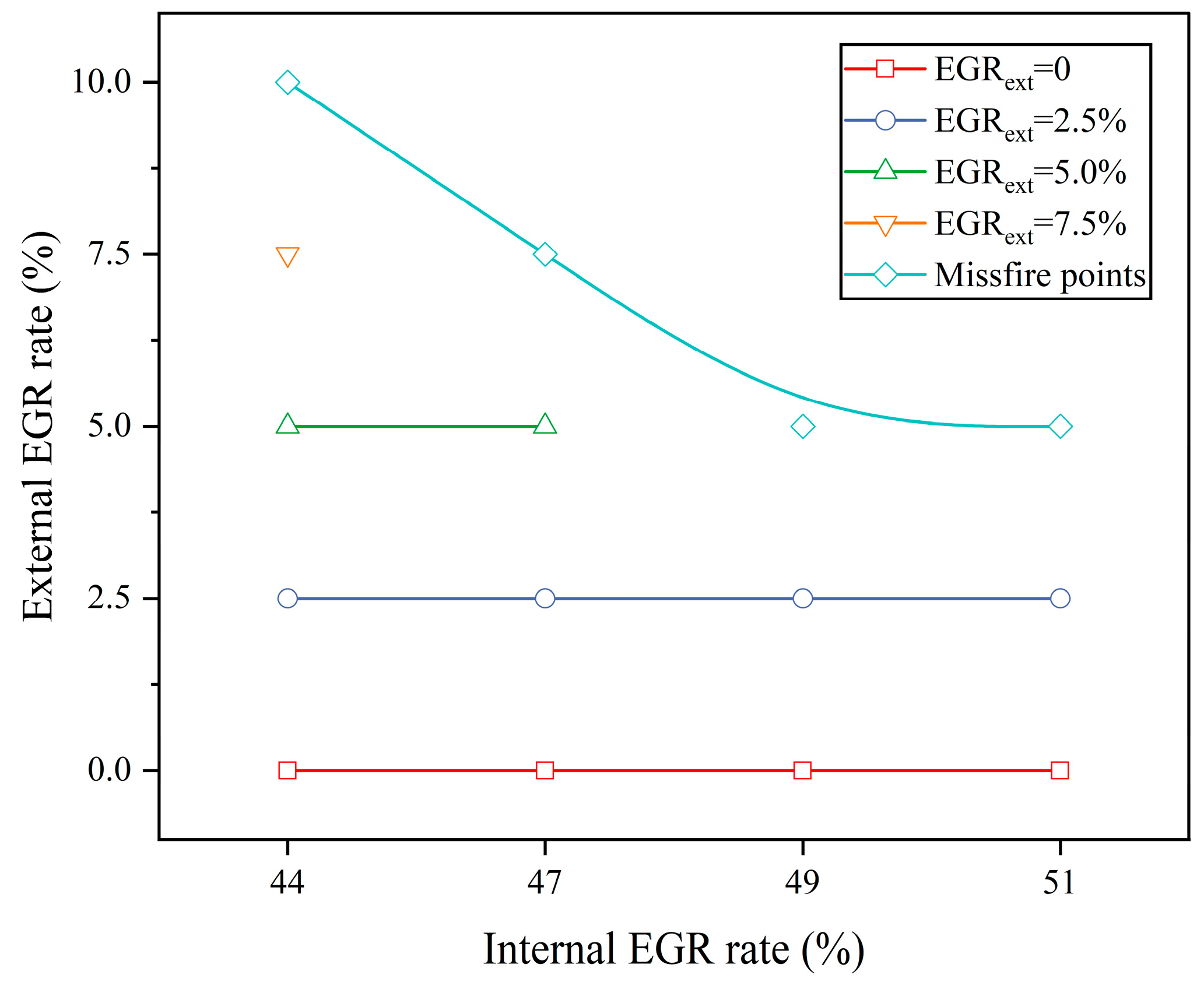

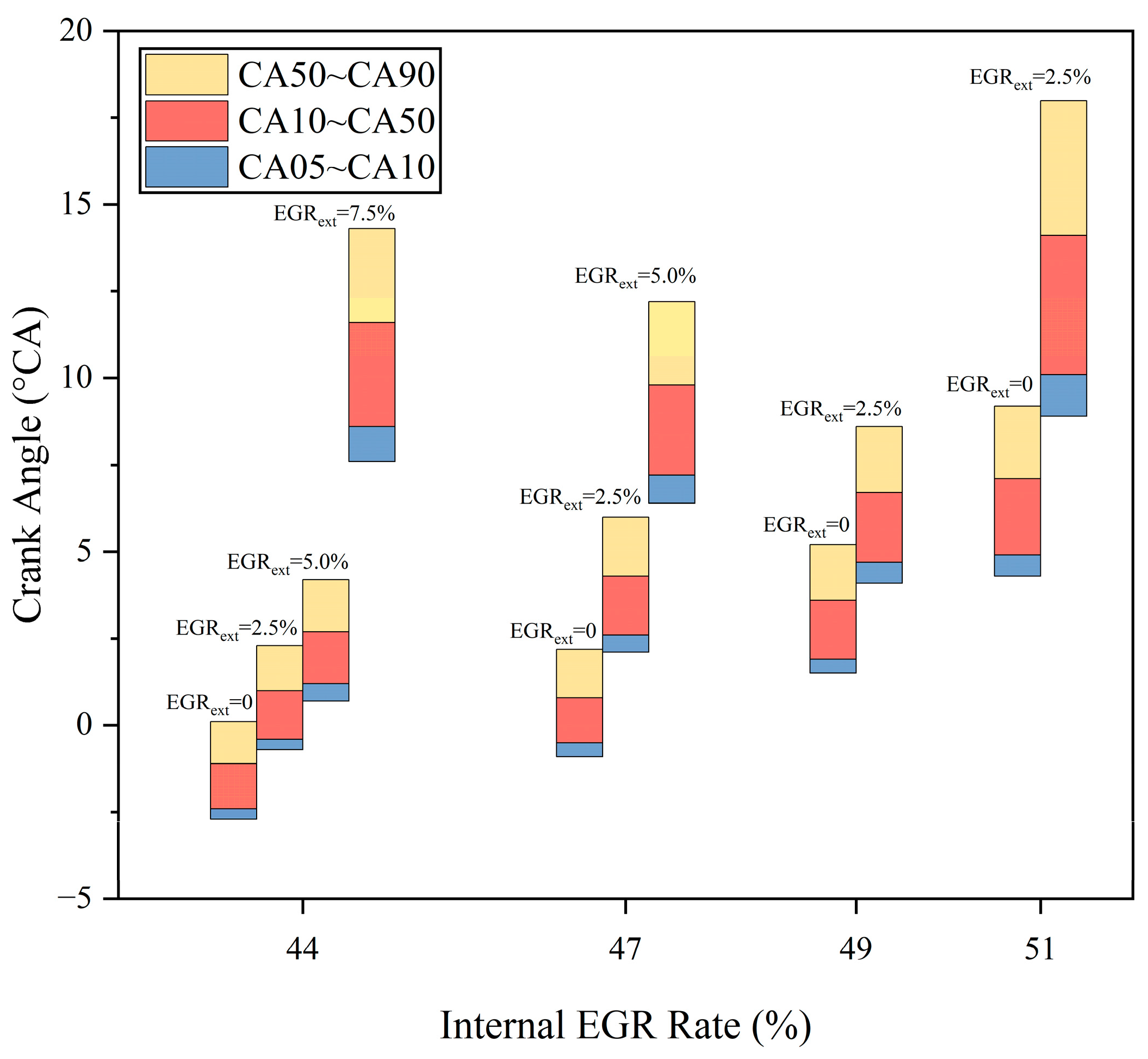

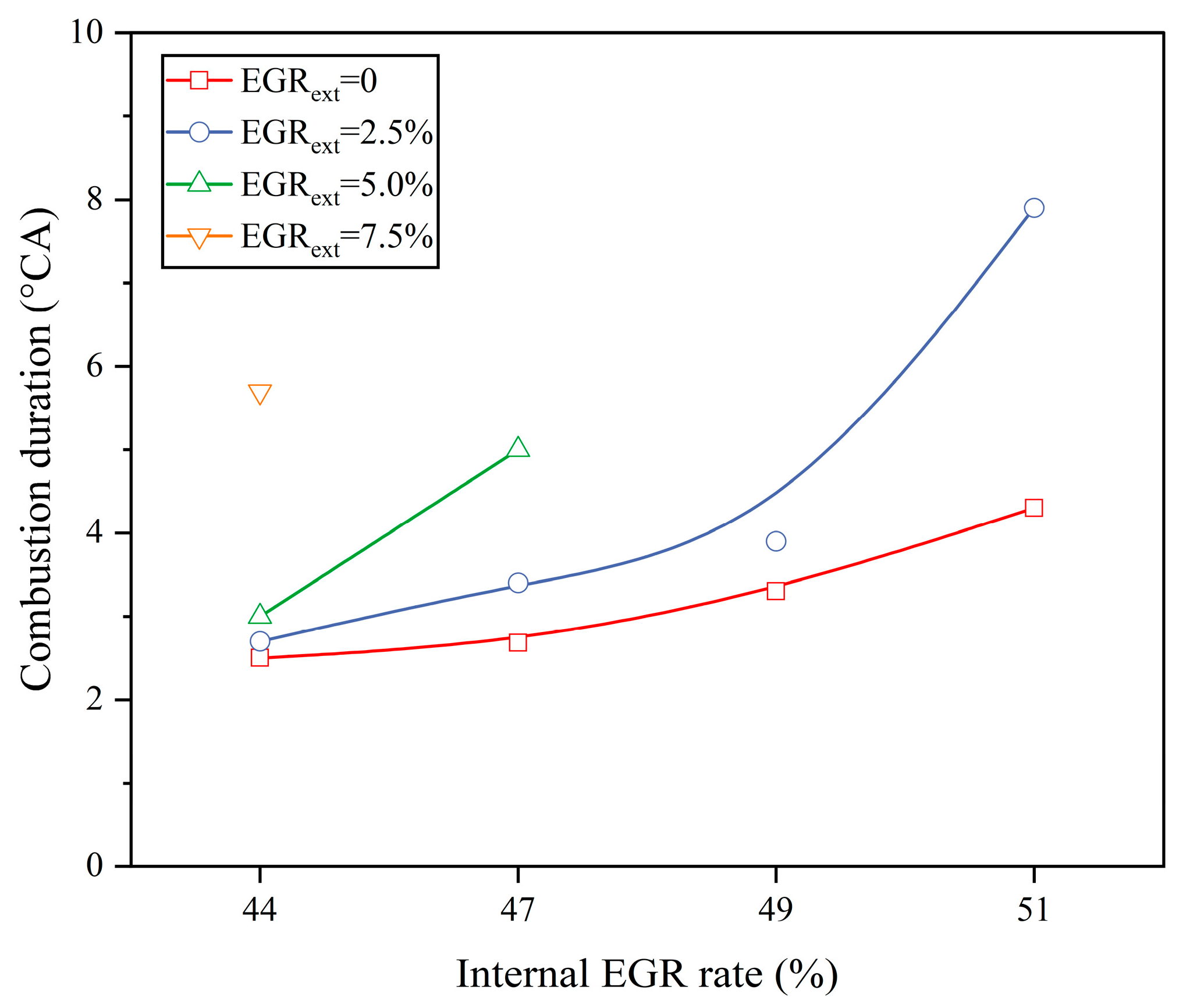

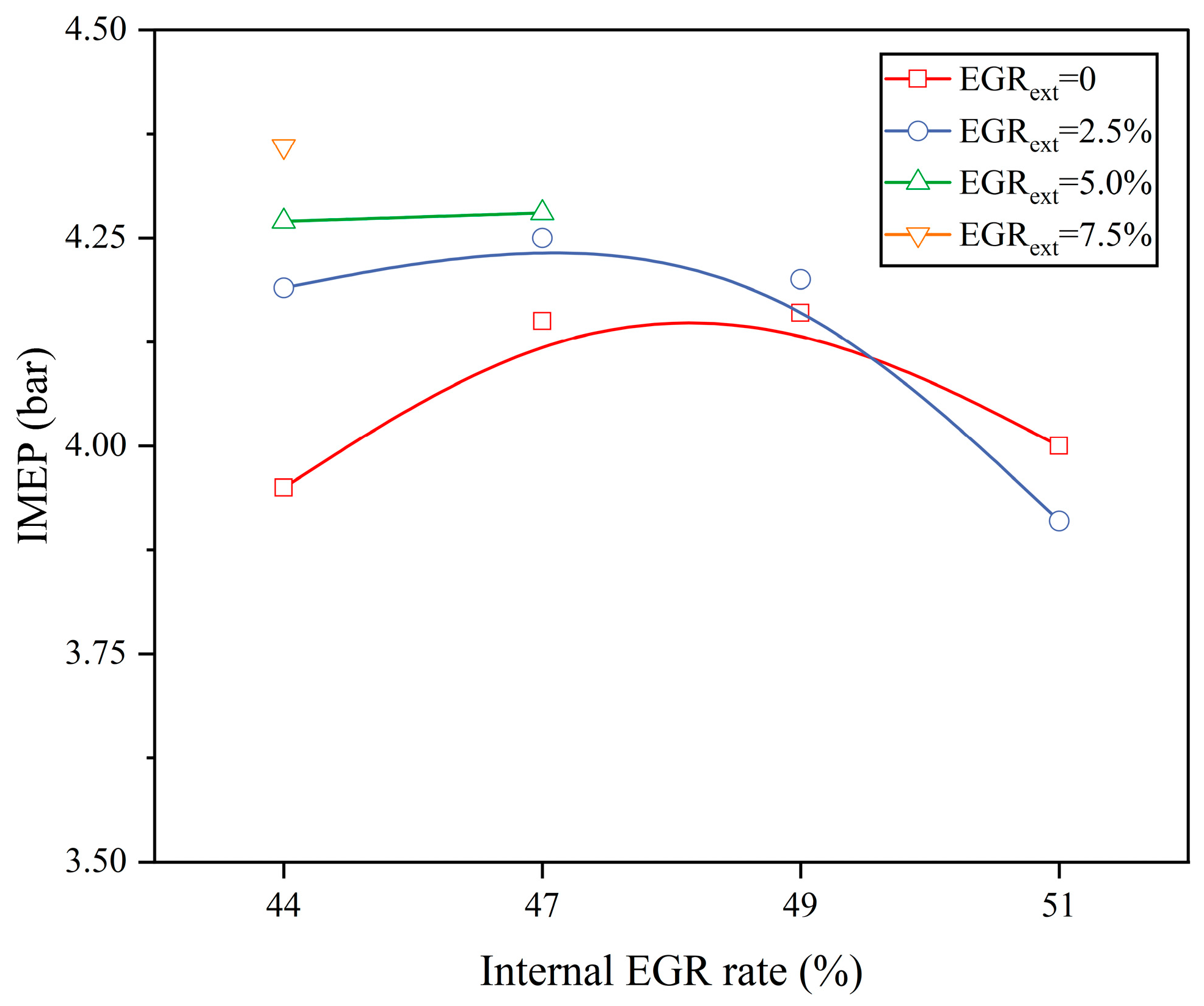

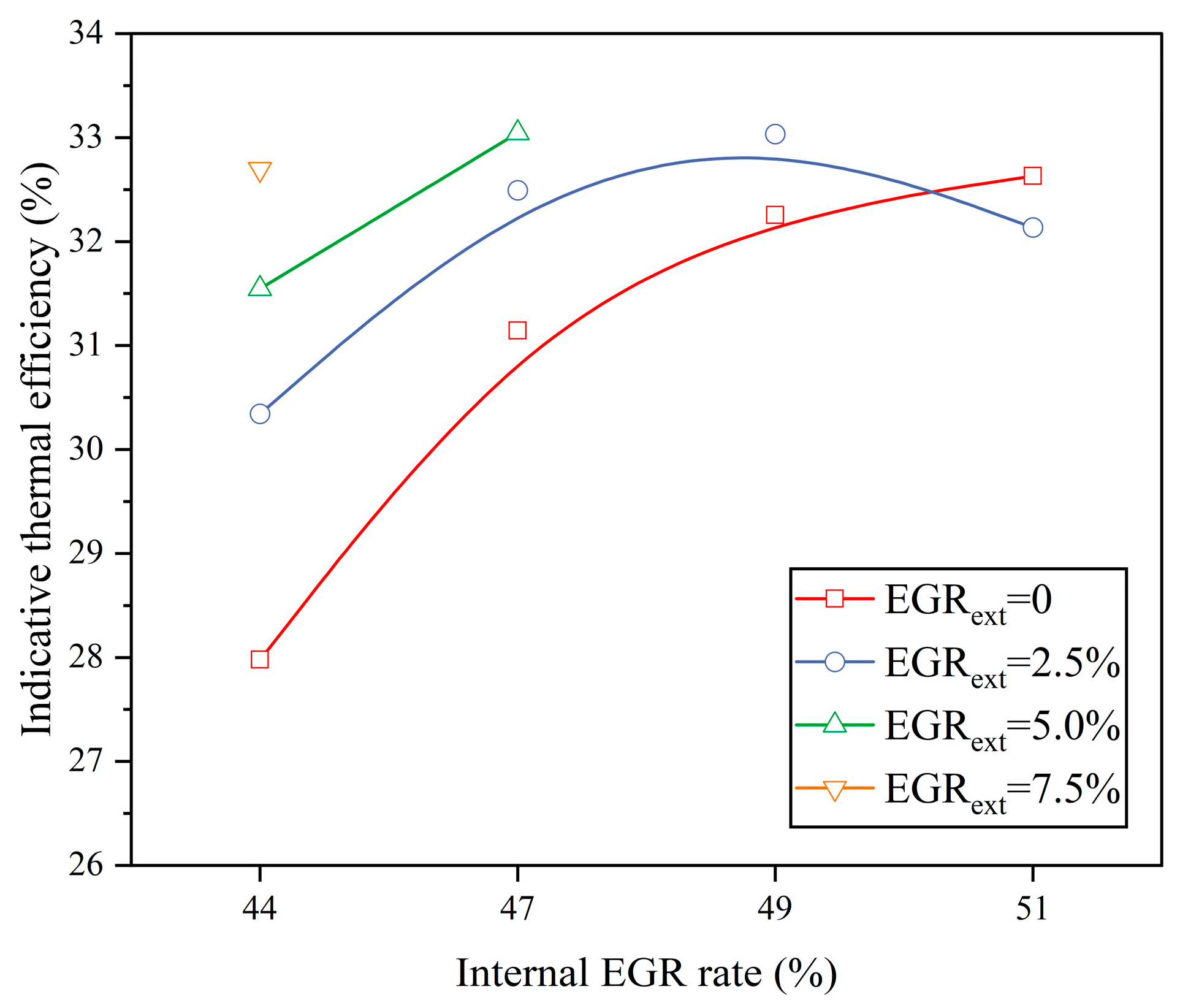

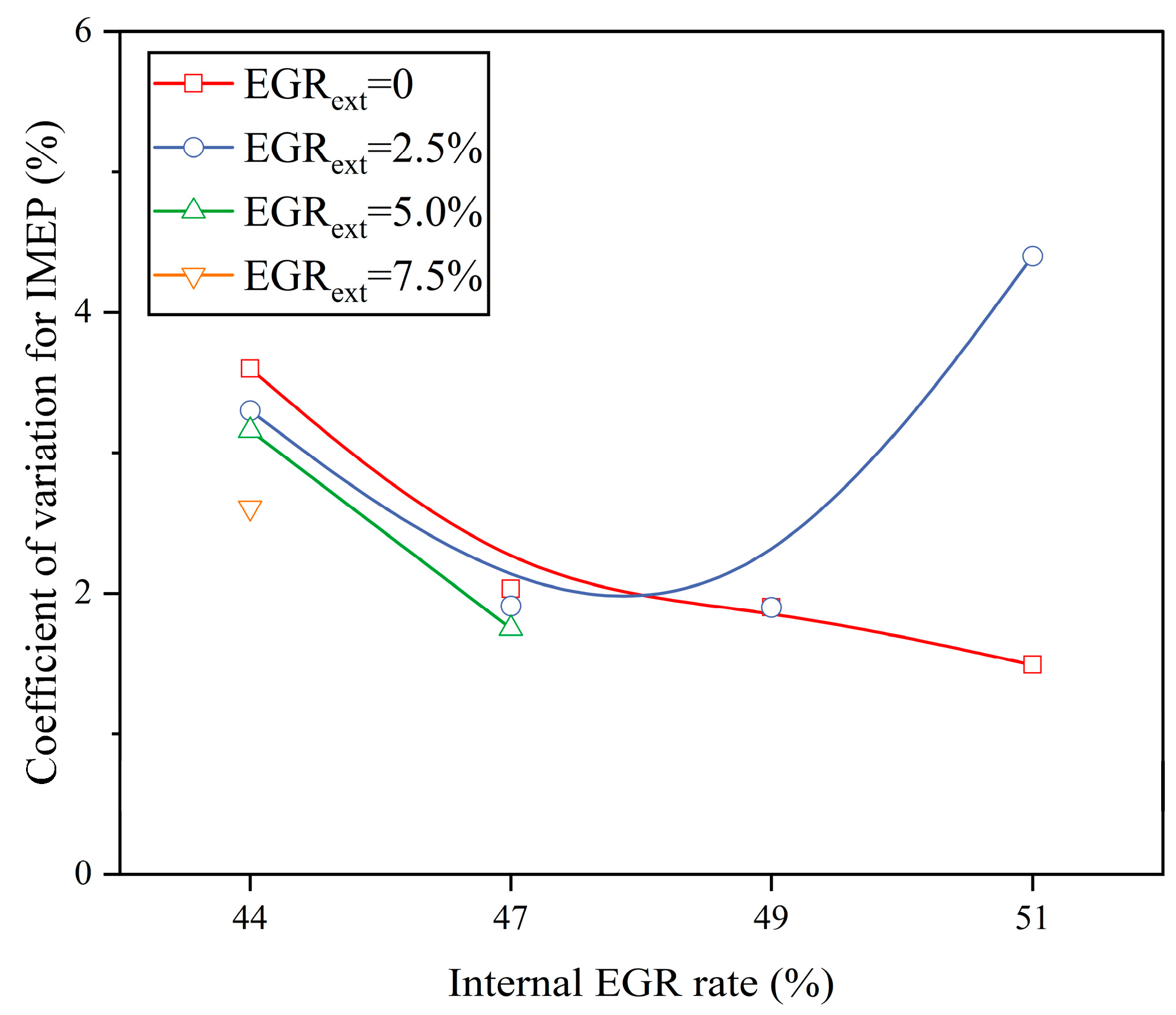

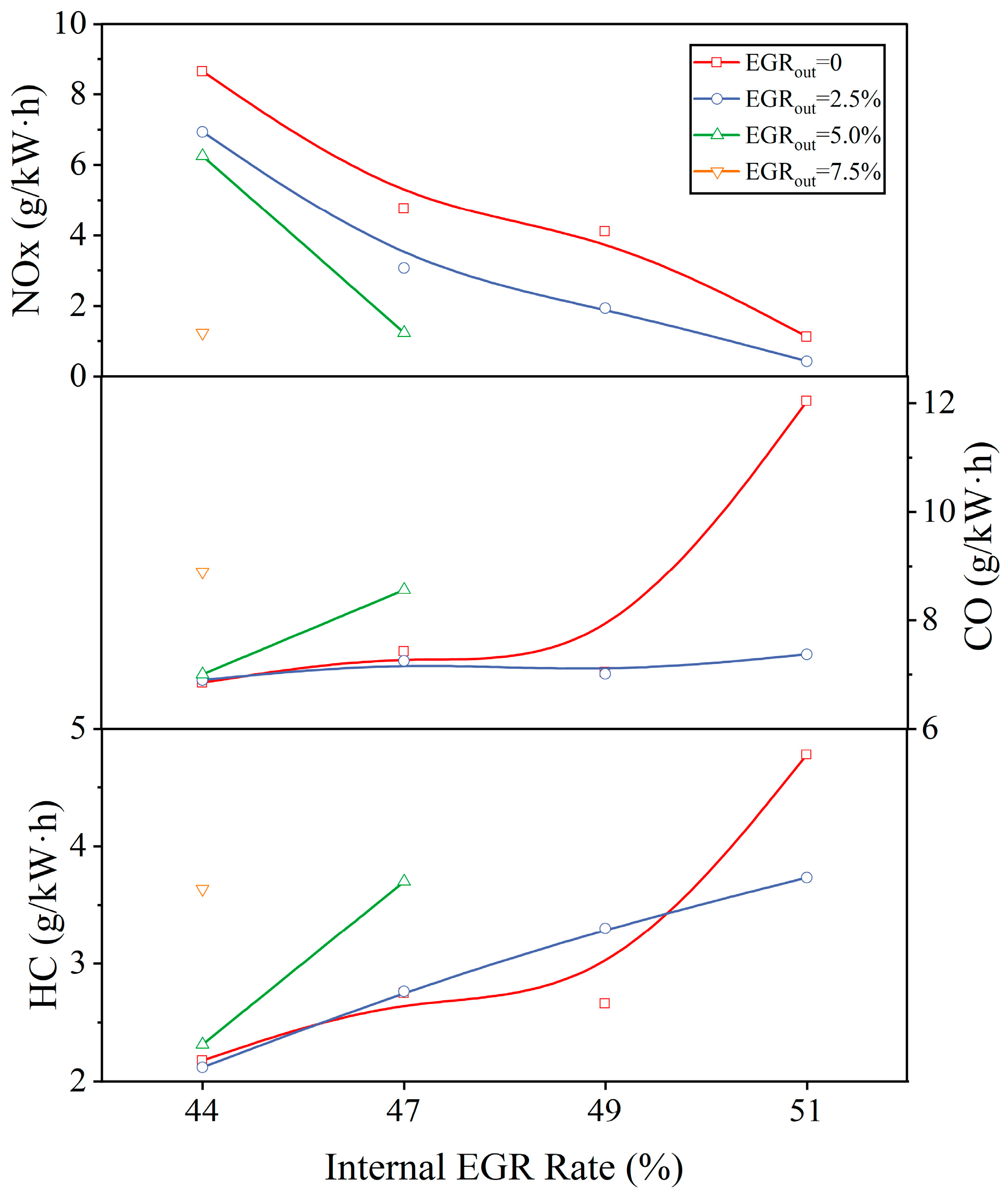

3.2. Effects of Internal and External EGR Coupling on HCCI Combustion and Emissions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Joshi, A. Review of Vehicle Engine Efficiency and Emissions. SAE Int. J. Adv. Curr. Pract. Mobil. 2022, 4, 1704–1733. [Google Scholar] [CrossRef]

- Zhao, W.; Wu, H.; Mi, S.; Zhang, Y.; He, Z.; Qian, Y.; Lu, X. Experimental investigation of the control strategy of high load extension under iso-butanol/biodiesel dual-fuel intelligent charge compression ignition (ICCI) mode. Renew. Sustain. Energy Rev. 2023, 172. [Google Scholar] [CrossRef]

- Lyu, M.; Bao, X.; Zhu, R.; Matthews, R. State-of-the-art outlook for light-duty vehicle emission control standards and technologies in China. Clean Technol. Environ. Policy 2020, 22, 757–771. [Google Scholar] [CrossRef]

- Duan, X.; Lai, M.-C.; Jansons, M.; Guo, G.; Liu, J. A review of controlling strategies of the ignition timing and combustion phase in homogeneous charge compression ignition (HCCI) engine. Fuel 2020, 285, 119142. [Google Scholar] [CrossRef]

- Noguchi, M.; Tanaka, Y.; Tanaka, T.; Takeuchi, Y. A Study on Gasoline Engine Combustion by Observation of Intermediate Reactive Products during Combustion. In Proceedings of the SAE International Off-Highway and Powerplant Congress and Exposition; Available online: https://saemobilus.sae.org/content/790840/ (accessed on 10 November 2023).

- Onishi, S.; Jo, S.H.; Shoda, K.; Jo, P.D.; Kato, S. Active Thermo-Atmosphere Combustion (ATAC)—A New Combustion Process for Internal Combustion Engines; SAE International: Warrendale, PA, USA, 1979. [Google Scholar]

- Waqas, M.U.; Hoth, A.; Kolodziej, C.P.; Rockstroh, T.; Gonzalez, J.P.; Johansson, B. Detection of low Temperature heat release (LTHR) in the standard Cooperative Fuel Research (CFR) engine in both SI and HCCI combustion modes. Fuel 2019, 256, 115745. [Google Scholar] [CrossRef]

- Calam, A.; Aydoğan, B.; Halis, S. The comparison of combustion, engine performance and emission characteristics of ethanol, methanol, fusel oil, butanol, isopropanol and naphtha with n-heptane blends on HCCI engine. Fuel 2020, 266, 117071. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.; Lu, H.; Schmitt, S.; Deng, J.; Rao, L. SI/HCCI Mode Switching Optimization in a Gasoline Direct Injection Engine Employing Dual Univalve System. J. Eng. Gas Turbines Power 2019, 141, 031001. [Google Scholar] [CrossRef]

- Li, J.; Zhao, H.; Ladommatos, N.; Ma, T. Research and Development of Controlled Auto-Ignition (CAI) Combustion in a 4-Stroke Multi-Cylinder Gasoline Engine. SAE International Fall Fuels & Lubricants Meeting & Exhibition. 2001. Available online: https://saemobilus.sae.org/content/2001-01-3608 (accessed on 10 November 2023).

- Nier, T.; Kulzer, A.; Karrelmeyer, R. Analysis of the Combustion Mode Switch between SI and Gasoline HCCI. In Proceedings of the SAE 2012 World Congress & Exhibition; 2012. Available online: https://saemobilus.sae.org/content/2012-01-1105/ (accessed on 10 November 2023).

- Manofsky, L.; Vavra, J.; Assanis, D.N.; Babajimopoulos, A. Bridging the Gap between HCCI and SI: Spark-Assisted Compression Ignition. SAE 2011 World Congress & Exhibition. 2011. Available online: https://saemobilus.sae.org/content/2011-01-1179/ (accessed on 10 November 2023).

- Li, L.; Xie, H.; Chen, T.; Yu, W.; Zhao, H. Experimental Study on Spark Assisted Compression Ignition (SACI) Combustion with Positive Valve Overlap in a HCCI Gasoline Engine. SAE 2012 World Congress & Exhibition. 2012. Available online: https://saemobilus.sae.org/content/2012-01-1126/ (accessed on 10 November 2023).

- Kulzer, A.; Nier, T.; Karrelmeyer, R. A Thermodynamic Study on Boosted HCCI: Experimental Results. SAE 2011 World Congress & Exhibition. 2011. Available online: https://saemobilus.sae.org/content/2011-01-0905/ (accessed on 10 November 2023).

- Cairns, A.; Blaxill, H. The Effects of Combined Internal and External Exhaust Gas Recirculation on Gasoline Controlled Auto-Ignition. SAE 2005 World Congress & Exhibition. 2005. Available online: https://saemobilus.sae.org/content/2005-01-0133/ (accessed on 10 November 2023).

- Xie, H.; Chen, T.; Zhang, Y.; Zhao, H. Influence of external EGR on expanding HCCI combustion operation range. Ranshao Kexue Yu Jishu/J. Combust. Sci. Technol. 2008, 14, 491–495. [Google Scholar]

- Xu, F.; Wang, Z.; Yang, D.; Wang, J. Potential of High Load Extension for Gasoline HCCI Engine Using Boosting and Exhaust Gas Recirculation. Energy Fuels 2009, 23, 2444–2452. [Google Scholar] [CrossRef]

- Xu, F.; Wang, Z.; Yang, D.-B.; Wang, J.-X. External EGR combined with internal EGR for high load extension on a gasoline HCCI engine. Neiranji Gongcheng/Chin. Intern. Combust. Engine Eng. 2010, 31, 6–10. [Google Scholar]

- Jin, Z.; Hong, W.; You, T.; Su, Y.; Li, X.; Xie, F. Effect of Multi-Factor Coupling on the Movement Characteristics of the Hydraulic Variable Valve Actuation. Energies 2020, 13, 2870. [Google Scholar] [CrossRef]

- Han, L.; Duan, J.; Qian, D.; Gong, Y.; Wang, Y.; Xie, F.; Su, Y. Research on Homogeneous Charge Compression Ignition Combustion of Intake Port Exhaust Gas Recirculation Based on Cam Drive Hydraulic Variable Valve Actuation Mechanism. Energies 2022, 15, 438. [Google Scholar] [CrossRef]

- How, H.; Masjuki, H.; Kalam, M.; Teoh, Y. An investigation of the engine performance, emissions and combustion characteristics of coconut biodiesel in a high-pressure common-rail diesel engine. Energy 2014, 69, 749–759. [Google Scholar] [CrossRef]

- Duan, X.; Li, Y.; Liu, J.; Guo, G.; Fu, J.; Zhang, Q.; Zhang, S.; Liu, W. Experimental study the effects of various compression ratios and spark timing on performance and emission of a lean-burn heavy-duty spark ignition engine fueled with methane gas and hydrogen blends. Energy 2018, 169, 558–571. [Google Scholar] [CrossRef]

- Yu, H.; Su, Y.; Shen, B.; Zhang, Y.; Wang, B.; Zhou, Y. Effect of direct methanol injection based on low-flow injector on knock of gasoline engine under heavy load condition. Fuel 2024, 357, 129899. [Google Scholar] [CrossRef]

- Ortiz-Soto, E.A.; Vavra, J.; Babajimopoulos, A. Assessment of Residual Mass Estimation Methods for Cylinder Pressure Heat Release Analysis of HCCI Engines with Negative Valve Overlap. J. Eng. Gas Turbines Power 2012, 134, 082802. [Google Scholar] [CrossRef]

- Yıldız, M.; Çeper, B.A. A comparative study on gasoline/diesel-fueled RCCI combustion at different premixed ratios and high-EGR diesel CI combustion in an IC engine under low load conditions. Fuel 2022, 324, 124596. [Google Scholar] [CrossRef]

- Sarıkoç, S. Effect of H2 addition to methanol-gasoline blend on an SI engine at various lambda values and engine loads: A case of performance, combustion, and emission characteristics. Fuel 2021, 297, 120732. [Google Scholar] [CrossRef]

| Engine Properties | Specifications |

|---|---|

| Engine type | Single cylinder |

| Combustion chamber type | ω |

| Bore/Stroke | 80 mm/80 mm |

| Displacement | 0.402 L |

| Compression ratio | 15.0:1 |

| Intake valve number | 1 |

| Exhaust valve number | 1 |

| Intake valve timing and lift | Continuously variable |

| Exhaust valve timing and lift | Continuously variable |

| Equipment | Type | Range | Accuracy | Uncertainty (±%) |

|---|---|---|---|---|

| Dynamometer | CW50 | Speed 0~6000 r/min | ≤±1 r/min | 0.1 |

| Torque 0~200 N·m | ≤±0.2 N·m | 1.5 | ||

| Pressure sensor | Kistler 6115B | 0~200 bar | ≤±0.6 bar | 0.3 |

| Lambda meter | ETAS LA4 | 0.65~5 | ≤±0.1% | 1 |

| Encoder | Kistler 2613B | 0~720 °CA | ≤±0.5 °CA | 0.07 |

| ECU | MotoHawk | - | - | - |

| Fuel consumption meter | ONOSOKKI DF2420 | 0.2~82 kg/h | ≤±0.01 g/s | 0.03 |

| CO | AVL GAS 1000 | 0~10 %vol | ≤±0.02% | 1 |

| HC | AVL GAS 1000 | 0~5000 ppm | ≤±4 ppm | 1.3 |

| NOx | AVL GAS 1000 | 0~4000 ppm | ≤±25 ppm | 1.5 |

| Combustion analyzer | AVL Indicom | - | - | - |

| Item | Parameter |

|---|---|

| Maximum intake valve lift | 3.5 mm |

| Maximum exhaust valve lift | 5.0 mm |

| Intake valve opening timing | −257 °CA ATDC |

| Intake valve closing timing | −153 °CA ATDC |

| Exhaust valve opening timing | 103 °CA ATDC |

| Exhaust valve closing timing | Variable |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, H.; Wang, J.; Zhang, R.; Wang, F.; Su, Y.; Wang, Y. Study on the Effect of Coupled Internal and External EGR on Homogeneous Charge Compression Ignition under High Pressure Rise Rate. Energies 2024, 17, 175. https://doi.org/10.3390/en17010175

Tian H, Wang J, Zhang R, Wang F, Su Y, Wang Y. Study on the Effect of Coupled Internal and External EGR on Homogeneous Charge Compression Ignition under High Pressure Rise Rate. Energies. 2024; 17(1):175. https://doi.org/10.3390/en17010175

Chicago/Turabian StyleTian, Huayu, Jun Wang, Ran Zhang, Fan Wang, Yan Su, and Yaodong Wang. 2024. "Study on the Effect of Coupled Internal and External EGR on Homogeneous Charge Compression Ignition under High Pressure Rise Rate" Energies 17, no. 1: 175. https://doi.org/10.3390/en17010175