Agricultural Research and Development Center Design with Building Integrated Photovoltaics in Fiji

Abstract

:1. Introduction

2. Literature Review of Facility Design Approaches

3. Agricultural Research and Development Center Design

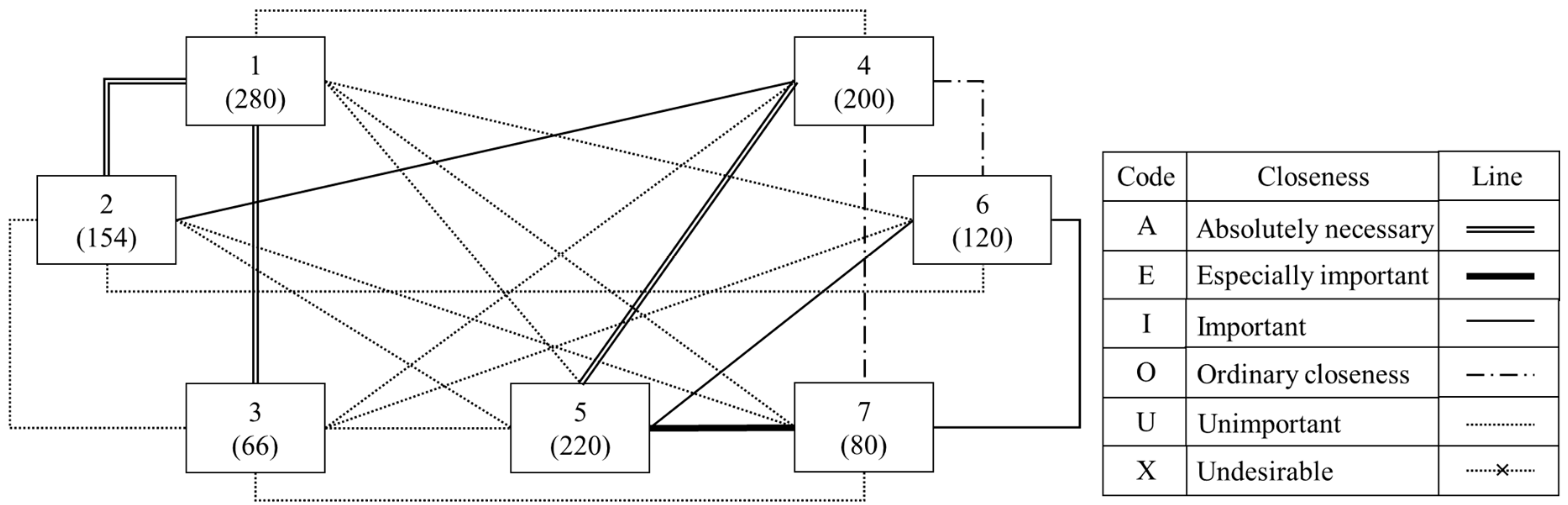

3.1. Activity Relationship Analysis

3.2. Space Requirement Analysis

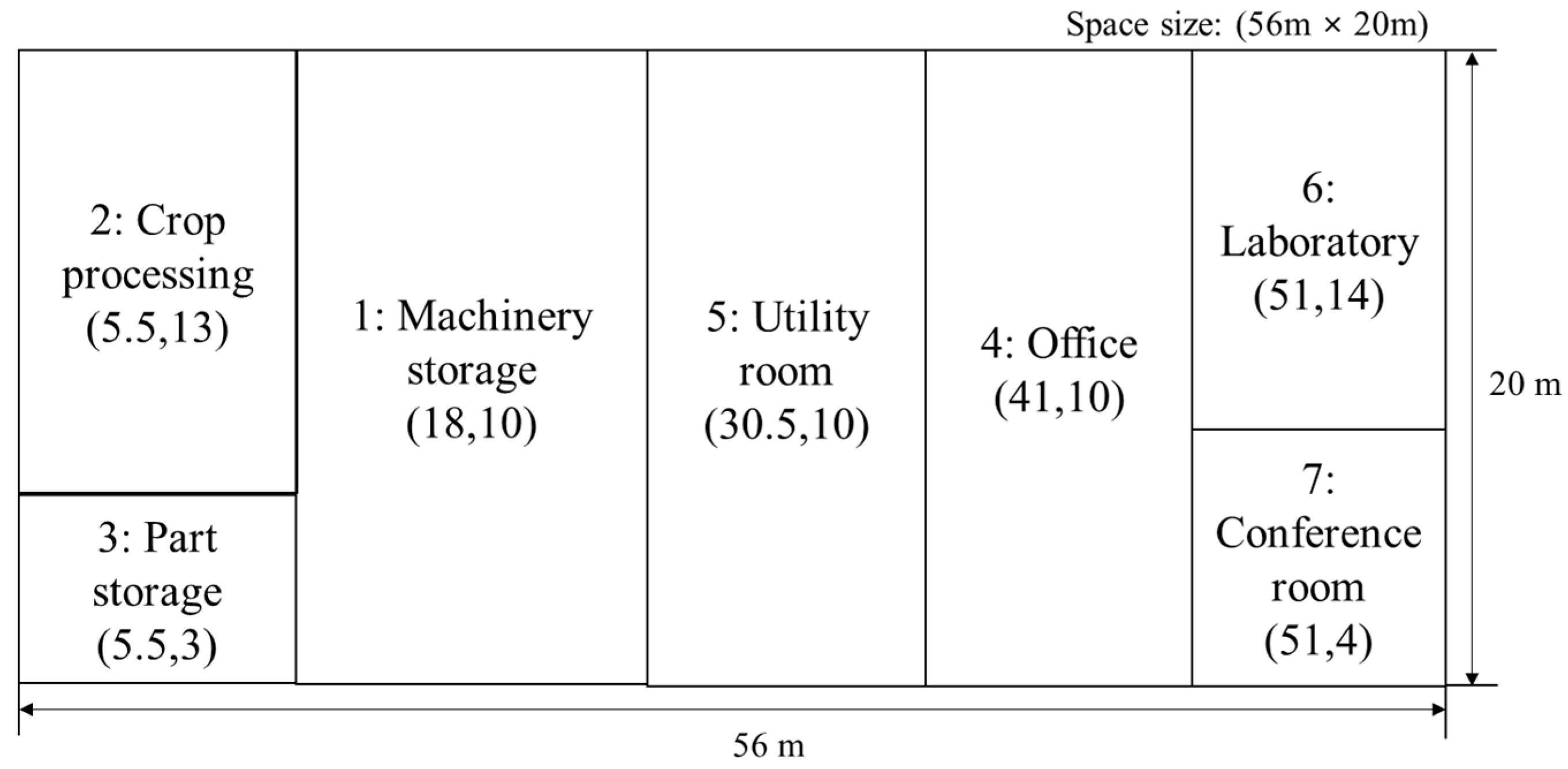

3.3. Alternative Layout Design

3.4. Layout Evaluation

3.5. Final Layout Determination

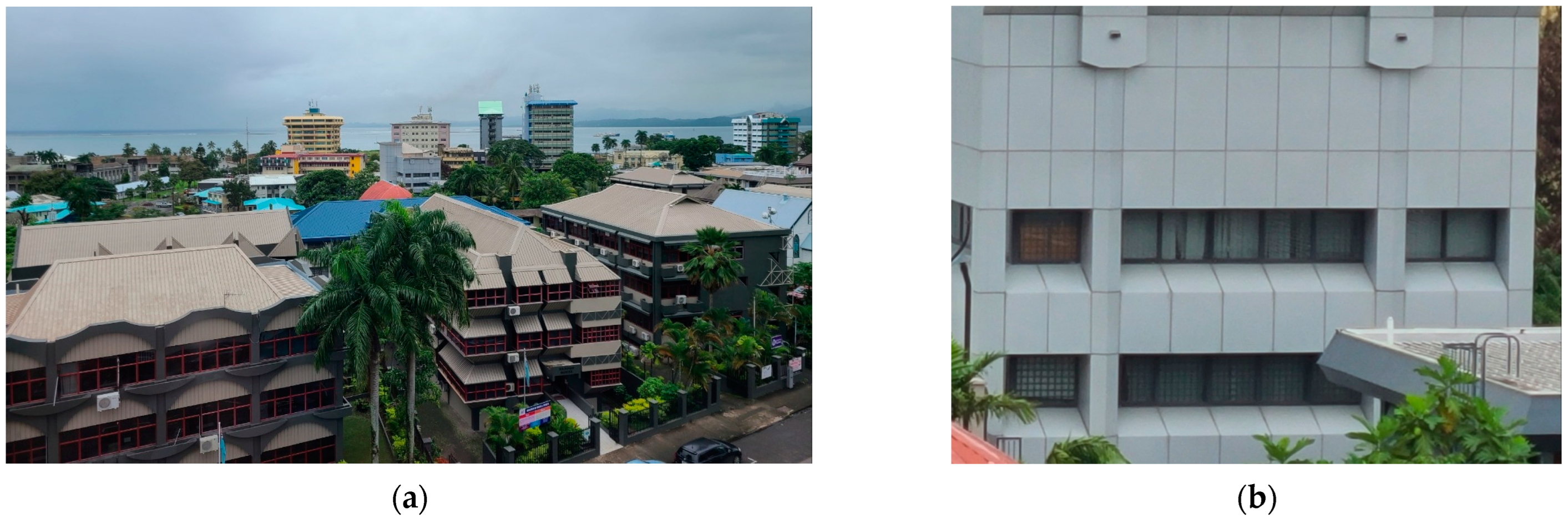

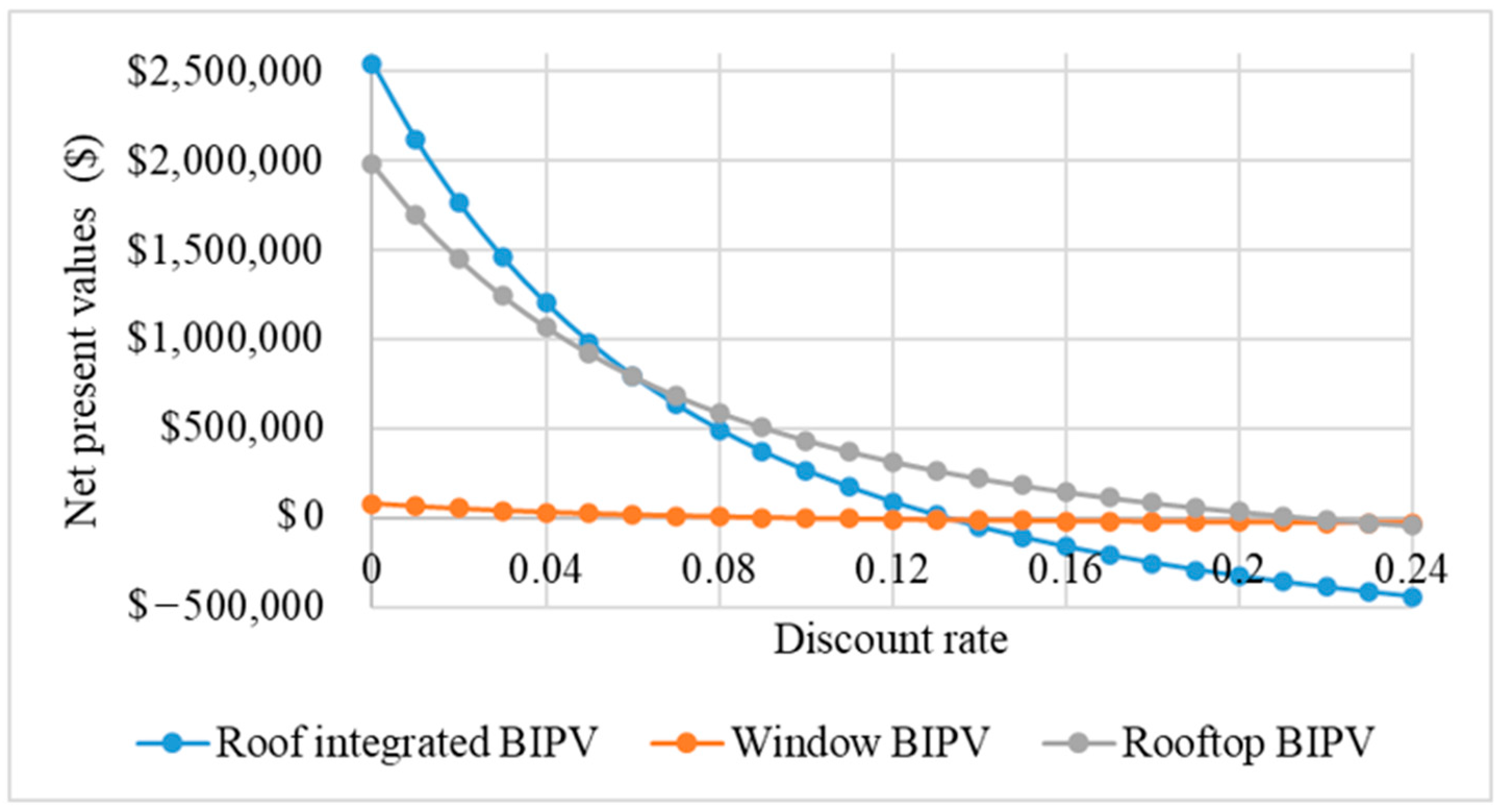

3.6. Feasibility Analysis for BIPV Installation

4. Feasibility Analysis of Building Materials

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Izam, N.S.M.N.; Itam, Z.; Sing, W.L.; Syamsir, A. Sustainable development perspectives of solar energy technologies with focus on solar Photovoltaic—A review. Energies 2022, 15, 2790. [Google Scholar] [CrossRef]

- IEA. Projected Costs of Generating Electricity 2020. Available online: https://www.iea.org/reports/projected-costs-of-generating-electricity-2020 (accessed on 12 August 2023).

- Comello, S.; Reichelstein, S. The US investment tax credit for solar energy: Alternatives to the anticipated 2017 step-down. Renew. Sustain. Energy Rev. 2016, 55, 591–602. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. Renewable Power Generation Costs in 2021. Available online: https://www.irena.org/publications/2022/Jul/Renewable-Power-Generation-Costs-in-2021 (accessed on 19 May 2023).

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Recent advancement in BIPV product technologies: A review. Energy Build. 2017, 140, 188–195. [Google Scholar] [CrossRef]

- Enkvist, P.A.; Dinkel, J.; Lin, C. Impact of the Financial Crisis on Carbon Economics: Version 2.1 of the Global Greenhouse Gas Abatement Cost Curve; McKinsey Co.: New York, NY, USA, 2010; p. 374. [Google Scholar]

- Yang, T.; Athienitis, A.K. A review of research and developments of building-integrated photovoltaic/thermal (BIPV/T) systems. Renew. Sustain. Energy Rev. 2016, 66, 886–912. [Google Scholar] [CrossRef]

- Yu, G.; Yang, H.; Luo, D.; Cheng, X.; Ansah, M.K. A review on developments and researches of building integrated photovoltaic (BIPV) windows and shading blinds. Renew. Sustain. Energy Rev. 2021, 149, 111355. [Google Scholar] [CrossRef]

- Debbarma, M.; Sudhakar, K.; Baredar, P. Comparison of BIPV and BIPVT: A review. Resour.-Effic. Technol. 2017, 3, 263–271. [Google Scholar] [CrossRef]

- Grand View Research. Building Integrated Photovoltaics Market Size Report, 2030. 2023. Available online: https://www.grandviewresearch.com/industry-analysis/building-integrated-photovoltaics-bipv-market (accessed on 2 April 2023).

- Prasad, N.H.; Rajyalakshmi, G.; Reddy, A.S. A typical manufacturing plant layout design using CRAFT algorithm. Procedia Eng. 2014, 97, 1808–1814. [Google Scholar] [CrossRef]

- Tompkins, J.A.; White, J.A.; Bozer, Y.A.; Tanchoco, J.M.A. Facilities Planning; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Singh, S.P.; Sharma, R.R. A review of different approaches to the facility layout problems. Int. J. Adv. Manuf. Technol. 2006, 30, 425–433. [Google Scholar] [CrossRef]

- Melachrinoudis, E.; Min, H. Redesigning a warehouse network. Eur. J. Oper. Res. 2007, 176, 210–229. [Google Scholar] [CrossRef]

- Joppolo, C.M.; Romano, F. HVAC system design in healthcare facilities and control of aerosol contaminants: Issues, tools, and experiments. Indoor Air Qual. Healthc. Facil. 2017, 83–94. [Google Scholar] [CrossRef]

- Kovács, G. Combination of Lean value-oriented conception and facility layout design for even more significant efficiency improvement and cost reduction. Int. J. Prod. Res. 2020, 58, 2916–2936. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Helmold, M.; Helmold, M. Seven Management Tools (M7). In Successful Management Strategies and Tools: Industry Insights, Case Studies and Best Practices; Springer: Cham, Switzerland, 2021; pp. 65–70. [Google Scholar] [CrossRef]

- Parmar, N.J.; James, A.T. Development of a framework for safety performance measurement of belt conveyor systems. Int. J. Product. Perform. Manag. 2023, 72, 1001–1024. [Google Scholar] [CrossRef]

- Xie, Y.; Gao, G.; Chen, X.A. Outlining the design space of explainable intelligent systems for medical diagnosis. arXiv 2019, arXiv:1902.06019. [Google Scholar]

- Kembro, J.H.; Norrman, A. Which future path to pick? A contingency approach to omnichannel warehouse configuration. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 48–75. [Google Scholar] [CrossRef]

- Kumanan, S.; Jegan Jose, G.; Raja, K. Multi-project scheduling using an heuristic and a genetic algorithm. Int. J. Adv. Manuf. Technol. 2006, 31, 360–366. [Google Scholar] [CrossRef]

- Nagy, D.; Villaggi, L.; Stoddart, J.; Benjamin, D. The buzz metric: A graph-based method for quantifying productive congestion in generative space planning for architecture. Technol. Archit. Des. 2017, 1, 186–195. [Google Scholar] [CrossRef]

- Hossain, M.R.; Rasel, M.K.; Talapatra, S. Increasing productivity through facility layout improvement using systematic layout planning pattern theory. Glob. J. Res. Eng. 2014, 14, 70–75. [Google Scholar]

- Ayvazoğluyüksel, Ö.; Filik, Ü.B. Estimation methods of global solar radiation, cell temperature and solar power forecasting: A review and case study in Eskişehir. Renew. Sustain. Energy Rev. 2018, 91, 639–653. [Google Scholar] [CrossRef]

- Mermoud, A. Pvsyst Version 7.1; PVsyst SA: Satigny, Switzerland, 2020. [Google Scholar]

- Prasad, M.; Prasad, R. Bifacial vs monofacial grid-connected solar photovoltaic for small islands: A case study of Fiji. Renew. Energy 2023, 203, 686–702. [Google Scholar] [CrossRef]

- Kim, S.; Meng, C.; Son, Y.J. Simulation-based machine shop operations scheduling system for energy cost reduction. Simul. Model. Pract. Theory 2017, 77, 68–83. [Google Scholar] [CrossRef]

- Mellit, A.; Sağlam, S.; Kalogirou, S.A. Artificial neural network-based model for estimating the produced power of a photovoltaic module. Renew. Energy 2013, 60, 71–78. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S.; Cho, J.; Park, S.; Jarrín Perez, F.X.; Kiniry, J.R. Simulated biomass, climate change impacts, and nitrogen management to achieve switchgrass biofuel production at diverse sites in US. Agronomy 2020, 10, 503. [Google Scholar] [CrossRef]

- Darling, S.B.; You, F.; Veselka, T.; Velosa, A. Assumptions and the levelized cost of energy for photovoltaics. Energy Environ. Sci. 2011, 4, 3133–3139. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S. Economic Feasibility Comparison between Building-Integrated Photovoltaics and Green Systems in Northeast Texas. Energies 2023, 16, 4672. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S. Design of an Agrivoltaic System with Building Integrated Photovoltaic. Agronomy 2023, 13, 2140. [Google Scholar] [CrossRef]

- Metframe. Roofing Iron. Available online: http://www.metframe.com.fj/product_category/roofing-iron/ (accessed on 20 June 2023).

- Lee, H.M.; Yoon, J.H.; Kim, S.C.; Shin, U.C. Operational power performance of south-facing vertical BIPV window system applied in office building. Sol. Energy 2017, 145, 66–77. [Google Scholar] [CrossRef]

- WEUP Power Co., Ltd. Products. Available online: https://www.weuppower.com/ (accessed on 20 June 2023).

- Wiser, R.H.; Bolinger, M.; Seel, J. Benchmarking Utility-Scale PV Operational Expenses and Project Lifetimes: Results from a Survey of US Solar Industry Professionals; Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 2020. [Google Scholar] [CrossRef]

- LG Solar Solutions. Solar Panel. Available online: https://www.lg.com/us/business/solar-panels/lg-lg405n2w-v5 (accessed on 12 August 2023).

- Oyewola, O.M.; Ismail, O.S.; Olasinde, M.O.; Ajide, O.O. Mapping of solar energy potential in Fiji using an artificial neural network approach. Heliyon 2022, 8, e09961. [Google Scholar] [CrossRef]

- Fiji Meteorological Service. The Climate of Fiji. Available online: https://www.met.gov.fj/ClimateofFiji.pdf (accessed on 12 August 2023).

- Energy Fiji Limited. Small Business Tariffs. Available online: https://efl.com.fj/your-business/electricity-tariffs-and-rates/small-business-tariffs/ (accessed on 12 August 2023).

- Frontini, F.; Bonomo, P.; Chatzipanagi, A.; Verberne, G.; van den Donker, M.; Sinapis, K.; Folkerts, W. BIPV Product Overview for Solar Facades and Roofs; Delft University of Technology: Delft, Netherlands, 2015. [Google Scholar]

- APEC Economic and Life Cycle Analysis of Photovoltaic System in APEC Region. Available online: https://www.apec.org/Publications/2019/04/Life-Cycle-Assessment-of-Photovoltaic-Systems-in-the-APEC-Region (accessed on 3 April 2023).

- Jones-Albertus, R.; Feldman, D.; Fu, R.; Horowitz, K.; Woodhouse, M. Technology advances needed for photovoltaics to achieve widespread grid price parity. Prog. Photovolt. Res. Appl. 2016, 24, 1272–1283. [Google Scholar] [CrossRef]

- Fu, R.; Feldman, D.J.; Margolis, R.M. US Solar Photovoltaic System Cost Benchmark: Q1 2018; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2018. [CrossRef]

- The Cove. Fiji—Economics. Available online: https://cove.army.gov.au/article/kyr-fiji-economy (accessed on 12 August 2023).

- Prasad, R.D.; Raturi, A. Solar energy for power generation in Fiji: History, barriers and potentials. In Translating the Paris Agreement into Action in the Pacific; Springer: Cham, Switzerland, 2020; pp. 177–199. [Google Scholar] [CrossRef]

| Origin | Destination | ||||||

|---|---|---|---|---|---|---|---|

| Machinery Storage | Crop Processing | Part Storage | Office | Utility Room | Laboratory | Conference Room | |

| Machinery storage | – | 120 | 144 | 26 | 32 | 12 | 12 |

| Crop processing | – | – | 36 | 72 | 36 | 24 | 24 |

| Part storage | – | – | – | 36 | 15 | 12 | 12 |

| Office | – | – | – | – | 144 | 47 | 53 |

| Utility room | – | – | – | – | – | 82 | 122 |

| Laboratory | – | – | – | – | – | – | 68 |

| Conference room | – | – | – | – | – | – | – |

| Area Identifier | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Area name | Machinery storage | Crop processing | Part storage | Office | Utility room | Laboratory | Conference room |

| Size (m2) | 280 | 154 | 66 | 200 | 220 | 120 | 80 |

| Origin | Destination | ||||||

|---|---|---|---|---|---|---|---|

| Machinery Storage | Crop Processing | Part Storage | Office | Utility Room | Laboratory | Conference Room | |

| Machinery storage | – | 15.5 | 19.5 | 23.0 | 12.5 | 37.0 | 39.0 |

| Crop processing | 15.5 | – | 10.0 | 38.5 | 28.0 | 46.5 | 54.5 |

| Part storage | 19.5 | 10.0 | – | 16.5 | 32.0 | 56.5 | 46.5 |

| Office | 23.0 | 38.5 | 16.5 | – | 10.5 | 14.0 | 16.0 |

| Utility room | 12.5 | 28.0 | 32.0 | 10.5 | – | 24.5 | 26.5 |

| Laboratory | 37.0 | 46.5 | 56.5 | 14.0 | 24.5 | – | 10.0 |

| Conference room | 39.0 | 54.5 | 46.5 | 16.0 | 26.5 | 10.0 | – |

| Origin | Destination | ||||||

|---|---|---|---|---|---|---|---|

| Machinery Storage | Crop Processing | Part Storage | Office | Utility Room | Laboratory | Conference Room | |

| Machinery storage | – | 1860 | 2808 | 598 | 400 | 444 | 468 |

| Crop processing | – | – | 360 | 2772 | 1008 | 1116 | 1308 |

| Part storage | – | – | – | 594 | 480 | 678 | 558 |

| Office | – | – | – | – | 1512 | 658 | 848 |

| Utility room | – | – | – | – | – | 2009 | 2968 |

| Laboratory | – | – | – | – | – | – | 680 |

| Conference room | – | – | – | – | – | – | – |

| Origin | Destination | ||||||

|---|---|---|---|---|---|---|---|

| Machinery Storage | Crop Processing | Part Storage | Office | Utility Room | Laboratory | Conference Room | |

| Machinery storage | – | 1860 | 2808 | 598 | 400 | 444 | 468 |

| Crop processing | – | – | 360 | 2772 | 1008 | 1116 | 1308 |

| Part storage | – | – | – | 594 | 480 | 678 | 558 |

| Office | – | – | – | – | 1512 | 658 | 848 |

| Utility room | – | – | – | – | – | 2009 | 2968 |

| Laboratory | – | – | – | – | – | – | 680 |

| Conference room | – | – | – | – | – | – | – |

| Category | BIPV Installation Alternatives | ||

|---|---|---|---|

| Roof-Integrated BIPV 3 | Window BIPV 3 | Rooftop BIPV 4 | |

| Size (m2) | 1160 | 56 | 784 |

| Capacity (kWp) | 227 | 11 | 153 |

| Installation cost | 1,184,782 | 57,196 | 548,458 |

| Operations (USD/year) 1 | 1791 | 86 | 1210 |

| Maintenance (USD/year) 2 | 1201 | 58 | 812 |

| Month | Solar Radiation (kWh/m2/day) | Electricity Generated (kWh/m2/day) | |||||

|---|---|---|---|---|---|---|---|

| Max | Min | Avg | Std | Roof-Integrated BIPV | Window BIPV | Rooftop BIPV | |

| Jan. | 6.62 | 5.67 | 6.17 | 0.36 | 0.86 | 0.33 | 0.83 |

| Feb | 6.34 | 5.36 | 5.89 | 0.36 | 0.89 | 0.34 | 0.87 |

| Mar. | 5.71 | 4.99 | 5.45 | 0.26 | 0.90 | 0.35 | 0.87 |

| Apr. | 5.09 | 4.40 | 4.78 | 0.23 | 0.84 | 0.32 | 0.82 |

| May | 4.63 | 4.00 | 4.26 | 0.21 | 0.78 | 0.30 | 0.75 |

| Jun. | 4.34 | 3.70 | 3.94 | 0.23 | 0.75 | 0.29 | 0.72 |

| Jul. | 4.61 | 3.91 | 4.17 | 0.25 | 0.77 | 0.30 | 0.74 |

| Aug. | 5.11 | 4.32 | 4.67 | 0.27 | 0.83 | 0.32 | 0.80 |

| Sep. | 5.70 | 4.89 | 5.28 | 0.27 | 0.89 | 0.34 | 0.86 |

| Oct. | 6.26 | 5.42 | 5.89 | 0.29 | 0.89 | 0.34 | 0.87 |

| Nov. | 6.49 | 5.61 | 6.14 | 0.34 | 0.86 | 0.33 | 0.84 |

| Dec. | 6.70 | 5.72 | 6.24 | 0.38 | 0.84 | 0.33 | 0.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Kim, S. Agricultural Research and Development Center Design with Building Integrated Photovoltaics in Fiji. Energies 2024, 17, 207. https://doi.org/10.3390/en17010207

Kim S, Kim S. Agricultural Research and Development Center Design with Building Integrated Photovoltaics in Fiji. Energies. 2024; 17(1):207. https://doi.org/10.3390/en17010207

Chicago/Turabian StyleKim, Sojung, and Sumin Kim. 2024. "Agricultural Research and Development Center Design with Building Integrated Photovoltaics in Fiji" Energies 17, no. 1: 207. https://doi.org/10.3390/en17010207