Experimental Study on Mechanical and Thermal Properties of Backfill Body with Paraffin Added

Abstract

:1. Introduction

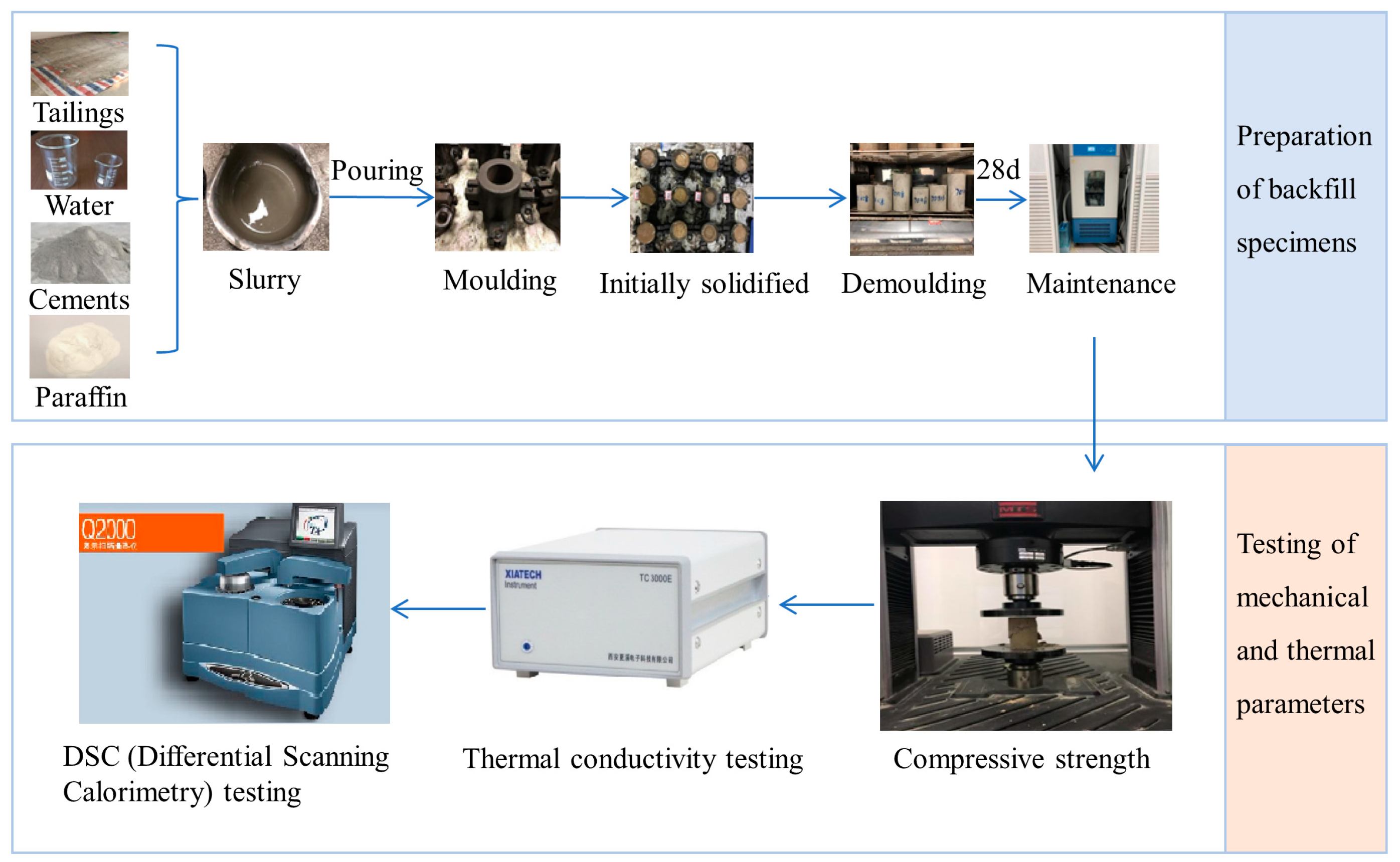

2. Experiment and Test

2.1. Material Preparation

2.2. Testing Methods

3. Test and Analysis on Mechanical Properties of Backfill Specimens

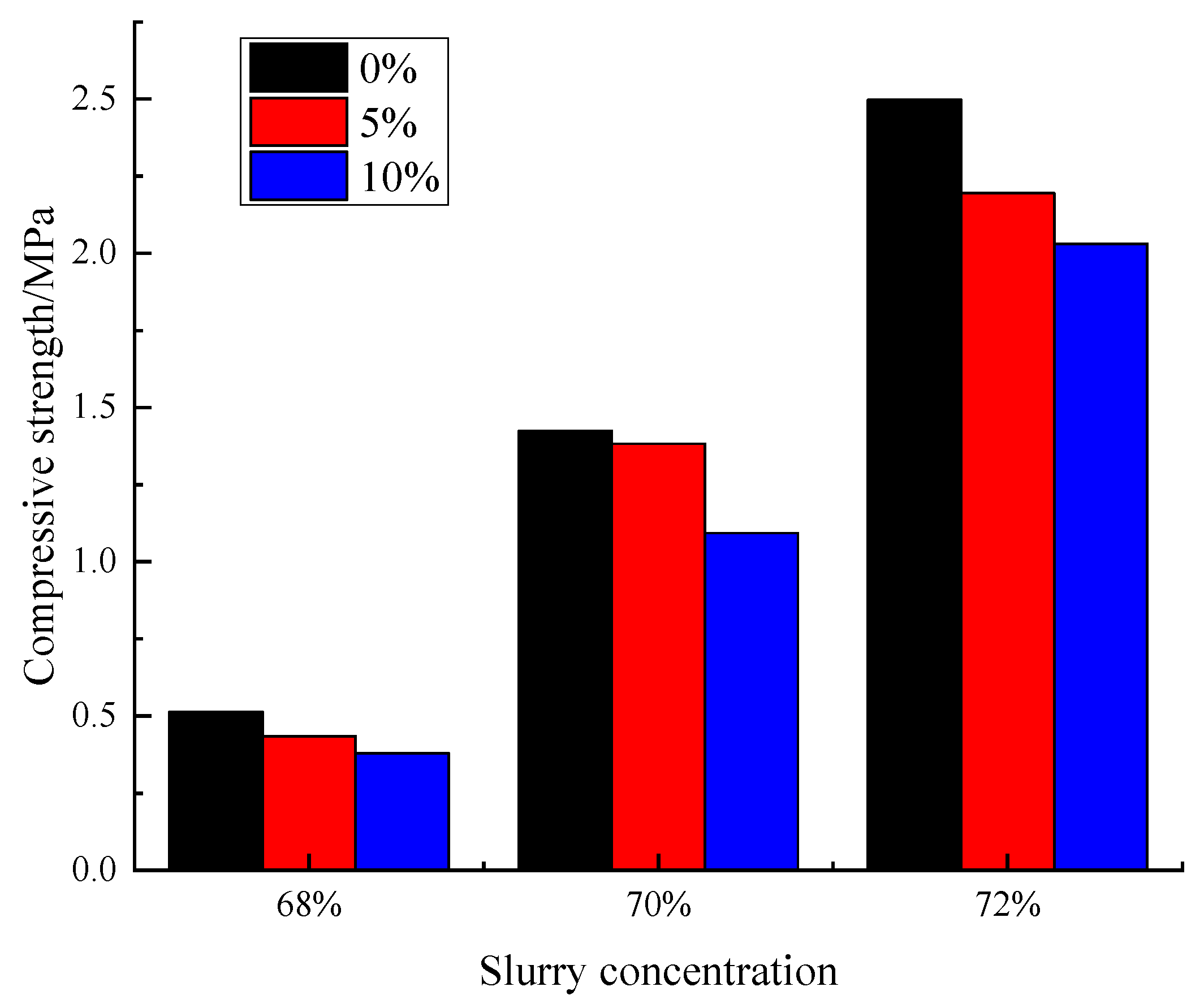

3.1. Analysis on Compressive Strength of Specimens

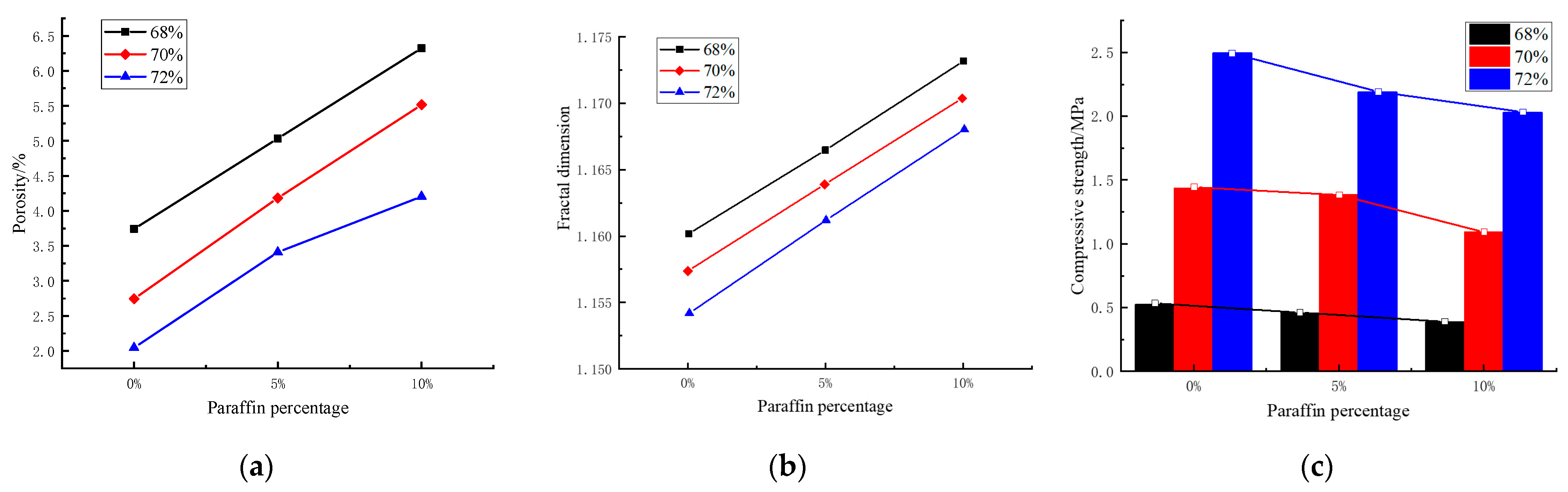

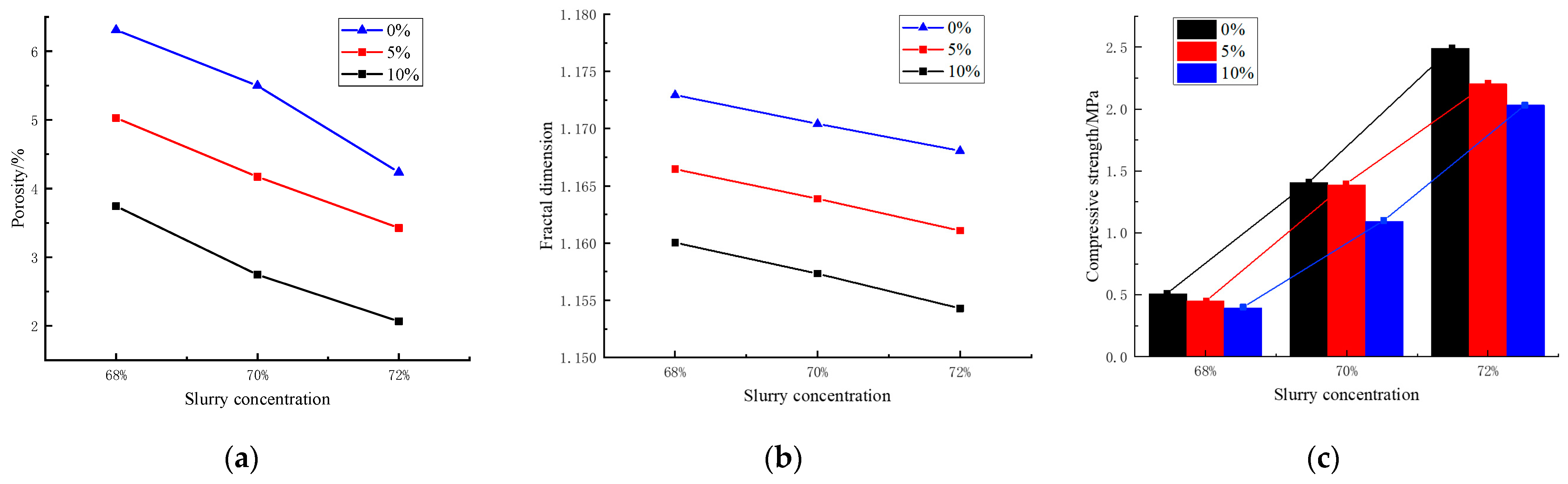

3.2. Slurry Proportion Porosity, Porosity Fractal Dimension and Mechanical Response

4. Test and Analysis on Mechanical Properties of Backfill Specimens

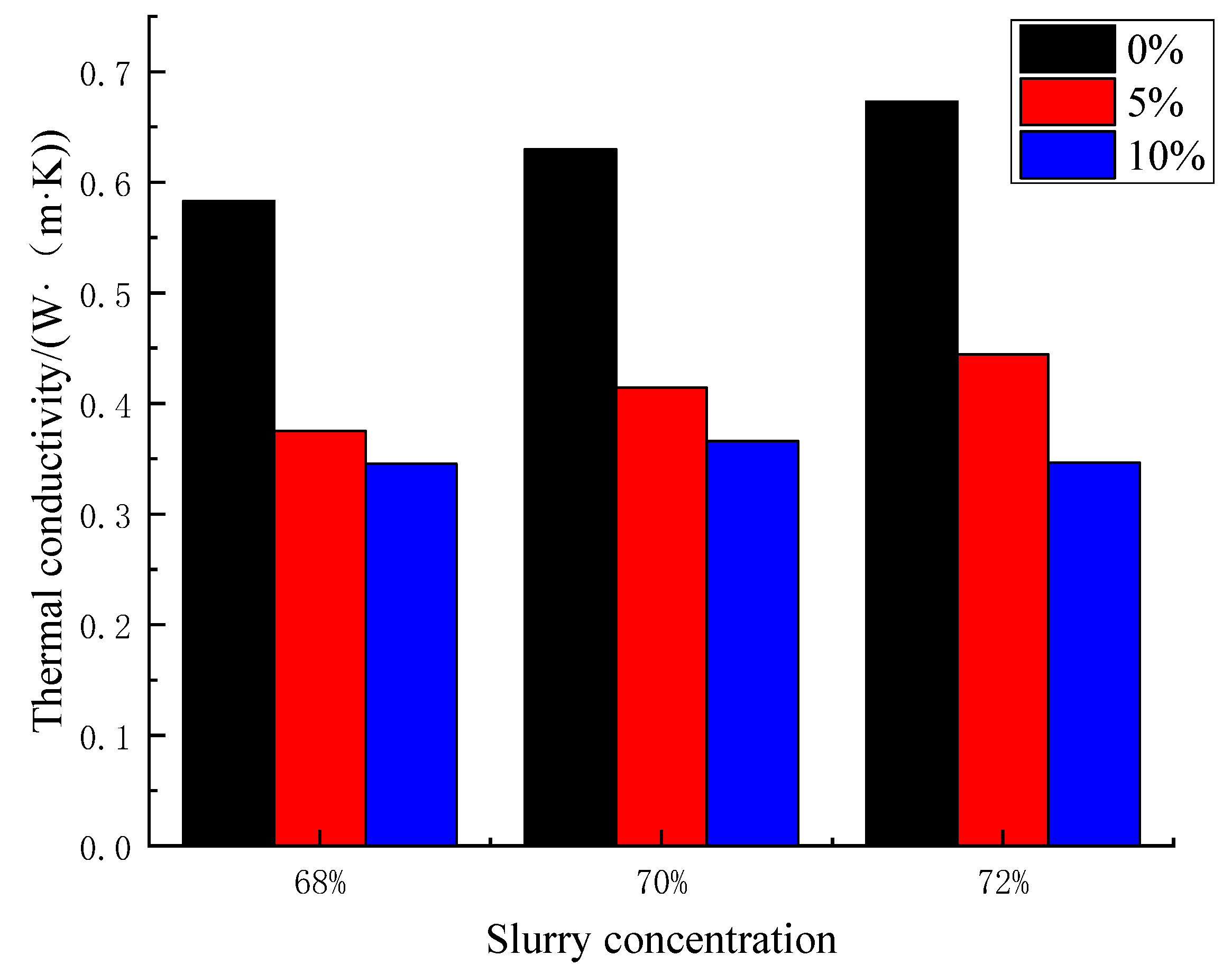

4.1. Thermal Conductivity

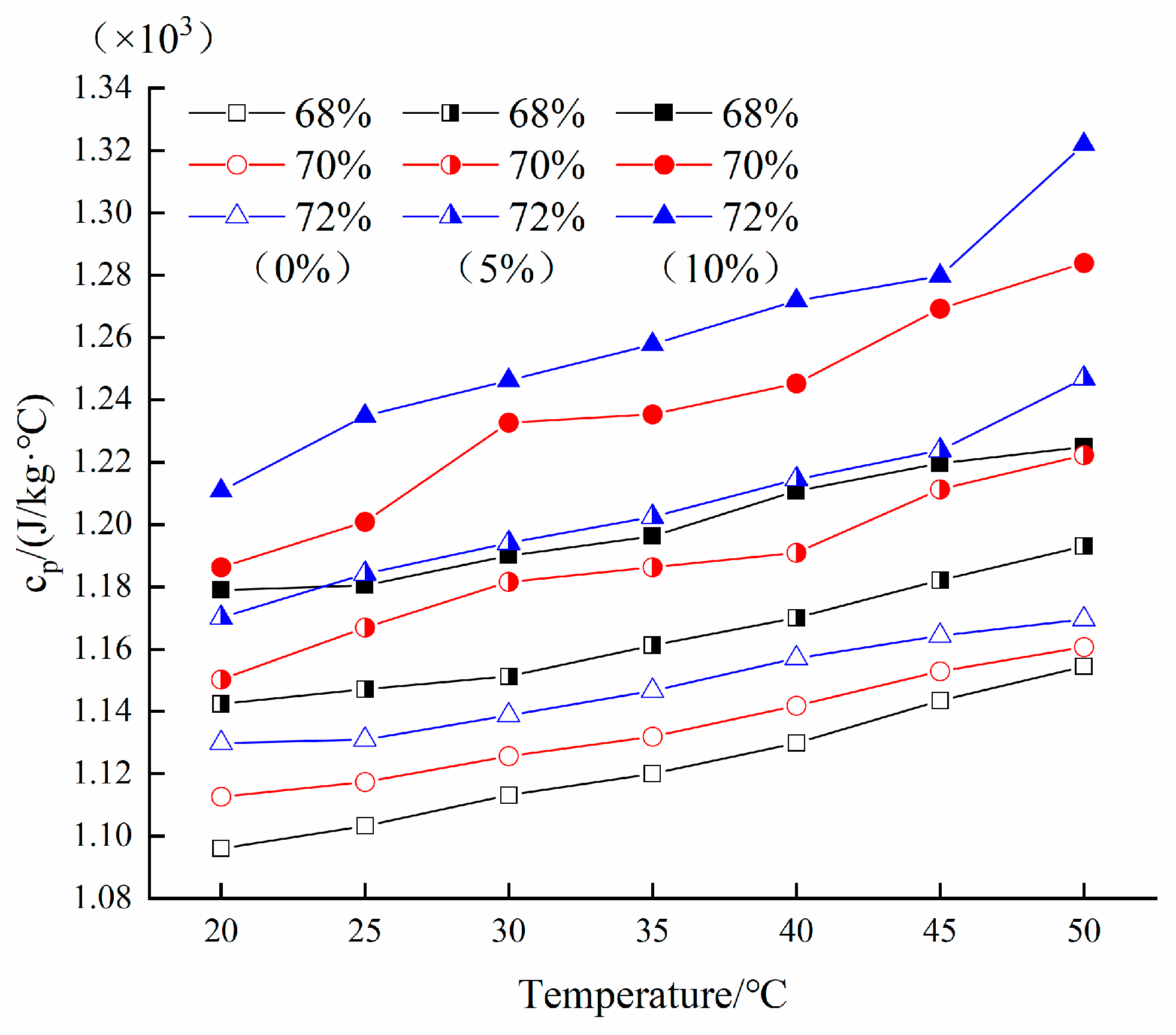

4.2. Specific Heat Capacity

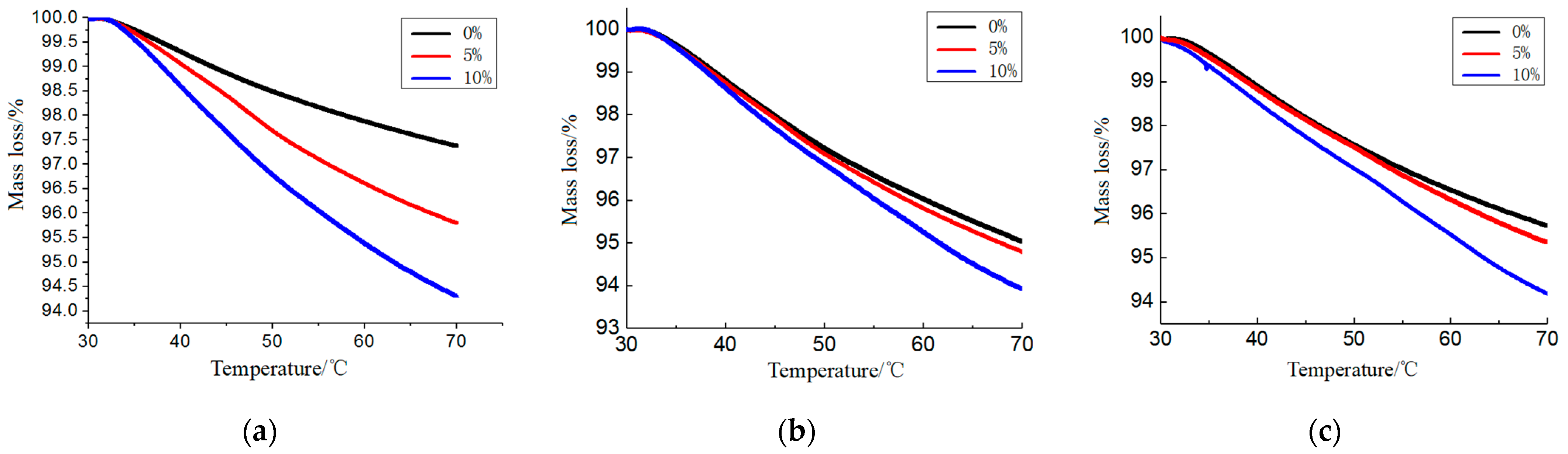

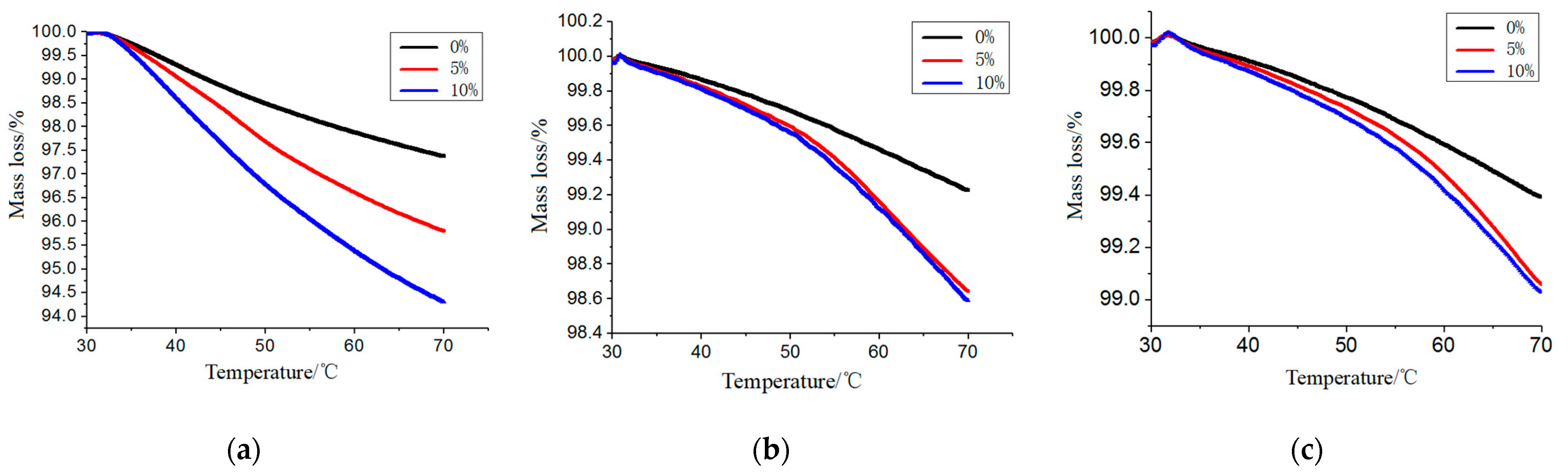

4.3. Thermogravimetric Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, L.; Xin, J.; Zhang, B.; Zhang, X.Y.; Wang, M.; Qiu, H.F. Basic theory and application exploration of functional filling in mines. Chin. J. Coal Sci. 2018, 7, 1811–1820. [Google Scholar]

- Cheng, A.; Shu, P.; Deng, D.; Zhou, C.; Huang, S.; Ye, Z. Microscopic acoustic emission simulation and fracture mechanism of cemented tailings backfill based on moment tensor theory. Constr. Build. Mater. 2021, 308, 125069. [Google Scholar] [CrossRef]

- Li, N.; Lv, S.; Wang, W.; Guo, J.; Jiang, P.; Liu, Y. Experimental investigations on the mechanical behavior of iron tailings powder with compound admixture of cement and nano-clay. Constr. Build. Mater. 2020, 254, 119259. [Google Scholar] [CrossRef]

- Zhou, N.; Du, E.; Zhang, J.; Zhu, C.; Zhou, H. Mechanical properties improvement of Sand-Based cemented backfill body by adding glass fibers of different lengths and ratios. Constr. Build. Mater. 2021, 280, 122408. [Google Scholar] [CrossRef]

- Qiu, H.; Liang, C.; Tu, B.; Liu, L.; Zhang, F.; Lv, W. Study on mechanical properties of cemented backfill with different mineral admixtures. Constr. Build. Mater. 2023, 367, 130251. [Google Scholar] [CrossRef]

- Wang, H.; Feng, G.; Qi, T.; Gao, X.; Wang, C.; Wang, L.; Zhang, Z. Influence of the use of corn straw fibers to connect the interfacial transition zone with the mechanical properties of cemented coal gangue backfill. Constr. Build. Mater. 2023, 367, 130334. [Google Scholar] [CrossRef]

- Song, X.; Hao, Y.; Wang, S.; Zhang, L.; Liu, W.; Li, J. Mechanical properties, crack evolution and damage characteristics of prefabricated fractured cemented paste backfill under uniaxial compression. Constr. Build. Mater. 2022, 330, 127251. [Google Scholar] [CrossRef]

- Xie, G.; Suo, Y.; Liu, L.; Yang, P.; Qu, H.; Zhang, C. Pore characteristics of sulfate-activated coal gasification slag cement paste backfill for mining. Environ. Sci. Pollut. Res. 2023, 30, 114920–114935. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, M.; Liu, L.; Huan, C.; Zhao, Y.; Qi, C.; Song, K.I. Experimental study on thermal and mechanical properties of cemented paste backfill with phase change material. J. Mater. Res. Technol. 2020, 9, 2164–2175. [Google Scholar] [CrossRef]

- Zhang, X.; Cao, T.; Liu, L.; Bu, B.; Ke, Y.; Du, Q. Experimental study on thermal and mechanical properties of tailings-based cemented paste backfill with CaCl2 · 6H2O /expanded vermiculite shape stabilized phase change materials. Int. J. Miner. Metall. Mater. 2023, 30, 250–259. [Google Scholar] [CrossRef]

- Ning, P.; Ju, F.; Xiao, M.; He, Z.; Wang, D. Study on the thermal-mechanical properties and heat transfer characteristics of heat storage functional backfill body. Geothermics 2023, 109, 102654. [Google Scholar] [CrossRef]

- Wan, R.; Shen, L.; Liu, H.; Ma, S.; Duan, S.; Kong, D.; Zheng, C. Effect of shape-stable phase change materials on heat transfer characteristics of ground source heat pump backfill materials. Geothermics 2023, 110, 102672. [Google Scholar]

- Beiranvand, M.; Mohaghegh, M.R. Energy analysis and simulation of PCM-enhanced building envelopes in commercial buildings: A case study. Energy Storage 2021, 3, e246. [Google Scholar] [CrossRef]

- Islam, M.N.; Ahmed, D.H. Delaying the temperature fluctuations through PCM integrated building walls—Room conditions, PCM placement, and temperature of the heat sources. Energy Storage 2021, 3, e245. [Google Scholar] [CrossRef]

- Kabdrakhmanova, M.; Memon, S.A.; Saurbayeva, A. Implementation of the panel data regression analysis in PCM integrated buildings located in a humid subtropical climate. Energy 2021, 237, 121651. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, W.; Fu, S.; Zhang, H. Study of a novel ceramsite-based shape-stabilized composite phase change material (PCM) for energy conservation in buildings. Constr. Build. Mater. 2020, 246, 118479. [Google Scholar] [CrossRef]

- Wu, D.; Rahim, M.; El Ganaoui, M.; Djedjig, R.; Bennacer, R.; Liu, B. Experimental investigation on the hygrothermal behavior of a new multilayer building envelope integrating PCM with bio-based material. Build. Environ. 2021, 201, 107995. [Google Scholar] [CrossRef]

- Liu, Z.; Zang, C.; Zhang, Y.; Jiang, J.; Yuan, Z.; Liu, G.; Li, H. Mechanical properties and antifreeze performance of cement-based composites with liquid paraffin/diatomite capsule low-temperature phase change. Constr. Build. Mater. 2022, 341, 127773. [Google Scholar] [CrossRef]

- Alsaadawi, M.M.; Amin, M.; Tahwia, A.M. Thermal, mechanical and microstructural properties of sustainable concrete incorporating Phase change materials. Constr. Build. Mater. 2022, 356, 129300. [Google Scholar] [CrossRef]

- Ryms, M.; Januszewicz, K.; Haustein, E.; Kazimierski, P.; Lewandowski, W.M. Thermal properties of a cement composite containing phase change materials (PCMs) with post-pyrolytic char obtained from spent tyres as a carrier. Energy 2022, 239, 121936. [Google Scholar] [CrossRef]

- Yu, K.; Liu, Y.; Yang, Y. Review on form-stable inorganic hydrated salt phase change materials: Preparation, characterization and effect on the thermophysical properties. Appl. Energy 2021, 292, 116845. [Google Scholar] [CrossRef]

- Lian, P.; Yan, R.; Wu, Z.; Wang, Z.; Chen, Y.; Zhang, L.; Sheng, X. Thermal performance of novel form-stable disodium hydrogen phosphate dodecahydrate-based composite phase change materials for building thermal energy storage. Adv. Compos. Hybrid Mater. 2023, 6, 74. [Google Scholar] [CrossRef]

- Ong, P.J.; Leow, Y.; Soo, X.Y.D.; Chua, M.H.; Ni, X.; Suwardi, A.; Zhu, Q. Valorization of Spent coffee Grounds: A sustainable resource for Bio-based phase change materials for thermal energy storage. Waste Manag. 2023, 157, 339–347. [Google Scholar] [CrossRef] [PubMed]

- Gencel, O.; Sarı, A.; Kaplan, G.; Ustaoglu, A.; Hekimoğlu, G.; Bayraktar, O.Y.; Ozbakkaloglu, T. Properties of eco-friendly foam concrete containing PCM impregnated rice husk ash for thermal management of buildings. J. Build. Eng. 2022, 58, 104961. [Google Scholar] [CrossRef]

- Sobolciak, P.; Karkri, M.; Al-Maadeed, M.A.; Krupa, I. Thermal characterization of phase change materials based on linear low-density polyethylene, paraffin wax and expanded graphite. Renew. Energy 2016, 88, 372–382. [Google Scholar] [CrossRef]

- Xiang, B.; Yang, Z.; Zhang, J. ASA/SEBS/paraffin composites as phase change material for potential cooling and heating applications in building. Polym. Adv. Technol. 2021, 32, 420–427. [Google Scholar] [CrossRef]

- Xie, Y.; Yang, Y.; Liu, Y.; Wang, S.; Guo, X.; Wang, H.; Cao, D. Paraffin/polyethylene/graphite composite phase change materials with enhanced thermal conductivity and leakage-proof. Adv. Compos. Hybrid Mater. 2021, 4, 543–551. [Google Scholar] [CrossRef]

- Chen, F.; Wolcott, M. Polyethylene/paraffin binary composites for phase change material energy storage in building: A morphology, thermal properties, and paraffin leakage study. Sol. Energy Mater. Sol. Cells 2015, 137, 79–85. [Google Scholar] [CrossRef]

- Wang, F.; Zheng, W.; Qiao, Z.; Qi, Y.; Chen, Z.; Li, H. Study of the structural-functional lightweight concrete containing novel hollow ceramsite compounded with paraffin. Constr. Build. Mater. 2022, 342, 127954. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Q.; Miao, W.; Su, Y.; He, X.; Strnadel, B. The thermal performances of cement-based materials with different types of microencapsulated phase change materials. Constr. Build. Mater. 2022, 345, 128388. [Google Scholar] [CrossRef]

- Gbekou, F.K.; Benzarti, K.; Boudenne, A.; Eddhahak, A.; Duc, M. Mechanical and thermophysical properties of cement mortars including bio-based microencapsulated phase change materials. Constr. Build. Mater. 2022, 352, 129056. [Google Scholar] [CrossRef]

- Zhang, X.; Wen, D.; Zhao, Y.; Liu, L.; Zhang, B.; Huan, C.; Wang, M.; Tu, B. Thermal mechanical performance and heat transfer process of mine thermal storage/energy storage filling materials. J. Coal Sci. 2021, 46, 3158–3171. [Google Scholar]

- Zhang, X.; Liu, L. Preparation and Thermology-Mechanics Properties of Filling Material Based on Mine Tailing with Heat Storage Function. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, July 2020. [Google Scholar]

| Material | Color | Physical State | Melting Point (°C) | Relative Density (g/cm3) | Specific Heat Capacity (J/(g·K)) | Heat of Melting (J/g) | Thermal Conductivity W/(m·K) |

|---|---|---|---|---|---|---|---|

| Paraffin | White | Waxy solid | 47–64 | 0.86–0.94 | 2.14–2.9 | 200~220 | 0.1–0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Han, Z.; Liu, L.; Xia, X.; Liu, Q.; Duan, Y.; Wang, X. Experimental Study on Mechanical and Thermal Properties of Backfill Body with Paraffin Added. Energies 2024, 17, 217. https://doi.org/10.3390/en17010217

Zhang X, Han Z, Liu L, Xia X, Liu Q, Duan Y, Wang X. Experimental Study on Mechanical and Thermal Properties of Backfill Body with Paraffin Added. Energies. 2024; 17(1):217. https://doi.org/10.3390/en17010217

Chicago/Turabian StyleZhang, Xiaoyan, Ziyi Han, Lang Liu, Xiang Xia, Qingjiang Liu, Yiran Duan, and Xuan Wang. 2024. "Experimental Study on Mechanical and Thermal Properties of Backfill Body with Paraffin Added" Energies 17, no. 1: 217. https://doi.org/10.3390/en17010217

APA StyleZhang, X., Han, Z., Liu, L., Xia, X., Liu, Q., Duan, Y., & Wang, X. (2024). Experimental Study on Mechanical and Thermal Properties of Backfill Body with Paraffin Added. Energies, 17(1), 217. https://doi.org/10.3390/en17010217