Exploring the Effects of Voltage Variation and Load on the Electrical and Thermal Performance of Permanent-Magnet Synchronous Motors

Abstract

:1. Introduction

1.1. General Considerations

1.2. Related Works

1.3. Motivation and Contribution

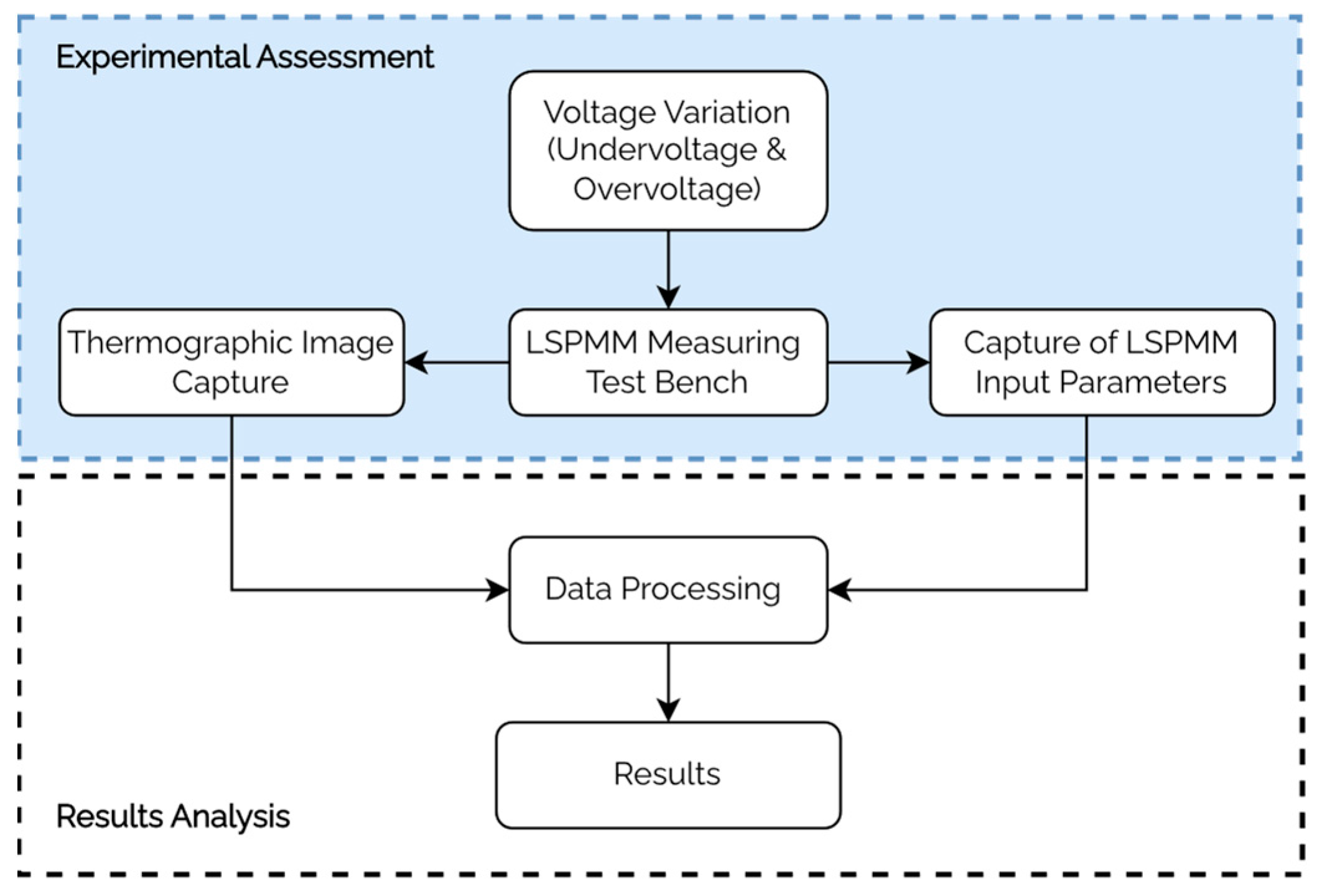

- Technical and economic evaluation of VV impacts: A comprehensive evaluation of the effects of VV under different load conditions is conducted. This study identifies the voltage magnitudes that exert the most substantial influence on motor behavior depending on the type of application and load conditions by assessing different non-nominal voltages. This analysis provides valuable insights into decision-making processes and offers guidance to specialists in optimizing motor performance.

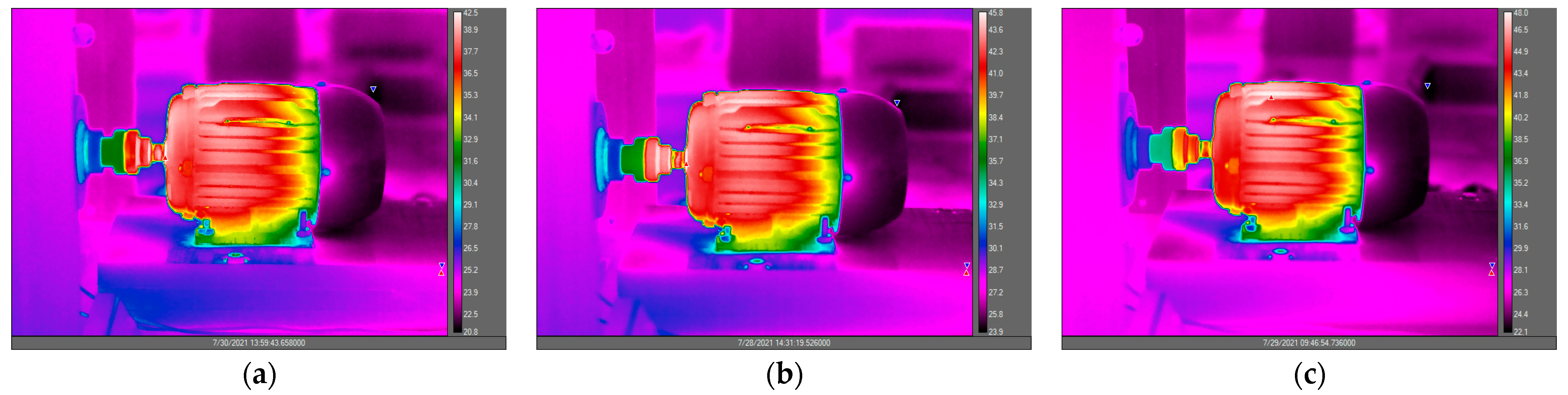

- Investigation of thermal impacts: This study investigates the thermal consequences of VV in permanent-magnet synchronous motors. To accomplish this, thermographic images and temperature curves were used to visualize and analyze how voltage magnitudes affect the internal components of the motors.

2. Theoretical Foundation

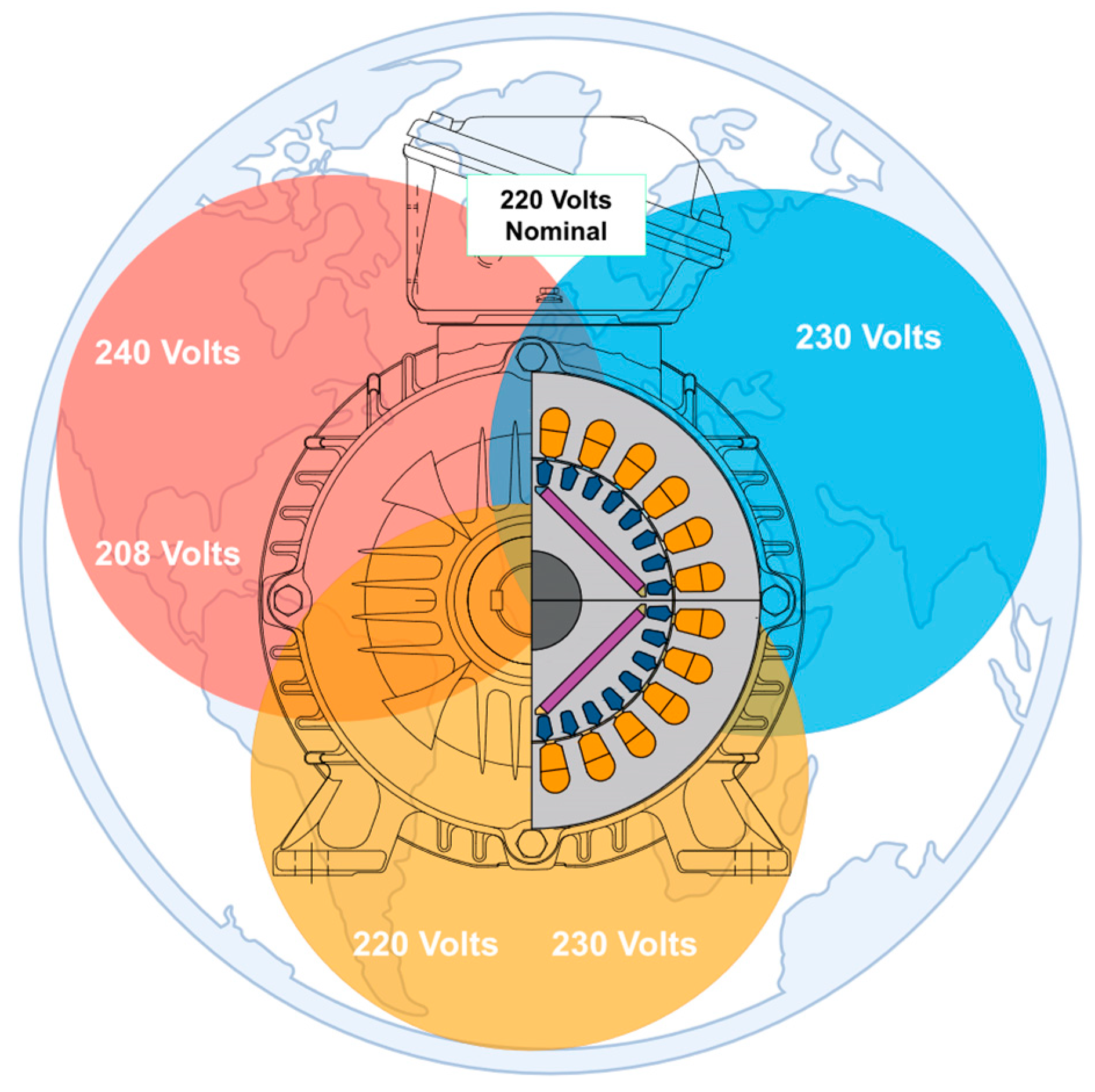

2.1. IEC 60038-2009

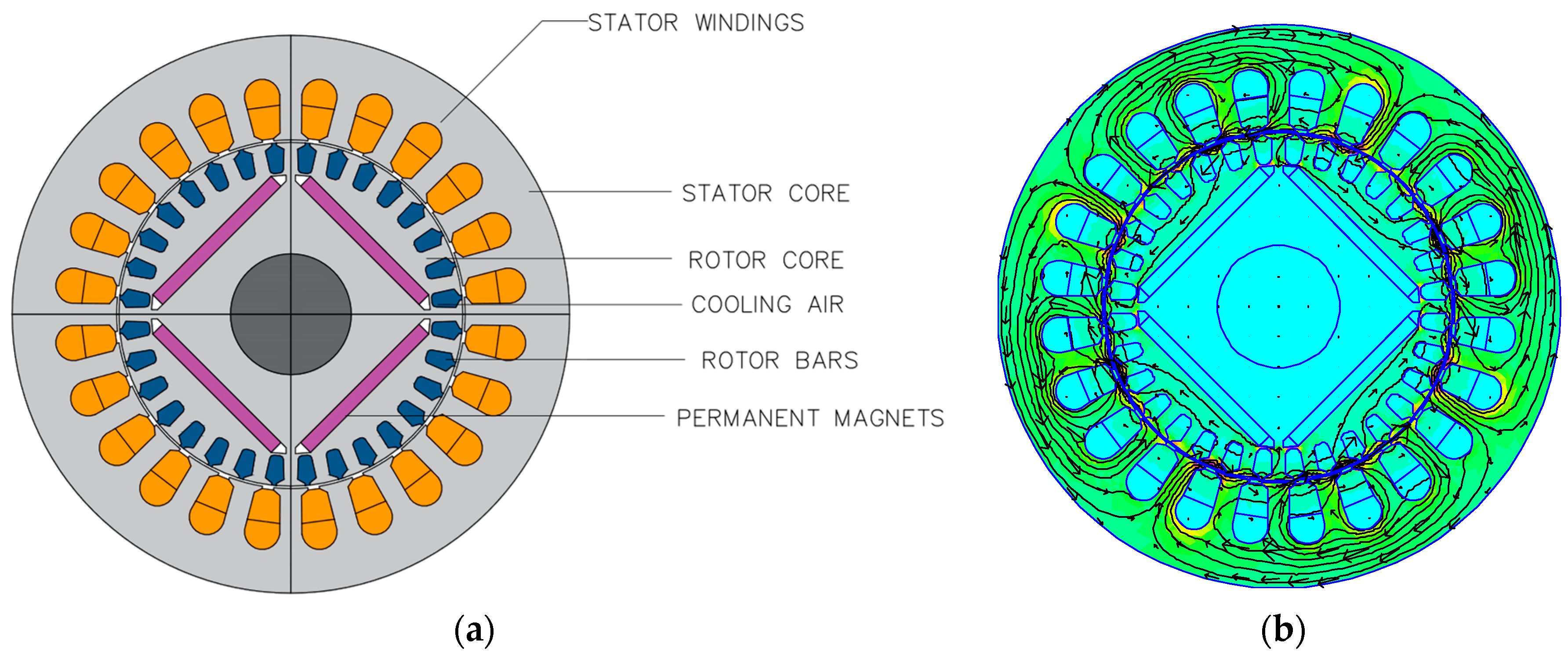

2.2. Permanent-Magnet Motors

3. Methodology

4. Results and Discussion

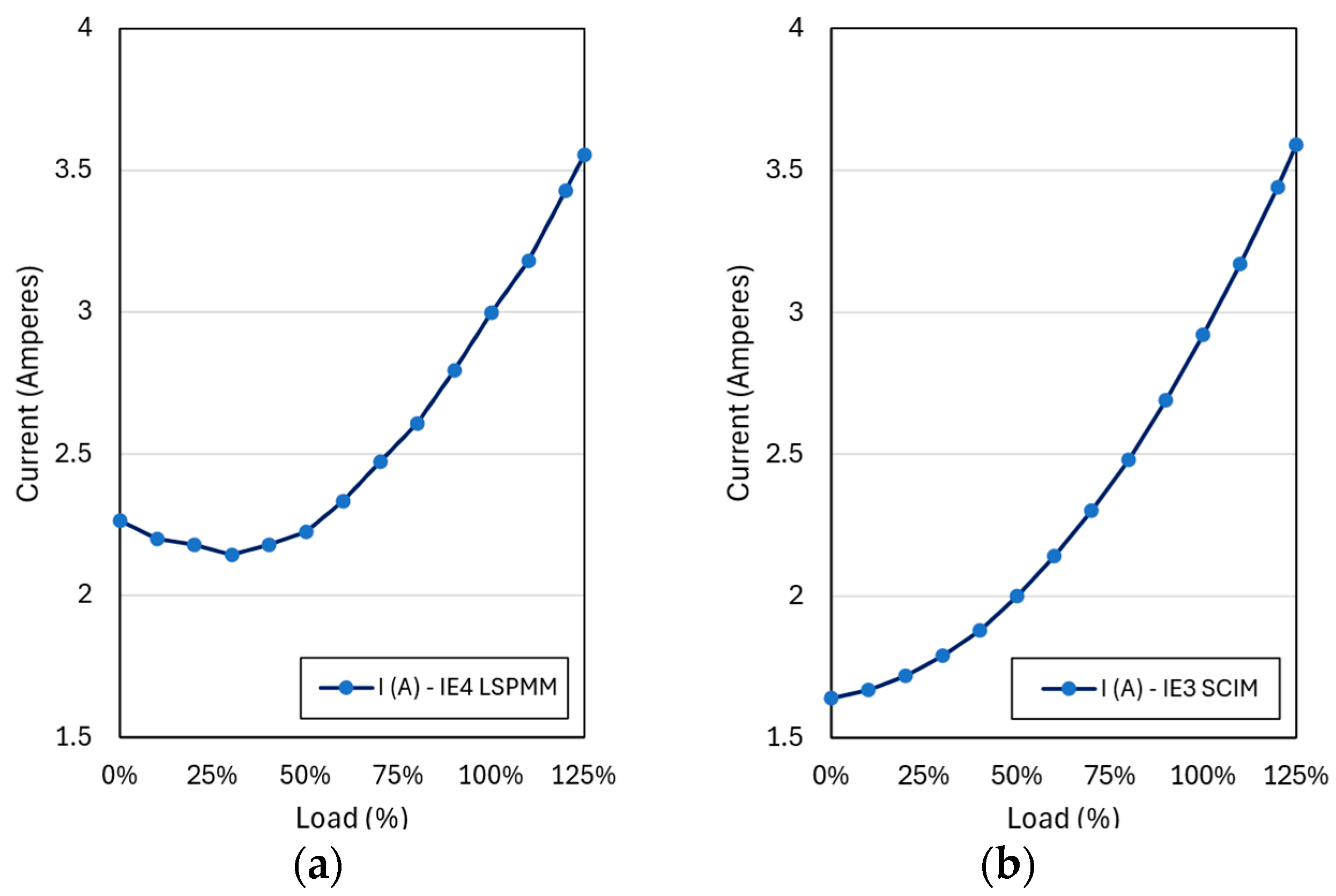

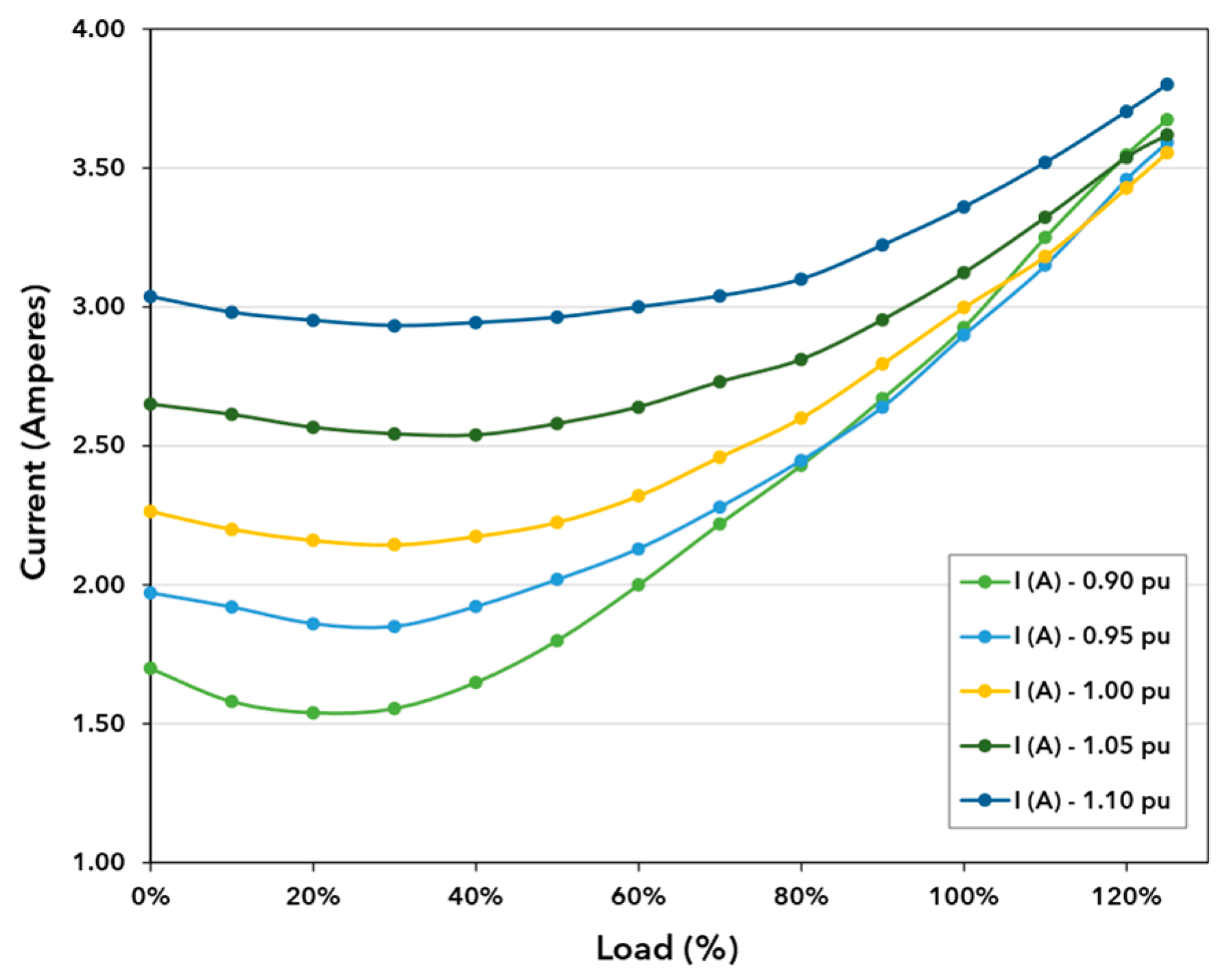

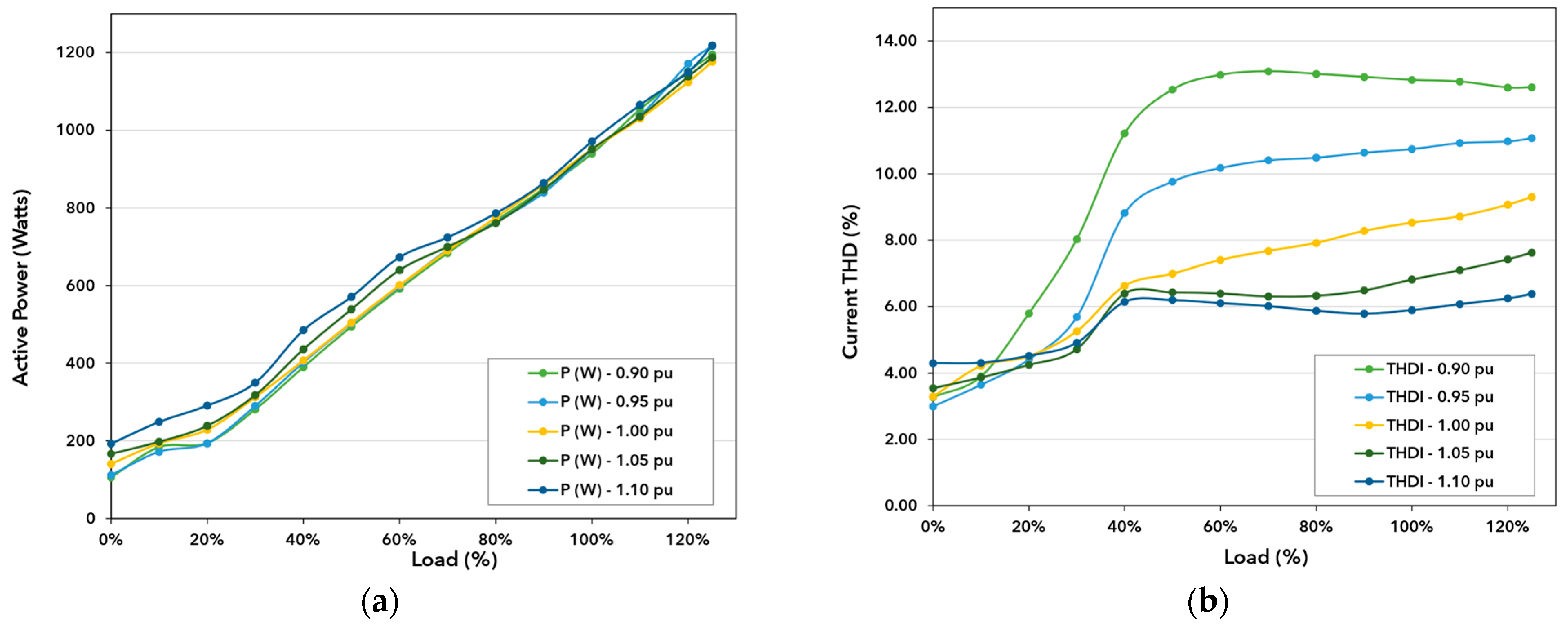

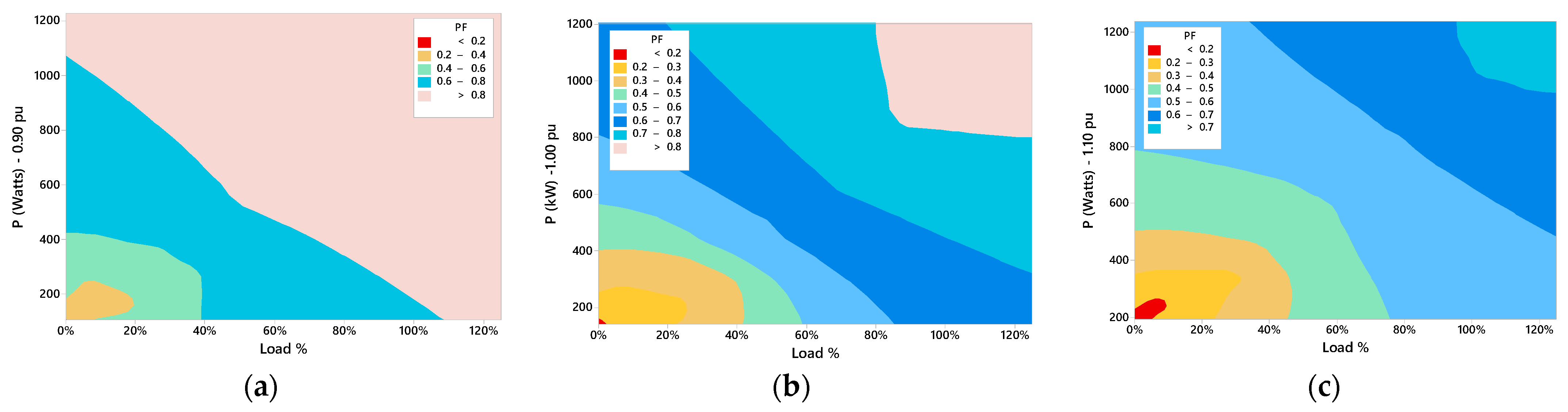

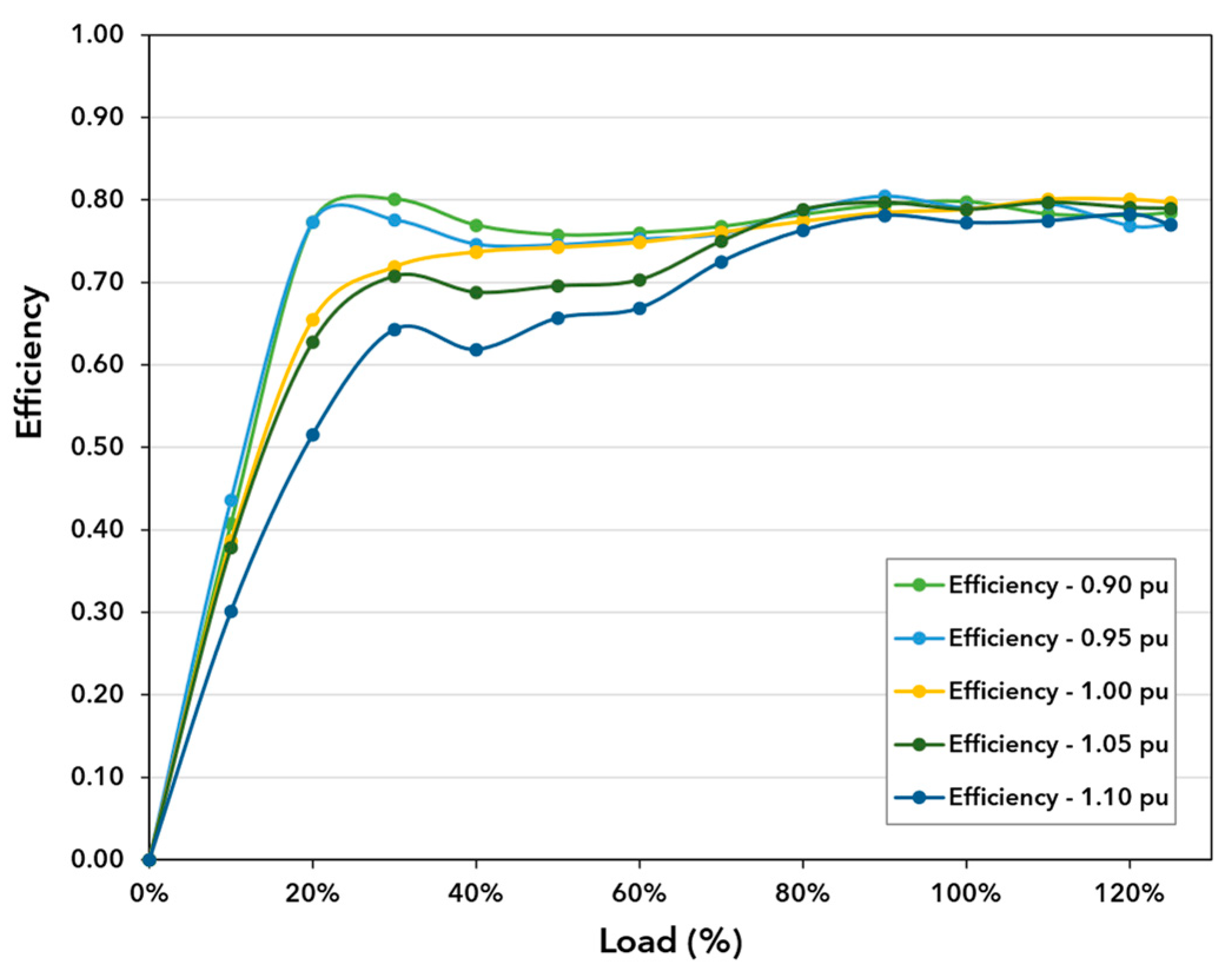

4.1. Technical Analysis

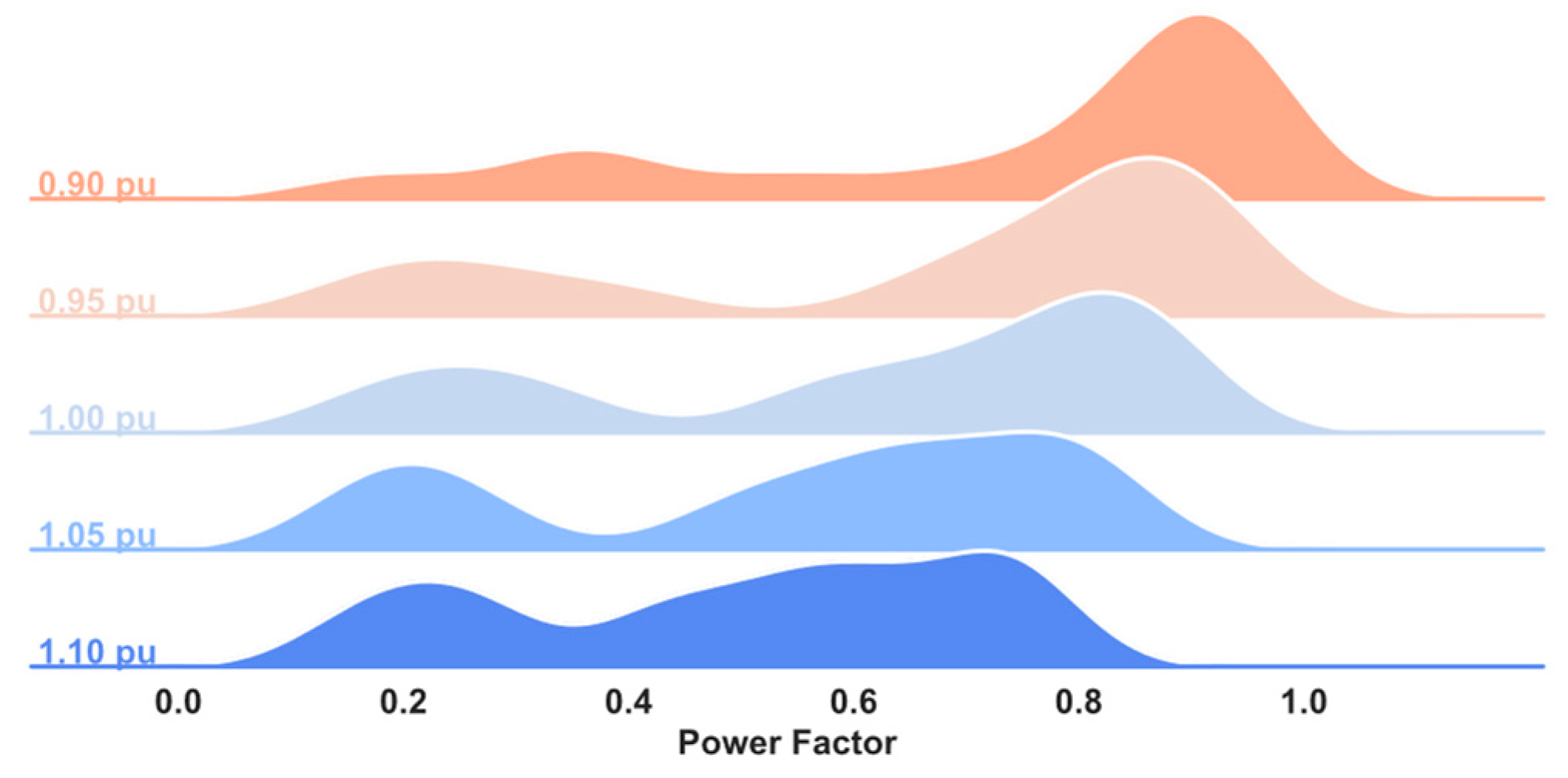

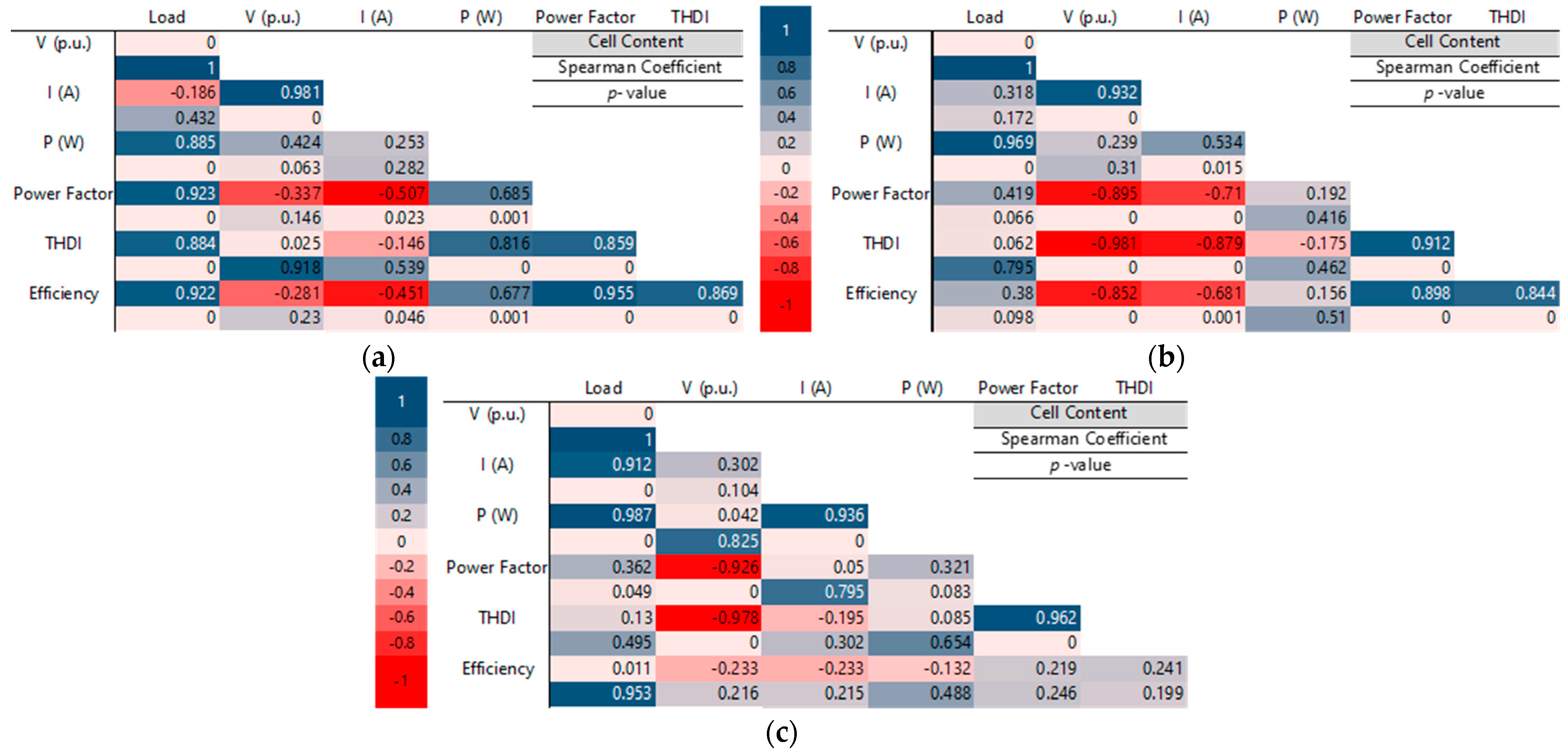

4.2. Statistical Analysis

4.3. Economic Analysis

4.4. Temperature Assessment

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEC 60034-2-1:2014|IEC Webstore|Energy Efficiency, Smart City. Available online: https://webstore.iec.ch/publication/121 (accessed on 27 July 2022).

- de Almeida, A.T.; Fong, J.; Falkner, H.; Bertoldi, P. Policy Options to Promote Energy Efficient Electric Motors and Drives in the EU. Renew. Sustain. Energy Rev. 2017, 74, 1275–1286. [Google Scholar] [CrossRef]

- De Almeida, A.; Fong, J.; Brunner, C.U.; Werle, R.; Van Werkhoven, M. New Technology Trends and Policy Needs in Energy Efficient Motor Systems—A Major Opportunity for Energy and Carbon Savings. Renew. Sustain. Energy Rev. 2019, 115, 109384. [Google Scholar] [CrossRef]

- Electric Motors and Variable Speed Drives. Available online: https://ec.europa.eu/info/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/energy-label-and-ecodesign/energy-efficient-products/electric-motors_en (accessed on 25 November 2022).

- Allan, J.T. The Effect of Voltage Variation on the Operation of Induction Motors. Trans. South Afr. Inst. Electr. Eng. 1929, 20, 137–155. [Google Scholar]

- Power Savings Obtained from Supply Voltage Variation on Squirrel Cage Induction Motors|IEEE Conference Publication|IEEE Xplore. Available online: https://ieeexplore.ieee.org/document/4763392 (accessed on 19 April 2023).

- Investigation of Voltage and Frequency Variation on Induction Motor Core and Copper Losses|IEEE Conference Publication|IEEE Xplore. Available online: https://ieeexplore.ieee.org/document/7934894 (accessed on 19 April 2023).

- Agamloh, E.B.; Peele, S.; Grappe, J. A Comparative Analysis of Voltage Magnitude Deviation and Unbalance on Standard and Premium Efficient Induction Motors. In Proceedings of the Conference Record of 2012 Annual IEEE Pulp and Paper Industry Technical Conference (PPIC), Portland, OR, USA, 17–21 June 2012; pp. 1–8. [Google Scholar]

- Bonnett, A.H. The Impact That Voltage and Frequency Variations Have on AC Induction Motor Performance and Life in Accordance with NEMA MG-1 Standards. In Proceedings of the Conference Record of 1999 Annual Pulp and Paper Industry Technical Conference (Cat. No.99CH36338), Seattle, WA, USA, 21–25 June 1999; pp. 16–26. [Google Scholar]

- Mendes, N.; Tabora, J.M.; de Lima Tostes, M.E.; Matos, E.O.d.; H.Bezerra, U.; Moura, P.; Mendes, J.; Ferreira, F.J.T.E.; de Almeida, A.T. ANN for Motor Loading Diagnosis under Voltage Variation Conditions. In Proceedings of the 2023 IEEE Kansas Power and Energy Conference (KPEC), Manhattan, KS, USA, 27–28 April 2023; pp. 1–6. [Google Scholar]

- Tabora, J.M.; Júnior, L.C.D.S.; Tostes, M.E.d.L.; Matos, E.O.d.; Bezerra, U.H. Efficient Electric Motors Performance Under Voltage Variation Conditions. In Proceedings of the 2023 IEEE Kansas Power and Energy Conference (KPEC), Manhattan, KS, USA, 27–28 April 2023; pp. 1–6. [Google Scholar]

- Kostic, M.; Ivanovic, M.; Minic, S. Reduction of Electric Energy Consumption in Induction Motor Drives by Setting Supply Voltage. In Proceedings of the 2012 2nd International Symposium On Environment Friendly Energies And Applications, Newcastle upon Tyne, UK, 25–27 June 2012; pp. 128–133. [Google Scholar]

- Zhao, K.; Cheng, L.; Zhang, C.; Nie, D.; Cai, W. Induction Motors Lifetime Expectancy Analysis Subject to Regular Voltage Fluctuations. In Proceedings of the 2017 IEEE Electrical Power and Energy Conference (EPEC), Saskatoon, SK, Canada, 22–25 October 2017; pp. 1–6. [Google Scholar]

- Wang, W.; Lu, Z. Analysis of Model Predictive Current-Controlled Permanent Magnet Synchronous Motor Drives with Inaccurate DC Bus Voltage Measurement. Energies 2020, 13, 353. [Google Scholar] [CrossRef]

- Lee, H.-J.; Shon, J.-G. Improved Voltage Flux-Weakening Strategy of Permanent Magnet Synchronous Motor in High-Speed Operation. Energies 2021, 14, 7464. [Google Scholar] [CrossRef]

- Sikora, A.; Zielonka, A.; Woźniak, M. Minimization of Energy Losses in the BLDC Motor for Improved Control and Power Supply of the System under Static Load. Sensors 2022, 22, 1058. [Google Scholar] [CrossRef] [PubMed]

- Sikora, A.; Woźniak, M. Impact of Current Pulsation on BLDC Motor Parameters. Sensors 2021, 21, 587. [Google Scholar] [CrossRef] [PubMed]

- World Energy Outlook 2019—Analysis. Available online: https://www.iea.org/reports/world-energy-outlook-2019 (accessed on 10 June 2022).

- de Almeida, A.T.; Ferreira, F.J.T.E.; Fong, J. Perspectives on Electric Motor Market Transformation for a Net Zero Carbon Economy. Energies 2023, 16, 1248. [Google Scholar] [CrossRef]

- de Souza, D.F.; Salotti, F.A.M.; Sauer, I.L.; Tatizawa, H.; de Almeida, A.T.; Kanashiro, A.G. An Assessment of the Impact of Brazilian Energy Efficiency Policies for Electric Motors. Energy Nexus 2022, 5, 100033. [Google Scholar] [CrossRef]

- Tabora, J.M.; Tshoombe, B.K.; Fonseca, W.d.S.; Tostes, M.E.d.L.; de Matos, E.O.; Bezerra, U.H.; Silva, M.d.O.e. Virtual Modeling and Experimental Validation of the Line-Start Permanent Magnet Motor in the Presence of Harmonics. Energies 2022, 15, 8603. [Google Scholar] [CrossRef]

- Ferreira, F.J.T.E.; Baoming, G.; de Almeida, A.T. Stator Winding Connection-Mode Management in Line-Start Permanent Magnet Motors to Improve Their Efficiency and Power Factor. IEEE Trans. Energy Convers. 2013, 28, 523–534. [Google Scholar] [CrossRef]

- Tabora, J.M.; de Lima Tostes, M.E.; de Matos, E.O.; Bezerra, U.H. Voltage Unbalance Amp; Variations Impacts on IE4 Class LSPMM. In Proceedings of the 2021 14th IEEE International Conference on Industry Applications (INDUSCON), São Paulo, Brazil, 15–18 August 2021; pp. 940–946. [Google Scholar]

- Tabora, J.M.; Vieira Bezerra, F.V.; Soares, T.M.; Ortiz de Matos, E.; de Lima Tostes, M.E.; Holanda Bezerra, U. Electric Motor Degradation Indicator in Non-Ideal Supply Conditions. In Proceedings of the 2023 IEEE Workshop on Power Electronics and Power Quality Applications (PEPQA), Cali, Colombia, 5–6 October 2023; pp. 1–5. [Google Scholar]

- IEC 60038:2009 | IEC Webstore | Rural Electrification, LVDC. Available online: https://webstore.iec.ch/publication/153 (accessed on 28 November 2022).

- Motors and Generators. Available online: https://www.nema.org/standards/view/motors-and-generators (accessed on 4 July 2022).

- Cui, J.; Kramer, M.; Zhou, L.; Liu, F.; Gabay, A.; Hadjipanayis, G.; Balasubramanian, B.; Sellmyer, D. Current Progress and Future Challenges in Rare-Earth-Free Permanent Magnets. Acta Mater. 2018, 158, 118–137. [Google Scholar] [CrossRef]

- Tshoombe, B.K.; Muñoz Tabora, J.; da Silva Fonseca, W.; Emília Lima Tostes, M.; de Matos, E.O. Voltage Harmonic Impacts on Line Start Permanent Magnet Motor. In Proceedings of the 2021 14th IEEE International Conference on Industry Applications (INDUSCON), São Paulo, Brazil, 16–18 August 2021; pp. 962–968. [Google Scholar]

- Minitab 18 Statistical Software; [Computer Software]; Minitab, Inc.: State College, PA, USA, 2010; Available online: https://www.minitab.com/ (accessed on 15 August 2019).

- Heumann, C. Introduction to Statistics and Data Analysis with Exercises, Solutions and Applications in R; Springer International Publishing: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Farah, A. Livro—Curso de Probabilidades e Estatísticas Inferencial: Teoria e Prática; Instituto de Engenharia: São Paulo, Brazil, 2018. [Google Scholar]

- Spearman’s Rank-Order Correlation—A Guide to When to Use It, What It Does and What the Assumptions Are. Available online: https://statistics.laerd.com/statistical-guides/spearmans-rank-order-correlation-statistical-guide.php (accessed on 16 June 2020).

- Minitab. A Comparison of the Pearson and Spearman Correlation Methods; Minitab 18, Support; Minitab, Inc.: State College, PA, USA, 2018. [Google Scholar]

- Dincer, I.; Abu-Rayash, A. Chapter 6—Sustainability Modeling. In Energy Sustainability; Dincer, I., Abu-Rayash, A., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 119–164. ISBN 978-0-12-819556-7. [Google Scholar]

| Induction Motor Class | IE4 Class LSPMM |

|---|---|

| Power | 0.75 kW |

| Voltage | 220/380 V |

| Speed (rpm) | 1800 |

| Current (A) | 3.08/1.78 |

| Efficiency (%) | 87.4 |

| Power factor | 0.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tabora, J.M.; Correa dos Santos Júnior, L.; Ortiz de Matos, E.; Mota Soares, T.; Arrifano Manito, A.R.; de Lima Tostes, M.E.; Holanda Bezerra, U. Exploring the Effects of Voltage Variation and Load on the Electrical and Thermal Performance of Permanent-Magnet Synchronous Motors. Energies 2024, 17, 8. https://doi.org/10.3390/en17010008

Tabora JM, Correa dos Santos Júnior L, Ortiz de Matos E, Mota Soares T, Arrifano Manito AR, de Lima Tostes ME, Holanda Bezerra U. Exploring the Effects of Voltage Variation and Load on the Electrical and Thermal Performance of Permanent-Magnet Synchronous Motors. Energies. 2024; 17(1):8. https://doi.org/10.3390/en17010008

Chicago/Turabian StyleTabora, Jonathan Muñoz, Lauro Correa dos Santos Júnior, Edson Ortiz de Matos, Thiago Mota Soares, Allan Rodrigo Arrifano Manito, Maria Emília de Lima Tostes, and Ubiratan Holanda Bezerra. 2024. "Exploring the Effects of Voltage Variation and Load on the Electrical and Thermal Performance of Permanent-Magnet Synchronous Motors" Energies 17, no. 1: 8. https://doi.org/10.3390/en17010008