An Overview of Phase Change Materials and Their Applications in Pavement

Abstract

1. Introduction

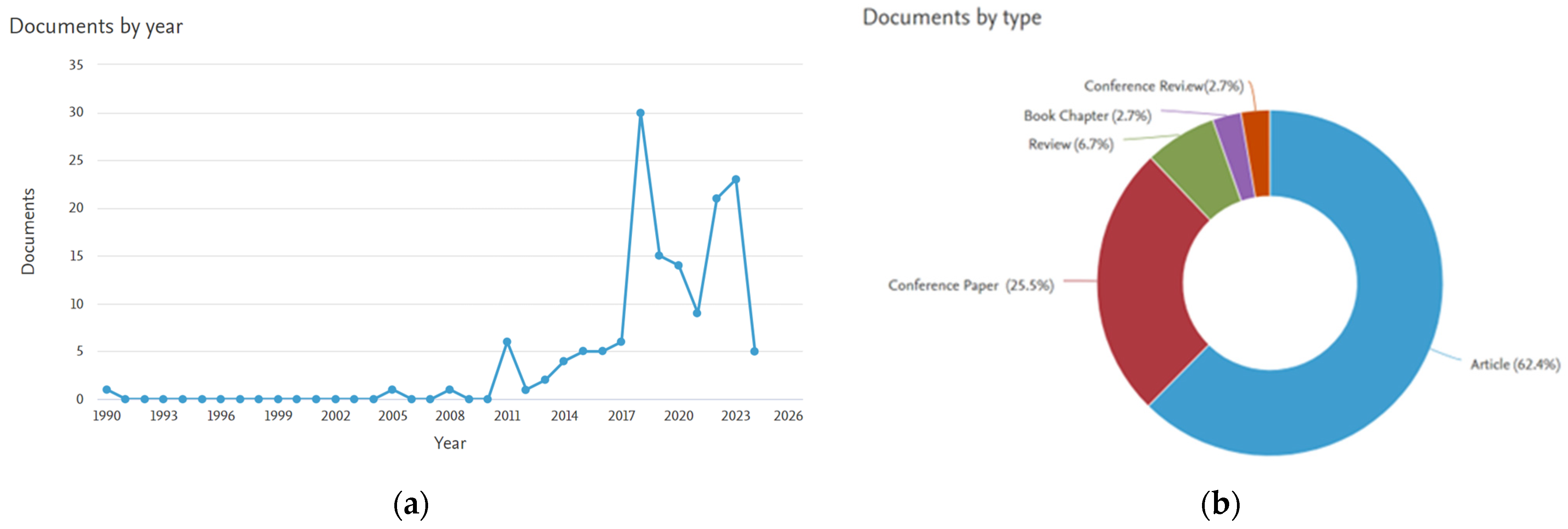

2. Methods

3. Phase Change Materials

3.1. Organic

3.2. Inorganic

3.3. Eutectic

3.4. Current Application of PCM

4. Pavement Application of Phase Change Materials

4.1. Main Area of Investigations

- Thermal properties: latent heat of fusion, thermal conductivity, specific heat capacity, and phase change temperature.

- Chemical properties: corrosive, toxicity, flammability, chemical stability.

- Physical properties: volume changes, density, durability against multiple freeze and thaw cycles.

- Kinetic: nucleation rate, speed of crystal growth, and supercooling.

- Economic factors: availability and price.

4.2. Technologies of Manufacturing Pavement Composite

4.3. Key Advantages

4.4. Main Challenges

5. Further Perspectives

6. Conclusions

- Improvement numerical modeling for complex problems;

- Development of modern PCM materials with wider possibilities;

- Development carriers, also with usage waste materials;

- Improvement of the technology of encapsulation and impregnation;

- Implementation of complex methods for environmental assessment.

Author Contributions

Funding

Conflicts of Interest

References

- Reddy, V.J.; Ghazali, M.F.; Kumarasamy, S. Advancements in Phase Change Materials for Energy-Efficient Building Construction: A Comprehensive Review. J. Energy Storage 2024, 81, 110494. [Google Scholar] [CrossRef]

- Łach, M.; Pławecka, K.; Bąk, A.; Adamczyk, M.; Bazan, P.; Kozub, B.; Korniejenko, K.; Lin, W.-T. Review of Solutions for the Use of Phase Change Materials in Geopolymers. Materials 2021, 14, 6044. [Google Scholar] [CrossRef] [PubMed]

- Kakar, M.R.; Refaa, Z.; Bueno, M.; Worlitschek, J.; Stamatiou, A.; Partl, M.N. Investigating Bitumen’s Direct Interaction with Tetradecane as Potential Phase Change Material for Low Temperature Applications. Road Mater. Pavement Des. 2020, 21, 2356–2363. [Google Scholar] [CrossRef]

- Fantini, P. Phase Change Memory Applications: The History, the Present and the Future. J. Phys. D Appl. Phys. 2020, 53, 283002. [Google Scholar] [CrossRef]

- Kheradmand, M.; Azenha, M.; De Aguiar, J.L.B.; Castro-Gomes, J. Experimental and Numerical Studies of Hybrid PCM Embedded in Plastering Mortar for Enhanced Thermal Behaviour of Buildings. Energy 2016, 94, 250–261. [Google Scholar] [CrossRef]

- Guarino, F.; Athienitis, A.; Cellura, M.; Bastien, D. PCM Thermal Storage Design in Buildings: Experimental Studies and Applications to Solaria in Cold Climates. Appl. Energy 2017, 185, 95–106. [Google Scholar] [CrossRef]

- Li, Y.; Nord, N.; Xiao, Q.; Tereshchenko, T. Building Heating Applications with Phase Change Material: A Comprehensive Review. J. Energy Storage 2020, 31, 101634. [Google Scholar] [CrossRef]

- Bouhal, T.; El Rhafiki, T.; Kousksou, T.; Jamil, A.; Zeraouli, Y. PCM Addition inside Solar Water Heaters: Numerical Comparative Approach. J. Energy Storage 2018, 19, 232–246. [Google Scholar] [CrossRef]

- Bąk, A.; Pławecka, K.; Łach, M. Comparison of Thermal Conductivity of Foamed Geopolymers Containing Phase Change Materials. J. Phys. Conf. Ser. 2023, 2423, 012003. [Google Scholar] [CrossRef]

- Bąk, A.; Pławecka, K.; Bazan, P.; Łach, M. Influence of the Addition of Phase Change Materials on Thermal Insulation Properties of Foamed Geopolymer Structures Based on Fly Ash. Energy 2023, 278, 127624. [Google Scholar] [CrossRef]

- Somani, P.; Gaur, A. Evaluation and Reduction of Temperature Stresses in Concrete Pavement by Using Phase Changing Material. Mater. Today Proc. 2020, 32, 856–864. [Google Scholar] [CrossRef]

- Partl, M.N. Quest for Improving Service Life of Asphalt Roads. RILEM Tech. Lett. 2020, 4, 154–162. [Google Scholar] [CrossRef]

- Mehling, H.; Brütting, M.; Haussmann, T. PCM Products and Their Fields of Application—An Overview of the State in 2020/2021. J. Energy Storage 2022, 51, 104354. [Google Scholar] [CrossRef]

- Li, F.; Zhou, S.; Chen, S.; Yang, J.; Zhu, X.; Du, Y.; Yang, Z. Low-Temperature Organic Phase Change Material Microcapsules for Asphalt Pavement: Preparation, Characterisation and Application. J. Microencapsul. 2018, 35, 635–642. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Wang, H.; You, Z.; Hossiney, N. Application of Phase Change Material in Asphalt Mixture—A Review. Constr. Build. Mater. 2020, 263, 120219. [Google Scholar] [CrossRef]

- Zhao, H.; Guo, J.; Ma, S.; Zhang, H.; Su, C.; Wang, X.; Li, Z.; Wei, J.; Cui, S. Effect of Solid-Solid Phase Change Material’s Direct Interaction on Physical and Rheological Properties of Asphalt. Coatings 2022, 12, 625. [Google Scholar] [CrossRef]

- Marani, A.; Nehdi, M.L. Integrating Phase Change Materials in Construction Materials: Critical Review. Constr. Build. Mater. 2019, 217, 36–49. [Google Scholar] [CrossRef]

- Barreneche, C.; Navarro, M.E.; Cabeza, L.F.; Fernández, A.I. New Database to Select Phase Change Materials: Chemical Nature, Properties, and Applications. J. Energy Storage 2015, 3, 18–24. [Google Scholar] [CrossRef]

- Farnam, Y.; Krafcik, M.; Liston, L.; Washington, T.; Erk, K.; Tao, B.; Weiss, J. Evaluating the Use of Phase Change Materials in Concrete Pavement to Melt Ice and Snow. J. Mater. Civ. Eng. 2016, 28, 04015161. [Google Scholar] [CrossRef]

- Sharifi, N.P.; Sakulich, A. Application of Phase Change Materials to Improve the Thermal Performance of Cementitious Material. Energy Build. 2015, 103, 83–95. [Google Scholar] [CrossRef]

- Ghasemi, K.; Tasnim, S.; Mahmud, S. PCM, Nano/Microencapsulation and Slurries: A Review of Fundamentals, Categories, Fabrication, Numerical Models and Applications. Sustain. Energy Technol. Assess. 2022, 52, 102084. [Google Scholar] [CrossRef]

- Analyze Search Results. Available online: https://www.scopus.com/Term/Analyzer.Uri?Sort=plf-f&src=s&sid=de161c49f931b5c99e9295953af65520&sot=a&sdt=a&sl=48&s=%28TITLE-ABS-KEY%28pavement%29+AND+TITLE-ABS-KEY%28PCM%29%29&origin=resultslist&count=10&analyzeResults=Analyze+results (accessed on 11 March 2024).

- Akeiber, H.J.; Hosseini, S.E.; Hussen, H.M.; Wahid, M.A.; Mohammad, A.T. Thermal Performance and Economic Evaluation of a Newly Developed Phase Change Material for Effective Building Encapsulation. Energy Convers. Manag. 2017, 150, 48–61. [Google Scholar] [CrossRef]

- Mizwar, I.K.; Napiah, M.; Sutanto, M.H. Thermal Properties of Cool Asphalt Concrete Containing Phase Change Material. IOP Conf. Ser. Mater. Sci. Eng. 2019, 527, 012049. [Google Scholar] [CrossRef]

- Kravchenko, E.; Liu, J.; Li, X. Numerical Modeling of the Thermal Performance of Soil Containing Microencapsulated PCM. Constr. Build. Mater. 2021, 298, 123865. [Google Scholar] [CrossRef]

- Farnam, Y.; Esmaeeli, H.S.; Zavattieri, P.D.; Haddock, J.; Weiss, J. Incorporating Phase Change Materials in Concrete Pavement to Melt Snow and Ice. Cem. Concr. Compos. 2017, 84, 134–145. [Google Scholar] [CrossRef]

- Manning, B.J.; Bender, P.R.; Cote, S.A.; Lewis, R.A.; Sakulich, A.R.; Mallick, R.B. Assessing the Feasibility of Incorporating Phase Change Material in Hot Mix Asphalt. Sustain. Cities Soc. 2015, 19, 11–16. [Google Scholar] [CrossRef]

- Zhang, D.; Muhammad Sani, B.; Xu, P.; Liu, K.; Gu, F. Preparation and Characterization of Binary Eutectic Phase Change Material Laden with Thermal Conductivity Enhancer for Cooling Steel Slag Asphalt Pavement. Constr. Build. Mater. 2023, 388, 131688. [Google Scholar] [CrossRef]

- Kim, A.; Wert, N.A.; Gowd, E.B.; Patel, R. Recent Progress in PEG-Based Composite Phase Change Materials. Polym. Rev. 2023, 63, 1078–1129. [Google Scholar] [CrossRef]

- Landi, S.; Segundo, I.R.; Homem, N.; Sousa, J.; Freitas, E.; Costa, M.F.M.; Carneiro, J. Reducing the Impact of the Sunlight in Urban Areas Using Asphalt Mixtures with Phase Change Materials: A Review in Scopus in the Last Three Years. J. Phys. Conf. Ser. 2022, 2407, 012022. [Google Scholar] [CrossRef]

- Ma, B.; Adhikari, S.; Chang, Y.; Ren, J.; Liu, J.; You, Z. Preparation of Composite Shape-Stabilized Phase Change Materials for Highway Pavements. Constr. Build. Mater. 2013, 42, 114–121. [Google Scholar] [CrossRef]

- Asadi, I.; Jacobsen, S.; Baghban, M.H.; Maghfouri, M.; Hashemi, M. Reviewing the Potential of Phase Change Materials in Concrete Pavements for Anti-Freezing Capabilities and Urban Heat Island Mitigation. Buildings 2023, 13, 3072. [Google Scholar] [CrossRef]

- Rajamony, R.K.; Paw, J.K.S.; Pasupuleti, J.; Pandey, A.K.; Yaw, C.T.; Tiong, S.K.; Yusaf, T.; Samykano, M.; Sofiah, A.G.N.; Laghari, I.A.; et al. Experimental Investigation on the Performance of Binary Carbon-Based Nano-Enhanced Inorganic Phase Change Materials for Thermal Energy Storage Applications. J. Energy Storage 2024, 86, 111373. [Google Scholar] [CrossRef]

- Bhamare, D.K.; Rathod, M.K.; Banerjee, J.; Arıcı, M. Investigation of the Effect of Air Layer Thickness on the Thermal Performance of the PCM Integrated Roof. Buildings 2023, 13, 488. [Google Scholar] [CrossRef]

- Ma, B.; Wei, K.; Huang, X.F.; Shi, W.S.; Chen, S.S.; Hu, Y.P.; Shi, H.T. Preparation and Investigation of NiTi Alloy Phase-Change Heat Storage Asphalt Mixture. J. Mater. Civ. Eng. 2020, 32, 04020250. [Google Scholar] [CrossRef]

- Dai, J.; Ma, F.; Fu, Z.; Liu, J.; Li, C.; Hou, Y.; Wu, H. Effectiveness of the Different Eutectic Phase-Change Materials in Cooling Asphalt Pavement. Constr. Build. Mater. 2023, 407, 133491. [Google Scholar] [CrossRef]

- Haily, E.; Ait Ousaleh, H.; Zari, N.; Faik, A.; Bouhfid, R.; Qaiss, A. Use of a Form-Stable Phase Change Material to Improve Thermal Properties of Phosphate Sludge-Based Geopolymer Mortar. Constr. Build. Mater. 2023, 386, 131570. [Google Scholar] [CrossRef]

- Baskar, I.; Chellapandian, M.; Jaswanth, S.S.H. Development of a Novel Composite Phase Change Material Based Paints and Mortar for Energy Storage Applications in Buildings. J. Energy Storage 2022, 55, 105829. [Google Scholar] [CrossRef]

- Anupam, B.R.; Sahoo, U.C.; Rath, P. Phase Change Materials for Pavement Applications: A Review. Constr. Build. Mater. 2020, 247, 118553. [Google Scholar] [CrossRef]

- Li, Y.; Du, Y.; Xu, T.; Wu, H.; Zhou, X.; Ling, Z.; Zhang, Z. Optimization of Thermal Management System for Li-Ion Batteries Using Phase Change Material. Appl. Therm. Eng. 2018, 131, 766–778. [Google Scholar] [CrossRef]

- Li, Z.; Gong, Y.; Xu, A.; Zhao, J.; Li, Q.; Dong, L.; Xiong, C.; Jiang, M. Relaxation-Induced Significant Room-Temperature Dielectric Pulsing Effects. Adv. Funct. Mater. 2023, 33, 2301009. [Google Scholar] [CrossRef]

- Gong, Y.; Zhao, J.; Li, Z.; Huang, J.; Zhang, Y.; Dong, L.; Xiong, C.; Jiang, M. Unparalleled Dielectric-Switching Effects Caused by Dual Polarization Synergy. Adv. Funct. Mater. 2023, 33, 2214544. [Google Scholar] [CrossRef]

- Korniejenko, K.; Nykiel, M.; Choinska, M.; Jexembayeva, A.; Konkanov, M.; Aruova, L. An Overview of Micro- and Nano-Dispersion Additives for Asphalt and Bitumen for Road Construction. Buildings 2023, 13, 2948. [Google Scholar] [CrossRef]

- Ricklefs, A.; Thiele, A.M.; Falzone, G.; Sant, G.; Pilon, L. Thermal Conductivity of Cementitious Composites Containing Microencapsulated Phase Change Materials. Int. J. Heat Mass Transf. 2017, 104, 71–82. [Google Scholar] [CrossRef]

- Šavija, B.; Schlangen, E. Use of Phase Change Materials (PCMs) to Mitigate Early Age Thermal Cracking in Concrete: Theoretical Considerations. Constr. Build. Mater. 2016, 126, 332–344. [Google Scholar] [CrossRef]

- Cerón, I.; Neila, J.; Khayet, M. Experimental Tile with Phase Change Materials (PCM) for Building Use. Energy Build. 2011, 43, 1869–1874. [Google Scholar] [CrossRef]

- Hyun, S.W.; Kim, S.; Jeong, H.; Ko, H.S.; Shin, D.H. Development of Snow Removal System Using Embedded Piped inside Road with Solar Thermal Energy Collector and Packed Bed Latent Heat Thermal Energy Storage. J. Energy Storage 2024, 83, 110737. [Google Scholar] [CrossRef]

- Guan, B.; Ma, B.; Qin, F. Application of Asphalt Pavement with Phase Change Materials to Mitigate Urban Heat Island Effect. In Proceedings of the 2011 International Symposium on Water Resource and Environmental Protection, Xi’an, China, 20–22 May 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 2389–2392. [Google Scholar]

- Anupam, B.R.; Sahoo, U.C.; Rath, P.; Pattnaik, S. Thermal Behavior of Phase Change Materials in Concrete Pavements: A Long-Term Thermal Impact Analysis of Two Organic Mixtures. Int. J. Pavement Res. Technol. 2022, 17, 366–378. [Google Scholar] [CrossRef]

- Zhang, J.; Dong, Z.; Sun, G. Properties of SBS Modified Asphalt Containing Phase Change Materials. In Proceedings of the International Conference on Road and Airfield Pavement Technology, Beijing, China, 6–8 February 2023; American Society of Civil Engineers: Reston, VA, USA, 2023; pp. 512–523. [Google Scholar]

- Najemi, L.; Belyamani, I.; Bouya, M. Effect of Blending of Medium-Temperature Phase Change Material on the Bitumen Storage Heat. Heliyon 2023, 9, e22040. [Google Scholar] [CrossRef]

- Saberi K., F.; Wang, Y.D.; Liu, J. Improving Rheological and Thermal Performance of Gilsonite-Modified Binder with Phase Change Materials. Constr. Build. Mater. 2023, 399, 132557. [Google Scholar] [CrossRef]

- Huang, Z.; Wei, J.; Fu, Q.; Zhou, Y.; Lei, M.; Pan, Z.; Zhang, X. Preparation and Experimental Study of Phase Change Materials for Asphalt Pavement. Materials 2023, 16, 6002. [Google Scholar] [CrossRef]

- Cheng, C.; Liu, J.; Gong, F.; Fu, Y.; Cheng, X.; Qiao, J. Performance and Evaluation Models for Different Structural Types of Asphalt Mixture Using Shape-Stabilized Phase Change Material. Constr. Build. Mater. 2023, 383, 131411. [Google Scholar] [CrossRef]

- Zhang, J.; Dong, Z.; Sun, G.; Qi, Y.; Zhu, X.; Li, Y. Roles of Phase Change Materials on the Morphological, Physical, Rheological and Temperature Regulating Performances of High-Viscosity Modified Asphalt. Sci. Total Environ. 2023, 875, 162632. [Google Scholar] [CrossRef] [PubMed]

- Jiao, W.; Sha, A.; Zhang, J.; Jia, M.; Jiang, W.; Hu, L. Design and Properties of Polyurethane Solid–Solid Phase-Change Granular Temperature Regulation Asphalt Mixtures. Sol. Energy 2023, 253, 47–57. [Google Scholar] [CrossRef]

- Anupam, B.R.; Sahoo, U.C.; Rath, P. Experimental and Numerical Investigations on an Organic Phase Change Material Incorporated Cool Concrete Pavement. TOCIEJ 2022, 17, e187414952210310. [Google Scholar] [CrossRef]

- Anupam, B.R.; Sahoo, U.C.; Rath, P.; Bhattacharya, A. Thermal Performance Assessment of PCM Incorporated Cool Concrete Pavements Using Numerical Analysis. Int. J. Pavement Eng. 2023, 24, 2089884. [Google Scholar] [CrossRef]

- Wang, X.; Ma, B.; Wei, K.; Si, W.; Kang, X.; Fang, Y.; Zhang, H.; Shi, J.; Zhou, X. Thermal Storage Properties of Polyurethane Solid-Solid Phase-Change Material with Low Phase-Change Temperature and Its Effects on Performance of Asphalt Binders. J. Energy Storage 2022, 55, 105686. [Google Scholar] [CrossRef]

- Betancourt-Jimenez, D.; Montoya, M.; Haddock, J.; Youngblood, J.P.; Martinez, C.J. Regulating Asphalt Pavement Temperature Using Microencapsulated Phase Change Materials (PCMs). Constr. Build. Mater. 2022, 350, 128924. [Google Scholar] [CrossRef]

- Ru, C.; Li, G.; Guo, F.; Sun, X.; Yu, D.; Chen, Z. Experimental Evaluation of the Properties of Recycled Aggregate Pavement Brick with a Composite Shaped Phase Change Material. Materials 2022, 15, 5565. [Google Scholar] [CrossRef] [PubMed]

- Dai, M.; Wang, S.; Deng, J.; Gao, Z.; Liu, Z. Study on the Cooling Effect of Asphalt Pavement Blended with Composite Phase Change Materials. Materials 2022, 15, 3208. [Google Scholar] [CrossRef]

- Dai, J.; Ma, F.; Fu, Z.; Li, C.; Wu, D.; Shi, K.; Dong, W.; Wen, Y.; Jia, M. Assessing the Direct Interaction of Asphalt Binder with Stearic Acid/Palmitic Acid Binary Eutectic Phase Change Material. Constr. Build. Mater. 2022, 320, 126251. [Google Scholar] [CrossRef]

- Ren, Y.-X.; Hao, P.-W. Low-Temperature Performance of Asphalt Mixtures Modified by Microencapsulated Phase Change Materials with Various Graphene Contents. Coatings 2022, 12, 287. [Google Scholar] [CrossRef]

- BR, A.; Sahoo, U.C.; Rath, P. Thermal and Mechanical Performance of Phase Change Material Incorporated Concrete Pavements. Road Mater. Pavement Des. 2022, 23, 1287–1304. [Google Scholar] [CrossRef]

- Cheng, C.; Gong, F.; Fu, Y.; Liu, J.; Qiao, J. Effect of Polyethylene Glycol/Polyacrylamide Graft Copolymerizaton Phase Change Materials on the Performance of Asphalt Mixture for Road Engineering. J. Mater. Res. Technol. 2021, 15, 1970–1983. [Google Scholar] [CrossRef]

- Cheng, C.; Cheng, G.; Gong, F.; Fu, Y.; Qiao, J. Performance Evaluation of Asphalt Mixture Using Polyethylene Glycol Polyacrylamide Graft Copolymer as Solid–Solid Phase Change Materials. Constr. Build. Mater. 2021, 300, 124221. [Google Scholar] [CrossRef]

- Dai, J.; Ma, F.; Fu, Z.; Li, C.; Jia, M.; Shi, K.; Wen, Y.; Wang, W. Applicability Assessment of Stearic Acid/Palmitic Acid Binary Eutectic Phase Change Material in Cooling Pavement. Renew. Energy 2021, 175, 748–759. [Google Scholar] [CrossRef]

- Liao, W.; Zeng, C.; Zhuang, Y.; Ma, H.; Deng, W.; Huang, J. Mitigation of Thermal Curling of Concrete Slab Using Phase Change Material: A Feasibility Study. Cem. Concr. Compos. 2021, 120, 104021. [Google Scholar] [CrossRef]

- Zhu, S.; Ji, T.; Niu, D.; Yang, Z. Investigation of PEG/Mixed Metal Oxides as a New Form-Stable Phase Change Material for Thermoregulation and Improved UV Ageing Resistance of Bitumen. RSC Adv. 2020, 10, 44903–44911. [Google Scholar] [CrossRef] [PubMed]

- Ma, B.; Chen, S.; Ren, Y.; Zhou, X. The Thermoregulation Effect of Microencapsulated Phase-Change Materials in an Asphalt Mixture. Constr. Build. Mater. 2020, 231, 117186. [Google Scholar] [CrossRef]

- Ma, B.; Wang, X.; Zhou, X.; Wei, K.; Huang, W. Measurement and Analysis of Thermophysical Parameters of the Epoxy Resin Composites Shape-Stabilized Phase Change Material. Constr. Build. Mater. 2019, 223, 368–376. [Google Scholar] [CrossRef]

- Kakar, M.R.; Refaa, Z.; Worlitschek, J.; Stamatiou, A.; Partl, M.N.; Bueno, M. Effects of Aging on Asphalt Binders Modified with Microencapsulated Phase Change Material. Compos. Part B Eng. 2019, 173, 107007. [Google Scholar] [CrossRef]

- Kakar, M.R.; Refaa, Z.; Worlitschek, J.; Stamatiou, A.; Partl, M.N.; Bueno, M. Thermal and Rheological Characterization of Bitumen Modified with Microencapsulated Phase Change Materials. Constr. Build. Mater. 2019, 215, 171–179. [Google Scholar] [CrossRef]

- Du, Y.; Liu, P.; Wang, J.; Wang, H.; Hu, S.; Tian, J.; Li, Y. Laboratory Investigation of Phase Change Effect of Polyethylene Glycolon on Asphalt Binder and Mixture Performance. Constr. Build. Mater. 2019, 212, 1–9. [Google Scholar] [CrossRef]

- Kakar, M.R.; Refaa, Z.; Worlitschek, J.; Stamatiou, A.; Partl, M.N.; Bueno, M. Use of Microencapsulated Phase Change Materials in Bitumen to Mitigate the Thermal Distresses in Asphalt Pavements. In RILEM 252-CMB Symposium; Poulikakos, L.D., Cannone Falchetto, A., Wistuba, M.P., Hofko, B., Porot, L., Di Benedetto, H., Eds.; RILEM Bookseries; Springer International Publishing: Cham, Switzerland, 2019; Volume 20, pp. 129–135. ISBN 978-3-030-00475-0. [Google Scholar]

- Mahedi, M.; Cetin, B.; Cetin, K.S. Freeze-Thaw Performance of Phase Change Material (PCM) Incorporated Pavement Subgrade Soil. Constr. Build. Mater. 2019, 202, 449–464. [Google Scholar] [CrossRef]

- Yeon, J.H.; Kim, K.-K. Potential Applications of Phase Change Materials to Mitigate Freeze-Thaw Deteriorations in Concrete Pavement. Constr. Build. Mater. 2018, 177, 202–209. [Google Scholar] [CrossRef]

- Zhou, X.; Kastiukas, G.; Lantieri, C.; Tataranni, P.; Vaiana, R.; Sangiorgi, C. Mechanical and Thermal Performance of Macro-Encapsulated Phase Change Materials for Pavement Application. Materials 2018, 11, 1398. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Huang, L.; Zhang, H. Study on Anti-Freezing Functional Design of Phase Change and Temperature Control Composite Bridge Decks. Constr. Build. Mater. 2016, 122, 714–720. [Google Scholar] [CrossRef]

- Tian, Y.; Ma, B.; Liu, F.; Li, N.; Zhou, X. Thermoregulation Effect Analysis of Microencapsulated Phase Change Thermoregulation Agent for Asphalt Pavement. Constr. Build. Mater. 2019, 221, 139–150. [Google Scholar] [CrossRef]

- She, Z.; Wei, Z.; Young, B.A.; Falzone, G.; Neithalath, N.; Sant, G.; Pilon, L. Examining the Effects of Microencapsulated Phase Change Materials on Early-Age Temperature Evolutions in Realistic Pavement Geometries. Cem. Concr. Compos. 2019, 103, 149–159. [Google Scholar] [CrossRef]

- Arora, A.; Sant, G.; Neithalath, N. Numerical Simulations to Quantify the Influence of Phase Change Materials (PCMs) on the Early- and Later-Age Thermal Response of Concrete Pavements. Cem. Concr. Compos. 2017, 81, 11–24. [Google Scholar] [CrossRef]

- Kim, S.; Oh, H.J.; Han, S.J.; Ko, H.S.; Shin, Y.; Shin, D.H. Development of Black-Ice Removal System with Latent Heat Thermal Energy Storage and Solar Thermal Collectors. Energy 2022, 244, 122721. [Google Scholar] [CrossRef]

- Pinheiro, C.; Landi, S.; Lima, O.; Ribas, L.; Hammes, N.; Segundo, I.R.; Homem, N.C.; Castelo Branco, V.; Freitas, E.; Costa, M.F.; et al. Advancements in Phase Change Materials in Asphalt Pavements for Mitigation of Urban Heat Island Effect: Bibliometric Analysis and Systematic Review. Sensors 2023, 23, 7741. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, Y.; Jia, J.; Sun, H.; Wang, H.; Qiao, H. Preparation and Characterization of Temperature-Adjusting Asphalt with Diatomite-Supported PEG as an Additive. J. Mater. Civ. Eng. 2020, 32, 04020019. [Google Scholar] [CrossRef]

- Yinfei, D.; Pusheng, L.; Jiacheng, W.; Hancheng, D.; Hao, W.; Yingtao, L. Effect of Lightweight Aggregate Gradation on Latent Heat Storage Capacity of Asphalt Mixture for Cooling Asphalt Pavement. Constr. Build. Mater. 2020, 250, 118849. [Google Scholar] [CrossRef]

- Giro-Paloma, J.; Martínez, M.; Cabeza, L.F.; Fernández, A.I. Types, Methods, Techniques, and Applications for Microencapsulated Phase Change Materials (MPCM): A Review. Renew. Sustain. Energy Rev. 2016, 53, 1059–1075. [Google Scholar] [CrossRef]

- Somani, P.; Gaur, A. Temperature Sensitivity Analysis on Mechanical Properties of Phase Changing Material Incorporated Rigid Pavement. Mater. Today Proc. 2023, 93, 387–393. [Google Scholar] [CrossRef]

- Zhang, Z.; Mao, H.; Kong, Y.; Niu, P.; Zheng, J.; Liu, P.; Wang, W.; Li, Y.; Yang, X. Re-Designing Cellulosic Core–Shell Composite Fibers for Advanced Photothermal and Thermal-Regulating Performance. Small 2024, 20, 2305924. [Google Scholar] [CrossRef]

- Yuan, J.; He, P.; Li, H.; Xu, X.; Sun, W. Preparation and Performance Analysis of Ceramsite Asphalt Mixture with Phase-Change Material. Materials 2022, 15, 6021. [Google Scholar] [CrossRef]

- Deng, Y.; Shi, X.; Kou, Y.; Chen, J.; Shi, Q. Optimized Design of Asphalt Concrete Pavement Containing Phase Change Materials Based on Rutting Performance. J. Clean. Prod. 2022, 380, 134787. [Google Scholar] [CrossRef]

- Sha, A.; Zhang, J.; Jia, M.; Jiang, W.; Jiao, W. Development of Polyurethane-Based Solid-Solid Phase Change Materials for Cooling Asphalt Pavements. Energy Build. 2022, 259, 111873. [Google Scholar] [CrossRef]

- Anupam, B.R.; Sahoo, U.C.; Chandrappa, A.K.; Rath, P. Emerging Technologies in Cool Pavements: A Review. Constr. Build. Mater. 2021, 299, 123892. [Google Scholar] [CrossRef]

- Sharifi, N.P.; Askarinejad, S.; Mahboub, K.C. Fracture Performance of a PCM-Rich Concrete Pavement under Thermal Stresses. Int. J. Pavement Eng. 2022, 23, 221–230. [Google Scholar] [CrossRef]

- Anupam, B.R.; Sahoo, U.C.; Rath, P. Effect of Two Organic Phase Change Materials on the Thermal Performance of Asphalt Pavements. Int. J. Pavement Eng. 2023, 24, 2215900. [Google Scholar] [CrossRef]

- Liston, L.C.; Farnam, Y.; Krafcik, M.; Weiss, J.; Erk, K.; Tao, B.Y. Binary Mixtures of Fatty Acid Methyl Esters as Phase Change Materials for Low Temperature Applications. Appl. Therm. Eng. 2016, 96, 501–507. [Google Scholar] [CrossRef]

- Young, B.A.; Falzone, G.; She, Z.; Thiele, A.M.; Wei, Z.; Neithalath, N.; Sant, G.; Pilon, L. Early-Age Temperature Evolutions in Concrete Pavements Containing Microencapsulated Phase Change Materials. Constr. Build. Mater. 2017, 147, 466–477. [Google Scholar] [CrossRef]

- Ryms, M.; Denda, H.; Jaskuła, P. Thermal Stabilization and Permanent Deformation Resistance of LWA/PCM-Modified Asphalt Road Surfaces. Constr. Build. Mater. 2017, 142, 328–341. [Google Scholar] [CrossRef]

- Cheng, P.; Chen, X.; Gao, H.; Zhang, X.; Tang, Z.; Li, A.; Wang, G. Different Dimensional Nanoadditives for Thermal Conductivity Enhancement of Phase Change Materials: Fundamentals and Applications. Nano Energy 2021, 85, 105948. [Google Scholar] [CrossRef]

- Acıkök, F.; Belendir, U.; Ardoğa, M.K.; Şahmaran, M. Multi-Functional Conductive Cementitious Composites Including Phase Change Materials (PCM) with Snow/Ice Melting Capability. Int. J. Pavement Eng. 2023, 24, 2248347. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, D.; Miao, Y.; Muhammad Sani, B.; Zhang, K. Development and Characterization of a Novel Steel Slag-Based Composite Phase Change Aggregate for Snow/Ice Melting of Asphalt Pavements. Constr. Build. Mater. 2022, 341, 127769. [Google Scholar] [CrossRef]

- Sharifi, N.P.; Jafferji, H.; Reynolds, S.E.; Blanchard, M.G.; Sakulich, A.R. Application of Lightweight Aggregate and Rice Husk Ash to Incorporate Phase Change Materials into Cementitious Materials. J. Sustain. Cem.-Based Mater. 2016, 5, 349–369. [Google Scholar] [CrossRef]

- Athukorallage, B.; Dissanayaka, T.; Senadheera, S.; James, D. Performance Analysis of Incorporating Phase Change Materials in Asphalt Concrete Pavements. Constr. Build. Mater. 2018, 164, 419–432. [Google Scholar] [CrossRef]

- Tahami, A.; Gholiakhani, M.; Dessouky, S.; Montoya, A.; Papagiannakis, A.T.; Fuentes, L.; Walubita, L.F. Evaluation of a Roadway Thermoelectric Energy Harvester through FE Analysis and Laboratory Tests. Int. J. Sustain. Eng. 2021, 14, 1016–1032. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, X.; Zhou, X.; Liu, B.; Wang, X.; Lin, X. Research and Exploration of Phase Change Materials on Solar Pavement and Asphalt Pavement: A Review. J. Energy Storage 2021, 35, 102246. [Google Scholar] [CrossRef]

- Qin, Y. A Review on the Development of Cool Pavements to Mitigate Urban Heat Island Effect. Renew. Sustain. Energy Rev. 2015, 52, 445–459. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Sharma, A. Heat Transfer Studies of Building Brick Containing Phase Change Materials. Sol. Energy 2017, 155, 1233–1242. [Google Scholar] [CrossRef]

- Li, Y.; Ding, Z.; Du, Y. Techno-Economic Optimization of Open-Air Swimming Pool Heating System with PCM Storage Tank for Winter Applications. Renew. Energy 2020, 150, 878–890. [Google Scholar] [CrossRef]

- Mohammadnejad, F.; Hossainpour, S. A CFD Modeling and Investigation of a Packed Bed of High Temperature Phase Change Materials (PCMs) with Different Layer Configurations. J. Energy Storage 2020, 28, 101209. [Google Scholar] [CrossRef]

- Deng, Y.; Shi, X.; Zhang, Y.; Chen, J. Numerical Modelling of Rutting Performance of Asphalt Concrete Pavement Containing Phase Change Material. Eng. Comput. 2023, 39, 1167–1182. [Google Scholar] [CrossRef]

- Salem, T.; Bichara, L. Mitigation of UHI Effect with the Incorporation of PCM in Concrete Pavement-Case Study: City of Rotterdam. In Proceedings of the 2023 Fifth International Conference on Advances in Computational Tools for Engineering Applications (ACTEA), Zouk Mosbeh, Lebanon, 5–7 July 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 93–97. [Google Scholar]

- Si, W.; Ma, B.; Ren, J.; Hu, Y.; Zhou, X.; Tian, Y.; Li, Y. Temperature Responses of Asphalt Pavement Structure Constructed with Phase Change Material by Applying Finite Element Method. Constr. Build. Mater. 2020, 244, 118088. [Google Scholar] [CrossRef]

- Nayak, S.; Krishnan, N.M.A.; Das, S. Microstructure-Guided Numerical Simulation to Evaluate the Influence of Phase Change Materials (PCMs) on the Freeze-Thaw Response of Concrete Pavements. Constr. Build. Mater. 2019, 201, 246–256. [Google Scholar] [CrossRef]

| No | Type of Application | Matrix | PCM | Main Findings | Reference |

|---|---|---|---|---|---|

| 1 | Snow removal system with solar thermal energy collector | Lack of typical matrix. Liquid was delivered to concrete material by the system of pipes. | Organic: n-octadecanol (agglomerated in cylindrical can made of aluminum) | PCM was used for storing thermal energy from solar collectors; it was possible to store 58 MJ. Thanks to the discharge of solar energy, the temperature of pavement rose by 30 °C. The test confirmed the possibility of effective snow removal: the pavement temperature was above 2 °C during a snowfall. | [47] |

| 2 | Reduction of the pavement surface temperature to avoid the thermal stress in high temperatures | Concrete | Organic (OM35 and OM42) encapsulated. | The most important for effective cooling are the latent heat and phase change temperature of PCM. In the night, the pavement surface temperature rose by approximately half of the reduction in temperature during the daytime. It was caused by the slower solidification rate of the PCMs. | [49] |

| 3 | Road temperature regulation | SBS-modified asphalt | HDPE, expanded graphite, and paraffin (directly mixed) | PCM addition influenced reduction consistency and temperature sensitivity. It also enhanced low-temperature performance. The deformation resistance of modified material decreased but the fatigue performance increased. The asphalt had good rutting resistance and elastic recovery ability at 64 °C. | [50] |

| 4 | Capacity to store thermal energy; slow down the cooling rate; improve of the thermomechanical characteristics | Bitumen | D-Mannitol (high-speed shearing with bitumen) | The melting point of the modified material was without significant changes. PCM improved the physical characteristics of the basic material. The specific heat capacity rose gradually with the PCM content. | [51] |

| 5 | Improving rheological and thermal properties | Gilsonite-modified asphalt binder | PEG (directly mixed) | PCM balances the impacts of gilsonite. The binder PCM and gilsonite have good rutting resistance and are possible for application in low temperatures (cracking resistance). | [52] |

| 6 | Temperature control (high-temperature reduction) | Cement | (1) paraffin wax (2) myristic acid (encapsulated) | Composites had low crushing ratios during rut-forming tests. PCMs were thermally and chemically stable (minimal mass loss at 180 °C, lack of PCM leakage). | [53] |

| 7 | Cooling asphalt pavement | Asphalt | Eutectic mixture of fatty acid (palmitic acid and stearic acid), incorporated in coarse steel slags aggregate | The composition had sufficient cooling performance and durability. Additions of PCM increased the high-temperature rutting resistance of pavement by 30.7%. | [28] |

| 8 | Temperature regulation and ice-melting effects | Asphalt | PEG 800, a phase change energy storage material and polyacrylamide backbone structure (directly mixed) | Investigated composites were in line with the specification requirements. The addition of PCM enhanced mechanical properties and moisture resistance. PCM positively influenced thermal insulation performance and heat storage efficiency. PCM reduced the long-term high-temperature performance and low-temperature strength. | [54] |

| 9 | Temperature regulation; reducing the urban heat island effect | High-viscosity modified asphalt (HVMA) | (1) Paraffin/expanded graphite/high-density polyethylene composite (2) polyethylene glycol (PEG) (mixed, not explained in detail) | PCMs were uniformly distributed in HVMA. PCMs did not affect the softening points of asphalt. Composites had excellent high-temperature rutting resistance regardless of PCM addition. The effect of the regulation of temperature was visible for both PCMs. | [55] |

| 10 | Temperature regulation | Asphalt | PCM based on polyurethane (included in fine aggregate) | The viscoelastic properties of composites were related to the curing temperature, loading frequency, PCMs content, and particle sizes. | [56] |

| 11 | Cooling pavement | Concrete | Organic (OM42), incorporated in expanded clay aggregate | PCM effectively decreased pavement surface temperature (2.24 °C was the annual average). | [57] |

| 12 | Cooling pavement | Concrete | Organic (OM35 and OM42), encapsulation | The cooling potential of pavements PCM improved by more than 80%. The thermal conductivity of the material increased. | [58] |

| 13 | Preventing the low-temperature impact on pavements | Asphalt | PCM based on polyurethane (directly mixed) | PCM slightly affected the high- and low-temperature performance. PCM improved the anti-aging properties. The energy storage properties of composition were found to be satisfactory. | [59] |

| 14 | Road temperature regulation | Hot-mix asphalt | Paraffin (microencapsulation) | PCM could withstand asphalt mixing and placement conditions. PCM reduced the dynamic modulus. | [60] |

| 15 | Increasing the functionality of pavements made from waste materials | OPC + waste materials (bricks) | PEG 400 Tetradecane (incorporated in recycled aggregate) | The study proved the possibility of using the waste materials as a matrix for PCMs for pavement applications. | [61] |

| 16 | Cooling pavement | Asphalt | Paraffin (mixed, not explained in detail) | PCM decreased the frequency of pavement high-temperature rutting damage. With the amount of PCM the cooling effect increased. | [62] |

| 17 | Preventing the temperature impact | Asphalt | Eutectic (solid-solid), directly mixed | PCM increased the physical properties of asphalt. PCM increased the high-temperature rutting resistance. PCM improved the low-temperature creep behavior. | [16] |

| 18 | Cooling pavement | Asphalt | Eutectic (stearic acid/palmitic acid), directly mixed | PCM application improved the rutting resistance. The structure of PCM inside the composite was stable and had a layered form. The distinguished temperature regulating property was clearly visible (more than 11 °C difference). The temperature peak was delayed 40 min. | [63] |

| 19 | Thermal stress reduction | Asphalt | Melamine–formaldehyde resin with graphene (microencapsulation) | PCM increased thermal conductivity and volume-specific heat capacity. The investigation confirmed reducing the temperature variation-induced cracking. | [64] |

| 20 | Temperature regulation; avoiding urban heat island | Concrete | Organic (OM35 and OM42) incorporation in expanded clay aggregates | PCM stored latent heat at different temperatures. The material is stable up to 196.6 °C. PCM reduced the maximum pavement surface temperature by approximately 2 °C. | [65] |

| 21 | Temperature regulation | Asphalt | PEG 800, a phase change energy storage material and polyacrylamide backbone structure (directly mixed) | PCM enhanced the moisture and low-temperature cracking resistance PCM increased the thermal conductivity. PCM improved the heat preservation capacity. | [66] |

| 22 | Temperature regulation | Asphalt | PEG 800, a phase change energy storage material and polyacrylamide backbone structure (directly mixed) | PCM improved the Marshall stability and flexural–tensile strain as well as other parameters such as moisture resistance, low-temperature crack resistance, and thermal insulation properties. PCM reduced the mechanical strength and long-term high-temperature stability performance. | [67] |

| 23 | Cooling pavement | Asphalt | Eutectic (stearic acid/palmitic acid)-directly mixed | Between PCM and asphalt, no chemical reaction was detected. PCM has to be applied at higher temperatures than traditional PCM, especially organic. | [68] |

| 24 | Improvement of thermomechanical characteristics; mitigation of thermal curling. | Concrete | Paraffin incorporated in porous lightweight aggregate | The element made from composite containing PCM had lower linear strain because of the lower coefficient of thermal expansion. | [69] |

| 25 | Regulating temperature and resisting UV aging | Bitumen | PEG–PCM ZnMgAl-mixed metal oxides support (directly mixed) | ZnMgAl mixed-metal oxides as a carrier can include up to 65% of PEG. This mix has good thermal and chemical stability, sufficient phase change enthalpy, and excellent UV absorption properties. | [70] |

| 26 | Low-temperature behavior, avoiding cracking | Bitumen | Tetradecane (directly mixed) | PCM raised penetration and lowered the conventional characteristics of bitumen such as softening temperature. Direct addition of PCM also significantly influenced the rheological properties of bitumen; because of that, encapsulation is recommended. | [3] |

| 27 | Temperature regulation | Asphalt | NiTi alloy (directly mixed; replacement for fine aggregate) | PCM was used as a replacement for aggregate (partially). PCM slightly reduced the water stability. PCM significantly reduced the heating rate. | [35] |

| 28 | Temperature regulation | Asphalt | Tetradecane (microencapsulation) | Different PCMs can have different thermoregulation ranges. PCM significantly improved its thermal behavior. | [71] |

| 29 | Improvement of thermophysical parameters | Asphalt | Pentadecane (microencapsulation) | The composition had good thermal stability, thermal storage performance, and mechanical properties | [72] |

| 30 | Aging | Asphalt | Tetradecane (microencapsulation) | PCM reduced temperature influence during seasonal and diurnal cycles. PCM gives only benefits in encapsulated form. The melting enthalpy decreases upon aging. PCM increased rheological properties. | [73] |

| 31 | Temperature regulation | Bitumen | Tetradecane (microencapsulation) | PCM did not affect rheological properties; it effectively regulated temperature variations. | [74] |

| 32 | Cooling pavement | Asphalt | PEG (directly mixed) | PCM complicated effect on the rheological properties. PCM harms the shear strength. | [75] |

| 33 | Temperature regulation, avoiding thermal distresses | Asphalt | PEG (microencapsulation) | Confirmation of thermal storage capacity. PCM positively influences rheological properties. | [76] |

| 34 | Freeze–thaw performance | Asphalt | Paraffin (pure and microencapsulated) | PCM helps in controlling freeze–thaw impact on subgrade soil | [77] |

| 35 | Freeze–thaw performance | Concrete | Paraffin (pure and microencapsulated) | PCM decreased the magnitude of the temperature drop. PCM deteriorated the mechanical properties. | [78] |

| 36 | Mechanical and thermal performance | Pavement (not specified) | Paraffin (macro encapsulation) | Anti-ice properties. PCM increased thermal stability and heat storage capacity. | [79] |

| 37 | Anti-freezing, temperature regulation bridge decks | Concrete | Composite organic polyol (seamless steel pipe layer with PCM) | Good effect on melting ice and snow. | [80] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korniejenko, K.; Nykiel, M.; Choinska, M.; Jexembayeva, A.; Konkanov, M.; Aruova, L. An Overview of Phase Change Materials and Their Applications in Pavement. Energies 2024, 17, 2292. https://doi.org/10.3390/en17102292

Korniejenko K, Nykiel M, Choinska M, Jexembayeva A, Konkanov M, Aruova L. An Overview of Phase Change Materials and Their Applications in Pavement. Energies. 2024; 17(10):2292. https://doi.org/10.3390/en17102292

Chicago/Turabian StyleKorniejenko, Kinga, Marek Nykiel, Marta Choinska, Assel Jexembayeva, Marat Konkanov, and Lyazat Aruova. 2024. "An Overview of Phase Change Materials and Their Applications in Pavement" Energies 17, no. 10: 2292. https://doi.org/10.3390/en17102292

APA StyleKorniejenko, K., Nykiel, M., Choinska, M., Jexembayeva, A., Konkanov, M., & Aruova, L. (2024). An Overview of Phase Change Materials and Their Applications in Pavement. Energies, 17(10), 2292. https://doi.org/10.3390/en17102292