A Reviewed Turn at of Methods for Determining the Type of Fault in Power Transformers Based on Dissolved Gas Analysis

Abstract

:1. Introduction

2. Gas Formation Mechanism in Oil-Immersed Transformers

- H2 and CH4 concentrations start to form at temperatures around 150 °C;

- H2 continues to increase with increasing temperature;

- At ~250 °C, C2H6 starts to form;

- At ~350 °C, C2H4 starts to form;

- Between 200 °C and 300 °C, CH4 production exceeds H2 production;

- At temperatures above ~275 °C, C2H6 production exceeds CH4 production;

- At a temperature between 500 °C and 700 °C, C2H2 formation starts and continues to increase so that at a temperature of ~800 °C, it has the highest concentration compared to the other gases;

- From ~455 °C to ~750–800 °C, H2 production exceeds other gases.

- PD—Partial discharge;

- D1—Low energy discharge;

- D2—High energy discharge;

- T1—Thermal failure at low temperature T < 300 °C;

- T2—Thermal failure at medium temperature 300 °C < T < 700 °C;

- T3—Thermal failure at high temperature T > 700 °C.

3. Analytical Methods for Fault Diagnosis

3.1. Key Gas Method

3.2. The Doernenburg Ratio Method

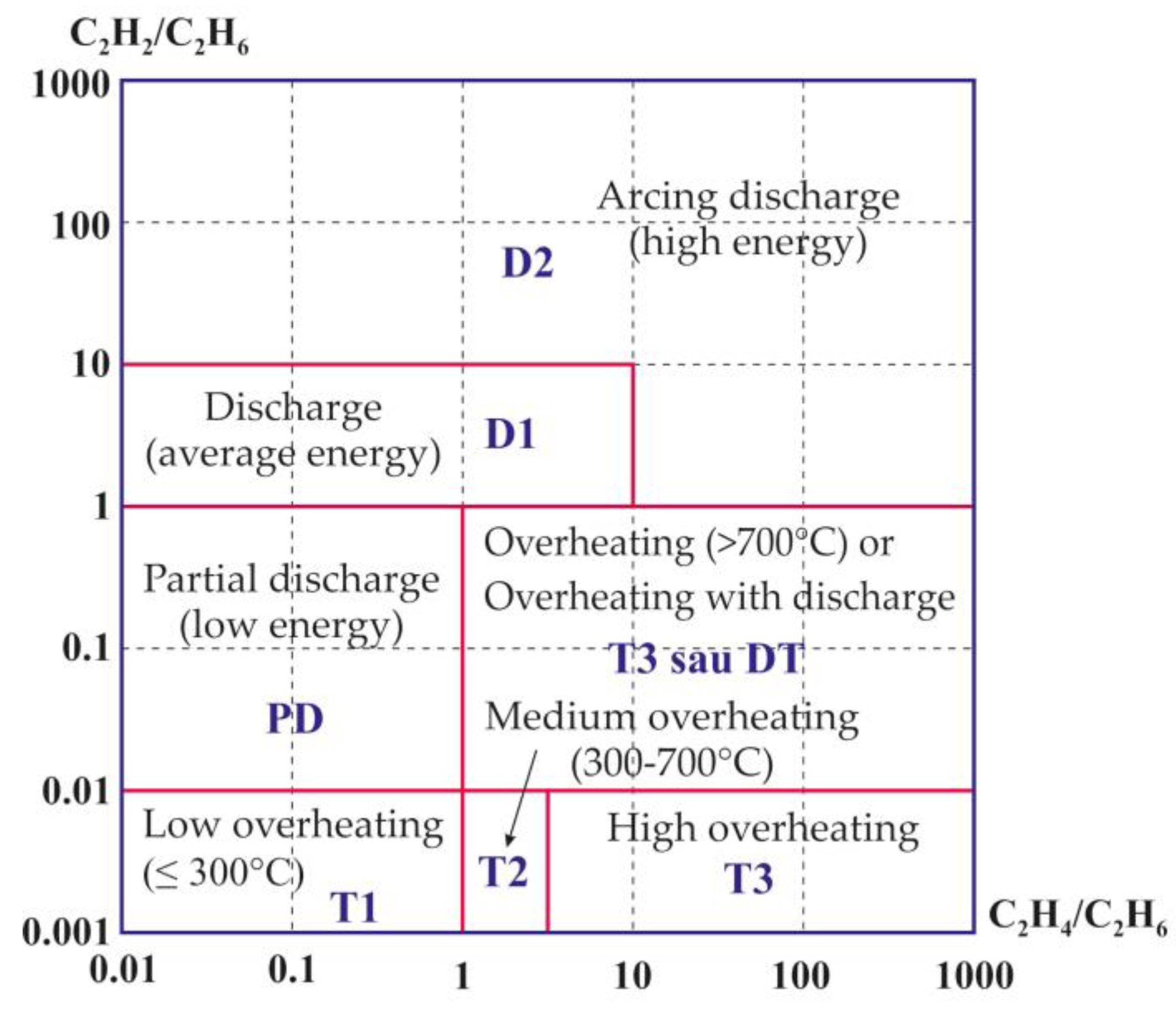

3.3. Rogers and IEC Ratio Methods

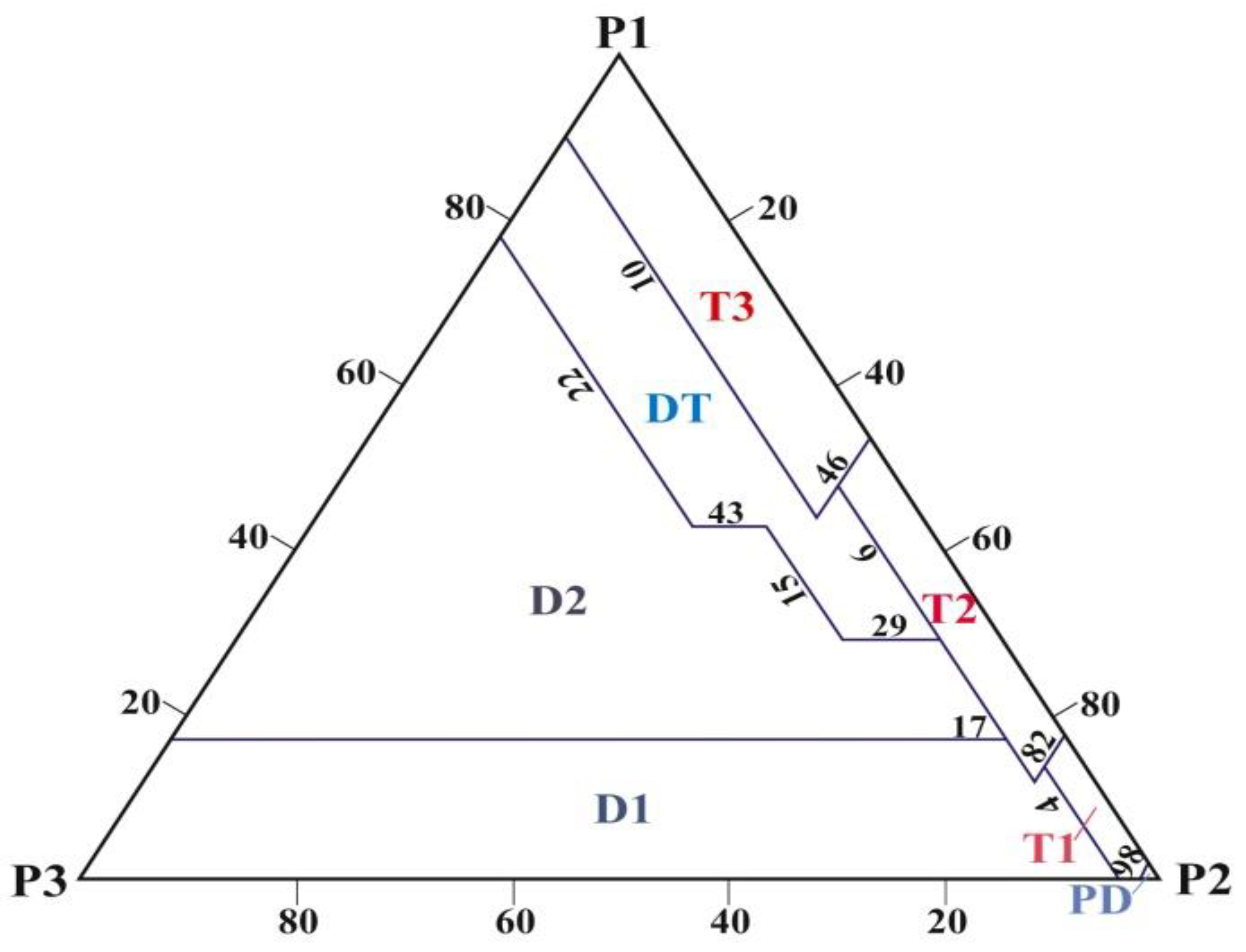

3.4. TRT (Three Ratio Technique)

3.5. Other Methods Using Ratios for Diagnosis

3.5.1. Single Gas Ratio Method

3.5.2. C3 Hydrocarbon Method

4. Graphical Fault Diagnosis Methods

4.1. Triangle-Based Graphical Diagnostic Methods

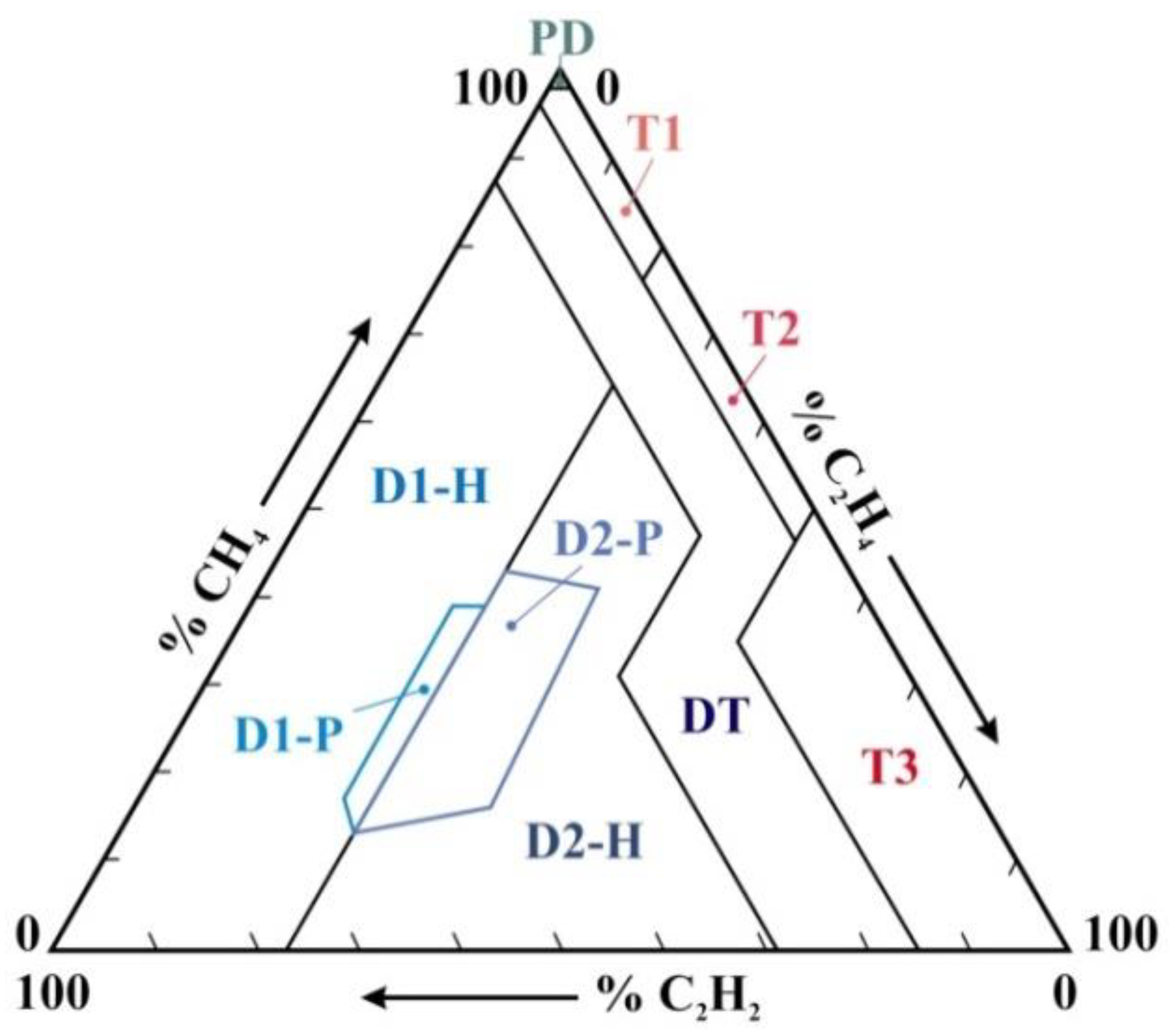

4.1.1. Duval Triangle

- Faults caused by low-energy (D1-P) and high-energy (D2-P) arcs in the cellulose insulation of transformers;

- Faults caused by low-energy (D1-H) and high-energy (D2-H) arcing in transformer insulating oil.

4.1.2. Gouda Triangle

- Step 1:

- Determination of gas concentrations using gas chromatography.

- Step 2:

- Verification of gaseous hydrocarbon concentration limits. If at least one of the gas concentrations (in ppm) of the five key gases exceeds the limit given in Table 2, the transformer is considered faulty, and the next step is taken.

- Step 3:

- Determination of ratios R1, R2 and R3 and calculation of relative percentages P1, P2 and P3.

- Step 4:

- Sequential comparison of each percentage with the values obtained from the flowchart in the order P1, P2 and P3.

- Step 5:

- If all the calculated percentages for a particular type of fault are within the values contained in the table, then the fault diagnosis is valid.

4.1.3. Low Energy Degradation Triangle (LEDT)

4.2. Pentagon-Based Graphical Diagnostic Techniques

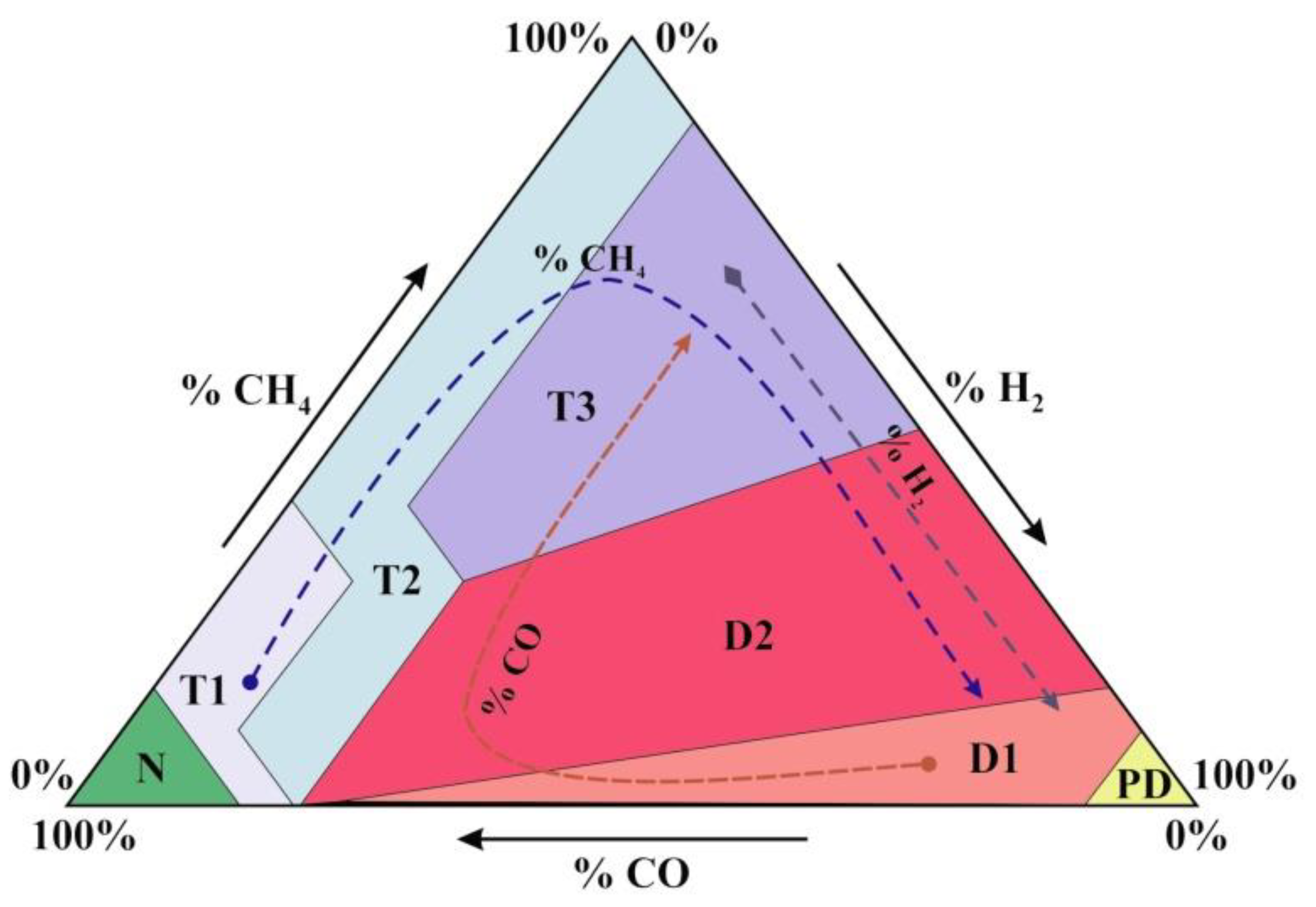

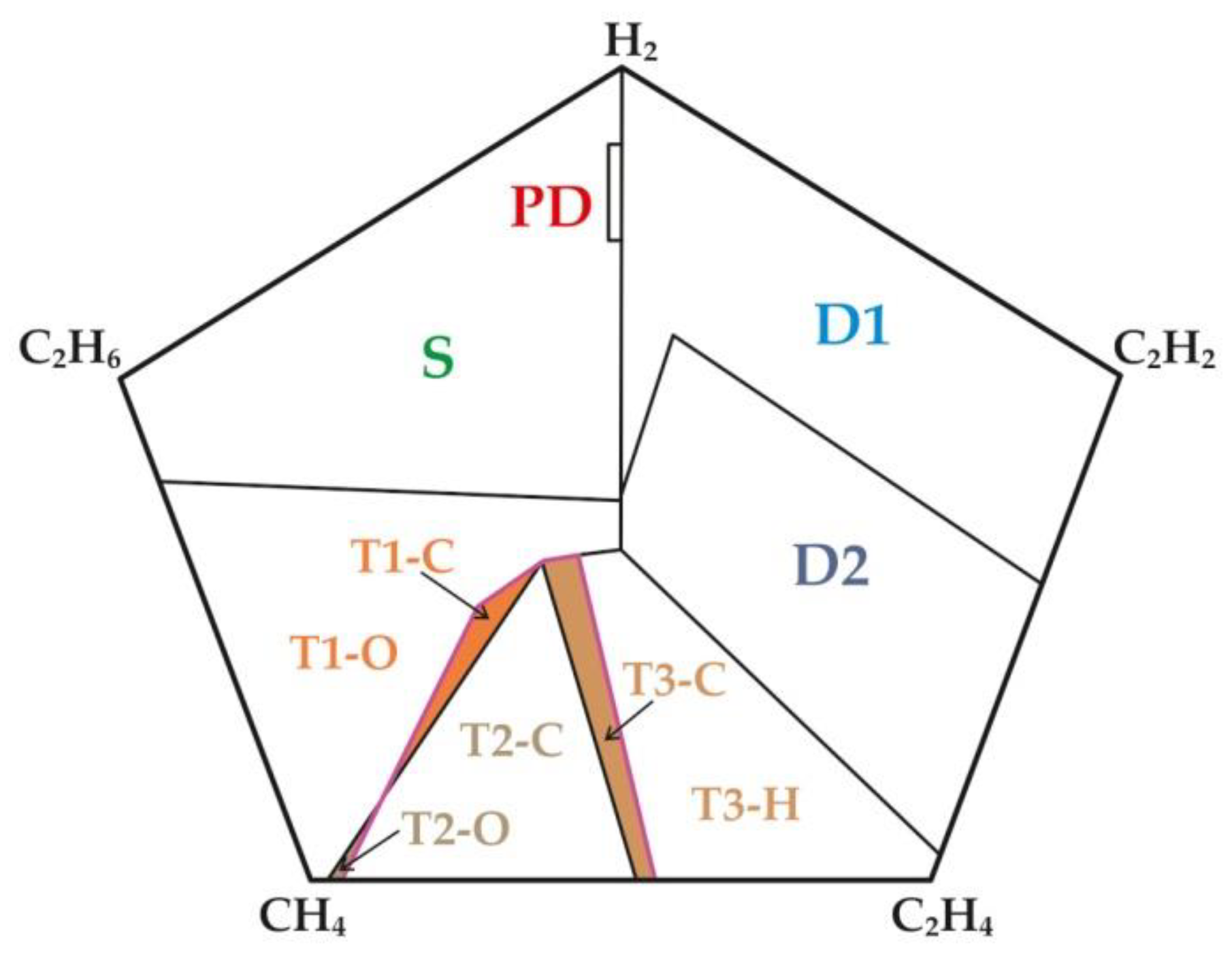

4.2.1. Duval Pentagons

- xi and yi are the coordinates of the five points;

- Cx and Cy (x, y) are the coordinates of the centroid;

- A is the area of the polygon given by the relation:

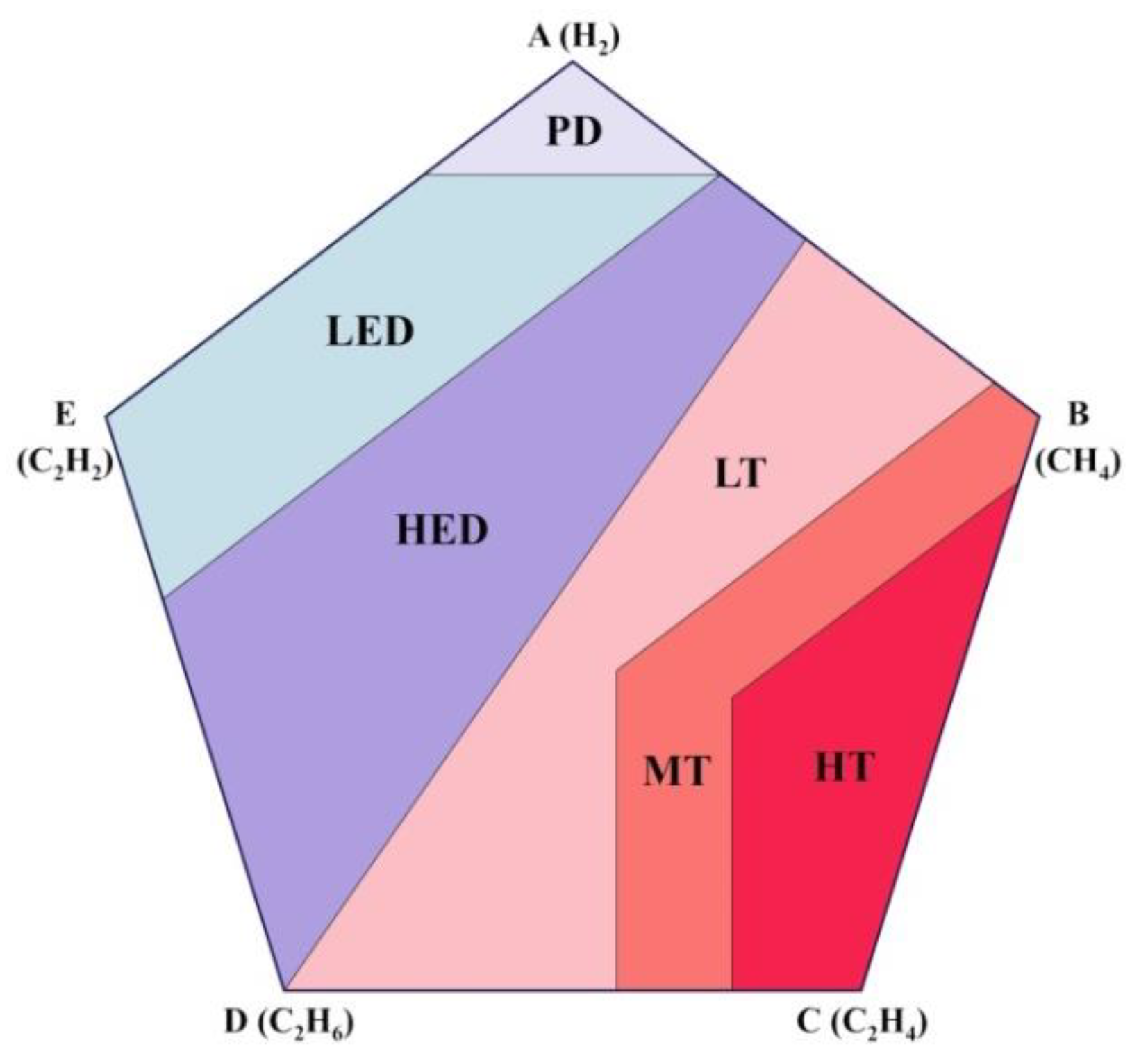

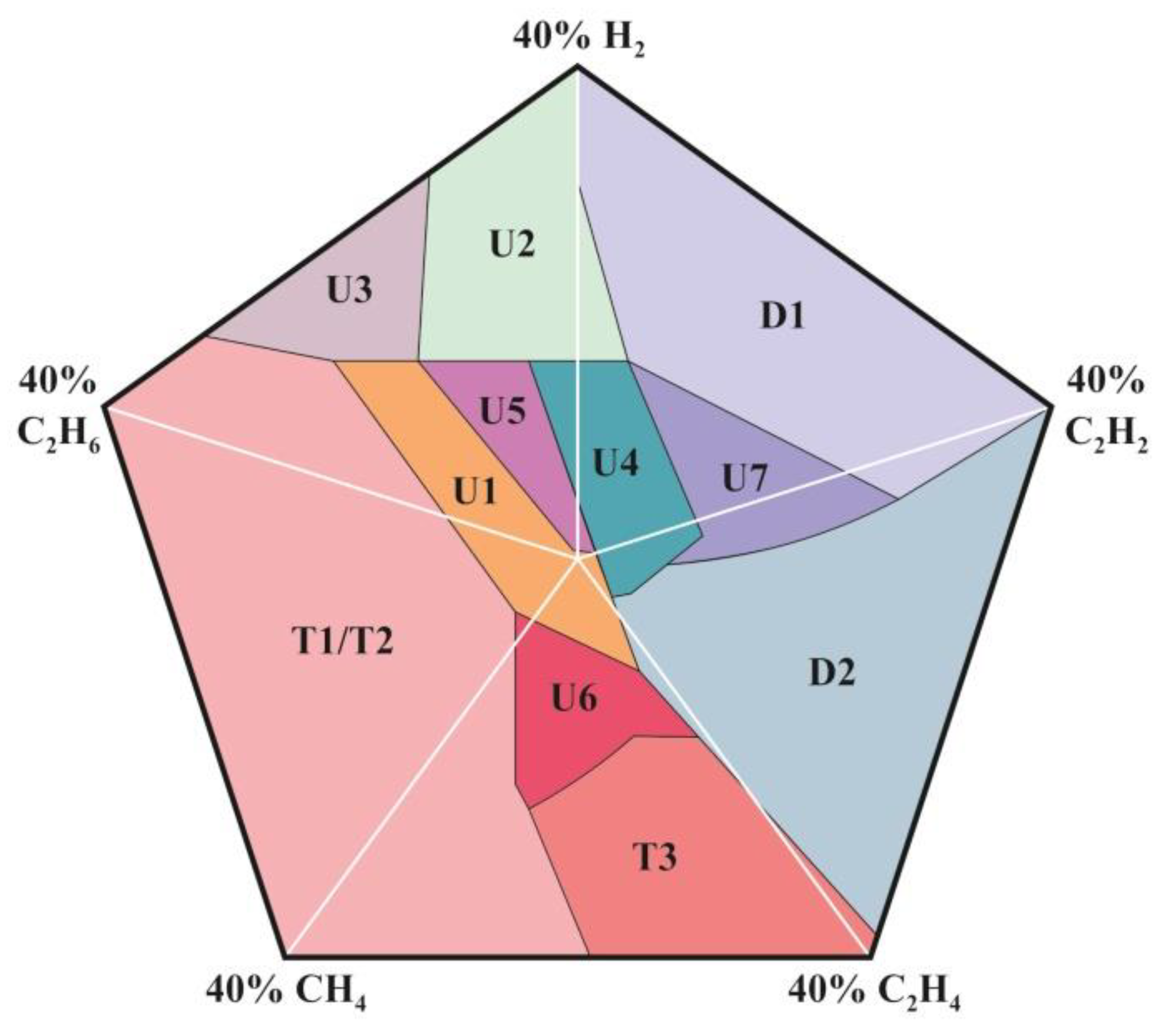

4.2.2. Mansour Pentagon

- (xi, yi) are the coordinates of each vertex of the pentagon;

- mi is the percentage concentration of each gas at the vertices of the pentagon;

- n is the number of peaks or combustible gases, in this case five.

4.3. Diagnostic Methods Based on Other Types of Graphs

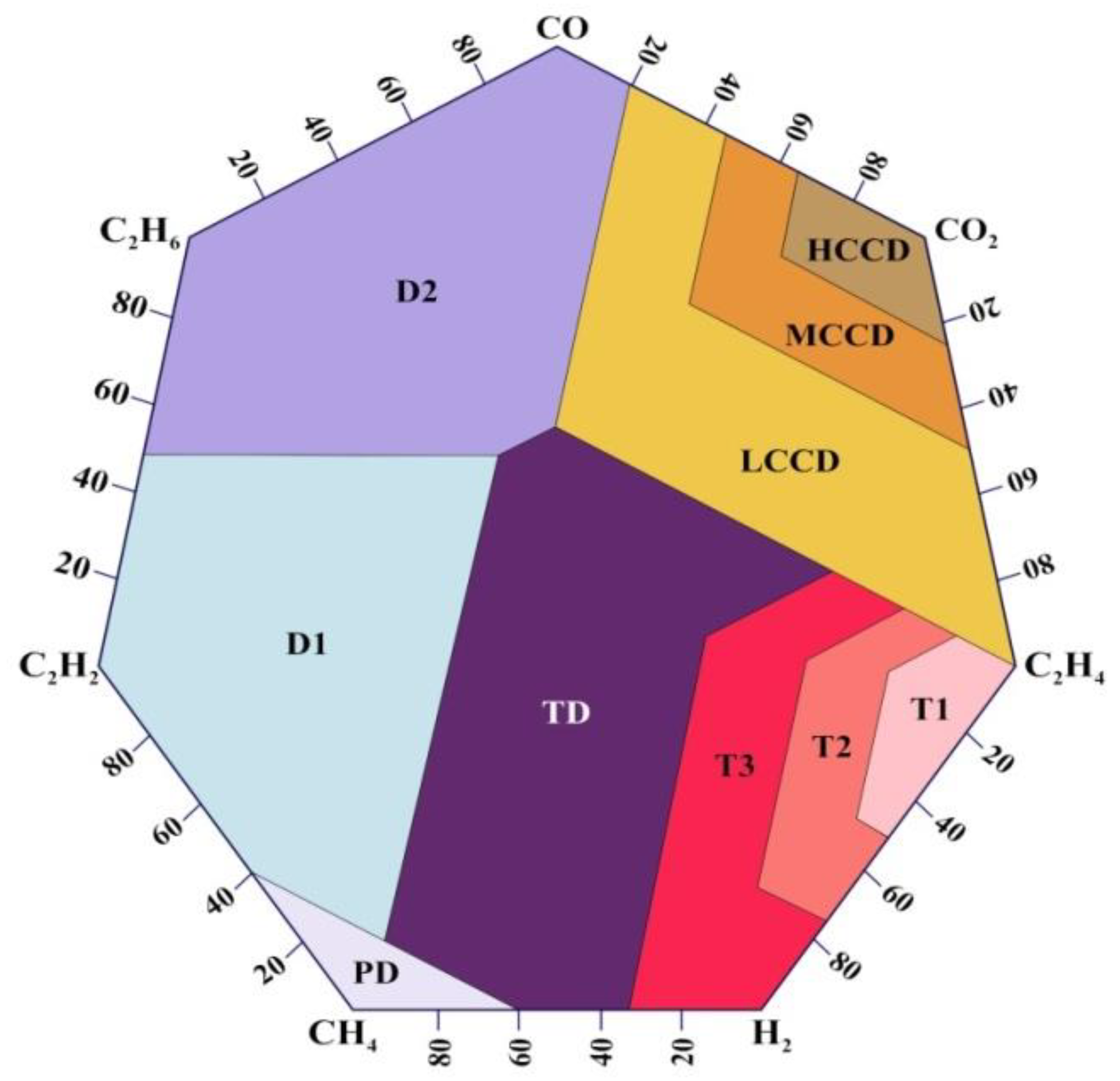

4.3.1. Heptagon Graph

- Step 1:

- Determination of gas concentrations using gas chromatography.

- Step 2:

- Verification of the concentration limits of the seven gases against the IEEE standard.

- Step 3:

- The transformer is considered faulty if at least one of the gas concentrations exceeds the limits in the standard.

- Step 4:

- Determination of the relative percentages for each gas using the equations given above.

- Step 5:

- Plotting the percentage of each gas on the heptagon graph, and the corresponding point for a given fault case is determined by the centre of mass of the percentage concentrations.

4.3.2. ETRA Square

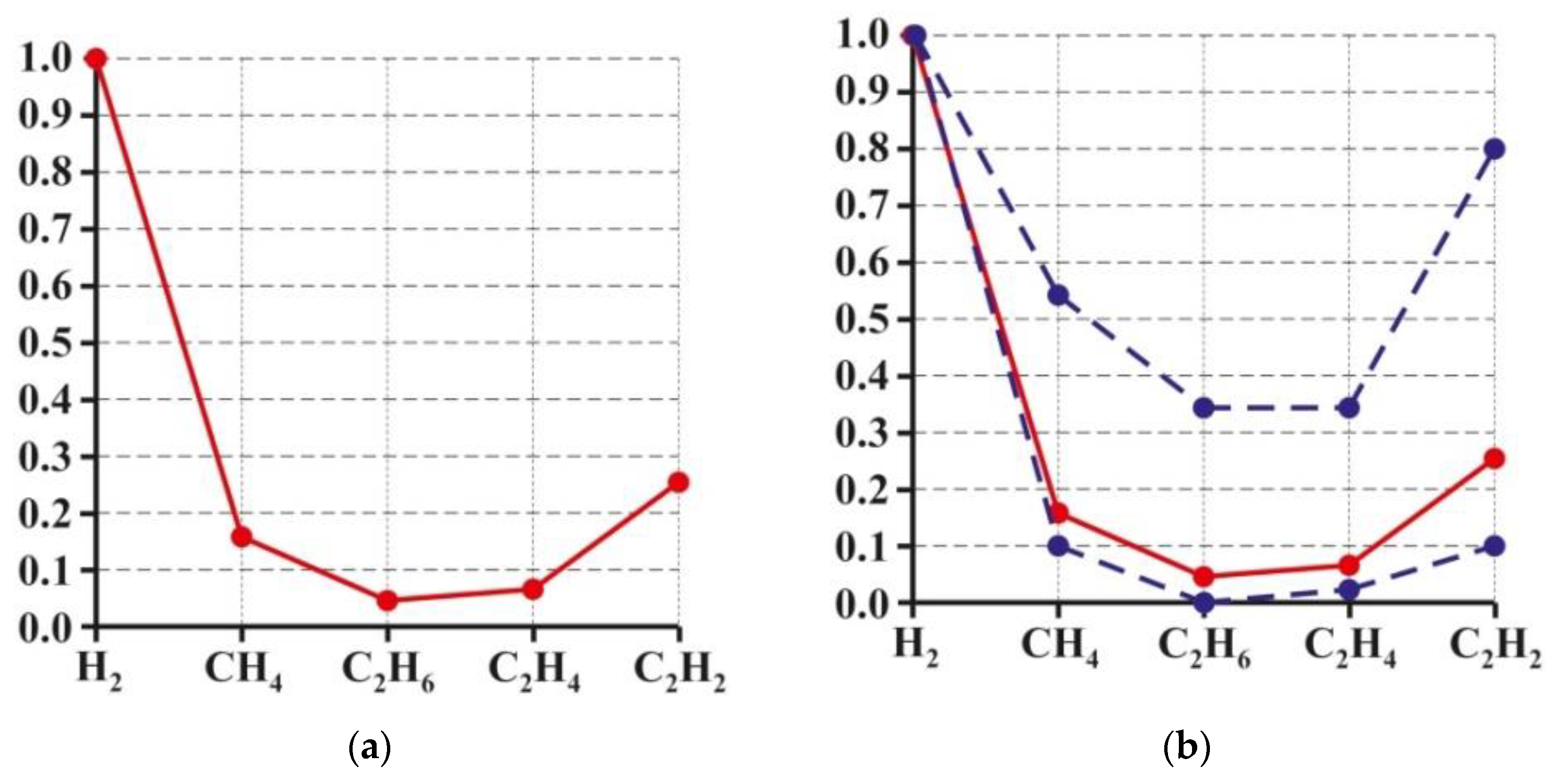

4.3.3. Nomogram Method

5. Improvement of the Efficiency of DGA-Based Fault Diagnosis Methods

Example of Using AI Techniques to Develop a New Graphical Technique for DGA

6. Conclusions

- The main disadvantage of the key gas method is the difficulty of interpreting a fault in practice due to the independent gases since during the occurrence of a fault in the transformer, traces of other gases are produced in addition to the gas corresponding to the fault. It is therefore advisable to establish a correlation between them using a correction factor;

- Fault diagnosis in the case of gas-ratio-based methods is determined when the fault code matches the code combination given by the ratios, but there are no available code combinations with specific fault codes, so the problem of the lack of a decision arises;

- Due to the incomplete use of diagnostic information, the presence of rigid boundaries and areas of mixed faults, graphical methods have some uncertainty in diagnosing certain faults (e.g., low overheating and partial discharge in Duval triangle 1);

- None of the methods based on artificial intelligence can be considered the best for diagnosing faults in power transformers, as they are more likely to provide directions for identifying the most appropriate algorithm for the most accurate interpretation of DGA data. We can conclude that complementing AI techniques with other conventional methods is recommended to improve their accuracy and precision.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| DGA | Dissolved Gas Analysis |

| H2 | Hydrogen |

| CH4 | Methane |

| C2H6 | Ethane |

| C2H4 | Ethylene |

| C2H2 | Acetylene |

| CO2 | Carbon Dioxide |

| CO | Carbon Monoxide |

| O2 | Oxygen |

| N2 | Nitrogen |

| OLTC | On-Load Tap-Changer |

| TRT | Three Ratio Technique |

| LEDT | Low Energy Degradation Triangle |

| ETRA | Electric Technology Research Association |

| AI | Artificial Intelligence |

| ROC | Region of Certainty |

| ROU | Region of Uncertainty |

Appendix A

| Method | Advantages | Disadvantages |

|---|---|---|

| Analytical Methods for Fault Diagnosis | ||

| Key gas method | Faults that can be detected: electric arcing in oil, partial discharges in oil, overtemperature in oil and cellulose overheating | It is not widely used for diagnosing transformer conditions. |

| The Doernenburg ratio method | Identify incipient faults in transformers such as thermal decomposition, partial discharge, arcing | It provides insufficient information, especially in the case of the existence of multiple faults and cases that fall outside the specified codes. |

| Rogers and IEC ratio methods | Identify faults PD, D1, D2, T1, T2, T3 | A part of the gas ratio values obtained does not fall within the specific range of values, making diagnosis of the fault inconclusive. There are overlapping situations for type D1 and D2 defects, resulting in the wrong interpretation of the intensity of the type of defect. |

| TRT (three ratio technique) | Identify faults PD1, PD2, D1, D2, T1, T2, T3, T0, DT. Has an accuracy of 99.86%, compared to 85.67% for the Duval triangle 1 method, 75.08% for the Doernenburg method, 47.34% for the IEC method and 39% for the Rogers method | It provides insufficient information, especially in the case of the existence of multiple faults and cases that fall outside the specified codes. |

| Single gas ratio method | Three unique gas ratios (CO2/CO, O2/N2 and C2H2/H2) can be used as complementary methods for diagnosing faults in transformers for the involvement of cellulose insulation, mineral oil oxidation, the possibility of contamination of the oil in the transformer main tank with oil or gas from the OLTC | It provides insufficient information, especially in the case of the existence of multiple faults and cases that fall outside the specified codes. |

| C3 hydrocarbon method | Used to confirm the temperature range for thermal defects | |

| Graphical fault diagnosis methods | ||

| Duval triangle 1 | Simplicity and robustness. Faults identified: PD, D1, D2, T1, T2, T3, DT. Is effective in determining the main type of fault. New sub-areas make it possible to specify whether arc faults D1 and D2 in operating transformers are in paper or oil. | At the boundary between two fault zones, it is difficult to distinguish which of the two faults is the real one. Because it uses only three dissolved gases, it provides insufficient information, especially in the case of the existence of multiple faults. Interaction of stray gases with the correct identification of faults. |

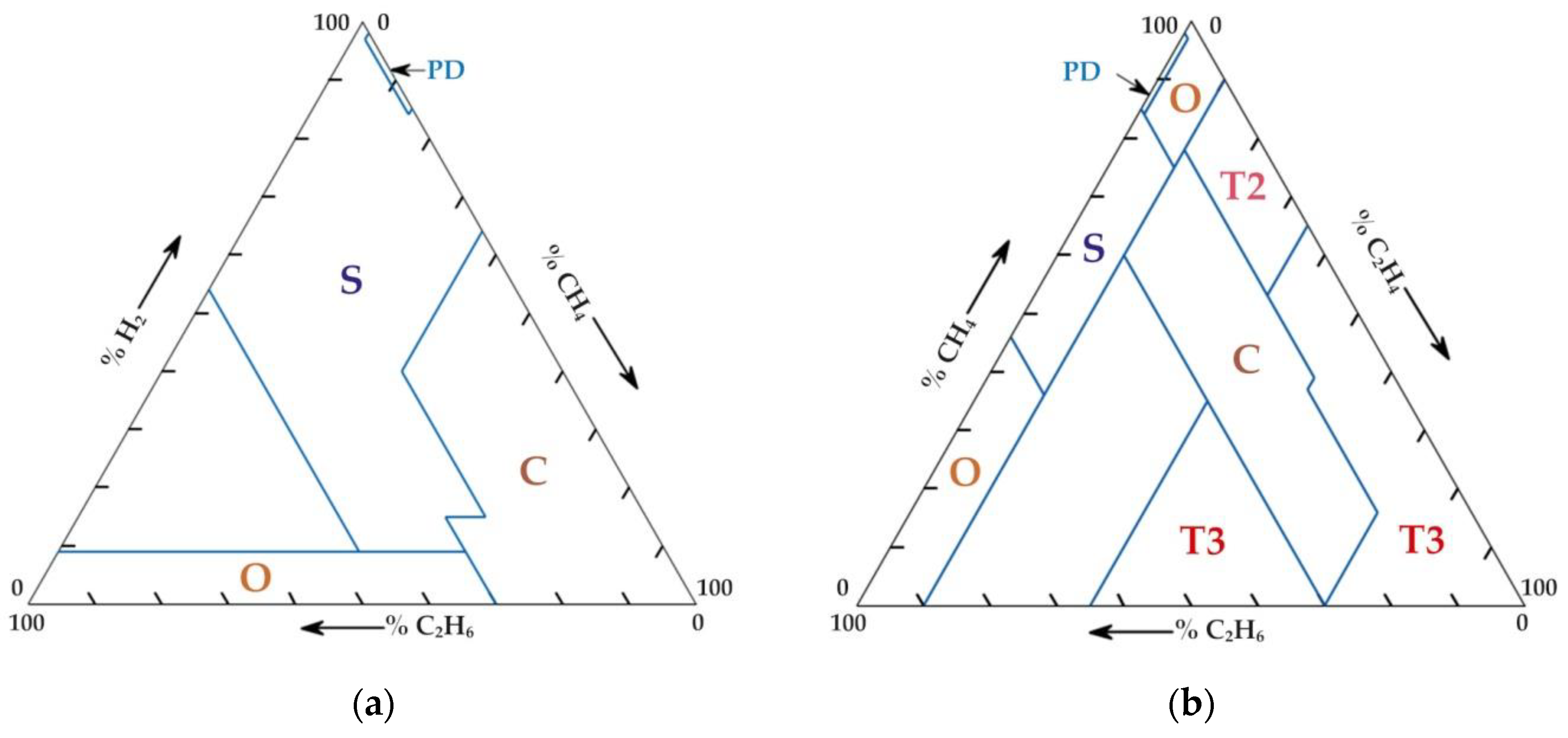

| Duval triangle 4 | Is used to obtain more information about low-temperature faults like PD, T1 or T2. Uses the “low-energy gases”: H2, CH4 and C2H6. Faults identified: PD, S, O, C. | Because it uses only three dissolved gases, it provides insufficient information, especially in the case of the existence of multiple faults. |

| Duval triangle 5 | It is used to obtain more information about T2- or T3-type thermal defects and to confirm defects that present uncertainty after using Duval triangle 4. Uses the “temperature gases”: C2H4, CH4 and C2H6. Faults identified: PD, S, O, C, T2, T3. The new sub-areas indicate the location of paper carbonisation faults. | Because it uses only three dissolved gases, it provides insufficient information, especially in the case of the existence of multiple faults |

| Gouda triangle | Resolve the inconsistencies that occur in Duval triangle 1. Faults identified: N, PD, D1, D2, T1, T2, T3, DT. Has an accuracy of 85.42%, compared with 77.21% for the Duval triangle, 56.58% for the IEC method, 65.33% for the Doernenburg method and 55.15% for the Rogers method, using the same set of data [12]. | Uncertainty—if at least one of the gas concentrations (in ppm) for the five key gases exceeds the limit, the transformer is considered faulty. At the boundary between two fault zones, it is difficult to distinguish which of the two faults is the real one. |

| Low Energy Degradation Triangle (LEDT) | Is sensitive to both cellulose and oil insulation degradation and the amount of energy that may be present, ensuring early detection of transformer condition changes from normal to fault conditions. Faults identified: N, PD, D1, D2, T1, T2, T3. | It is only effective when applied to on-line dissolved gas samples, where the dissolved gas trend plays a key role in detecting early changes in the level of insulation degradation. |

| Duval pentagon 1 | Is designed for the general analysis of fault types and in addition shows the stray gas “S” area associated with the production of gases during the normal ageing process. | They are used after analysis with the Duval triangles and are complementary. |

| Pentagon 2 | Suggests filtering the analysis if T1, T2 or T3 failures are identified in Duval pentagon 1. New sub-areas make it possible to specify whether arc faults D1 and D2 in operating transformers are in paper or oil, and also the location of paper carbonisation faults is specified. | |

| Combined Duval pentagon | Facilitates the automatic detection of faults in power transformers in service. Has fewer defect areas than if both Duval pentagons were used separately. | |

| Mansour pentagon | Eliminates the shortcomings of the Duval triangle 1 method. | It provides insufficient information, especially in the case of the existence of multiple faults. |

| Heptagon graph | Takes into account carbon oxide. It assesses failures caused by overtemperature and low energy discharges. It distinguishes between electrical and thermal faults. The accuracy of this method reached 89.41%, while the Doernenburg, Rogers, IEC and Duval triangle 1 methods have accuracy percentages of 38.48%, 46.43%, 54.67% and 64.67%, respectively, for the same number of samples [17]. | |

| ETRA square | Shows reliability in identifying faults compared to classical methods. | Because it uses only three dissolved gases, it provides insufficient information, especially in the case of the existence of multiple faults. |

| Nomogram method | It use the ratio of the five key gases to the gas of the maximum concentration to identify the type of faults in the DGA results. | It provides insufficient information, especially in the case of the existence of multiple faults and cases that fall outside the specified codes. |

References

- Soni, R.; Mehta, B. Review on asset management of power transformer by diagnosing incipient faults and faults identification using various testing methodologies. Eng. Fail. Anal. J. 2021, 128, 105634. [Google Scholar] [CrossRef]

- Shutenko, O.; Kulyk, O. Method of fault-type recognition based on the dissolved gas analysis using a set of diagnostic criteria. IET Gener. Transm. Distrib. 2023, 17, 5511–5523. [Google Scholar] [CrossRef]

- CIGRÉ. Life Extension of Oil Filled Transformers and Shunt Reactors, W.G. A2.55; Brochure 887; CIGRÉ: Paris, France, 2022; ISBN 978-2-85873-592-1. [Google Scholar]

- Rangel Bessa, A.; Farias Fardin, J.; Marques Ciarelli, P.; Frizera Encarnação, L. Conventional Dissolved Gases Analysis in Power Transformers: Review. Energies 2023, 16, 7219. [Google Scholar] [CrossRef]

- Wattakapaiboon, W.; Pattanadech, N. The state of the art for dissolved gas analysis based on interpretation techniques. In Proceedings of the IEEE International Conference on Condition Monitoring and Diagnosis (CMD), Xi’an, China, 25–28 September 2016; pp. 60–63. [Google Scholar] [CrossRef]

- Shutenko, O.; Kulyk, O. Comparative Analysis of the Defect Type Recognition Reliability in High-Voltage Power Transformers Using Different Methods of DGA Results Interpretation. In Proceedings of the IEEE Problems of Automated Electrodrive. Theory and Practice (PAEP), Kremenchuk, Ukraine, 21–25 September 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Wani, S.A.; Rana, A.S.; Sohail, S.; Rahman, O.; Parveen, S.; Khan, S.A. Advances in DGA based condition monitoring of transformers: A review. Renew. Sustain. Energy Rev. J. 2021, 149, 111347. [Google Scholar] [CrossRef]

- Bustamante, S.; Manana, M.; Arroyo, A.; Castro, P.; Laso, A.; Martinez, R. Dissolved Gas Analysis Equipment for Online Monitoring of Transformer Oil: A Review. Sensors 2019, 19, 4057. [Google Scholar] [CrossRef] [PubMed]

- Nanfak, A.; Eke, S.; Kom, C.H.; Mouangue, R.; Fofana, I. Interpreting dissolved gases in transformer oil: A new method based on the analysis of labelled fault data. IET Gener. Transm. Distrib. 2021, 15, 3032–3047. [Google Scholar] [CrossRef]

- Shutenko, O.; Kulyk, O. Analysis of Gas Content in Oil-Filled Equipment with Low Energy Density Discharges. Int. J. Electr. Eng. Inform. 2020, 12, 258–277. [Google Scholar] [CrossRef]

- Faiz, J.; Soleimani, M. Dissolved gas analysis evaluation in electric power transformers using conventional methods a review. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1239–1248. [Google Scholar] [CrossRef]

- Gouda, O.E.; El-Hoshy, S.H.; Hassan, H.; E.L.-Tamaly, H.H. Condition assessment of power transformers based on dissolved gas analysis. IET Gener. Transm. Distrib. 2019, 13, 2299–2310. [Google Scholar] [CrossRef]

- Mansour, D.-E.A. Development of a new graphical technique for dissolved gas analysis in power transformers based on the five combustible gases. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2507–2512. [Google Scholar] [CrossRef]

- Chatterjee, K.; Dawn, S.; Jadoun, V.K.; Jarial, R.K. Novel prediction-reliability based graphical DGA technique using multi-layer perceptron network & gas ratio combination algorithm. IET Sci. Meas. Technol. 2019, 13, 836–842. [Google Scholar] [CrossRef]

- Ashkezari, D.; Saha, T.K.; Ekanayake, C.; Ma, H. Evaluating the accuracy of different DGA techniques for improving the transformer oil quality interpretation. In Proceedings of the AUPEC 2011, Brisbane, QLD, Australia, 25–28 September 2011; pp. 1–6. [Google Scholar]

- Duval, M.; Lamarre, L. The Duval Pentagon—A new complementary tool for the interpretation of dissolved gas analysis in Transformers. IEEE Electr. Insul. Mag. 2014, 30, 9–12. [Google Scholar]

- Gouda, O.E.; El-Hoshy, S.H.; Hassan, H.; El-Tamaly, H.H. Proposed heptagon graph for DGA interpretation of oil transformers. IET Gener. Transm. Distrib. 2018, 12, 490–498. [Google Scholar] [CrossRef]

- Power Transformer Health—Low Energy Degradation Triangle (LEDT). Available online: https://powertransformerhealth.com/2020/04/29/low-energy-degradation-triangle-ledt/ (accessed on 12 December 2023).

- CEI/IEC 60599; Mineral Oil-Impregnated Electrical Equipment in Service—Guide to the Interpretation of Dissolved and Free Gas Analysis. IEC: Geneva, Switzerland, 2022.

- IEEE Std C57.104™-2019; Guide for the Interpretation of Gases Generated in Mineral Oil-Immersed Transformers. IEEE: Piscataway, NJ, USA, 2019; ISBN 978-1-5044-5973-0.

- CIGRÉ. Advances in DGA Interpretation; JWG D1/A2.47; Brochure 771; CIGRE: Paris, France, 2019; ISBN 978-2-85873-473-3. [Google Scholar]

- Muniz, R.N.; da Costa Júnior, C.T.; Buratto, W.G.; Nied, A.; González, G.V. The Sustainability Concept: A Review Focusing on Energy. Sustainability 2023, 15, 14049. [Google Scholar] [CrossRef]

- Aciu, A.-M.; Nicola, C.-I.; Nicola, M.; Nițu, M.-C. Complementary Analysis for DGA Based on Duval Methods and Furan Compounds Using Artificial Neural Networks. Energies 2021, 14, 588. [Google Scholar] [CrossRef]

- Gouda, O.E.; El-Hoshy, S.H.; E.L.-Tamaly, H.H. Proposed three ratios technique for the interpretation of mineral oil transformers based dissolved gas analysis. IET Gener. Transm. Distrib. 2018, 12, 2650–2661. [Google Scholar] [CrossRef]

- Duval, M. The Duval Triangle for Load Tap Changers, Non-Mineral Oils and Low Temperature Faults in Transformers. IEEE Electr. Insul. Mag. 2008, 24, 22–29. [Google Scholar] [CrossRef]

- Duval, M.; Buchacz, J. Gas Formation from Arcing Faults in Transformers—Part II. IEEE Electr. Insul. Mag. 2022, 38, 12–15. [Google Scholar] [CrossRef]

- Duval, M.; Buchacz, J. Detection of Carbonization of Paper in Transformers Using Duval Pentagon 2 and Triangle 5. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 1534–1539. [Google Scholar] [CrossRef]

- Cheim, L.; Duval, M.; Haider, S. Combined Duval Pentagons: A Simplified Approach. Energies 2020, 13, 2859. [Google Scholar] [CrossRef]

- Duval, M.; Buchacz, J. Identification of Arcing Faults in Paper and Oil in Transformers—Part I: Using the Duval Pentagons. IEEE Electr. Insul. Mag. 2022, 38, 19–23. [Google Scholar] [CrossRef]

- Mori, E.; Taukioka, H.; Takamoto, K.; Miyamoto, N.; Kobayashi, T.; Kobayashi, S.; Okubo, H. Latest Diagnostic Methods of Gas-in-oil Analysis for Oil-filled Transformer in Japan. In Proceedings of the IEEE 13th International Conference on Dielectric Liquids (ICDL’99) (Cat. No.99CH36213), Nara, Japan, 25–25 July 1999; pp. 503–508. [Google Scholar] [CrossRef]

- Kawamura, T.; Kawada, N.; Ando, K.; Yamaoka, M.; Maeda, T.; Takatsu, T. Analyzing Gases Dissolved in Oil and Its Application to Maintenance of Transformers; CIGRE Session; Report 12–05; CIGRE: Paris, France, 1986; pp. 1–5. [Google Scholar]

- Dukarm, J.; Draper, Z.; Piotrowski, T. Diagnostic Simplexes for Dissolved-Gas Analysis. Energies 2020, 13, 6459. [Google Scholar] [CrossRef]

- Fan, J.; Wang, F.; Sun, Q.; Bin, F.; Liang, F.; Xiao, X. Hybrid RVM–ANFIS algorithm for transformer fault diagnosis. IET Gener. Transm. Distrib. 2017, 11, 3637–3643. [Google Scholar] [CrossRef]

- Hendel, M.; Meghnefi, F.; Senoussaoui, M.E.A.; Fofana, I.; Brahami, M. Using Generic Direct M-SVM Model Improved by Kohonen Map and Dempster–Shafer Theory to Enhance Power Transformers Diagnostic. Sustainability 2023, 15, 15453. [Google Scholar] [CrossRef]

- Lin, C.-H.; Wu, C.-H.; Huang, P.-Z. Grey clustering analysis for incipient fault diagnosis in oil-immersed transformers. Expert Syst. Appl. 2009, 36, 1371–1379. [Google Scholar] [CrossRef]

- Cui, Y.; Ma, H.; Saha, T. Pattern recognition techniques for power transformer insulation diagnosis—A comparative study part 2: Implementation, case study, and statistical analysis. Int. Trans. Electr. Energy Syst. 2015, 25, 2260–2274. [Google Scholar] [CrossRef]

- Wang, T.; Li, Q.; Yang, J.; Xie, T.; Wu, P.; Liang, J. Transformer Fault Diagnosis Method Based on Incomplete Data and TPE-XGBoost. Appl. Sci. 2023, 13, 7539. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, H.; Li, B.; Wu, R.; Jiang, J. Power Transformer Diagnosis Based on Dissolved Gases Analysis and Copula Function. Energies 2022, 15, 4192. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Z.; Zhu, J.; Li, X.; Dong, F.; Wan, S. Improved Support Vector Machine for Voiceprint Diagnosis of Typical Faults in Power Transformers. Machines 2023, 11, 539. [Google Scholar] [CrossRef]

- Hadjadj, Y.; Fofana, I.; van der Voort, F.R.; Bussieres, D. Potential of Determining Moisture Content in Mineral Insulating Oil by FTIR Spectroscopy. IEEE Electr. Insul. Mag. 2016, 32, 34–39. [Google Scholar] [CrossRef]

- Kornatowski, E.; Banaszak, S.; Molenda, P. Quality Index for Assessment of the Mechanical Condition of Transformers’ Active Part with Frequency Response and Vibroacoustic Measurements. Energies 2024, 17, 1431. [Google Scholar] [CrossRef]

- Quintella, C.M.; Meira, M.; Silva, W.L.; Filho, R.G.D.; Araújo, A.L.C.; Elias, T.S., Jr.; Sales, L.J.O. Development of a spectrofluorimetry-based device for determining the acetylene content in the oils of power transformers. Talanta 2013, 117, 263–267. [Google Scholar] [CrossRef]

- IEEE Std C57.104™-2008; Guide for the Interpretation of Gases Generated in Mineral Oil-Immersed Transformers. IEEE: New York, NY, USA, 2009; ISBN 978-0-7381-5834-1.

| Type of Fault | Gases Generated | Key Gas |

|---|---|---|

| Electric arc in oil |

| C2H2 |

| Partial discharges in oil |

| H2 |

| Over-temperature in oil |

| C2H4 |

| Cellulose overheating |

| CO and CO2 |

| Dissolved Gases | H2 | CH4 | CO | C2H2 | C2H4 | C2H6 | CO2 |

|---|---|---|---|---|---|---|---|

| Reference concentrations | 100 | 120 | 350 | 1 | 50 | 65 | 2500 |

| Type of Fault | CH4/H2 | C2H2/C2H4 | C2H2/CH4 | C2H6/C2H2 |

|---|---|---|---|---|

| Thermal decomposition | >1 | <0.75 | <0.3 | >0.4 |

| Corona (low-intensity PD) | <0.1 | negligible | <0.3 | >0.4 |

| Arcing (high-intensity PD) | >0.1 ÷ <1 | >0.75 | >0.3 | <0.4 |

| Type of Fault | C2H2/C2H4 | CH4/H2 | C2H4/C2H6 |

|---|---|---|---|

| Normal unit | <0.1 | >0.1 to <1 | <1 |

| Partial discharge | <0.1 | <0.1 | <1 |

| Arcing | 0.1 to 3.0 | 0.1 to 1 | >3 |

| Low thermal temperature | <0.1 | >0.1 to <1 | 1 to 3 |

| Thermal < 700 °C | <0.1 | >1 | 1 to 3 |

| Thermal > 700 °C | <0.1 | >1 | >3 |

| Fault Code | Type of Fault | C2H2/C2H4 | CH4/H2 | C2H4/C2H6 |

|---|---|---|---|---|

| PD | Partial discharge | NS | <0.1 | <0.2 |

| D1 | Low energy discharge | >1 | 0.1 ÷ 0.5 | >1 |

| D2 | High energy discharge | 0.6 ÷ 2.5 | 0.1 ÷ 1 | >2 |

| T1 | Thermal: <300 °C | NS | >1 but NS | <1 |

| T2 | Thermal: 300 °C < T < 700 °C | <0.1 | >1 | 1 ÷ 4 |

| T3 | Thermal: >700 °C | <0.2 | >1 | >4 |

| Ratio Range | Code | ||

|---|---|---|---|

| R1 | R2 | R3 | |

| R1 < 0.05 | R2 < 1 | R3 < 0.05 | 0 |

| 0.05 ≤ R1 ≤ 0.9 | 1 ≤ R2 ≤ 3.5 | 0.05 ≤ R3 ≤ 0.5 | 1 |

| R1 > 0.9 | R1 > 3.5 | R3 > 0.5 | 2 |

| R1 | R2 | R3 | Type of Fault | Fault Code |

|---|---|---|---|---|

| 1 or 2 | 0 | 0 or 1 | High-temperature thermal fault T > 700 °C | T3 |

| 1 or 2 | 1 | 0 or 1 | Medium-temperature thermal fault 300 °C < T < 700 °C | T2 |

| 1 or 2 | 2 | 0 or 1 | Low-temperature thermal fault 150 °C < T < 300 °C | T1 |

| 1 | ― | 0 | Low-temperature thermal fault T < 150 °C | T0 |

| 0 | 1 or 2 | 0 or 1 | Low partial discharge | PD1 |

| 0 | 1 or 2 | 2 | High partial discharge | PD2 |

| 0 or 1 | 0 or 1 | 2 | High energy discharge | D2 |

| 1 or 2 | 2 | 2 | Low energy discharge | D1 |

| 2 | 0 or 1 | 2 | Combination of electrical and thermal faults | DT |

| Gas Ratios | Temperature Range [°C] | ||

|---|---|---|---|

| 150 ÷ 300 | 300 ÷ 700 | >700 | |

| C3H6/C3H8 | <2 | 2 ÷ 6 | >6 |

| C2H4/C3H8 | <3 | 3 ÷ 15 | >15 |

| Fault Code | Type of Fault or Stress |

|---|---|

| PD | Corona-type partial discharges |

| D1 | Low energy discharges |

| D2 | High energy discharges |

| T1 | Thermal faults due to temperature < 300 °C |

| T2 | Thermal faults due to temperature 300 °C < T < 700 °C |

| T3 | Thermal faults due to temperature > 700 °C |

| DT | Combination of electrical and thermal faults |

| Fault Code | Type of Fault or Stress |

|---|---|

| PD | Corona-type partial discharges |

| S | Stray gassing of mineral oil |

| C | Hot spots accompanied by paper carbonisation (T > 300 °C) |

| O | Overheating (T < 250 °C) |

| T2 | Thermal faults due to temperature 300 °C < T < 700 °C |

| T3 | Thermal faults at very high temperatures (T > 700 °C) |

| Fault Code | Type of Fault or Stress in Sub-Areas |

|---|---|

| C1 | carbonisation fault between winding turns or inside windings |

| C2 | carbonisation fault on the outside of the windings |

| C3 | carbonisation fault in cables |

| 4 | overheating O, only with browning of the paper |

| Fault Code | Type of Fault or Stress |

|---|---|

| T1 | Thermal faults T < 300 °C |

| T2 | Thermal faults 300 < T < 700 °C |

| T3 | Thermal faults T > 700 °C |

| PD | Corona-type partial discharge |

| D1 | Low energy discharge |

| D2 | High energy discharge |

| DT | Combination of electrical and thermal fault |

| N | Normal ageing |

| Fault Code | Type of Thermal Faults or Stress |

|---|---|

| O | overheating < 250 °C |

| C | thermal faults with/followed by paper carbonisation |

| T3-H | high-temperature faults that only occur in the oil |

| Fault Area Code | Definition of Fault Areas |

|---|---|

| PD | Corona-type partial discharges |

| D1 | Low-energy electrical discharges |

| D2 | High-energy electrical discharges |

| S | Stray gassing of mineral oil |

| T1-O | Thermal faults at temperatures < 300 °C but without solid insulation carbonisation |

| T1-C | Thermal faults at temperatures < 300 °C, with probable involvement of solid insulation, possible carbonisation |

| T2-O | Thermal faults at temperatures between 300 °C and 700 °C, but with little chance of solid insulation or paper carbonisation |

| T2-C | Thermal faults at temperatures between 300 °C and 700 °C, with a high probability of solid insulation involvement (around 80%) |

| T3-H | Thermal faults in oil only, temperature range > 700 °C |

| T3-C | Thermal failures at high temperatures (over 700 °C) with solid insulation involved in the fault (paper carbonisation) |

| Name of Fault Area | Fault Area Code in Mansour Pentagon | Fault Area Code in IEC 60599 [19] |

|---|---|---|

| Low thermal fault—T < 300 °C | LT | T1 |

| Medium thermal fault—300 °C < T < 700 °C | MT | T2 |

| High thermal fault—T > 700 °C | HT | T3 |

| Low energy discharge | LED | D1 |

| High energy discharge | HED | D2 |

| Partial discharge | PD | PD |

| Definition of Fault Areas | Fault Area Code |

|---|---|

| High concentration of cellulose degradation | HCCD |

| Average cellulose degradation concentration | MCCD |

| Low cellulose degradation concentration | LCCD |

| Thermal fault < 300 °C | T1 |

| Thermal fault from 300 °C to 700 °C | T2 |

| Thermal fault > 700 °C | T3 |

| Electrical and thermal failure | TD |

| Low energy consumption discharges | D1 |

| High energy discharges | D2 |

| Partial discharges | PD |

| Definition of ROCs | ROC Code |

|---|---|

| Low energy discharge | D1 |

| High energy arcing | D2 |

| Thermal fault: T < 300 °C/300 °C < T < 700 °C | T1/T2 |

| Thermal fault T > 700 °C | T3 |

| ROU Code | Set of Faults | ROU Code | Set of Faults |

|---|---|---|---|

| U1 | T1/T2, PD, D2 | U5 | PD, D1, D2, T1/T2, |

| U2 | PD, D1 | U6 | D2, T1/T2, T3 |

| U3 | T1/T2, PD, | U7 | D1, D2 |

| U4 | PD, D1, D2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aciu, A.-M.; Enache, S.; Nițu, M.-C. A Reviewed Turn at of Methods for Determining the Type of Fault in Power Transformers Based on Dissolved Gas Analysis. Energies 2024, 17, 2331. https://doi.org/10.3390/en17102331

Aciu A-M, Enache S, Nițu M-C. A Reviewed Turn at of Methods for Determining the Type of Fault in Power Transformers Based on Dissolved Gas Analysis. Energies. 2024; 17(10):2331. https://doi.org/10.3390/en17102331

Chicago/Turabian StyleAciu, Ancuța-Mihaela, Sorin Enache, and Maria-Cristina Nițu. 2024. "A Reviewed Turn at of Methods for Determining the Type of Fault in Power Transformers Based on Dissolved Gas Analysis" Energies 17, no. 10: 2331. https://doi.org/10.3390/en17102331

APA StyleAciu, A.-M., Enache, S., & Nițu, M.-C. (2024). A Reviewed Turn at of Methods for Determining the Type of Fault in Power Transformers Based on Dissolved Gas Analysis. Energies, 17(10), 2331. https://doi.org/10.3390/en17102331