Abstract

The utilization of phase change materials (PCMs) in solar water heating systems (SWHS) has undergone notable advancements, driven by a rising demand for systems delivering superior performance and efficiency. Extensive research suggests that enhancing heat transfer (HTE) in storage systems is crucial for achieving these improvements. This review employs a bibliometric analysis to track the evolution of HTE methods within this field. While current literature underscores the necessity for further exploration into hot water generation applications, several methodologies exhibit significant promise. Particularly, strategies such as fins, encapsulation, and porous media emerge as prominent HTE techniques, alongside nanofluids, which hold the potential for augmenting solar water heating systems. This review also identifies numerous unexplored techniques awaiting investigation, aiming to pave new paths in research and application within the field of hot water generation. It highlights methods that could be used independently or alongside predominantly used techniques.

1. Introduction

The escalating effects of climate change and expanding populations fuel a greater need for building energy. This underscores the urgency of transitioning to cleaner energy sources to diminish dependence on fossil fuels, especially for vital requirements like heating water. Solar energy offers a sustainable solution to decrease conventional energy consumption, cut costs, and mitigate greenhouse gas emissions [1,2,3]. Despite the promising strides in solar energy applications, challenges persist, including intermittency, lower thermal efficiency compared to conventional sources, and temporal imbalances [4]. Addressing these hurdles requires tapping into the energy storage capabilities of specific materials to guarantee availability when required [5].

The literature discusses various heat storage methods: latent heat thermal storage (LHTS), sensible heat thermal storage (SHTS), and thermochemical heat thermal storage (THTS). LHTS involves a phase change of a material within a specified temperature range to store and release energy for tailored thermal applications. SHTS stores thermal energy in a material, maintaining its physical state, with energy correlated to temperature, quantity, and specific heat changes. THTS employs reversible physicochemical reactions for thermal energy storage (TES) and release [6,7]. Compared with SHTS, LHTS can be smaller, which is a significant advantage for use in domestic or residential areas [8,9,10]. It also allows energy to be recovered at a constant temperature [11]. Furthermore, several authors [6,12,13,14,15] have shown that integrating both SHTS and LHTS can reduce costs, enhance efficiency, minimize temperature drops, improve heat transfer, and decrease storage space requirements.

Over the years, significant advancements have been made in LHTS, especially with the integration of solar energy, which has proven highly effective in providing clean energy for various applications [16,17,18,19]. LHTS can employ phase change materials (PCMs), which absorb and release energy during phase transitions. These PCMs are categorized into three types: solid–liquid, solid–gas, and liquid–gas. Solid–liquid PCMs, particularly organic PCMs like paraffin, are most commonly used for hot water generation due to their suitability for low-temperature applications [10,20,21,22]. Organic PCMs (paraffins and fatty acids) exhibit extended operating lifespans, enduring thousands of freeze/melt cycles [23,24,25]. Paraffins, in particular, can maintain their functionality for up to 30 years without degradation [26,27]. For hot water generation, PCMs with a melting temperature range of 50 to 60 °C are recommended to ensure optimal efficiency and performance [28]. The application of PCMs in water heating has been documented since 2003, experiencing a notable increase in research and implementation between 2018 and 2022 [29,30].

PCMs provide significant benefits, including a high energy storage capacity, decreased corrosion, and thermal stability [8,31,32,33], making them highly suitable for hot water generation systems (HWGS). Such systems experience enhanced efficiency and prolonged operational periods [34,35]. At present, there are patents for TES [36], SWHS [37], and also for integrating PCM into aforementioned systems [38,39,40]. SWHS typically comprises three key components: the solar collector, storage tank (optional in some systems), and heat transfer fluid (HTF—with good thermal conductivity) [41]. HTF serves as a medium for energy transfer in heat exchange systems, whether PCM is employed or not [42,43]. Typically used in hot water generation, HTF, such as water [44], facilitates human consumption in various applications [45]. PCMs demonstrate efficient heat transfer during their molten phase, primarily facilitated by natural convection. However, as they solidify, due to their low thermal conductivity, a reduced heat transfer and performance between the PCM and the HTF is shown [3,46]. Consequently, charging and discharging times are prolonged, and the energy storage and release capacity of PCMs are reduced [22,33,47,48]. Lastly, convective boundary conditions in heat transfer occur due to forced convection from/to the HTF, allowing energy release or absorption [33]. Researchers have developed various techniques to enhance the heat transfer system between PCM and HTF in TES systems [22,49]. These include improving PCM properties, optimizing collector design for better heat transfer, enhancing HTF, and incorporating larger surfaces [13,50,51,52,53].

Harris et al. [16] emphasize that improving heat transfer in water solar heaters (WSH) with PCM presents a promising avenue for research, supported by numerous studies confirming its efficacy in achieving system autonomy. Furthermore, the authors suggest expanding this research to encompass investigations into diverse climatic conditions, economic implications, and health considerations related to heat transfer enhancements (HTEs) or PCMs. A growing body of research is dedicated to finding innovative ways to store more energy in less time using PCMs alongside other materials and techniques like nanoparticles and fins [54,55,56,57]. Some of these HTEs involve integrating various methods to enhance efficiency and storage capacity while reducing the duration of charging and discharging periods [12,22] or using PCM encapsulation to increase the stratification capacity of a TES tank and have hot water available for longer. This is achieved as the temperature difference between the HTF and PCM increases [58]. There are various patents on HTE, including encapsulation [59], porous media [60], coils [61], and nanoparticles [62]. This research exclusively concentrates on the advancements in LHTS and explores potential enhancements that can be implemented in this type of storage.

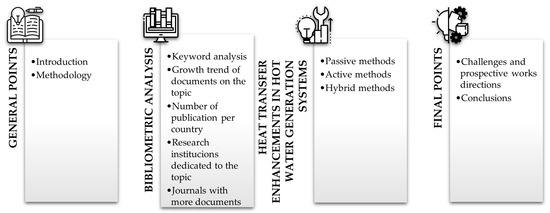

This paper presents a comprehensive review and bibliometric analysis of HTEs applicable to HWGS using PCMs or other HTFs. Previous literature reviews have demonstrated significant progress in various HTE methods across different applications, including those relevant to this study. However, this new review offers a more focused approach, highlighting the most commonly used techniques and those with potential for future research in this field. As such, our analysis categorizes advancements into three primary groups, active, passive, and hybrid methods employing PCMs, while also exploring the use of nanofluids in solar collectors as an innovative heat storage solution. The main objective is to chart a course for HTEs that have seen widespread use or potential for future application in HWGS incorporating PCMs. Figure 1 illustrates the structural framework of this review article.

Figure 1.

The structural framework of this review.

2. Methodology

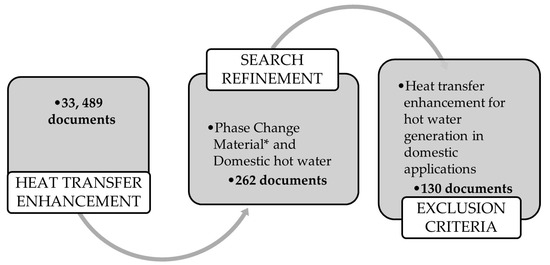

This article employs bibliometric analysis, using the Scopus scientific database as its primary methodology. The search was conducted until December 2023 to identify leading countries and influential institutions that have significantly contributed to this topic. Initially, the focus was on advancements in heat transfer using PCMs for energy storage. Consequently, the initial search was conducted using the keyword “heat transfer enhancement” without any year or document type restrictions, resulting in 33,489 documents. To refine the search, two specific keywords, “Domestic hot water” and “Phase Change Material*” were added to narrow down the search to more relevant articles. The asterisk (*) within the word facilitated our incorporation of the terms “Phase Change Material” and “Phase Change Materials”. This refined approach ultimately led to the identification of 262 pertinent articles. Additionally, an exclusion criterion was implemented, specifically targeting documents detailing methods of heat transfer enhancement (HTE) applicable to domestic or residential hot water generation. Figure 2 visually represents the proposed methodology, which will be employed in the subsequent sections.

Figure 2.

Methodology used to search for information in Scopus.

3. Bibliometric Analysis

Following the methodology outlined in Figure 2, the search resulted in 130 final documents, forming the basis for the bibliometric analysis. In the initial analysis phase, research trends were analyzed over the years to create a comprehensive overview.

3.1. Keyword Analysis

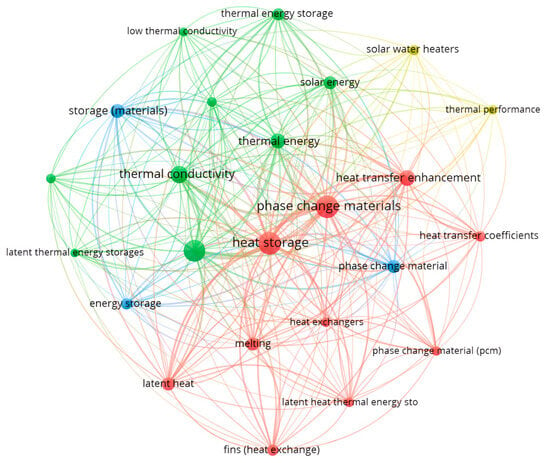

The co-occurrence of keywords in the documents was explored using VOSviewer software, version 1.6.18. Figure 3 illustrates the frequency of keyword appearances, drawn from a pool of 466 keywords. Only those mentioned at least five times were included in the mapping, culminating in 24 distinct keywords. Notably, terms such as ‘Phase Change Materials’, ‘heat storage’, ‘heat transfer’, ‘thermal conductivity’, and ‘heat transfer enhancement’ attracted attention are illustrated by larger circles in Figure 3, indicating their frequent recurrence in the studied documents.

Figure 3.

Keyword co-occurrence network in heat transfer enhancement literature for latent heat thermal storage.

As illustrated in Figure 3, the interrelationships among keywords delineate a comprehensive network, suggesting that each keyword is intricately connected to others identified in the study. Furthermore, it is notable that terms such as ‘Phase Change Materials’ and ‘heat transfer enhancement’ exhibit frequent associations with concepts such as ‘fin’, ‘solar energy’, ‘solar water heaters’, ‘latent heat thermal energy storage’, and ‘solar heating’.

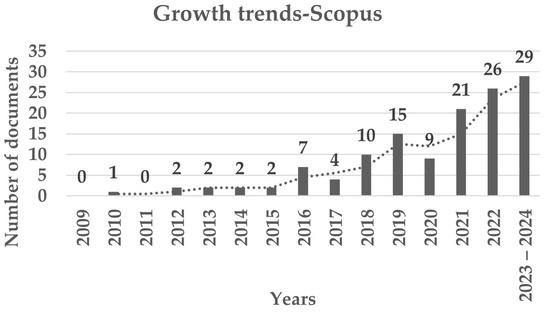

3.2. Growth Trend of Documents on the Topic

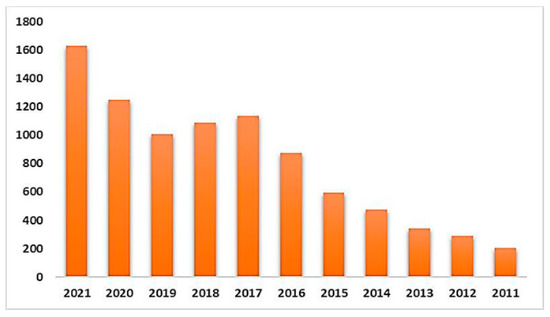

Figure 4 depicts the number of documents indexed in Scopus regarding the topic, offering a glimpse into the progression of this topic over time. This figure reveals a significant uptick in research and publications in the last three years (2021 to 2023). This notable surge implies a growing interest in the topic, potentially driven by advancements in PCMs for heat transfer applications, hot water generation, and building efficiency.

Figure 4.

The trend of annual document publication in Scopus.

3.3. Number of Publications per Country

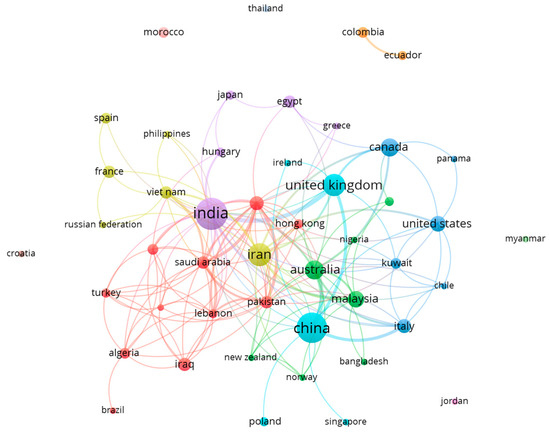

To investigate the global influence of the topic under investigation, a mapping was conducted using the VOSviewer program (version 1.6.18), identifying contributions from 47 countries. Figure 5 showcases India in the lead with 38 documents, followed by China with 34, and Iran with 17, underscoring their substantial research output. The nations’ populations may contribute to their prominent positions in publication volume within this domain [63]. Furthermore, VOSviewer’s analysis delves into the collaborative relationships between countries, as evidenced by their joint research efforts. A notable partnership between India and the United Kingdom is depicted by a sky-blue thicker line in Figure 5, symbolizing their robust research collaboration. Additionally, the United Kingdom leads in the number of citations with 2953, followed by China with 2476, and India with 1614, indicating the widespread global impact and recognition of their scientific contributions.

Figure 5.

Global co-authorship network map in heat transfer enhancement for latent heat thermal storage research.

3.4. Global Research Institutions Specializing in Heat Transfer Enhancement for LHTS

The analysis aimed to identify institutions distinguished for their prolific output or trending productivity in publications. Consequently, a total of 334 entities were delineated, both in higher education institutions and research organizations. Noteworthy entities leading the list with a minimum of three publications include the Department of Refrigeration and Cryogenic Engineering at Xi’an Jiaotong University in China, the Department of Mechanical Engineering at Babol Noshirvani University of Technology in Iran, and the Center for Advanced Studies in Energy (USP-CAS-E) at the National University of Sciences and Technology (NUST) in the U.S.–Pakistan collaboration. This investigation underscores the pivotal role of academic institutions in driving research within this domain.

3.5. Journals with More Documents

Table 1 shows the scientific journal articles that the authors used to disseminate their research findings. Initially, 64 journals were identified through the analysis, but the table has been refined to feature only those with at least two publications. Notably, the ‘Journal of Energy Storage’ emerges as the leading publication venue for articles on the topic, based on author contributions. Furthermore, the analysis indicates a prevalent focus on engineering and energy across most journals. Additional thematic areas encompass environmental science, materials science, and social sciences, especially in research that intersects sustainability with implementing HTEs in systems.

Table 1.

Impactful journals on heat transfer enhancement for latent heat thermal storage research.

After conducting the bibliometric analysis, it was possible to examine bibliometric data from documents identified as relevant according to the applied methodology. The techniques from various methods for enhancing heat transfer, as used in the field of potable hot water generation, are analyzed based on the works of other authors, as illustrated in Figure 1.

4. Heat Transfer Enhancements (HTEs) in Hot Water Generation Systems (HWGS)

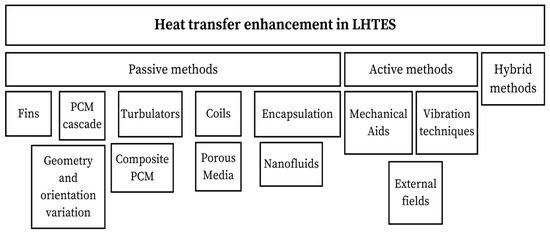

The literature describes various methods to enhance heat transfer in HWGS. These enhancements may involve modifications to the properties of the PCM [64] and alterations to the generation system itself [65]. Figure 6 illustrates various techniques for enhancing heat transfer in LHTS systems based on the conducted study. Other authors classify these techniques based on enhancements in thermal conductivity (such as carbon materials, nanoparticles, metal foams, and graphite foams), enhancements in heat transfer efficiency through convection (related to geometry), and optimization of the structure of phase change devices (including fins, heat pipes, geometric configuration, and materials) [20,28,66,67]. In addition to the methods and classifications detailed above, various other techniques exist, including bubble agitation, metal rings, multitubes, carbon brushes, metal matrix, graphite flakes, module beam, polypropylene flat panel, and compact flat panel. These methods enhance heat transfer and find application across diverse contexts [68].

Figure 6.

Heat transfer enhancement methods employed in this review.

Furthermore, an unconventional technique involving microorganisms has been identified [69]. However, this approach is considered somewhat inappropriate due to its association with water intended for human consumption, posing potential health risks. Nevertheless, integrating it with other techniques to develop a safe heat storage system without contaminating the water remains a subject for further exploration.

In order to implement these enhancements in HWGS employing PCM, a wide range of PCM options must be considered, as this selection significantly influences the effectiveness of the heat storage system. Therefore, the primary properties to be evaluated during this selection process include the temperature range, density, thermal conductivity, specific heat capacity, cost, and latent heat of fusion. Various approaches have been used to customize the selection of materials according to specific requirements. These approaches encompass multi-criteria decision-making methods (MCDM), such as the Analytic Hierarchy Process (AHP), TOPSIS (Technique for Order Performance by Similarity to Ideal Solution), COPRAS (Complex Proportional Assessment), VIKOR (Vise Kriterijumska Optimizacija Kompromisno Resenje), and others, serving as methodologies for material selection [3,5,70]. When choosing a PCM, volume variation is another crucial criterion, as it can significantly impact system efficiency. The PCM needs to exhibit minimal volume changes [35,68,71,72]. While organic PCMs are often suggested for their potential to minimize volume changes [12,20,67,73], thorough verification is necessary to ensure future operational integrity. In examining the volume variation of PCMs across different HTE techniques, only a limited number of studies were discovered that illustrate PCM volume changes as per the employed methodology. These studies indicate the following:

- PCM volume fluctuations during a phase change can potentially harm composite PCMs (Graphite + PCM), yet they do not impair the heat transfer surface of the system during solidification/melting cycles [74].

- To mitigate pressure drops resulting from PCM volume changes, leaving a void space within the tubes to accommodate PCM volume fluctuations is essential. Typically, only 90% of the evacuated tube solar collector’s tube is filled for this purpose [75].

- When employing porous media, ensuring sufficient impregnation of PCM within the foam facilitates the filling of empty pores during PCM volume alterations. This safeguards the TES capacity from being compromised [12,66,76].

- PCM encapsulation can mitigate volume changes resulting from phase transitions. Macroencapsulation, in particular, is employed to increase the heat transfer area, thus offsetting PCM volume changes [44].

- Holes in PCM capsules can act as buffers for PCM volume expansion, typically used in spherical encapsulation designs [20,77].

- Due to PCM volume changes, high stresses occur in the annular fins after a certain number of cycles. However, further research is needed on fluid–structure interaction in TES systems with annular fins [71].

The subsequent subsections explore the methods that have been used or have the potential to be employed in hot water generation, whether within storage tanks, shell-and-tube TES units, solar collectors, or other relevant systems. These methods were selected based on the articles reviewed in the bibliometric analysis.

4.1. Passive Methods

Passive methods are extensively embraced due to their reliance on surface modifications rather than external sources, resulting in simpler experimental development. These methods are cost-effective compared to active approaches and provide versatility for many applications [69]. Below, various techniques identified in the analysis of the selected articles are outlined.

4.1.1. Fins

Fins represent a common method for enhancing the thermal conductivity heat transfer coefficient and achieving a faster solidification process in heat exchangers [78,79]. Their popularity stems from their simplicity, ease of manufacture, and cost-effectiveness [80]. Fins are typically extended on the PCM rather than the HTF side to enhance efficiency [42]. Fins facilitate heat transfer within these systems, and increasing their number and size can significantly enhance system performance [43,81,82]. This assertion is supported by studies such as Hosseine et al. [83], which propose that fin length is a critical parameter capable of augmenting absorbed energy and reducing melting temperatures. Additionally, Kalbasi and Salimbur [84] observe that a greater number of fins can lead to a more uniform temperature distribution, optimizing the time required to reach peak temperature. Khan et al. [85] corroborate these findings. Conversely, Al-Abidi et al. [49] suggest that fin thickness, length, number, and the geometry of PCM units in Triplex Tube Heat Exchangers (TTHX), as well as TTHX material and Stefan number, are pivotal parameters for hastening PCM fusion. Tavakoli et al. [86] and Mao et al. [87] indicate that various geometric parameters can influence the PCM melting time, along with the TES model in which the fins are situated. However, Dinker et al. [10] note that reducing the fusion time may inversely impact the overall system efficiency. Therefore, it is imperative to consider various parameters such as inlet temperature, shape, and HTF flow rate during the charging period to mitigate PCM melting time [88,89].

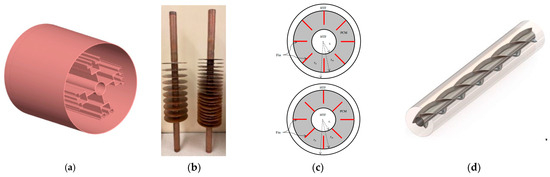

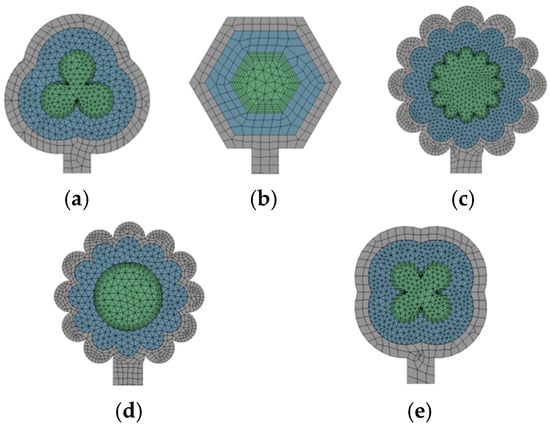

Fins can be manufactured in various shapes, including flat rectangular fins, rod-shaped fins, and other irregular configurations, as illustrated in Figure 7. Research conducted by Zhang et al. [71] indicates that longitudinal and annular fins have acquired the most attention in the past decade. However, helical and topologically optimized fins (depicted in Figure 7d) demonstrate exceptional potential due to their superior performance compared to traditional fins. This observation suggests that fins can be further improved using various active and passive techniques for HTE.

Hosseini and Rahimi [90] highlight in their research that the position and size of rectangular fins can significantly influence heat transfer distribution within energy storage systems. So, to have a shorter melting time of the PCM, one must consider these parameters in rectangular fins and possibly in other configurations. Amagour et al. [91] present a three-dimensional numerical study of a fin-tube heat exchanger to assess HTE performance. The findings indicate that increasing the HTF (water) flow rate reduces both charging and discharging times. Conversely, elevating the HTF temperature accelerates the melting process by up to 30% when there is a 10 °C temperature difference between the HTF and the PCM; however, this also prolongs the solidification process.

Moreover, augmenting the number of fins decreases the heat transfer time and enhances the energy storage capacity. Nonetheless, the study suggests an upper limit to the number of fins for effective enhancement. Additionally, the authors recommend positioning the fins in the middle of the heat exchanger, increasing fin thickness, and using copper material, as these measures reduce the total melting time. In another study, Amagour et al. [92] indicate that a minimum of 8 h of hot water is required for residential construction. Conversely, Chow and Lyu [27] propose a minimum requirement of 18 h (from 7:00 am to 12:00 am) for residential applications.

Figure 7.

Different shapes of fins: (a) branch-shaped fins [78] (CC by 4.0); (b) annular fins [43] (CC by 4.0); (c) rectangular fins [93] (Copyright © 2013 Elsevier Ltd.); (d) twisted fins [94] (Copyright © 2013 Elsevier Ltd.); (e) different fins of various researchers [95] (CC by 4.0).

Moreover, using copper strips shows promising potential for conduction HTE, thereby reducing melting time by 16% [96]. Authors conducting numerical simulations employ various methods to analyze fins in heat storage systems, including the Finite Volume and Enthalpy-Porosity methods [94]. Table 2 summarizes selected research studies employing fins as an HTE technique.

Table 2.

Most relevant research on fins in latent heat thermal storage.

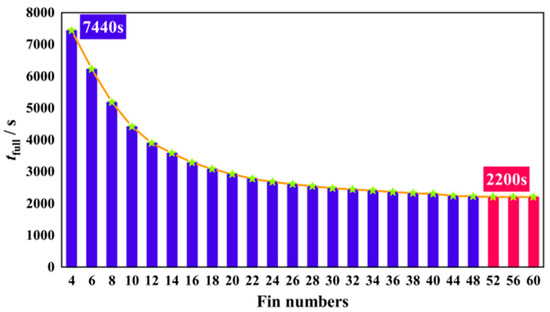

The literature review underscores the widespread utilization of rectangular fins for HTE across various applications. Their simplicity in design and low manufacturing complexity renders them highly favored. The findings of these studies highlight a significant potential for improving heat transfer in LHTESS. Notably, the methodology employed revealed a paucity of studies addressing the real-world application of hot water, with most being either numerical or laboratory-scale investigations. Consequently, a research gap exists regarding both simple and complex-shaped fins’ ability to enhance heat transfer in these systems. In addition to numerical analyses, experimental studies are imperative to validate the efficacy of this technique in HWGS. The outcomes of these studies underscore the pivotal role of the number of fins in LHTESS. While some studies suggest a progressive improvement in heat transfer efficiency with an increased number of fins, others indicate that this relationship has a finite range beyond which further enhancement ceases. Therefore, it is crucial to corroborate this information, as only numerical data are available on this aspect (see Figure 8). Moreover, investigating the use of various fin shapes in LHTESS is essential, as it can explain which of the shapes studied in the literature yield superior results.

Figure 8.

Total melting time for various fin numbers [99] (Copyright © 2021 Elsevier B.V.).

4.1.2. Turbulators

Turbulators represent passive methods characterized by spiral inserts elevating fluid velocity within tubes. Turbulators use discs, twisted tapes, wire coils, and others. Turbulators look like fins but differ in their twisted geometry [104]. Typically composed of carbon steel, stainless steel, or copper, turbulators promote HTE and increase flow turbulence [105,106]. Research indicates that this method of heat enhancement surpasses the efficacy of using simple-shaped tubes in SWHS [107]. The subsequent section outlines selected studies from the literature pertaining to this topic.

Twisted tapes and turbulators can potentially increase heat transfer and performance, contingent upon the type of solar collector employed. Nevertheless, this passive technique exhibits somewhat restricted applicability in hot water generation or solar collectors [108,109]. Jaisankar et al. [110] undertook a study to investigate the impact of heat transfer from a collector enhanced with a helically twisted tape. Their findings revealed that using a helically twisted tape can elevate the heat transfer rate, pressure drop, and thermal efficiency by enhancing the tape’s solar radiation and twist ratio.

Li et al. [94] conducted a similar study, only that they are called twisted fins or helical fins since these are located outside the tube through which the HTF (water) passes. In their numerical investigation, they examined the application of shell-and-tube-based heat storage with twisted fins to enhance the performance of this storage type. Their study encompassed various configurations of twisted fins, ranging from 0 to 4 fins positioned around the base tube, and was conducted in two orientations: vertical and horizontal. Their findings indicate that the configuration featuring three twisted fins enhances the melting time of the PCM in the vertical orientation, while in the horizontal orientation, the configuration with two twisted fins yielded the most favorable melting time. Consequently, the authors concluded that increasing the number of twisted fins does not necessarily correspond to a performance enhancement.

Not all researchers confirm the efficacy of turbulator-based enhancement methods. For instance, Hobbi et al. [111] explored the influence of various passive devices (including twisted strips, coil-spring wires, and conical ridges) on a flat plate solar collector. Their findings suggest that these turbulence enhancement techniques fail to significantly increase heat transfer, as evidenced by the absence of discernible differences in the heat flow to the fluid.

The use of turbulators in LHTESS remains limited. Nevertheless, considering their association with fins, it represents an area warranting further investigation and expansion. The literature review reveals divergent viewpoints regarding the effectiveness of turbulators, which may stem from variations in methodology, collector size, or experimental setups adopted by researchers. The studies identified in this review primarily focused on systems employing tubes or solar collectors, as turbulators are commonly deployed to augment fluid velocity within the tubes. Notably, no explicit investigations were found about using coils in storage tanks. This presents a research opportunity to enhance HTF velocity within the coils, potentially improving the melting efficiency.

4.1.3. Porous Media (PM) or Foams

PCMs represent a promising avenue for enhancing energy efficiency and sustainability within systems. Researchers have explored various methodologies to augment thermal conductivity, among which the utilization of PM or metal foams stands out. These materials are favored for their robust, highly conductive, and permeable structures. The literature reveals a diversity of models, materials, pore densities, and porosities employed in fabricating foams or PM. However, the efficacy of this technique is compromised by the inherent natural convection of the material [12,44]. Moreover, numerous numerical methods are available for modeling this technique, with the Lattice Boltzmann method emerging as the most prevalent [112,113]. Alternatively, Habibishandiz et al. [69] demonstrate several models capable of simulating velocity within the PM, including the Darcy model, Darcy–Forchheimer (DF) model, Darcy–Brinkman (DB) model, and Darcy–Brinkman–Forchheimer (DBF) model.

Majdi et al. [114] indicate that incorporating PM within a tank can significantly extend the thermal storage duration compared to systems lacking such media. Furthermore, the thermal conductivity of PCMs can be substantially augmented through metallic foams, with copper foam exhibiting a 44-fold increase and aluminum foam exhibiting a remarkable 218-fold increase when configured with 89% and 71% porosities, respectively. Additionally, employing the impregnation method proves beneficial in minimizing empty pores within the PCM, thereby mitigating undesired thermal resistance [76]. It is important to acknowledge that these enhancements may vary based on several factors inherent to the system; nonetheless, experimental investigations have demonstrated HTEs of up to 400% [115,116]. Conversely, Zhang et al. [117] illustrate that the effectiveness of metallic foam in HTE is contingent upon factors such as porosity, pore density, and thermal conductivity.

The utilization of metallic foams in various applications has acquired significant interest. In a study by Xiao et al. [118], two types of metallic foams, copper and nickel, were compared for their effectiveness in creating a composite PCM. Their findings revealed that the copper metal foam exhibited a superior enhancement in thermal conductivity compared to its nickel counterpart. Similarly, Aramesh and Shabani [75] conducted a comparative analysis involving different setups: (a) no PCM, (b) pure PCM, (c) PCM with fins, and (d) PCM with metal foam in an evacuated tube solar collector. While the absence of PCMs (setup a) resulted in a higher outlet temperature, it lacked the energy storage capability observed in setups involving PCM (b, c, d). Notably, setup (d) incorporating PCM with metal foam exhibited a reduced temperature drop, enhanced heat storage, improved heat transfer performance within the tubes, and higher overall efficiency. Further investigations exploring the application of this technique can be found in Table 3.

The remarkable thermal conductivity of metallic foams facilitates the solidification and melting processes of PCMs. However, choosing an appropriate position when placing the PCM is necessary, as this will allow for a more efficient heat transfer. This observation was only made in LHTESS with tubes. Regarding the application of this technique, few current studies validate the results in hot water generation, whether using solar collectors or storage tanks. Nevertheless, the collective evidence from reviewed studies consistently highlights the exceptional performance of copper metallic foams. Therefore, it is recommended to prioritize investigations focusing on copper metallic foams as a foundational starting point for future research endeavors in this domain.

Table 3.

Research about porous media in the literature.

Figure 9.

Different configurations about the use of porous media [120] (Copyright © 2013 Elsevier Ltd.).

Table 3.

Research about porous media in the literature.

| Author | PCM/HTF | Porous Media | Type Study 3 | Focus Study | Results |

|---|---|---|---|---|---|

| Zhu et al. [65] | Paraffin wax 2 | Copper metal foam | N/E | Melting process |

|

| Zhu et al. [119] | Paraffin wax 2 | Copper metal foam | E | Melting process |

|

| Alam et al. [120] | n-eicosane/H2O | Copper metal foam | N | Solidification process |

|

| Wang et al. [121] | Paraffin wax 2 | Copper metal foam (Porosity 95%, pore density 5PPI) | E | Melting process |

|

| Yang et al. [122] | Paraffin/H2O | Open-cell metal foam | E | Melting process |

|

| Baruah et al. [123] | PCM 1,2 | Capsules of metal foam | N | Melting process |

|

1 PCM is not specified/disclosed. 2 HTF is not specified/disclosed. 3 Type of study: N = numerical and E = experimental.

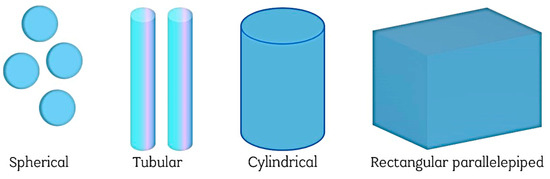

4.1.4. Encapsulation

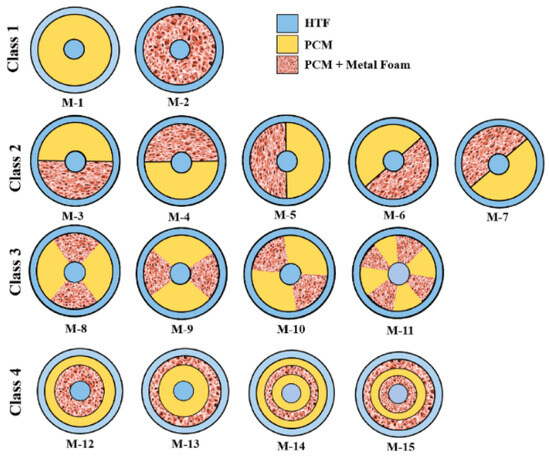

Encapsulation involves enveloping a material with a protective coating, which is crucial in LHTESS. Various types of coatings, including metallic, inorganic, and plastic, necessitate careful selection for optimal performance [21]. Encapsulation serves several key purposes, including isolating the PCM from the external environment, preventing direct contact with the HTF, mitigating external volume change reactions, enhancing system efficiency, and augmenting the heat transfer surface [85]. Different integration methods for PCM encapsulation exist, such as macroencapsulation (approximately 1 mm), microencapsulation (0–1000 μm), nanoencapsulation (0–1000 nm), immersion, and direct incorporation [44,72,124]. While various PCMs can be encapsulated, paraffin wax and sodium acetate trihydrate are commonly employed in this context. Among the available encapsulation materials, plastic, aluminum, and stainless steel are frequently used for macroencapsulation [125]. In contrast, although more intricate in manufacturing, microencapsulation offers superior heat transfer capabilities [126]. Encapsulation with metallic materials like copper, aluminum, and steel presents an attractive option for enhancing thermal conductivity. However, it poses manufacturing challenges [85]. Figure 10 illustrates diverse ways of PCM encapsulation.

Figure 10.

Various configurations of PCM encapsulation [126] (Copyright © 2012 Elsevier Ltd.).

Different parameters must be considered when encapsulating a PCM, as they can affect or enhance heat transfer. These parameters are the shell material, geometry, and core-to-coating ratio (decides the encapsulated PCM’s mechanical strength and thermal stability). Additionally, factors such as the Stefan number, the temperature range of the PCM, and the volumetric concentration of the microcapsule can exert a significant influence on heat transfer [126]. One of the significant challenges associated with encapsulating materials is the risk of leakage. Therefore, conducting leakage analysis on the PCM during encapsulation is essential to ensure its reliability before deploying it in practical applications. Leakage analysis involves subjecting the encapsulated PCM to thermal cycling and thorough cleaning procedures to assess its integrity and performance [127].

Microencapsulation presents an opportunity to improve the energy storage efficiency and enhance various thermal properties in direct absorption solar collectors [128]. This is because there is no change in the velocity of water and microencapsulated PCM product of microencapsulation; a diameter of 5 μm is recommended to enhance the performance [129]. Nanoencapsulation of PCM offers benefits such as improved thermal conductivity, leakage prevention, reduced overcooling, and increased suspension capacity at the melting temperature [124,130].

Certain investigations into cylindrical macroencapsulation have demonstrated its potential to increase energy storage density and prolong the storage duration. However, simply increasing the PCM amount does not necessarily improve the system’s thermal performance, as a critical threshold exists for PCM quantity [131,132]. In a study by Sun et al. [133], an experimental–numerical analysis was conducted to evaluate the impact of integrating encapsulated PCMs into a water storage tank linked to four unglazed monocrystalline photovoltaic–thermal (PVT) modules. Their findings indicated a slight increase in average and overall electrical efficiency; however, the authors caution that alterations may influence these values in the flow rate.

Other studies have explored spherical encapsulation, such as the investigation by Nallusamy et al. [15], who employed spherically encapsulated paraffin with high-density polyethylene in a hybrid storage system combining sensible and latent heat. Their findings indicated a faster discharge period, suggesting this hybrid system is well-suited for intermittent hot water discharge systems. In a separate study, Shin et al. [77] compared elliptical and spherical capsules with the elliptical capsule, composed of polyethylene, aimed at enhancing heat transfer. The results demonstrated that the elliptical geometry could increase the Nusselt number by fivefold, reducing the charging and discharging times by 50% and 35%, respectively. Moreover, this experiment, conducted on a large scale, exhibited favorable charge and discharge times, suggesting its potential as a thermal battery.

PCM encapsulation is common in storage tanks, particularly for prolonged hot water generation. Macroencapsulation, owing to its affordability, has garnered significant attention, especially in mixed heat storage systems like LHTS-SHTS. However, real-world applications of encapsulation in solar collectors remain largely unexplored, predominantly confined to laboratory-scale investigations, thus presenting a promising avenue for future research. Additionally, exploring diverse macroencapsulation geometries can enhance heat transfer efficiency by augmenting the surface area for heat transfer. Nonetheless, while microencapsulation demonstrates promising outcomes, its high manufacturing cost poses a significant limitation, rendering it less accessible for LHTESS applications.

Furthermore, a techno-economic analysis was conducted to investigate the casing cost and encapsulation methods [47]. Findings revealed that PCM encapsulated with aluminum alloy, titanium, and carbonate tubes offer a cost-effective solution for their deployment. Moreover, the overall cost of encapsulation is contingent upon the casing material and encapsulation technique employed, with due consideration to the minimal cost associated with PCM itself.

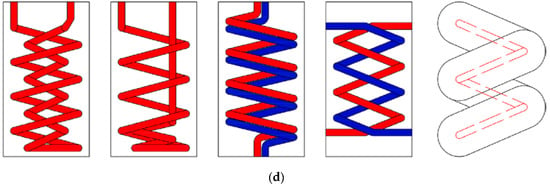

4.1.5. Geometry and Orientation Variation

The geometry and orientation of TES systems play a crucial role in determining their performance. Therefore, it is essential to select a geometry that ensures uniform temperature distribution within the TES system and to consider the container orientation, which can influence heat transfer [85]. Various LHTS geometries are available, including circular, cylindrical shell and tube, rectangular, and triplex tube configurations (which consist of a cylinder with two tubes of different sizes inside, facilitating the exchange of HTF and PCM) [6]. This method offers long-term viability compared to alternative techniques like nanoparticles and fins. Notably, the container’s inclination angle can impact melting and solidification rates [134]. Additionally, the TES system can be enhanced by modifying the container geometry or the tubes through which the HTF flows.

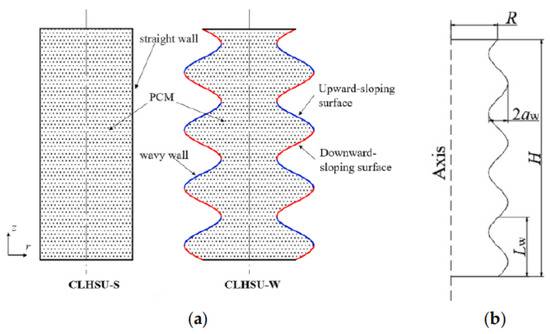

Yan et al. [135] conducted a numerical study investigating the impact of altering the shape of a cylindrical latent heat storage unit (CLHSU) on both the charging and discharging times. Figure 11 illustrates the CLHSU before and after the geometry modification. The study focused on varying the wavelength (Lw) and wavelength amplitude (aw) to assess their effects on the charging and discharging times. Results indicated significant changes in the heat transfer coefficient and the velocity of PCM during these processes. During discharging, the heat transfer coefficient experienced a slight 2% decrease due to the corrugated wall but remained higher than that of the CLHU-S model.

Figure 11.

Geometry changed by Yan et al. [135] (Copyright © 2023 Elsevier Ltd.): (a) cylindrical latent heat storage unit without waves (CLHSU-S) and without waves (CLHSU-W); (b) computational domain of the CLHSU-W.

Moreover, it was noted that the parameters Lw and aw played a minor role in the discharging process but had a more pronounced impact during charging. Additionally, Aggarwal et al. [17] highlighted in their research the significance of the tilt angle of evacuated tube solar collectors (ETSCs) in enhancing effectiveness and cost efficiency across different geographical regions. Thus, it is imperative to consider this factor when planning the installation of a HWGS based on the specific location of the study.

Although the numerical investigation conducted by Quitiaquez et al. [136] focuses on enhancing heat transfer within a solar collector/evaporator primarily used in heating systems, it reveals a notable improvement in heat generation when modifying the cross-section of the tubes, as illustrated in Figure 12. As a result, alternative geometries are being considered for HWGS. However, an economic analysis is imperative to determine whether this enhancement is economically viable for enhancing system performance. Additionally, experimental validation is essential to ascertain whether altering tube or storage tank geometry can enhance efficiency and reduce the charging and discharging times of LHTESS.

Figure 12.

Different geometries [136] (CC by 4.0). (a) Three-leaf clover; (b) hexagonal; (c) flower; (d) internal circular section with a flower shape in the external profile; (e) four-leaf clover.

4.1.6. Composite Phase Change Materials (CPCMs)

CPCMs are favored for energy storage due to their exceptional thermal conductivity, low cost, enhanced productivity, chemical stability, corrosion resistance, and thermal diffusivity [81]. Certain CPCMs incorporate nanofillers like graphite, graphene oxide (GO), and hexagonal boron nitride (HBN), which significantly augment the thermal properties of the PCM, thereby benefiting solar energy storage systems [137]. Additionally, CPCMs with additives or nanoparticles such as expanded graphite (EG) and carbon fiber (CF) exhibit favorable thermochemical properties, high thermal conductivity, and remarkable heat storage capacity [44].

Nanoparticles, characterized by their dimensions smaller than 100 nm, exhibit thermal conductivity influenced by several factors such as concentration, temperature, particle size, pH, shape, material composition, and potentially the manufacturing process [1]. The literature highlights diverse methods for synthesizing nanoparticles from disposable materials, as delineated in Table 4. However, exploring the feasibility of producing nanoparticles from waste materials remains relatively unexplored. Conversely, limited research delves into the cost-effectiveness of incorporating nanoparticles in PCM preparation, particularly regarding implementation expenses for specific applications. While some studies demonstrate the enhancement of PCM thermal conductivity by adding expanded graphite or graphite nanoparticles, it is noteworthy that this augmentation affects thermal conductivity, melting time, and overall thermal performance positively [138,139,140].

Table 4.

Nanoparticles consisting of industrial waste materials [141].

D’Oliveira et al. [141] demonstrated the capacity of highly conductive nanoparticles to augment the thermal conductivity of PCM with low melting temperatures (ranging from 20 to 70 °C). The literature underscores the potential of carbon-based nanoparticles to supplant conventional metallic nanoparticles due to their commendable stability and ability to enhance PCM thermal conductivity [45,147,148]. In comparison, H.M Teamah and M. Teamah [149] agree on carbon-based nanoparticles but indicate that metallic foams are also strong candidates. In a study by Cabeza et al. [150], a CPCM comprising 10% volume of graphite and 90% volume of sodium acetate was investigated for hot water generation. Their findings revealed that employing this CPCM could extend the duration of hot water availability, contingent upon the number of bottles used. Although their study assessed 2, 4, and 6 bottles, it clarified that the energy storage density surged to 40%, 57.2%, and 66.7%, respectively.

In contrast, Xie et al. [151] present a study demonstrating the feasibility of utilizing environmentally sustainable materials in creating CPCMs. They employed coconut shell charcoal (CSC) as the primary material in their investigation. Focused on optimizing the PCM charging process, they augmented the PCM with CSC, modified the supporting material (H2O2), and evaluated its thermal characteristics in domestic solar energy applications. Their findings revealed that the CPCM exhibited a nearly threefold increase in thermal conductivity compared to non-CSC variants. Moreover, the CPCM displayed altered phase change temperatures, reduced latent heat, and improved efficiency. Furthermore, they evaluated the material’s performance in a tankless solar water heater, demonstrating its ability to store energy for subsequent use after sunset effectively. Additional significant studies are cataloged in Table 5.

Table 5.

Research covering composite phase change materials in the literature.

This approach can be combined with other methodologies like microencapsulation, thereby augmenting the thermal characteristics of the PCM and promoting uniform temperature dispersion [157]. The utilization of CPCMs is highly prevalent in hot water generation. Consequently, there is a proposition to fabricate CPCMs incorporating nanoparticles sourced from both organic and inorganic waste materials. Despite the extensive literature review, only limited instances of CPCMs formulated from organic waste have been identified. Moreover, no numerical or experimental studies have been encountered that validate their application in LHTESS.

It is important to acknowledge that this observation might stem from the relatively low conductivity of these materials, unlike the case with metallic nanoparticles. However, this inference remains speculative due to the absence of supporting studies. A thorough examination of the literature reveals that most authors have primarily combined nanoparticles with paraffin waxes. This highlights a potential way for further investigation to explore the utilization of nanoparticles with alternative PCMs. Such exploration could yield significant advancements in properties and heat transfer mechanisms.

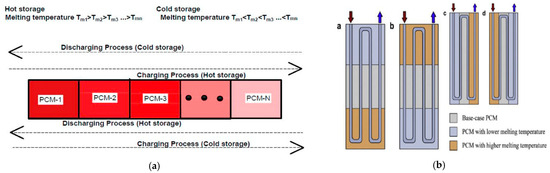

4.1.7. Multiple PCMs (M-PCMs) or Cascade LHTES System

TES systems employing M-PCMs offer a promising solution to mitigate thermal distortion during the charging and discharging phases. Numerous studies suggest that these systems can significantly improve efficiency and expedite charging processes, contingent upon the specific thermal properties of the PCMs used, such as the phase change temperature, latent heat, thermal conductivity, and mass ratio [158,159]. Therefore, carefully selecting materials is imperative to realize performance enhancements [160]. This advancement can potentially optimize heat transfer during latent heat storage periods, offering superior efficiency and flexibility in energy storage and delivery [160,161,162]. The position of PCMs within the system is dictated by their respective melting temperatures, as illustrated in Figure 13. As depicted in Figure 13a, for heat storage, PCMs should be positioned in decreasing order along the flow direction of the HTF, while during discharge, the HTF flows in the opposite direction [158]. Figure 13b showcases various shapes applicable to U-tube TES systems, demonstrating potential up to 30% enhancements in the charging process [163].

Figure 13.

Operation of energy storage for various phase change materials by (a) Christopher et al. [158] (Copyright © 2021 Elsevier Ltd.); (b) Kurnia et al. [163] (Copyright © 2012 Elsevier Ltd.).

Paraffin waxes (such as paraffin wax, RT60, and others) and fatty acids (including myristic acid, stearic acid, lauric acid, and others) are commonly used for energy storage. Moreover, several studies have carried out investigations using two to five PCMs to achieve expedited charging and discharging cycles and heightened thermal storage efficiency [48]. However, it is worth noting that a study suggests a limit of three stages, as stages after this threshold produce negligible performance improvements [164].

One notable study employing this technique is conducted by Wang et al. [165], wherein an experimental investigation involving a cylindrical capsule with three distinct PCMs (stearic acid, paraffin, and lauric acid) demonstrates that employing a cascade system can augment both the charging period and velocity. Similarly, Mazman et al. [166] explore the utilization of three CPCMs (paraffin–palmitic acid, paraffin–stearic acid, and stearic acid–myristic acid) and report favorable outcomes regarding the average water temperature throughout the full charging cycle of a storage tank. They note that during the tank’s complete discharging phase, the average water temperature remains below the PCM’s flow temperature, with the stearic acid–paraffin CPCM exhibiting superior thermal performance. Conversely, Lim et al. [167] show findings from their experimental study, highlighting a 28% increase in thermal performance when employing two distinct PCMs within a storage unit compared to just using one.

Khor et al. [168] investigated the charging process of three different PCMs configurations, revealing a reduction in charging time with this setup. Their findings underscore an effective arrangement for positioning various PCMs within a LHTESS. Conversely, Pu et al. [169] conducted a numerical study, corroborated by experimental validation, to assess whether employing M-PCMs could augment heat transfer efficiency and expedite PCM melting. Their investigation employed a shell-and-tube TES unit featuring three PCMs arranged radially alongside copper foam. A comparison was drawn with the utilization of a single PCM. Contrary to expectations, the results indicated that employing M-PCMs did not yield significantly higher HTE compared to using a single PCM. Additionally, the authors suggested optimizing thermal performance by adjusting the porosity distribution within the copper foam.

In this technique, careful PCM selection is imperative, as the integration of cascading PCMs that do not contribute to smooth heat transfer may adversely impact the system’s HTE. Hence, consideration of the thermal properties of the PCM is vital in this regard. It is noteworthy that, for the effective implementation of this method, PCMs with phase change temperatures not surpassing 60 °C are recommended. However, this recommendation depends on the prevailing climatic conditions in the desired hot water generation setting, as it necessitates a progressive phase change within the system. Numerous experimental studies validating HTE were identified for this technique, involving blending various PCMs such as fatty acids and paraffin waxes or using only paraffin waxes. Furthermore, it was observed that while this technique is commonly employed in TES tanks, it is less prevalent in solar collectors or shell-and-tube TES units. Determination of the optimal quantity of PCM modules for this technique is crucial, as divergent opinions exist regarding the maximum amount of PCMs to be employed.

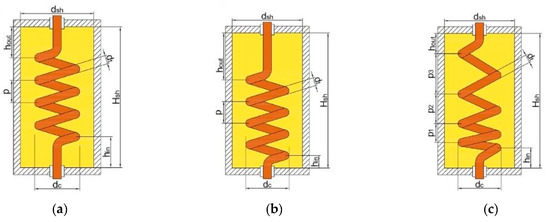

4.1.8. Coils

Based on previous observations, researchers tend to prioritize the augmentation of surface area in storage systems. Hence, one viable approach is adopting coil or spiral/helical tube configurations. Such arrangements can potentially improve system performance, elevate energy efficiency, and decrease the PCM’s melting duration [170].

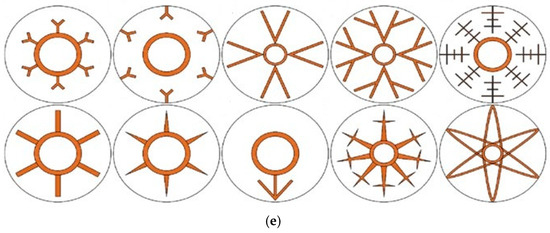

Based on the investigation conducted by Rogowski and Andrzejczyk [95], various research studies are delving into the coil geometry to augment the solidification and melting characteristics of PCMs. Primarily experimental, these studies predominantly focus on low-temperature PCMs, commonly employed in hot water generation. Figure 14 illustrates some examples of used coils, while Table 6 presents a compilation of research efforts concerning coil utilization in LHTESS.

Figure 14.

Different geometries coils. (a) Simple helicoidal coil; (b) non-equidistantly spaced helical coil; (c) helical coil with a variable pitch; (d) complex helicoidal coils, red (hot fluid) and blue (cold fluid) [95] (CC by 4.0).

This approach circumvents health concerns by averting direct contact between the PCM or any fluid and the HTF within LHTESS. Its applicability extends to SHTS systems, ensuring the storage material remains isolated from the HTF. Multiple experimental investigations in this methodology corroborate its efficacy in enhancing heat transfer, albeit most of these studies are conducted at the laboratory scale. Therefore, validating this technique for hot water generation in real-world scenarios is advisable to ascertain its potential for efficiently improving heat transfer in such systems.

4.1.9. Nanofluids

Nanofluids offer distinct advantages in solar systems or collectors compared to traditional fluids. They can augment heat transfer rates and find utility across various applications [171,172]. Nanofluids are derived from nanoparticles (Al, Au, Ag, Cu) with sizes below 100 nm dispersed in water or other fluids [173]. Hybrid nanofluids are also prevalent, containing two types of nanoparticles within a fluid. Employing stable hybrid nanofluids with reduced viscosity and heightened thermal conductivity can elevate the efficacy of solar collectors [1]. These fluids serve as a potential alternative to enhance heat transfer efficiency in PCMs, alter thermal conductivity, boost the effectiveness of heat storage systems, or serve as substitutes for HTF [106,174]. Nanofluids can be integrated with other methodologies like encapsulations or used independently to amplify the thermal performance of solar collectors [1,108,175,176,177].

Table 6.

Use of coil in latent heat storage systems according to the literature.

Table 6.

Use of coil in latent heat storage systems according to the literature.

| Author | Type of Study 1 | Overview |

|---|---|---|

| Kabbara et al. [42] | E | The system’s performance was analyzed by incorporating a helical coil into a storage tank with lauric acid PCM. Temperature variations were notable during charging and discharging. However, the authors emphasize the need to explore different coil geometries and flow rates to fully grasp the system’s dynamics. |

| Anish et al. [178] | E | Using a double helix coil consisting of a tube, a significant difference in the temperatures of the top and bottom of the tank was obtained in the melting process. Moreover, the solidification process occurred uniformly in the tank. |

| Korti and Tlemsani [179] | E | Using a copper helical coil with various PCM types, charging temperatures and flow rates revealed a higher efficiency during the charging process compared to discharging. This discrepancy is due to convection dominance during melting. Additionally, charging temperatures notably impacted the results. |

| Dinker et al. [180] | E | A study was conducted in a rectangular storage tank with PCM (beeswax) and HTF (water) flowing in a helical coil with different temperatures and flow rates. Their results show that temperature can significantly influence the efficiency of the solidification and melting processes. |

| Saydam et al. [181] | E | A study investigated the solidification and melting processes of a PCM (Paraffin wax) in a storage tank with a helical coil. Findings revealed faster melting of the PCM on the tank’s periphery and slower near the axis during both processes. However, the authors suggest adding more coils at the tank’s bottom for improved discharge efficiency. It was found that the flow direction of the HTF (ethylene glycol (EG)–water mixture) had a negligible impact on the charging and discharging period but did influence the temperature fluctuations of the PCM within the energy storage unit. |

| Rahimi et al. [182] | E | The impact of charging temperature on the coil storage tank’s performance was assessed alongside the introduction of a dimensionless parameter known as the Stefan number. The findings indicate that a specific Stefan number can decrease the PCM’s melting time. |

1 Type of study: E = experimental.

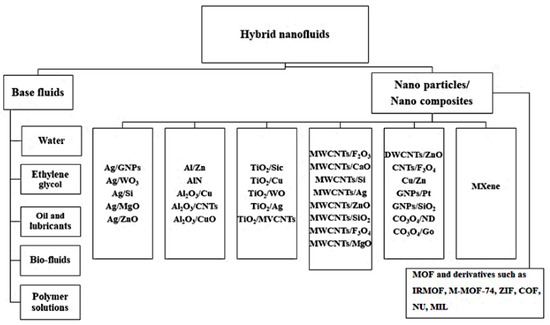

Using nanofluids in solar systems offers several advantages, including reducing the required heat transfer area, high density, conductivity, and thermal properties, along with favorable optical characteristics and stability [183]. When combined with PCMs possessing good HTE and thermal stability, nanofluids can extend operational time and decrease energy consumption [184]. However, their main disadvantages include high costs, thermal instability, chemical compatibility issues, and complexities in the manufacturing process [183]. Over the years, nanofluid technology has advanced, as depicted in Figure 15 and Figure 16, showcasing the diverse fluids and nanoparticles used in preparing nanofluids or hybrid nanofluids. Commonly employed nanoparticles in solar collectors encompass CeO2, SiO2, Al2O3, CuO, graphene, and TiO2 [4,17,108,185]. Additionally, carbon-based nanomaterials exhibit superior thermal conductivity for such applications [141,176]. Nonetheless, a primary challenge lies in selecting appropriate nanoparticles and fluids for specific applications [52]. Aggarwal et al. [17] have demonstrated that PCMs and nanofluids can synergize to enhance heat transfer in solar water heaters, including evacuated tube solar collectors (ETSCs) and flat plate solar collectors (FPSCs), leveraging the manifold advantages offered by nanofluids.

Figure 15.

Published articles about nanofluids in the literature by Muhamude et al. [1] (CC by 4.0).

Figure 16.

Different nanoparticles and fluids used to create hybrid nanofluids [1] (CC by 4.0).

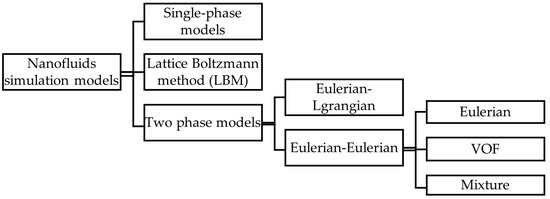

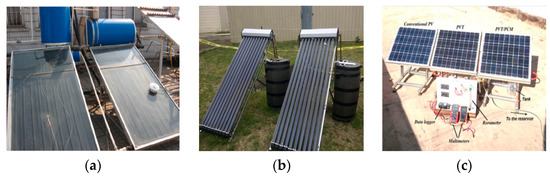

Figure 17 displays various models for simulating nanofluids, with the mixture model being the most prevalent due to its ability to simulate different velocities across phases and its applicability in interpenetrating phases [186]. Solar collectors are commonly used for low-temperature systems, particularly in hot water generation [187]. Figure 18 showcases examples of solar collectors in the literature, providing insight into where nanofluids have been employed for enhancement. Subsequently, this paper will outline research conducted with nanofluids in solar collectors, structured into three sections to facilitate comprehension.

Figure 17.

Different approaches are used to simulate nanofluids in various applications [69] (Copyright © 2022 Elsevier Ltd.).

Figure 18.

Types of solar collectors: (a) flat plate solar collector [188] (Copyright © 2010 Elsevier Ltd.); (b) evacuated tube solar collectors [189] (Copyright © 2016 Elsevier Ltd.); (c) photovoltaic/thermal solar collector [190] (Copyright © 2016 Elsevier B.V.).

- Flat plate solar collectors (FPSCs)

Using PCMs in FPSCs can extend hot water availability and enhance system efficiency. However, outcomes are contingent on factors such as the degree of inclination, PCM–collector contact, solar radiation, and thermal stratification in the storage tank [191]. FPSCs are frequently employed in research due to their accessibility and affordability, leading to numerous studies aimed at improving heat transfer (via nanofluids), maintaining stable temperatures (with PCMs), or enhancing system thermal capacity (through nanofluid–PCM integration) [177,184]. Table 7 presents a selection of studies conducted with FPSCs.

Table 7.

Studies on the use of nanofluids in flat plate solar collectors.

- 2

- Evacuated tube solar collectors (ETSCs)

ETSCs feature parallel tubes designed to withstand reflection and absorb high solar radiation with specialized glass coatings, enhancing efficiency, thermal conductivity, and energy storage [177,195]. Hence, they are extensively employed in domestic applications [196]. As of 2020, thermosyphon-type ETSCs are the most commonly utilized [183]. Table 8 showcases notable studies conducted with ETSCs.

- 3

- Photovoltaic–thermal collectors

Kezemian et al. [197] conducted a 3D numerical study to enhance solar collector performance using various hybrid nanofluids: MWCNT–aluminum oxide, MWCNT–silicon carbide, graphene–aluminum oxide, and graphene–silicon carbide. Their findings reveal that the MWCNT–silicon carbide hybrid nanofluid exhibits superior electrical and thermal energy efficiency compared to others. Similarly, Khodadadi and Sheikholeslami [198] demonstrated that incorporating nanoparticles such as MWCNT, SiC, Cu, Ag, Al2O3, and ZnO in water and PCM boosts the charging rate while marginally reducing unit and coolant temperatures. Additionally, they observed changes in the PCM’s liquid fraction with alterations in the system’s flow rate.

Table 8.

Studies on the use of nanofluids in evacuated tube solar collectors.

Table 8.

Studies on the use of nanofluids in evacuated tube solar collectors.

| Author | Nanofluid Based on | Type of Study 1 | Results |

|---|---|---|---|

| Tabarhoseini et al. [199] | Nanoparticles of CuO/pure H2O | N |

|

| Ghaderian et al. [200] | Nanoparticles of CuO/H2O | E |

|

| Al-Mashat and Hasan et al. [201] | Al2O3/water | N/E |

|

| Eltaweel et al. [196] | MWCNT/water | E |

|

| Mahbubul et al. [202] | Single-walled carbon nanotubes (SWCNT)/water | E |

|

| Daghigh and Zandi [203] | water/TiO2, water/CuO and water/MWCNT | T/E |

|

| Kumar and Kaushal [204] | Nanoparticles of graphene- ethylene glycol/water | E |

|

| Ghaderian and Sidik [205] | Al2O3/distilled water | E |

|

1 Type of study: N = numerical, T = theorical, and E = experimental.

In conclusion, passive methods, including nanofluids, encapsulation, fins, M-PCMs, and porous media, are deemed most effective for hot water generation applications. Among these, fins are considered practical, especially with simple configurations during system installation. Additionally, M-PCMs are seen as advantageous when proper PCM selection is used. These techniques are commonly employed due to their low costs, except for nanofluids, which incur higher manufacturing costs. However, it is essential to note that the literature does not have data on the construction, creation, or operational costs of these methods in energy storage systems; thus, our perspective is solely based on selected document readings.

4.2. Active Methods

Active methods, unlike passive ones, employ external sources or auxiliary tools to enhance heat transfer [69]. Shank and Tiari [46] highlighted various approaches to improve HTE in PCM systems, such as mechanical aids, vibration, jet impingement, injection, and external fields. Three of these techniques stand out as potential starting points for further research in hot water generation. Below are summarized conclusions regarding each method as indicated by these authors.

- Mechanical aids, such as rotating cylinders, rotary systems, and scraped surfaces, play a significant role in the charging and discharging processes of PCM systems, reducing the solidification time and enhancing heat transfer. However, their use entails complex system designs, increased manufacturing and maintenance requirements, and safety risks due to the constant movement of the liquid PCM during operation.

- Vibration: Although vibration has shown promise in enhancing PCM fusion during the charging process, further investigation is needed, particularly regarding its effectiveness during discharge. It is important to note that this technique operates with high amplitudes and frequencies, posing potential safety risks during operation.

- External fields: This method introduces a novel approach to improve the thermal behavior of LHTES systems. However, it may encounter conflicts with system components due to the involvement of magnetic, electric, and ultrasonic fields. Further studies across various fields (electric, magnetic, and ultrasonic) are necessary to determine its potential for enhancing heat transfer in HWGS with PCMs.

Alternatively, Yan et al. [8] performed an experimental investigation employing ultrasound to improve heat transfer. Their study aimed to assess the impact of ultrasound on the charging process of PCMs. Results demonstrated a significant reduction in charging time (60.69%) and a substantial increase in the heat transfer coefficient (250.97%) at a constant temperature of 60 °C and a flow rate of 3 L/min. Additionally, enhanced natural convection within the PCM was observed. Thus, ultrasound demonstrates the potential for enhancing PCM utilization in hot water systems.

A notable disparity in operational cost and safety risk arises when comparing active and passive methods, particularly without adequate installation measures. Consequently, many researchers lean towards passive methods, which is evident in the abundance of results observed in Section 4.1 and this section. However, given the lack of research validating a fair comparison, investigations with existing setups tailored to active methods are recommended. This is crucial to ascertain the potential of these methods for residential or industrial hot water generation. Furthermore, economic studies are essential to evaluate the long-term benefits of employing active methods, considering the financial investment.

4.3. Hybrid Methods

A hybrid approach combines at least two active or passive techniques, offering potentially higher efficiency than individual methods. Recent studies have underscored the significance of exploring these hybrid methods [26,72]. Below, various combined techniques found in the analysis of this work are presented.

Asgari et al. [78] conducted numerical research on fin utilization for improving heat transfer and PCM solidification, exploring various synthetic forms of Al2O3-Cu nanoparticles (brick, cylindrical, platelet, and lamina). They concluded that increasing the volume fraction of hybrid nanoparticles accelerates solidification and enhances heat transfer. The study suggests that nanoparticles are essential for faster solidification in a finned system. Conversely, Kazaz et al. [175] demonstrated that nano-encapsulation of paraffin PCM can boost energy storage, varying efficacy based on the type of nanoparticles used.

Zhu et al. [206] propose evaluating the energy storage efficiency of a composite consisting of PCM with metal foam, finned metal foam with graded porosity (PCM-FFGP), and fin. Their numerical study demonstrates that PCM-FFGP significantly improves system performance and reduces the PCM melting time by facilitating the PCM melting sequence with the fin and enhancing heat transfer between the heat source and PCM through the metal foam. They suggest that increasing the number of pores per inch may reduce natural convection heat transfer in PCM-FFGP. Therefore, they recommend a 3% porosity gradient along with a 5 mm thickness of the fins for better energy storage capacity. Conversely, Cui et al. [12] suggest that porous media can achieve higher heat transfer enhancement based on research conducted until early 2022. Lastly, although the work of Sathyamurthy et al. [207] is not directly related to hot water generation, it suggests a potential application of a hybrid method by using soda cans encapsulated with black paint and carbon soot nanoparticles to enhance thermal conductivity and heat absorption of the PCM. Other hybrid methods from the literature are summarized in Table 9.

Table 9.

Different hybrid methods found in the literature review.

Combining different techniques in LHTESS can significantly enhance heat transfer efficiency by improving multiple parameters simultaneously, such as increasing the heat transfer surface area and the thermal conductivity of the PCM. Table 9 highlights various combinations, with nanoparticles being prevalent in most cases, aligning with the findings of Asgari et al. [78] and underscoring the importance of nanoparticles in systems employing diverse techniques. Exploring combinations involving more than two techniques or integrating passive and active techniques presents promising research possibilities for further investigation.

5. Challenges and Prospective Directions

The review indicates a scarcity of studies focusing on enhancing hot water generation applications. Nonetheless, this study serves as a guide for advancements in HTE within this domain. While most HTE investigations in domestic settings center on fins, porous media, and encapsulation techniques, further research is needed to explore other methods and their efficacy across different global climates. Moreover, there is a lack of experimental data documenting the economic and health implications of employing the various techniques discussed in this paper.

Regarding active methods, only a single study has been undertaken using ultrasound on a laboratory scale. While its outcomes appear promising, further assessment within a full-scale system is imperative to ascertain its efficacy in hot water generation. Conversely, hybrid methods present a broad research method, as numerous combinations of techniques can be explored, encompassing both passive–passive and passive–active approaches. Notably, the literature exploration yielded no information on mixtures of active–active and passive–active methods.

Despite the promising potential of nanofluids, further studies are needed to evaluate their performance under various climatic conditions and to assess their environmental impact at the end of their lifecycle. These investigations are essential for validating their use or substitution for traditional refrigerants in solar collectors.

6. Conclusions

This document provides a bibliographic study of numerical, experimental, and laboratory-scale research on HTE in LHTESS that may be useful for hot water generation through low-temperature PCMs. Firstly, the bibliometric analysis of the selected documents revealed a trend over the years towards improving heat transfer in energy storage systems, providing a global overview of the topic. Additionally, extensive research by academic institutions and predominant article publications in Asian countries was observed. Despite the selected documents being related to PCMs and domestic hot water, there was limited connection with solar energy or solar water heaters. This could indicate the need for further studies on various techniques presented using solar water heaters. Based on the analysis of the selected documents, the main conclusions are summarized below:

- The most dominant phenomena in the solidification and melting processes are natural convection and conduction, so improving the thermal conductivity of PCM can contribute to these two phenomena.

- HTE enables better solidification and melting processes of PCM, in addition to increasing the efficiency and performance of the heat exchanger. According to the literature, passive methods are the most commonly used due to their simple application and low cost.

- Microencapsulation with a metallic coating has promising potential in various applications, such as hot water generation.

- More simulations were conducted on the geometric variation technique, indicating that, in some cases, manufacturing processes may be difficult to validate experimentally, even if the results are promising.

- When using various PCMs, the predominant parameters are PCM selection, and the amount of PCM used. Poor selection of the quantity and type of PCM can lead to unpromising results in energy storage.

- Carbon-based nanoparticles could have a promising future in TES, but the use of recyclable or organic media cannot be ruled out, as it may positively impact the environment.

- According to the literature found on hot water generation, there is a lack of understanding of how these HTE techniques behave under user demand. This contributes to a new research point, as it would provide a better estimate for real-world applications. In particular, most HTE studies applied to hot water generation were conducted at the laboratory scale, with constant flow rates.

- No research was found comparing various HTE techniques in a single heat storage model. Therefore, it is recommended that studies focused on these comparisons be conducted to determine which technique yields better results in terms of system efficiency improvement and solidification and melting processes.

- According to the applied methodology, few documents were found on using active methods in hot water generation. However, this article presents new techniques that could help initiate new research through active methods or even generate new hybrid methods by combining passive and active ones.

- When comparing methods (active, passive, and hybrid) primarily used in hot water generation applications, passive methods prevail due to their lower complexity. However, hybrid methods may provide a good option for a more efficient system and have gained significant popularity recently. Currently, only hybrid methods combining passive techniques have been found.

- Nanofluids can enhance PCM’s properties or replace HTF in solar energy applications. Nanofluids have made substantial advancements over the last decade due to their ability to improve efficiency, thermal conductivity, and the geometry of solar collectors.

- Few studies were found discussing economic studies to assess the viability or profitability of using different techniques. This could create a new research point, as it would allow for comparing scientific results with creation and operation costs, thereby determining which techniques are promising and cost-effective to apply in the field of hot water generation.

Ultimately, this research opens up new opportunities for study and a deeper understanding of the techniques commonly used for HTE in HWGS.

Author Contributions

Conceptualization D.I.B., J.B.R., M.D.L.A.O.D.R., A.M.J.R. and I.H.; Methodology, and draft preparation, D.I.B.; review and editing, J.B.R., M.D.L.A.O.D.R. and A.M.J.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially funded by Secretaría Nacional de Ciencia, Tecnología e Innovación (SENACYT) in support of the Master of Science in Mechanical Engineering program, VI Cohort.

Data Availability Statement

Not applicable.

Acknowledgments

The authors express their gratitude for the financial support provided by the Master of Science Program in Mechanical Engineering at the Faculty of Mechanical Engineering (https://fim.utp.ac.pa/ accessed on 11 February 2024), the Universidad Tecnológica de Panamá (https://utp.ac.pa/ accessed on 11 February 2024), along with the Secretaría Nacional de Ciencia, Tecnología e Innovación (SENACYT) and The National Research System (Sistema Nacional de Investigación, SNI) of the Panamanian Government. Furthermore, special acknowledgment is given to SENACYT for granting access to the Scientific Bibliography Access Platform (Plataforma de Acceso a Bibliografía Científica, ABC), which facilitated the retrieval of information from the Scopus database. Finally, we extend our gratitude to the biosolids laboratory at the Centro de Investigaciones Hidráulicas e Hidrotécnicas (CIHH—https://codigestion.utp.ac.pa/ accessed on 10 May 2024), and specifically acknowledge the invaluable assistance rendered by its researchers, Daniel Nieto, Marian Ramírez, and Euclides Deago, during the course of this investigation.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mahamude, A.S.F.; Kamarulzaman, M.K.; Harun, W.S.W.; Kadirgama, K.; Ramasamy, D.; Farhana, K.; Bakar, R.A.; Yusaf, T.; Subramanion, S.; Yousif, B. A Comprehensive Review on Efficiency Enhancement of Solar Collectors Using Hybrid Nanofluids. Energies 2022, 15, 1391. [Google Scholar] [CrossRef]

- Quitiaquez, W.; Estupinán-Campos, J.; Nieto-Londoño, C.; Isaza-Roldán, C.A.; Quitiaquez, P.; Toapanta-Ramos, F. CFD Analysis of Heat Transfer Enhancement in a Flat-Plate Solar Collector with Different Geometric Variations in the Superficial Section. Int. J. Adv. Sci. Eng. Inf. Technol. 2021, 11, 2039–2045. [Google Scholar] [CrossRef]

- Sikiru, S.; Oladosu, T.L.; Amosa, T.I.; Kolawole, S.Y.; Soleimani, H. Recent advances and impact of phase change materials on solar energy: A comprehensive review. J. Energy Storage 2022, 53, 105200. [Google Scholar] [CrossRef]

- Senthil, R.; Madurai Elavarasan, R.; Pugazhendhi, R.; Premkumar, M.; Vengadesan, E.; Navakrishnan, S.; Islam, M.R.; Natarajan, S.K. A holistic review on the integration of heat pipes in solar thermal and photovoltaic systems. Sol. Energy 2021, 227, 577–605. [Google Scholar] [CrossRef]

- Harris Bernal, I.A.; James Rivas, A.M.; Ortega Del Rosario, M.D.L.A.; Saghir, M.Z. A Redesign Methodology to Improve the Performance of a Thermal Energy Storage with Phase Change Materials: A Numerical Approach. Energies 2022, 15, 960. [Google Scholar] [CrossRef]

- Suresh, C.; Saini, R.P. Review on solar thermal energy storage technologies and their geometrical configurations. Int. J. Energy Res. 2020, 44, 4163–4195. [Google Scholar] [CrossRef]

- Prasad, D.M.R.; Senthilkumar, R.; Lakshmanarao, G.; Krishnan, S.; Naveen Prasad, B.S. A critical review on thermal energy storage materials and systems for solar applications. AIMS Energy 2019, 7, 507–526. [Google Scholar] [CrossRef]

- Yan, Z.; Yu, Z.J.; Yang, T.; Li, S.; Zhang, G. Impact of ultrasound on the melting process and heat transfer of phase change material. Energy Procedia 2019, 158, 5014–5019. [Google Scholar] [CrossRef]

- Arunachalam, S. Latent Heat Storage: Container Geometry, Enhancement Techniques, and Applications—A Review. J. Sol. Energy Eng. 2019, 141, 050801. [Google Scholar] [CrossRef]