Jerusalem Artichoke: Energy Balance in Annual and Perennial Cropping Systems—A Case Study in North-Eastern Poland

Abstract

1. Introduction

2. Materials and Methods

2.1. Field Experiment

- K–Selyaninov index (K: 0–0.5—extreme dry spell, 0.6–1.0—dry spell, 1.1–2.0—humid spell, >2.1—wet spell),

- ΣP—total precipitation in the analyzed period,

- ΣT—total mean daily temperature in the analyzed period,

- 0.1—constant.

2.2. Energy Input Analysis

- EI—total energy input for Jerusalem artichoke production technology (GJ ha−1),

- EId—energy input for diesel fuel consumption (GJ ha−1),

- EIf—energy input for fixed assets (GJ ha−1),

- EIm—energy input for materials (GJ ha−1),

- EIl—energy input for human labor (GJ ha−1).

2.3. Biomass Yields

- W—moisture content (%),

- Mw—wet sample weight, before drying (g),

- Md—dry sample weight, after drying (g).

- DMY—dry matter yield (Mg ha−1),

- FMY—fresh matter yield (Mg ha−1),

- DM—dry matter content (%).

2.4. Energy Output Analysis

- LHV—lower heating value of aerial biomass or tubers determined on a wet basis (MJ kg−1),

- HHV—higher heating value of aerial biomass or tubers determined on a dry basis (MJ kg−1),

- W—moisture content of aerial biomass or tubers (%),

- 0.0244—correction coefficient for water vaporization enthalpy (MJ kg−1 per 1% moisture content).

2.5. Energy Gain and the Energy Efficiency Ratio

2.6. Statistical Analysis

3. Results

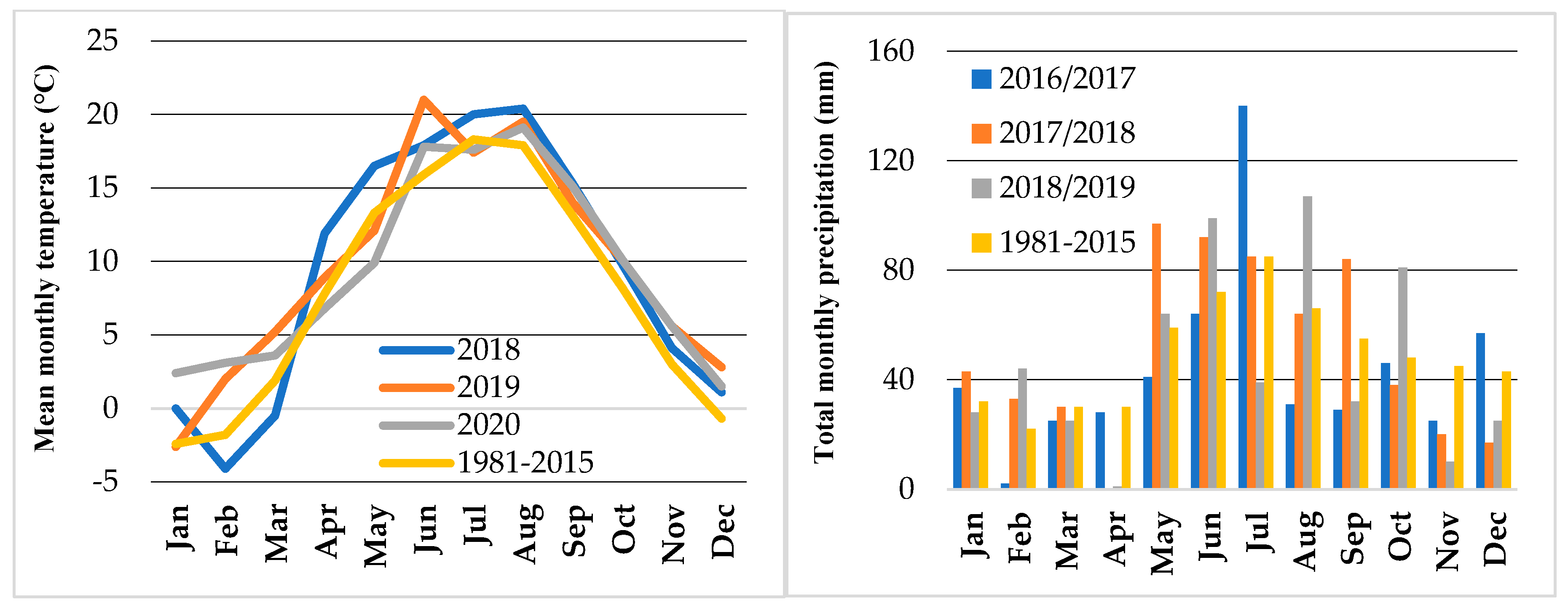

3.1. Weather Conditions

3.2. Energy Inputs

3.3. Biomass Yield

3.4. Energy Output

3.5. Energy Gain and the Energy Efficiency Ratio

4. Discussion

4.1. Energy Inputs

4.2. Biomass Yield

4.3. Energy Output

4.4. Energy Gain and the Energy Efficiency Ratio

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ritchie, H.; Rosado, P. Energy Mix. 2024. Available online: https://ourworldindata.org/energy-mix?country=#energy-mix-what-sources-do-we-get-our-energy-from (accessed on 14 March 2024).

- Shafiee, S.; Topal, E. When will fossil fuel reserves be diminished? Energy Policy 2009, 37, 181–189. [Google Scholar] [CrossRef]

- Madan, K.; Singh, O.K. Second law-based assessment of combined cycle power plant. Evergreen 2023, 10, 356–365. [Google Scholar] [CrossRef]

- Zybert, M.; Ronduda, H.; Raróg-Pilecka, W.; Wieczorek, W. Application of rare earth elements as modifiers for Ni-rich cathode materials for Li-ion batteries: A mini review. Front. Energy Res. 2023, 11, 1248641. [Google Scholar] [CrossRef]

- Axon, C.J.; Darton, R.C. The causes of risk in fuel supply chains and their role in energy security. J. Clean. Prod. 2021, 324, 129254. [Google Scholar] [CrossRef]

- Cui, L.; Yue, S.; Nghiem, X.H.; Duan, M. Exploring the risk and economic vulnerability of global energy supply chain interruption in the context of Russo-Ukrainian war. Res. Policy 2023, 81, 103373. [Google Scholar] [CrossRef]

- Szabó, Z.T.; Chuluunbaatar, E.; Alpek, B.L. The shortening of sustainable supply chains in Hungary and Europe. J. Cent. Eur. Green Innov. 2023, 11, 93–110. [Google Scholar] [CrossRef]

- Bełdycka-Bórawska, A.; Bórawski, P.; Borychowski, M.; Wyszomierski, R.; Bórawski, M.B.; Rokicki, T.; Ochnio, L.; Jankowski, K.; Mickiewicz, B.; Dunn, J.W. Development of solid biomass production in Poland, especially pellet, in the Context of the World’s and the European Union’s climate and energy policies. Energies 2021, 14, 3587. [Google Scholar] [CrossRef]

- Igliński, B.; Pietrzak, M.B.; Kiełkowska, U.; Skrzatek, M.; Kumar, G.; Piechota, G. The assessment of renewable energy in Poland on the background of the world renewable energy sector. Energy 2022, 261, 125319. [Google Scholar] [CrossRef]

- WBA (World Bioenergy Association). Global Bioenergy Statistics. 2022. Available online: https://www.worldbioenergy.org/uploads/221223%20WBA%20GBS%202022.pdf (accessed on 27 February 2024).

- Janiszewska, D.; Ossowska, L. The role of agricultural biomass as a renewable energy source in European Union countries. Energies 2022, 15, 6756. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.F.; Taylor, N.; Banja, M.; Sanchez Lopez, J.; Avraamides, M. Brief on Biomass for Energy in the European Union; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Janiszewska, D.; Ossowska, L. Spatial differentiation of agricultural biomass potential in Polish voivodeships. Energies 2023, 16, 6828. [Google Scholar] [CrossRef]

- Statistics Poland. Energy from Renewable Sources in 2022; Statistical Analyses: Warszawa, Poland, 2023. (In Polish) [Google Scholar]

- IRENA (International Renewable Energy Agency). REmap 2030: A Renewable Energy Roadmap, June 2014. Abu Dhabi. Available online: https://www.irena.org/publications/2014/Jun/REmap-2030-Full-Report (accessed on 14 March 2024).

- Lewandowski, I.; Bahrs, E.; Dahmen, N.; Hirth, T.; Rausch, T.; Weidtmann, A. Biobased value chains for a growing bioeconomy. GCB Bioenergy 2019, 1, 4–8. [Google Scholar] [CrossRef]

- Elbersen, W.; Gursel, I.V.; Voogt, J.; Meesters, K.; Kulisic, B. To Be or Not to Be a Biobased Commodity: Assessing Requirements and Candidates for Lignocellulosic Based Commodities IEA Bioenergy: Task 43; Food & Biobased Research: Wageningen, The Netherlands, 2022; pp. 2–21. [Google Scholar]

- Von Cossel, M. Renewable energy from wildflowers—Perennial wild plant mixtures as a social-ecologically sustainable biomass supply system. Adv. Sustain. Syst. 2020, 4, 2000037. [Google Scholar] [CrossRef]

- Jablonowski, N.D.; Kollmann, T.; Nabel, M.; Damm, T.; Klose, H.; Müller, M.; Blasing, M.; Seebold, S.; Krafft, S.; Kuperjans, I.; et al. Valorization of Sida (Sida hermaphrodita) biomass for multiple energy purposes. Glob. Change Biol. Bioenergy 2017, 9, 202–214. [Google Scholar] [CrossRef]

- Akter, M.M.; Surovy, I.Z.; Sultana, N.; Faruk, M.O.; Gilroyed, B.H.; Tijing, L.; Arman; Shon, H.K.; Nam, S.Y.; Kabir, M.M. Techno-economics and environmental sustainability of agricultural biomass-based energy potential. Appl. Energ. 2024, 359, 122662. [Google Scholar] [CrossRef]

- Blair, M.J.; Gagnon, B.; Klain, A.; Kulišić, B. Contribution of biomass supply chains for bioenergy to Sustainable Development Goals. Land 2021, 10, 181. [Google Scholar] [CrossRef]

- United Nations. Agenda for Sustainable Development; United Nations: New York, NY, USA, 2019; Available online: https://www.un.org/sustainabledevelopment/sustainable-development-goals/ (accessed on 2 May 2024).

- Güney, T.; Kantar, K. Biomass energy consumption and sustainable development. Int. J. Sustain. Dev. World Ecol. 2020, 27, 762–767. [Google Scholar] [CrossRef]

- Von Cossel, M.; Pereira, L.A.; Lewandowski, I. Deciphering substrate-specific methane yields of perennial herbaceous wild plant species. Agronomy 2021, 11, 451. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Dubis, B.; Budzyński, W.S.; Bórawski, P.; Bułkowska, K. Energy efficiency of crops grown for biogas production in a large-scale farm in Poland. Energy 2016, 109, 277–286. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Dubis, B.; Sokólski, M.M.; Załuski, D.; Bórawski, P.; Szempliński, W. Productivity and energy balance of maize and sorghum grown for biogas in a large-area farm in Poland: An 11-year field experiment. Ind. Crops Prod. 2020, 148, 112326. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Warmiński, K.; Tworkowski, J.; Szczukowski, S.; Olba–Zięty, E.; Gołaszewski, J. Energy efficiency of perennial herbaceous crops production depending on the type of digestate and mineral fertilizers. Energy 2017, 134, 50–60. [Google Scholar] [CrossRef]

- Dubis, B.; Jankowski, K.J.; Załuski, D.; Bórawski, P.; Szempliński, W. Biomass production and energy balance of Miscanthus over a period of 11 years: A case study in a large-scale farm in Poland. GCB Bioenergy 2019, 11, 1187–1201. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Dubis, B.; Sokólski, M.M.; Załuski, D.; Bórawski, P.; Szempliński, W. Biomass yield and energy balance of Virginia fanpetals in different production technologies in north-eastern Poland. Energy 2019, 185, 612–623. [Google Scholar] [CrossRef]

- Bogucka, B.; Jankowski, K.J. The effect of harvest strategy on the energy potential of Jerusalem artichoke. Ind. Crops Prod. 2022, 177, 114473. [Google Scholar] [CrossRef]

- Kays, S.J.; Nottingham, S.F. Biology and Chemistry of Jerusalem Artichoke: Helianthus tuberosus L.; CRC Press, Taylor and Francis Group: London, UK, 2008; p. 478. [Google Scholar]

- Rossini, F.; Provenzano, M.E.; Kuzmanović, L.; Ruggeri, R. Jerusalem artichoke (Helianthus tuberosus L.): A versatile and sustainable crop for renewable energy production in Europe. Agronomy 2019, 9, 528. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Dubis, B.; Kozak, M. Sewage sludge and the energy balance of Jerusalem artichoke production—A case study in north-eastern Poland. Energy 2021, 236, 121545. [Google Scholar] [CrossRef]

- Mu, Y.; Gao, W.; Lv, S.; Li, F.; Lu, Y.; Zhao, C. The antioxidant capacity and antioxidant system of Jerusalem artichoke (Helianthus tuberosus L.) tubers in relation to inulin during storage at different low temperatures. Ind. Crops Prod. 2021, 161, 113229. [Google Scholar] [CrossRef]

- Swanton, C.J.; Cavers, P.B.; Clements, D.R.; Moore, T.M. The biology of Canadian weeds. 101. Helianthus tuberosus L. Can. J. Plant Sci. 1992, 72, 1367–1382. [Google Scholar] [CrossRef]

- Long, X.H.; Shaob, H.B.; Liu, L.; Liu, L.P.; Liua, Z.U. Jerusalem artichoke: A sustainable biomass feedstock for biorefinery. Renew. Sustain. Energy Rev. 2016, 54, 1382–1388. [Google Scholar] [CrossRef]

- Gunnarsson, I.B.; Svensson, S.E.; Johansson, E.; Karakashev, D.; Angelidaki, I. Potential of Jerusalem artichoke (Helianthus tuberosus L.) as a biorefinery crop. Ind. Crops Prod. 2014, 56, 231–240. [Google Scholar] [CrossRef]

- Rubel, I.A.; Iraporda, C.; Manrique, G.D.; Genovese, D.B.; Abraham, A.G. Inulin from Jerusalem artichoke (Helianthus tuberosus L.): From its biosynthesis to its application as bioactive ingredient. Bioact. Carbohydr. Diet. Fibre 2021, 26, 100281. [Google Scholar] [CrossRef]

- Sawicka, B.; Danilenko, H.; Jariene, E.; Skiba, D.; Rachoń, L.; Barbaś, P.; Pszczółkowski, P. Nutritional value of jerusalem artichoke tubers (Helianthus tuberosus L.) grown in organic system under Lithuanian and Polish conditions. Agriculture 2021, 11, 440. [Google Scholar] [CrossRef]

- Wierzbowska, J.; Cwalina-Ambroziak, B.; Waskiewicz, A.; Bogucka, B. Influence of nitrogen fertilizers on the concentrations of inulin and micronutrients in Jerusalem artichoke tubers and root chicory. J. Elementol. 2023, 28, 793–814. [Google Scholar] [CrossRef]

- Lv, S.; Wang, R.; Xiao, Y.; Li, F.; Mu, Y.; Lu, T.; Gao, W.; Yang, B.; Kou, Y.; Zeng, J.; et al. Growth, yield formation, and inulin performance of a non-food energy crop, Jerusalem artichoke (Helianthus tuberosus L.), in a semi-arid area of China. Ind. Crops Prod. 2019, 134, 71–79. [Google Scholar] [CrossRef]

- Smekalova, T.N.; Lebedeva, N.V.; Novikova, L.Y. Morphological analysis of Jerusalem artichoke (Helianthus tuberosus L.) accessions of different origin from vir collection. Proc. Latv. Acad. Sci. Sect. B 2019, 73, 502–512. [Google Scholar] [CrossRef]

- Englert, H.; Lewandowski, I.; Böhmel, C.; Vetter, A.; Hartmann, H. Biomass production. In Energie aus Biomasse: Grundlagen, Techniken und Verfahren; Kaltschmitt, M., Hartmann, H., Hofbauer, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 75–134. (In Germany) [Google Scholar]

- Sawicka, B. Jerusalem artichoke (Helianthus tuberosus L.). In Biology, Culture, the Importance of Utility; University of Life Sciences Publishing House: Lublin, Poland, 2016; p. 241. (In Polish) [Google Scholar]

- Slimestad, R.; Seljaasen, R.; Meijer, K.; Skar, S.L. Norwegian-grown Jerusalem artichoke (Helianthus tuberosus L.): Morphology and content of sugars and fructo-oligosaccharides in stems and tubers. J. Sci. Food Agric. 2010, 90, 956–964. [Google Scholar] [CrossRef] [PubMed]

- Yaroshevich, M.I.; Gil, T.; Savic, I.M. Study, justification and development of major agrotechnical methods topinambur growing in Belarus. In Proceedings of the International Conference on Jerusalem Artichoke, Moskva, Russia, 24–25 October 2011; pp. 24–27. (In Russian). [Google Scholar]

- Lewandowski, I.; Clifton-Brown, J.C.; Scurlock, J.M.O.; Huisman, W. Miscanthus: European experience with a novel energy crop. Biomass Bioenergy 2000, 19, 209–227. [Google Scholar] [CrossRef]

- Chekroun, M.B.; Amzile, J.; Yachioui, M.E.E.; Haloui, N.E.E.; Prevost, J. Qualitative and quantitative development of carbohydrate reserves during the biological cycle of Jerusalem artichoke (Helianthus tuberosus L.) tubers. N. Z. J. Crop Horti. Sci. 1994, 22, 31–37. [Google Scholar] [CrossRef]

- Sawicka, B.; Skiba, D.; Bienia, B.; Kiełtyka-Dadasiewicz, A.; Danilčenko, H. Jerusalem artichoke (Helianthus tuberosus L.) as energy raw material. In Proceedings of the 9th International Scientific Conference Rural Development, Kovno, Lithuania, 26–28 September 2019; pp. 336–342. [Google Scholar]

- Sawicka, B.; Skiba, D.; Pszczółkowski, P.; Aslan, I.; Sharifi-Rad, J.; Krochmal-Marczak, B. Jerusalem artichoke (Helianthus tuberosus L.) as a medicinal plant and its natural products. Cell. Mol. Biol. 2020, 66, 160–177. [Google Scholar] [CrossRef] [PubMed]

- Dybek, B.; Anders, D.; Hołaj-Krzak, J.T.; Hałasa, Ł.; Maj, G.; Kapłan, M.; Klimek, K.; Filipczak, G.; Wałowski, G. Assessment of the prospects of Polish non-food energy agriculture in the context of a renewable energy source. Energies 2023, 16, 3315. [Google Scholar] [CrossRef]

- Kaszás, L.; Alshaal, T.; El-Ramady, H.; Kovács, Z.; Koroknai, J.; Elhawat, N.; Nagy, E.; Cziáky, Z.; Fári, M.; Domokos-Szabolcsy, E. Identification of bioactive phytochemicals in leaf protein concentrate of Jerusalem artichoke (Helianthus tuberosus L.). Plants 2020, 9, 889. [Google Scholar] [CrossRef]

- Piskier, T. A method of estimation of the caloric value of the biomass. Part I—Biomass energy potential. J. Mech. Energy Eng. 2017, 1, 189–194. [Google Scholar]

- Mehmood, M.A.; Ahmad, M.S.; Liu, Q.; Liu, C.G.; Tahir, M.H.; Aloqbi, A.A.; Tarbiah, N.I.; Alsufiani, H.M.; Gull, M. Helianthus tuberosus as a promising feedstock for bioenergy and chemicals appraised through pyrolysis, kinetics, and TG–FTIR–MS based study. Energy Convers. Manag. 2019, 194, 37–45. [Google Scholar] [CrossRef]

- Matías, J.; Encinar, J.M.; González, J.; González, J.F. Optimisation of ethanol fermentation of Jerusalem artichoke tuber juice using simple technology for a decentralised and sustainable ethanol production. Energy Sustain. Dev. 2015, 25, 34–39. [Google Scholar] [CrossRef]

- Qiu, Y.; Lei, P.; Zhang, Y.; Sha, Y.; Zhan, Y.; Xu, Z.; Li, S.; Xu, H.; Ouyang, P. Recent advances in bio-based multi-products of agricultural Jerusalem artichoke resources. Biotechnol. Biofuels. 2018, 11, 151. [Google Scholar] [CrossRef] [PubMed]

- Kowalczyk-Juśko, A.; Pochwatka, P.; Zaborowicz, M.; Czekała, W.; Mazurkiewicz, J.; Mazur, A.; Janczak, D.; Marczuk, A.; Dach, J. Energy value estimation of silages for substrate in biogas plants using an artificial neural network. Energy 2020, 202, 117729. [Google Scholar] [CrossRef]

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative lignocellulosic raw materials in particleboard production: A review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Piskier, T. The energy potential of Jerusalem artichoke. Probl. Inżynierii Rol. 2009, 1, 133–136. (In Polish) [Google Scholar]

- Fang, Y.R.; Liu, J.A.; Steinberger, Y.; Xie, G.H. Energy use efficiency and economic feasibility of Jerusalem artichoke production on arid and coastal saline lands. Ind. Crops Prod. 2018, 117, 131–139. [Google Scholar] [CrossRef]

- Ivanova, T.; Muntean, A.; Titei, V.; Havrland, B.; Kolarikova, M. Energy crops utilization as an alternative agricultural production. Agron. Res. 2015, 13, 311–317. [Google Scholar]

- Jankowski, K.J.; Sokólski, M.M.; Dubis, B.; Załuski, D.; Szempliński, W. Sweet sorghum—Biomass production and energy balance at different levels of agricultural inputs. A six-year field experiment in north-eastern Poland. Eur. J. Agron. 2020, 119, 126119. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Kołodziej, B.; Dubis, B.; Sugier, D.; Antonkiewicz, J.; Szatkowski, A. The effect of sewage sludge on the energy balance of cup plant biomass production. A six-year field experiment in Poland. Energy 2023, 276, 127478. [Google Scholar] [CrossRef]

- Dubis, B.; Jankowski, K.J.; Sokólski, M.; Załuski, D.; Bórawski, P.; Szempliński, W. Biomass yield and energy balance of fodder galega in different production technologies: An 11-year field experiment in a large-area farm in Poland. Renew. Energy 2020, 154, 813–825. [Google Scholar] [CrossRef]

- Gao, K.; Zhu, T.-X.; Wang, Q.-B. Nitrogen fertilization, irrigation, and harvest times affect biomass and energy value of Helianthus tuberosus L. J. Plant Nutr. 2016, 39, 1906–1914. [Google Scholar]

- Angelini, L.G.; Ceccarini, L.; Di Nasso, N.N.; Bonari, E. Comparison of Arundo donax L. and Miscanthus giganteus in a long-term field experiment in Central Italy: Analysis of productive characteristics and energy balance. Biomass Bioenergy 2009, 33, 635–643. [Google Scholar] [CrossRef]

- Iqbal, Y.; Gauder, M.; Claupein, W.; Graeff-Höonninger, S.; Lewandowski, I. Yield and quality development comparison between miscanthus and switchgrass over a period of 10 years. Energy 2015, 89, 268–276. [Google Scholar] [CrossRef]

- Muylle, H.; Van Hullea, S.; De Vliegher, A.; Baert, J.; Van Bockstaele, E.; Roldán-Ruiz, I. Yield and energy balance of annual and perennial lignocellulosic crops for bio-refinery use: A 4-year field experiment in Belgium. Eur. J. Agron. 2015, 63, 62–70. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Warmiński, K.; Olba-Zięty, E.; Penni, D.; Bordiean, A. Energy efficiency indices for lignocellulosic biomass production: Short rotation coppices versus grasses and other herbaceous crops. Ind. Crops Prod. 2019, 135, 10–20. [Google Scholar] [CrossRef]

- Dubis, B.; Jankowski, K.J.; Załuski, D.; Sokólski, M. The effect of sewage sludge fertilization on the biomass yield of giant miscanthus and the energy balance of the production process. Energy 2020, 206, 118189. [Google Scholar] [CrossRef]

- IUSS Working Group WRB. World Reference Base for Soil Resources. In International Soil Classification System for Naming Soils and Creating Legends for Soil Maps, 4th ed.; FAO: Vienna, Austria, 2022; p. 234. [Google Scholar]

- Molga, M. Agricultural Meteorology. PWRiL: Warszawa, Poland, 1958; pp. 550–556. (In Polish) [Google Scholar]

- Wójcicki, Z. Equipment, Materials and Energy Inputs in Growth-Oriented Farms; IBMER: Warszawa, Poland, 2000. (In Polish) [Google Scholar]

- PN-EN ISO 14780:2017; Solid Biofuels—Sample Preparation. Polish Committee for Standardization: Warszawa, Poland, 2017. (In Polish)

- PN-EN ISO 18125:2017; Solid Biofuels—Determination of Calorific Value. Polish Committee for Standardization: Warszawa, Poland, 2017. (In Polish)

- Kopetz, H.; Jossart, J.; Ragossnig, H.; Metschina, C. European Biomass Statistics; European Biomass Association (AEBIOM): Brussels, Belgium, 2007. [Google Scholar]

- TIBCO Software Inc. Statistica (Data Analysis Software System), Version 13; TIBCO Software Inc.: Palo Alto, CA, USA, 2017.

- Labergh, C.; Sackston, W.E. Adaptability and diseases of Jerusalem artichoke (Helianthus tuberosus) in Quebec. Can. J. Plant Sci. 1987, 67, 349–353. [Google Scholar] [CrossRef]

- Baldini, M.; Danuso, F.; Turi, M.; Vannozzi, G.P. Evaluation of new clones of Jerusalem artichoke (Helianthus tuberosus L.) for inulin and sugar yield from stalks and tubers. Ind. Crops Prod. 2004, 19, 25–40. [Google Scholar] [CrossRef]

- Liebhard, P.; Zeitlhofer, C.; Kaul, H.P.; Amon, T. Methanbildungsvermögen und Biogasqualität bei der Vergärung von Topinamburkraut. In Topinambur—Eine Pflanze Mit Vielen Verwendungsmöglichkeiten; Landwirtschaftliches Technologiezentrum Augustenberg (LTZ): Karlsruhe, Germany, 2009; pp. 2.11–2.17. Available online: http://www.topinambur-verein.de/Download/Wissenswertes/Workshop-Tagungsband.pdf (accessed on 28 March 2024). (In Germany)

- Liu, Z.X.; Spiertz, J.H.J.; Sha, J.; Xue, S.; Xie, G.H. Growth and yield performance of Jerusalem artichoke clones in a semiarid region of China. Agron. J. 2012, 104, 1538–1546. [Google Scholar] [CrossRef]

- Slepetys, J.; Kadziuliene, Z.; Sarunaite, L.; Tilvikiene, V.; Kryzeviciene, A. Biomass potential of plants grown for bioenergy production. In Growing and Processing Technologies of Energy Crops, Proceedings of the International Scientific Conference Renewable Energy and Energy Efficiency, 28–30 May 2012, Jelgava, Latvia, 2012; Rivža, P., Rivža, S., Eds.; pp. 66–72. Available online: https://www.researchgate.net/profile/Shiplu-Sarker/publication/234033439_Biofuel_from_the_anaerobic_co-digestion_of_the_macro-algae_ulva_lactuca_and_laminaria_digitata/links/0fcfd50e6a3785130d000000/Biofuel-from-the-anaerobic-co-digestion-of-the-macro-algae-ulva-lactuca-and-laminaria-digitata.pdf#page=66 (accessed on 28 March 2024).

- Cepl, J.; Kasal, P.; Souckova, H.; Svobodova, A.; Bucher, P. Non-food production of Jerusalem artichoke (Helianthus tuberosus) and possibilities of its energetic utilization. In Proceedings of the Actual Tasks on Agricultural Engineering: Proceedings of the 40th International Symposium on Agricultural Engineering, Opatija, Croatia, 21–24 February 2012; pp. 517–526. [Google Scholar]

- Matías, J.; González, J.; Cabanillas, J.; Royano, L. Influence of NPK fertilisation and harvest date on agronomic performance of Jerusalem artichoke crop in the Guadiana Basin (Southwestern Spain). Ind. Crops Prod. 2013, 48, 191–197. [Google Scholar] [CrossRef]

- Epie, K.E.; Santanen, A.; Mäkelä, P.S.; Stoddard, F. Fertilizer and intercropped legumes as nitrogen source for Jerusalem artichoke (Helianthus tuberosus L.) tops for bioenergy. Agric. Food Sci. 2018, 27, 199–205. [Google Scholar] [CrossRef]

- Farzinmehr, S.; Rezaei, J.H.; Fazaeli, H. Effect of harvesting frequency and maturity stage of Jerusalem artichoke forage on yield, chemical composition and in vitro fermentation of the tubers and forage. Span. J. Agric. Res. 2020, 18, 1–12. [Google Scholar] [CrossRef]

- Bogucka, B.; Jankowski, K. Jerusalem artichoke: Quality response to potassium fertilization and irrigation in Poland. Agronomy 2020, 10, 1518. [Google Scholar] [CrossRef]

- Bogucka, B.; Pszczółkowska, A.; Okorski, A.; Jankowski, K. The effects of potassium fertilization and irrigation on the yield and health status of Jerusalem artichoke (Helianthus tuberosus L.). Agronomy 2021, 11, 234. [Google Scholar] [CrossRef]

- Chupina, M.P.; Stepanov, A.F. Assessment of Photosynthetic Productivity of New Perennial Forage Crops in Forest-Steppe Conditions of Western Siberia. IOP Conf. Ser. Earth Environ. Sci. 2021, 624, 012121. Available online: https://iopscience.iop.org/article/10.1088/1755-1315/624/1/012121/pdf (accessed on 14 March 2024). [CrossRef]

- Wierzbowska, J.; Cwalina-Ambroziak, B.; Bogucka, B. The Effect of Nitrogen Fertilization on Yield and macronutrient concentrations in three cultivars of Jerusalem Artichoke (Helianthus tuberosus L.). Agronomy 2021, 11, 2161. [Google Scholar] [CrossRef]

- Ruttanaprasert, R.; Jogloy, S.; Vorasoot, N.; Kesmala, T.; Kanwar, R.S.; Holbrook, C.C.; Patanothai, A. Effects of water stress on total biomass, tuber yield, harvest index and water use efficiency in Jerusalem artichoke. Agric. Water Manag. 2016, 166, 130–138. [Google Scholar] [CrossRef]

| Farming Operation | Perennial Cropping System | Annual Cropping System |

|---|---|---|

| Tillage | Skimming (5–8 cm); fall plowing (18–22 cm); two treatments with a cultivation unit (5–8 cm) * | Skimming (5–8 cm); fall plowing (18–22 cm); two treatments with a cultivation unit (5–8 cm) ** |

| Tuber planting | 30 April 2018; cv. Medius; row spacing: 75 × 30 cm; planting depth: 6–8 cm; density: 4.4 tubers m−2 * | 1 May 2018; 19 April 2019; 30 April 2020; cv. Medius; row spacing: 75 × 30 cm; planting depth: 6–8 cm; density: 4.4 tubers m−2 ** |

| Mineral fertilization | 80 kg N ha−1 (ammonium nitrate, 34%); 70 kg P2O5 ha−1 (enriched superphosphate, 40%); 150 kg K2O ha−1 (potash salt, 60%) ** | 80 kg N ha−1 (ammonium nitrate, 34%); 70 kg P2O5 ha−1 (enriched superphosphate, 40%); 150 kg K2O ha−1 (potash salt, 60%) ** |

| Weed control | Two disc hilling treatments between rows ** | Two disc hilling treatments between rows ** |

| Harvest | Aerial biomass only (26 October 2018; 21 October 2018; 26 October 2020) ** | Aerial biomass (26 October 2018; 21 October 2018; 26 October 2020) ** and tubers (30 October 2018; 23 October 2019; 28 October 2020) ** |

| Source | Unit | Input | References |

|---|---|---|---|

| Labor | MJ hour−1 | 80 | Wójcicki [73] |

| Tractors | MJ kg−1 | 125 | Wójcicki [73] |

| Machines | MJ kg−1 | 110 | Wójcicki [73] |

| Diesel oil | MJ kg−1 | 48 | Wójcicki [73] |

| Plant material (tubers) | MJ kg−1 | 3.2 | Fang et al. [60] |

| N | MJ kg−1 | 77 | Wójcicki [73] |

| P2O5 | MJ kg−1 | 15 | Wójcicki [73] |

| K2O | MJ kg−1 | 10 | Wójcicki [73] |

| Year | Month | ||||||

|---|---|---|---|---|---|---|---|

| April | May | June | July | August | September | November | |

| 2018 | 0.78 | 0.80 | 1.19 | 2.26 | 0.49 | 0.63 | 1.51 |

| 2019 | 0.00 | 2.59 | 1.46 | 1.58 | 1.06 | 2.00 | 1.21 |

| 2020 | 0.05 | 2.09 | 0.54 | 0.71 | 1.81 | 0.71 | 2.59 |

| Specification | 2018 | 2019 | 2020 | |||

|---|---|---|---|---|---|---|

| Cropping Systems | ||||||

| Perennial | Annual | Perennial | Annual | Perennial | Annual | |

| GJ ha−1 y−1 | ||||||

| Tillage | 2.64 | 2.64 | 0.00 | 2.64 | 0.00 | 2.64 |

| Tuber planting | 8.07 | 8.07 | 0.00 | 8.07 | 0.00 | 8.07 |

| Fertilization | 8.77 | 8.77 | 8.77 | 8.77 | 8.77 | 8.77 |

| Weed management | 1.26 | 1.26 | 1.26 | 1.26 | 1.26 | 1.26 |

| Harvest and transport | 4.42 | 16.33 | 3.41 | 15.32 | 2.21 | 10.71 |

| Total | 25.16 | 37.07 | 13.44 | 36.06 | 12.24 | 31.45 |

| % | ||||||

| Tillage | 10.5 | 7.1 | 0.0 | 7.3 | 0.0 | 8.4 |

| Tuber planting | 32.1 | 21.8 | 0.0 | 22.4 | 0.0 | 25.7 |

| Fertilization | 34.9 | 23.7 | 65.2 | 24.3 | 71.7 | 27.9 |

| Weed management | 5.0 | 3.4 | 9.4 | 3.5 | 10.3 | 4.0 |

| Harvest and transport | 17.6 | 44.1 | 25.4 | 42.5 | 18.1 | 34.1 |

| Total | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Specification | 2018 | 2019 | 2020 | |||

|---|---|---|---|---|---|---|

| Cropping Systems | ||||||

| Perennial | Annual | Perennial | Annual | Perennial | Annual | |

| GJ ha−1 y−1 | ||||||

| Labor | 0.65 | 0.83 | 0.28 | 0.79 | 0.24 | 0.72 |

| Tractors and machines | 1.83 | 7.91 | 1.10 | 7.64 | 0.82 | 5.89 |

| Fuel | 6.93 | 12.58 | 3.35 | 11.88 | 2.47 | 9.09 |

| Materials: | 15.75 | 15.75 | 8.71 | 15.75 | 8.71 | 15.75 |

| 7.04 | 7.04 | 0.00 | 7.04 | 0.00 | 7.04 |

| 8.71 | 8.71 | 8.71 | 8.71 | 8.71 | 8.71 |

| Total | 25.16 | 37.07 | 13.44 | 36.06 | 12.24 | 31.45 |

| % | ||||||

| Labor | 2.6 | 2.2 | 2.1 | 2.2 | 2.0 | 2.3 |

| Tractors and machines | 7.3 | 21.3 | 8.2 | 21.2 | 6.7 | 18.7 |

| Fuel | 27.5 | 33.9 | 25.0 | 32.9 | 20.2 | 28.9 |

| Materials: | 62.6 | 42.5 | 64.8 | 43.7 | 71.2 | 50.1 |

| 28.0 | 19.0 | 0.0 | 19.5 | 0.0 | 22.4 |

| 34.6 | 23.5 | 64.8 | 24.2 | 71.2 | 27.7 |

| Total | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Year | Cropping Systems | ||

|---|---|---|---|

| Perennial | Annual | ||

| 2018 | 41.53 b | 93.53 a | 67.53 a |

| 2019 | 32.00 bc | 81.83 a | 56.91 b |

| 2020 | 17.03 c | 44.98 b | 31.01 c |

| 30.19 b | 73.45 a | – | |

| Year | Cropping Systems | |||

|---|---|---|---|---|

| Perennial | Annual | |||

| Aerial Biomass | Aerial Biomass | Tubers | ||

| 2018 | 335.44 | 356.36 | 223.70 | 305.17 |

| 2019 | 350.00 | 379.73 | 223.86 | 317.86 |

| 2020 | 350.30 | 357.27 | 238.47 | 315.35 |

| 345.25 a | 364.46 a | 228.68 b | ||

| Year | Cropping Systems | ||

|---|---|---|---|

| Perennial | Annual | ||

| 2018 | 13.75 b | 26.65 a | 20.20 a |

| 2019 | 11.20 b | 23.42 a | 17.31 b |

| 2020 | 5.97 c | 12.86 b | 9.41 c |

| 10.30 b | 20.98 a | – | |

| Year | Cropping Systems | |||

|---|---|---|---|---|

| Perennial | Annual | |||

| Aerial Biomass | Aerial Biomass | Tubers | ||

| 2018 | 3.52 | 4.04 | 1.52 | 3.03 |

| 2019 | 4.13 | 4.73 | 1.55 | 3.47 |

| 2020 | 4.36 | 4.54 | 1.83 | 3.58 |

| 4.01 a | 4.44 a | 1.63 c | – | |

| Year | Cropping Systems | ||

|---|---|---|---|

| Perennial | Annual | ||

| 2018 | 193.33 | 338.54 | 265.94 a |

| 2019 | 178.29 | 310.98 | 244.63 a |

| 2020 | 100.35 | 176.67 | 138.51 b |

| 157.32 b | 275.40 a | – | |

| Year | Cropping Systems | ||

|---|---|---|---|

| Perennial | Annual | ||

| 2018 | 168.17 | 301.47 | 234.82 a |

| 2019 | 164.84 | 274.92 | 219.88 a |

| 2020 | 88.11 | 145.22 | 116.66 b |

| 140.37 b | 240.54 a | – | |

| Year | Cropping Systems | ||

|---|---|---|---|

| Perennial | Annual | ||

| 2018 | 7.68 bc | 9.13 b | 8.41 b |

| 2019 | 13.26 a | 8.62 bc | 10.94 a |

| 2020 | 8.20 bc | 5.62 c | 6.91 b |

| 9.72 a | 7.79 b | – | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jankowski, K.J.; Bogucka, B. Jerusalem Artichoke: Energy Balance in Annual and Perennial Cropping Systems—A Case Study in North-Eastern Poland. Energies 2024, 17, 2511. https://doi.org/10.3390/en17112511

Jankowski KJ, Bogucka B. Jerusalem Artichoke: Energy Balance in Annual and Perennial Cropping Systems—A Case Study in North-Eastern Poland. Energies. 2024; 17(11):2511. https://doi.org/10.3390/en17112511

Chicago/Turabian StyleJankowski, Krzysztof Józef, and Bożena Bogucka. 2024. "Jerusalem Artichoke: Energy Balance in Annual and Perennial Cropping Systems—A Case Study in North-Eastern Poland" Energies 17, no. 11: 2511. https://doi.org/10.3390/en17112511

APA StyleJankowski, K. J., & Bogucka, B. (2024). Jerusalem Artichoke: Energy Balance in Annual and Perennial Cropping Systems—A Case Study in North-Eastern Poland. Energies, 17(11), 2511. https://doi.org/10.3390/en17112511