Enhancing Injectivity in Lithuanian Hydrocarbon Reservoirs through Wettability-Altering Surfactant Injection

Abstract

:1. Introduction

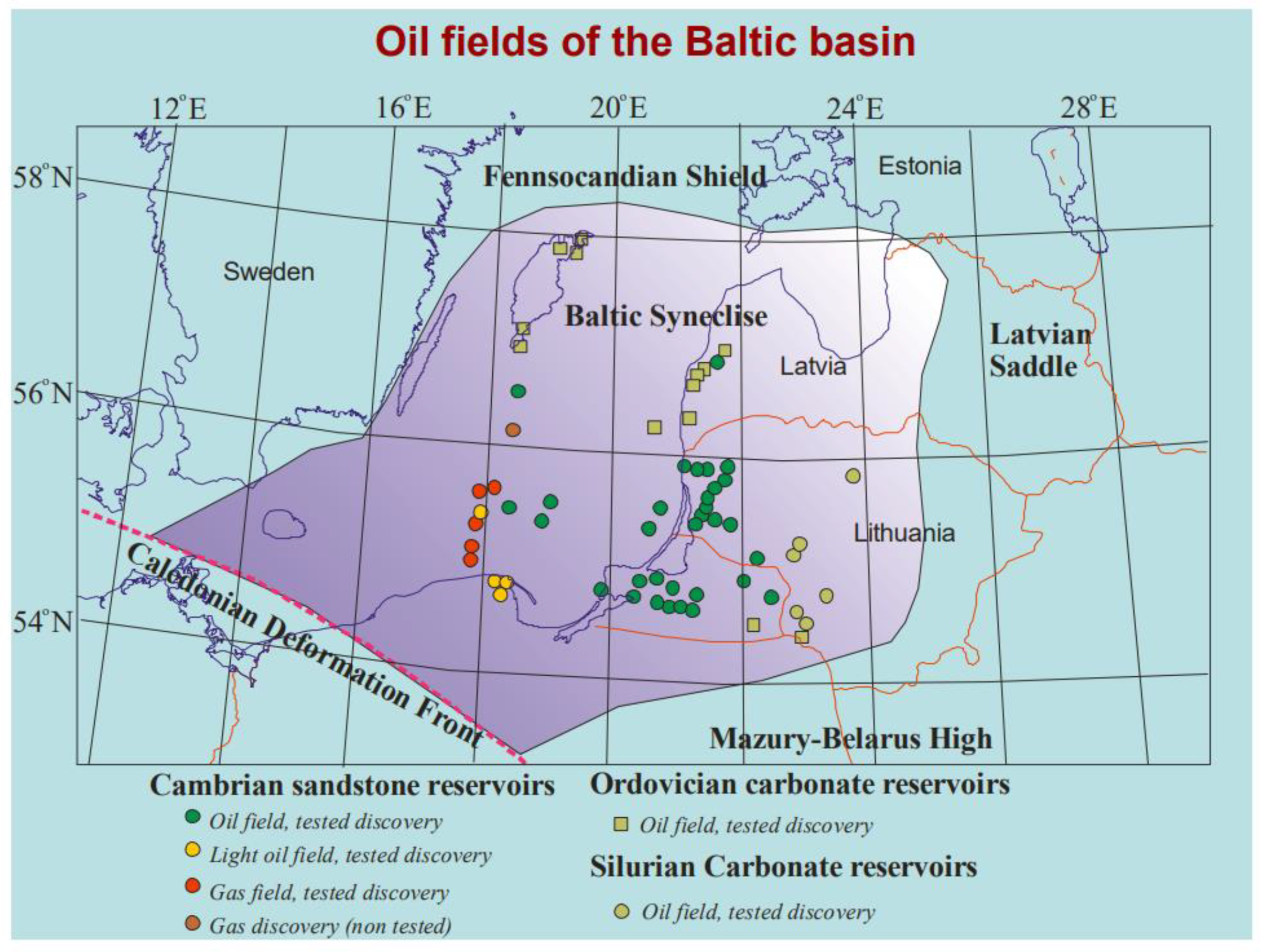

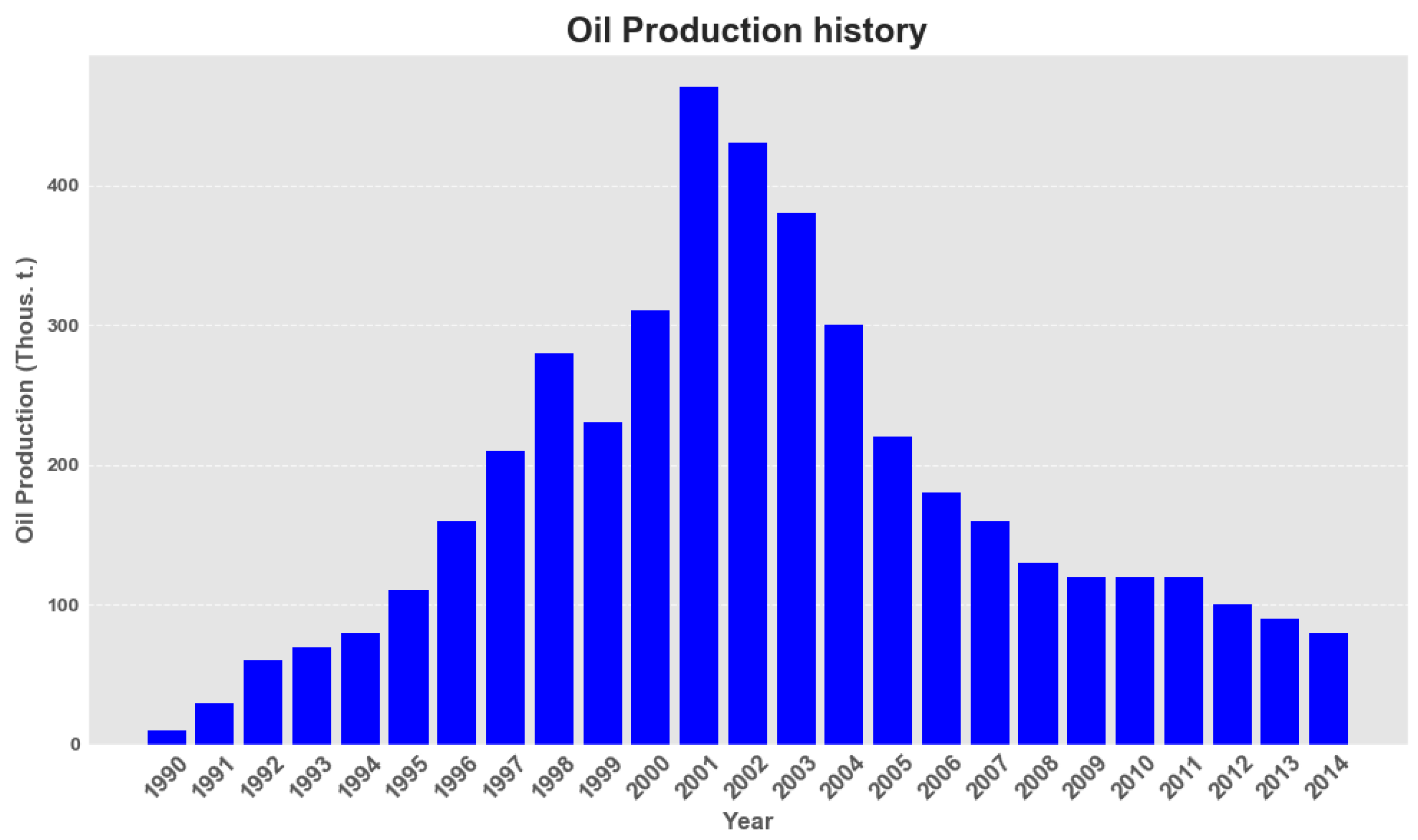

2. Field Data

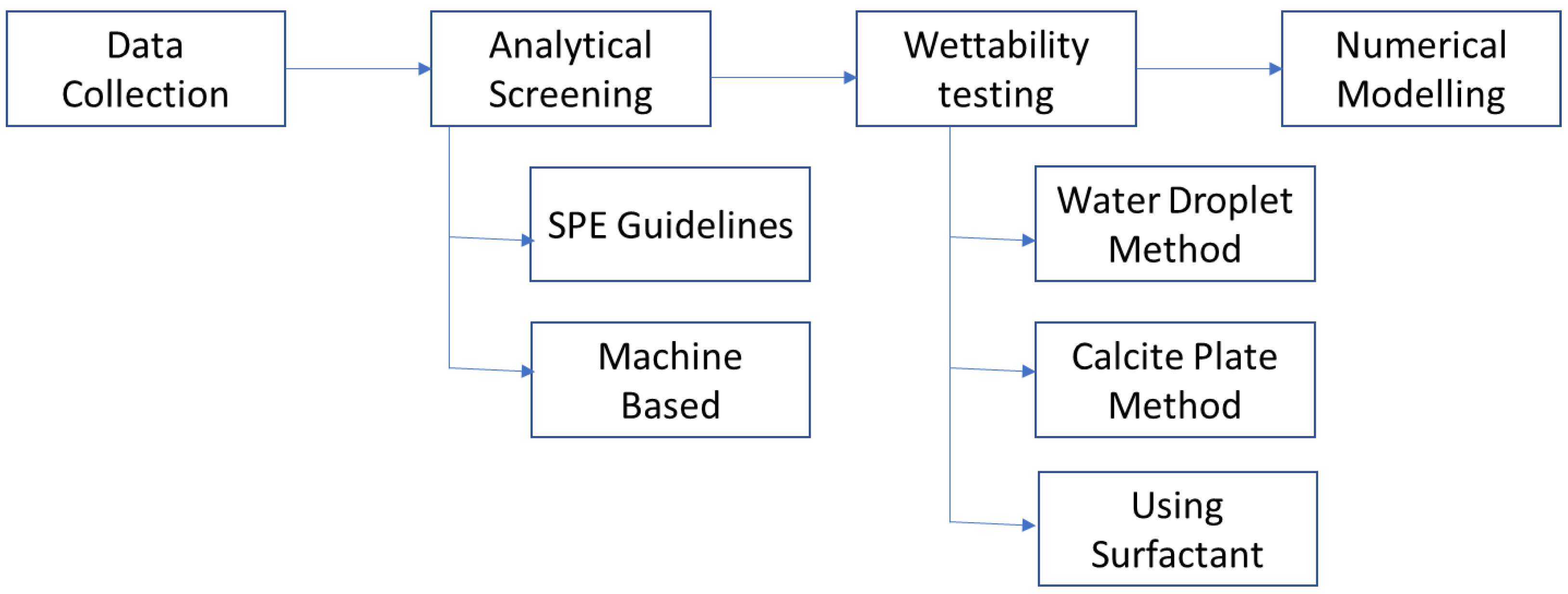

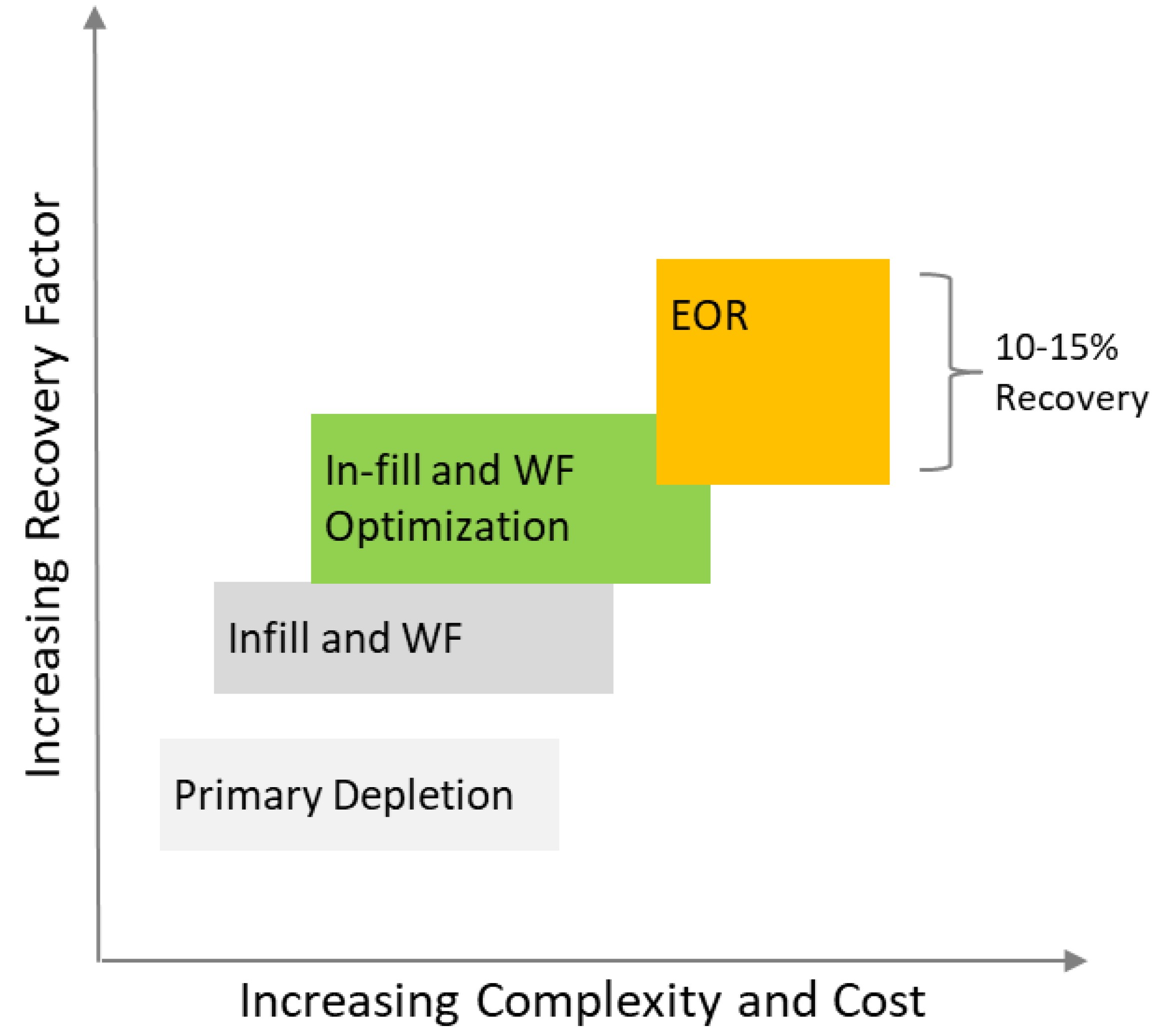

3. Enhanced Oil Recovery Screening

3.1. Analytical Screening Using SPE Guidelines

3.2. Machine-Learning-Based Screening

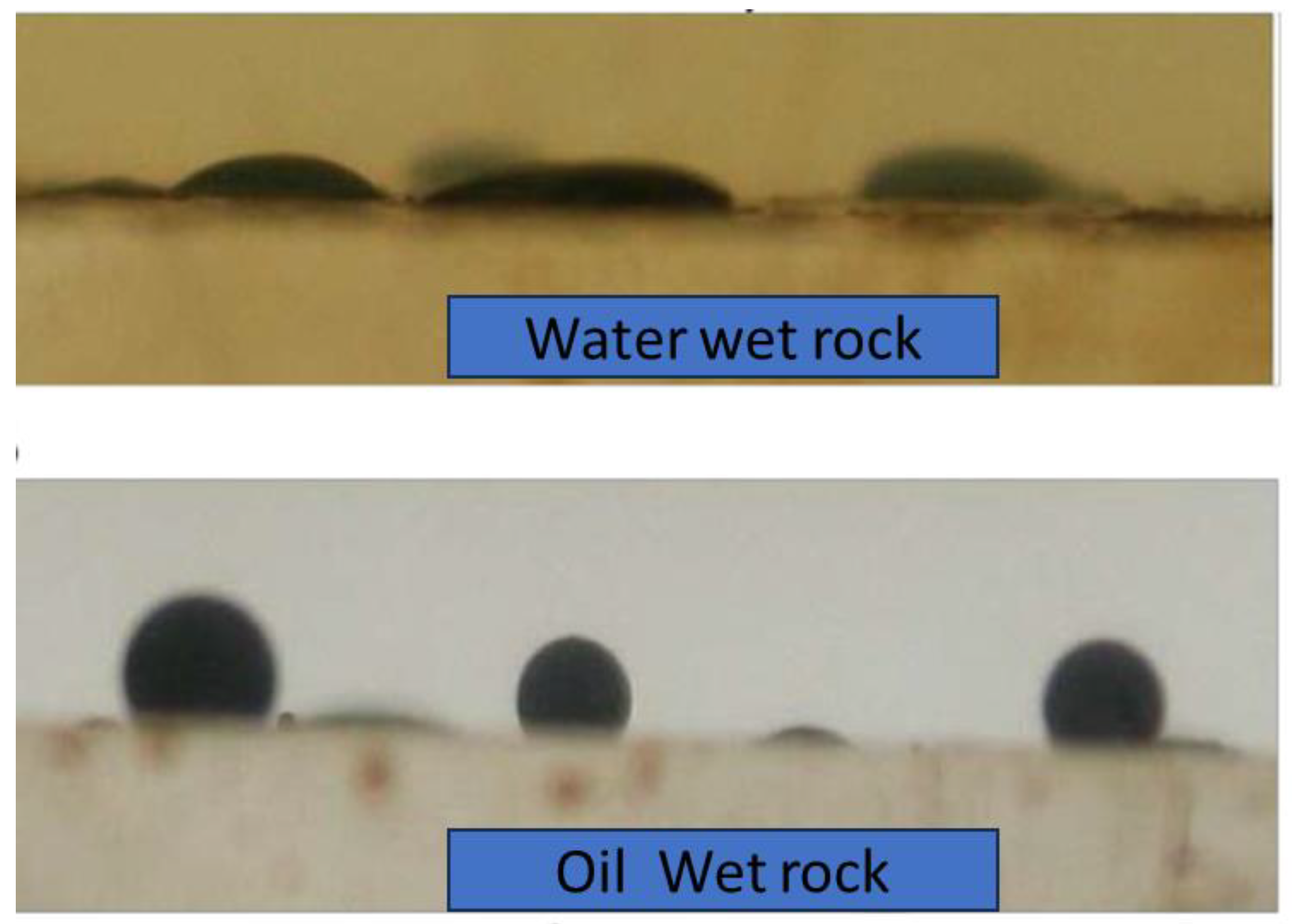

4. Rock Wettability Assessment

4.1. Water Droplet Method and Quantification of Wettability

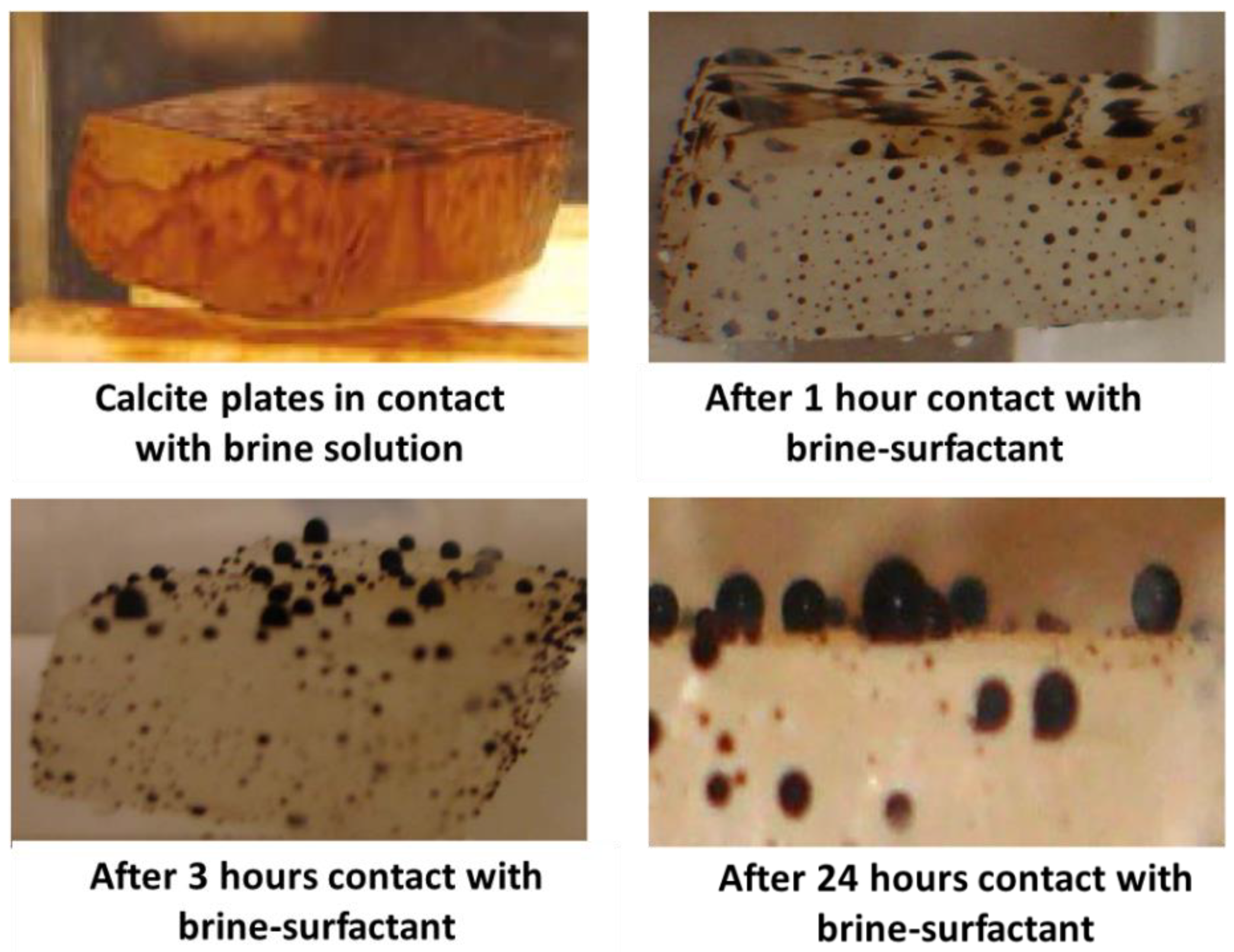

4.2. Calcite Plate Test for Wettability Alteration

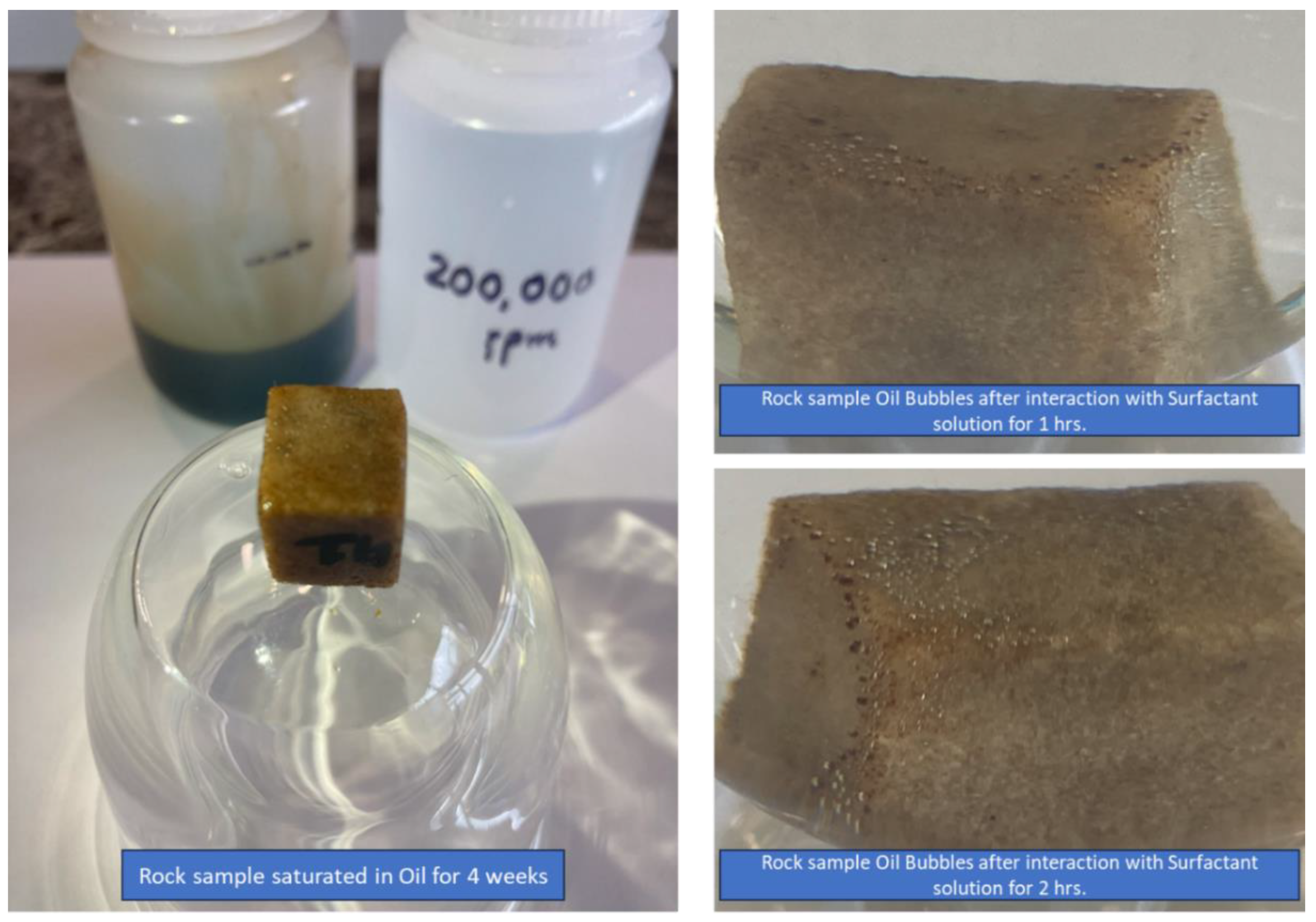

4.3. Wettability Alteration Using Surfactant

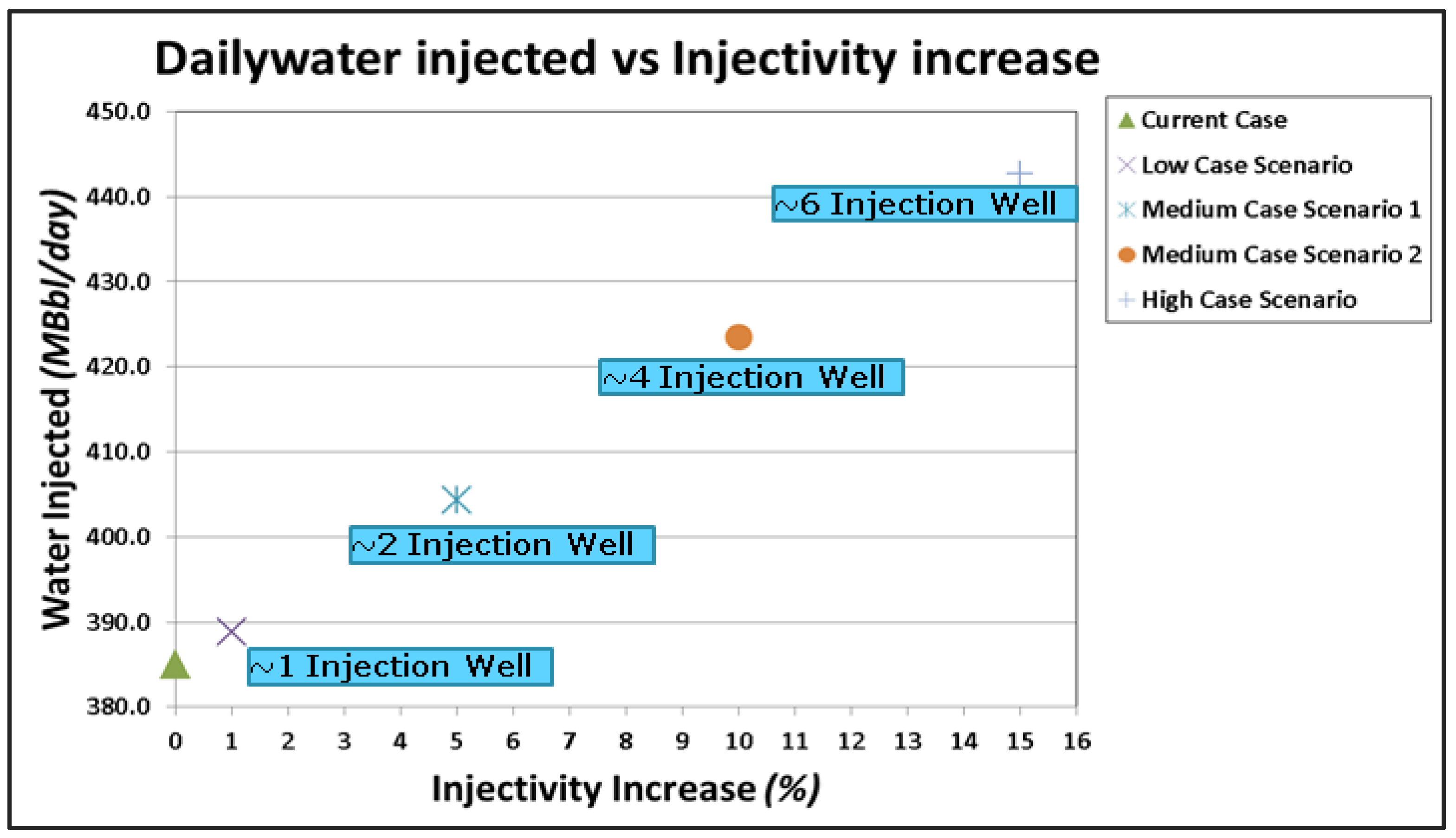

5. Injection Improvement via Wettability Alteration

6. Conclusions

7. Recommendation

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shogenova, A.; Sliaupa, S.; Vaher, R.; Shogenov, K.; Pomeranceva, R. Balti bassein: Ehitus, reservuaarikivimite omadused ja CO2 geoloogilise ladustamise võimalused. Est. J. Earth Sci. 2009, 58, 259–267. [Google Scholar] [CrossRef]

- Terasmaa, J. Estonia, the land of lakes. J. Int. Géosciences Environ. 2018, 358–366. [Google Scholar] [CrossRef]

- Rashid, A.; Malik, S.; Karaliute, V.; Makauskas, P.; Kaminskaite, I.; Pal, M. Lithuania’s geo-energy landscape: A brief overview of CCUS, hydrogen, and geothermal. Adv. Carbon Capture Util. Storage 2023, 1, 33–43. [Google Scholar] [CrossRef]

- Haselton, T.M.; Nafta, M. Exploiting the ROZ in Lithuania. In Proceedings of the 19th Annual CO2 Flooding Conference, Midland, TX, USA, 14 December 2013; Volume 14. [Google Scholar]

- Brock, W.; Bryan, L. Exxon Co USA, “SPE”. 1989. Available online: http://onepetro.org/SPERMPTC/proceedings-pdf/89LPR/All-89LPR/SPE-18977-MS/3214040/spe-18977-ms.pdf/1 (accessed on 23 February 2024).

- Manrique, E.; Thomas, C.; Ravikiran, R.; Izadi, M.; Lantz, M.; Romero, J.; Alvarado, V. SPE 130113 EOR: Current Status and Opportunities. 2010. Available online: http://onepetro.org/SPEIOR/proceedings-pdf/10IOR/All-10IOR/SPE-130113-MS/1771110/spe-130113-ms.pdf/1 (accessed on 23 February 2024).

- Hill, L.B.; Li, X.C.; Wei, N. CO2-EOR in China: A comparative, review. Int. J. Greenh. Gas Control 2020, 103, 103173. [Google Scholar] [CrossRef]

- Ghedan, S. SPE/EAGE Reservoir Characterization and Simulation Conference. 2009. Available online: http://onepetro.org/SPERCSC/proceedings-pdf/09RCSC/All-09RCSC/SPE-125581-MS/2720391/spe-125581-ms.pdf/1 (accessed on 23 February 2024).

- Haselton, T.M.; Nafta, M. Minijos Nafta Clean Energy Project; Baltic Carbon Forum: Tallinn, Estonia, 2019. [Google Scholar]

- Mathisen, A.; Skagestad, R. Utilization of CO2 from Emitters in Poland for CO2-EOR. Energy Procedia 2017, 114, 6721–6729. [Google Scholar] [CrossRef]

- Dangi, S.L.; Malik, S.; Makauskas, P.; Karliute, V.; Sharma, R.; Pal, M. An approach for assessment of CO2 leakage using mechanistic modelling: CO2 injection in deep saline aquifer of Lithuanian basin in presence of fault and fractures. Adv. Carbon Capture Util. Storage 2024. [Google Scholar] [CrossRef]

- Dangi, S.L.; Malik, S.; Makauskas, P.; Karliute, V.; Sharma, R.; Pal, M. Assessment of CO2 leakage using mechanistic modelling approach for CO2 injection in deep saline aquifer of Lithuanian basin in presence of fault and fractures. Balt. Carbon Forum 2023, 2, 15–16. [Google Scholar] [CrossRef]

- Dangi, S.L.; Malik, S.; Sharma, R.; Pal, M. Geomechanical Implications of CO2 Sequestration in Saline Aquifers. In Proceedings of the 14th Biennial International Conference SPG 2023, Kochi, India, 3–5 November 2023; Available online: https://spgindia.org/Kochi2023-expanded-abstracts/14th-conference-kochi23-top-177.pdf (accessed on 23 February 2024).

- Dicelytics Pvt. Ltd. Available online: https://www.linkedin.com/company/dicelytics/ (accessed on 23 February 2024).

- Taber, J.J.; Martin, F.D.; Seright, R.S. EOR Screening Criteria Revisited Part 1: Introduction to Screening Criteria and Enhanced Recovery Field Projects. 1997. Available online: http://onepetro.org/RE/article-pdf/12/03/189/2532146/spe-35385-pa.pdf/1 (accessed on 23 February 2024).

- Taber, J.J.; Martin, F.D.; Seright, R.S. EOR Screening Criteria Revisited-Part 2: Applications and Impact of Oil Prices. SPE Reserv. Eng. 1997, 12, 199–206. [Google Scholar] [CrossRef]

- Aladasani, A.; Bai, B. SPE 130726 Recent Developments and Updated Screening Criteria of Enhanced Oil Recovery Techniques. Available online: http://onepetro.org/SPEIOGCEC/proceedings-pdf/10IOGCEC/All-10IOGCEC/SPE-130726-MS/2342995/spe-130726-ms.pdf/1 (accessed on 23 February 2024).

- Šliaupa, S.; Šliaupienė, R. Prospects of Geological Storage of CO2 in Lithuania BALTIC CARBON FORUM 2021. In Baltic Carbon Forum; Gamtos Tyrimu Centras: Vilnius, Lithuania, 2021; Available online: https://bcforum.net/presentations2021/0303_Saulius%20Sliaupa.pdf (accessed on 23 February 2024).

- “Pal V15 Kerno Drėkinimo Testai”. Minijos Nafta Internal Report 1997—SCAL Analysis. Available online: www.minijosnafta.com/en (accessed on 23 February 2024).

- Morrow, “Wettability and Its Effect on Oil Recovery”. 1990. Available online: http://onepetro.org/JPT/article-pdf/42/12/1476/2222566/spe-21621-pa.pdf/1 (accessed on 27 March 2024).

- Abdallah, W.; Buckley, J.S.; Carnegie, A.; Edwards, J.; Herold, B.; Fordham, E.; Graue, A.; Habashy, T.; Seleznev, N.; Signer, C.; et al. Fundamentals of Wettability. Technology 1986, 38, 268. [Google Scholar]

- Hirasaki, G.; Zhang, D.L. Surface Chemistry of Oil Recovery from Fractured, Oil-Wet, Carbonate Formations. 2004. Available online: http://onepetro.org/SJ/article-pdf/9/02/151/2572183/spe-88365-pa.pdf/1 (accessed on 23 February 2024).

- Jadhunandan, P.P.; Morrow, N.R. Spontaneous Imbibition of Water by Crude Oil/Brine/Rock Systems. In Situ 1991, 15. Available online: https://www.osti.gov/biblio/5847471 (accessed on 23 February 2024).

- Sheng, J.J. Chapter 12. Surfactant Enhanced Oil Recovery in Carbonate Reservoirs Review of Surfactant Enhanced Oil Recovery in Carbonate Reservoirs. Adv. Pet. Explor. Dev. 2013, 6, 281–299. [Google Scholar]

- Rohilla, N.; Hirasaki, G.J. Pore Structure of Vuggy Carbonates and Rate Dependent Displacement in Carbonate Rocks. SCA2011-21. 2011. Available online: https://jgmaas.com/SCA/2011/SCA2011-21.pdf (accessed on 23 February 2024).

- Rohilla, N.; Ravikiran, R.; Carlisle, C.T.; Jones, N.; Davis, M.B.; Finch, K.B.H. Design of a Robust ASP Formulation for Clay Rich and Moderate Permeability Sandstone Reservoir: From Laboratory to Single Well Chemical Tracer Test in the Field. In Proceedings of the SPE-DOE Improved Oil Recovery Symposium Proceedings, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar] [CrossRef]

- Mohan, K.; Gupta, R.; Mohanty, K.K. Wettability altering secondary oil recovery in carbonate rocks. Energy Fuels 2011, 25, 3966–3973. [Google Scholar] [CrossRef]

- Patil, P.D.; Rohilla, N.; Katiyar, A.; Yu, W.; Nelson, C.; Falcone, S.; Rozowski, P. Surfactant Based EOR for Tight Oil Unconventional Reservoirs through Wettability Alteration: Novel Surfactant Formulations and Their Efficacy to Induce Spontaneous Imbibition. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference 2018, URTC 2018, Houston, TX, USA, 23–25 July 2018. [Google Scholar] [CrossRef]

- Patil, P.D.; Rohilla, N.; Katiyar, A.; Yu, W.; Falcone, S.; Nelson, C.; Rozowski, P. Surfactant Based EOR for Tight oil Reservoirs through Wettability Alteration: Novel Surfactant Formulations and Their Efficacy to Induce Spontaneous Imbibition. In Proceedings of the Society of Petroleum Engineers-SPE EOR Conference at Oil and Gas West Asia 2018, Muscat, Oman, 21–23 March 2016. [Google Scholar] [CrossRef]

- Standnes, D.C. Analysis of oil recovery rates for spontaneous imbibition of aqueous surfactant solutions into preferential oil-wet carbonates by estimation of capillary diffusivity coefficients. Colloids Surf. A Physicochem. Eng. Asp. 2004, 251, 93–101. [Google Scholar] [CrossRef]

- Standnes, D.C.; Austad, T. Wettability alteration in chalk 2. Mechanism for wettability alteration from oil-wet to water-wet using surfactants. J. Pet. Sci. Eng. 2000, 28, 123–143. [Google Scholar] [CrossRef]

- Standnes, D.C.; Austad, T. Wettability alteration in carbonates: Low-cost ammonium surfactants based on bio-derivatives from the coconut palm as active chemicals to change the wettability form oil-wet to water-wet conditions. Colloids Surf. A Physicochem. Eng. Asp. 2003, 218, 161–173. [Google Scholar] [CrossRef]

- Standnes, D.C.; Austad, T. Nontoxic low-cost amines as wettability alteration chemicals in carbonates. J. Pet. Sci. Eng. 2003, 39, 431–446. [Google Scholar] [CrossRef]

- Strand, S.; Standnes, D.C.; Austad, T. Spontaneous imbibition of aqueous surfactant solutions into neutral to oil-wet carbonate cores: Effects of brine salinity and composition. Energy Fuels 2003, 17, 1133–1144. [Google Scholar] [CrossRef]

- Seethepalli, A.; Adibhatla, B.; Mohanty, K.K. Physicochemical interactions during surfactant flooding of fractured carbonate reservoirs. SPE J. 2004, 9, 411–418. [Google Scholar] [CrossRef]

- Xie, X.; Weiss, W.W.; Tong, Z.; Morrow, N.R. Improved oil recovery from carbonate reservoirs by chemical stimulation. SPE J. 2005, 10, 276–285. [Google Scholar] [CrossRef]

- Gupta, R.; Mohan, K.; Mohanty, K.K. Surfactant Screening for Wettability Alteration in Oil-Wet Fractured Carbonates. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar] [CrossRef]

- Sharma, G.; Mohanty, K.K. Wettability alteration in high-temperature and high-salinity carbonate reservoirs. SPE J. 2013, 18, 646–655. [Google Scholar] [CrossRef]

- Bennetzen, M.V.; Mogensen, K.; Frank, S.; Mohanty, K. Dilute surfactant flooding studies in a low-permeability oil-wet Middle East carbonate. In Proceedings of the Society of Petroleum Engineers-International Petroleum Technology Conference 2014, IPTC 2014: Unlocking Energy Through Innovation, Technology and Capability, Kuala Lumpur, Malaysia, 10–12 December 2014. [Google Scholar] [CrossRef]

- Pal, M.; Gilani, S.F.; Tarsaulia, G.; Geremia, G. SPE-190373-MS Offshore Surfactant Injectivity Trials: From Core to Successful Field Trials in the Al-Shaheen Field. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 26–28 March 2018. [Google Scholar] [CrossRef]

- Rohilla, N.; Katiyar, A.; Saxena, P.; Pal, M.; Rozowski, P.; Gentilucci, A. Successful Wettability Alteration Pilot in an Offshore Reservoir: Laboratory Analysis to Support Planning, Implementation and Interpretation; IOR: Austria, 2021; Available online: https://www.earthdoc.org/content/papers/10.3997/2214-4609.202133124 (accessed on 23 February 2024).

- Pal, M.; Saxena, P.; Rohilla, N.; Katiyar, A.; Rozowski, P.; Knight, T. Successful Wettability Alteration Pilot in Offshore Reservoir: Pilot Planning, Execution, Monitoring and Interpretation. 2021. Available online: https://www.earthdoc.org/content/papers/10.3997/2214-4609.202133109?crawler=true (accessed on 23 February 2024).

- Malik, S.; Makauskas, P.; Karaliūtė, V.; Pal, M.; Sharma, R. Assessing the geological storage potential of CO2 in Baltic Basin: A case study of Lithuanian hydrocarbon and deep saline reservoirs. Int. J. Greenh. Gas Control 2024, 133, 104097. [Google Scholar] [CrossRef]

- Chavan, H.K.; Sinharay, R.K.; Kumar, V.; Patel, D. An approach of using machine learning classification for screening of enhanced oil recovery techniques. Pet. Sci. Technol. 2023, 1–19. [Google Scholar] [CrossRef]

- Aminzadeh, F.; Temizel, C.; Hajizadeh, Y. Machine Learning Applications in Enhanced Oil Recovery (EOR). In Artificial Intelligence and Data Analytics for Energy Exploration and Production; Wiley: Hoboken, NJ, USA, 2022. [Google Scholar] [CrossRef]

- You, J.; Ampomah, W.; Sun, Q.; Kutsienyo, E.J.; Balch, R.S.; Dai, Z.; Cather, M.; Zhang, X. Machine learning based co-optimization of carbon dioxide sequestration and oil recovery in CO2-EOR project. J. Clean Prod. 2020, 260, 120866. [Google Scholar] [CrossRef]

- Cheraghi, Y.; Kord, S.; Mashayekhizadeh, V. Application of machine learning techniques for selecting the most suitable enhanced oil recovery method; challenges and opportunities. J. Pet. Sci. Eng. 2021, 205, 108761. [Google Scholar] [CrossRef]

- Salehi, E.; Mohammadi, M.R.; Hemmati-Sarapardeh, A.; Mahdavi, V.R.; Gentzis, T.; Liu, B.; Ostadhassan, M. Modeling Interfacial Tension of N2/CO2 Mixture + n-Alkanes with Machine Learning Methods: Application to EOR in Conventional and Unconventional Reservoirs by Flue Gas Injection. Minerals 2022, 12, 252. [Google Scholar] [CrossRef]

- Pirizadeh, M.; Alemohammad, N.; Manthouri, M.; Pirizadeh, M. A new approach for ranking enhanced oil recovery methods based on multi-gene genetic programming. Pet. Sci. Technol. 2023, 41, 64–85. [Google Scholar] [CrossRef]

- Karovic-Maricic, V.; Lekovic, B.; Danilovic, D. Factors influencing successful implementation of enhanced oil recovery projects. Podzemn. Rad. 2014, 22, 41–50. [Google Scholar] [CrossRef]

- McDougall, S.R.; Sorbie, K.S. The Impact of Wettability on Waterflooding: Pore-Scale Simulation. SPE Res. Eng. 1995, 10, 208–213. [Google Scholar] [CrossRef]

- Al-Nofli, K.; Pourafshary, P.; Mosavat, N.; Shafiei, A. Effect of Initial Wettability on Performance of Smart Water Flooding in Carbonate Reservoirs—An Experimental Investigation with IOR Implications. Energies 2018, 11, 1394. [Google Scholar] [CrossRef]

- Agbalaka, C.; Dandekar, A.Y.; Patil, S.L.; Khataniar, S.; Hemsath, J.R. The Effect of Wettability on Oil Recovery: A Review. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 20–22 October 2008. [Google Scholar] [CrossRef]

| Field Name/Location | Gargzdai Reservoir (Western Lithuania) |

|---|---|

| Geological basin | Baltic basin |

| Formation name | Cambrian |

| Discovery year | 1960–1970 |

| Type of rock (sandstone/carbonate/shale) | Sandstone |

| Rock heterogeneity info | Very heterogeneous (0.01–100 md) |

| Mineral composition | 95% or more quartz |

| Clay content (% of clay in rock) | 3–7, some placed up to 20 |

| Average porosity, % | 1–12 |

| Average permeability, md | 0.01–100 |

| Depth, m | 1975–1992.5 |

| Reservoir area (acres) | 200 sq. km—total 8 reservoirs |

| Average pay thickness, m | 70–80 m |

| Reservoir temperature, °C | 85 |

| Original reservoir pressure, psi | 2750 |

| Injection well bottom hole pressure, psi | 3000 |

| Initial oil and water saturation ratios | 30–56% residual oil saturation |

| Average connate water saturation, % | ~20 |

| Current oil cut, % | High water cut up to 90–95 |

| Secondary recovery, % | 27% (with water flood) |

| Start year of water flooding/injection | 21+ years |

| Current average daily injection rate per well (Water) bbls/day | 500 |

| Number of producing wells | 11 wells |

| Number of injection wells | 4 |

| Oil production from entire field, bbl/day | ~200 (from 4 wells—around 60 bb/day) |

| Well configuration—horizontal/vertical | Vertical |

| Well spacing per well, meters | 300–1000 |

| Current average daily injection rate per well (Water), m3/day | 500 (~3200 bbls per day) |

| Reservoir Mechanism | |

| Primary producing mechanism | Water flooding |

| Current injection rate, m3/day | 500 |

| Average wellhead injection pressure and BHP, bars | 250–350 (depending on wells) |

| Water Properties | |

| Density of original connate/formation water, kg/m3 | 1127 |

| Salinity/total dissolved solids: Original formation water, wt % | 20 |

| Oil Properties | |

| API | 43.4 |

| Viscosity at reservoir temperature, cp | 0.63–0.8 (in situ), 1.44 (dead oil) |

| Other information | |

| Reservoir pressure, bars | 220 |

| Wettability | Oil-wet |

| Initial water saturation, % | 26 |

| Recovery factor, % | 27 |

| Well spacing, ha/well | 98 |

| Average reservoir thickness, m | 9.15 |

| Parameter | Value |

|---|---|

| API Gravity | 43.4 |

| Oil Viscosity | 1.44 |

| Residual Oil Saturation | 30% |

| Depth, ft | 6479.659 |

| Temperature, °C | 85 |

| Permeability, md | 100 |

| Porosity | 10% |

| Formation | Sandstone |

| Thickness | >20 ft No dip |

| Composition | High % C1–C7 |

| Flooding Method | Result |

|---|---|

| HOT WATER | 100.00% |

| CHEMICAL | 80.78% |

| I-HC | 62.37% |

| I-CO2 | 41.84% |

| POLYMER | 21.32% |

| Flooding Method | Result |

|---|---|

| HOT WATER | 100.00% |

| I-CO2 | 80.63% |

| CHEMICAL | 60.21% |

| I-HC | 41.49% |

| POLYMER | 21.07% |

| Flooding Method | Result |

|---|---|

| HOT WATER | 100.00% |

| CHEMICAL | 75.71% |

| I-HC | 52.29% |

| POLYMER | 26.58% |

| Wetting Condition | Contact Angle (Degrees) |

|---|---|

| Moderately water–wet | 30–75 |

| Neutrally wet | 75–105 |

| Moderately oil–wet | 105–150 |

| Strongly oil–wet | 150–180 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dangi, S.L.; Pal, M. Enhancing Injectivity in Lithuanian Hydrocarbon Reservoirs through Wettability-Altering Surfactant Injection. Energies 2024, 17, 2726. https://doi.org/10.3390/en17112726

Dangi SL, Pal M. Enhancing Injectivity in Lithuanian Hydrocarbon Reservoirs through Wettability-Altering Surfactant Injection. Energies. 2024; 17(11):2726. https://doi.org/10.3390/en17112726

Chicago/Turabian StyleDangi, Shankar Lal, and Mayur Pal. 2024. "Enhancing Injectivity in Lithuanian Hydrocarbon Reservoirs through Wettability-Altering Surfactant Injection" Energies 17, no. 11: 2726. https://doi.org/10.3390/en17112726