Optimization and Modeling of a Dual-Chamber Microbial Fuel Cell (DCMFC) for Industrial Wastewater Treatment: A Box–Behnken Design Approach

Abstract

1. Introduction

- The utilization of raw industrial wastewater sources harvested from local wastewater treatment plants, effectively emulating the complexity and variability of industrial wastewater substrates based on day-to-day industrial activities.

- The employment of freshly harvested and well-acclimatized heterotrophic biomass consortia, specifically Protobacteria and Bacteriodota, as a combined biomass population to enhance biodegradability in the microbial fuel cell.

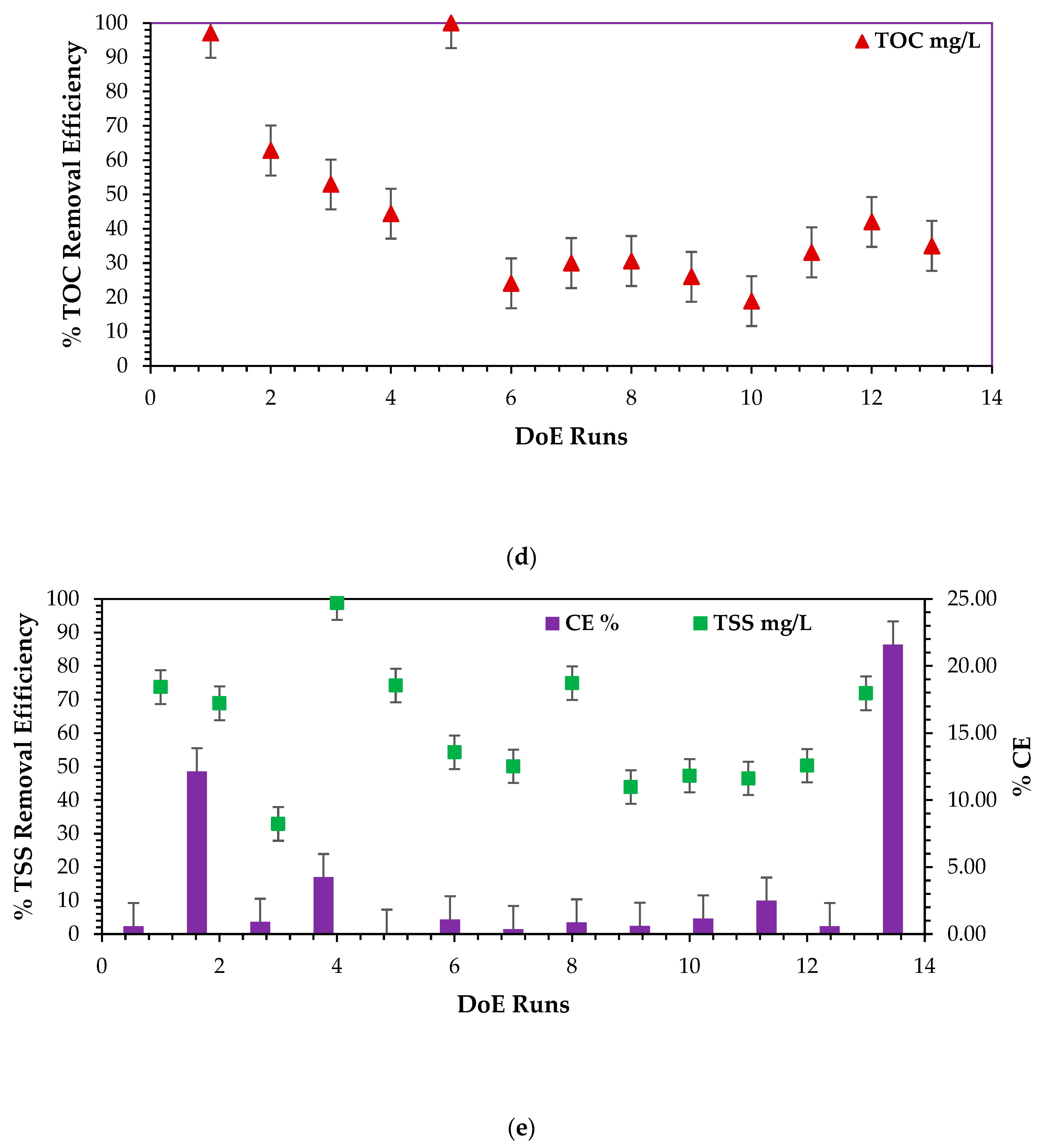

2. Results and Discussion

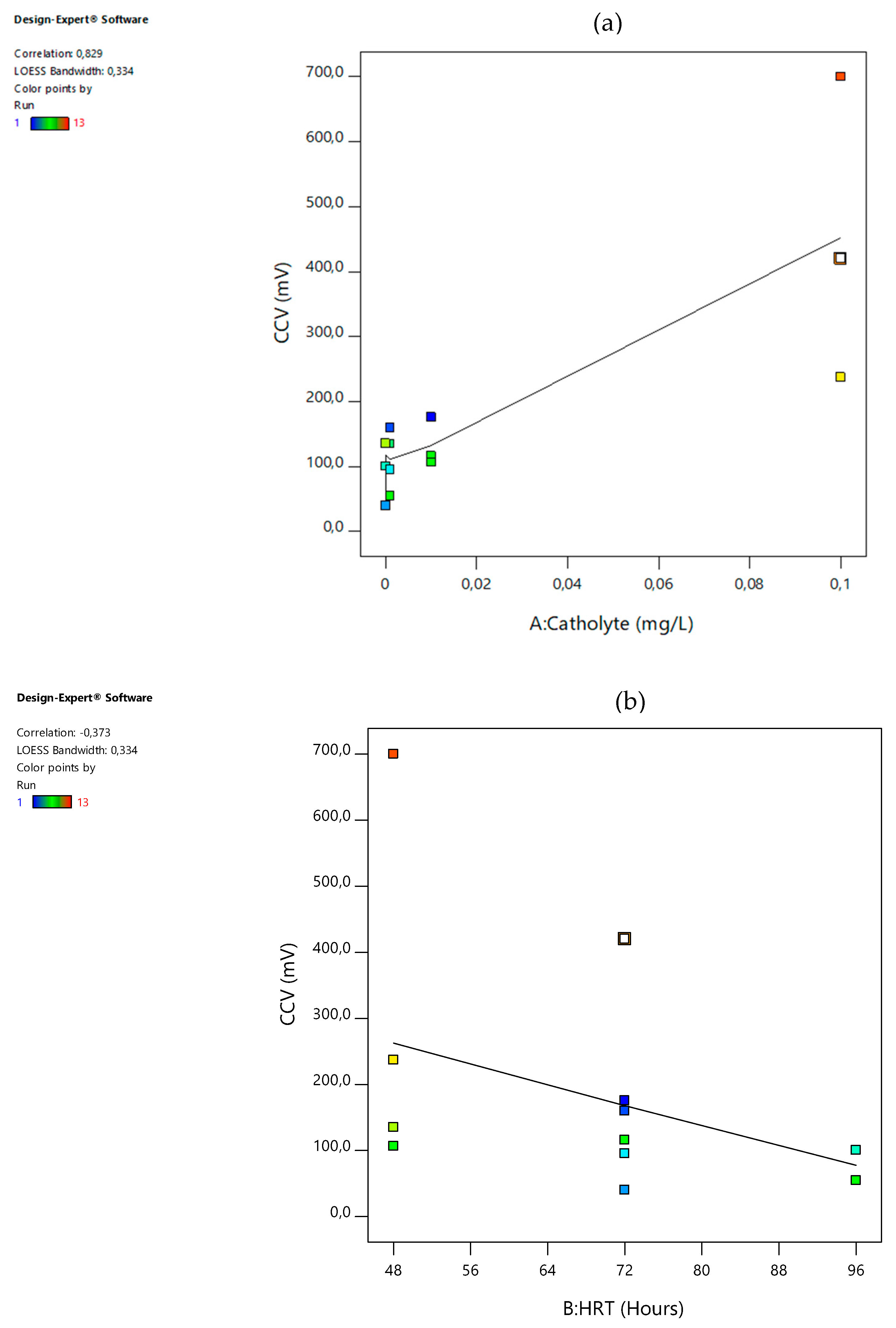

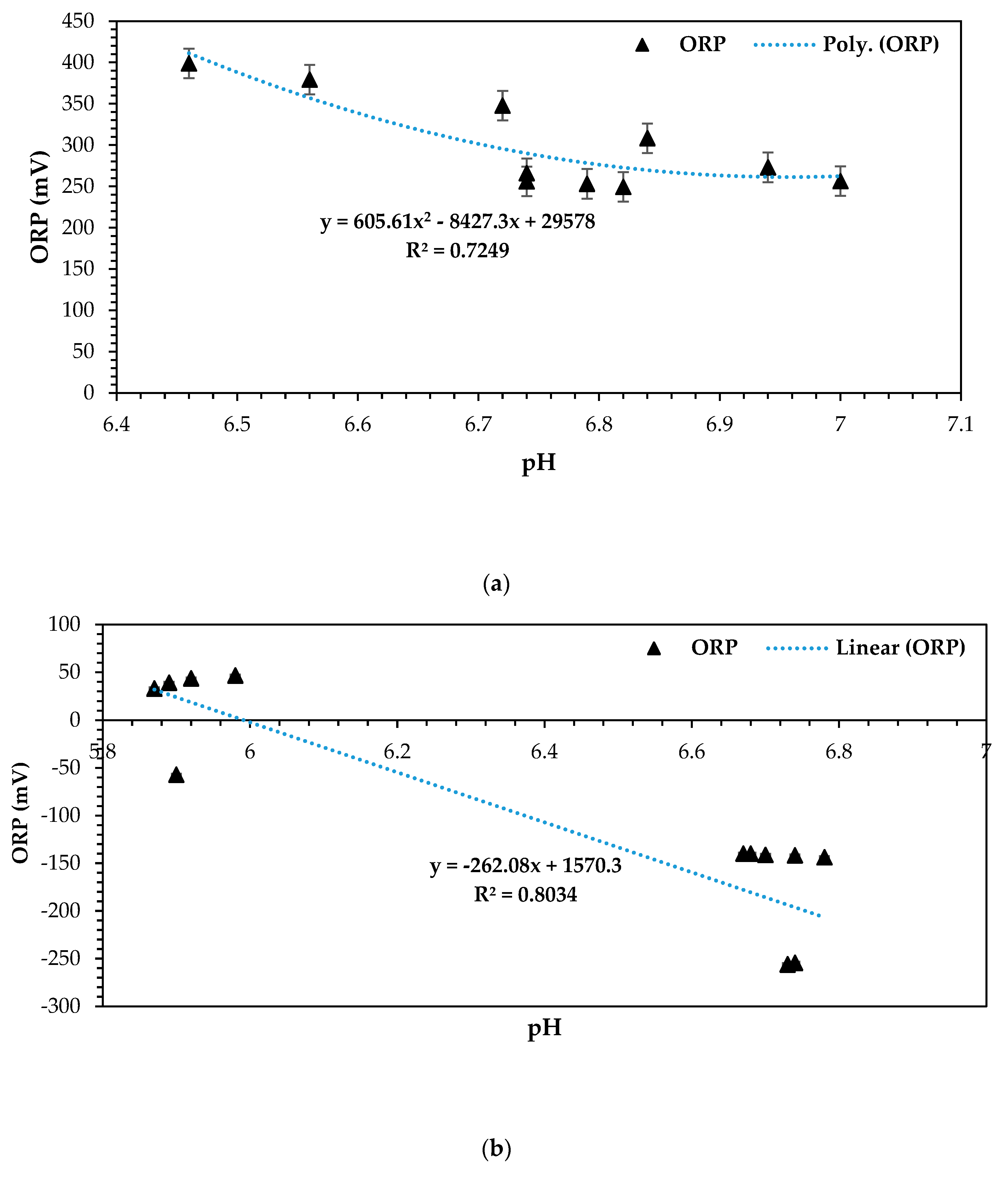

2.1. Influence of Input Variables on the Responses

2.2. Regression Model and Fit Summary

2.3. Analysis of Variance (ANOVA) Test and Fit Statistics

37.03 × BD + 77.33 × CD + 95.75 × A2

× BC + 0.432 × BD − 1.59 × CD

57.48 × D − 48.18 × BD + 59.06 × D2

(HRT) + 96.34 × (catholyte) × (surface area) − 67.34 × (HRT) × (temperature) − 37.03 × (HRT) × (surface area) + 77.33 ×

(temperature) × (surface area) + 95.75 × (catholyte)2

(HRT) − 4.23 × (catholyte) × (temperature) + 20.62 × (catholyte) × (surface area) + 2.40 × (HRT) × (temperature) + 0.432 ×

(HRT) × (surface area) − 1.59 × (temperature) × (surface area)

(HRT) − 17.49 × (catholyte) × (temperature) + 20.76 × (catholyte) × (surface area) − 1.19 × (temperature) − 57.48 ×

(surface area) − 48.18 × (HRT) × (surface area) + 59.06 × (surface area)2

(surface area) + 59.06 × (surface area)2

(temperature) − 0.904 × (HRT) × (surface area) + 0.729 × (HRT)2

(HRT) − 23.72 × (catholyte) × (surface area) − 63.68 × (temperature)2

(temperature) − 24.73 × (temperature) × (surface area)

2.4. Validation of the Numerical BBD–RSM Models

2.5. Numerical Optimization Based on Ramp Plots for Desirability Analysis

2.6. The Yield of Optimization Experiments: RSM–BBD Optimization of All Response Parameters

2.6.1. Effect of Catholyte Concentration, Surface Area, HRT, and Temperature Optimization Combinations

2.6.2. Optimum Closed-Circuit Voltage (CCV) vs. Open-Circuit Voltage (OCV) Outputs (mV) Based on RSM–BBD Prediction

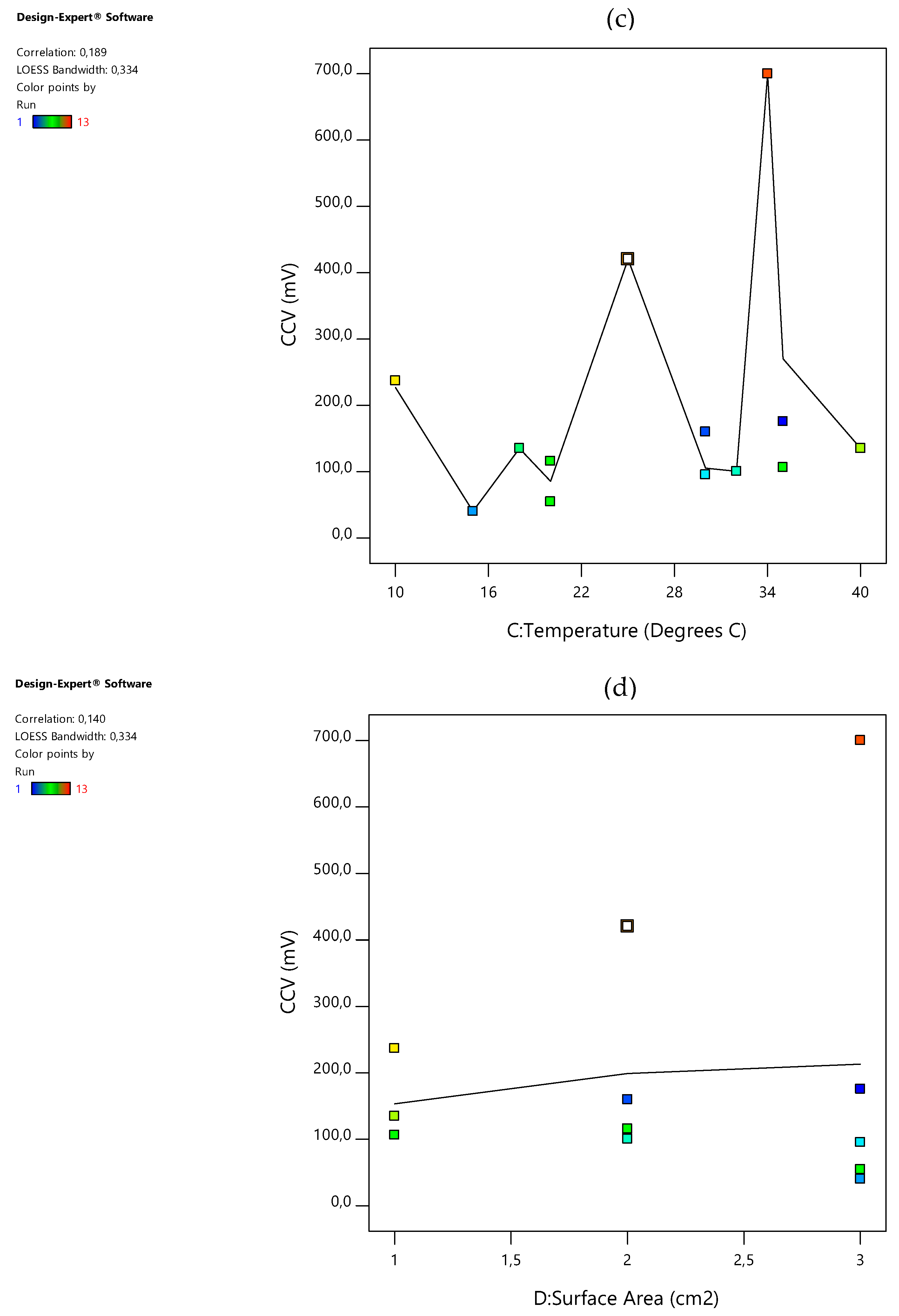

2.6.3. Optimum DCMFC Electromotive Cell Voltage () vs. Anodic ( vs. Cathodic ( Half–Cell Potentials Based on Reference Electrode—AG/AgCl (mV)

2.6.4. Optimum Correlation Curves for Power Density (mW/m2) vs. Current Density (mA/m2) vs. CVV (mV) Yield in Optimizing the DCMFC

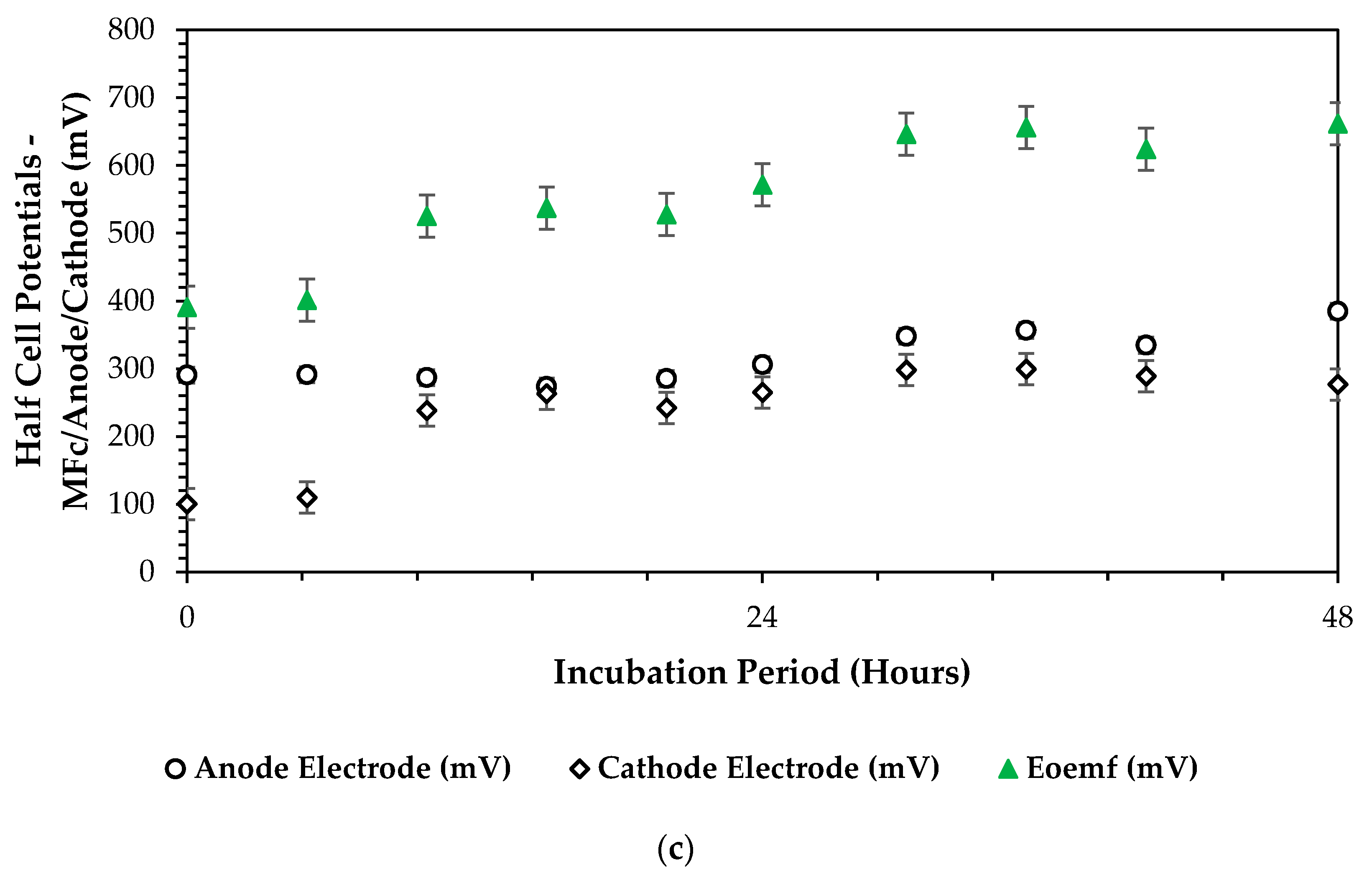

2.6.5. RSM–BBD Application for Optimized ORP (mV) vs. pH Correlation in the DCMFC

2.6.6. RSM–BBD Application for Optimized Correlation on −ΔGr (J) vs. ORP (mV) Relationship in the DCMFC

2.7. Summary Results for All Factor Combinations on the Optimization of the DCMFC for Bioelectricity Generation

2.8. Validation of Predicted Optimum Voltage Yield and Optimum Complex Substrates Source for Scaling Up Bioelectricity Generation in the DCMFC

2.9. Comparison with Previous Studies on RSM–BBD Methodology

3. Materials and Methods

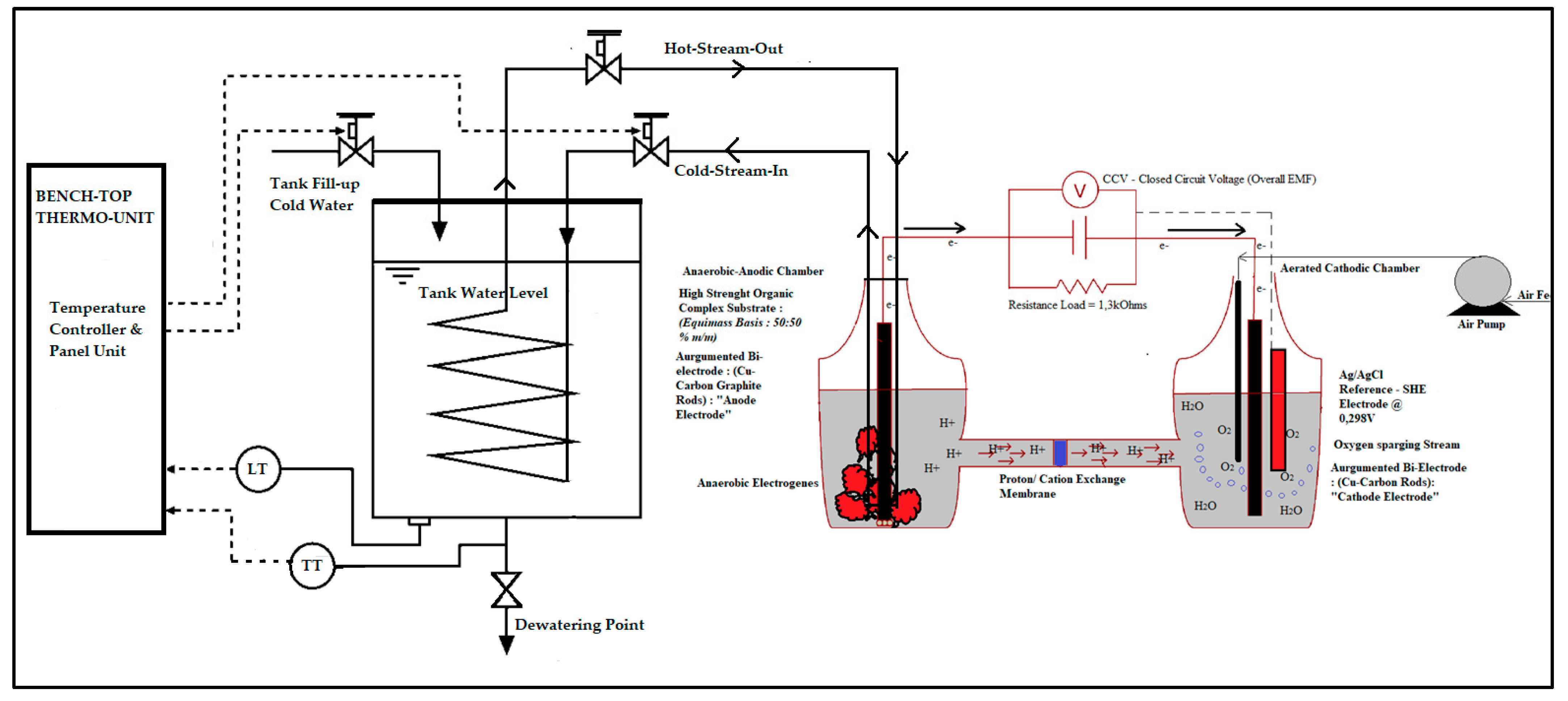

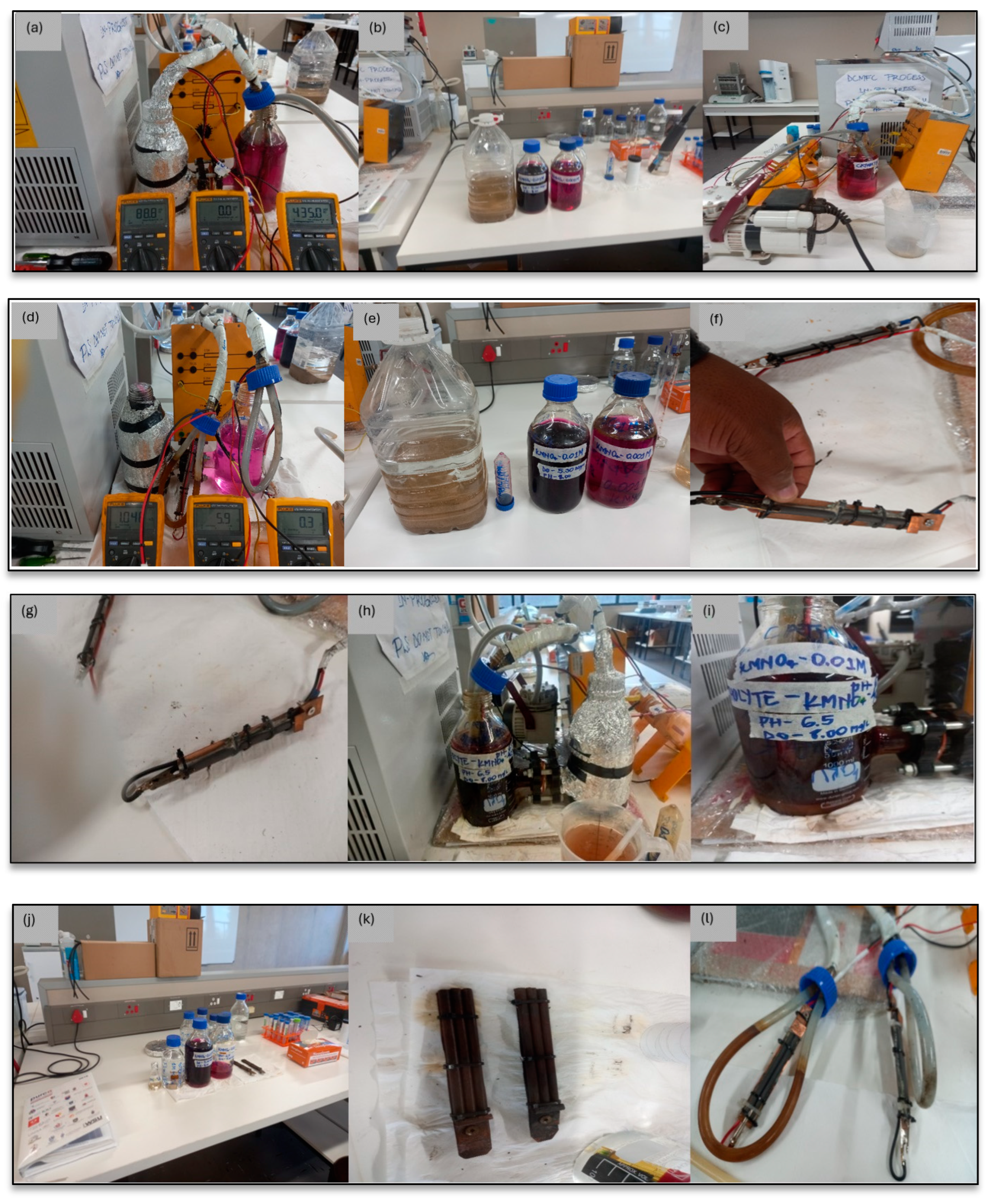

3.1. DCMFC Experimental Configuration and Installation and Commissioning of the DCMFC

Installation and Commissioning of DMFC Cell

3.2. DCMFC Data Analysis

3.3. Wastewater Sample Analytical Methods

3.4. Design of Experiment (DoE) Using Response Surface Methodology (RSM)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raychaudhuri, A.; Behera, M. Review of the Process Optimization in Microbial Fuel Cell using Design of Experiment Methodology. J. Hazard. Toxic Radioact. Waste 2020, 24, 4020013. [Google Scholar] [CrossRef]

- Kloch, M.; Toczyłowska-Mamí, R. Toward Optimization of Wood Industry Wastewater Treatment in Microbial Fuel Cells-Mixed Wastewaters Approach. Available online: https://www.mdpi.com/journal/energies (accessed on 22 May 2024).

- Hyun, K.; Kim, S.; Kwon, Y. Performance evaluations of yeast based microbial fuel cells improved by the optimization of dead zone inside carbon felt electrode. Korean J. Chem. Eng. 2021, 38, 2347–2352. [Google Scholar] [CrossRef]

- Ahn, Y.; Hatzell, M.C.; Zhang, F.; Logan, B.E. Different electrode configurations to optimize performance of multi-electrode microbial fuel cells for generating power or treating domestic wastewater. J. Power Sources 2014, 249, 440–445. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, J.; Yang, Q.; Feng, C.; Zhu, Y.; Ye, Z.; Ni, J. Investigation, and optimization of the novel UASB–MFC integrated system for sulfate removal and bioelectricity generation using the response surface methodology (RSM). Bioresour. Technol. 2012, 124, 1–7. [Google Scholar] [CrossRef]

- Gil, G.C.; Chang, I.S.; Kim, B.H.; Kim, M.; Jang, J.K.; Park, H.S.; Kim, H.J. Operational parameters affecting the performance of a mediator-less microbial fuel cell. Biosens Bioelectron. 2003, 18, 327–334. [Google Scholar] [CrossRef] [PubMed]

- Identifying Optimized Conditions for Concurrent Electricity Production and Phosphorus Recovery in a Mediator-Less Dual Chamber Microbial Fuel Cell—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0306261918312789?fr=RR-2&ref=pdf_download&rr=84264e8bfbe54ecc (accessed on 8 January 2024).

- Xia, C.; Zhang, D.; Pedrycz, W.; Zhu, Y.; Guo, Y. Models for Microbial Fuel Cells: A critical review. J. Power Sources 2018, 373, 119–131. [Google Scholar] [CrossRef]

- Logan, B.E.; Hamelers, B.; Rozendal, R.; Schröder, U.; Keller, J.; Freguia, S.; Aelterman, P.; Verstraete, W.; Rabaey, K. Microbial fuel cells: Methodology and technology. Environ. Sci. Technol. 2006, 40, 5181–5192. [Google Scholar] [CrossRef]

- Guelpa, E.; Verda, V. Model for optimal malfunction management in extended district heating networks. Appl. Energy 2018, 230, 519–530. [Google Scholar] [CrossRef]

- Cano, V.; Chrispim, M.C.; de Souza, T.S.O.; Penteado, E.D. Novel bioelectrochemical processes focused on nitrogen in wastewater: Energy generation and resource recovery. Water Manag. Circ. Econ. 2023, 233–272. [Google Scholar]

- Wang, L.; Tai, Y.; Zhao, X.; He, Q.; Hu, Z.; Li, M. Phosphorus recovery directly from sewage sludge as vivianite and simultaneous electricity production in a dual chamber microbial fuel cell. J. Environ. Chem. Eng. 2023, 11, 110152. [Google Scholar] [CrossRef]

- Hosseinpour, M.; Vossoughi, M.; Alemzadeh, I. An efficient approach to cathode operational parameters optimization for mi-crobial fuel cell using response surface methodology. J. Environ. Health Sci. Eng. 2014, 12, 33. [Google Scholar] [CrossRef]

- Benayyad, A.; Kameche, M.; Kebaili, H.; Innocent, C. Design of a Microbial Fuel Cell Used as a Biosensor of Pollution Emitted by Oxidized Organic Matter. In Advances in Renewable Hydrogen and Other Sustainable Energy Carriers; Springer Nature: Singapore, 2021; pp. 279–284. [Google Scholar]

- Shabangu, K.P.; Mthembu, N.; Chetty, M.; Bakare, B.F. Validation of RSM Predicted Optimum Scaling-Up Factors for Generating Electricity in a DCMFC: MATLAB Design and Simulation Model. Fermentation 2023, 9, 856. [Google Scholar] [CrossRef]

- Noori, T.; Ganta, A.; Tiwari, B.R. Recent Advances in the Design and Architecture of Bioelectrochemical Systems to Treat Wastewater and to Produce Choice-Based Byproducts. J. Hazard. Toxic Radioact. Waste 2020, 24, 04020023. [Google Scholar] [CrossRef]

- Muchtar, A.; Tambunan, A.H.; Machfud, M. Preliminary Analysis of Single-Flash Geothermal Power Plant by Using Exergy Method: A Case Study from Ulubelu Geothermal Power Plant in Indonesia Bioethanol from Brown Seaweed View Project PRODUCTION SYSTEM DESIGN OF BANANA BASED ENERGY BAR INDUSTRY View Project. 2018. Available online: https://www.researchgate.net/publication/335175433 (accessed on 22 May 2024).

- Aghababaie, M.; Farhadian, M.; Jeihanipour, A.; Biria, D. Environmental Technology Reviews Effective Factors on the Performance of Microbial Fuel Cells in Wastewater Treatment—A Review. 2015. Available online: https://www.tandfonline.com/action/journalInformation?journalCode=tetr20 (accessed on 8 January 2024).

- Sun, D.; Gao, Y.; Hou, D.; Zuo, K.; Chen, X.; Liang, P.; Zhang, X.; Ren, Z.J.; Huang, X. Energy-neutral sustainable nutrient recovery incorporated with the wastewater purification process in an enlarged microbial nutrient recovery cell. J. Power Sources 2018, 384, 160–164. [Google Scholar] [CrossRef]

- He, Z.; Huang, Y.; Manohar, A.K.; Mansfeld, F. Effect of electrolyte pH on the rate of the anodic and cathodic reactions in an air-cathode microbial fuel cell. Bioelectrochemistry 2008, 74, 78–82. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; He, W.; Ren, L.; Stager, J.; Evans, P.J.; Logan, B.E. COD removal characteristics in air-cathode microbial fuel cells. Bioresour. Technol. 2015, 176, 23–31. [Google Scholar] [CrossRef] [PubMed]

- Cercado-Quezada, B.; Delia, M.-L.; Bergel, A. Testing various food-industry wastes for electricity production in microbial fuel cells. Bioresour. Technol. 2010, 101, 2748–2754. [Google Scholar] [CrossRef]

- Kim, J.H.; An, B.M.; Lim, D.H.; Park, J.Y. Electricity production and phosphorous recovery as struvite from synthetic wastewater using magnesium-air fuel cell electrocoagulation. Water Res. 2018, 132, 200–210. [Google Scholar] [CrossRef]

- Blöcher, C.; Niewersch, C.; Melin, T. Phosphorus recovery from sewage sludge with a hybrid process of low-pressure wet oxidation and nanofiltration. Water Res. 2012, 46, 2009–2019. [Google Scholar] [CrossRef]

- Zhang, L.; Li, C.; Ding, L.; Xu, K.; Ren, H. Influences of initial pH on performance and anodic microbes of fed-batch microbial fuel cells. J. Chem. Technol. Biotechnol. 2011, 86, 1226–1232. [Google Scholar] [CrossRef]

- Zhao, H.; Kong, C.-H. Elimination of pyraclostrobin by simultaneous microbial degradation coupled with the Fenton process in microbial fuel cells and the microbial community. Bioresour. Technol. 2018, 258, 227–233. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Dai, H.; Wu, Y.; Peng, Y.; Lu, X. A comprehensive review of phosphorus recovery from wastewater by crystallization processes. Chemosphere 2018, 197, 768–781. [Google Scholar] [CrossRef] [PubMed]

- Pasupuleti, S.B.; Srikanth, S.; Mohan, S.V.; Pant, D. Continuous mode operation of microbial fuel cell (MFC) stack with dual gas diffusion cathode design for the treatment of dark fermentation effluent. Int. J. Hydrog. Energy 2015, 40, 12424–12435. [Google Scholar] [CrossRef]

- Elhenawy, S.; Khraisheh, M.; AlMomani, F.; Al-Ghouti, M.; Hassan, M.K. From Waste to Watts: Updates on Key Applications of Microbial Fuel Cells in Wastewater Treatment and Energy Production. Sustainability 2022, 14, 955. [Google Scholar] [CrossRef]

- Mohammadi, A.; Khadir, A.; Tehrani, R.M.A. Optimization of nitrogen removal from an anaerobic digester effluent by electro-coagulation process. J. Environ. Chem. Eng. 2019, 7, 103195. [Google Scholar] [CrossRef]

- Numbi, B.; Xia, X. Systems optimization model for energy management of a parallel HPGR crushing process. Appl. Energy 2015, 149, 133–147. [Google Scholar] [CrossRef]

- Pandit, S.; Ghosh, S.; Ghangrekar, M.M.; Das, D. Performance oof an Anion Exchange Membrane in Association with Cathodic Parameters in a Dual Chamber Microbial Fuel Cell. 2012. Available online: www.sciencedirect.com (accessed on 8 January 2024).

- Puig, S.; Serra, M.; Coma, M.; Balaguer, M.D.; Colprim, J. Simultaneous domestic wastewater treatment and renewable energy production using microbial fuel cells (MFCs). Water Sci. Technol. 2011, 64, 904–909. [Google Scholar] [CrossRef]

- Jadhav, D.A.; Carmona-Martínez, A.A.; Chendake, A.D.; Pandit, S.; Pant, D. Modeling, and optimization strategies towards perfor-mance enhancement of microbial fuel cells. Bioresour. Technol. 2021, 320, 124256. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Conesa, E.J.; Ortiz-Martínez, V.M.; Salar-García, M.J.; Ríos, A.P.D.L.; Hernández-Fernández, F.J.; Lozano, L.J.; Godínez, C. A Box–Behnken Design-Based Model for Predicting Power Performance in Microbial Fuel Cells Using Wastewater. Chem. Eng. Commun. 2016, 204, 97–104. [Google Scholar] [CrossRef]

- Behera, M.; Ghangrekar, M.M. Optimization of Operating Conditions for Maximizing Power Generation and Organic Matter Removal in Microbial Fuel Cell. J. Environ. Eng. 2017, 143, 04016090. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Cecconet, D.; Molognoni, D. An integrated mathematical model of microbial fuel cell processes: Bioelectro-chemical and microbiologic aspects. Processes 2017, 5, 73. [Google Scholar] [CrossRef]

- Chen, S.; Patil, S.A.; Brown, R.K.; Schröder, U. Strategies for optimizing the power output of microbial fuel cells: Transitioning from fundamental studies to practical implementation. Appl. Energy 2018, 233–234, 15–28. [Google Scholar] [CrossRef]

- Recio-Garrido, D.; Perrier, M.; Tartakovsky, B. Modeling, optimization, and control of bioelectrochemical systems. Chem. Eng. J. 2016, 289, 180–190. [Google Scholar] [CrossRef]

- Kadivarian, M.; Karamzadeh, M. Electrochemical modeling of microbial fuel cells performance at different operating and structural conditions. Bioprocess Biosyst. Eng. 2019, 43, 393–401. [Google Scholar] [CrossRef] [PubMed]

- Gupta, R.; Sethi, S.; Bharshankh, A.; Sahu, R.; Biswas, R. A perspective on Bio-Electrochemical System (BES) as a tool for boosting the performance of the nonperforming anaerobic units. Clean. Circ. Bioeconomy 2023, 6, 100066. [Google Scholar] [CrossRef]

- Optimization of Enhanced Bioelectrical Reactor with Electricity from Microbial Fuel Cells for Groundwater Nitrate Removal [Internet]. Available online: https://www.tandfonline.com/doi/epdf/10.1080/09593330.2015.1096962?needAccess=true (accessed on 8 January 2024).

- Bagchi, S.; Behera, M. Pharmaceutical wastewater treatment in ceramic separator MFC: Optimisation of operating parameters to improve organic removal and power generation. Clean. Circ. Bioeconomy 2023, 6, 100063. [Google Scholar] [CrossRef]

- Shabangu, K.P.; Bakare, B.F.; Bwapwa, J.K. Microbial Fuel Cells for Electrical Energy: Outlook on Scaling-up and Application Possibilities Towards South African Energy Grid. Sustainability 2022, 14, 14268. [Google Scholar] [CrossRef]

- Armah, E.K.; Chetty, M.; Adedeji, J.A.; Kukwa, D.T.; Mutsvene, B.; Shabangu, K.P.; Bakare, B.F. Emerging Trends in Wastewater Treatment Technologies: The Current Perspective. In Promising Techniques for Wastewater Treatment and Water Quality Assessment; IntechOpen: London, UK, 2021. [Google Scholar]

- Shabangu, K.P.; Mthembu, N.; Chetty, M.; Bwapwa, J.K.; Bakare, B.F. A comparative analysis of organic substrates from industrial wastewater streams for enhanced electricity production using a double chamber microbial fuel cell (DCMFC). Energy Rep. 2024, 11, 3050–3063. [Google Scholar] [CrossRef]

- He, L.; Huang, G.H.; Lu, H.W. A stochastic optimization model under modeling uncertainty and parameter certainty for groundwater remediation design-Part I. Model development. J. Hazard. Mater. 2010, 176, 521–526. [Google Scholar] [CrossRef] [PubMed]

- Rahmani Eliato, T.; Pazuki, G.; Majidian, N. Potassium permanganate as an electron receiver in a microbial fuel cell Potassium permanganate as an electron receiver in a microbial fuel cell. Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 644–651. [Google Scholar]

- Tahir, C.A.; Pásztory, Z.; Agarwal, C.; Csóka, L. Electricity Generation and Wastewater Treatment with Membrane-Less Microbial Fuel Cell. Appl. Microbes Environ. Microb. Biotechnol. 2022, 235–261. [Google Scholar]

- ATP Monitoring Technology for Microbial Growth Control in Potable Water Systems. Available online: https://www.spiedigitallibrary.org/conference-proceedings-of-spie/6203/62030N/ATP-monitoring-technology-for-microbial-growth-control-in-potable-water/10.1117/12.673425 (accessed on 12 February 2024).

- García, V.G.; Bartolomé, M.M. Rural electrification systems based on renewable energy: The social dimensions of an innovative technology. Technol. Soc. 2010, 32, 303–311. [Google Scholar] [CrossRef]

- Marone, A.; Varrone, C.; Fiocchetti, F.; Giussani, B.; Izzo, G.; Mentuccia, L.; Rosa, S.; Signorini, A. Optimization of substrate composition for biohy-drogen production from buffalo slurry co-fermented with cheese whey and crude glycerol, using microbial mixed culture. Int. J. Hydrog. Energy 2015, 40, 209–218. [Google Scholar] [CrossRef]

- Jadhav, D.A.; Ghangrekar, M.M. Optimising the proportion of pure and mixed culture in inoculum to enhance the performance of microbial fuel cells. Int. J. Environ. Technol. Manag. 2020, 23, 50. [Google Scholar] [CrossRef]

- Fang, F.; Zang, G.-L.; Sun, M.; Yu, H.-Q. Optimizing multi-variables of microbial fuel cells for electricity generation with an integrated modeling and experimental approach. Appl. Energy 2013, 110, 98–103. [Google Scholar] [CrossRef]

- Ishii, S.; Suzuki, S.; Norden-Krichmar, T.M.; Wu, A.; Yamanaka, Y.; Nealson, K.H.; Bretschger, O. Identifying the microbial communities and operational conditions for optimized wastewater treatment in microbial fuel cells. Water Res. 2013, 47, 7120–7130. [Google Scholar] [CrossRef] [PubMed]

- Logan, B.E.; Rabaey, K. Conversion of Wastes into Bioelectricity and Chemicals by Using Microbial Electrochemical Technologies. Science 2012, 337, 686–690. [Google Scholar] [CrossRef] [PubMed]

- Logan, B.E.; Regan, J.M. Electricity-producing bacterial communities in microbial fuel cells. Trends Microbiol. 2006, 14, 512–518. [Google Scholar] [CrossRef] [PubMed]

- Yu, R.-F.; Chen, H.-W.; Cheng, W.-P.; Lin, Y.-J.; Huang, C.-L. Monitoring of ORP, pH and DO in heterogeneous Fenton oxidation using nZVI as a catalyst for the treatment of azo-dye textile wastewater. J. Taiwan Inst. Chem. Eng. 2014, 45, 947–954. [Google Scholar] [CrossRef]

- Khumalo, S.M.; Bakare, B.F.; Rathilal, S.; Tetteh, E.K. Characterization of South African Brewery Wastewater: Oxidation-Reduction Potential Variation. Water 2022, 14, 1604. [Google Scholar] [CrossRef]

- Silva-Illanes, F.; Tapia-Venegas, E.; Schiappacasse, M.C.; Trably, E.; Ruiz-Filippi, G. Impact of hydraulic retention time (HRT) and pH on dark fermentative hydrogen production from glycerol. Energy 2017, 141, 358–367. [Google Scholar] [CrossRef]

- Margaria, V.; Tommasi, T.; Pentassuglia, S.; Agostino, V.; Sacco, A.; Armato, C.; Chiodoni, A.; Schilirò, T.; Quaglio, M. Effects of pH variations on anodic marine con-sortia in a dual chamber microbial fuel cell. Int. J. Hydrog. Energy 2017, 42, 1820–1829. [Google Scholar] [CrossRef]

- Kim, M.Y.; Kim, C.; Ainala, S.K.; Bae, H.; Jeon, B.-H.; Park, S.; Kim, J.R. Metabolic shift of Klebsiella pneumoniae L17 by electrode-based electron transfer using glycerol in a microbial fuel cell. Bioelectrochemistry 2018, 125, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Park, Y.; Widyaningsih, E.; Kim, S.; Kim, Y.; Lee, T. Microbial fuel cells: Devices for real wastewater treatment, rather than electricity production. Sci. Total. Environ. 2021, 775, 145904. [Google Scholar] [CrossRef]

- Kim, J.R.; Min, B.; Logan, B.E. Evaluation of procedures to acclimate a microbial fuel cell for electricity production. Appl. Microbiol. Biotechnol. 2005, 68, 23–30. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.H.; Chang, I.S.; Gadd, G.M. Challenges in microbial fuel cell development and operation. Appl. Microbiol. Biotechnol. 2007, 76, 485–494. [Google Scholar] [CrossRef]

- Ahn, Y.; Logan, B.E. Effectiveness of domestic wastewater treatment using microbial fuel cells at ambient and mesophilic tem-peratures. Bioresour. Technol. 2010, 101, 469–475. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.F.; Mofijur, M.; Islam, N.; Parisa, T.A.; Rafa, N.; Bokhari, A.; Klemeš, J.J.; Mahlia, T.M.I. Insights into the development of microbial fuel cells for generating biohydrogen, bioelectricity, and treating wastewater. Energy 2022, 254, 124163. [Google Scholar] [CrossRef]

- Khandaker, S.; Das, S.; Hossain, M.T.; Islam, A.; Miah, M.R.; Awual, M.R. Sustainable approach for wastewater treatment using mi-crobial fuel cells and green energy generation—A comprehensive review. J. Mol. Liq. 2021, 344, 117795. [Google Scholar] [CrossRef]

| Study | Application | Design | Findings |

|---|---|---|---|

| [32] | Optimization of cathodic parameters | BBD (Three-factor, three-level) | The cathode surface area was found to be the most significant parameter in MFC performance. |

| [33] | Factors affecting continuous-flow BER-MFC | BBD (Three-factor, three-level) | The order of significance: COD load > HRT > nitrate load. |

| [34] | Maximizing power density in dual-chamber MFC | BBD (Four-factor, three-level) | Temperature and external resistance were identified as significant parameters. |

| [35] | Pyraclostrobin elimination in MFC–Fenton | BBD (Three-factor, three-level) | Catholyte pH significantly affected Fenton reaction performance. |

| [36] | Dual-chamber MFC performance evaluation | BBD (Four-factor, three-level) | pH and inoculum composition interactions impacted MFC performance. |

| [37,38,39] | Influence of glucose concentration on MFC | BBD (Three-factor, three-level) | High OCV was obtained at a high glucose/yeast ratio and low glucose concentration. |

| [32,35,36,37,40,41,42] | Oxyfluorfen degradation in dual-chamber MFC | BBD (Three-factor, three-level) | Optimal conditions of temperature, pH, and initial oxyfluorfen concentration were identified. |

| [43] | Effect of operating parameters on ceramic MFC | BBD (Three-factor, three-level) | Optimum conditions for maximizing power output were established. |

| Fit-Statistical Parameter | CVV-Yield | Power Density | Current Density | % COD | % CE | % TSS | % TOC | |

|---|---|---|---|---|---|---|---|---|

| Standard Deviation | 28.69 | 2.38 | 1.67 | 9.81 | 0.1922 | 4.68 | 9.44 | 13.92 |

| Mean | 190.48 | 9.99 | 18.47 | 42.54 | 47.32 | 3.58 | 60.59 | 45.92 |

| Coefficient of Variation (%) | 15.06 | 23.82 | 9.05 | 23.06 | 0.40 | 130.59 | 15.57 | 30.32 |

| R2 | 0.99 | 0.99 | 0.99 | 0.84 | 1 | 0.89 | 0.88 | 0.85 |

| Predicted R2 | 0.97 | 0.98 | 0.98 | 0.69 | 0.99 | 0.73 | 0.72 | 0.71 |

| Adequate Precision | 25.22 | 33.64 | 33.49 | 8.45 | 215.97 | 9.51 | 8.17 | 7.54 |

| Solution 1 of 92 | n | ANOVA Model Predicted Values | Actual Validation Values (Biorefinery-WW) | Actual Validation Values (Mix-WW) | Actual Validation Values (Dairy WW) | Std Dev (Predicted: Actual) |

|---|---|---|---|---|---|---|

| CCV (mV) | 3 | 613.71 | 640.2 | 566.9 | 350.7 | - |

| PD (mW/m2) | 3 | 80.15 | 61.67 | 48.36 | 18.50 | - |

| ID (mA/m2) | 3 | 72.38 | 49.78 | 44.08 | 27.27 | - |

| % COD | 3 | 35.93 | 62 | 39 | 94 | 39.56 |

| % | 3 | 100.00 | 61 | 64 | 58.1 | 36.11 |

| % TSS | 3 | 74.20 | 65 | 61.4 | 81 | 42.65 |

| Factor | Name | Units | Type | Minimum | Maximum | Coded Low | Coded High | Mean | Std. Dev. |

|---|---|---|---|---|---|---|---|---|---|

| A | Catholyte | mg/L | Numeric | 0 | 0,1 | −1 ↔ 0.00 | +1 ↔ 0.10 | 0.0257 | 0.0425 |

| B | HRT | Hours | Numeric | 48 | 96 | −1 ↔ 48.00 | +1 ↔ 96.00 | 66.46 | 17.4 |

| C | Temperature | °C | Numeric | 10 | 40 | −1 ↔ 10.00 | +1 ↔ 40.00 | 26.46 | 9.13 |

| D | Surface area | m2 | Numeric | 1 | 3 | −1 ↔ 1.00 | +1 ↔ 3.00 | 2.08 | 0.8623 |

| Response Name | Units | Observations | Minimum | Maximum | Mean | Std. Dev. | Ratio | Model |

|---|---|---|---|---|---|---|---|---|

| CCV | mV | 13 | 40.2 | 700 | 190.48 | 18.88 | 17.41 | Reduced Quadratic |

| PD | mW/m2 | 13 | 0.13 | 73.74 | 9,99 | 20.36 | 544.68 | 2FI |

| ID | mA/m2 | 13 | 2.70 | 54.43 | 18.47 | 15 | 20.11 | 2FI |

| COD | % | 13 | 18 | 92 | 42.54 | 17.7 | 5.11 | Reduced Quadratic |

| % | 13 | 28.1 | 68 | 47.32 | 11.8 | 2.42 | Reduced Quadratic | |

| CE | % | 13 | 0.079 | 21.59 | 3.59 | 6.29 | 273 | Linear |

| TSS | % | 13 | 32.9 | 98.8 | 60.59 | 18.02 | 3 | Reduced Quadratic |

| TOC | % | 13 | 18.9 | 100 | 45.92 | 26.25 | 5.29 | Reduced 2FI |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shabangu, K.P.; Chetty, M.; Bakare, B.F. Optimization and Modeling of a Dual-Chamber Microbial Fuel Cell (DCMFC) for Industrial Wastewater Treatment: A Box–Behnken Design Approach. Energies 2024, 17, 2740. https://doi.org/10.3390/en17112740

Shabangu KP, Chetty M, Bakare BF. Optimization and Modeling of a Dual-Chamber Microbial Fuel Cell (DCMFC) for Industrial Wastewater Treatment: A Box–Behnken Design Approach. Energies. 2024; 17(11):2740. https://doi.org/10.3390/en17112740

Chicago/Turabian StyleShabangu, Khaya Pearlman, Manimagalay Chetty, and Babatunde Femi Bakare. 2024. "Optimization and Modeling of a Dual-Chamber Microbial Fuel Cell (DCMFC) for Industrial Wastewater Treatment: A Box–Behnken Design Approach" Energies 17, no. 11: 2740. https://doi.org/10.3390/en17112740

APA StyleShabangu, K. P., Chetty, M., & Bakare, B. F. (2024). Optimization and Modeling of a Dual-Chamber Microbial Fuel Cell (DCMFC) for Industrial Wastewater Treatment: A Box–Behnken Design Approach. Energies, 17(11), 2740. https://doi.org/10.3390/en17112740