Effect Evaluation of Staged Fracturing and Productivity Prediction of Horizontal Wells in Tight Reservoirs

Abstract

:1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Geological Characteristics and Flow Mechanism of Tight Reservoirs

3.2. Seepage Characteristics of Fractured Horizontal Wells

3.3. Physical Model of Horizontal Well Fracturing in Tight Reservoir

4. Result

4.1. Effect Evaluation of Fractured Horizontal Well

4.2. Study on Fracturing Productivity of Horizontal Wells in Tight Reservoirs

- There is a cuboid closed-boundary reservoir, whose dimensions are successively long xe, wide ye and high ze.

- There is a cuboid source of production in the reservoir, and its flow rate is q. Assuming that it obeys a uniform flow rate, its center position is (cx, cy, cz) and its size is (2wx, 2wy, 2wz).

- The fluid flows isothermally and conforms to Darcy’s law, regardless of the interference of capillary force and gravity.

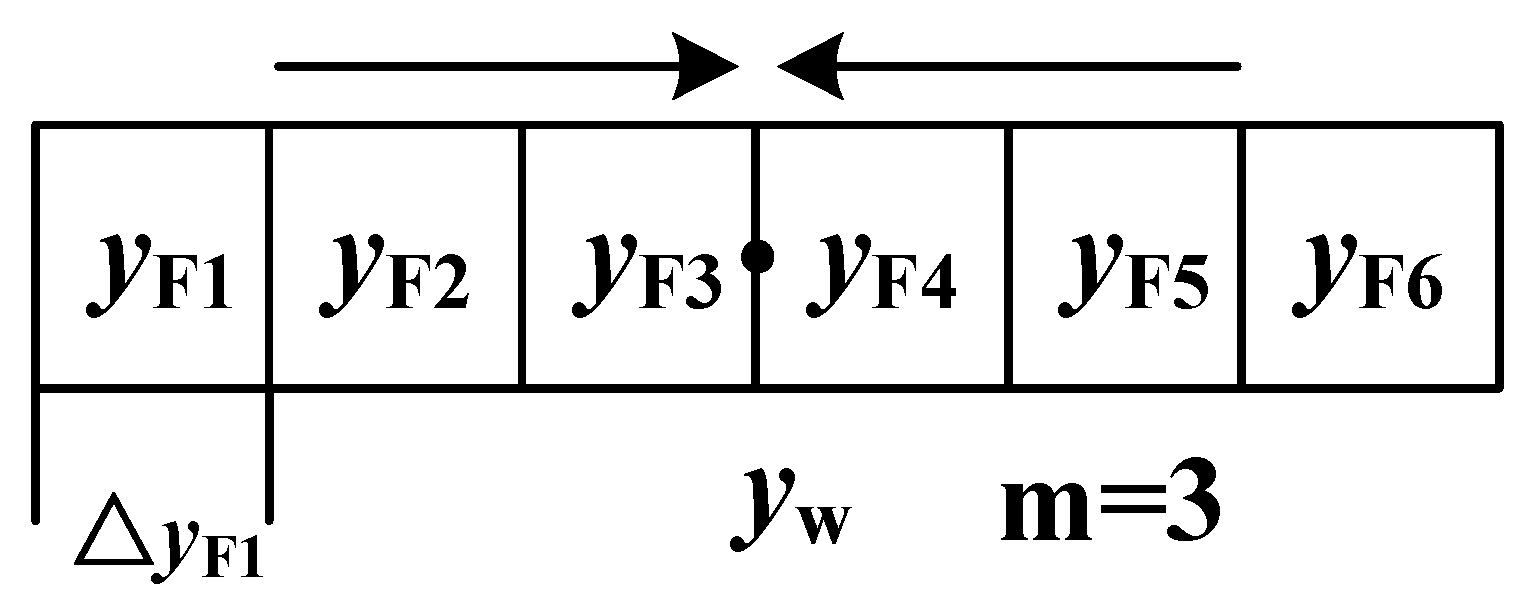

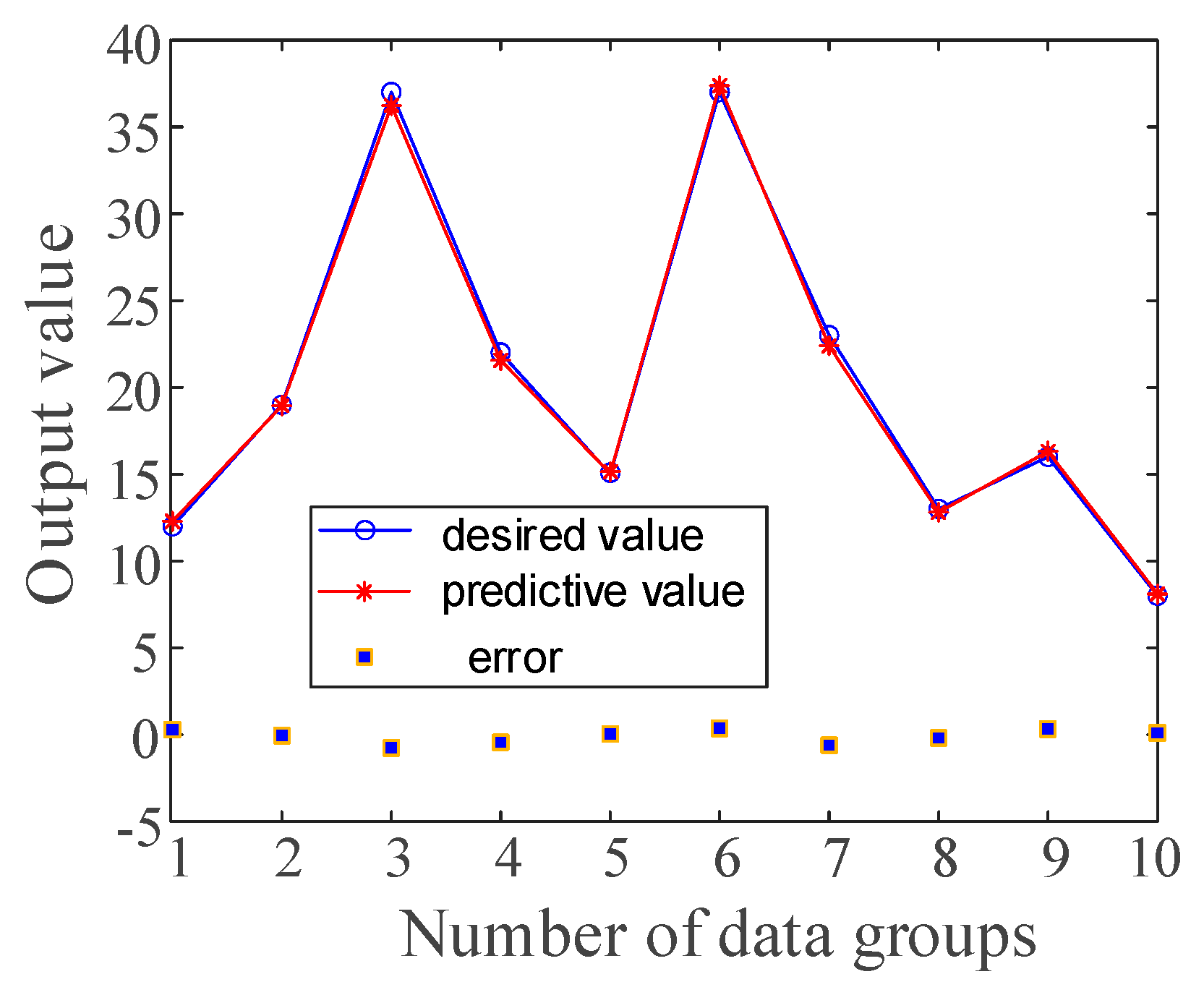

4.3. Effect Evaluation and Productivity Prediction Based on Deep Learning

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiaoguang, T.O.N.G.; Zhang, G.; Zhaoming, W.A.N.G.; Zhixin, W.; Zuoji, T.; Hongjun, W.; Feng, M.A.; Yiping, W. Distribution and potential of global oil and gas resources. Pet. Explor. Dev. 2018, 45, 779–789. [Google Scholar]

- Lee, W.J.; Hopkins, C.W. Characterization of tight reservoirs. J. Pet. Technol. 1994, 46, 956–964. [Google Scholar] [CrossRef]

- Yang, W.; Hou, J.; Liu, Y.; Dou, L.; Wang, X. The pore structures of different lithofacies in low-permeability sandy conglomerate reservoirs and their diagenetic impacts: A case study from the Es4 member of the northern steep slope in Dongying depression, Bohai Bay Basin, NE China. Mar. Pet. Geol. 2022, 136, 105481. [Google Scholar] [CrossRef]

- Zhu, R.; Zou, C.; Mao, Z.; Yang, H.; Hui, X.; Wu, S.; Cui, J.; Su, L.; Li, S.; Yang, Z. Characteristics and distribution of continental tight oil in China. J. Asian Earth Sci. 2019, 178, 37–51. [Google Scholar] [CrossRef]

- Qun, L.E.I.; Yun, X.U.; Bo, C.A.I.; Baoshan, G.; Xin, W.; Guoqiang, B.I.; Hui, L.I.; Shuai, L.I.; Bin, D.; Haifeng, F.U.; et al. Progress and prospects of horizontal well fracturing technology for shale oil and gas reservoirs. Pet. Explor. Dev. 2022, 49, 191–199. [Google Scholar]

- Wattenbarger, R.A.; El-Banbi, A.H.; Villegas, M.E.; Maggard, J.B. Production analysis of linear flow into fractured tight gas wells. In Proceedings of the SPE Rocky Mountain Petroleum Technology Conference/Low-Permeability Reservoirs Symposium, Denver, Colorado, 5–8 April 1998; p. SPE-39931. [Google Scholar]

- Liu, X.P.; Guo, C.Z.; Jiang, Z.X.; Liu, X.G.; Guo, S.P. The model coupling fluid flow in the reservoir with flow in the horizontal wellbore. Acta Pet. Sin. 1999, 20, 82–86. [Google Scholar]

- Fan, Z.F. Study for horizontal well’s productivity formula in bottom-water drive reservoir. Pet. Explor. Dev. 1993, 20, 71–75. [Google Scholar]

- Ping, X.; Hailong, L.; Haixia, H.; Guan, W. A new way to calculate flow pressure for low permeability oil well with partially penetrating fracture. Math. Probl. Eng. 2018, 2018, 4570539. [Google Scholar] [CrossRef]

- Zeng, Y.; Wang, Q.; Ning, Z.; Sun, H. A mathematical pressure transient analysis model for multiple fractured horizontal wells in shale gas reservoirs. Geofluids 2018, 2018, 8065949. [Google Scholar] [CrossRef]

- Fan, Y.; Lifeng, L.; Qiquan, R.; Jinping, K.; Mengya, X.; Jiaxin, D. The characteristics of unconventional tight oil reservoir and its modification technology and productivity prediction. Earth Sci. Res. J. 2020, 24, 507–512. [Google Scholar] [CrossRef]

- Weiyao, Z.; Zhiping, W.; Ming, Y. A New Method to Predict Production of Fracured Horizontal Well with Multi-Field Coupling Flow. Phys. Numer. Simul. Geotech. Eng. 2016, 28. Available online: https://www.proquest.com/openview/7c9085b34146e53f864885dbe84b7a3e/1?pq-origsite=gscholar&cbl=2028703 (accessed on 10 June 2024).

- Liang, Y.; Cheng, Y.; Han, Z.; Pidho, J.J.; Yan, C. Study on Multiscale Fluid–Solid Coupling Theoretical Model and Productivity Analysis of Horizontal Well in Shale Gas Reservoirs. Energy Fuels 2023, 37, 5059–5077. [Google Scholar] [CrossRef]

- Mingqiang, H.; Yongle, H.; Xingfan, Z. Computational Method for Hydraulic Fractures Spacing of Multi-Fractured Horizontal Well in Ultra Low Permeability Reservoirs. In Proceedings of the International Petroleum Technology Conference, Bangkok, Thailand, 14–16 November 2016; p. D021S022R001. [Google Scholar]

- Ding, Y.P.; Wang, X.D.; Xing, J. A Method of Productivity Calculation for Fractured Horizontal Well. Spec. Oil Gas Reserv. 2008, 15, 64–68. [Google Scholar]

- Pang, X.; Shao, X.; Li, M.; Hu, T.; Chen, Z.; Zhang, K.; Jiang, F.; Chen, J.; Chen, D.; Peng, J.; et al. Correlation and difference between conventional and unconventional reservoirs and their unified genetic classification. Gondwana Res. 2021, 97, 73–100. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Y.; Yu, X.; Wang, C.; Yao, B.; Wang, S.; Winterfeld, P.H.; Wang, X.; Yang, Z.; Wang, Y.; et al. Advances in improved/enhanced oil recovery technologies for tight and shale reservoirs. Fuel 2017, 210, 425–445. [Google Scholar] [CrossRef]

- Ying, L.; Wang, J.; Li, A. Effect of non-Darcy seepage on productivity of tight gas reservoir. IOP Conf. Ser. Earth Environ. Sci. 2021, 859, 012067. [Google Scholar] [CrossRef]

- Liu, B.; Yang, Y.; Li, J.; Chi, Y.; Li, J.; Fu, X. Stress sensitivity of tight reservoirs and its effect on oil saturation: A case study of Lower Cretaceous tight clastic reservoirs in the Hailar Basin, Northeast China. J. Pet. Sci. Eng. 2020, 184, 106484. [Google Scholar] [CrossRef]

- Chen, A.; Zhou, Y.; Song, R.; Song, Y.; Cheng, H.; Cadasse, D. Complexity Model for Predicting Oil Displacement by Imbibition after Fracturing in Tight-Oil Reservoirs. Complexity 2023, 2023, 2140631. [Google Scholar] [CrossRef]

- He, J.; Niu, X.; Meng, Q.; Guo, F.; Wang, H.; Liu, Y.; Wang, L.; Kang, Y.; Hu, K.; Zhu, Y. Analysis of seepage mechanism and productivity model of multi-stage fractured horizontal well in tight sandstone gas reservoir. Pet. Sci. Technol. 2023, 41, 2055–2070. [Google Scholar] [CrossRef]

- Cheng, H.L.; Cheng, Z.Y.; Qin, Q.; Chen, H.; Wan, F.; Zhao, J.Y.; Li, J.P. Production Analysis of Multi-Stage Fractured Horizontal Wells in Tight Oil Reservoirs. In International Field Exploration and Development Conference; Springer Nature: Singapore, 2023; pp. 1363–1375. [Google Scholar]

- Yuan, B.; Su, Y.; Moghanloo, R.G.; Rui, Z.; Wang, W.; Shang, Y. A new analytical multi-linear solution for gas flow toward fractured horizontal wells with different fracture intensity. J. Nat. Gas Sci. Eng. 2015, 23, 227–238. [Google Scholar] [CrossRef]

- Zhou, L.; Li, H.; Ren, X.; Chen, J.; Cai, J. Hydraulic fracturing of unconventional reservoirs aided by simulation technologies. In Sustainable Natural Gas Reservoir and Production Engineering; Gulf Professional Publishing: Oxford, UK, 2022; pp. 107–141. [Google Scholar]

- Restrepo, D.P. Pressure Behavior of a System Containing Multiple Vertical Fractures; The University of Oklahoma: Norman, OK, USA, 2008. [Google Scholar]

- Liu, Z.; Li, Z.; Yang, H.; Han, J.; Zhu, M.; Dong, S.; Yu, Z. A New Rough Fracture Permeability Model of Coal With Injected Water Based on Damaged Tree-Like Branching Network. Fractals 2024, 32, 2450057. [Google Scholar] [CrossRef]

- Hu, B.; Wang, J.; Ma, Z. A fractal discrete fracture network based model for gas production from fractured shale reservoirs. Energies 2020, 13, 1857. [Google Scholar] [CrossRef]

- Song, Y.; Song, Z.; Guo, J.; Feng, D.; Bai, B.; Liu, Y. Confinement effect on the fluid phase behavior and flow in shale oil reservoirs. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Virtual, 20–22 July 2020; p. D033S086R008. [Google Scholar]

| Port Symbol | Variable (Fracture Physical Information) |

|---|---|

| Input I1 | Length |

| Input I2 | Width |

| Input I3 | Density |

| Input I4 | Diversion capacity |

| Output O1 | Yield |

| Group | I1 | I2 | I3 | I4 | O1 |

|---|---|---|---|---|---|

| 1 | 0.73 | 0.88 | 0.14 | 0.72 | 0.97 |

| 2 | 0.25 | 0.42 | 0.79 | 0.33 | 0.86 |

| 3 | 0.89 | 0.76 | 0.38 | 0.95 | 0.56 |

| 4 | 0.46 | 0.09 | 0.67 | 0.18 | 0.72 |

| 5 | 0.62 | 0.57 | 0.50 | 0.61 | 0.85 |

| 6 | 0.17 | 0.31 | 0.92 | 0.48 | 0.63 |

| 7 | 0.98 | 0.64 | 0.26 | 0.87 | 0.58 |

| 8 | 0.34 | 0.93 | 0.61 | 0.26 | 0.71 |

| 9 | 0.51 | 0.20 | 0.05 | 0.59 | 0.99 |

| 10 | 0.05 | 0.71 | 0.83 | 0.10 | 0.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Chen, J.; Wu, Z.; Xiao, Y.; Xu, Z.; Cheng, H.; Zhang, B. Effect Evaluation of Staged Fracturing and Productivity Prediction of Horizontal Wells in Tight Reservoirs. Energies 2024, 17, 2894. https://doi.org/10.3390/en17122894

Zhang Y, Chen J, Wu Z, Xiao Y, Xu Z, Cheng H, Zhang B. Effect Evaluation of Staged Fracturing and Productivity Prediction of Horizontal Wells in Tight Reservoirs. Energies. 2024; 17(12):2894. https://doi.org/10.3390/en17122894

Chicago/Turabian StyleZhang, Yuan, Jianyang Chen, Zhongbao Wu, Yuxiang Xiao, Ziyi Xu, Hanlie Cheng, and Bin Zhang. 2024. "Effect Evaluation of Staged Fracturing and Productivity Prediction of Horizontal Wells in Tight Reservoirs" Energies 17, no. 12: 2894. https://doi.org/10.3390/en17122894